Critical Success Factors for Supply Chain Sustainability in the Wood Industry: An Integrated PCA-ISM Model

Abstract

:1. Introduction

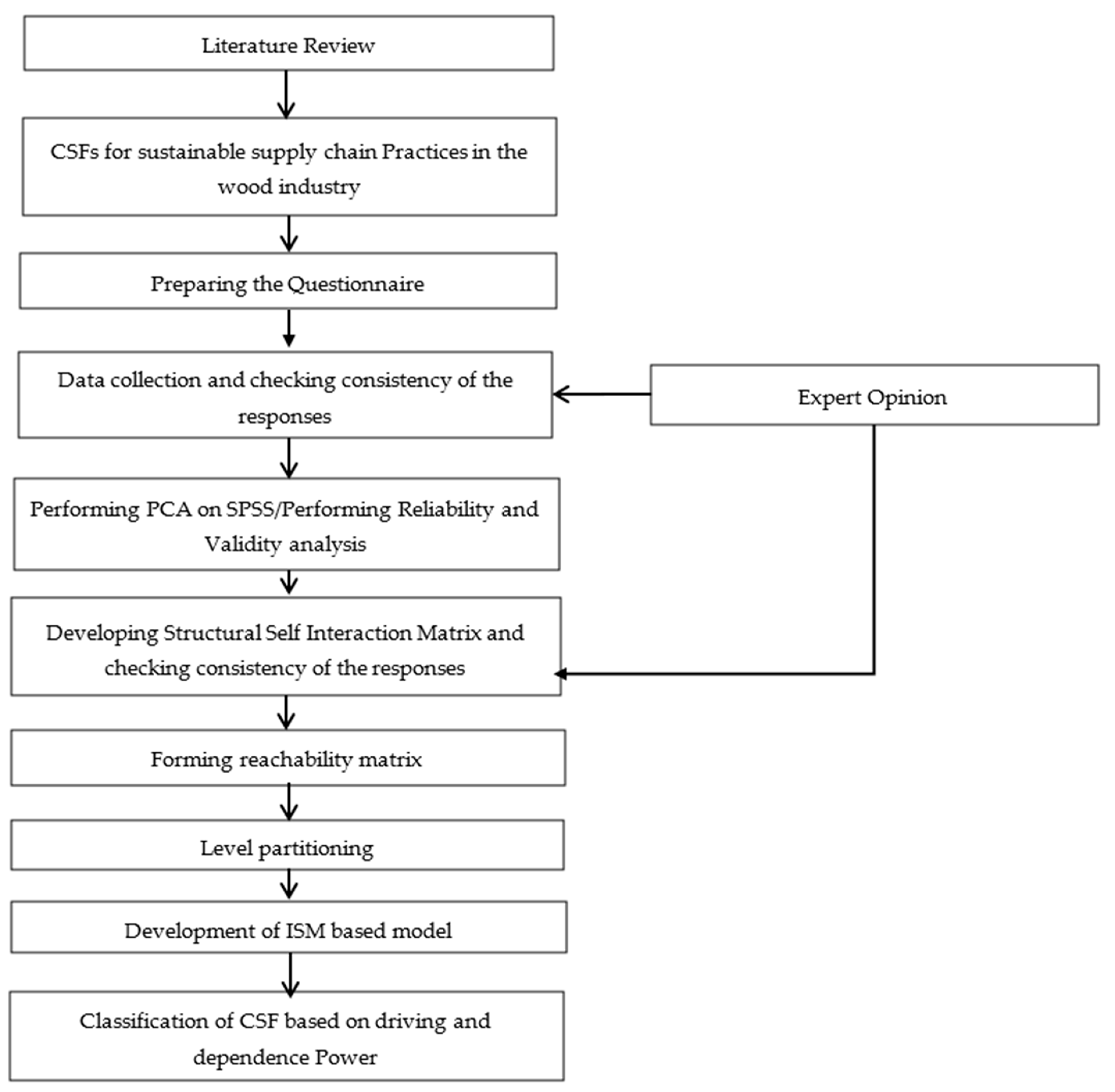

2. Materials and Methods

2.1. Conceptualization of Critical Success Factor

2.2. Proposed Approach

2.2.1. Identifying CSFs Using PCA

2.2.2. Identification of the CSFs’ Driving and Dependence Power

- V-CSF: i facilitates reaching j

- A-CSF: j facilitates reaching i

- X-CSF: i and j facilitate reaching each other

- O-CSF: i and j are not connected

2.2.3. Model Validation

3. Results and Discussions

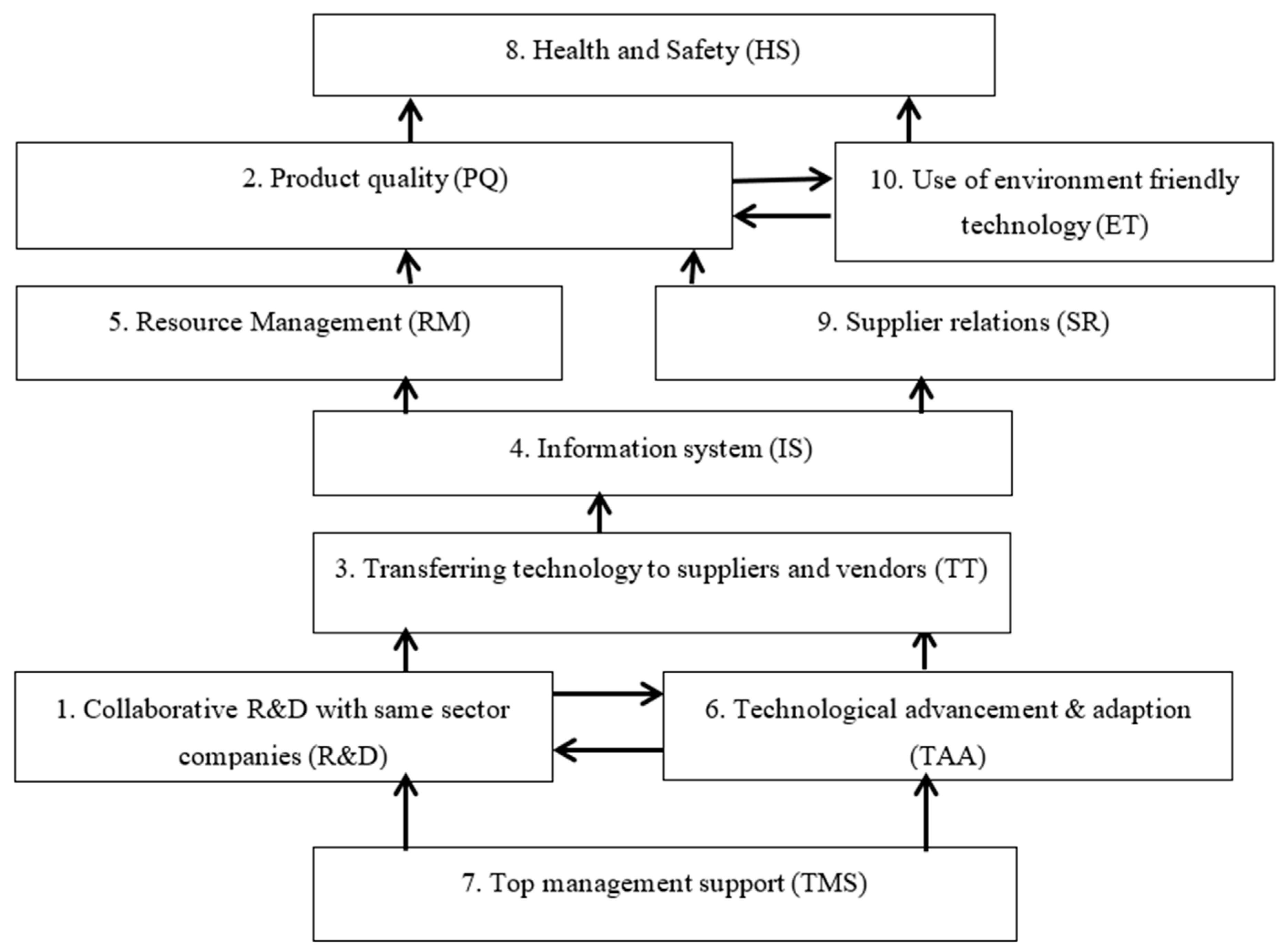

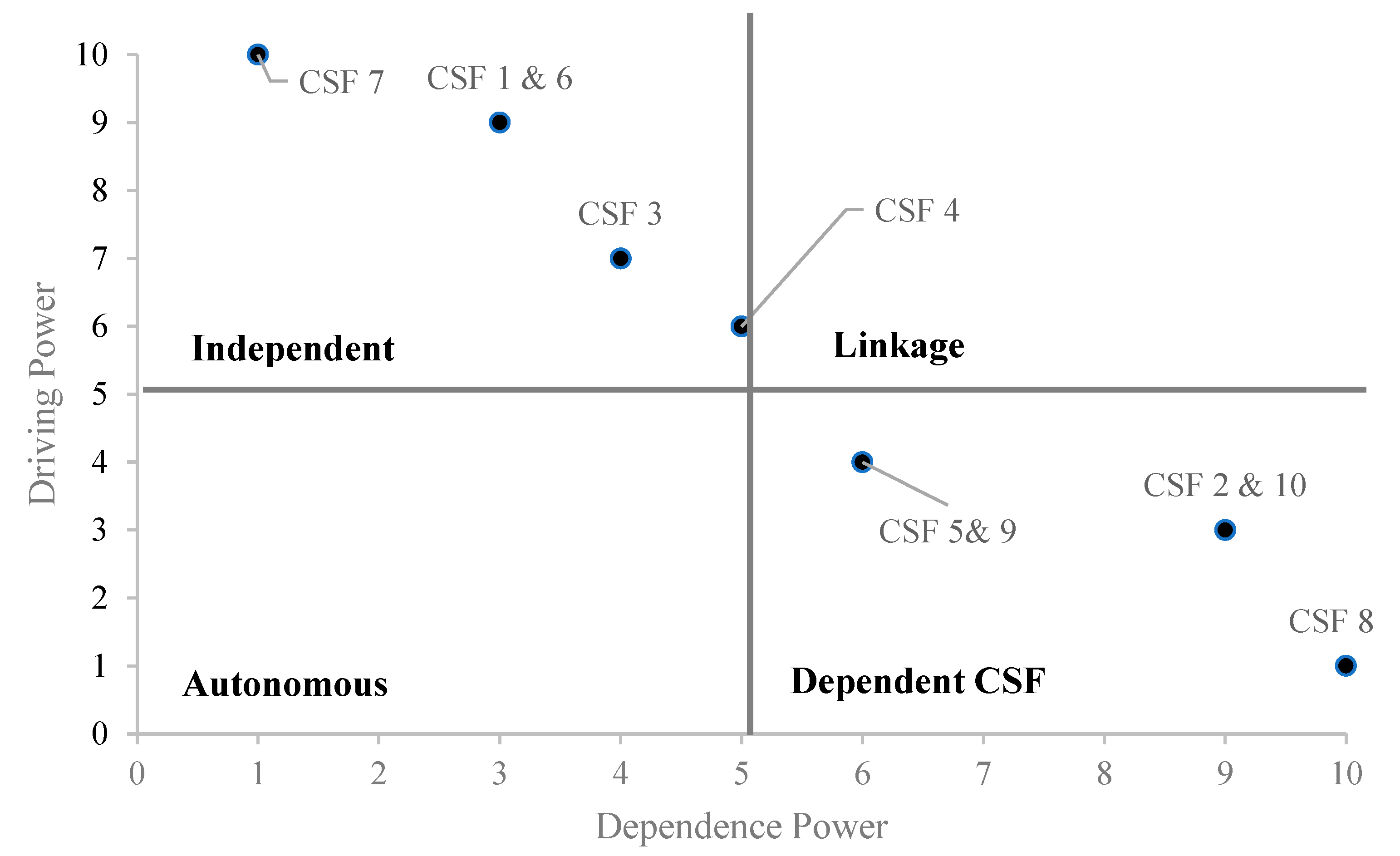

- Research and development (CSF 1), supplier relations (CSF 9), and using eco-friendly technology (CSF 10) are the top-ranked CSFs. In Bangladesh, there is a low level of R&D, as it is an emerging economy. As a result, there is limited engagement with eco-friendly technology. Many companies are not interested in adopting an effluent treatment plant, as it would increase their operating costs. Additionally, good relationships with suppliers help organizations to ensure their long-term growth. The selected ten CSFs are divided into four categories: product quality and well-being of the organization, supplier relations, eco-friendly technology, and health and safety.

- There are no autonomous CSFs (Figure 3), suggesting that all of the considered CSFs are relevant to this study.

- The dependent CSFs (Figure 3) are product quality, resource management, health and safety, supplier relations, and using eco-friendly technology. These factors have weak driving power but strong dependence power. These CSFs certainly have associated costs in terms of resources, time, and focus that an organization may be unwilling to spend as part of its competitive strategy. To implement these CSFs, top management must actively support them.

- The independent CSFs (Figure 3) are collaborative R&D with same-sector companies, transferring technology to suppliers and vendors, technology advancement and adaption, and top management support. These CSFs are vital to the implementation of dependent and linkage CSFs. As shown in Figure 2, top management support is the most important independent CSF in terms of pursuing SSCM practices, making it a driving force for the other three CSFs in this category. As the Bangladeshi wood industry is technologically lagging and more R&D efforts are required to substitute wood with non-wood fibres in papermaking to limit deforestation [11,72,73], top management support is necessary to foster it.

- The only linkage CSF (Figure 3) is “information system.” With high driving power and high dependence power, it has a significant role in the implementation of a sustainable supply chain. Moreover, its presence in the linkage category suggests that the Bangladeshi industry is aware of the potential requirement of information systems in the various processes and purposes of a business.

4. Managerial Implications

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| Sl. No. | Success Factor | Description |

|---|---|---|

| 1 | Recycling and waste management (RWM) | Recycling focuses on the regeneration of renewable resources after use. The principles of waste management are elimination, reduction, reuse, recovery, and disposal. |

| 2 | Using eco-friendly technology (ET) | Using eco-friendly technology that conserves energy and reduces resource consumption. |

| 3 | Sharing natural resources (NR) | The long-term availability and sharing of natural resources. |

| 4 | Product responsibility (PR) | Product responsibility covers the entire life cycle, including the raw materials, product development, production, use, and recycling. |

| 5 | Designing products for recyclability, reusability, and material recoverability (RRR) | Designing for deconstruction to ensure that deconstruction processes retain maximum material value. |

| 6 | Supplier environmental evaluation and feedback (SEEF) | Suppliers are evaluated on several criteria: no child labour, working hours, no forced labour, no discrimination, employment compensation, freedom of association, use of eco-friendly materials, and health and safety practices. |

| 7 | Using eco-friendly materials (EFM) | Using eco-friendly materials. |

| 8 | Managing hazardous substances (MHS) | Managing wood-industry-specific hazardous chemicals, which are endorsed by the Occupational Safety and Health Regulations 1996 and have specific safety requirements. |

| 9 | Support from customers (SC) | Awareness among customers motivates manufacturers to produce green products. |

| 10 | Training programs for supplier and vendors (SV) | Training, implementing special projects, and monitoring performance. |

| 11 | Collaborative R&D with same-sector companies (R&D) | Collaboration on green research and development with suppliers and companies in the same sector. |

| 12 | Flexible working arrangements (FWA) | Flexible working—also known as flextime or flexitime—refers to non-traditional working arrangements that consider employees’ personal needs, often involving working from home and flexible hours. |

| 13 | Supplier evaluation and selection (SES) | Environmental auditing and supplier evaluation to ensure that products conform to regulations. |

| 14 | Supplier relations (SR) | Supplier relations reflect the extent to which an organization has a collaborative relationship with its suppliers. |

| 15 | Stability in policy and regulations (PS) | Stability in policies and regulations, which is often tied to political stability. |

| 16 | Health and safety (HS) | Manual lifting, forceful gripping, wood dust, and hazardous substances are the reported common risk factors in the wood industry. Inhaling hazardous substances and getting caught in moving parts are common injuries in the industry. The most prominent prior risk is inadequate personal protective equipment. |

| 17 | Gender diversity (GD) | Fair representation of people of different genders at various stages of the supply chain. |

| 18 | Government legislation (GL) | Regulations pressure suppliers and organizations to use eco-friendly products and processes to improve operational performances. |

| 19 | Top management support (TMS) | Top management support is crucial to the successful implementation of SSCM. |

| 20 | Resource management (RM) | Optimal resource usage helps firms achieve economic sustainability in the supply chain. |

| 21 | Supplier audit (SA) | Supplier audits have the potential to enhance supply chains’ environmental and social performance. |

| 22 | Product quality (PQ) | Sustainable supply chains can be achieved by producing high-quality products with a longer product life. |

| 23 | Technological advancement and adaption (TAA) | Willingness to research developing technologies and adopt new technologies in the pursuit of greater sustainability. |

| 24 | Technology transfer (TT) | Transferring technology to supply chain partners helps firms achieve long-term sustainability. |

| 25 | Information system (IS) | Information systems impact SSCM on various processes, such as planning, sourcing, and delivering, and at various levels, including tactical operations and organizational strategy. |

References

- Dey, B.K.; Bhuniya, S.; Sarkar, B. Involvement of Controllable Lead Time and Variable Demand for a Smart Manufacturing System under a Supply Chain Management. Expert Syst. Appl. 2021, 184, 115464. [Google Scholar] [CrossRef]

- Bhuniya, S.; Pareek, S.; Sarkar, B. A supply chain model with service level constraints and strategies under uncertainty. Alex. Eng. J. 2021, 60, 6035–6052. [Google Scholar] [CrossRef]

- Mahapatra, A.S. A Continuous Review Production-Inventory System with a Variable Preparation Time in a Fuzzy Random Environment. Mathematics 2021, 9, 747. [Google Scholar] [CrossRef]

- Sardar, S.K.; Sarkar, B.; Kim, B. Integrating Machine Learning, Radio Frequency Identification, and Consignment Policy for Reducing Unreliability in Smart Supply Chain Management. Processes 2021, 9, 247. [Google Scholar] [CrossRef]

- Krysiak, F.C. Risk management as a tool for sustainability. J. Bus. Ethics 2009, 85, 483–492. [Google Scholar] [CrossRef] [Green Version]

- Dias, C.; Gouveia-Rodrigues, R.; Ferreira, J.J. Small agricultural businesses’ performance—What is the role of dynamic capabilities, entrepreneurial orientation, and environmental sustainability commitment? Bus. Strategy Environ. 2021, 30, 1898–1912. [Google Scholar] [CrossRef]

- Nguyen, T.H.; Elmagrhi, M.H.; Ntim, C.G.; Wu, Y. Environmental performance, sustainability, governance and financial performance: Evidence from heavily polluting industries in China. Bus. Strategy Environ. 2021, 30, 2313–2331. [Google Scholar] [CrossRef]

- Pádua, S.I.D.; Jabbour, C.J.C. Promotion and evolution of sustainability performance measurement systems from a perspective of business process management: From a literature review to a pentagonal proposal. Bus. Process Manag. J. 2015, 21, 403–418. [Google Scholar] [CrossRef]

- Moktadir, M.A.; Ali, S.M.; Jabbour, C.J.C.; Paul, A.; Ahmed, S.; Sultana, R.; Rahman, T. Key factors for energy-efficient supply chains: Implications for energy policy in emerging economies. Energy 2019, 189, 116129. [Google Scholar] [CrossRef]

- Mark, P.; Shevchenko, A. Why Research in Sustainable Supply Chain Management Should Have No Future. J. Supply Chain. Manag. 2015, 50, 1. [Google Scholar]

- Kannan, D. Role of multiple stakeholders and the critical success factor theory for the sustainable supplier selection process. Int. J. Prod. Econ. 2018, 195, 391–418. [Google Scholar] [CrossRef]

- Luthra, S.; Garg, D.; Haleem, A. An analysis of interactions among critical success factors to implement green supply chain management towards sustainability: An Indian perspective. Resour. Policy 2015, 46, 37–50. [Google Scholar] [CrossRef]

- Moktadir, M.A.; Dwivedi, A.; Khan, N.S.; Paul, S.K.; Khan, S.A.; Ahmed, S.; Sultana, R. Analysis of risk factors in sustainable supply chain management in an emerging economy of leather industry. J. Clean. Prod. 2021, 283, 124641. [Google Scholar] [CrossRef]

- Al Zaabi, S.; Al Dhaheri, N.; Diabat, A. Analysis of interaction between the barriers for the implementation of sustainable supply chain management. Int. J. Adv. Manuf. Technol. 2013, 68, 895–905. [Google Scholar] [CrossRef]

- Jahan, M.S.; Gunter, B.G.; Rahman, A.F.M.A. Substituting Wood with Nonwood Fibers in Papermaking: A Win-Win Solution for Bangladesh; SSRN: Rochester, NY, USA, 2009. [Google Scholar]

- Razzaque, M.; Hasan, E.; Rahman, J. Furniture Exports from Bangladesh: An Analysis of Market Prospects and Policy Support; Enterprise Institute: Dhaka, Bangladesh, 2019. [Google Scholar]

- Bovea, M.D.; Vidal, R. Materials selection for sustainable product design: A case study of wood based furniture eco-design. Mater. Des. 2004, 25, 111–116. [Google Scholar] [CrossRef]

- González-García, S.; Berg, S.; Feijoo, G.; Moreira, M.T. Environmental impacts of forest production and supply of pulpwood: Spanish and Swedish case studies. Int. J. Life Cycle Assess. 2009, 14, 340–353. [Google Scholar] [CrossRef]

- Romagnoli, M.; Fragiacomo, M.; Brunori, A.; Follesa, M.; Scarascia-Mugnozza, G. Solid wood and wood based composites: The challenge of sustainability looking for a short and smart supply chain. In Lecture Notes in Civil Engineering; Springer: Cham, Switzerland, 2019. [Google Scholar]

- Khan, S.; Haleem, A.; Khan, M.I.; Abidi, M.H.; Al-Ahmari, A. Implementing Traceability Systems in Specific Supply Chain Management (SCM) through Critical Success Factors (CSFs). Sustainability 2018, 10, 204. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Z.; Zhang, Q.; Liu, Z.; Zheng, X. Static and Dynamic Pricing Strategies in a Closed-Loop Supply Chain with Reference Quality Effects. Sustainability 2018, 10, 157. [Google Scholar] [CrossRef] [Green Version]

- Lopez, M.; Paes, Y.; Gustave, J.B.; Gonçalves, D.; Méndez, F.G.; Theodoro-Nantet, A.C. Production of wood-plastic composites using cedrela odorata sawdust waste and recycled thermoplastics mixture from post-consumer products—A sustainable approach for cleaner production in Cuba. J. Clean. Prod. 2020, 244, 118723. [Google Scholar] [CrossRef]

- Zineldin, M.; Jonsson, P. An examination of the main factors affecting trust/commitment in supplier-dealer relationships: An empirical study of the Swedish wood industry. TQM Mag. 2000, 12, 245–266. [Google Scholar] [CrossRef] [Green Version]

- Quesada, H.; Gazo, R. Methodology for determining key internal business processes based on critical success factors: A case study in furniture industry. Manag. J. 2007, 13, 5–20. [Google Scholar] [CrossRef]

- Daian, G.; Ozarska, B. Wood waste management practices and strategies to increase sustainability standards in the Australian wooden furniture manufacturing sector. J. Clean. Prod. 2009, 17, 1594–1602. [Google Scholar] [CrossRef]

- Dewitt, T.; Giunipero, L.C.; Melton, H.L. Clusters and supply chain management: The Amish experience. Int. J. Phys. Distrib. Logist. Manag. 2010, 36, 289–308. [Google Scholar] [CrossRef]

- Gomez, L.S.S. Identifying Success Factors in the Wood Pallet Supply Chain; Virginia Polytechnic Institute and State University: Blacksburg, VA, USA, 2011. [Google Scholar]

- Quesada-Pineda, H.; Araman, P.A. A Quantitative Study of the U.S. Wood Pallet Industry Based on Supply Chain Management Practices. J. Appl. Packag. Res. 2012, 6, 1–26. [Google Scholar]

- Quesada, H.; Gazo, R.; Sanchez, S. Critical Factors Affecting Supply Chain Management: A Case Study in the US Pallet Industry. In Pathways to Supply Chain Excellence; BoD—Books on Demand: Norderstedt, Germany, 2012; pp. 33–56. [Google Scholar] [CrossRef]

- Penfield, P.C.; Germain, R.; Smith, W. Assessing the supply chain efficiency of hardwood sawmills in new york state through case study analysis and data envelopment analysis modeling. For. Prod. J. 2014, 64, 90–96. [Google Scholar] [CrossRef]

- Larsson, M.; Stendahl, M.; Roos, A. Supply chain management in the Swedish wood products industry—A need analysis. Scand. J. For. Res. 2016, 31, 777–787. [Google Scholar] [CrossRef]

- Sương, T.T. Influential Factors on Supply Chain Collaboration in Vietnam’S Wood Processing Industry. J. Econ. Dev. 2018, 36–43. [Google Scholar]

- Kogler, C.; Rauch, P. A discrete-event simulation model to test multimodal strategies for a greener and more resilient wood supply. Can. J. For. Res. 2019, 49, 1298–1310. [Google Scholar] [CrossRef]

- Ebrahimi, M.; Tavakkoli-Moghaddam, R. A Robust Optimization Model for Joint Maintenance and Build-To-Order Supply Chain under Uncertainties: A Case Study. In Proceedings of the 15th Iran International Industrial Engineering Conference, IIIEC, Yazd, Iran, 23–24 January 2019. [Google Scholar]

- Susanty, A.; Tjahjono, B.; Sulistyani, R.E. An investigation into circular economy practices in the traditional wooden furniture industry. Prod. Plan. Control 2020, 31, 1336–1348. [Google Scholar] [CrossRef]

- Chu, J.; Kumar, A. Assessment of wood industrial pollutants based on emission coefficients in China. Holzforschung 2020, 74, 1071–1078. [Google Scholar] [CrossRef]

- Ratnasingam, J.; Ioras, F.; Ark, C.K.; Latib, H.A. Success Factors of Wood Veneer as an Overlay Material for Panel-based Furniture Manufacturing in Malaysia. BioResources 2020, 15, 1311–1322. [Google Scholar]

- Navarro, N.; Daniela, P.; Valverde, F.; Quesada, H.J.; Madrigal-sánchez, J. Industry. BioResources 2020, 15, 1959–1977. [Google Scholar]

- Rajput, S.; Singh, S.P. Identifying Industry 4.0 IoT enablers by integrated PCA-ISM-DEMATEL approach. Manag. Decis. 2019, 57, 1784–1817. [Google Scholar] [CrossRef]

- Chowdhury, N.A.; Ali, S.M.; Mahtab, Z.; Rahman, T.; Kabir, G.; Paul, S.K. A structural model for investigating the driving and dependence power of supply chain risks in the readymade garment industry. J. Retail. Consum. Serv. 2019, 51, 102–113. [Google Scholar] [CrossRef]

- Devi, K.; Paranitharan, K. Interpretive framework by analysing the enablers for implementation of Industry 4.0: An ISM approach. Total Qual. Manag. Bus. Excel. 2020, 32, 1494–1514. [Google Scholar] [CrossRef]

- Pluskal, J.; Šomplák, R.; Nevrlý, V.; Smejkalová, V.; Pavlas, M. Strategic decisions leading to sustainable waste management: Separation, sorting and recycling possibilities. J. Clean. Prod. 2020, 278, 123359. [Google Scholar] [CrossRef]

- Yang, G.; Zhou, C.; Wang, W.; Ma, S.; Liu, H.; Liu, Y.; Zhao, Z. Recycling sustainability of wastepaper industry in Beijing City: An analysis based on value chain and GIS model. Waste Manag. 2020, 106, 62–70. [Google Scholar] [CrossRef] [PubMed]

- Bag, S.; Wood, L.C.; Xu, L.; Dhamija, P.; Kayikci, Y. Big data analytics as an operational excellence approach to enhance sustainable supply chain performance. Resour. Conserv. Recycl. 2019, 153, 104559. [Google Scholar] [CrossRef]

- Rejeb, A.; Rejeb, K. Blockchain and supply chain sustainability. Logforum 2015, 16, 363–372. [Google Scholar] [CrossRef]

- Zhang, A.; Zhong, R.Y.; Farooque, M.; Kang, K.; Venkatesh, V.G. Blockchain-based life cycle assessment: An implementation framework and system architecture. Resour. Conserv. Recycl. 2019, 152, 104512. [Google Scholar] [CrossRef]

- Nandi, S.; Sarkis, J.; Hervani, A.A.; Helms, M.M. Redesigning Supply Chains using Blockchain-Enabled Circular Economy and COVID-19 Experiences. Sustain. Prod. Consum. 2020, 27, 10–22. [Google Scholar] [CrossRef]

- Feitó-Cespón, M.; Costa, Y.; Pishvaee, M.S.; Cespón-Castro, R. A fuzzy inference-based scenario building in two-stage optimization framework for sustainable recycling supply chain redesign. Expert Syst. Appl. 2020, 165, 113906. [Google Scholar] [CrossRef]

- Hu, A.H.; Hsu, C. Critical factors for implementing green supply chain management practice. Manag. Res. Rev. 2010, 33, 586–608. [Google Scholar] [CrossRef]

- Kusi-Sarpong, S.; Gupta, H.; Sarkis, J. A supply chain sustainability innovation framework and evaluation methodology. Int. J. Prod. Res. 2018, 57, 1990–2008. [Google Scholar] [CrossRef] [Green Version]

- Tay, M.Y.; Rahman, A.A.; Aziz, Y.A.; Sidek, S. A Review on Drivers and Barriers towards Sustainable Supply Chain Practices. Int. J. Soc. Sci. Humanit. 2015, 5, 892–897. [Google Scholar] [CrossRef] [Green Version]

- Gouda, S.K.; Saranga, H. Sustainable supply chains for supply chain sustainability: Impact of sustainability efforts on supply chain risk. Int. J. Prod. Res. 2018, 56, 5820–5835. [Google Scholar] [CrossRef]

- Eltayeb, T.K.; Zailani, S.; Ramayah, T. Green supply chain initiatives among certified companies in Malaysia and environmental sustainability: Investigating the outcomes. Resour. Conserv. Recycl. 2011, 55, 495–506. [Google Scholar] [CrossRef]

- Chkanikova, O.; Sroufe, R. Third-party sustainability certifications in food retailing: Certification design from a sustainable supply chain management perspective. J. Clean. Prod. 2020, 282, 124344. [Google Scholar] [CrossRef]

- Amiri, M.; Hashemi-Tabatabaei, M.; Ghahremanloo, M.; Keshavarz-Ghorabaee, M.; Zavadskas, E.K.; Banaitis, A. A new fuzzy BWM approach for evaluating and selecting a sustainable supplier in supply chain management. Int. J. Sustain. Dev. World Ecol. 2020, 28, 125–142. [Google Scholar] [CrossRef]

- Atz, U.; Van Holt, T.; Douglas, E.; Whelan, T. The Return on Sustainability Investment (ROSI): Monetizing Financial Benefits of Sustainability Actions in Companies, Review of Business. Interdiscip. J. Risk Soc. 2019, 39, 1–31. [Google Scholar]

- Power, D.J.; Sohal, A.S.; Rahman, S. Critical success factors in agile supply chain management—An empirical study. Int. J. Phys. Distrib. Logist. Manag. 2001, 31, 247–265. [Google Scholar] [CrossRef]

- Ahmad, N.K.W.; De Brito, M.P.; Rezaei, J.; Tavasszy, L.A. An integrative framework for sustainable supply chain management practices in the oil and gas industry. J. Environ. Plan. Manag. 2016, 60, 577–601. [Google Scholar] [CrossRef] [Green Version]

- Sudusinghe, J.I.; Seuring, S. Social Sustainability Empowering the Economic Sustainability in the Global Apparel Supply Chain. Sustainability 2020, 12, 2595. [Google Scholar] [CrossRef] [Green Version]

- Gopalakrishnan, K.; Yusuf, Y.Y.; Musa, A.; Abubakar, T.; Ambursa, H.M. Sustainable supply chain management: A case study of British Aerospace (BAe) Systems. Int. J. Prod. Econ. 2012, 140, 193–203. [Google Scholar] [CrossRef]

- Gardas, B.B.; Raut, R.D.; Narkhede, B. Identifying critical success factors to facilitate reusable plastic packaging towards sustainable supply chain management. J. Environ. Manag. 2019, 236, 81–92. [Google Scholar] [CrossRef] [PubMed]

- Tran, T.M.T.; Yuen, K.F.; Li, K.X.; Balci, G.; Ma, F. A theory-driven identification and ranking of the critical success factors of sustainable shipping management. J. Clean. Prod. 2019, 243, 118401. [Google Scholar] [CrossRef]

- Gonzalez-Padron, T.L. Ethics in the Supply Chain: Follow-Up Processes to Audit Results. J. Mark. Channels 2016, 23, 22–33. [Google Scholar] [CrossRef]

- Saberi, S.; Kouhizadeh, M.; Sarkis, J.; Shen, L. Blockchain technology and its relationships to sustainable supply chain man-agement. Int. J. Prod. Res. 2019, 57, 2117–2135. [Google Scholar] [CrossRef] [Green Version]

- Schilling, L.; Seuring, S. Sustainable value creation through information technology-enabled supply chains in emerging markets. Int. J. Logist. Manag. 2021. (ahead of print). [Google Scholar] [CrossRef]

- Corsi, A.; Pagani, R.N.; Kovaleski, J.L.; da Silva, V.L. Technology transfer for sustainable development: Social impacts depicted and some other answers to a few questions. J. Clean. Prod. 2019, 245, 118522. [Google Scholar] [CrossRef]

- de Camargo Fiorini, P.; Jabbour, C.J.C. Information systems and sustainable supply chain management towards a more sustainable society: Where we are and where we are going. Int. J. Inf. Manag. 2017, 37, 241–249. [Google Scholar] [CrossRef] [Green Version]

- Hasan, M.A.; Shankar, R.; Sarkis, J. A study of barriers to agile manufacturing. Int. J. Agil. Syst. Manag. 2007, 2, 1–22. [Google Scholar] [CrossRef]

- Hasan, M.A.; Sarkis, J.; Shankar, R. Interpretive structural modelling of agility enhancing management practices for agile manufacturing. Int. J. Agil. Syst. Manag. 2013, 6, 361. [Google Scholar] [CrossRef]

- Bolanos, R.B.; Emilio, F.; Alfredo, N. Using interpretive structural modelling in strategic decision-making groups. J. Manag. Decis. 2005, 43, 877–895. [Google Scholar] [CrossRef]

- Wold, S.; Esbensen, K.; Geladi, P. Principal Component Analysis. Chemometrics and Intelligent Laboratory Systems; Elsevier: Amsterdam, The Netherlands, 1987; pp. 37–52. [Google Scholar]

- Elias, A.A.; Donadelli, F.; Paiva, E.L.; Araujo, P.P.B. Analysing the complexities of sustainable wood supply chain in the Amazon: A systems thinking approach. Int. J. Logist. Manag. 2021, 32, 1481–1505. [Google Scholar] [CrossRef]

- Santos, A.; Carvalho, A.; Barbosa-póvoa, A.P.; Marques, A.; Amorim, P. Forest Policy and Economics Assessment and optimization of sustainable forest wood supply chains—A systematic literature review. For. Policy Econ. 2019, 105, 112–135. [Google Scholar] [CrossRef]

- Bryant, F.B.; Yarnold, P.R. Principal-components analysis and exploratory and confirmatory factor analysis. In Reading and Understanding Multivariate Statistics; Grimm, L.G., Yarnold, P.R., Eds.; American Psychological Association: Washington, DC, USA, 1995; pp. 99–136. [Google Scholar]

- Diabat, A.; Jebali, A. Multi-product and multi-period closed loop supply chain network design undertake-back legislation. Int. J. Prod. Econ. 2020, 231, 107879. [Google Scholar] [CrossRef]

- Gopal, P.; Thakkar, J. Analysing critical success factors to implement sustainable supply chain practices in Indian automobile industry: A case study. Prod. Plan. Control 2016, 27, 1005–1018. [Google Scholar] [CrossRef]

- Giannakis, M.; Dubey, R.; Vlachos, I.; Ju, Y. Supplier sustainability performance evaluation using the analytic network process. J. Clean. Prod. 2019, 247, 119439. [Google Scholar] [CrossRef]

| Authors | Methods Used | Region of Study | Main Contribution |

|---|---|---|---|

| Zineldin et al. [23] | Survey | Sweden | Identifying factors influencing supplier–dealer relationship |

| Quesada et al. [24] | Survey using five-point Likert scale | USA | Identification and ranking of CSFs for sustainability |

| Daian et al. [25] | Survey | Australia | Assessment of generation of wod waste to enhance sustainability standards |

| Dewitt et al. [26] | Case study | USA | Demonstration of a link between Porter’s cluster theory and supply chain management |

| Gomez [27] | Survey | USA | Identification of the CSFs for sustainability in the U.S. pallet-manufacturing industry after surveying 1500 manufacturers |

| Ratnasingam et al. [37] | Survey and PCA | Malaysia | Identification of the CSFs for sustainability in panel-based furniture-manufacturing industry |

| Navarro et al. [38] | Integration of AHP and TOPSIS | USA | Identification of sustainable suppliers in the wood fibre supply industry |

| Rajput et al. [39] | Integration of PCA, ISM, and DEMATEL | India | Identification of IoT enablers in Industry 4.0 and the relationships between these enablers |

| Chowdhury et al. [40] | Integration of ISM and MICMAC | Bangladesh | Identification of the CSFs for sustainability in ready-made garments industry and their interrelationships |

| Devi et al. [41] | Integration of PCA, ISM and MICMAC | India | Analyze IoT enablers in Industry 4.0 |

| This study | Integration of PCA, ISM and MICMAC | Bangladesh | Evaluation of valuate the supply chain sustainability in the wood industry |

| Sl. No. | Success Factor | Description | References |

|---|---|---|---|

| 1 | Recycling and waste management (RWM) | Recycling focuses on the regeneration of renewable resources after use. The principles of waste management are elimination, reduction, reuse, recovery, and disposal. | [38,39] |

| 2 | Using eco-friendly technology (ET) | Using eco-friendly technology that conserves energy and reduces resource consumption. | [5,7] |

| 3 | Sharing natural resources (NR) | The long-term availability and sharing of natural resources. | [40,41] |

| 4 | Product responsibility (PR) | Product responsibility covers the entire life cycle, including the raw materials, product development, production, use, and recycling. | [7,42] |

| 5 | Designing products for recyclability, reusability, and material recoverability (RRR) | Designing for deconstruction to ensure that deconstruction processes retain maximum material value. | [43,44] |

| 6 | Supplier environmental evaluation and feedback (SEEF) | Suppliers are evaluated on several criteria: no child labour, working hours, no forced labour, no discrimination, employment compensation, freedom of association, use of eco-friendly materials, and health and safety practices. | [8,45] |

| 7 | Using eco-friendly materials (EFM) | Using eco-friendly materials. | [46] |

| 8 | Managing hazardous substances (MHS) | Managing wood-industry-specific hazardous chemicals, which are endorsed by the Occupational Safety and Health Regulations 1996 and have specific safety requirements. | [47] |

| 9 | Support from customers (SC) | Awareness among customers motivates manufacturers to produce green products. | [48] |

| 10 | Training programs for supplier and vendors (SV) | Training, implementing special projects, and monitoring performance. | [49] |

| 11 | Collaborative R&D with same-sector companies (R&D) | Collaboration on green research and development with suppliers and companies in the same sector. | [50] |

| 12 | Flexible working arrangements (FWA) | Flexible working—also known as flextime or flexitime—refers to non-traditional working arrangements that consider employees’ personal needs, often involving working from home and flexible hours. | [7] |

| 13 | Supplier evaluation and selection (SES) | Environmental auditing and supplier evaluation to ensure that products conform to regulations. | [36,51] |

| 14 | Supplier relations (SR) | Supplier relations reflect the extent to which an organization has a collaborative relationship with its suppliers. | [52,53] |

| 15 | Stability in policy and regulations (PS) | Stability in policies and regulations, which is often tied to political stability. | [54] |

| 16 | Health and safety (HS) | Manual lifting, forceful gripping, wood dust, and hazardous substances are the reported common risk factors in the wood industry. Inhaling hazardous substances and getting caught in moving parts are common injuries in the industry. The most prominent prior risk is inadequate personal protective equipment. | [36,55] |

| 17 | Gender diversity (GD) | Fair representation of people of different genders at various stages of the supply chain. | [56] |

| 18 | Government legislation (GL) | Regulations pressure suppliers and organizations to use eco-friendly products and processes to improve operational performances. | [57] |

| 19 | Top management support (TMS) | Top management support is crucial to the successful implementation of SSCM. | [58] |

| 20 | Resource management (RM) | Optimal resource usage helps firms achieve economic sustainability in the supply chain. | [59] |

| 21 | Supplier audit (SA) | Supplier audits have the potential to enhance supply chains’ environmental and social performance. | [60] |

| 22 | Product quality (PQ) | Sustainable supply chains can be achieved by producing high-quality products with a longer product life. | [36] |

| 23 | Technological advancement and adaption (TAA) | Willingness to research developing technologies and adopt new technologies in the pursuit of greater sustainability. | [59,61] |

| 24 | Technology transfer (TT) | Transferring technology to supply chain partners helps firms achieve long-term sustainability. | [62] |

| 25 | Information system (IS) | Information systems impact SSCM on various processes, such as planning, sourcing, and delivering, and at various levels, including tactical operations and organizational strategy. | [63] |

| Organization Type/Pseudocode | Designation | No. of Experts | Average Work Experience (n) | |

|---|---|---|---|---|

| Academia | A001 | Professor | 4 | n > 15 |

| Assistant professor | 2 | n > 5 | ||

| Associate professor | 1 | n > 7 | ||

| A002 | Professor | 3 | n > 10 | |

| Assistant professor | 1 | n > 5 | ||

| Associate professor | 2 | n > 7 | ||

| A003 | Professor | 4 | n > 15 | |

| Assistant professor | 3 | n > 5 | ||

| Associate professor | 2 | n > 7 | ||

| A004 | Professor | 2 | n > 15 | |

| Assistant professor | 1 | n > 5 | ||

| Associate professor | 2 | n > 7 | ||

| A005 | Professor | 2 | n > 12 | |

| Assistant professor | 1 | n > 7 | ||

| Industry | Furniture | Quality managers | 20 | n > 15 |

| Supply chain managers | 40 | n > 10 | ||

| Operation process managers | 10 | n > 10 | ||

| Paper mills | Quality managers | 15 | n > 10 | |

| Supply chain managers | 10 | n > 10 | ||

| Operation process managers | 30 | n > 10 | ||

| Total | 150 |

| CSFs | Rotated Component Matrix (Factor Loading Less than 0.1 is Omitted) | Mean | Standard Deviation | Rank | |||

|---|---|---|---|---|---|---|---|

| Component 1 | Component 2 | Component 3 | Component 4 | ||||

| R&D | 0.818 | 3.85 | 0.706 | 1 | |||

| SR | 0.857 | 3.84 | 0.680 | 2 | |||

| ET | 0.930 | 3.84 | 0.595 | 2 | |||

| HS | 0.875 | 3.81 | .711 | 3 | |||

| TMS | 0.690 | 3.08 | 1.106 | 4 | |||

| RM | 0.689 | 3.02 | 1.032 | 5 | |||

| PQ | 0.681 | 2.40 | 1.561 | 6 | |||

| TT | 0.744 | 2.14 | 1.089 | 7 | |||

| TAA | 0.784 | 2.06 | 1.051 | 8 | |||

| IS | 0.770 | 2.06 | 1.030 | 9 | |||

| Extraction Method: Principal Component Analysis. Rotation Method: Varimax with Kaiser Normalization. | Cronbach alpha—0.93 Kaiser–Meyer–Olkin Measure of Sampling Adequacy—0.948 | ||||||

| Bartlett’s Test of Sphericity | Approx. Chi-Square—859.184 Df—55 Sig.—0.000 | ||||||

| Extracted Components | CSFs Selected from PCA |

|---|---|

| Product quality and well-being of the organization | Collaborative Research & Development with same sector companies (R&D) |

| Product quality (PQ) | |

| Transferring technology to suppliers and vendors (TT) | |

| Information System (IS) | |

| Resource Management (RM) | |

| Technology advancement and adaption (TAA) | |

| Top management support (TMS) | |

| Health and safety | Health and safety (HS) |

| Supplier relations | Supplier relations (SR) |

| Environment friendly technology | Use of environment friendly technology (ET) |

| CSFs | ET | SR | HS | TMS | TAA | RM | IS | TT | PQ |

|---|---|---|---|---|---|---|---|---|---|

| R&D | V | O | V | A | X | V | X | V | V |

| PQ | X | A | V | A | A | A | A | A | |

| TT | V | V | O | A | A | V | V | ||

| IS | O | V | O | A | X | V | |||

| RM | O | O | O | A | A | ||||

| TAA | V | O | V | A | |||||

| TMS | V | V | V | ||||||

| HS | A | O | |||||||

| SR | O | ||||||||

| ET |

| CSFs | 1. R&D | 2. PQ | 3. TT | 4. IS | 5. RM | 6. TAA | 7. TMS | 8. HS | 9. SR | 10. ET |

|---|---|---|---|---|---|---|---|---|---|---|

| 1. R&D | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 1 | 0 | 1 |

| 2. PQ | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 1 |

| 3. TT | 0 | 1 | 1 | 1 | 1 | 0 | 0 | 0 | 1 | 1 |

| 4. IS | 1 | 1 | 0 | 1 | 1 | 1 | 0 | 0 | 1 | 0 |

| 5. RM | 0 | 1 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 |

| 6. TAA | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 1 | 0 | 1 |

| 7. TMS | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| 8. HS | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 |

| 9. SR | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 |

| 10. ET | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 1 |

| CSFs | R&D | PQ | TT | IS | RM | TAA | TMS | HS | SR | ET | Driving Power |

|---|---|---|---|---|---|---|---|---|---|---|---|

| R&D | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 1 | 1 | 1 | 9 |

| PQ | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 1 | 3 |

| TT | 0 | 1 | 1 | 1 | 1 | 0 | 0 | 1 | 1 | 1 | 7 |

| IS | 0 | 1 | 0 | 1 | 1 | 0 | 0 | 1 | 1 | 1 | 6 |

| RM | 0 | 1 | 0 | 0 | 1 | 0 | 0 | 1 | 0 | 1 | 4 |

| TAA | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 1 | 1 | 1 | 9 |

| TMS | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 10 |

| HS | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 1 |

| SR | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 1 | 1 | 1 | 4 |

| ET | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 1 | 3 |

| Dependence Power | 3 | 9 | 4 | 5 | 6 | 3 | 1 | 10 | 6 | 9 | 56 |

| CSF | Reachability Set | Antecedent Set | Intersection Set | Level |

|---|---|---|---|---|

| R&D | 1,2,3,4,5,6,8,9,10 | 1,6,7 | 1,6 | 6 |

| PQ | 2,8,10 | 1,2,3,4,5,6,7,9,10 | 2,10 | 2 |

| TT | 2,3,4,5,8,9,10 | 1,3,6,7 | 3 | 5 |

| IS | 2,4,5,8,9,10 | 1,3,4,6,7 | 4 | 4 |

| RM | 2,5,8,10 | 1,3,4,5,6,7 | 5 | 3 |

| TAA | 1,2,3,4,5,6,8,9,10 | 1,6,7 | 1,6 | 6 |

| TMS | 1,2,3,4,5,6,7,8,9,10 | 7 | 7 | 7 |

| HS | 8 | 1,2,3,4,5,6,7,8,9,10 | 8 | 1 |

| SR | 2,8,9,10 | 1,3,4,6,7,9 | 9 | 3 |

| ET | 2,8,10 | 1,2,3,4,5,6,7,9,10 | 2,10 | 2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Paul, S.; Ali, S.M.; Hasan, M.A.; Paul, S.K.; Kabir, G. Critical Success Factors for Supply Chain Sustainability in the Wood Industry: An Integrated PCA-ISM Model. Sustainability 2022, 14, 1863. https://doi.org/10.3390/su14031863

Paul S, Ali SM, Hasan MA, Paul SK, Kabir G. Critical Success Factors for Supply Chain Sustainability in the Wood Industry: An Integrated PCA-ISM Model. Sustainability. 2022; 14(3):1863. https://doi.org/10.3390/su14031863

Chicago/Turabian StylePaul, Sumit, Syed Mithun Ali, Mohd Asif Hasan, Sanjoy Kumar Paul, and Golam Kabir. 2022. "Critical Success Factors for Supply Chain Sustainability in the Wood Industry: An Integrated PCA-ISM Model" Sustainability 14, no. 3: 1863. https://doi.org/10.3390/su14031863

APA StylePaul, S., Ali, S. M., Hasan, M. A., Paul, S. K., & Kabir, G. (2022). Critical Success Factors for Supply Chain Sustainability in the Wood Industry: An Integrated PCA-ISM Model. Sustainability, 14(3), 1863. https://doi.org/10.3390/su14031863