Achieving Circularity through Novel Product-Service Systems in the Mining Industry: An Opportunity for Circularity

Abstract

:1. Introduction

- How has PSS evolved?

- How can PSS be implemented in the mining industry?

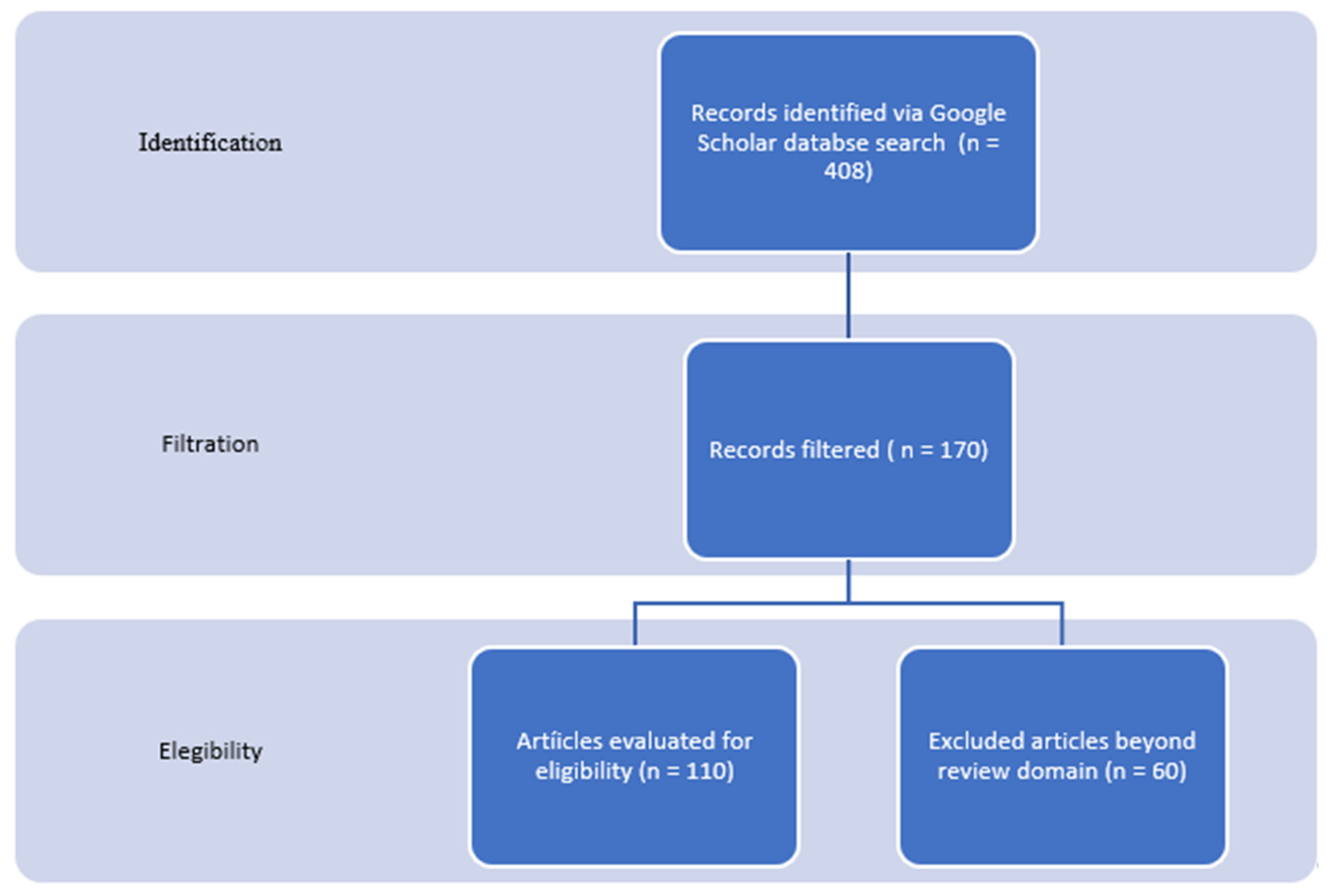

2. Materials and Methods

2.1. Search Strategy

- What benefits does PSS contribute, and what are its implementation barriers?

- What other concepts are related to PSS?

- How has PSS been adopted in the mining industry?

2.2. Inclusion and Exclusion Criteria

2.3. Data Collection

2.4. Data Synthesis and Analysis

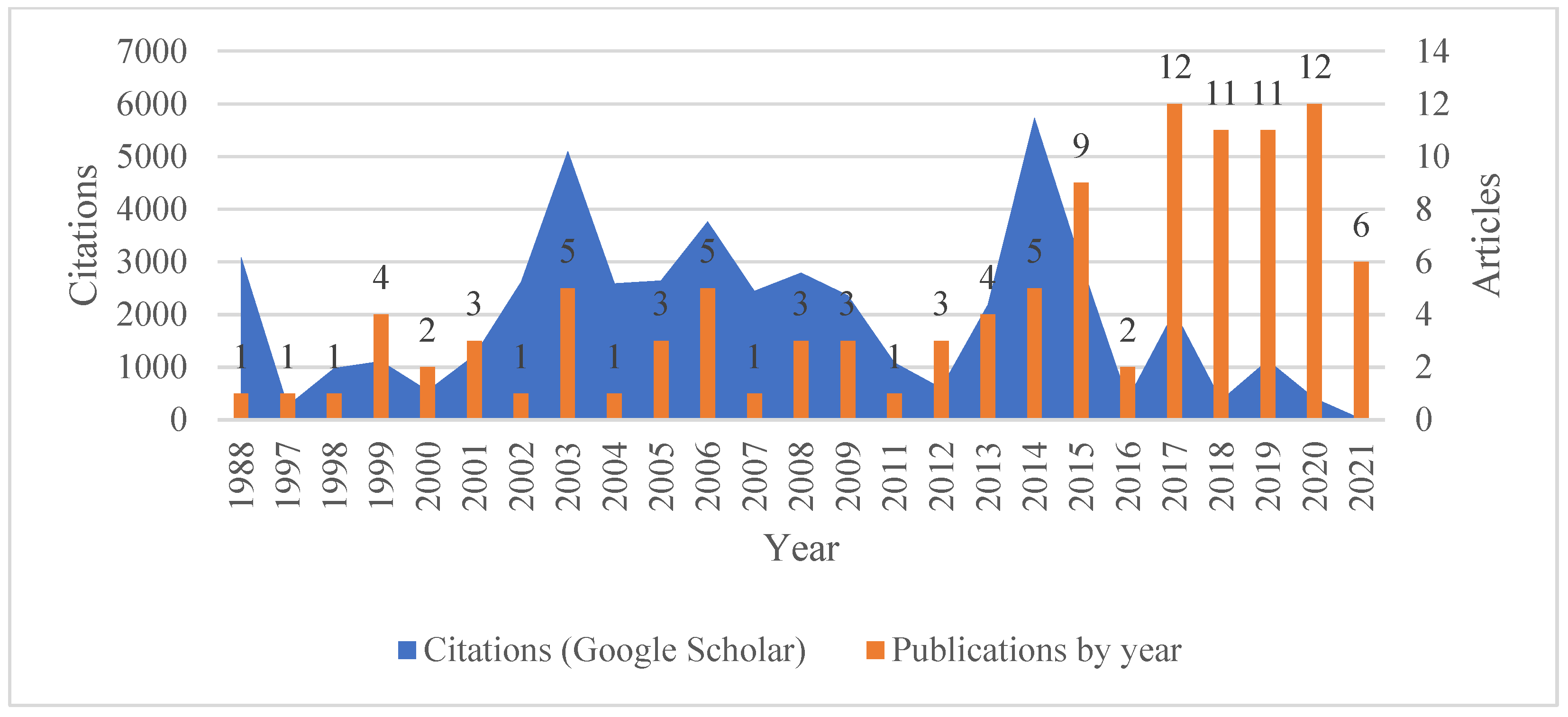

2.5. Descriptive/Thematic Analysis

2.6. Temporal and Journal Distribution of the Literature

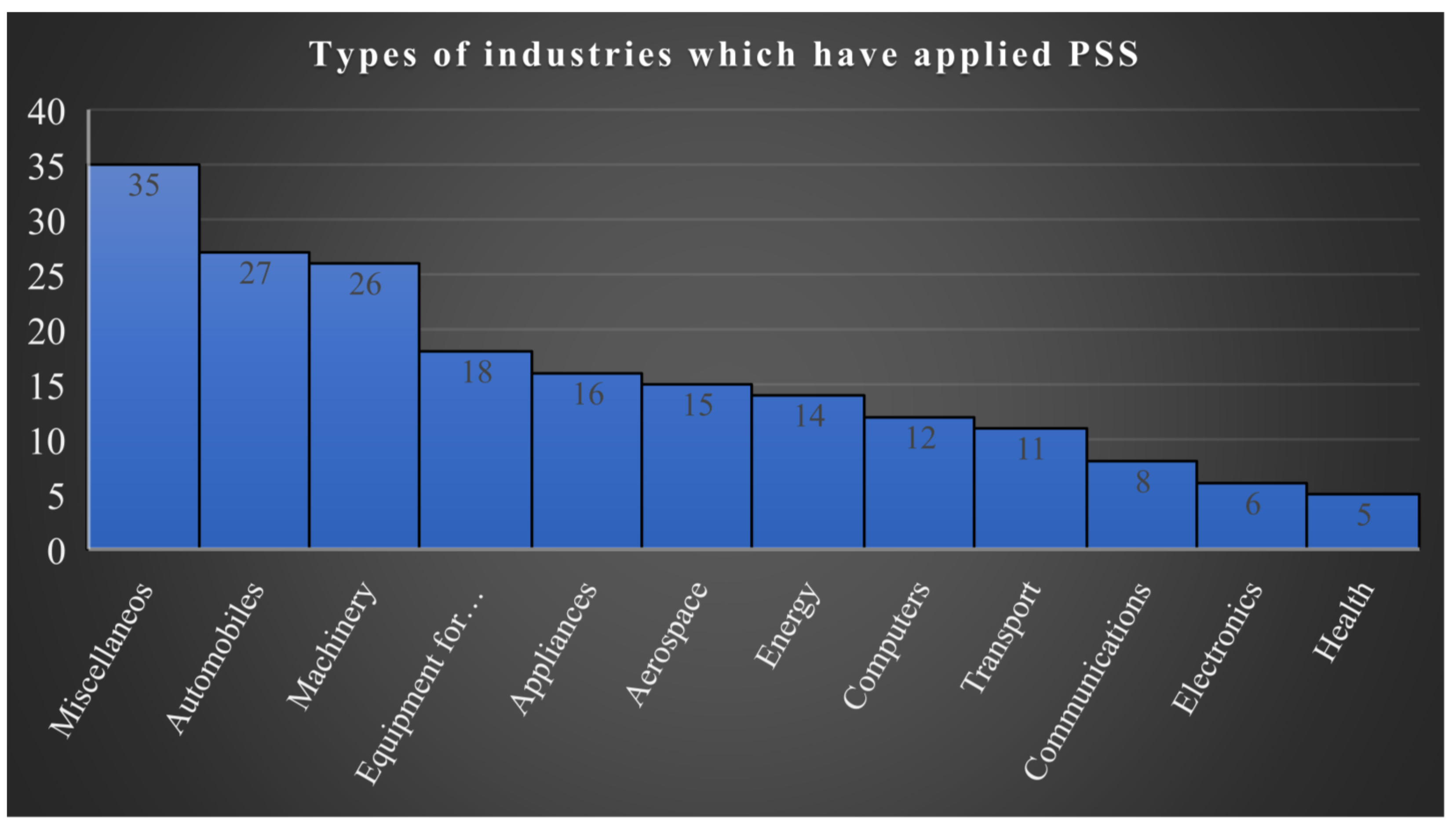

2.7. Industrial Sectors

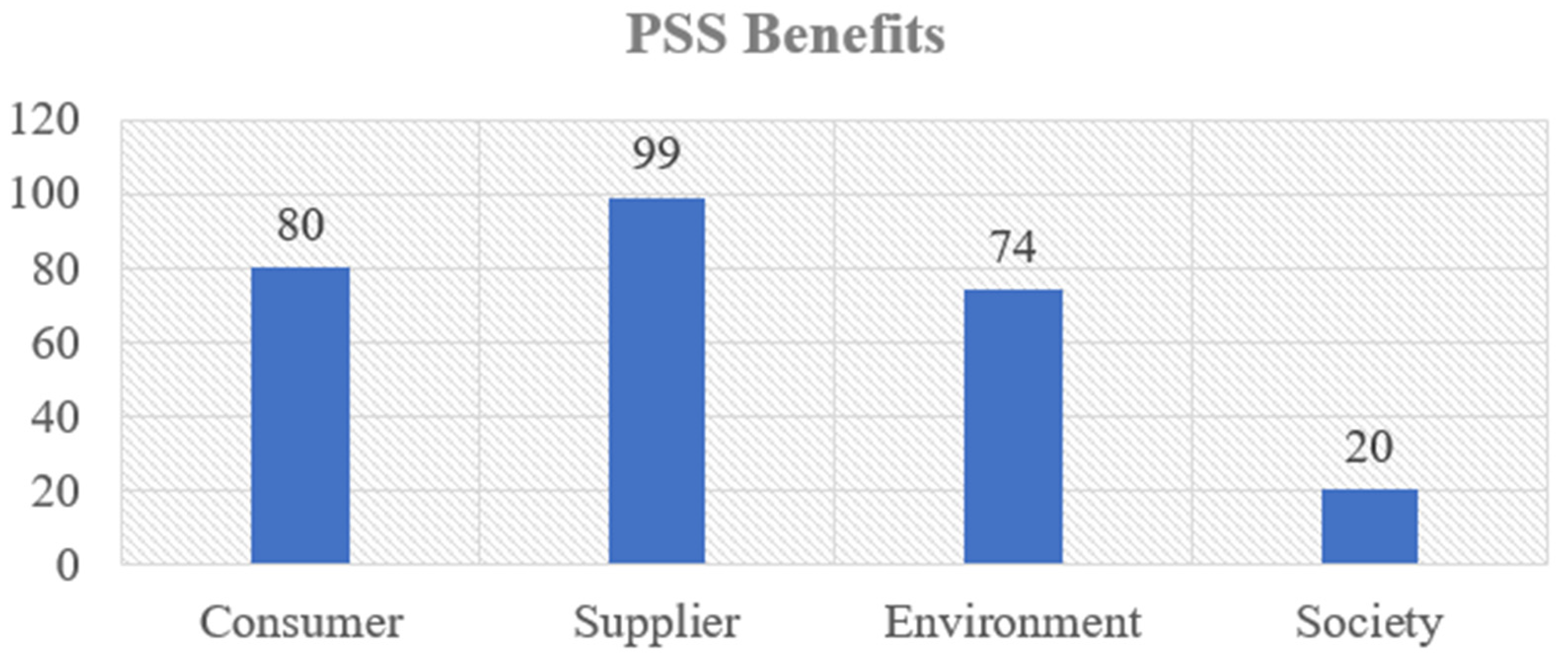

2.8. Benefits

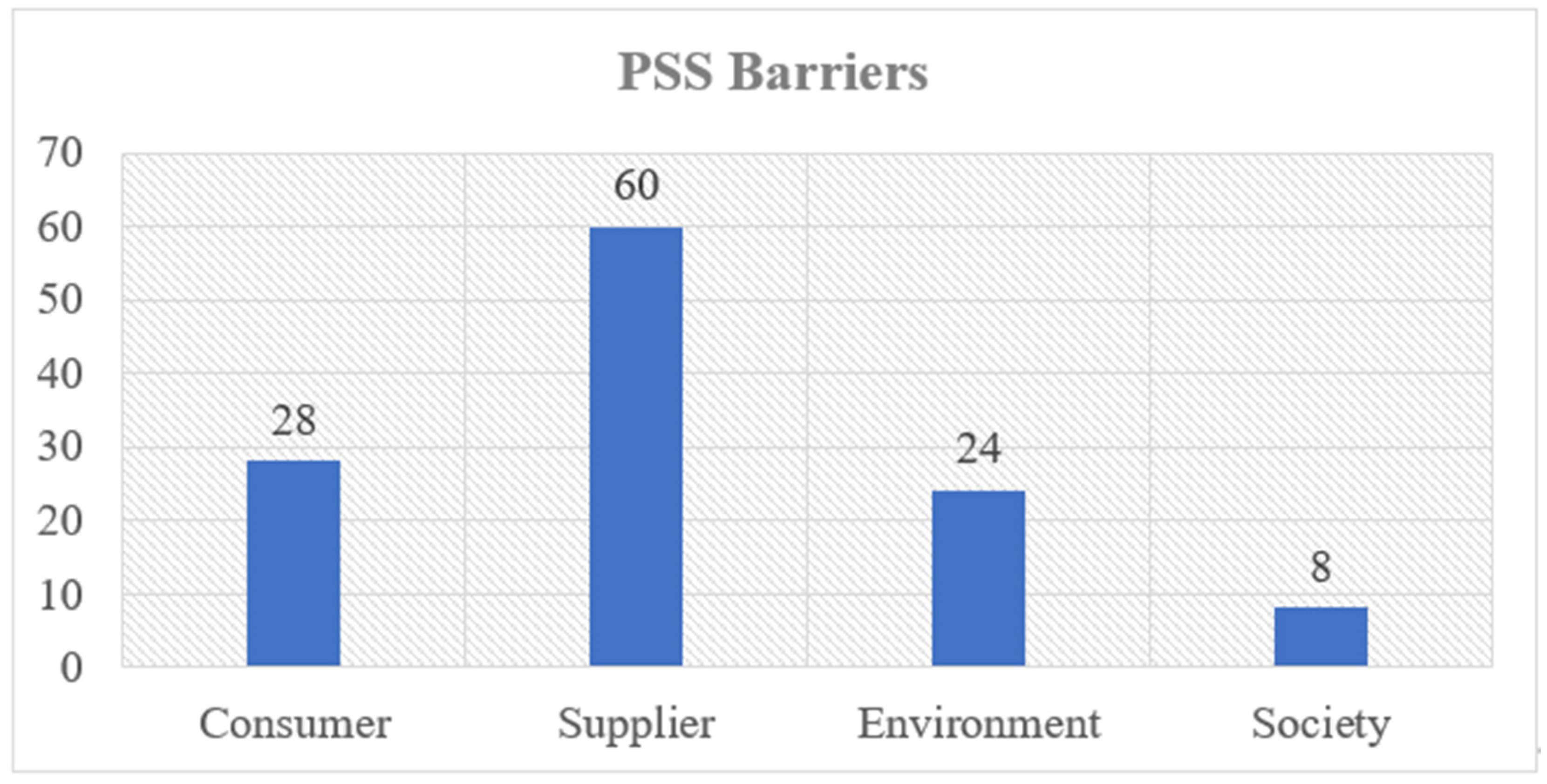

2.9. Barriers

3. Results

- Regarding the environment, the definitive goal of servitization is to have a smaller environmental impact to achieve sustainability in a circular economy. Smart PSS has great potential to deal with sustainability problems such as improving resource efficiency, extending service life and closing cycles [40]. To strengthen this effect, various results-oriented services are proposed, since in contrast to product-oriented services or use-oriented services, they have the highest environmental improvement potential. Using materials becomes a mere cost factor, where using more materials or creating more products does not lead to higher incomes. This creates an incentive to reduce costs for materials, using less, using them for longer periods, etc. [28].

- Incorporating digital technologies contributes other improvements apart from sustainability. Digitalization increases supplier-customer interaction, facilitating value cocreation [67]. With an IoT-based PSS, suppliers can track machine conditions and act to prevent or correct any current or additional technical problem [68]. Thus, once they have a well-planned, IoT-supported servitization strategy, companies can create a solid value proposition based on reliable data about product use and performance. Services can also be created or adjusted to increase profitability and improve customer satisfaction [69].

- Due to the complexity and range of various PSS offers, developing integrated business solutions with long-term success requires implementing modularity [70], which can satisfy requirements for personalized solutions [71]. Process modularization has been identified as a promising approach [51]. Product units should implement common technology and standardized product platforms which can be easily arranged to provide more efficient solutions for customers’ needs. The modular reusable approach cuts costs and improves integrated solutions’ reliability [72]. Different PSS can also be formed by combining modular components’ design [28,73].

- Lean engineering practices have emerged as possible solutions to support effectiveness (improved product quality) and efficiency (time to market and lower development costs) [74]. To complement environmental performance of the model, lean bundles are considered (JIT: just-in-time, TQM: total quality management, and HRM: human resource management). When these bundles are simultaneously implemented along with a servitization strategy, they significantly improve sustainable development, although individual application does not always deliver positive performance [75]. Lean thinking also prevents wasting time and efforts during manufacturing activities and service operations [76]. Any activities that do not add value to the product/service and waste knowledge, time and resources must be eliminated from the process [77]. It is also important for the Lean PSS life cycle to be circular, which is fed from the start by customer value, leading the integration of products and services from the conceptual phase. This integration is supported during the design phase via problem-solving methods such as design for X (DfX) and TRIZ, encouraging the concurrent engineering of PSS and allowing engineers to consider new aspects under innovative management. The life cycle is divided into various stages: development, production, service use and operation, and end of life/disposal [78]. Including lean and DfX improves PSS, making the product components better suited to handle service characteristics from the beginning of their development process [79].

4. Discussion

An Approximation to a Road Map

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Global Footprint Network. Available online: https://www.footprintnetwork.org/ (accessed on 5 October 2021).

- Pearce, D.W.; Turner, R.K. Economics of Natural Resources and the Environment; The Johns Hopkins University Press: Baltimore, MD, USA, 1990; pp. 29–41. [Google Scholar]

- Towards the Circular Economy. Available online: https://ellenmacarthurfoundation.org/publications (accessed on 28 September 2021).

- Vandermerwe, S.; Rada, J. Servitization of business: Adding value by adding services. Eur. Manag. J. 1990, 6, 314–324. [Google Scholar] [CrossRef]

- Goedkoop, M.J.; van Halen, C.J.G.; te Riele, H.R.M.; Rommens, P.J.M. Product Service Systems, Ecological and Economic Basics; Report No. 1999/36; Dutch Ministries of Environment and Economic Affairs: Hague, The Netherlands, 1999.

- Baines, T.S.; Lightfoot, H.W.; Benedettini, O.; Kay, J.M. The servitization of manufacturing: A review of literature and reflection on future challenges. J. Manuf. Technol. Manag. 2009, 20, 547–567. [Google Scholar] [CrossRef] [Green Version]

- Annarelli, A.; Battistella, C.; Nonino, F. Product service system: A conceptual framework from a systematic review. J. Clean. Prod. 2016, 139, 1011–1032. [Google Scholar] [CrossRef]

- Reim, W.; Parida, V.; Örtqvist, D. Product-Service Systems (PSS) business models and tactics—A systematic literature review. J. Clean. Prod. 2015, 97, 61–75. [Google Scholar] [CrossRef]

- Matschewsky, J. Unintended Circularity?—Assessing a product-service system for its potential contribution to a circular economy. Sustainability 2019, 11, 2725. [Google Scholar] [CrossRef] [Green Version]

- Bocken, N.M.P.; de Pauw, I.; Bakker, C.; van der Grinten, B. Product design and business model strategies for a circular economy. J. Ind. Prod. Eng. 2016, 33, 308–320. [Google Scholar] [CrossRef] [Green Version]

- Stahel, W.R. The Preformance Economy, 2nd ed.; Palgrave Macmillan: New York, NY, USA, 2010; pp. 191–201. [Google Scholar]

- Stahel, W.R. The Utilization-Focused Service Economy: Resource Efficiency and Product-Life Extension. In The Greening of Industrial Ecosystems; Richards, D.J., Allenby, B.R., Eds.; National Academy Press: Washington, DC, USA, 1994; pp. 178–190. [Google Scholar]

- McDonough, W.; Braungart, M. Cradle to Cradle (De la Cuna a la Cuna): Rediseñando la Forma en que Hacemos las Cosas; MC Graw Hill: Madrid, Spain, 2005; pp. 87–111. [Google Scholar]

- Hidalgo-Carvajal, D.; Carrasco-Gallego, R.; Morales-Alonso, G. From goods to services and from linear to circular: The role of servitization’s challenges and drivers in the shifting process. Sustainability 2021, 13, 4539. [Google Scholar] [CrossRef]

- Bocken, N.M.P.; Short, S.W.; Rana, P.; Evans, S. A literature and practice review to develop sustainable business model archetypes. J. Clean. Prod. 2014, 65, 42–56. [Google Scholar] [CrossRef] [Green Version]

- Rosa, P.; Sassanelli, C.; Terzi, S. Circular Business Models versus circular benefits: An assessment in the waste from Electrical and Electronic Equipments sector. J. Clean. Prod. 2019, 231, 940–952. [Google Scholar] [CrossRef]

- Rosa, P.; Sassanelli, C.; Terzi, S. Towards Circular Business Models: A systematic literature review on classification frameworks and archetypes. J. Clean. Prod. 2019, 236, 117696. [Google Scholar] [CrossRef]

- Behrendt, S.; Jasch, C.; Kortman, J.; Hrauda, G.; Pfitzner, R.; Velte, D. Eco-Service Development: Reinventing Supply and Demand in the European Union, 1st ed.; Routledge: London, UK, 2003; pp. 14–20. [Google Scholar]

- Brezet, H.; Bijma, A.S.; Ehrenfeld, J.R.; Silvester, S. The Design of Eco-Efficient Services: Method, Tools and Review of the Case Study Based ‘Designing Eco-Efficient Services’ Project; Industrieel Ontwerpen: Delft, The Netherlands, 2001; pp. 8–12. [Google Scholar]

- Zaring, O.; Bartolomeo, M.; Eder, P.; Hopkinson, P.; Groenewegen, P.; James, P.; de Jong, P.; Nijhuis, L.; Scholl, G.; Slob, A.; et al. Creating Eco-Efficient Producer Services; Gothenburg Research Institute: Gothenburg, Sweden, 2001; pp. 119–140. [Google Scholar]

- Chou, C.J.; Chen, C.W.; Conley, C. An approach to assessing sustainable product-service systems. J. Clean. Prod. 2015, 86, 277–284. [Google Scholar] [CrossRef]

- Bressanelli, G.; Adrodegari, F.; Perona, M.; Saccani, N. Exploring how usage-focused business models enable circular economy through digital technologies. Sustainability 2018, 10, 639. [Google Scholar] [CrossRef] [Green Version]

- Kohtamäki, M.; Parida, V.; Oghazi, P.; Gebauer, H.; Baines, T. Digital servitization business models in ecosystems: A theory of the firm. J. Bus. Res. 2019, 104, 380–392. [Google Scholar] [CrossRef]

- Paschou, T.; Rapaccini, M.; Adrodegari, F.; Saccani, N. Digital servitization in manufacturing: A systematic literature review and research agenda. Ind. Mark. Manag. 2020, 89, 278–292. [Google Scholar] [CrossRef]

- Pirola, F.; Boucher, X.; Wiesner, S.; Pezzotta, G. Digital technologies in product-service systems: A literature review and a research agenda. Comput. Ind. 2020, 123, 103301. [Google Scholar] [CrossRef]

- Vendrell-Herrero, F.; Bustinza, O.F.; Parry, G.; Georgantzis, N. Servitization, digitization and supply chain interdependency. Ind. Mark. Manag. 2017, 60, 69–81. [Google Scholar] [CrossRef] [Green Version]

- Tukker, A.; Tischner, U. New Business for Old Europe. Product-Service Development, Competitiveness and Sustainability; Greenleaf Publishing: Sheffield, UK, 2006; pp. 12–14. [Google Scholar]

- Tukker, A. Product services for a resource-efficient and circular economy—A review. J. Clean. Prod. 2015, 97, 76–91. [Google Scholar] [CrossRef]

- Liberati, A.; Altman, D.G.; Tetzlaff, J.; Mulrow, C.; Gøtzsche, P.C.; Ioannidis, J.P.A.; Clarke, M.; Devereaux, P.J.; Kleijnen, J.; Moher, D. The PRISMA statement for reporting systematic reviews and meta-analyses of studies that evaluate healthcare interventions: Explanation and elaboration. BMJ 2009, 339, 57–58. [Google Scholar] [CrossRef] [Green Version]

- Kowalkowski, C.; Gebauer, H.; Kamp, B.; Parry, G. Servitization and deservitization: Overview, concepts, and definitions. Ind. Mark. Manag. 2017, 60, 4–10. [Google Scholar] [CrossRef]

- Mont, O.K. Clarifying the concept of product–service system. J. Clean. Prod. 2002, 10, 237–245. [Google Scholar] [CrossRef]

- Gershenson, J.K.; Prasad, G.J.; Zhang, Y. Product modularity: Definitions and benefits. J. Eng. Des. 2003, 14, 295–313. [Google Scholar] [CrossRef]

- Valencia, A.; Mugge, R.; Schoormans, J.P.L.; Schifferstein, H.N.J. The design of smart product-service systems (PSSs): An exploration of design characteristics. Int. J. Des. 2015, 9, 13–28. [Google Scholar]

- Lee, J.; Kao, H.A.; Yang, S. Service innovation and smart analytics for Industry 4.0 and big data environment. Procedia CIRP 2014, 16, 3–8. [Google Scholar] [CrossRef] [Green Version]

- Laney, D. 3D Data Management: Controlling Data Volume, Velocity and Variety; META Group: Stamford, CT, USA, 2001; pp. 1–3. [Google Scholar]

- Soderborg, N. Lean product development. In Proceedings of the WCBF Design for Six Sigma Conference, Las Vegas, NV, USA, 10 February 2008. [Google Scholar]

- Baines, T.S.; Lightfoot, H.W.; Evans, S.; Neely, A.; Greenough, R.; Peppard, J.; Roy, R.; Shehab, E.; Braganza, A.; Tiwari, A.; et al. State-of-the-art in product-service systems. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2007, 221, 1543–1552. [Google Scholar] [CrossRef] [Green Version]

- Baines, T.; Ziaee, A.; Bustinza, O.F.; Shi, V.G.; Baldwin, J.; Ridgway, K. Servitization: Revisiting the state-of-the-art and research priorities. Int. J. Oper. Prod. Manag. 2017, 37, 256–278. [Google Scholar] [CrossRef]

- Paiola, M.; Gebauer, H. Internet of things technologies, digital servitization and business model innovation in BtoB manufacturing firms. Ind. Mark. Manag. 2020, 89, 245–264. [Google Scholar] [CrossRef]

- Zheng, P.; Wang, Z.; Chen, C.H.; Pheng Khoo, L. A survey of smart product-service systems: Key aspects, challenges and future perspectives. Adv. Eng. Inform. 2019, 42, 100973. [Google Scholar] [CrossRef]

- Frank, A.G.; Mendes, G.H.S.; Ayala, N.F.; Ghezzi, A. Servitization and Industry 4.0 convergence in the digital transformation of product firms: A business model innovation perspective. Technol. Forecast. Soc. Chang. 2019, 141, 341–351. [Google Scholar] [CrossRef]

- Porter, M.E.; Heppelmann, J.E. How smart, connected products are transforming competition. Harv. Bus. Rev. 2014, 92, 64–88. [Google Scholar]

- Kohtamäki, M.; Parida, V.; Patel, P.C.; Gebauer, H. The relationship between digitalization and servitization: The role of servitization in capturing the financial potential of digitalization. Technol. Forecast. Soc. Chang. 2020, 151, 119804. [Google Scholar] [CrossRef]

- Oliva, R.; Kallenberg, R. Managing the transition from products to services. Int. J. Serv. Ind. Manag. 2003, 14, 160–172. [Google Scholar] [CrossRef] [Green Version]

- Neely, A. Exploring the financial consequences of the servitization of manufacturing. Oper. Manag. Res. 2008, 1, 103–118. [Google Scholar] [CrossRef] [Green Version]

- Beuren, F.H.; Gomes Ferreira, M.G.; Cauchick Miguel, P.A. Product-service systems: A literature review on integrated products and services. J. Clean. Prod. 2013, 47, 222–231. [Google Scholar] [CrossRef]

- Maxwell, D.; Van der Vorst, R. Developing sustainable products and services. J. Clean. Prod. 2003, 11, 883–895. [Google Scholar] [CrossRef]

- Sundin, E.; Lindahl, M.; Ijomah, W. Product design for product/service systems: Design experiences from Swedish industry. J. Manuf. Technol. Manag. 2009, 20, 723–753. [Google Scholar] [CrossRef]

- Kohtamäki, M.; Einola, S.; Rabetino, R. Exploring servitization through the paradox lens: Coping practices in servitization. Int. J. Prod. Econ. 2020, 226, 107619. [Google Scholar] [CrossRef]

- Frambach, R.T.; Wels-Lips, I.; Gündlach, A. Proactive product service strategies: An application in the European health market. Ind. Mark. Manag. 1997, 26, 341–352. [Google Scholar] [CrossRef]

- Aurich, J.C.; Fuchs, C.; Wagenknecht, C. Life cycle-oriented design of technical Product-Service Systems. J. Clean. Prod. 2006, 14, 1480–1494. [Google Scholar] [CrossRef]

- Mathieu, V. Service strategies within the manufacturing sector: Benefits, costs and partnership. Int. J. Serv. Ind. Manag. 2001, 12, 451–475. [Google Scholar] [CrossRef]

- Tukker, A.; Tischner, U. Product-services as a research field: Past, present and future. Reflections from a decade of research. J. Clean. Prod. 2006, 14, 1552–1556. [Google Scholar] [CrossRef]

- Meijkamp, R. Changing consumer behaviour through eco-efficient services: An empirical study of car sharing in the Netherlands. Bus. Strateg. Environ. 1998, 7, 234–244. [Google Scholar] [CrossRef] [Green Version]

- Roy, R. Sustainable product-service systems. Futures 2000, 32, 289–299. [Google Scholar] [CrossRef]

- Manzini, E.; Vezzoli, C. A strategic design approach to develop sustainable product service systems: Examples taken from the “environmentally friendly innovation” Italian prize. J. Clean. Prod. 2003, 11, 851–857. [Google Scholar] [CrossRef]

- Lerch, C.; Gotsch, M. Digitalized product-service systems in manufacturing firms: A case study analysis. Res. Technol. Manag. 2015, 58, 45–52. [Google Scholar] [CrossRef]

- Gebauer, H.; Fleisch, E.; Friedli, T. Overcoming the service paradox in manufacturing companies. Eur. Manag. J. 2005, 23, 14–26. [Google Scholar] [CrossRef]

- White, A.; Stoughton, M.; Feng, L. Servicizing: The Quiet Transition to Extended Product Responsibility; Tellus Institute: Boston, MA, USA, 1999; pp. 29–33. [Google Scholar]

- Rabetino, R.; Kohtamäki, M.; Gebauer, H. Strategy map of servitization. Int. J. Prod. Econ. 2017, 192, 144–156. [Google Scholar] [CrossRef]

- Morelli, N. Developing new product service systems (PSS): Methodologies and operational tools. J. Clean. Prod. 2006, 14, 1495–1501. [Google Scholar] [CrossRef]

- Ulaga, W.; Reinartz, W.J. Hybrid Offerings: How Manufacturing Firms Combine Goods and Services Successfully. J. Mark. 2011, 75, 5–23. [Google Scholar] [CrossRef]

- Cavalieri, S.; Pezzotta, G. Product-service systems engineering: State of the art and research challenges. Comput. Ind. 2012, 63, 278–288. [Google Scholar] [CrossRef]

- Tukker, A. Eight types of product-service system: Eight ways to sustainability? Experiences from suspronet. Bus. Strat. Environ. 2004, 13, 246–260. [Google Scholar] [CrossRef]

- Visnjic Kastalli, I.; Van Looy, B. Servitization: Disentangling the impact of service business model innovation on manufacturing firm performance. J. Oper. Manag. 2013, 31, 169–180. [Google Scholar] [CrossRef] [Green Version]

- The Benefits of Remanufacturing. Available online: https://www.caterpillar.com/en/company/sustainability/remanufacturing/benefits.html (accessed on 17 November 2021).

- Lenka, S.; Parida, V.; Wincent, J. Digitalization capabilities as enablers of value co-creation in servitizing firms. Psychol. Mark. 2017, 34, 92–100. [Google Scholar] [CrossRef] [Green Version]

- Zancul, E.D.S.; Takey, S.M.; Barquet, A.P.B.; Kuwabara, L.H.; Cauchick Miguel, P.A.; Rozenfeld, H. Business process support for IoT based product-service systems (PSS). Bus. Process. Manag. J. 2016, 22, 305–323. [Google Scholar] [CrossRef]

- Rymaszewska, A.; Helo, P.; Gunasekaran, A. IoT powered servitization of manufacturing—An exploratory case study. Int. J. Prod. Econ. 2017, 192, 92–105. [Google Scholar] [CrossRef]

- Rajala, R.; Brax, S.A.; Virtanen, A.; Salonen, A. The next phase in servitization: Transforming integrated solutions into modular solutions. Int. J. Oper. Prod. Manag. 2019, 39, 630–657. [Google Scholar] [CrossRef] [Green Version]

- Larsen, M.S.S.; Andersen, A.-L.N.K.; Brunoe, T.D. Modularity in Product-Service Systems: Literature Review and Future Research Directions. In Advances in Production Management Systems. Production Management for Data-Driven, Intelligent, Collaborative, and Sustainable Manufacturing; Moon, I., Lee, G., Park, J., Kiritsis, D., von Cieminski, G., Eds.; Springer: Cham, Switzerland, 2018; pp. 150–158. [Google Scholar]

- Davies, A.; Brady, T.; Hobday, M. Charting a path toward integrated solutions. MIT Sloan Manag. Rev. 2006, 47, 39–48. [Google Scholar]

- Johnson, M.; Roehrich, J.K.; Chakkol, M.; Davies, A. Reconciling and reconceptualising servitization research: Drawing on modularity, platforms, ecosystems, risk and governance to develop mid-range theory. Int. J. Oper. Prod. Manag. 2021, 41, 465–493. [Google Scholar] [CrossRef]

- Sassanelli, C.; Pezzotta, G.; Rossi, M.; Terzi, S.; Cavalieri, S. Towards a lean Product Service Systems (PSS) design: State of the art, opportunities and challenges. Procedia CIRP 2015, 30, 191–196. [Google Scholar] [CrossRef] [Green Version]

- Hao, Z.; Liu, C.; Goh, M. Determining the effects of lean production and servitization of manufacturing on sustainable performance. Sustain. Prod. Consum. 2021, 25, 374–389. [Google Scholar] [CrossRef]

- Romero, D.; Rossi, M. Towards Circular Lean Product-Service Systems. Procedia CIRP 2017, 64, 13–18. [Google Scholar] [CrossRef] [Green Version]

- Pezzotta, G.; Sassanelli, C.; Pirola, F.; Sala, R.; Rossi, M.; Fotia, S.; Koutoupes, A.; Terzi, S.; Mourtzis, D. The Product Service System Lean Design Methodology (PSSLDM): Integrating product and service components along the whole PSS lifecycle. J. Manuf. Technol. Manag. 2018, 29, 1270–1295. [Google Scholar] [CrossRef] [Green Version]

- Sassanelli, C.; Rossi, M.; Pezzotta, G.; de Jesus Pacheco, D.A.; Terzi, S. Defining lean product service systems features and research trends through a systematic literature review. Int. J. Prod. Lifecycle Manag. 2019, 12, 37–61. [Google Scholar] [CrossRef]

- Sassanelli, C.; Pezzotta, G.; Pirola, F.; Sala, R.; Margarito, A.; Lazoi, M.; Corallo, A.; Rossi, M.; Terzi, S. Using design rules to guide the PSS design in an engineering platform based on the product service lifecycle management paradigm. Int. J. Prod. Lifecycle Manag. 2018, 11, 91–115. [Google Scholar] [CrossRef] [Green Version]

- Fernandes, S.C.; Pigosso, D.C.A.; McAloone, T.C.; Rozenfeld, H. Towards product-service system oriented to circular economy: A systematic review of value proposition design approaches. J. Clean. Prod. 2020, 257, 120507. [Google Scholar] [CrossRef]

- Kjaer, L.L.; Pigosso, D.C.A.; Niero, M.; Bech, N.M.; McAloone, T.C. Product/Service-Systems for a Circular Economy: The Route to Decoupling Economic Growth from Resource Consumption? J. Ind. Ecol. 2019, 23, 22–35. [Google Scholar] [CrossRef] [Green Version]

- Michelini, G.; Moraes, R.N.; Cunha, R.N.; Costa, J.M.H.; Ometto, A.R. From Linear to Circular Economy: PSS Conducting the Transition. Procedia CIRP 2017, 64, 2–6. [Google Scholar] [CrossRef]

- Sklyar, A.; Kowalkowski, C.; Tronvoll, B.; Sörhammar, D. Organizing for digital servitization: A service ecosystem perspective. J. Bus. Res. 2019, 104, 450–460. [Google Scholar] [CrossRef]

- Mudd, G.M. Sustainability reporting and water resources: A preliminary assessment of embodied water and sustainable mining. Mine Water Environ. 2008, 27, 136–144. [Google Scholar] [CrossRef]

- Cifras Actualizadas de Minería. Available online: https://consejominero.cl/mineria-en-chile/cifras-actualizadas-de-la-mineria/ (accessed on 17 November 2021).

- Collahuasi se Transforma en la Primera Minera en Incorporar la Economía Circular en la Compra de Bienes y Contratos de Servicios. Available online: https://www.collahuasi.cl/collahuasi-se-transforma-en-la-primera-minera-en-incorporar-la-economia-circular-en-la-compra-de-bienes-y-contratos-de-servicios/ (accessed on 17 November 2021).

| Item | Definition | References |

|---|---|---|

| Servitization | The transformational process where a company changes from a product-centered business logic and model toward one centered on services. | [30] |

| Circular economy | An industrial economy that is restorative on purpose or by design. | [3] |

| Product-service systems (PSS) | A system of products and services supporting networks and infrastructure that is designed to be competitive, satisfy customers’ needs and have lower environmental impact than traditional business models. | [31] |

| Modularity | Products that decompose into subassemblages and components. This division facilitates component standardization and increases product variety. | [32] |

| Smart PSS | Integrating smart products and e-services in unique solutions. Smart products use ICT (information and communication technologies) to gather, process and produce data, while e-services are web portals, apps and media, which aid supplier-consumer communication. | [33] |

| Digitalization servitization | The transition toward smart product-servicesoftware systems that aid in value creation and capture via monitoring, control, optimization and autonomous function. | [23] |

| Internet of Things | Intelligence inserted into software integrated in industrial products and systems | [34] |

| Big Data | High volume, velocity and variety. | [35] |

| Lean | The practice (or group of practices) of eliminating and avoiding waste, adding more value to products and processes. | [36] |

| Journal | # of Articles | % |

|---|---|---|

| Journal of Cleaner Production | 20 | 18.18% |

| Procedia CIRP | 8 | 7.27% |

| Sustainability | 7 | 6.36% |

| International Journal of Operations & Production Management | 7 | 6.36% |

| Industrial Marketing Management | 6 | 5.45% |

| International Journal of Production Research | 5 | 4.55% |

| International Journal of Production Economics | 4 | 3.64% |

| Journal of Manufacturing Technology Management | 3 | 2.73% |

| Business Strategy and the Environment | 3 | 2.73% |

| CIRP Journal of Manufacturing Science and Technology | 2 | 1.82% |

| Journal of Marketing | 2 | 1.82% |

| International Journal of Service Industry Management | 2 | 1.82% |

| European Management Journal | 2 | 1.82% |

| Technological Forecasting and Social Change | 2 | 1.82% |

| Advanced Engineering Informatics | 2 | 1.82% |

| Journal of Business Research | 2 | 1.82% |

| Others | 33 | 30.00% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vargas, J.P.; Muñoz Lagos, A.P.; Feriz Torres, J.G.; Kinney, I.S.; Pérez Cortés, S.; Hurtado, J.P. Achieving Circularity through Novel Product-Service Systems in the Mining Industry: An Opportunity for Circularity. Sustainability 2022, 14, 3614. https://doi.org/10.3390/su14063614

Vargas JP, Muñoz Lagos AP, Feriz Torres JG, Kinney IS, Pérez Cortés S, Hurtado JP. Achieving Circularity through Novel Product-Service Systems in the Mining Industry: An Opportunity for Circularity. Sustainability. 2022; 14(6):3614. https://doi.org/10.3390/su14063614

Chicago/Turabian StyleVargas, Juan Pablo, Angélica Patricia Muñoz Lagos, José Guillermo Feriz Torres, Ian Scott Kinney, Sebastián Pérez Cortés, and Juan Pablo Hurtado. 2022. "Achieving Circularity through Novel Product-Service Systems in the Mining Industry: An Opportunity for Circularity" Sustainability 14, no. 6: 3614. https://doi.org/10.3390/su14063614

APA StyleVargas, J. P., Muñoz Lagos, A. P., Feriz Torres, J. G., Kinney, I. S., Pérez Cortés, S., & Hurtado, J. P. (2022). Achieving Circularity through Novel Product-Service Systems in the Mining Industry: An Opportunity for Circularity. Sustainability, 14(6), 3614. https://doi.org/10.3390/su14063614