Pecan (Carya illinoinensis) and Dairy Waste Stream Utilization: Properties and Economics of On-Farm Windrow Systems

Abstract

:1. Introduction

- All three treatments—PM (pecan and manure), PM/A (pecan, manure, and additions), and PMG/A (pecan, manure, “green chop”, and additions)—will result in the same quality of compost due to similar compost quality indicators based on selected physical, chemical and microbial properties of the finished compost product. Additions (A) were prescribed by the compost consulting company and included proprietary unknown inoculants; clay; unfinished compost from a past windrow processing; and community landscape material. The use of “green-chop” was also prescribed by the consulting company which included on-farm produced and harvested legumes.

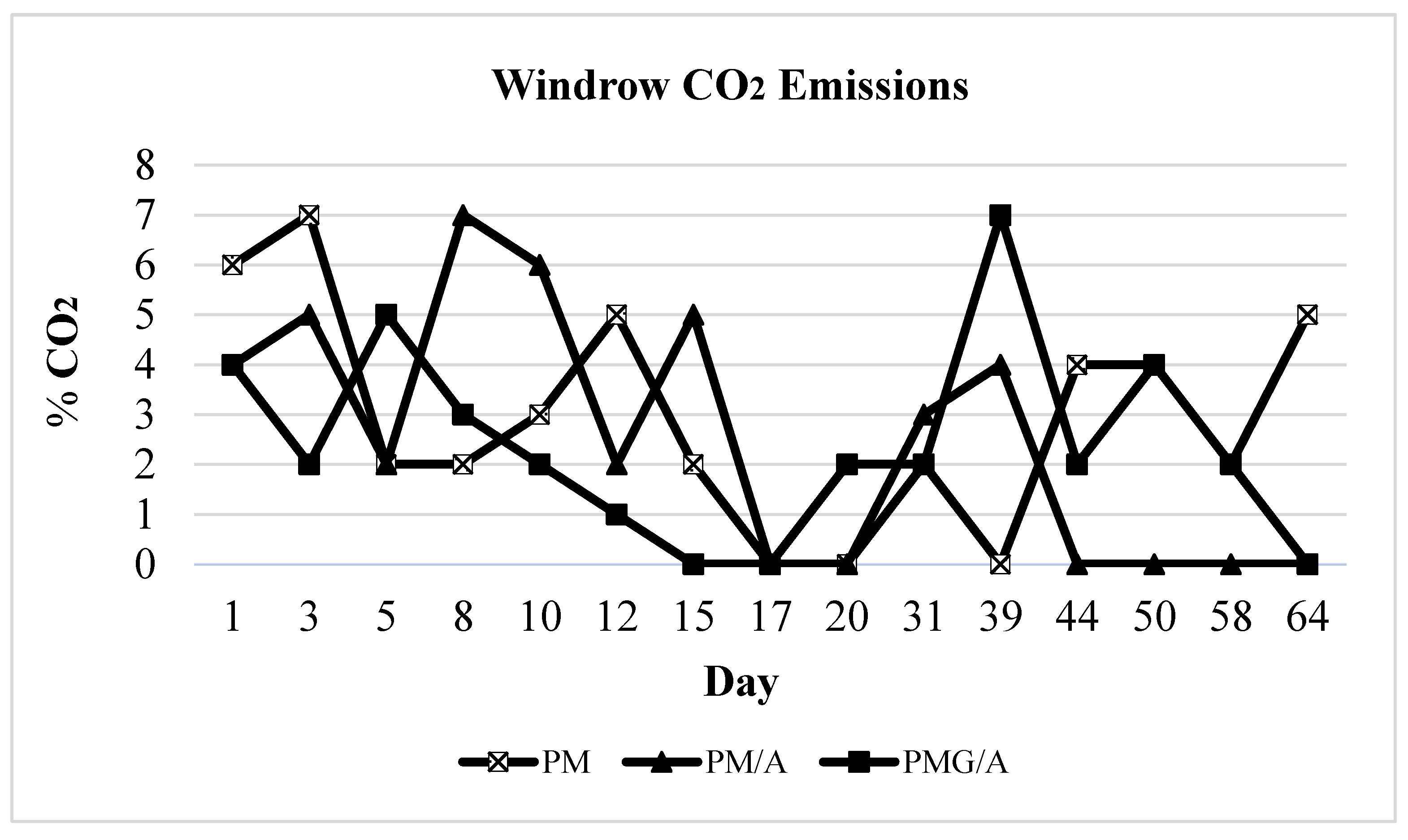

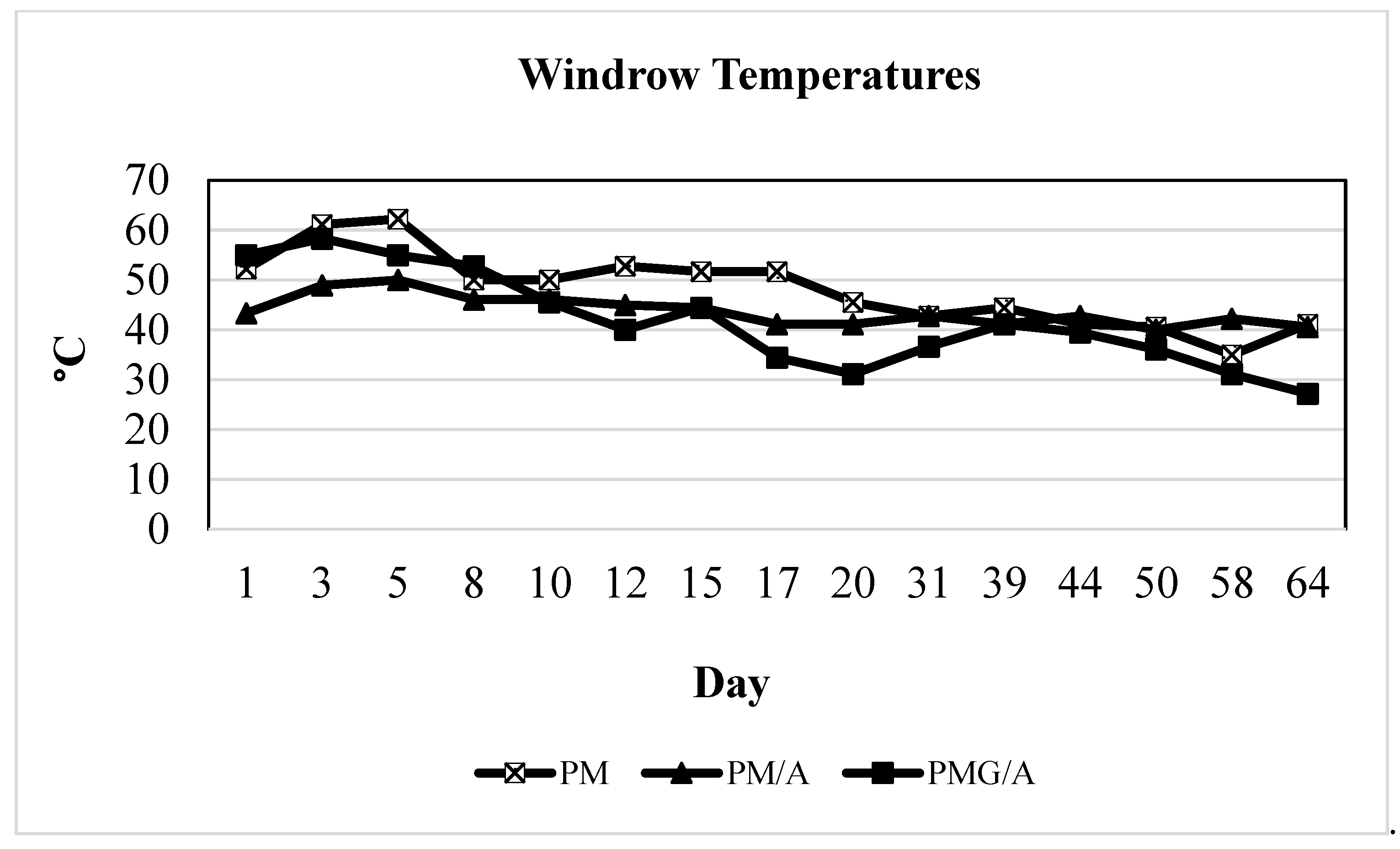

- The increased treatment turning/aeration and moisture inputs of the Additions (A) treatments will result in more rapid compost completion times because of faster decomposition kinetics. Treatment temperature thermodynamics will be positively impacted by treatment turning and moisture levels due to increased microbial activity. Treatment carbon dioxide rates will increase due to increased microbial respiration rates. The clay addition input will increase available moisture, resulting in higher microbial biomass [17].

- The higher relative amount of treatment manure in the PM treatment will result in both higher EC and overall microbial biomass because of the higher salt content and initial microorganisms present in the cattle dairy manure. More nitrate-N will be present in treatments higher in initial dairy manure [18]. More P and K values will be present in treatments with higher manure input treatments. The treatments with A inputs will be higher in secondary and micronutrients due to the additional nutrients in the substrate materials.

2. Materials and Methods

2.1. Windrow Site, Primary Substrate Descriptions, and Economic Analyses

2.2. Fixed Costs

2.3. Variable Costs: Pecan Biomass

2.4. Variable Costs: Dairy Manure

2.5. Pecan and Manure (PM) Windrow Economics

2.6. PM/A and PMG/A Windrows: Additional Windrow Input Economics

2.7. Compost Characterization

2.8. Treatment Statistical Analysis

3. Results and Discussion

3.1. Economic Windrow Comparisons

3.2. Compost Characterization

- All three treatments varied in initial estimated C:N substrate ratios and finished treatment mineralized macro, secondary and micronutrients. TKN and nitrate-N were not significantly different due to high variability among treatments. Higher P and K values were seen in the PM treatment. As an indicator of compost quality, all treatments were within acceptable amendment EC and pH ranges. All treatments varied in bulk density and microbial biomass; however, the PM treatment was highest in microbial biomass, likely because of the naturally inoculated manure treatment input and the PM treatment did include any additional non-inoculated inputs. Bulk density plays a critical role in relation to financial factors with materials transportation and with buyers in greenhouse application settings, etc., where the compost may be the primary plant growing medium.

- Only the PM/A treatment, not the PMG/A treatment, displayed faster decomposition kinetics, but this was not due to increased microbial biomass. The PMG/A treatment showed similar decomposition kinetics as the standard, minimally turned and watered PM treatment. The PMG/A and PM treatments showed similar carbon dioxide emission rates.

- The PM treatment was significantly highest in both EC and total microbial biomass, likely due to the high manure input. There was no significant difference amongst treatments for nitrate-N. Higher P and K values were seen in the higher volume ratio manure input PM treatment likely because of the higher initial P and K availabilities in manure. The treatments with “additional” inputs were not, in most cases, higher than the PM treatment in secondary and micronutrients. As the addition compost treatments did not display additional biological, chemical and physical attributes, the windrow additions do not justify the additional costs.

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| Windrow Turner and Water Applier | Salvage Value | Yearly Depreciation |

|---|---|---|

| - The windrow turner is affixed with a 500 gallon water drum and sprayer. - Water is supplied at no cost via grandfathered on-farm water rights and solar generated water pumping. - The 180-PTO diesel tractor powering the turner has a listed price of $200,000. With an estimated economic life of 15 years, a 180-PTO diesel tractor can be used approximately 400 h per year [21]. | Salvage value (current list price × remaining value factor): $200,000 × 23% = $46,000 Total depreciation = purchase price−salvage value= $180,000−$46,000 = $134,000 | Windrow turner/water applier yearly depreciation: $125,000 × 29% is $36,250; $88,750/15 (yearly depreciation) = $5916.67 |

| PM Finished Compost | PM/A Finished Compost | PMG/A Finished Compost |

|---|---|---|

| 129 m³ + 27 m³ = 156 m³ (initial substrate material) | 126 m³ + 38 m³ + 38 m³ + 25 m³ + 25 m³ = 252 m³ (initial substrate material) | 61 m³ + 15 m³ + 90 m³ + 15 m³ + 15 m³ = 196 m³ (initial substrate material) |

| (1000 lbs./yd³ (density of finished compost) × 1 tonne/2204.62 lbs. × 1.3 yd³/1 m³ × 156 m³) × 0.5 (compost decomposition rate) = 46 tonnes | (1000 lbs./yd³ (density of finished compost) × 1 tonne/2204.62 lbs. × 1.3 yd³/1 m³ × 252 m³) × 0.5 (compost decomposition rate) = 74 tonnes | (1000 lbs./yd³ (density of finished compost) × 1 tonne/2204.62 lbs. × 1.3 yd³/1 m³ × 196 m³) × 0.5 (compost decomposition rate) = 58 tonnes |

| On-Farm Pecan Biomass | Pecan Carbon Biomass Economic Factors | Pecan Shredding Labor Factors |

|---|---|---|

| 67.5 (acres/year trimmed) × 50 (trees/acre) × 258 (lbs. of tree mass trimmed) = 870,750 lbs. = 394.97 tonnes | Pecan rental limb horizonal grinder per year: $15,000 $15,000/394.97 tonnes = $37.98/tonne | For a 175 PTO tractor with $196,751 estimated price: Cost ($/hour) of use: Total = Overhead + Fuel + Labor Per Hour = $90.54 [22] |

| Dairy Manure | Relevant Parameters | Economic Factors |

|---|---|---|

| Dairy manure is approximately 17% of the total PM (control treatment) windrow volume. The density of dairy manure is 1674 lbs./cubic yard [31]. Initial dairy manure substrate for the PM compost treatment was 27 cubic yards. To determine dairy manure initial PM treatment substrate, in tonnes: 1674 lbs./cubic yard (density of dairy manure [31]) × 1 cubic yard/0.765 cubic meter × 1 metric ton/2204.62 lbs. × 27 cubic meters (initial dairy manure substrate material) = 27 tonnes. | PM treatment: 129 cubic meters of initial pecan biomass substrate | Density is 61 lbs./cubic foot for pecan biomass [32]. 61 (density) lbs./cubic foot × 1 tonne/2204.62 lbs. × 35.31 cubic feet/1 cubic meter × 129 cubic meters = 126 tonne $6/ton for manure delivery: $6/ton × 0.907 metric ton/ton = $6.62/tonne |

References

- NMDA (New Mexico Department of Agriculture). Preliminary Data Shows New Mexico’s 2019 Pecan Production Reached Record High. 2020. Available online: http://www.nmda.nmsu.edu/2020/01/preliminary-data-shows-new-mexicos-2019-pecan-production-reached-record-high/ (accessed on 28 August 2019).

- Kallestad, J.; Mexal, J.; Sammi, T.W. Mesilla Valley Pecan Orchard Pruning Residues: Biomass Estimates and Value-Added Opportunities Research Report 764; New Mexico State University Cooperative Extension Service and Agricultural Experiment Station Publications: Las Cruces, NM, USA, 2008. [Google Scholar]

- New Mexico Environment Department (NMED), Air Quality Bureau. New Mexico’s Smoke Management Program. 2018. Available online: https://www.env.nm.gov/air/quality/smp (accessed on 6 July 2020).

- Cabrera, V.E.; Hagevoort, R.G. Importance of the New Mexico Dairy Industry; CR 613; College of Agricultural, Consumer and Environmental Sciences, New Mexico State University: Las Cruces, NM, USA, 2007; Available online: https://aces.nmsu.edu/pubs/_circulars/CR613/welcome.html (accessed on 11 April 2020).

- NMDA. New Mexico Agricultural Statistics. 2017. Available online: http://www.nmda.nmsu.edu/wp-content/uploads/2019/01/BULLSTNM-Final-Revision-with-NMDA1.pdf (accessed on 24 March 2019).

- NMED Water Program. Water Resources & Management. 2019. Available online: https://www.env.nm.gov/water/ (accessed on 7 October 2020).

- FDA Food Safety Modernization Act (FSMA). Raw Manure under the FSMA Final Rule on Produce Safety. 2018. Available online: https://www.fda.gov/food/guidanceregulation/fsma/ucm482426.htm (accessed on 14 April 2020).

- Buchanan, L.B.; Doyle, M.P. Foodborne disease significance of Escherichia coli O157:H7 and other enterohemorrhagic E. coli. Food Tech. 1997, 51, 69–76. [Google Scholar]

- Davis, J.G.; Kendall, P. Preventing E. coli from Garden to Plate; Fact Sheet No. 9.369 Food and Nutrition Series Food Safety; Colorado State University Extension: Fort Collins, CO, USA, 2012; Available online: https://extension.colostate.edu/topic-areas/nutrition-food-safety-health/preventing-e-coli-from-garden-to-plate-9-369/ (accessed on 8 February 2020).

- Hess, T.F.; Grdzelishvili, I.; Sheng, H.; Hovde, C.J. Heat inactivation of E. coli during manure composting. Compost Sci. Util. 2004, 12, 314–322. [Google Scholar] [CrossRef]

- USDA, Economic Research Service. Organic Agriculture. 2018. Available online: https://www.ers.usda.gov/topics/natural-resources-environment/organic-agriculture/ (accessed on 5 March 2020).

- Viaene, J.; Lancker, J.V.; Vandecasteele, B.; Willekens, K.; Bijttebier, J.; Ruysschaert, G.; De Neve, S.; Reubens, B. Opportunities and barriers to on-farm composting and compost application: A case study from northwestern Europe. Waste Manag. 2016, 48, 181–192. [Google Scholar] [CrossRef] [PubMed]

- Chen, G.; Zhu, H.; Zhang, Y. Soil microbial activities and carbon and nitrogen fixation. Res. Microbiol. 2003, 154, 393–398. [Google Scholar] [CrossRef]

- Mylona, P.; Pawlowski, K.; Bisseling, T. Symbiotic Nitrogen Fixation. Plant Cell. 1995, 7, 869–885. [Google Scholar] [CrossRef] [PubMed]

- Kato, K.; Miura, N. Effect of matured compost as a bulking and inoculating agent on the microbial community and maturity of cattle manure compost. Bioresour. Technol. 2008, 99, 3372–3380. [Google Scholar] [CrossRef] [PubMed]

- Morris, J.; Bagby, J. Measuring Environmental Value for Natural Lawn and Garden Care Practices. Int. J. Life Cycle Assess. 2008, 13, 226–234. [Google Scholar] [CrossRef]

- Cooperband, L.R.; Ravet, J.L.; Fryda, M.R.; Stone, A.G. Relating compost measures of stability and maturity to plant growth. Compost Sci. Util. 2003, 11, 113–124. [Google Scholar] [CrossRef]

- Walker, K.M. Suitability of Composted Dairy Manure for Plant Production in New Mexico. Master’s Thesis, New Mexico State University, Las Cruces, NM, USA, 1999. [Google Scholar]

- Idrovo-Novillo, J.; Gavilanes-Terán, I.; Angeles Bustamante, M.; Paredes, C. Composting as a method to recycle renewable plant resources back to the ornamental plant industry: Agronomic and economic assessment of composts. Process Saf. Environ. Prot. Trans. Inst. Chem. Eng. Part B 2018, 116, 388–395. [Google Scholar] [CrossRef]

- Sierra Vista Growers; Anthony, N.M. Bulk Materials. 2020. Available online: https://www.sierravistagrowers.net/products-bulk-materials (accessed on 7 September 2020).

- Edwards, W. Estimating Farm Machinery Costs; Ag Decision Maker; Iowa State University Extension and Outreach: Ames, IA, USA, 2015; Available online: https://www.extension.iastate.edu/agdm/crops/html/a3-29.html (accessed on 6 July 2021).

- Lattz, D.; Schnitkey, G. Machinery Cost Estimates Summary. Summary of costs for Field Operations, Harvest Operations, Tractor and Forage Operations. In Illinois Farm Management Handbook; University of Illinois Extension: Urbana, IL, USA, 2019; Available online: https://farmdoc.illinois.edu/wp-content/uploads/2019/08/machinery-cost-estimates_summary.pdf (accessed on 30 January 2022).

- US Composting Council. Compost Sample Collection and Laboratory Preparation. Field Sampling of Compost Materials and Test Methods for the Examination of Composting. 2018. Available online: https://www.compostingcouncil.org/ (accessed on 5 February 2020).

- Levanon, D.; Pluda, D. Chemical, physical and biological criteria for maturity in composts for organic farming. Compost Sci. Util. 2002, 10, 339–346. [Google Scholar] [CrossRef]

- Gavlak, R.G.; Horneck, D.A.; Miller, R.O. Plant, Soil and Water Reference Methods for the Western Region; WREP 125; University of Alaska: Fairbanks, AK, USA, 1994. [Google Scholar]

- Lindsay, W.L.; Norvell, W.A. Development of a DTPA soil test for zinc, iron, manganese, and copper. Soil Sci. Soc. Am. J. 1978, 42, 421–428. [Google Scholar] [CrossRef]

- Ward Laboratories, Inc. PLFA. 2019. Available online: https://www.wardlab.com/plfa/#:~:text=PLFA%20Soil%20biological%20testing%20at%20Ward%20Laboratories%20is,functional%20groups%20of%20interest%20through%20known%20PLFA%20biomarkers (accessed on 12 January 2022).

- Sullivan, D.; Bary, A.I.; Miller, R.O.; Brewer, L.J. Interpreting Compost Analyses; EM 9217, Oregon State University Extension Service. 2018. Available online: https://catalog.extension.oregonstate.edu/sites/catalog/files/project/pdf/em9217.pdf (accessed on 1 July 2020).

- McKenzie, N.J.; Jacquier, D.J.; Isbell, R.F.; Brown, K.L. Australian Soils and Landscapes an Illustrated Compendium; CSIRO Publishing: Clayton, VIC, Australia, 2004. [Google Scholar] [CrossRef]

- Iannotti, D.A.; Grebus, M.E.; Toth, B.L.; Madden, L.V.; Hoitink, H.A.J. Oxygen respirometry to assess stability and maturity of composted municipal solid waste. J. Environ. Qual. 1994, 23, 1177–1183. [Google Scholar] [CrossRef]

- Lorimor, J.; Powers, W.; Sutton, A. Manure Characteristics MWPS-18 Section 1, Second Edition Manure Management Systems Series; MidWest Plan Service, Iowa State University: Ames, IA, USA, 2004; Available online: https://www.canr.msu.edu/uploads/files/ManureCharacteristicsMWPS-18_1.pdf (accessed on 1 May 2019).

- United States Forest Service. Weights of Various Woods Grown in the United States; Technical Note, Number 218; Forest Products Laboratory: Madison, WI, USA, 1931. Available online: https://www.fpl.fs.fed.us/documnts/fpltn/fpltn-218-1931.pdf (accessed on 2 September 2021).

| Treatment | Substrates and Quantities | Windrow Maintenance Procedures |

|---|---|---|

| PM | Pecan tree biomass (P): 129 m³ (83%) Manure (M): 27 m³ (17%) | Weekly turning and watering |

| PM/A | Pecan tree biomass (P): 126 m³ (50%) Manure (M): 38 m³ (15%) Landscaping material (Addition “A”): 38 m³ (15%) Compost, unfinished (A): 25 m³ (10%) Clay (A): 25 m³ (10%) | One-time clay and unfinished compost applications Daily turning and watering Weekly combining Daily edge cleaning |

| PMG/A | Pecan tree biomass (P): 61 m³ (31%) Manure (M): 15 m³ (8%) Compost, unfinished (Addition “A”): 15 m³ (8%) Clay (A): 15 m³ (8%) Green-chop (G): 90 m³ (46%) | One-time clay and unfinished compost applications One-time green-chop application Daily turning and watering Weekly combining Daily edge cleaning |

| Quantity | Unit | Price ($) | Total ($) | |

|---|---|---|---|---|

| Revenue ($) | 517 | tonnes | 110.00 | 56,870.00 |

| Variable costs ($/quantity) | ||||

| Pecan shredding’s, labor ($/hour) | 17 | hour | 15.00 | 255 |

| Pecan limb grinder for shreddings production | 17 | hour | 62.37 | 1060.29 |

| Manure | 161 | tonnes | 6.62 | 1065.82 |

| A (Additions inputs) | ||||

| “Inoculant combination pack” (/application) | 11 | application | 719.49 | 7914.39 |

| “N-Converter” | 11 | application | 128.16 | 1409.76 |

| Green-chop | 11 | application | 1200.00 | 13,200.00 |

| Clay ($/application) | 11 | application | 725.67 | 7982.37 |

| Compost (unfinished) | 11 | application | 895.44 | 9849.84 |

| Windrow management | ||||

| John Deere tractor 6120R | 17 | hour | 18.37 | 312.29 |

| John Deere frontend loader | 17 | hour | 29.00 | 493 |

| Bobcat skid steer | 17 | hour | 6.58 | 111.86 |

| Windrow establishment labor ($/hour labor) | 17 | hour | 15.00 | 255.00 |

| Windrow processing (turning and watering) | 990 | hour | 15.00 | 14,850 |

| Variable costs total ($) | 58,759.62 | |||

| Fixed costs ($/hour/year) | ||||

| John Deere tractor 6120R (windrow processing) | 990 | hour | 18.37 | 18,186.30 |

| Aeromaster PT-130 compost turner (windrow processing) | 990 | hour | 0.41 | 405.90 |

| Aeromaster WT-3000 water wagon (windrow processing) | 990 | hour | 0.21 | 207.90 |

| Hydraulic pump & miscellaneous equipment (windrow processing) | 990 | hour | 0.03 | 29.70 |

| Fixed costs total ($) | 18,829.80 | |||

| Total cost ($) | 77,589.42 | |||

| Breakeven price ($) | 150.00 | |||

| Contribution margin (net return) ($) | −20,719.42 | |||

| Quantity | Unit | Price ($) | Total ($) | |

|---|---|---|---|---|

| Revenue ($) | 660 | tonnes | 110.00 | 72,600 |

| Variable costs ($/quantity) | ||||

| Pecan shredding’s ($/hr of labor) | 17 | hour | 15.00 | 255.00 |

| Pecan limb horizontal grinder for shedding’s production $/hr | 15 | hour | 62.37 | 935.55 |

| Manure ($/quantity) | 135 | tonnes | 6.62 | 893.70 |

| Windrow management | ||||

| Windrow establishment labor | 15 | hour | 15.00 | 225.00 |

| John Deere tractor 6120R (establishment) | 10 | hour | 18.37 | 183.70 |

| John Deere front end loader (used for establishment only) | 10 | hour | 29.00 | 290.00 |

| Bobcat skid steer (used for establishment only) | 5 | hour | 6.58 | 32.90 |

| Windrow processing (turning and watering) $/hr | 55 | hour | 15.00 | 825.00 |

| Variable costs total ($) | 3640.85 | |||

| Fixed cost ($/hour/year) | ||||

| John Deere tractor 6120R (windrow processing) | 55 | hour | 18.37 | 1010.35 |

| Aeromaster PT-130 compost turner | 55 | hour | 0.41 | 22.55 |

| Aeromaster WT-3000 water wagon | 55 | hour | 0.21 | 11.55 |

| Hydraulic pump and miscellaneous equipment | 55 | hour | 0.03 | 1.65 |

| Fixed cost total ($) | 1046.10 | |||

| Total cost ($) | 4686.95 | |||

| Breakeven price ($) | 7.00 | |||

| Contribution margin (net return) ($) | 68,023.05 | |||

| Quantity | Unit | Price ($) | Total ($) | |

|---|---|---|---|---|

| Revenue | 420 | tonnes | 110.00 | 46,200.00 |

| Variable costs ($/quantity) | ||||

| Pecan shredding’s ($/hours of labor) | 15 | hour | 15.00 | 225.00 |

| Pecan limb horizontal grinder for shredding’s production | 15 | hour | 62.37 | 935.55 |

| Dairy Manure | 185 | tonnes | 6.62 | 1224.70 |

| A (Additional inputs) | ||||

| “Inoculant combination pack” ($/application) | 5 | applied | 719.49 | 3597.45 |

| “N-Converter” ($/application) | 5 | applied | 128.16 | 640.80 |

| Clay ($/application) | 5 | applied | 725.67 | 3628.35 |

| Compost (unfinished)($/application) | 5 | applied | 895.44 | 4477.20 |

| Windrow management | ||||

| John Deere tractor 6120R (establishment) | 10 | hour | 18.37 | 183.70 |

| John Deere tractor front-end loader for establishment only. | 10 | hour | 29.00 | 290.00 |

| Bobcat skid steer (used for establishment only) | 5 | hour | 6.58 | 32.90 |

| Windrow establishment labor ($/hour of labor) | 15 | hour | 15.00 | 225.00 |

| Windrow processing (turning and watering) ($/hour of labor) | 350 | hour | 15 | 5250.00 |

| Total variable costs ($) | 20,710.65 | |||

| Fixed costs ($/hour/year) | ||||

| John Deere tractor 6120R (windrow processing) | 350 | hour | 18.37 | 6429.50 |

| Aeromaster PT-130 compost turner (windrow processing) | 350 | hour | 0.41 | 143.50 |

| Aeromaster WT-3000 water wagon (windrow processing) | 350 | hour | 0.21 | 73.50 |

| Hydraulic pump and miscellaneous equipment (windrow processing) | 350 | hour | 0.03 | 10.50 |

| Fixed costs total ($) | 6657.00 | |||

| Total cost ($) | 27,367.65 | |||

| Breakeven price ($) | 65.00 | |||

| Contribution margin (net return) | 18,832.35 | |||

| Selected Variables | PM | PM/A | PMG/A | p-Value |

|---|---|---|---|---|

| TKN (mg kg−1) | 12,782 † | 5508 | 7666 | 0.6166 |

| Nitrate_N (mg kg−1) | 10.45 | 813.2 | 1279 | 0.1066 |

| P (mg kg−1) | 536.9 a | 414.9 b | 350.8 b | 0.0089 |

| K (mg kg−1) | 4722 a | 2018 b | 2365 b | 0.0269 |

| Ca (mg kg−1) | 49.50 a | 34.60 b | 21.73 c | 0.0078 |

| Mg (mg kg−1) | 37.77 a | 23.67 b | 11.66 c | 0.0001 |

| Fe (mg kg−1) | 13.85 | 16.57 | 10.13 | 0.0533 |

| Mn (mg kg−1) | 24.53 b | 17.13 c | 29.07 a | 0.0027 |

| Zn (mg kg−1) | 25.29 a | 16.67 b | 20.00 b | 0.0131 |

| Cu (mg kg−1) | 3.31 a | 2.31 b | 2.24 b | 0.0091 |

| EC (dS/m) | 16.93 a | 12.54 b | 11.38 b | 0.0012 |

| SAR (meg/L) | 6.54 b | 9.02 a | 6.68 b | 0.0015 |

| Na (meg/L) | 43.13 a | 48.77 a | 27.33 b | 0.0028 |

| pH | 7.63 | 7.73 | 7.67 | 0.4444 |

| Organic matter (%) | 24.30 | 13.38 | 20.31 | 0.2389 |

| Organic carbon (%) | 14.14 | 7.78 | 11.81 | 0.2395 |

| Bulk density (g/cm³) | 0.44 c | 0.63 a | 0.51 b | 0.0005 |

| Diversity indices | 1.30 | 1.33 | 1.37 | 0.8291 |

| Total microbial biomass (ng/g) | 12,860 a | 4908 c | 8208 b | 0.0017 |

| Volumetric water content (%) | 32.92 | 37.06 | 24.06 | 0.2937 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Creegan, E.F.; Flynn, R.; Torell, G.; Brewer, C.E.; VanLeeuwen, D.; Acharya, R.N.; Heerema, R.J.; Darapuneni, M. Pecan (Carya illinoinensis) and Dairy Waste Stream Utilization: Properties and Economics of On-Farm Windrow Systems. Sustainability 2022, 14, 2550. https://doi.org/10.3390/su14052550

Creegan EF, Flynn R, Torell G, Brewer CE, VanLeeuwen D, Acharya RN, Heerema RJ, Darapuneni M. Pecan (Carya illinoinensis) and Dairy Waste Stream Utilization: Properties and Economics of On-Farm Windrow Systems. Sustainability. 2022; 14(5):2550. https://doi.org/10.3390/su14052550

Chicago/Turabian StyleCreegan, Emily F., Robert Flynn, Greg Torell, Catherine E. Brewer, Dawn VanLeeuwen, Ram N. Acharya, Richard J. Heerema, and Murali Darapuneni. 2022. "Pecan (Carya illinoinensis) and Dairy Waste Stream Utilization: Properties and Economics of On-Farm Windrow Systems" Sustainability 14, no. 5: 2550. https://doi.org/10.3390/su14052550

APA StyleCreegan, E. F., Flynn, R., Torell, G., Brewer, C. E., VanLeeuwen, D., Acharya, R. N., Heerema, R. J., & Darapuneni, M. (2022). Pecan (Carya illinoinensis) and Dairy Waste Stream Utilization: Properties and Economics of On-Farm Windrow Systems. Sustainability, 14(5), 2550. https://doi.org/10.3390/su14052550