Abstract

Microbial-induced calcium carbonate precipitation (MICP) has the potential to be an environmentally friendly technique alternative to traditional methods for sustainable coastal stabilization. This study used a non-pathogenic strain that exists in nature to experimentally investigate the application of the MICP technique on mitigating sandy beach erosion. First, the unconfined compressive strength (UCS) test was adopted to explore the consolidation performance of beach sand after the MICP treatment, and then model tests in a wave flume were conducted to investigate the MICP ability to mitigate beach erosion by plunger waves. This study also employed field emission scanning electron microscopy (FE-SEM) and energy-dispersive X-ray spectroscopy (EDS) to observe the crystal forms of MICP-treated sand after wave action. The results reveal that the natural beach sand could be consolidated by the MICP treatment, and the compressive strength increased with the increase in the cementation media concentration. In this study, the maximum compressive strength could be achieved was 517.3 kPa. The one-phase and two-phase MICP treatment strategies were compared of sandy beach erosion tests with various spray and injection methods on the beach surface. The research results indicate that the proper MICP treatment could mitigate beach erosion under various wave conditions; the use of MICP reduced beach erosion up to 33.9% of the maximum scour depth.

1. Introduction

Coastal beaches are precious due to their ecological and recreational value for mostly island countries. However, coastal beaches are likely eroded by extreme waves and the rise in sea level due to global climate change. Except for a small number of estuaries and seashores with siltation, most of the beaches in Taiwan are eroded by various wave and nearshore current forces [1]. In areas with severe erosion, the engineering agency has built traditional seawalls or placed tetrapods to defend against storm waves. Unfortunately, these conventional forms of hard engineering degrade the coastal landscape aesthetically and might also accelerate the loss of the beach in front of the seawall due to toe scouring. Thus, it is important to search for alternative methods for environmentally friendly coastal stabilization.

Recent studies have proposed an environmentally friendly technique for geological improvement based on the treatment of microbial-induced calcium carbonate precipitation (MICP). In this technique, microorganisms that exist in nature are used to accelerate diagenesis, thereby crystallizing and solidifying sand and soil to increase their stability. The MICP-based technique currently features various mechanisms, such as urea hydrolysis, sulfate reduction, ferric iron reduction, and denitrification, for inducing calcium carbonate precipitation according to the type of microorganism involved. Among them, mainstream techniques use microorganisms involved in urea hydrolysis; they are widely distributed in the soil, exert straightforward effects, and have a minimal environmental impact [2,3]. The chemical equations associated with urea hydrolysis are shown in Equations (1)–(5) [4]. These mainstream techniques generally achieve soil consolidation by filling the interstitial spaces of the soil with calcium carbonate generated after calcification, thereby cementing the soil. Numerous studies have demonstrated that a properly applied MICP technique can allow microorganisms to deposit abundant calcium carbonate (CaCO3) in the interstices of the soil over a short period and cement them into agglomerates. Therefore, biomineralization, which normally takes several years in nature, can be shortened to just a few days. Should this MICP technique be optimized for use in natural environments such as coasts, it could improve the ability of beaches to resist erosion by waves or become a method for biotechnical-based coastal stabilization. Compared with conventional rigid construction methods [5], this technique is more sustainable, durable, flexible, aesthetically pleasing, environmentally friendly, and economical [6].

(NH2)2CO + H2O → 2NH3 + CO2

2NH3 + 2H2O → 2NH4+ + 2OH−

CO2 + 2OH− → HCO3−

HCO3− + OH− → CO32− + H2O

Ca2+ + CO32− → CaCO3↓

Applications of MICP have been proposed in the literature. Montoya et al. [7] experimentally demonstrated that MICP-improved soil cementation can mitigate soil liquefaction and increase foundation stability. Wang et al. [8] studied the application of the MICP technique in an embankment erosion test, and the results indicate that the MICP-treated samples effectively resisted the erosion at a certain depth below the surface. Rong [9] applied the MICP technique on fine-grained slopes in a rainfall test, and indicated that the MICP treatment efficiently reduced the mass loss rate and improved the acid corrosion resistance of the slopes. In addition, Van Paassen et al. [10] conducted a large-scale consolidation test and found that loose sand after MICP treatment was successfully cemented into agglomerates and the rigidity improved. Gomez et al. [11] demonstrated through field-scale experiments that MICP can improve the erosion resistance of loose sand samples and inhibit dust to achieve surface stability.

The MICP technique has been recently investigated to mitigate beach erosion. Nayanthara et al. [12] reported that the MICP technique can improve resistance to beach erosion without disturbing the hydraulics of soil samples. Imran et al. [13] also reported that, in contrast to conventional materials, which are neither viable over the long term nor environmentally friendly, the MICP technique is suitable for protecting coastal structures. Shahin et al. [14] used a hydraulic model test to demonstrate that the MICP technique can be used to control the beach erosion of a 45° sandy slope to within 5%. Liu et al. [15] tested the enzymatically induced calcium carbonate precipitation (EICP) and the MICP in protecting coastal dunes, and revealed that both MICP and EICP produce excellent erosion resistance ability under the short duration action in typical wave conditions. The soil consolidation force generated by MICP is not only affected by the bacterial species and the cement composition but also (and to a great extent) by the MICP treatment strategy used. MICP treatment strategies could be divided into one-phase and two-phase [16,17,18]. The aim of these treatment strategies is to enhance the effects of MICP by preventing the rapid reaction of microorganisms and cement, which can cause clogging between sand bodies and lead to uneven consolidation.

This study investigates the effectiveness of MICP in mitigating beach erosion for coastal stabilization. First, a UCS test was performed to determine the MICP-induced compressive strength of the beach sand on the coast site. On the basis of the test results, a novel one-phase low-pH injection method and a two-phase method were experimentally evaluated, and a suitable construction method for mitigating beach erosion was proposed. Subsequently, MICP was used to mitigate beach erosion under various wave conditions. The second section of this study describes the microbial species, microorganism culture and expansion, cement composition, and UCS results; it also describes the configuration of, method of application in, and elemental analyzer used in the wave scour tests. The effects of various treatment strategies are evaluated in the Results and Discussion Section. Finally, the effectiveness of MICP in mitigating beach erosion under different wave conditions are addressed briefly.

2. Materials and Methods

2.1. Microbe, Chemicals, and the Environment

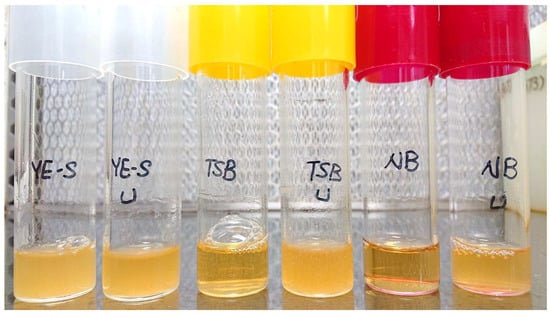

In this study, Sporosarcina Pasteurii (BCRC11596) was used as the microorganism for the MICP technique. The strain is Gram positive, rod shaped, and ubiquitous in soil. It can secrete urease to hydrolyze urea rapidly; the urease has high activity and no NH4+ inhibition, and is an ideal strain for the MICP technique. In addition, it has no risk of pathogenicity or genetic modification [19]. This study cultivated S. Pasteurii according to the formula, nutrient broth (NB), trypticase soy broth (TSB), and yeast extract and sucrose broth (YES) recommended by the Bioresources Collection and Research Center, Leibniz Institute (DSMZ)-German Collection of Microorganisms and Cell Cultures GmbH, and American Type Culture Collection. The broth also added urea according to the common formula for testing. Figure 1 shows the photo of each cultivated medium after 72 h of culture, in which the notation “U” denotes that the urea was added to the solution. It can be seen that TSB and NB were still in a clear state in the absence of urea, indicating that TSB and NB could not be implemented to cultivate S. Pasteurii without urea. These results are consistent with those of Ma et al. [20]. The obviously turbid culture media were subjected to photometric measurement, where the medium with the highest turbidity was TSB with urea (OD600 = 2.870). Thus, the culture and expansion for the consolidation tests were conducted using TSB with urea. Referring to the results of Wang et al. [21], this study set the culture temperature in the experiment to 30 °C and the target culture and expansion concentration to OD600 = 1.2. In addition, this study obtained calcium by applying the method of Abo-El-Enein et al. [22] and referenced Achal et al. [23] to use calcium chloride (CaCl2) as the cementation media. The number of days over which the reaction was allowed to occur was based on the results obtained in [24], and curing was performed at room temperature for 7 days when the reaction was completed.

Figure 1.

Photo of each cultivated medium after 72 h of culture. YE-S: yeast extract and sucrose broth; TSB: trypticase soy broth; NB: nutrient broth; U: urea added.

2.2. Solidification Test

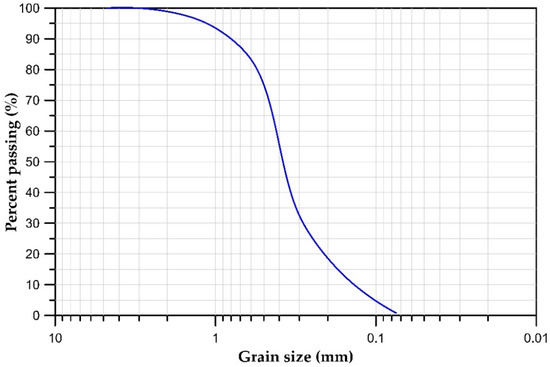

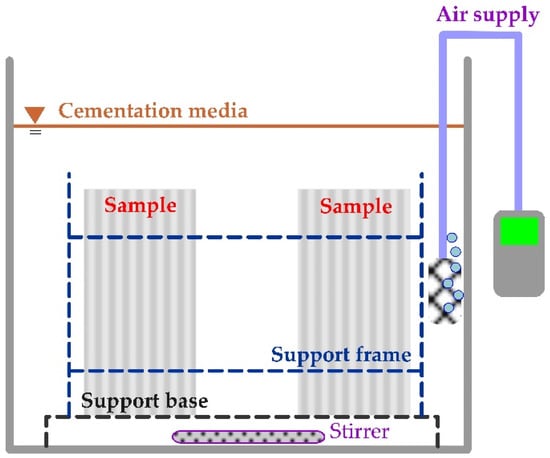

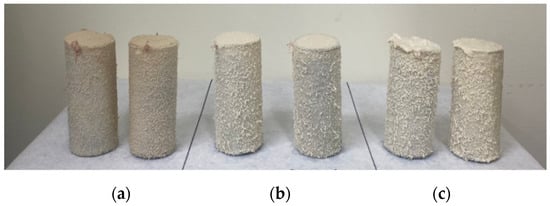

This study conducted a preliminary test of the solidification of the MICP technique on beach sand, and the maximum compressive strength was determined through the UCS test. Sea sand from the west coast of Taiwan was used to test how natural sand in Taiwan reacts when subjected to MICP treatment. The specific gravity of the sea sand samples was 2.67 and the median diameter D50 was 0.403 mm (Figure 2). In this test, the cementation media were tested at three ratios of CaCl2 to urea, wherein each ratio had 0.5 M, 1.0 M, and 1.5 M CaCl2 solution (Table 1). In addition, TSB and urea were added to maintain the supply of nutrients at the level needed by the bacteria throughout the reaction. In this study, nonwoven geotextiles were used to make specimens for the UCS test. First, the nonwoven geotextiles were used to preliminarily bundle the loose sand samples that were then placed into the batch reactor. The reactor had a porous base and a support frame and could thus maintain the cylindrical shape of the samples. During the reaction, a magnetic stirrer was used to facilitate microorganism flow, and gas was provided to increase the oxygen content. The reactor is illustrated in Figure 3. The reactor allowed the samples to immerse completely in the microorganisms. After the reaction was completed, the samples were taken out and air dried at room temperature for 7 days (Figure 4).

Figure 2.

Particle size distribution curve of sand used in the present experiment.

Table 1.

Concentration of cementation solution.

Figure 3.

Sketch of the sample batch reactor.

Figure 4.

Photograph of UCS samples after the reactions in the full-contact flexible mold, with cementation solution (a) 0.5 M, (b) 1.0 M, and (c) 1.5 M.

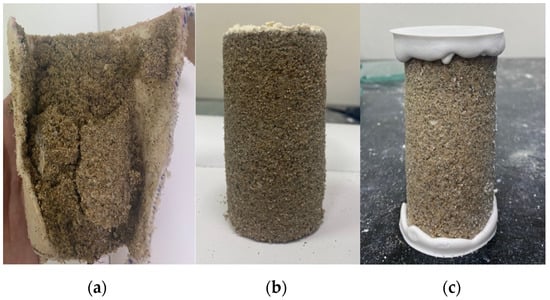

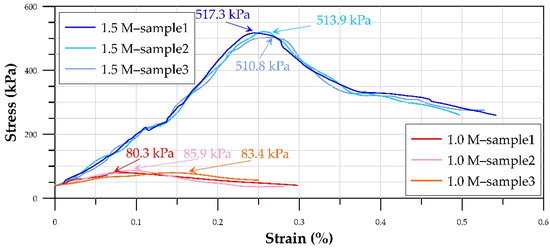

After the reaction, the samples were placed under a compression tester (YS/7000-LA25T) for the UCS test. Because the 0.5 M sample was not well cemented, it began to break after demolding and its UCS test could not be conducted (see Figure 5a). Therefore, the UCS test results were only for 1.0 M and 1.5 M (Figure 6). According to the results, higher compressive strength could be achieved at higher cement concentrations. As shown in Figure 6, at 1.5 M all samples had a compressive strength exceeding 500 kPa, which was equivalent to approximately 5 kg/cm2. Therefore, the subsequent tests were conducted with 1.5 M cementation media.

Figure 5.

UCS samples after casting off, with cementation solution (a) 0.5 M, (b) 1.0 M, and (c) 1.5 M.

Figure 6.

Stress–strain curve of the UCS samples.

2.3. Setup of Erosion Test

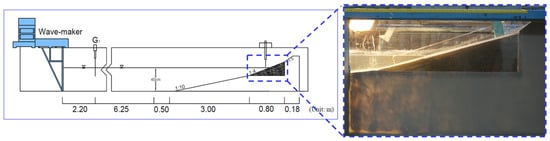

A movable bed model test of beach erosion was implemented in a wave flume. As depicted in Figure 7, the wave flume was 15.0 m long, 0.5 m wide, and 0.6 cm high. The bottom of the wave flume was made of a smooth piece of stainless steel. The lateral walls of the wave flume were made of tempered glass to facilitate observation during the test. One end of the wave flume had a crankshaft wave maker, and the other end housed the sandy beach model with a 1:4 slope for the test. The depth gauge with 0.1 mm resolution was mounted on the carrier and moved along the flume with a 1.0 cm interval to measure the scouring profile. The capacitance-type wave gauge was set 2.2 m in front of the wave maker to measure the waveform of the incident wave and verify that the wave characteristics met the test requirements. The incident wave conditions were designed with reference to the surf similarity parameter (ξ) defined by Battjes [25], and the plunging wave breaker on the slope was performed to ensure that the test waves exhibited erosive characteristics. The wave conditions in the experiments are listed in Table 2.

Figure 7.

Setup of the experimental sandy beach and the wave flume.

Table 2.

Test wave conditions.

2.4. Treatment Strategies

The MICP treatment strategies in this experiment included one-phase and two-phase strategies. The one-phase strategy was implemented per the results of Cheng et al. [26], wherein the pH value of the microorganisms was reduced to 5.0 to achieve one-phase soil cementation. When the microorganisms have a relatively low pH value, the rapid reaction of the bacteria in contact with Ca2+ can be easily controlled and the clogging caused by rapid precipitation can be prevented. Moreover, at a relatively low pH value, the urea hydrolysis reaction initially neutralizes the pH value in the solution; only when the pH value gradually increases to a level that meets the alkaline environment requirements for the formation of CaCO3 precipitation does the cementation reaction gradually begin. The two-phase strategy referenced the method proposed by Shahrokhi-Shahraki et al. [18]. The microorganisms were added to the soil and set for 6 h before the cementation media were added. The advantage of such a method is that it can make the microorganisms fully penetrate the soil and prevent the formation of excessive CaCO3 deposited at the injection port from causing clogging.

2.5. FE-SEM and EDS Analyses

In this study, a JEOL JSM-7800F Prime Schottky Field Emission Scanning Electron Microscope (FE-SEM) from National Chung Hsing University was used to analyze the sand samples after the MICP reaction. The device had equipment for energy-dispersive X-ray spectroscopy (EDS), which enabled further qualitative and quantitative micro-area element analyses on the surface of the sand samples; the resolution reached 0.8 nm at 15 kV and 1.2 nm at 1 kV.

3. Results and Discussion

3.1. Influences of Treatment Strategies

The treatment strategies were preliminarily tested at a fixed wave condition of H0/L0 = 0.0215 for the beach erosion. An initial microorganism concentration of OD600 = 1.2 with a cement concentration of 1.5 M was used to treat the beach sand. The tests were conducted with both one-phase and two-phase treatment strategies, referring to the methods of Cheng et al. [17] and Shahrokhi-Shahraki et al. [18]. Each strategy was carried out by both the surface spray method and surface spray with injection method. The total volume of cementation was 12.0 L and was sprayed using a rate of around 1 L/min. After completing the treatment of each strategy, they were cured for 7 days before the wave action. The four test strategies were denoted by Case1-S, Case1-SI, Case2-S, and Case2-SI and are listed in Table 3.

Table 3.

Treatment strategies.

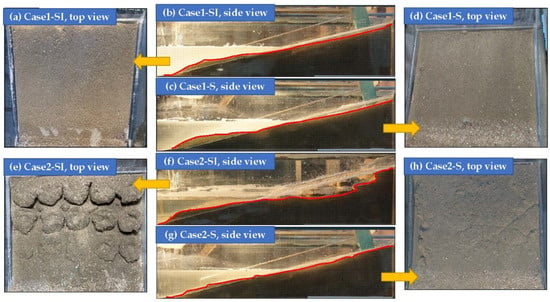

Figure 8 illustrates the side and top views after the wave scours in each case. All cases exhibited erosion above the average water level, and the eroded sand formed a sand bar on the front beach. There was no obvious difference in erosion surface between the one-phase treatment strategy using surface spray (Case1-S) and surface spray with injection (Case1-SI). Nevertheless, in the two-phase strategy using surface spray with injection (Case2-SI), the sand samples formed a cylindrical consolidated aggregate outward from the injection point, as illustrated in Figure 8e and Figure 9. In addition, the sand samples outside the cylindrical consolidation were severely eroded due to their relative low consolidation strength. This uneven consolidation was induced by the clogging caused by the rapid reaction between the microorganisms and the cementation media.

Figure 8.

Top and side view of the experimental sandy beach after the 200 times of wave action.

Figure 9.

The consolidated column of the two-phase surface spray with injection (Case2-SI) treatment strategy.

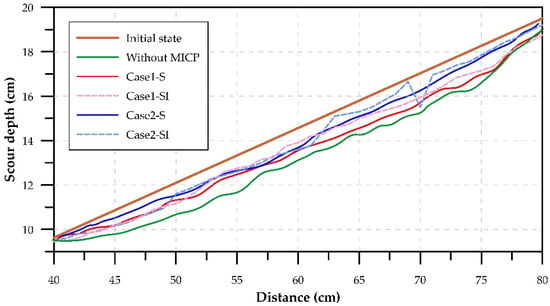

Figure 10 shows the results of the scouring profile at center section after 200 times of wave action for the four MICP treatment strategies and without MICP treatment. It can be observed that the erosion depth with MICP treatments was significantly less than that without MICP treatment. This indicates that the MICP technique mitigated beach erosion. When comparing the profiles of different MICP treatment strategies, it was found that the performance of the two-phase strategy was better than that of the one-phase strategy, especially at a distance of 60–80 cm. Regardless of whether the one-phase or two-phase strategy was used, the amount of erosion for the surface spray with injection method was also less than that of the surface spray method. However, as illustrated in Figure 8e, the two-phase surface spray with injection strategy (Case2-SI) resulted in an irregular erosion surface due to uneven consolidation of the sand. Thus, it was concluded that the two-phase surface spray strategy (Case2-S) is the most suitable MICP treatment for mitigating beach erosion.

Figure 10.

Erosion profiles in each treatment strategy.

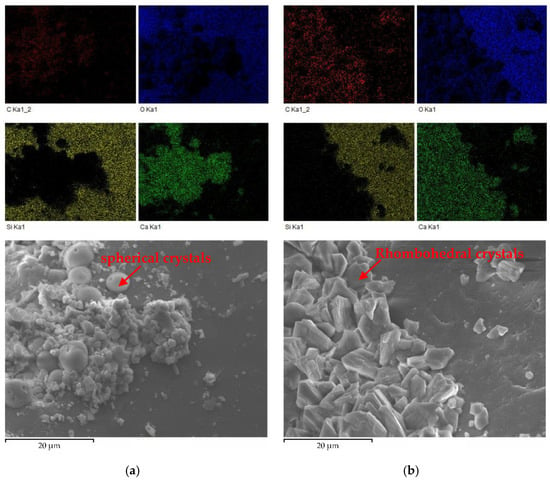

The sand samples subject to the one-phase and two-phase strategies with surface spray (Case1-S and Case2-S, respectively) were taken out after wave making and air dried at room temperature for 7 days. Emission scanning electron microscopy (FE-SEM) and energy dispersive X-ray spectroscopy (EDS) were then employed to observe the distributions of C (in red), O (in blue), Si (in yellow), and Ca (in green) in the sands, as shown in Figure 11. Figure 11a presents the results of the MICP-treated sand with the one-phase strategy (Case1-S), and Figure 11b shows the results of the MICP-treated sand with the two-phase strategy (Case2-S). The EDS results indicate that the elements detected on the surface of the sand samples were mostly Si and O, consistent with those of the main component of the original sand samples, i.e., silicon dioxide (SiO2). On the other hand, the crystalline part was mostly composed of Ca, C, and O, indicating that this crystalline part was CaCO3, the product after MICP treatment. As clearly illustrated in the figure, the crystalline substances produced by the one-phase and two-phase strategies differed. The one-phase strategy yielded a variety of spherical crystals, the same as in Van Paassen [26] and Qabany et al. [27]. In contrast, the two-phase strategy yielded noticeable rhombohedral crystals, which is a feature of calcite. Previous studies [28,29] indicated that the calcite precipitation transfers from a spherical crystal into more stable rhombohedral crystals during MICP processes. The bond strength of the rhombohedral crystal form is stronger than that of the spherical crystal form, thus producing larger erosion resistance of the sand sample and demonstrating better performance to mitigate beach erosion under plunger wave action.

Figure 11.

FE-SEM and EDS images of the sandy particles in (a) Case1-S and (b) Case2-S after MICP treatment.

3.2. Tests of Erosion Mitigation

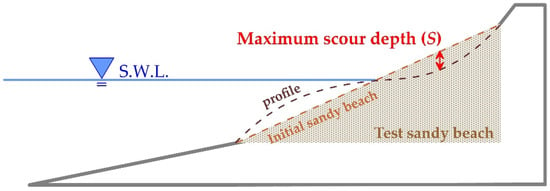

Based on the results presented in the previous section, the two-phase strategy with surface spray was adopted in evaluations of the effectiveness of MICP in mitigating beach erosion. The initial microorganisms and cement concentrations were OD600 = 1.2 M and 1.5 M, respectively. The wave conditions were performed by four different cases for testing, namely, H0/L0 = 0.0129, 0.0172, 0.0215, and 0.0258, as shown in Table 2. Erosion was judged based on the maximum scour depth (S), as shown in Figure 12, which has generally been used to discuss the scouring and erosion situations in front of coastal structures [30].

Figure 12.

Sketch defining the maximum scour depth (S) of the scour profile.

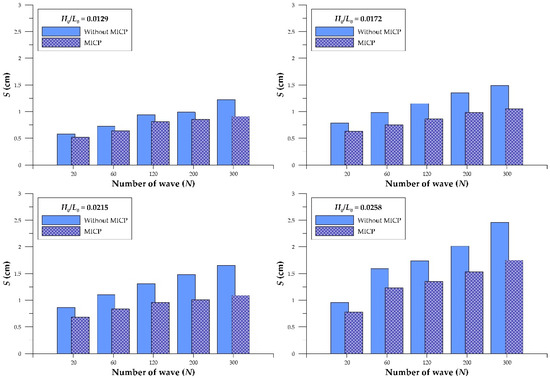

Figure 13 illustrates the relationship between the maximum scour depth (S) and the number of wave actions (N) under various wave conditions. The results show that the S value of the beach surface after MICP treatment was significantly smaller than that without MICP treatment, demonstrating that the MICP technique is capable of mitigating wave-induced beach erosion. The beach erosion shown in Figure 10 and Figure 12 was mainly caused by rapidly cycling actions of uprush and backwash water flow due to breaking waves. The uprush and backwash cycles detached the beach sand and induced beach erosion. Nevertheless, it can be seen from Figure 13 that the scour depth of the MICP-treated case using the two-phase strategy with the surface spray method did approach a constant value after 200 times of wave action. It was noted that the deterioration mechanism of sand under breaking wave action is different with slow tidal cycles on slope erosion [31], as well as with the wet–dry cycle or freeze–thaw cycle on the soil [32,33,34].

Figure 13.

Maximum scour depth (S) against the number of wave actions (N).

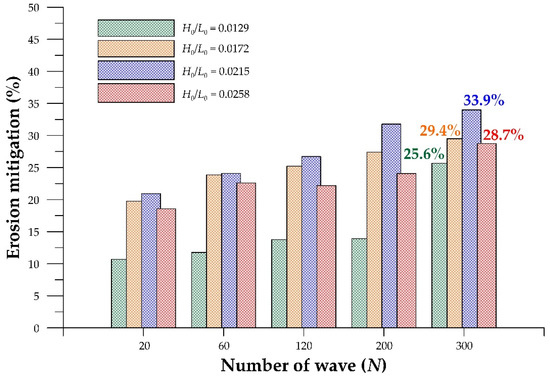

A comparison of the beach erosion mitigation with and without MICP treatment under each wave condition is depicted in Figure 14, in which the percentage of erosion mitigation was calculated by . It shows that, after 300 wave scours, MICP treatment reduced S by 25.6% (H0/L0 = 0.0129) at minimum. In essence, erosion mitigation increased with wave steepness, as shown in Figure 13. However, the percentage of erosion mitigation achieved at the maximum wave steepness of this test (H0/L0 = 0.0258) was obviously lower than that achieved at H0/L0 = 0.0215. This was probably because the impact of the wave was sufficient to break the consolidation force of the sand grains. This similar finding was also reported by Liu et al. [15]. The maximum erosion mitigation in this study occurred at H0/L0 = 0.0215, where S was reduced by 33.9% after 300 wave actions.

Figure 14.

Erosion mitigation (%) against the different wave conditions.

4. Conclusions

The microbial-induced calcium carbonate precipitation (MICP) technique on mitigating beach erosion was investigated in this study by means of a series of experiments for its potential application. The culture and expansion conditions of S. Pasteurii were first evaluated, and the UCS test was adopted to investigate the compressive strength of the sand samples after the MICP treatment. After the optimal consolidation conditions were determined, the effect of different treatment strategies was tested in a wave flume. In addition, the crystal forms of MICP were analyzed using FE-SEM and EDS after the wave tests. Finally, the erosion resistances of the sandy beach after MICP treatment were compared under various wave conditions. The conclusions obtained through the experiments are as follows.

Natural beach sand on the west coast of Taiwan can be consolidated with the MICP technique, and the compressive strength increases with cement concentration. In the UCS test, when the initial microorganism concentration was OD600 = 1.2 and the cement concentration was 1.5 M, a maximum compressive strength of 517.3 kPa was achieved.

Through the experiments using different treatment strategies, this study revealed that the two-phase treatment strategy had a better compressive strength than that of the one-phase treatment strategy. The FE-SEM and EDS images indicated that the crystal phase caused by the two strategies differed, wherein the crystal phase from the one-phase strategy was spherical and that from the two-phase strategy was rhombohedral. The crystal-phase difference may explain the different corrosion resistance. The most suitable treatment strategy obtained in this study was the two-phase method with surface spray, which maintained a satisfactory consolidation effect. The MICP technique can effectively mitigate beach erosion under all experimental wave conditions. In this study, MICP reduced maximum scour depth by 25.6–33.9%.

The eco-friendly MICP treatment technique was investigated in this study for mitigating beach erosion. Nevertheless, this eco-friendly treatment technique may release ammonium ions as by-products [35,36]. It is therefore recommended to work on a removal technique for beach sand in a future study.

Author Contributions

C.-P.T. conceived and supervised this study and edited the paper; J.-H.Y. conducted the experiments and analyzed the data; C.-H.K. conducted the experiments and drafted the manuscript; Y.-R.L. took part in the experiments and discussion. All authors have read and agreed to the published version of the manuscript.

Funding

This research was supported by the Ministry of Science and Technology, Taiwan, via grant No. MOST 106-2221-E-005-046-MY3.

Institutional Review Board Statement

Exclude this statement.

Informed Consent Statement

Not applicable.

Data Availability Statement

Exclude this statement.

Acknowledgments

We would like to express our appreciation to the Valuable Instrument Center of the Office of Research and Development of National Chung Hsing University for assisting in the FE-SEM and EDS imaging.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Hsu, T.W.; Lin, T.Y.; Tseng, I.F. Human impact on coastal erosion in Taiwan. J. Coast. Res. 2007, 234, 961–973. [Google Scholar] [CrossRef]

- Bachmeier, K.L.; Williams, A.E.; Warmington, J.R.; Bang, S. Urease activity in microbiologically-induced calcite precipitation. J. Biotechnol. 2002, 93, 171–181. [Google Scholar] [CrossRef]

- Muynck, D.W.; Belie, D.N.; Verstraete, W. Microbial carbonate precipitation in construction materials: A review. Ecol. Eng. 2010, 36, 118–136. [Google Scholar] [CrossRef]

- DeJong, J.T.; Mortensen, B.M.; Martinez, B.C.; Nelson, D.C. Bio-mediated soil improvement. Ecol. Eng. 2010, 36, 197–210. [Google Scholar] [CrossRef]

- National Research Council. Managing Coastal Erosion; The National Academies Press: Washington, DC, USA, 1990.

- Borsje, B.W.; van Wesenbeeck, B.K.; Dekker, F.; Paalvast, P.; Bouma, T.J.; van Katwijk, M.M.; de Vries, M.B. How ecological engineering can serve in coastal protection. Ecol. Eng. 2011, 37, 113–122. [Google Scholar] [CrossRef]

- Montoya, B.M.; Dejong, J.T.; Boulanger, R.W.; Willson, D.W. Liquefaction mitigation using microbial induced calcite precipitation. In GeoCongress 2012: State of the Art and Practice in Geotechnical Engineering; ASCE: Reston, VA, USA, 2012; pp. 1918–1927. [Google Scholar]

- Wang, Z.; Zhang, N.; Jin, Y.; Li, Q.; Xu, J. Application of microbially induced calcium carbonate precipitation (MICP) in sand embankments for scouring/erosion control. Mar. Georesour. Geotechnol. 2021, 39, 1459–1471. [Google Scholar] [CrossRef]

- Rong, H. Microbial Cement Development and Cementing Mechanism. Ph.D. Thesis, Southeast University, Nanjing, China, 2014. [Google Scholar]

- Van Paassen, L.A.; Ghose, R.; van der Linden, T.J.M.; van der Star, W.R.L.; van Loosdrecht, M.C.M. Quantifying biomediated ground improvement by ureolysis: Large-scale biogrout experiment. J. Geotech. Geoenviron. Eng. 2010, 136, 1721–1728. [Google Scholar] [CrossRef]

- Gomez, M.G.; Martinez, B.C.; Dejong, J.T. Bio-mediated soil improvement field study to stabilize mine sands. In GeoMontreal 2013; Ontario Water Works Association: Montreal, QC, Canada, 2013. [Google Scholar]

- Nayanthara, P.G.N.; Dassanayake, A.B.N.; Nakashima, K.; Kawasaki, S. Microbial induced carbonate precipitation using a native inland bacterium for beach sand stabilization in nearshore areas. Appl. Sci. 2019, 9, 3201. [Google Scholar] [CrossRef] [Green Version]

- Imran, M.A.; Kimura, S.; Nakashima, K.; Evelpidou, N.; Kawasaki, S. Feasibility study of native ureolytic bacteria for biocementation towards coastal erosion protection by MICP method. Appl. Sci. 2019, 9, 4462. [Google Scholar] [CrossRef] [Green Version]

- Shahin, M.A.; Jamieson, K.; Cheng, L. Microbial-induced carbonate precipitation for coastal erosion mitigation of sandy slopes. Géotech. Lett. 2020, 10, 211–215. [Google Scholar] [CrossRef]

- Liu, K.W.; Jiang, N.J.; Qin, J.D. An experimental study of mitigating coastal sand dune erosion by microbial- and enzymatic-induced carbonate precipitation. Acta Geotech. 2010, 16, 467–480. [Google Scholar] [CrossRef]

- Stocks-Fischer, S.; Galinat, J.K.; Bang, S.S. Microbiological precipitation of CaCO3. Soil Biol. Biochem. 1999, 31, 1563–1571. [Google Scholar] [CrossRef]

- Cheng, L.; Shahin, M.A.; Chu, J. Soil bio-cementation using a new one-phase low-pH injection method. Acta Geotech. 2018, 14, 615–626. [Google Scholar] [CrossRef] [Green Version]

- Shahrokhi-Shahraki, R.; Zomorodian, S.M.A.; Niazi, A.; O’Kelly, B.C. Improving sand with microbial-induced carbonate precipitation. Proc. Inst. Civ. Eng.-Ground Improv. 2014, 168, 1–14. [Google Scholar] [CrossRef]

- Whiffin, V.S. Microbial CaCO3 Precipitation for the Production of Biocement. Ph.D. Thesis, Murdoch University, Murdoch, Australia, 2004. [Google Scholar]

- Ma, L.; Pang, A.P.; Luo, Y.; Lu, X.; Lin, F. Beneficial factors for biomineralization by ureolytic bacterium Sporosarcina pasteurii. Microb. Cell Fact. 2020, 19, 12. [Google Scholar] [CrossRef] [PubMed]

- Wang, R.X.; Qian, C.X.; Wang, J.Y. Study on microbiological precipitation of CaCO3. J. Southeast Univ. 2005, 35, 191–195. [Google Scholar]

- Abo-El-Enein, S.A.; Ali, A.H.; Talkhan, F.N.; Abdel-Gawwad, H.A. Utilization of microbial induced calcite precipitation for sand consolidation and mortar crack remediation. HBRC J. 2012, 8, 185–192. [Google Scholar] [CrossRef] [Green Version]

- Achal, V.; Pan, X. Influence of calcium sources on microbially induced calcium carbonate precipitation by Bacillus sp. CR2. Appl. Biochem. Biotechnol. 2014, 173, 307–317. [Google Scholar] [CrossRef]

- Zhao, Q. Experimental Study on Soil Improvement Using Microbial Induced Calcite Precipitation. Ph.D. Thesis, China University of Geosciences, Beijing, China, 2014. [Google Scholar]

- Battjes, J. Surf similarity. Coast. Eng. Proc. 1974, 1, 26. [Google Scholar] [CrossRef]

- Van Paassen, L.A. Biogrout: Ground improvement by microbially induced carbonate precipitation. Ph.D. Thesis, Delft University of Technology, Delft, The Netherlands, 2009. [Google Scholar]

- Qabany, A.; Soga, K.; Santamarina, C. Factors affecting efficiency of microbially induced calcite precipitation. J. Geotech. Geoenviron. Eng. 2012, 138, 992–1001. [Google Scholar] [CrossRef]

- Terzis, D.; Bernier-Latmani, R.; Laloui, L. Fabric characteristics and mechanical response of bio-improved sand to various treatment conditions. Géotech. Lett. 2016, 6, 50–57. [Google Scholar] [CrossRef] [Green Version]

- Mujah, D.; Cheng, L.; Shahin, M.A. Microstructural and geomechanical study on biocemented sand for optimization of MICP process. J. Mater. Civil Eng. 2019, 31, 04019025. [Google Scholar] [CrossRef] [Green Version]

- Tsai, C.P.; Chen, H.B.; You, S.S. Toe scour of seawall on a steep seabed by breaking waves. J. Waterw. Port Coast. Ocean Eng. 2009, 135, 61–68. [Google Scholar] [CrossRef]

- Salifu, E.; MacLachlan, E.; Iyer, K.R.; Knapp, C.W.; Tarantino, A. Application of microbially induced calcite precipitation in erosion mitigation and stabilisation of sandy soil foreshore slopes: A preliminary investigation. Eng. Geol. 2016, 201, 96–105. [Google Scholar] [CrossRef] [Green Version]

- Liu, S.H.; Wen, K.J.; Armwood, C.; Bu, C.M.; Li, C.; Amini, F.; Li, L. Enhancement of MICP-treated sandy soils against environmental deterioration. J. Mater. Civil Eng. 2019, 31, 04019294. [Google Scholar] [CrossRef]

- Gowthaman, S.; Nakashima, K.; Kawasaki, S. Effect of wetting and drying cycles on the durability of bio-cemented soil of expressway slope. Int. J. Environ. Sci. Technol. 2021, 1–14. [Google Scholar] [CrossRef]

- Gowthaman, S.; Nakashima, K.; Kawasaki, S. Freeze-thaw durability and shear responses of cemented slope soil treated by microbial induced carbonate precipitation. Soils Found. 2020, 60, 840–855. [Google Scholar] [CrossRef]

- Keykha, H.A. Ammonium-free carbonate producing bacteria as an ecofriendly soil biostabilizer. Geotech. Test. J. 2018, 42, 19–29. [Google Scholar] [CrossRef]

- Mohsenzadeh, A.; Aflaki, E.; Gowthaman, S. A two-stage treatment process for the management of produced ammonium by-products in ureolytic bio-cementation process. Int. J. Environ. Sci. Technol. 2022, 19, 449–462. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).