Modeling the Sustainable Integration of Quality and Energy Management in Power Plants

Abstract

:1. Introduction

2. Research Hypotheses Development

2.1. Problem Statement

2.2. Energy Management System

2.3. Quality Management

2.4. Justifications of Integration of Energy Management and Quality Management

2.5. Sustainable Integrated Quality and Energy Management (IQEM)

2.6. Independent Variables

2.6.1. Service Quality Improvement (SQI)

2.6.2. Energy Management Team (EMT)

2.6.3. Energy Audit (EA)

2.6.4. Strategic Planning (SP)

2.6.5. Energy Policy (EP)

2.6.6. Top Management Support (TMS)

2.6.7. Awareness (A)

2.7. Dependent Variable: Energy Management Integration Success (EMIS)

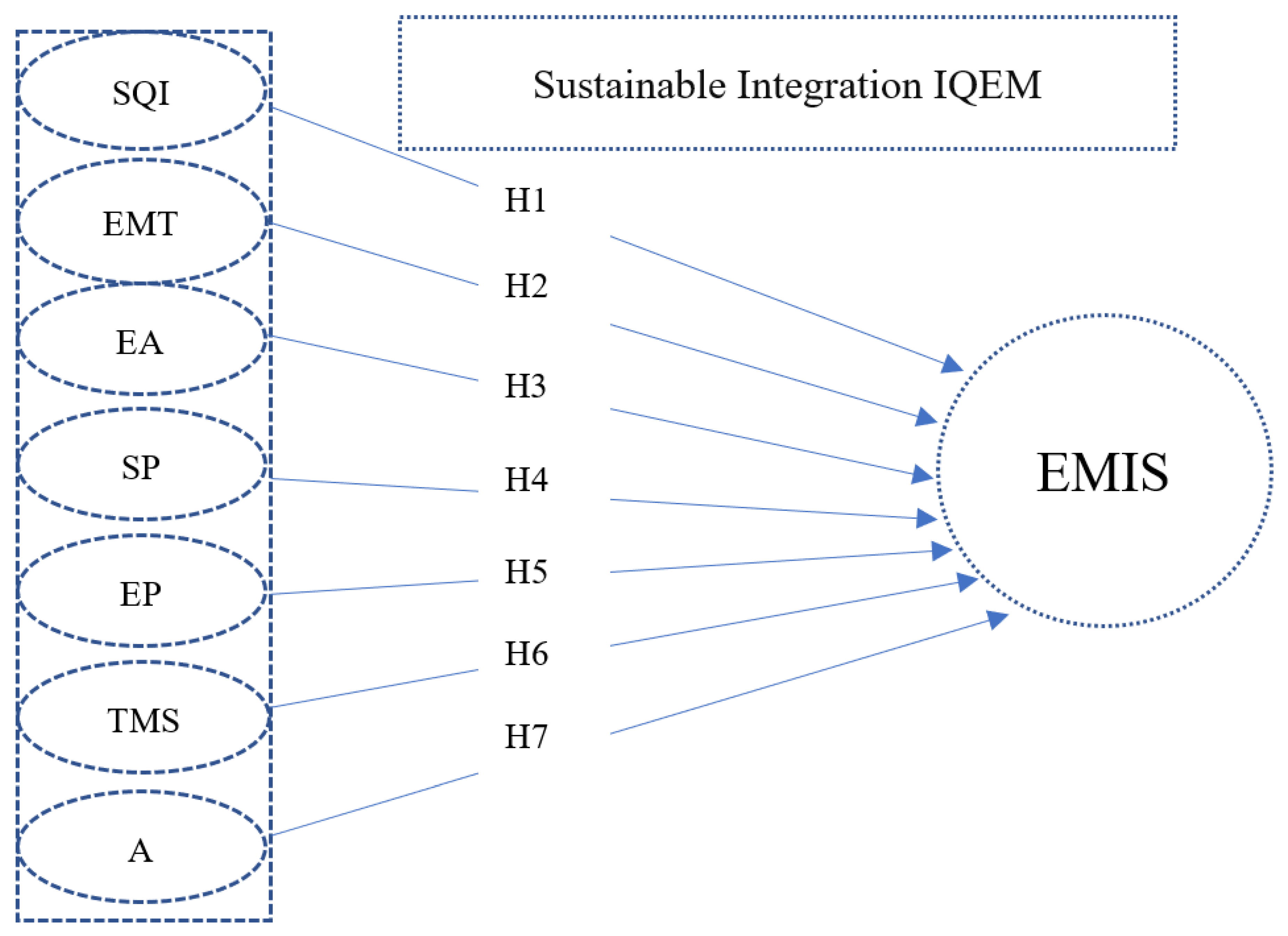

2.8. Conceptual Framework

Theoretical Background of the Study

3. Methodology

3.1. Data Collection

3.2. Questionnaire

3.3. Sample Size

3.4. Data Analysis

4. Results and discussion

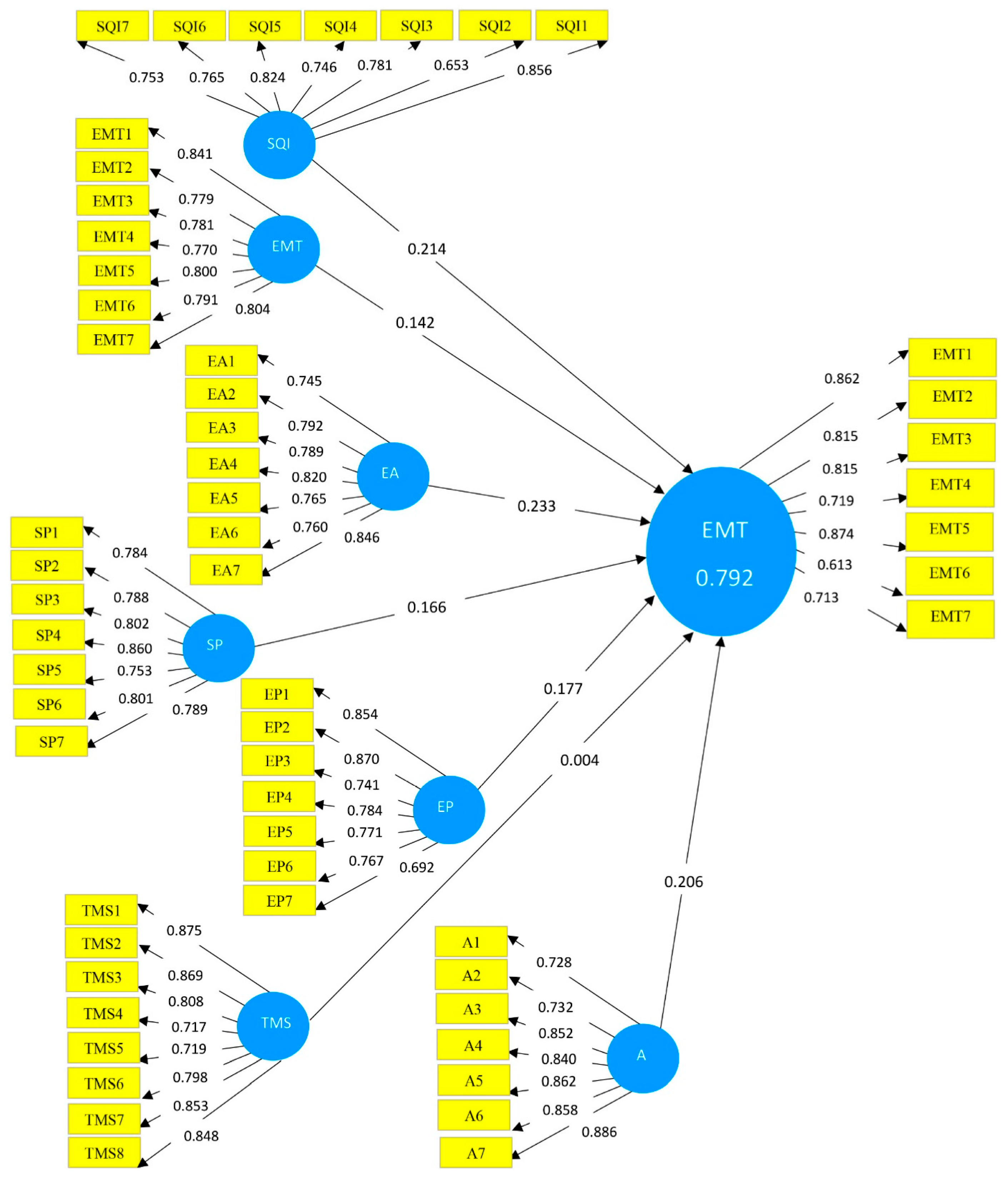

4.1. Measurement Model Assessment

4.2. Structural Model Assessment (Inner Model)

5. Conclusions

Research Implications

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Istepanian, H.H. Iraq’s electricity crisis. Electr. J. 2014, 27, 51–69. [Google Scholar] [CrossRef]

- AL-Batat, K.A.; Mohammed, H.B. Analysis of the Electric Energy Indicators in Iraq for the Duration of 2006–2016. Ahl Al-Bait J. 2022, 1, 476–491. [Google Scholar]

- Avdiu, N.; Hamiti, A. The new generation investment and electricity market development in Kosovo. In Proceedings of the 2011 8th International Conference on the European Energy Market (EEM), Zagreb, Croatia, 25–27 May 2011; pp. 929–934. [Google Scholar]

- Khan, M. Power Sector Strategy for the Afghanistan National Development Strategy; Ministry of Energy & Water: Kapul, Afghanistan, 2007; Available online: https://policy.asiapacificenergy.org/node/402 (accessed on 3 January 2022).

- Sabory, N.R.; Danish, M.S.S.; Senjyu, T. Afghanistan’s Energy and Environmental Scenario. In Energy and Environmental Outlook for South Asia; CRC Press: Boca Raton, FL, USA, 2020; pp. 17–38. [Google Scholar]

- Mahmood, N.S.; Ajmi, A.A.; Sarip, S.; Jamaludin, K.R.; Kaidi, H.M.; Talib, H.A. Implications COVID-19 on Performance and Energy Management in the Production Electricity. Comput. Mater. Contin. 2021, 69, 895–911. [Google Scholar] [CrossRef]

- Al-Abrrow, H.; Alnoor, A.; Abbas, S. The effect of organizational resilience and CEO’s narcissism on project success: Organizational risk as mediating variable. Organ. Manag. J. 2019, 16, 1–13. [Google Scholar] [CrossRef]

- Al-Rikabi, H. An Assessment of Electricity Sector Reforms in Iraq; Al-Bayan Center for Planning and Studies: Baghdad, Iraq, 2017. [Google Scholar]

- Mohammad, A.T.; Ismael, A.I. An equivalent photovoltaic solar system to solve the problems of electricity in Iraqi houses. AIMS Energy 2019, 7, 660–670. [Google Scholar] [CrossRef]

- Mills, R.; Salman, M. Powering Iraq: Challenges Facing the Electricity Sector in Iraq; Al-Bayan Center for Planning and Studies: Baghdad, Iraq, 2020; pp. 1–30. [Google Scholar]

- Al-Janabi, D. An Investigation into the Relationship between Organisational Culture and Maintenance Implementation in Iraqi Power Plants; Northumbria University: Newcastle upon Tyne, UK, 2017. [Google Scholar]

- Al-Khafaji, H. Electricity Generation in Iraq Problems and Solutions; Al-Bayan Center for Planning and Studies: Baghdad, Iraq, 2018; pp. 1–12. Available online: www.bayancenter.org (accessed on 3 January 2022).

- Ajmi, A.A.; Mahmood, N.S.; Kamat, S.R. Increase the Performance of Power Station: Results and Analysis of an Empirical Study of the ISO 50001 Energy Management Systems in the Iraqi Ministry of Electricity. MAGNT Res. Rep. 2017, 4, 75–86. [Google Scholar]

- Abass, K.I.; Al-Waeli, A.A.K.; Al-Asadi, K.A.N. Energy Audit and Energy Conservation in Iraq: A Case Study. Int. J. Trend Res. Dev. 2018, 5, 6–10. [Google Scholar]

- Saleh, A.A.; Hashim, H.; Awang, M.; Zawawi, Z.A.; Aswad, M.K.; Sudirman, M.D. A partial least squares structural equation modeling (PLS-SEM) of energy management critical success factors to sustainable university in malaysia. J. Crit. Rev. 2020, 7, 1330–1338. [Google Scholar]

- Tuama, H.; Abbas, H.; Alseelawi, N.S.; ALRikabi, H.T.S. Bordering a set of energy criteria for the contributing in the transition level to sustainable energy in electrical Iraqi Projects. Period. Eng. Nat. Sci. 2020, 8, 516–525. [Google Scholar]

- Jabbour, A.; Verderio, S.A.; Jabbour, C.J.C.; Leal, W.; Campos, L.S.; De Castro, R. Toward greener supply chains: Is there a role for the new ISO 50001 approach to energy and carbon management? Energy Effic. 2017, 10, 777–785. [Google Scholar] [CrossRef] [Green Version]

- Kurniawan, R.; Feinnudin, A. Assessing the Implementation of the Energy Management System in the First ISO 50001 Building in Indonesia. Indones. J. Energy 2021, 4, 129–139. [Google Scholar] [CrossRef]

- Andreeva, T.; Zhulina, E.; Popova, L.; Yashin, N. Integration of strategic and quality management in oil and gas companies of Russia. Calitatea 2018, 19, 81–84. [Google Scholar]

- Sanchez-Lizarraga, M.A.; Limon-Romero, J.; Tlapa, D.; Baez-Lopez, Y.; Puerta-Sierra, L.; Maciel-Monteon, M. Enablers and Barriers for a Quality Management System Implementation in Mexico: An Exploratory Analysis. Trends Ind. Eng. Appl. Manuf. Process 2021, 263–287. [Google Scholar]

- Wardell, M. All together now: The benefits of integrating management systems. Quality 2019, 58, 32–34. [Google Scholar]

- Chiu, T.Y.; Lo, S.L.; Tsai, Y.Y. Establishing an Integration-Energy-Practice Model for Improving Energy Performance Indicators in ISO 50001 Energy Management Systems. Energies 2012, 5, 5324–5339. [Google Scholar] [CrossRef] [Green Version]

- Carvalho, L.M.; de Souza, C.F.; da Cunha Reis, A.; Freitag, A.E.B. Total Quality Management: The case of an electricity distribution company. Braz. J. Oper. Prod. Manag. 2019, 16, 53–65. [Google Scholar]

- Soroush, G.; Cambini, C.; Jamasb, T.; Llorca, M. Network Utilities Performance and Institutional Quality: Evidence from the Italian Electricity Sector. Energy Econ. 2019, 96, 10577. [Google Scholar] [CrossRef]

- Wang, S.; Fisher, E.B.; Feng, L.; Zhong, X.; Ellis, J.H.; Hobbs, B.F. Linking energy sector and air quality models through downscaling: Long-run siting of electricity generators to account for spatial variability and technological innovation. Sci. Total Environ. 2021, 772, 145504. [Google Scholar] [CrossRef]

- Mahmood, N.S.; Ajmi, A.A.; Sarip, S.; Kaidi, H.M.; Jamaludin, K.R.B.; Talib, H.A. From Literature to Integrated Intelligent framework for Energy Management Success in Power Plants. In Proceedings of the IEEE 19th Student Conference on Research and Development (SCOReD), Kota Kinabalu, Malaysia, 23–25 November 2021. [Google Scholar]

- Ajmi, A.A.; Mahmood, N.S.; Jamaludin, K.R.; Talib, H.H.A.; Sarip, S.; Kaidi, H.M. Intelligent Integrated Model for Improving Performance in Power Plants. CMC-Comput. Mater. Contin. 2022, 70, 5783–5801. [Google Scholar] [CrossRef]

- Majernik, M.; Bosak, M.; Stofova, L.; Szaryszova, P. Innovative model of integrated energy management in companies. Qual. Innov. Prosper. 2015, 19, 22–32. [Google Scholar] [CrossRef]

- Al Kadhimi, B.M.; Mohammed, A.B. Reduction of Energy Losses within Electrical Industrial System. J. Green Eng. 2020, 10, 4851–4873. [Google Scholar]

- Al-Waeli, A.H.; Sopian, K.; Kazem, H.A.; Chaichan, M.T. Photovoltaic/Thermal (PV/T) systems: Status and future prospects. Renew. Sustain. Energy Rev. 2017, 77, 109–130. [Google Scholar] [CrossRef]

- Istepanian, H. Electricity Sector Reform Post-Isis: Lessons to Learn; Iraq Energy Institute: London, UK, 2017; Available online: https://iraqenergy.org/product/electricity-sector-reform-post-isis-lessons-to-learn/ (accessed on 6 January 2022).

- CSO. Annual Report. Available online: http://www.cosit.gov.iq/en/ (accessed on 6 January 2022).

- Purwanggono, B.; Ferastra, K.; Bachtiar, A. Critical Success Factors Evaluation of the ISO 50001 Energy Management System Implementation (Case study: PT. APAC INTI CORPORA, Bawen, Semarang Indonesia). In Proceedings of the IOP Conference Series: Materials Science and Engineering, Semarang, Indonesia, 23–24 April 2019. [Google Scholar]

- Zakuan, N.; Yusof, S.M.; Laosirihongthong, T.; Shaharoun, A.M. Proposed relationship of TQM and organisational performance using structured equation modelling. Total Qual. Manag. 2010, 21, 185–203. [Google Scholar] [CrossRef]

- Sciarelli, M.; Gheith, M.H.; Tani, M. The relationship between soft and hard quality management practices, innovation and organizational performance in higher education. TQM J. 2020, 32, 1349–1372. [Google Scholar] [CrossRef]

- Asif, M. Are QM models aligned with Industry 4.0? A perspective on current practices. J. Clean. Prod. 2020, 258, 120820. [Google Scholar] [CrossRef]

- Fernandes, A.C.; Vilhena, E.; Oliveira, R.; Sampaio, P.; Carvalho, M.S. Supply chain quality management impact on organization performance: Results from an international survey. Int. J. Qual. Reliab. Manag. 2021, 39, 630–646. [Google Scholar] [CrossRef]

- Salis, L.C.R.; Abadie, M.; Wargocki, P.; Rode, C. Towards the definition of indicators for assessment of indoor air quality and energy performance in low-energy residential buildings. Energy Build. 2017, 152, 492–502. [Google Scholar] [CrossRef]

- Wen, X.; Cao, H.; Hon, B.; Chen, E.; Li, H. Energy value mapping: A novel lean method to integrate energy efficiency into production management. Energy 2021, 217, 119353. [Google Scholar] [CrossRef]

- Ajmi, A.A.; Mahmood, N.S.; Jamaludin, K.R.; Talib, H.H.A.; Sarip, S.; Kaidi, H.B.M. An efficient framework for identifying current open issues to prevent human errors in maintaining power plants: Research gap. Mater. Today Proc. 2021, in press. [Google Scholar] [CrossRef]

- Teng, T.; Zhang, X.; Dong, H.; Xue, Q. A comprehensive review of energy management optimization strategies for fuel cell passenger vehicle. Int. J. Hydrogen Energy 2020, 45, 20293–20303. [Google Scholar] [CrossRef]

- Lira, J.M.S.; Salgado, E.G.; Beijo, L.A. Which factors does the diffusion of ISO 50001 in different regions of the world is influenced? J. Clean. Prod. 2019, 226, 759–767. [Google Scholar] [CrossRef]

- ISO (International Organization for Standardization). 2019. Available online: https://www.iso.org/home.html (accessed on 6 January 2022).

- Nunhes, T.V.; Motta, L.C.F.; de Oliveira, O.J. Evolution of integrated management systems research on the Journal of Cleaner Production: Identification of contributions and gaps in the literature. J. Clean. Prod. 2016, 139, 1234–1244. [Google Scholar] [CrossRef] [Green Version]

- Wilson, J.P.; Campbell, L. Developing a knowledge management policy for ISO 9001: 2015. J. Knowl. Manag. 2016, 20. [Google Scholar] [CrossRef]

- Wilson, J.P.; Campbell, L. ISO 9001: 2015: The evolution and convergence of quality management and knowledge management for competitive advantage. Total Qual. Manag. Bus. Excell. 2020, 31, 761–776. [Google Scholar] [CrossRef]

- Fonseca, L.; Domingues, J.P.; Baylina, P.; Calderón, M. Management system certification benefits: Where do we stand? J. Ind. Eng. Manag. 2017, 10, 476–494. [Google Scholar]

- Zimon, D.; Zimon, G. The impact of implementation of standardized quality management systems on management of liabilities in group purchasing organizations. Qual. Innov. Prosper. 2019, 23, 60–73. [Google Scholar] [CrossRef] [Green Version]

- Durakbasa, N.M. Micro-and nano-scale manufacturing development through precision metrology. TQM J. 2016, 28, 685–703. [Google Scholar] [CrossRef]

- Dahlin, G.; Isaksson, R. Integrated management systems–interpretations, results, opportunities. TQM J. 2017, 29, 528–542. [Google Scholar] [CrossRef]

- Laskurain, I.; Heras-Saizarbitoria, I.; Casadesús, M. Do energy management systems add value to firms with environmental management systems? Environ. Eng. Manag. J. (EEMJ) 2019, 18, 17–30. [Google Scholar]

- Cardenas Escorcia, Y.; Acevedo Peñaloza, C.H.; Valencia Ochoa, G.E. A systematic procedure to combine the integral management systems in a services sector company. Chem. Eng. Trans. 2018, 67, 373–378. [Google Scholar]

- Klute-Wenig, S.; Refflinghaus, R. Integrating sustainability aspects into an integrated management system. TQM J. 2015, 27, 303–315. [Google Scholar] [CrossRef]

- Teixeira, M.R.; Mendes, P.; Murta, E.; Nunes, L.M. Performance indicators matrix as a methodology for energy management in municipal water services. J. Clean. Prod. 2016, 125, 108–120. [Google Scholar] [CrossRef]

- Çop, S.; Olorunsola, V.O.; Alola, U.V. Achieving environmental sustainability through green transformational leadership policy: Can green team resilience help? Bus. Strategy Environ. 2021, 30, 671–682. [Google Scholar] [CrossRef]

- Zeng, S.; Xie, X.; Tam, C.M.; Shen, L. An empirical examination of benefits from implementing integrated management systems (IMS). Total Qual. Manag. 2011, 22, 173–186. [Google Scholar] [CrossRef]

- Simon, A.; Karapetrovic, S.; Casadesús, M. Difficulties and benefits of integrated management systems. Ind. Manag. Data Syst. 2012, 112, 828–846. [Google Scholar] [CrossRef]

- Abad, J.; Dalmau, I.; Vilajosana, J. Taxonomic proposal for integration levels of management systems based on empirical evidence and derived corporate benefits. J. Clean. Prod. 2014, 78, 164–173. [Google Scholar] [CrossRef]

- Tarí, J.J.; Claver-Cortés, E.; Pereira-Moliner, J.; Molina-Azorín, J.F. Levels of quality and environmental management in the hotel industry: Their joint influence on firm performance. Int. J. Hosp. Manag. 2010, 29, 500–510. [Google Scholar] [CrossRef]

- Thollander, P.; Palm, J. Improving Energy Efficiency in Industrial Energy Systems: An Interdisciplinary Perspective on Barriers, Energy Audits, Energy Management, Policies, and Programs; Springer Science & Business Media: Linköping, Sweden, 2012. [Google Scholar]

- Mahmood; Ali; Sarip; Kaidi; Jamaludin; Talib, A. Energy management cultures assessment and its impact on the quality of service in power plants a research gap for future studies. PalArchs J. Archaeol. Egypt/Egyptol. 2020, 17, 11398–11412. [Google Scholar]

- Molina-Azorín, J.F.; Tarí, J.J.; Claver-Cortés, E.; López-Gamero, M.D. Quality management, environmental management and firm performance: A review of empirical studies and issues of integration. Int. J. Manag. Rev. 2009, 11, 197–222. [Google Scholar] [CrossRef]

- Bernardo, M.; Casadesus, M.; Karapetrovic, S.; Heras, I. How integrated are environmental, quality and other standardized management systems? An empirical study. J. Clean. Prod. 2009, 17, 742–750. [Google Scholar] [CrossRef]

- Ahadzie, D.K.; Ankrah, N.A.; Low, S.P.; Gao, S.; Tay, W.L. Comparative study of project management and critical success factors of greening new and existing buildings in Singapore. Struct. Surv. 2014, 32, 413–433. [Google Scholar] [CrossRef]

- Shieh, J.-I.; Wu, H.-H.; Huang, K.-K. A DEMATEL method in identifying key success factors of hospital service quality. Knowl.-Based Syst. 2010, 23, 277–282. [Google Scholar] [CrossRef]

- Hua, W.; Chan, A.; Mao, Z. Critical success factors and customer expectation in budget hotel segment—A case study of China. J. Qual. Assur. Hosp. Tour. 2009, 10, 59–74. [Google Scholar] [CrossRef]

- Irfan, S.; Kee, D. Critical success factors of TQM and its impact on increased service quality: A case from service sector of Pakistan. Middle-East J. Sci. Res. 2013, 15, 61–74. [Google Scholar]

- Talib, F.; Rahman, Z. Critical success factors of TQM in service organizations: A proposed model. Serv. Mark. Q. 2010, 31, 363–380. [Google Scholar] [CrossRef]

- Zhou, T. Examining the critical success factors of mobile website adoption. Online Inf. Rev. 2011, 35, 636–652. [Google Scholar] [CrossRef]

- Brunsgaard, C.; Dvořáková, P.; Wyckmans, A.; Stutterecker, W.; Laskari, M.; Almeida, M.; Kabele, K.; Magyar, Z.; Bartkiewicz, P.; Op’t Veld, P. Integrated energy design – Education and training in cross-disciplinary teams implementing energy performance of buildings directive (EPBD). Build. Environ. 2014, 72, 1–14. [Google Scholar] [CrossRef]

- Sebora, T.C.; Lee, S.M.; Sukasame, N. Critical success factors for e-commerce entrepreneurship: An empirical study of Thailand. Small Bus. Econ. 2009, 32, 303–316. [Google Scholar] [CrossRef]

- Roy, J.; Adhikary, K.; Kar, S.; Pamucar, D. A rough strength relational DEMATEL model for analysing the key success factors of hospital service quality. Decis. Mak. Appl. Manag. Eng. 2018, 1, 121–142. [Google Scholar] [CrossRef]

- Chang, L.-M.; Chang, S.-I.; Ho, C.-T.; Yen, D.C.; Chiang, M.-C. Effects of IS characteristics on e-business success factors of small-and medium-sized enterprises. Comput. Hum. Behav. 2011, 27, 2129–2140. [Google Scholar] [CrossRef] [Green Version]

- Landrum, H.; Prybutok, V.R. A service quality and success model for the information service industry. Qual. Control. Appl. Stat. 2005, 50, 93–96. [Google Scholar] [CrossRef]

- Zhang, M.; Jin, B.; Wang, G.A.; Goh, T.N.; He, Z. A study of key success factors of service enterprises in China. J. Bus. Ethics 2016, 134, 1–14. [Google Scholar] [CrossRef]

- Storey, C.; Cankurtaran, P.; Papastathopoulou, P.; Hultink, E.J. Success factors for service innovation: A meta-analysis. J. Prod. Innov. Manag. 2016, 33, 527–548. [Google Scholar] [CrossRef]

- Parsazadeh, N.; Zainuddin, N.M.M.; Ali, R.; Hematian, A. A review on the success factors of e-learning. In Proceedings of the Second International Conference on e-Technologies and Networks for Development, Kuala Lumpur, Malaysia, 4–6 March 2013. [Google Scholar]

- Kutlu, A.C.; Kadaifci, C. Analyzing critical success factors of total quality management by using fuzzy cognitive mapping. J. Enterp. Inf. Manag. 2014, 27, 561–575. [Google Scholar] [CrossRef]

- Yusof, S.R.M.; Aspinwall, E. Critical success factors for total quality management implementation in small and medium enterprises. Total Qual. Manag. 1999, 10, 803–809. [Google Scholar] [CrossRef]

- Wang, Z.; Meckl, R. Critical success factors of total quality management in autonomous driving business models. Cogent Eng. 2020, 7, 1767018. [Google Scholar] [CrossRef]

- Khoo, H.H.; Tan, K.C. Critical success factors for quality management implementation in Russia. Ind. Commer. Train. 2002, 34, 263–268. [Google Scholar] [CrossRef]

- Manhas, V.K.; Gupta, P.; Gupta, H. Developing and validating critical success factors of TQM implementation in MSMEs of Punjab in India. Int. J. Indian Cult. Bus. Manag. 2015, 11, 405–421. [Google Scholar] [CrossRef]

- Lynn, A. Supply Chain Quality Management. In Supply Chain Management: Pathways for Research and Practice; Dilek, O., Ed.; IntechOpen: London, UK, 2011. [Google Scholar] [CrossRef] [Green Version]

- Hietschold, N.; Reinhardt, R.; Gurtner, S. Measuring critical success factors of TQM implementation successfully—A systematic literature review. Int. J. Prod. Res. 2014, 52, 6254–6272. [Google Scholar] [CrossRef]

- Karuppusami, G.; Gandhinathan, R. Pareto analysis of critical success factors of total quality management: A literature review and analysis. TQM Mag. 2006, 18, 372–385. [Google Scholar] [CrossRef]

- Mensah, J.O.; Copuroglu, G.; Fening, F.A. Total quality management in ghana: Critical success factors and model for implementation of a quality revolution. J. Afr. Bus. 2012, 13, 123–133. [Google Scholar] [CrossRef]

- Dayton, N.A. Total quality management critical success factors, a comparison: The UK versus the USA. Total Qual. Manag. 2001, 12, 293–298. [Google Scholar] [CrossRef]

- Porter, L.J.; Parker, A.J. Total quality management—The critical success factors. Total Qual. Manag. 1993, 4, 13–22. [Google Scholar] [CrossRef]

- Fryer, K.J.; Antony, J.; Douglas, A. Critical success factors of continuous improvement in the public sector: A literature review and some key findings. TQM Mag. 2007, 19, 497–517. [Google Scholar] [CrossRef] [Green Version]

- Nunayon, S.S.; Olanipekun, E.A.; Famakin, I.O. Determining key drivers of efficient electricity management practices in public universities in Southwestern Nigeria: An empirical study. Int. J. Sustain. High. Educ. 2020, 21, 281–314. [Google Scholar] [CrossRef]

- Prasad, S.; Baltov, M.; Rao, N.; Lanka, K. Interdependency analysis of lean manufacturing practices in case of Bulgarian SMEs: Interpretive structural modelling and interpretive ranking modelling approach. Int. J. Lean Six Sigma 2020, 12, 503–535. [Google Scholar] [CrossRef]

- Peters, J. Continuous improvement: The ten essential criteria. Meas. Bus. Excell. 2002, 6, 49–51. [Google Scholar] [CrossRef]

- Li, Y.; Song, H.; Sang, P.; Chen, P.-H.; Liu, X. Review of Critical Success Factors (CSFs) for green building projects. Build. Environ. 2019, 158, 182–191. [Google Scholar] [CrossRef]

- Zhang, Y.; Han, Q.; Liu, C.; Sun, J. Analysis for critical success factors of energy performance contracting (EPC) projects in China. In Proceedings of the 2008 IEEE International Conference on Industrial Engineering and Engineering Management, Singapore, 8–11 December 2008. [Google Scholar]

- Maqbool, R.; Sudong, Y. Critical success factors for renewable energy projects; empirical evidence from Pakistan. J. Clean. Prod. 2018, 195, 991–1002. [Google Scholar] [CrossRef]

- Rebelo, M.F.; Santos, G.; Silva, R. Integrated management systems: Critical success factors. J. Glob. Econ. Manag. Bus. Res. 2015, 5, 109–124. [Google Scholar]

- Sinha, M.; Karcher, P.; Jochem, R. Success factors and organizational approaches for the implementation of energy management systems according to ISO 50001. TQM J. 2015, 27, 361–381. [Google Scholar]

- Thollander, P.; Maria, J. Energy management in industry-success factors and way forward. In Proceedings of the World Engineering Conference and Convention (WECC), Kyoto, Japan, 28 November–4 December 2015. [Google Scholar]

- Cherubini, S.; Iasevoli, G.; Michelini, L. Product-service systems in the electric car industry: Critical success factors in marketing. J. Clean. Prod. 2015, 97, 40–49. [Google Scholar] [CrossRef]

- Johansson, M.T.; Thollander, P. A review of barriers to and driving forces for improved energy efficiency in Swedish industry–Recommendations for successful in-house energy management. Renew. Sustain. Energy Rev. 2018, 82, 618–628. [Google Scholar] [CrossRef]

- Luthra, S.; Garg, D.; Haleem, A. The impacts of critical success factors for implementing green supply chain management towards sustainability: An empirical investigation of Indian automobile industry. J. Clean. Prod. 2016, 121, 142–158. [Google Scholar] [CrossRef]

- Sambasivan, M.; Fei, N.Y. Evaluation of critical success factors of implementation of ISO 14001 using analytic hierarchy process (AHP): A case study from Malaysia. J. Clean. Prod. 2008, 16, 1424–1433. [Google Scholar] [CrossRef]

- Kowalski, K.B.; Swanson, J.A. Critical success factors in developing teleworking programs. Benchmark. Int. J. 2005, 12, 236–249. [Google Scholar] [CrossRef]

- Antwi-Afari, M.; Li, H.; Pärn, E.; Edwards, D. Critical success factors for implementing building information modelling (BIM): A longitudinal review. Autom. Constr. 2018, 91, 100–110. [Google Scholar] [CrossRef]

- Adabre, M.A.; Chan, A.P. Critical success factors (CSFs) for sustainable affordable housing. Build. Environ. 2019, 156, 203–214. [Google Scholar] [CrossRef]

- Rasool, S.F.; Chin, T.; Wang, M.; Asghar, A.; Khan, A.; Zhou, L. Exploring the role of organizational support, and critical success factors on renewable energy projects of Pakistan. Energy 2022, 243, 2022. [Google Scholar] [CrossRef]

- Jin, Y.; Long, Y.; Jin, S.; Yang, Q.; Chen, B.; Li, Y.; Xu, L. An energy management maturity model for China: Linking ISO 50001: 2018 and domestic practices. J. Clean. Prod. 2021, 290, 125168. [Google Scholar] [CrossRef]

- Saleh, A.A.; Mohammed, A.H.; Abdullah, M.N. Critical success factors for sustainable university: A framework from the energy management view. Procedia-Soc. Behav. Sci. 2015, 172, 503–510. [Google Scholar] [CrossRef] [Green Version]

- Lawrence, A.; Nehler, T.; Andersson, E.; Karlsson, M.; Thollander, P. Drivers, barriers and success factors for energy management in the Swedish pulp and paper industry. J. Clean. Prod. 2019, 223, 67–82. [Google Scholar] [CrossRef]

- Xu, P.; Chan, E.H.-W.; Qian, Q.K. Success factors of energy performance contracting (EPC) for sustainable building energy efficiency retrofit (BEER) of hotel buildings in China. Energy Policy 2011, 39, 7389–7398. [Google Scholar] [CrossRef]

- Razman, R.; Muslim, R. A review on critical success factors of governance towards sustainable campus operations. IOP Conf. Ser. Mater. Sci. Eng. 2017, 226, 012057. [Google Scholar]

- Clegg, B.; Rees, C.; Titchen, M. A study into the effectiveness of quality management training: A focus on tools and critical success factors. TQM J. 2010, 22, 188–208. [Google Scholar] [CrossRef]

- Aquilani, B.; Silvestri, C.; Ruggieri, A.; Gatti, C. A systematic literature review on total quality management critical success factors and the identification of new avenues of research. TQM J. 2017, 29, 184–213. [Google Scholar] [CrossRef]

- Raut, R.D.; Narkhede, B.; Gardas, B.B. To identify the critical success factors of sustainable supply chain management practices in the context of oil and gas industries: ISM approach. Renew. Sustain. Energy Rev. 2017, 68, 33–47. [Google Scholar] [CrossRef]

- Zhao, G.; Ahmed, R.I.; Ahmad, N.; Yan, C.; Usmani, M.S. Prioritizing critical success factors for sustainable energy sector in China: A DEMATEL approach. Energy Strategy Rev. 2021, 35, 100635. [Google Scholar] [CrossRef]

- Abiodun, O.E.; Segbenu, N.S. Critical Success Factors as a Tool for Sustainable Efficient Electricity Management in Nigerian Public Universities. Engineering 2017, 7, 6–22. [Google Scholar]

- Moktadir, M.A.; Ali, S.M.; Jabbour, C.J.C.; Paul, A.; Ahmed, S.; Sultana, R.; Rahman, T. Key factors for energy-efficient supply chains: Implications for energy policy in emerging economies. Energy 2019, 189, 116129. [Google Scholar] [CrossRef]

- Worsley, D.; King, S.; Gurin, C.; Macklin, K.; Schnell, T. Success Factors for Utility-Sponsored Strategic Energy Management Initiatives. ACEEE Summer Study Energy Effic. Ind. 2015, 1–13. Available online: https://www.aceee.org/files/proceedings/2015/data/papers/1-131.pdf (accessed on 3 January 2022).

- Bukar, A.L.; Tan, C.W.; Said, D.M.; Dobi, A.M.; Ayop, R.; Alsharif, A. Energy management strategy and capacity planning of an autonomous microgrid: Performance comparison of metaheuristic optimization searching techniques. Renew. Energy Focus 2022, 40, 48–66. [Google Scholar] [CrossRef]

- Choong, W.W.; Chong, Y.F.; Low, S.T. Implementation of energy management key practices in Malaysian universities. Int. J. Emerg. Sci. 2012, 2, 455. [Google Scholar]

- Sivill, L.; Manninen, J.; Hippinen, I.; Ahtila, P. Success factors of energy management in energy-intensive industries: Development priority of energy performance measurement. Int. J. Energy Res. 2013, 37, 936–951. [Google Scholar] [CrossRef]

- Edvardsson, B. Service quality improvement. Manag. Serv. Qual. Int. J. 1998, 8, 142–149. [Google Scholar] [CrossRef]

- Marimon, F.; Casadesús, M. Reasons to adopt ISO 50001 energy management system. Sustainability 2017, 9, 1740. [Google Scholar] [CrossRef] [Green Version]

- Rampasso, I.S.; Melo Filho, G.P.; Anholon, R.; de Araujo, R.A.; Alves Lima, G.B.; Perez Zotes, L.; Leal Filho, W.J.S. Challenges presented in the implementation of sustainable energy management via ISO 50001:2011. Sustainability 2019, 11, 6321. [Google Scholar] [CrossRef] [Green Version]

- Escolar, S.; Chessa, S.; Carretero, J. Energy management in solar cells powered wireless sensor networks for quality of service optimization. Pers. Ubiquitous Comput. 2014, 18, 449–464. [Google Scholar] [CrossRef]

- Pinto, J.K.; Kharbanda, O. Successful Project Managers: Leading Your Team to Success. Appl. Occup. Environ. Hyg. 1996, 9, 1163. [Google Scholar]

- Lopes, M.; Antunes, C.H.; Janda, K.B. Energy and Behaviour: Towards a Low Carbon Future; Academic Press: San Diego, CA, USA, 2019. [Google Scholar]

- Bosak, J.; Dawson, J.; Flood, P.; Peccei, R. Employee involvement climate and climate strength: A study of employee attitudes and organizational effectiveness in UK hospitals. J. Organ. Eff. People Perform. 2017, 4, 18–38. [Google Scholar] [CrossRef] [Green Version]

- Brooks, A.; Zeitz, G. The effects of total quality management and perceived justice on organizational commitment of hospital nursing staff. J. Qual. Manag. 1999, 4, 69–93. [Google Scholar] [CrossRef]

- Katzenbach, J.; Thomas, J.; Anderson, G. The Critical Few: Energize Your Company’s Culture by Choosing What Really Matters; Berrett-Koehler Publishers: Oakland, CA, USA, 2019. [Google Scholar]

- AlFaris, F.; Juaidi, A.; Manzano-Agugliaro, F. Improvement of efficiency through an energy management program as a sustainable practice in schools. J. Clean. Prod. 2016, 135, 794–805. [Google Scholar] [CrossRef]

- Kaziliūnas, A. Problems of auditing using quality management systems for sustainable development of organizations. Technol. Econ. Dev. Econ. 2008, 14, 64–75. [Google Scholar] [CrossRef]

- Molina-Azorín, J.F.; Claver-Cortés, E.; Pereira-Moliner, J.; Tarí, J.J. Environmental practices and firm performance: An empirical analysis in the Spanish hotel industry. J. Clean. Prod. 2009, 17, 516–524. [Google Scholar] [CrossRef]

- Walker, A.; Beattie, D.; Thomas, K.; Davis, K.; Sim, M.; Jhaveri, A. Strategic Plan for Sustainable Energy Management and Environmental Stewardship for Los Angeles Unified School District; National Renewable Energy Lab. (NREL): Golden, CO, USA, 2007. [Google Scholar]

- Talib, H.H.A.; Ali, K.A.M.; Idris, F. Critical success factors of quality management practices among SMEs in the food processing industry in Malaysia. J. Small Bus. Enterp. Dev. 2014, 21, 25. [Google Scholar]

- Kaynak, H. The relationship between total quality management practices and their effects on firm performance. J. Oper. Manag. 2003, 21, 405–435. [Google Scholar] [CrossRef]

- Chienwattanasook, K.; Jermsittiparsert, K. Effect of Technology Capabilities on Sustainable Performance of Pharmaceutical firms in Thailand with moderating role of Organizational Culture. Syst. Rev. Pharm. 2019, 10, 188–197. [Google Scholar]

- Bredenkamp, J.I.; Mathews, M.J.; Vosloo, J.C. An integrated energy management strategy for the deep-level gold mining industry. In Proceedings of the 2016 International Conference on the Industrial and Commercial Use of Energy (ICUE), Cape Town, South Africa, 16–17 August 2016. [Google Scholar]

- Liu, J.; Liu, Y.; Yang, L. Uncovering the influence mechanism between top management support and green procurement: The effect of green training. J. Clean. Prod. 2020, 251, 119674. [Google Scholar] [CrossRef]

- Zhang, Y.; Wei, Y.; Zhou, G. Promoting firms’ energy-saving behavior: The role of institutional pressures, top management support and financial slack. Energy Policy 2018, 115, 230–238. [Google Scholar] [CrossRef]

- Khurshid, M.A.; Amin, M.; Ismail, W.K.W. Total quality and socially responsible management (TQSR-M): An integrated conceptual framework. Benchmarking Int. J. 2018, 25, 2566–2588. [Google Scholar] [CrossRef]

- Ahmed, M.S.; Mohamed, A.; Homod, R.Z.; Shareef, H.; Khalid, K. Awareness on energy management in residential buildings: A case study in Kajang and Putrajaya. J. Eng. Sci. Technol. 2017, 12, 1280–1294. [Google Scholar]

- Oomes, A. Organization awareness in crisis management. In Proceedings of the ISCRAM 2004—1st International Workshop on Information Systems for Crisis Response and Management, Brussels, Belgium, 3–4 May 2004; pp. 63–68. [Google Scholar]

- Schulze, M.; Nehler, H.; Ottosson, M.; Thollander, P. Energy management in industry—A systematic review of previous findings and an integrative conceptual framework. J. Clean. Prod. 2016, 112, 3692–3708. [Google Scholar] [CrossRef] [Green Version]

- Liu, H.; Du, K.; Li, J. An improved approach to estimate direct rebound effect by incorporating energy efficiency: A revisit of China’s industrial energy demand. Energy Econ. 2019, 80, 720–730. [Google Scholar] [CrossRef]

- Singh, A.K.; Pal, B. Dynamic Estimation and Control of Power Systems; EC2Y 5AS; Academic Press: Cambridge, MA, USA; Elsevier: London, UK, 2018. [Google Scholar]

- Topcu, E.; Altinoz, B.; Aslan, A. Global evidence from the link between economic growth, natural resources, energy consumption, and gross capital formation. Resour. Policy 2020, 66, 101622. [Google Scholar] [CrossRef]

- Kahouli, B. The short and long run causality relationship among economic growth, energy consumption and financial development: Evidence from South Mediterranean Countries (SMCs). Energy Econ. 2017, 68, 19–30. [Google Scholar] [CrossRef]

- Schneider, N.; André, P.; Könyves, V.; Bontemps, S.; Motte, F.; Federrath, C.; Ward-Thompson, D.; Arzoumanian, D.; Benedettini, M.; Bressert, E. What determines the density structure of molecular clouds? A case study of Orion B with Herschel. Astrophys. J. Lett. 2013, 766, L17. [Google Scholar] [CrossRef] [Green Version]

- Shahzad, F.; Luqman, R.A.; Khan, A.R.; Shabbir, L. Impact of organizational culture on organizational performance: An overview. Interdiscip. J. Contemp. Res. Bus. 2012, 3, 975–985. [Google Scholar]

- Nwibere, B. The influence of corporate culture on managerial leadership style: The niigerian experience. Int. J. Bus. Public Adm. 2013, 10, 166–187. [Google Scholar]

- Sola, A.V.; Mota, C.M. Influencing factors on energy management in industries. J. Clean. Prod. 2020, 248, 119263. [Google Scholar] [CrossRef]

- Tachmitzaki, E.V.; Didaskalou, E.A.; Georgakellos, D.A. Energy Management Practices’ Determinants in Greek Enterprises. Sustainability 2020, 12, 133. [Google Scholar] [CrossRef] [Green Version]

- Dincbas, T.; Ergeneli, A.; Yigitbasioglu, H. Clean technology adoption in the context of climate change: Application in the mineral products industry. Technol. Soc. 2021, 64, 101478. [Google Scholar] [CrossRef]

- Prentkovskis, O.; Erceg, Ž.; Stević, Ž.; Tanackov, I.; Vasiljević, M.; Gavranović, M. A new methodology for improving service quality measurement: Delphi-FUCOM-SERVQUAL model. Symmetry 2018, 10, 757. [Google Scholar] [CrossRef] [Green Version]

- Psomas, E.L.; Jaca, C. The impact of total quality management on service company performance: Evidence from Spain. Int. J. Qual. Reliab. Manag. 2016, 33, 380–398. [Google Scholar] [CrossRef]

- Ajmi, A.A.; Mahmood, N.S.; Kamat, S.R. Thermal comfort at the turbine room in the power station: A systematic review. J. Adv. Manuf. Technol. (JAMT) 2016, 10, 79–90. [Google Scholar]

- Nunnally, J.C. Psychometric Theory, 2nd ed.; McGraw-Hill: New York, NY, USA, 1978; pp. 1–640. [Google Scholar]

- Fink, A. How to Sample in Surveys, 2nd ed.; Sage: London, UK, 2003; Available online: https://methods.sagepub.com/book/how-to-sample-in-surveys (accessed on 3 January 2022).

- Sekaran, U.; Bougie, R. Research Methods for Business: A Skill Building Approach; John Wiley & Sons: Hong Kong, China, 2016; pp. 1–448. [Google Scholar]

- Ahmad, H.; Halim, H. Determining Sample Size for Research Activities. Selangor Bus. Rev. 2017, 2, 20–34. [Google Scholar]

- Krejcie, R.V.; Morgan, D.W. Determining sample size for research activities. Educ. Psychol. Meas. 1970, 30, 607–610. [Google Scholar] [CrossRef]

- Tavakol, M.; Dennick, R. Making sense of Cronbach’s alpha. Int. J. Med. Educ. 2011, 2, 53. [Google Scholar] [CrossRef]

- Hair, J.F., Jr.; Hult, G.T.M.; Ringle, C.M.; Sarstedt, M. A Primer on Partial Least Squares Structural Equation Modeling (PLS-SEM); Sage Publications: London, UK, 2021; pp. 211–213. [Google Scholar]

- Muhammad, L.; Mahadi, B.; Hussin, N. Influence of social capital on customer’s relationship satisfaction in the Pakistani banking industry. Asia Pac. J. Mark. Logist. 2017, 29, 1036–1054. [Google Scholar] [CrossRef]

- Anderson, J.C.; Gerbing, D.W. Structural equation modeling in practice: A review and recommended two-step approach. Psychol. Bull. 1988, 103, 411. [Google Scholar] [CrossRef]

- Ramayah, T.; Lee, J.W.C.; In, J.B.C. Network collaboration and performance in the tourism sector. Serv. Bus. 2011, 5, 411–428. [Google Scholar] [CrossRef]

- Chin, W.W. Commentary: Issues and Opinion on Structural Equation Modeling. MIS Q. 1998, 22, 7–16. [Google Scholar]

- Fornell, C.; Larcker, D.F. Evaluating structural equation models with unobservable variables and measurement error. J. Market. Res. 1981, 18, 39–50. [Google Scholar] [CrossRef]

- Henseler, J.; Hubona, G.; Ray, P.A. Using PLS path modeling in new technology research: Updated guidelines. Ind. Manag. Data Syst. 2016, 116, 2–20. [Google Scholar] [CrossRef]

- Mohammad, J.; Quoquab, F.; Makhbul, Z.M.; Ramayah, T. Bridging the gap between justice and citizenship behavior in Asian culture. Cross Cult. Strateg. Manag. 2016, 23, 633–656. [Google Scholar] [CrossRef]

| CSFs | QM CSFs Proposed by Previous Studies | EMs CSFs Proposed by Previous Studies | No. | % |

|---|---|---|---|---|

| SQI | [63,64,65,66,67,68,69,70,71,72,73,74,75,76,77,78,79,80,81,82,83,84,85,86,87,88,89,90,91,92] | [93,94,95,96,97,98] | 30 | 18% |

| EP | [64,66,75,78,90] | [15,33,63,93,94,95,96,97,98,99,100,101,102,103,104,105,106,107,108,109,110,111] | 27 | 16% |

| A | [74,77,78,79,80,82,84,85,86,87,88,89,90,92,112,113] | [15,93,94,96,97,102,107,108,109,110,114] | 27 | 16% |

| TMS | [78,79,80,81,82,83,84,85,86,87,88,89,90,91,92,112,113] | [15,93,94,95,107,108,111,115,116] | 26 | 15% |

| SP | [78,82,83,84,86,88,89,92,112,113] | [15,33,94,96,97,107,109,111,116,117] | 20 | 12% |

| EMT | [64,68,78,82,84,113] | [15,33,65,93,95,96,97,98,108,110,111,116,117,118] | 20 | 12% |

| EA | [90] | [15,33,94,95,96,98,107,108,109,110,111,116,117,118,119,120,121] | 18 | 11% |

| Total | 168 | 100% | ||

| CSFs | CA | CR | AVE | SQI | EMT | EA | SP | EP | TMS | A | EMIS |

|---|---|---|---|---|---|---|---|---|---|---|---|

| SQI | 0.800 | 0.805 | 0.540 | 0.840 | |||||||

| EMT | 0.782 | 0.945 | 0.575 | 0.423 | 0.780 | ||||||

| EA | 0.989 | 0.810 | 0.630 | 0.586 | 0.687 | 0.765 | |||||

| SP | 0.830 | 0.797 | 0.685 | 0.441 | 0.446 | 0.610 | 0.763 | ||||

| EP | 0.815 | 0.825 | 0.524 | 0.383 | 0.517 | 0.573 | 0.416 | 0.749 | |||

| TMS | 0.914 | 0.727 | 0.620 | 0.489 | 0.420 | 0.610 | 0.511 | 0.471 | 0.757 | ||

| A | 0.902 | 0.861 | 0.684 | 0.574 | 0.425 | 0.617 | 0.429 | 0.439 | 0.492 | 0.768 | |

| EMIS | 0.703 | 0.903 | 0.533 | 0.441 | 0.406 | 0.472 | 0.390 | 0.306 | 0.323 | 0.336 | 0.780 |

| Const | SQI | EMT | EA | SP | EP | TMS | A | EMIS |

|---|---|---|---|---|---|---|---|---|

| SQI | ||||||||

| EMT | 0.720 | |||||||

| EA | 0.830 | 0.718 | ||||||

| SP | 0.741 | 0.504 | 0.760 | |||||

| EP | 0.783 | 0.401 | 0.745 | 0.730 | ||||

| TMS | 0.569 | 0.325 | 0.752 | 0.457 | 0.452 | |||

| A | 0.677 | 0.562 | 0.425 | 0.543 | 0.442 | 0.721 | ||

| EMIS | 0.644 | 0.423 | 0.589 | 0.596 | 0.369 | 0.523 | 0.688 |

| Hypt | Path | Path Coefficient | t-Values | p-Values | Decision |

|---|---|---|---|---|---|

| H1 | SQI E → MIS | 0.214 | 3.728 | 0.000 | Support |

| H2 | EMT → EMIS | 0.142 | 2.350 | 0.019 | Support |

| H3 | EA → EMIS | 0.233 | 1.800 | 0.073 | Not Support |

| H4 | SP → EMIS | 0.166 | 3.346 | 0.010 | Support |

| H5 | EP → EMIS | 0.177 | 4.405 | 0.000 | Support |

| H6 | TMS → EMIS | 0.004 | 0.066 | 0.948 | Not Support |

| H7 | A → EMIS | 0.206 | 3.942 | 0.003 | Support |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mahmood, N.S.; Ajmi, A.A.; Sarip, S.B.; Kaidi, H.M.; Jamaludin, K.R.; Talib, H.H.A. Modeling the Sustainable Integration of Quality and Energy Management in Power Plants. Sustainability 2022, 14, 2460. https://doi.org/10.3390/su14042460

Mahmood NS, Ajmi AA, Sarip SB, Kaidi HM, Jamaludin KR, Talib HHA. Modeling the Sustainable Integration of Quality and Energy Management in Power Plants. Sustainability. 2022; 14(4):2460. https://doi.org/10.3390/su14042460

Chicago/Turabian StyleMahmood, Noor Shakir, Ahmed Ali Ajmi, Shamsul Bin Sarip, Hazilah Mad Kaidi, Khairur Rijal Jamaludin, and Hayati Habibah Abdul Talib. 2022. "Modeling the Sustainable Integration of Quality and Energy Management in Power Plants" Sustainability 14, no. 4: 2460. https://doi.org/10.3390/su14042460

APA StyleMahmood, N. S., Ajmi, A. A., Sarip, S. B., Kaidi, H. M., Jamaludin, K. R., & Talib, H. H. A. (2022). Modeling the Sustainable Integration of Quality and Energy Management in Power Plants. Sustainability, 14(4), 2460. https://doi.org/10.3390/su14042460