Evaluating Evaporative Cooling Assisted Solid Desiccant Dehumidification System for Agricultural Storage Application

Abstract

1. Introduction

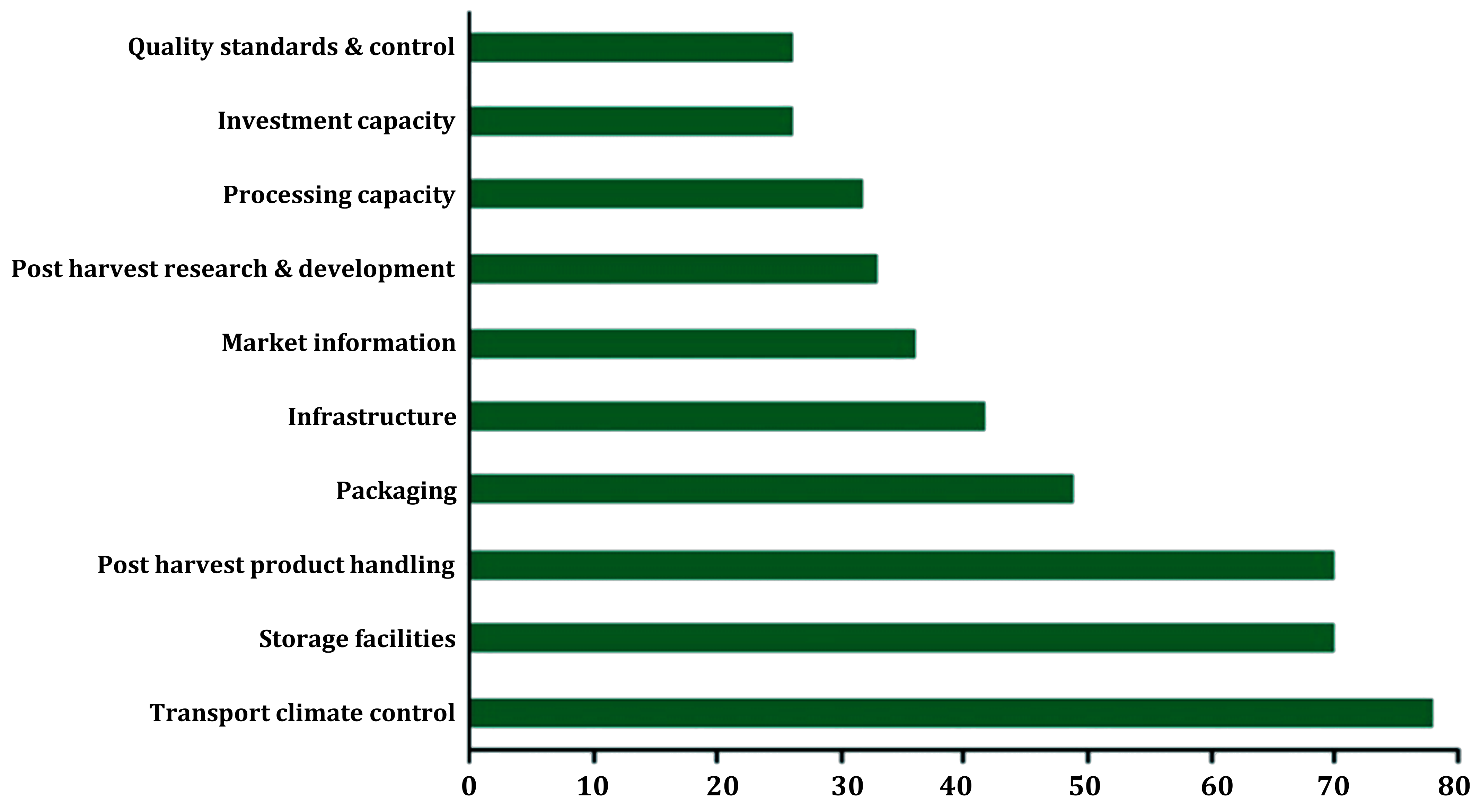

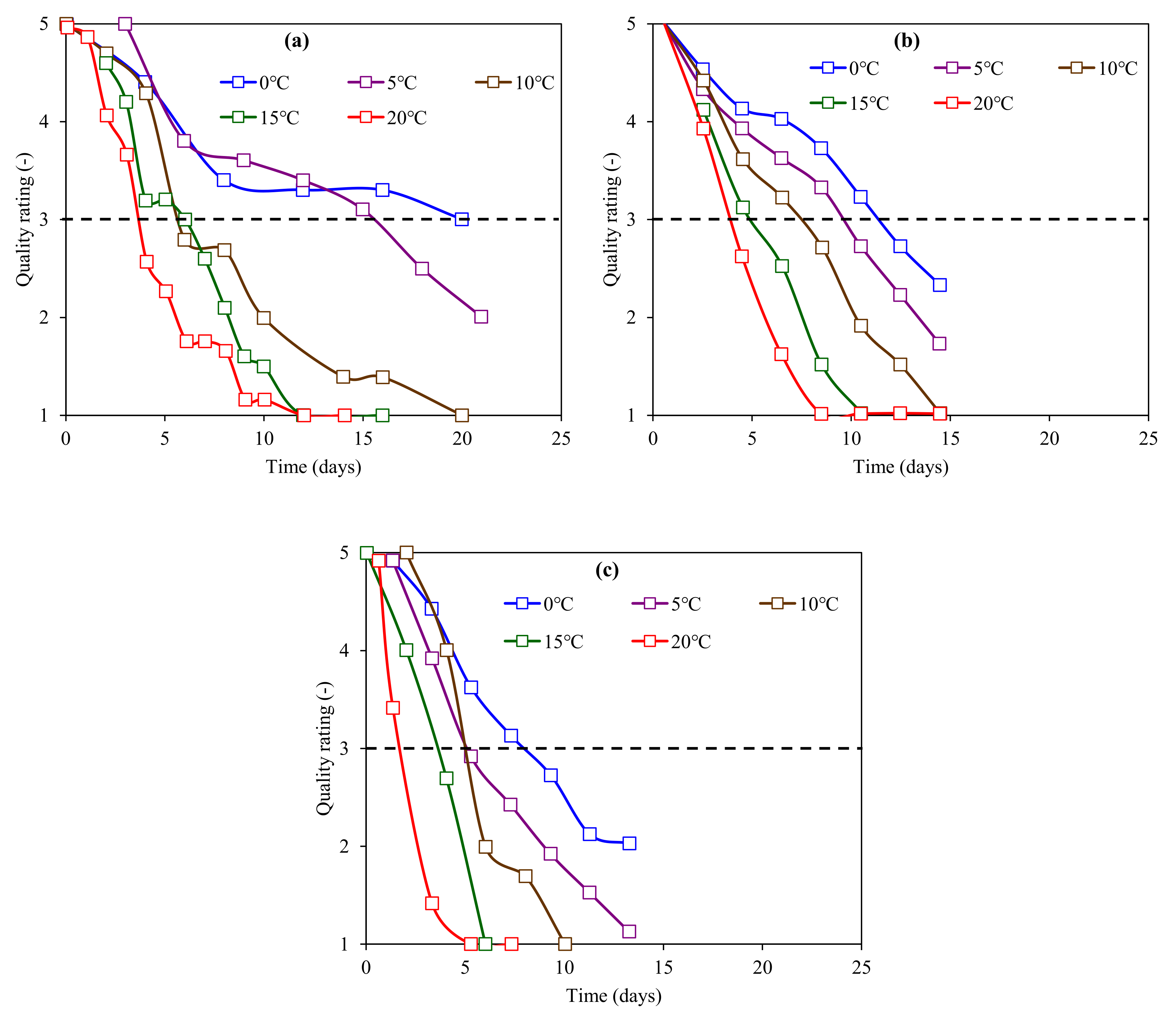

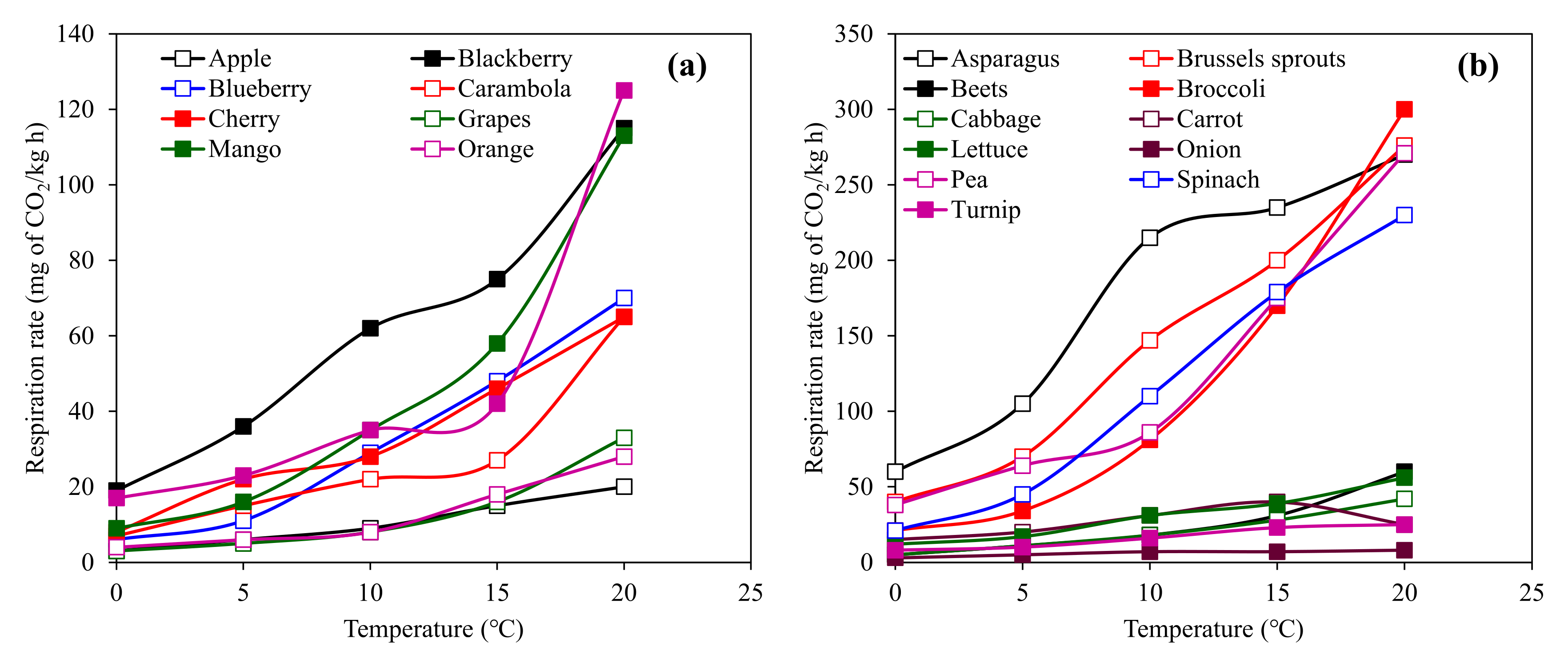

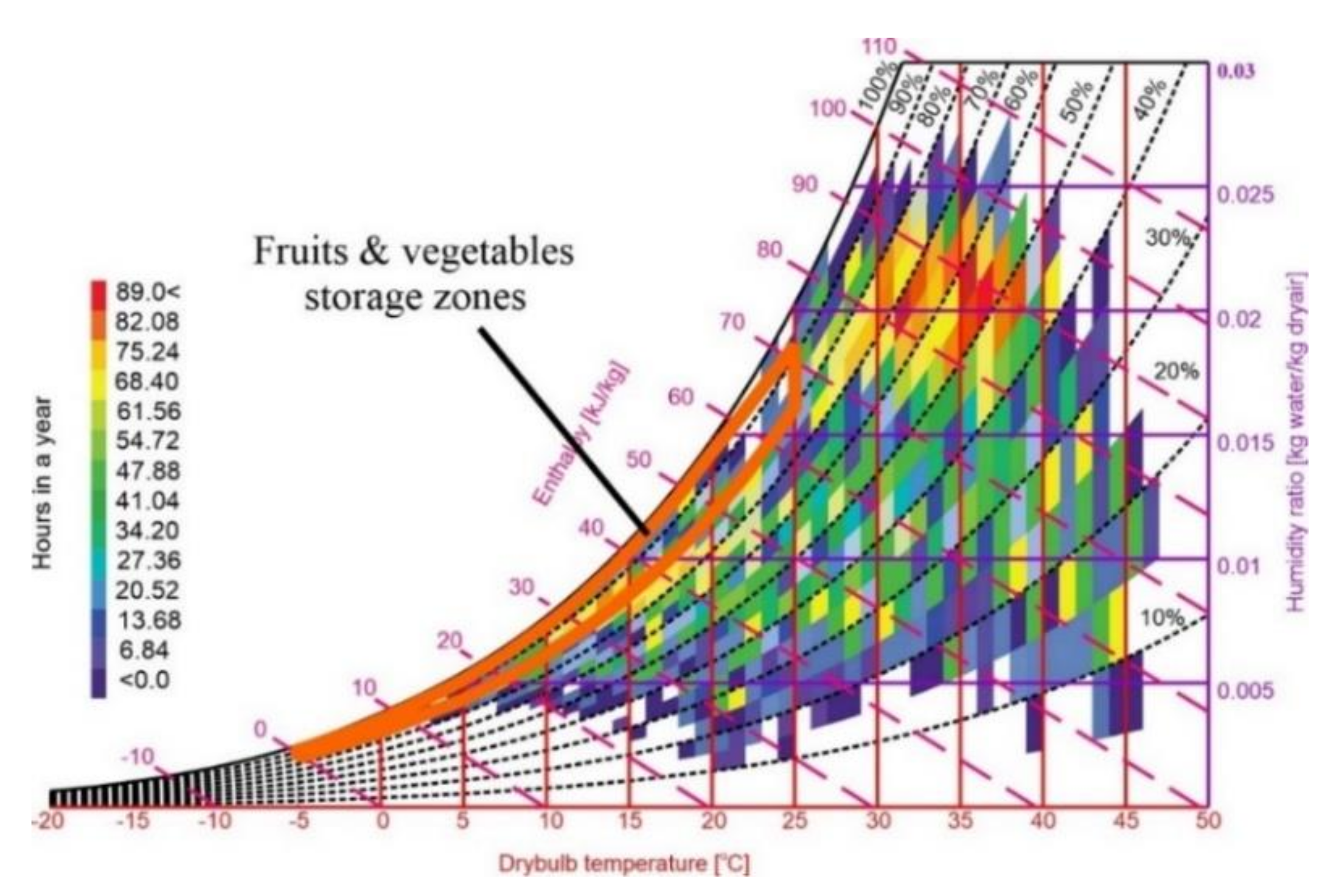

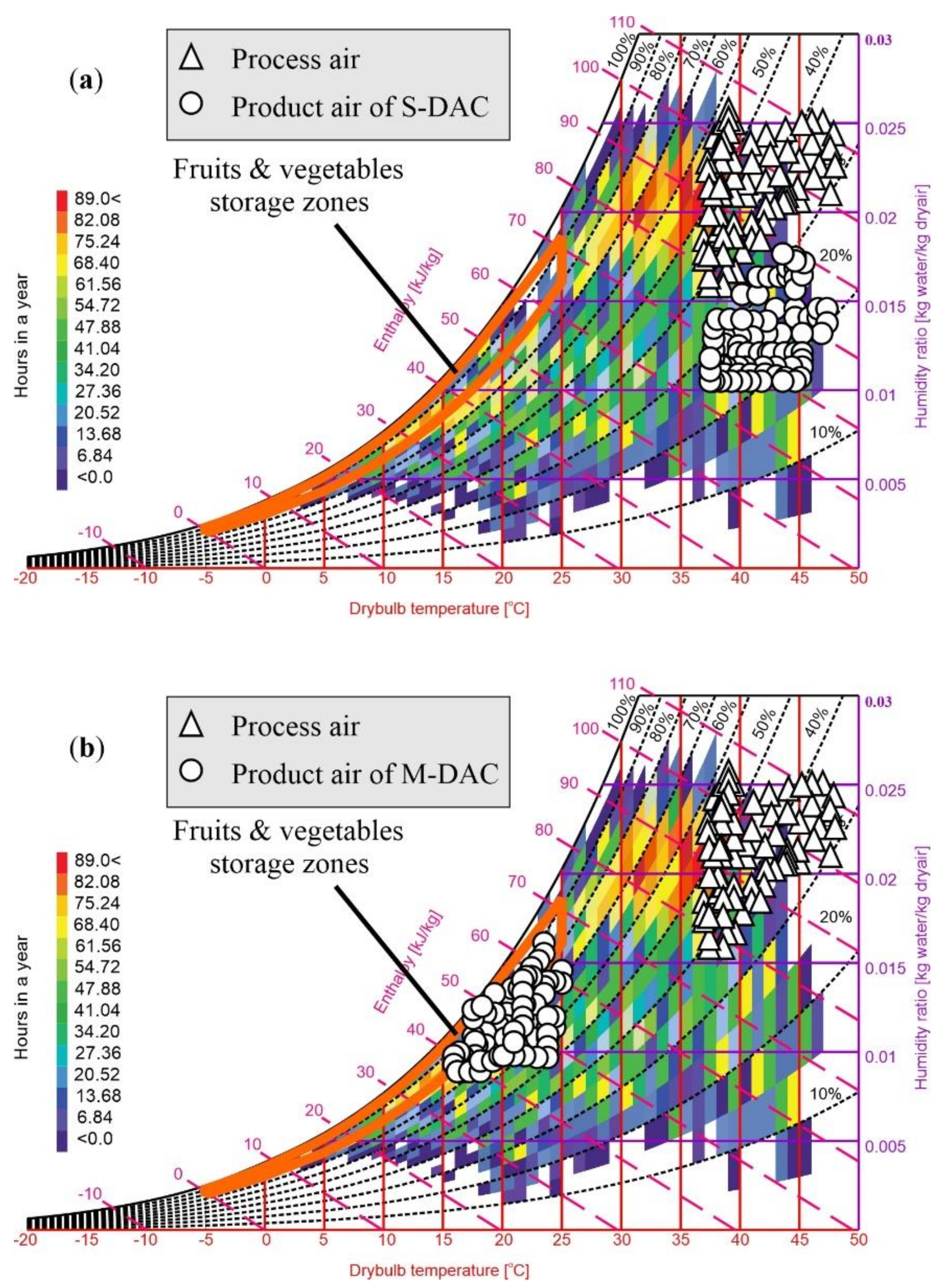

Temperature/Humidity Requirements for Agricultural Storage Application

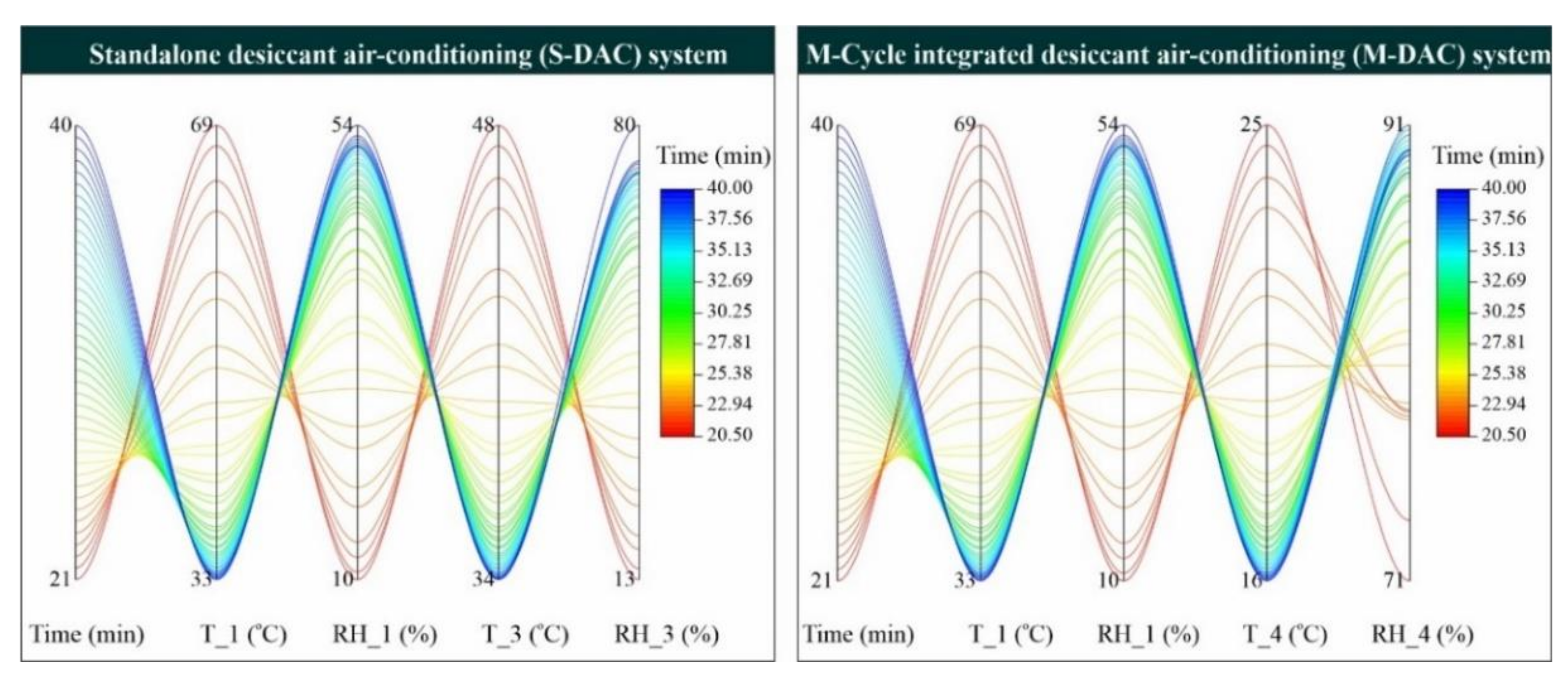

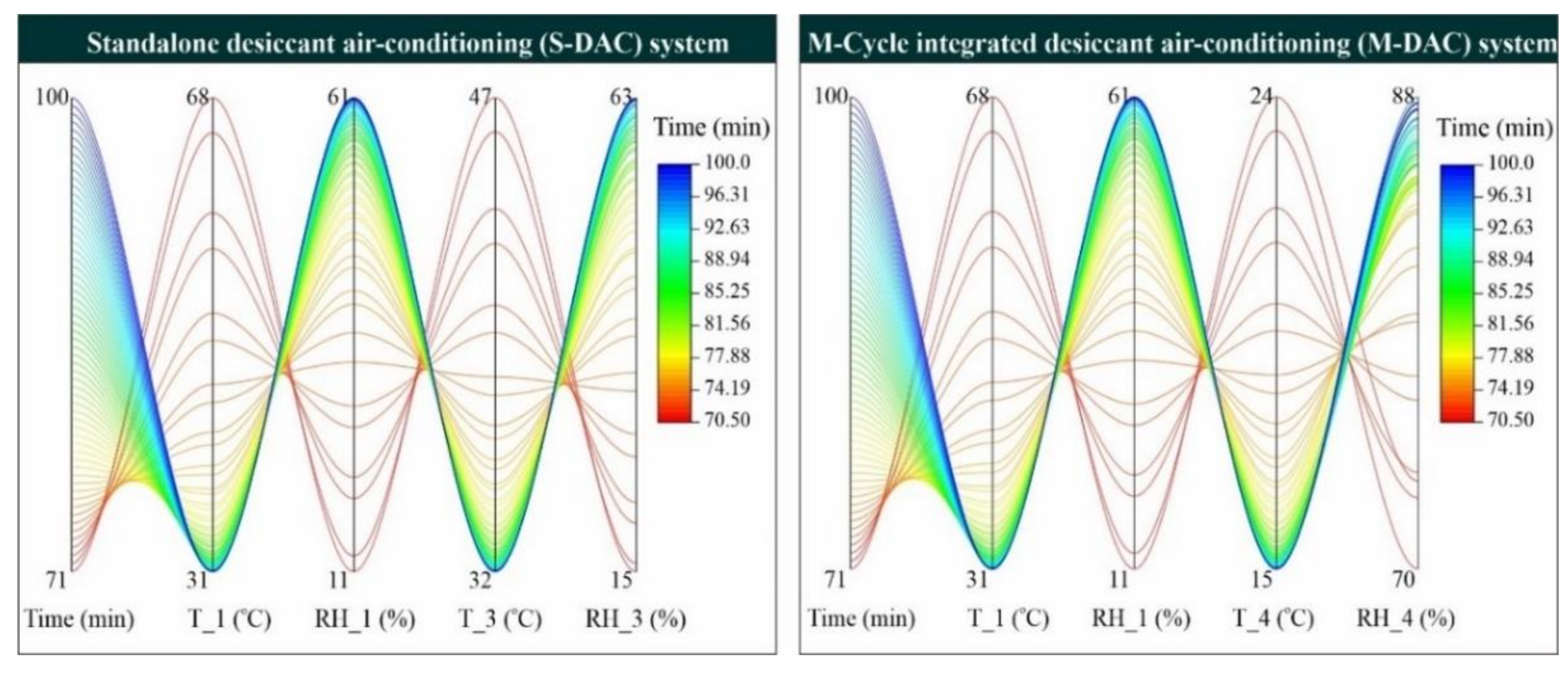

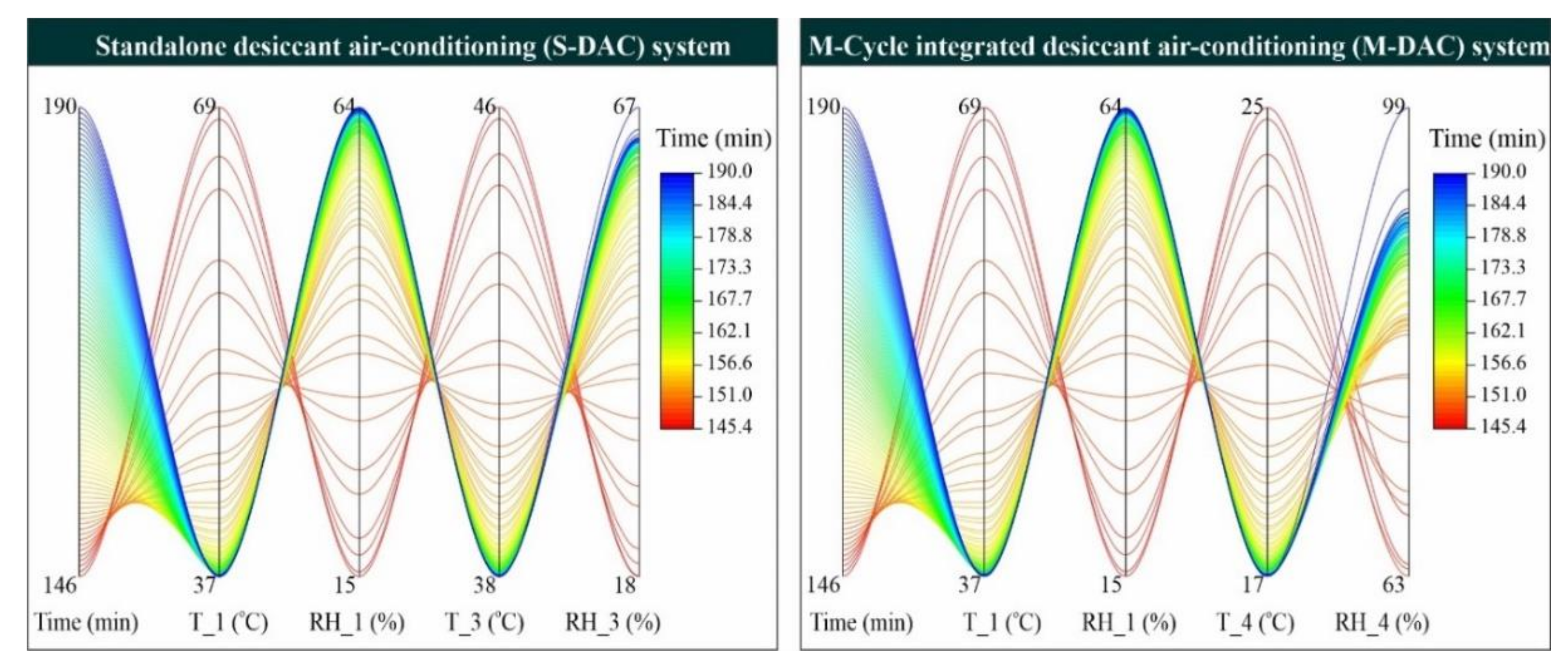

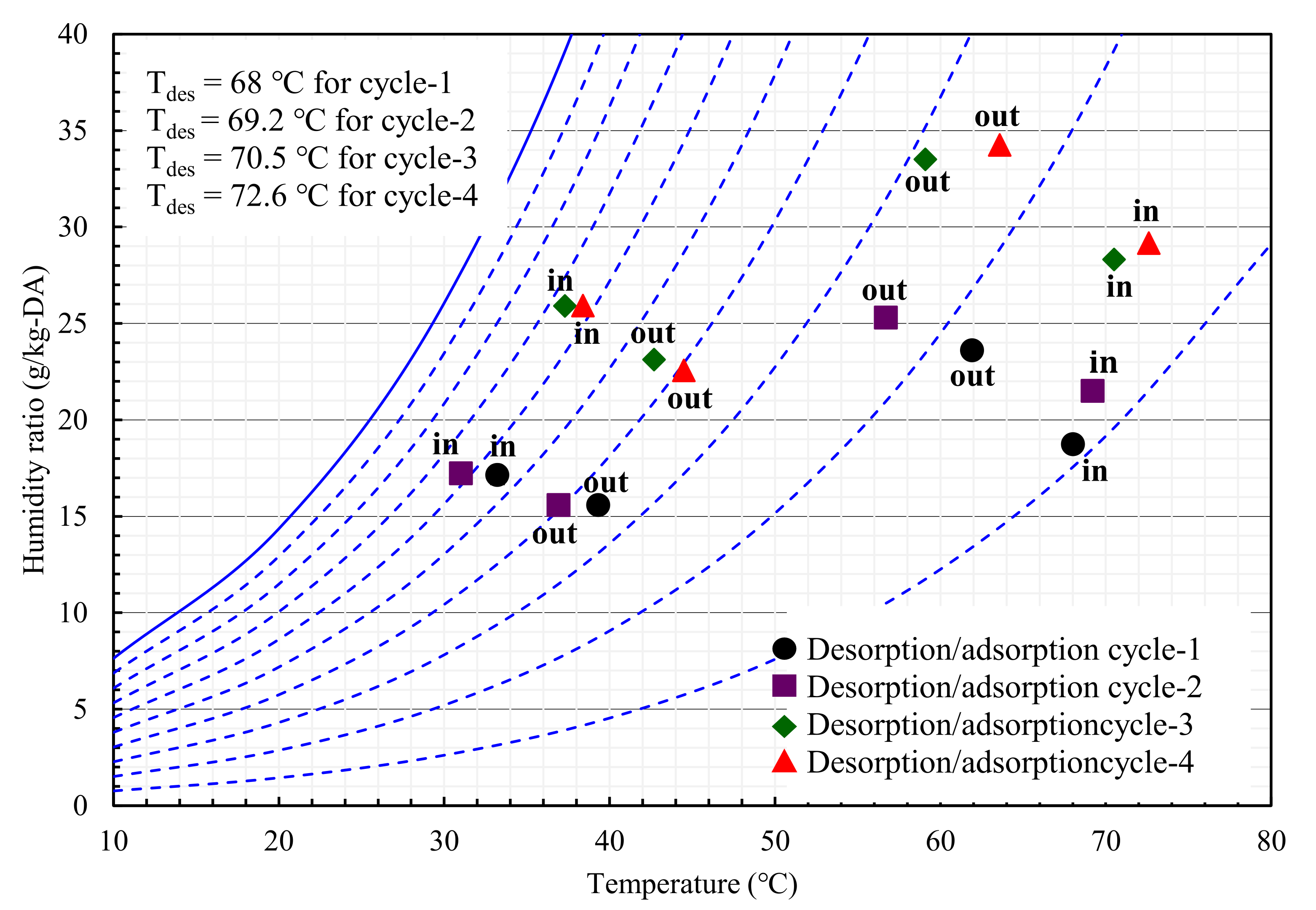

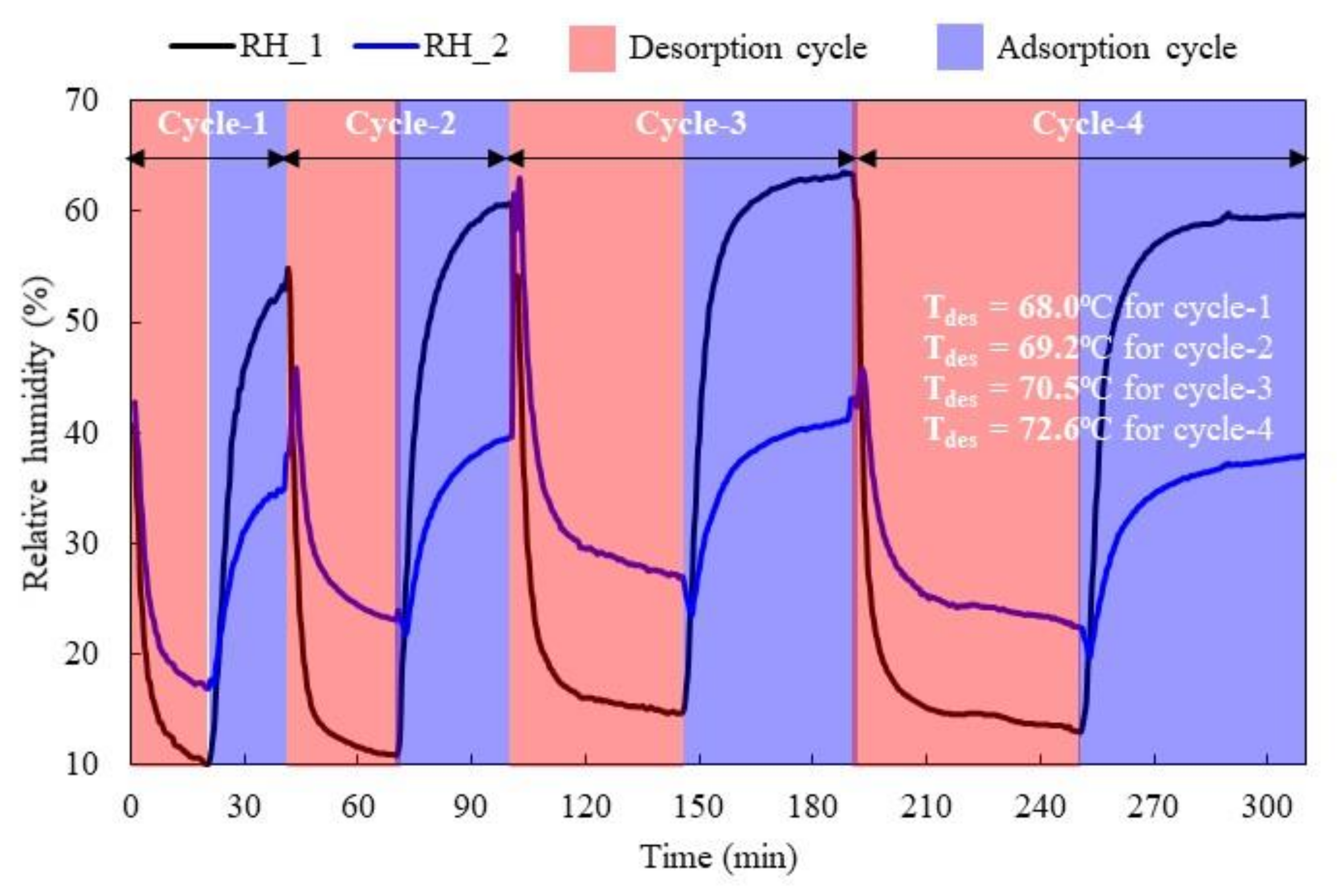

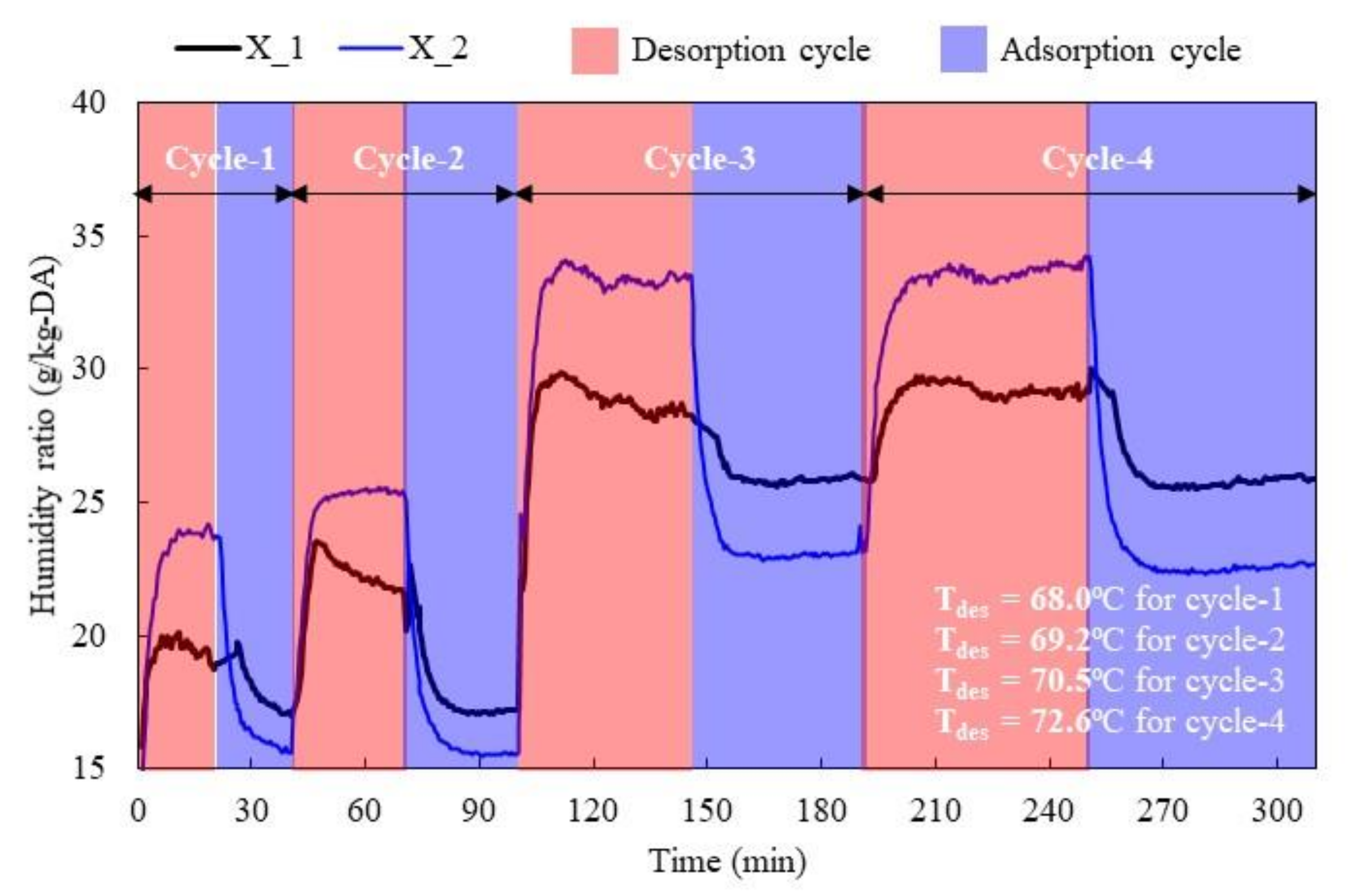

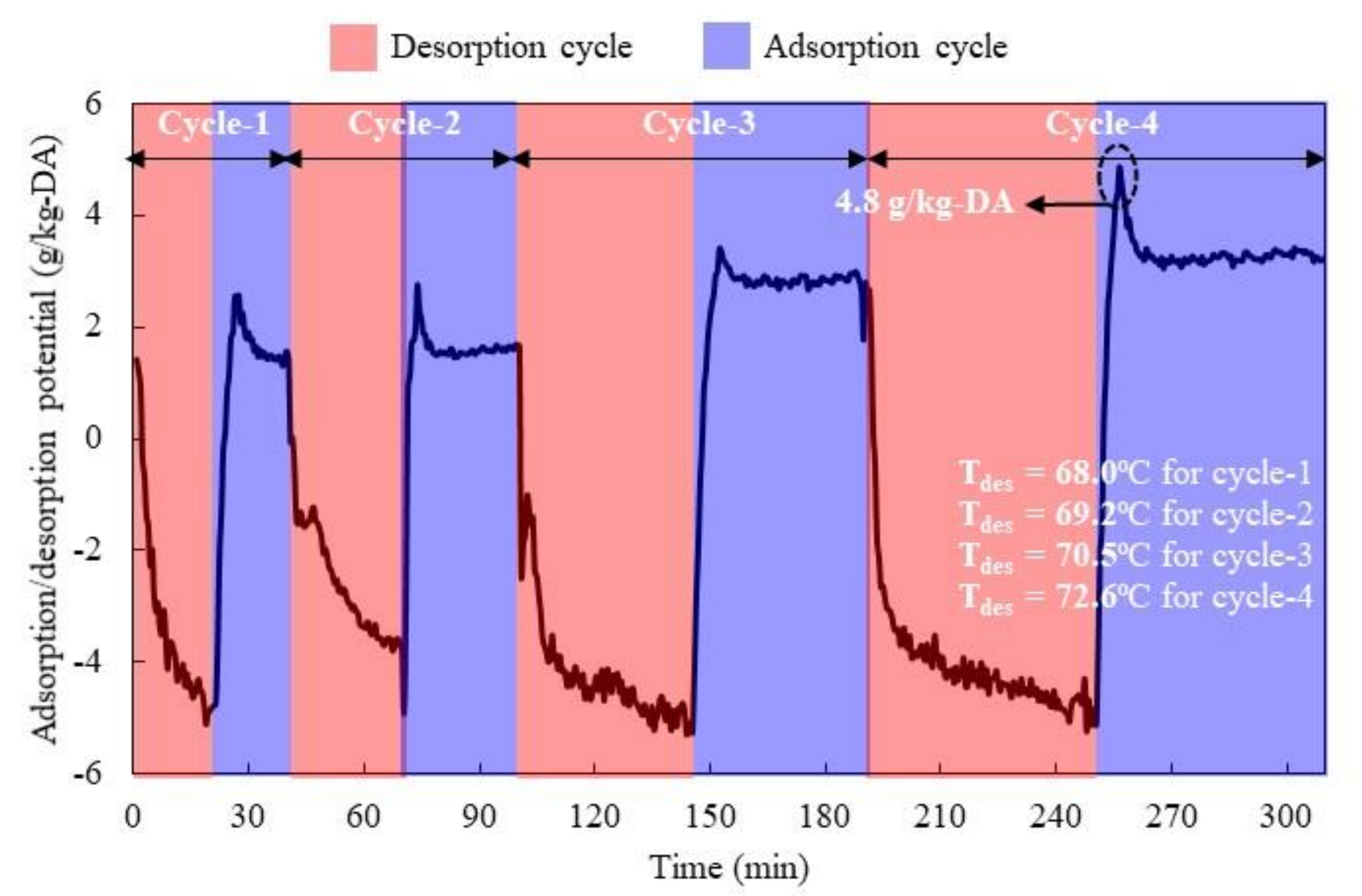

2. Proposed Systems

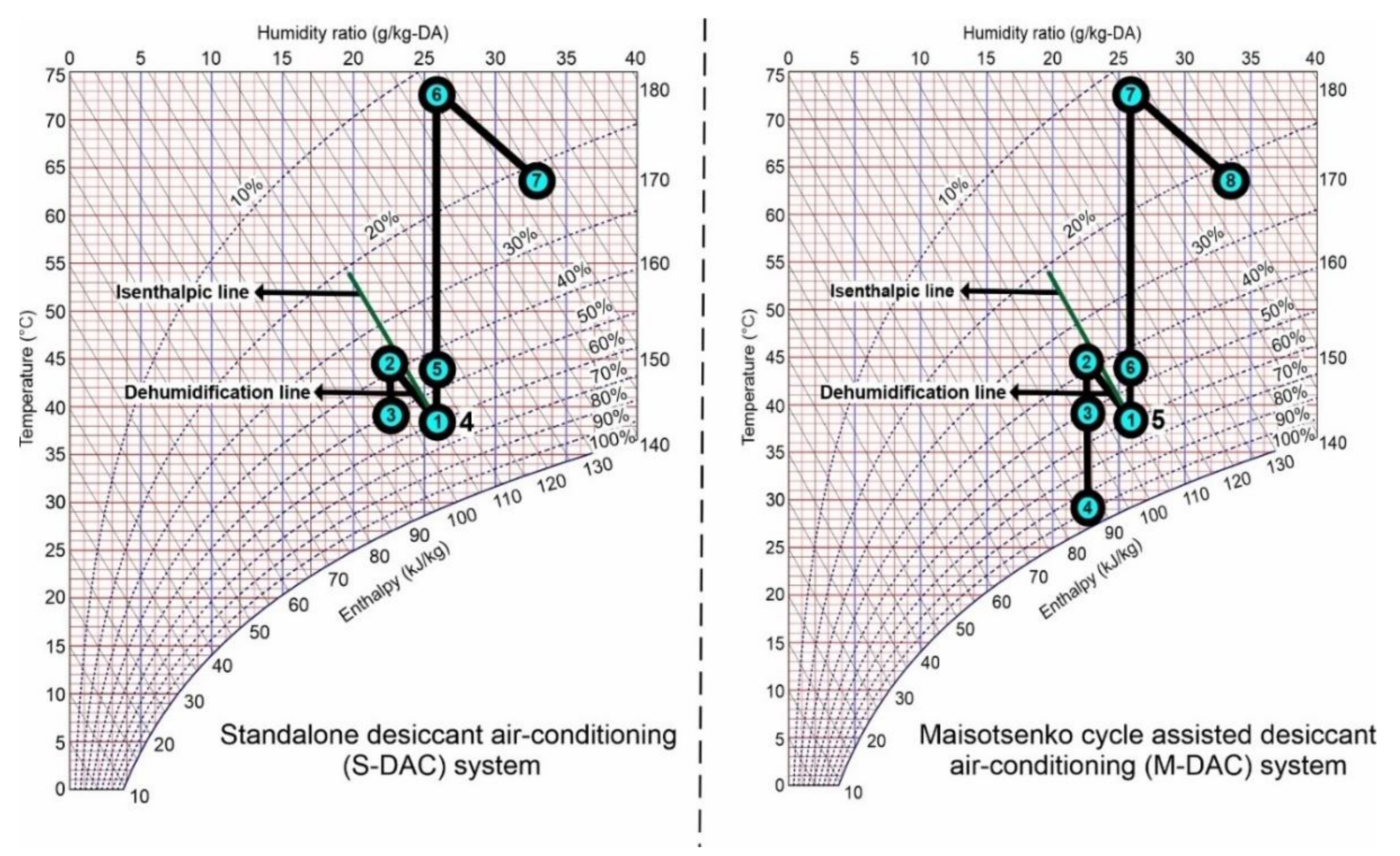

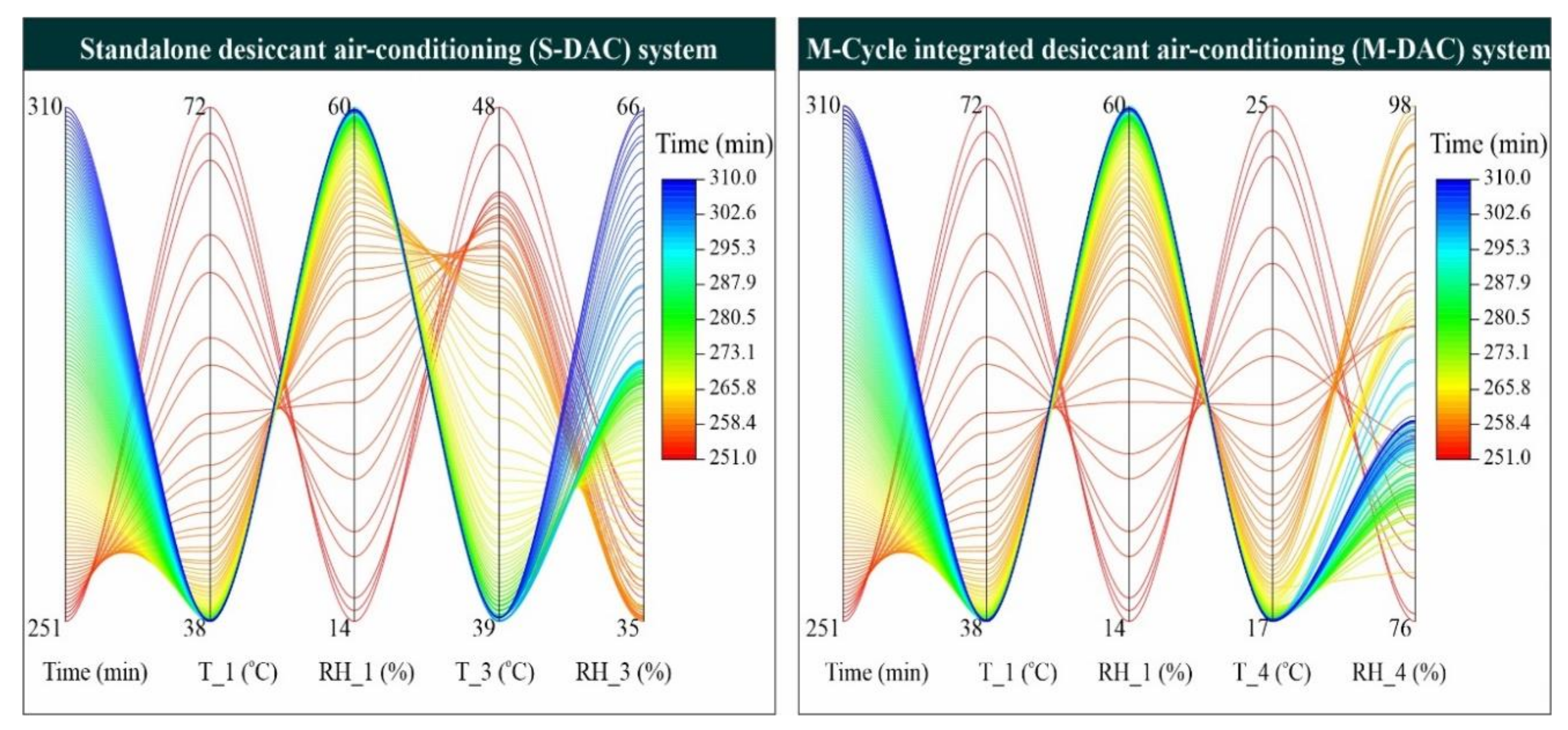

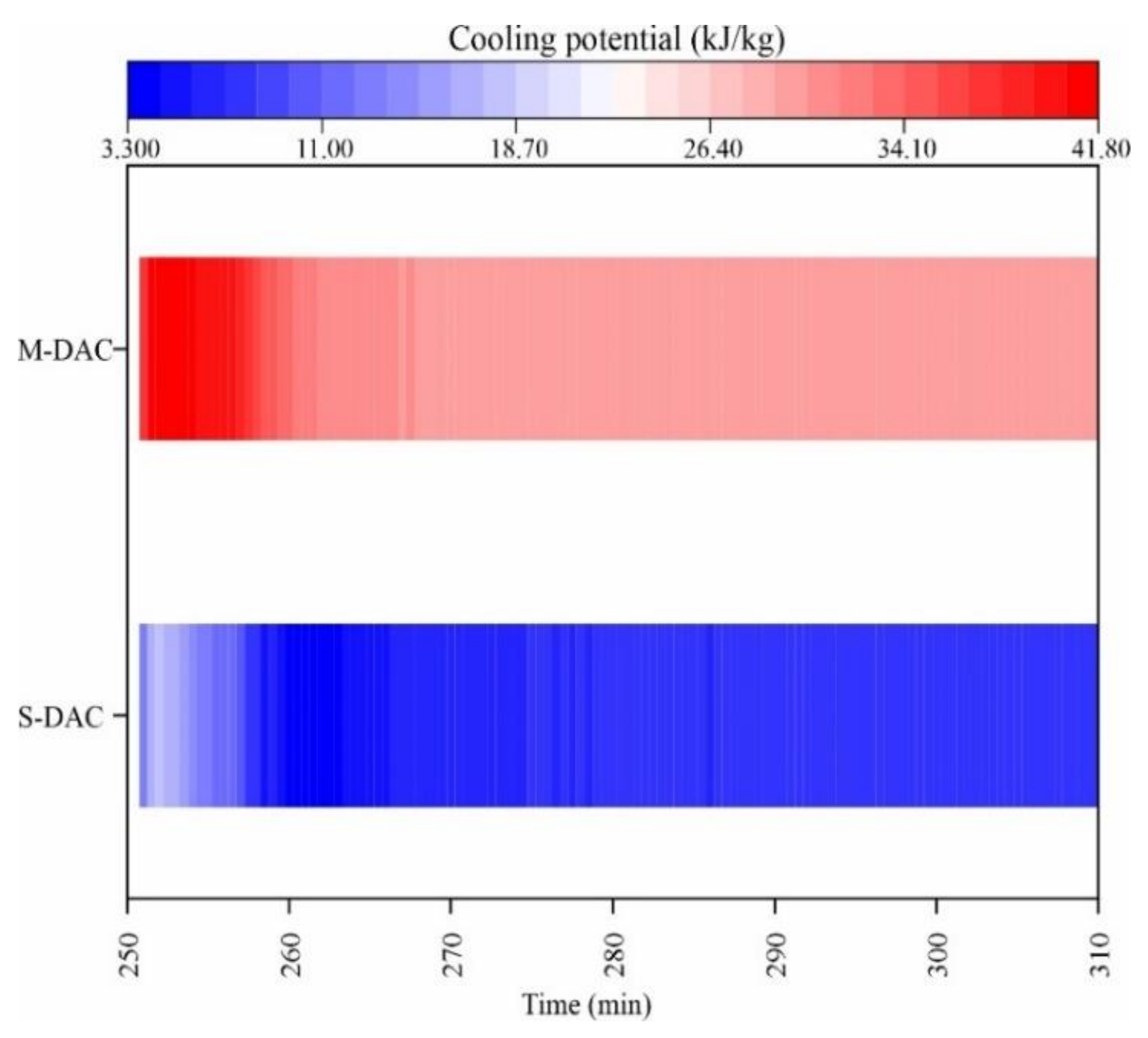

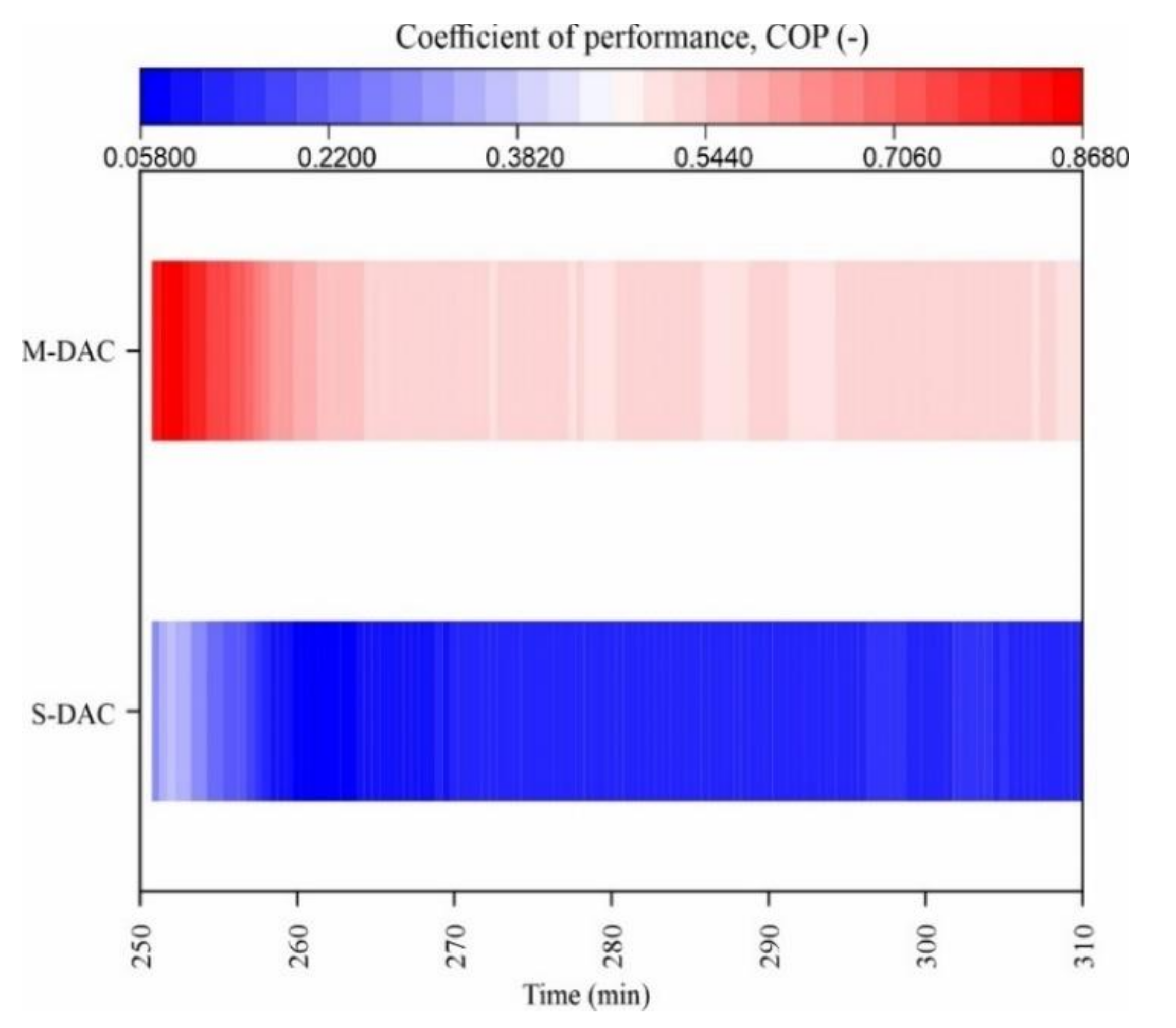

2.1. Standalone Desiccant Air-Conditioning (S-DAC) System

2.2. M-Cycle Integrated Desiccant Air-Conditioning (M-DAC) System Collection

3. Materials and Methods

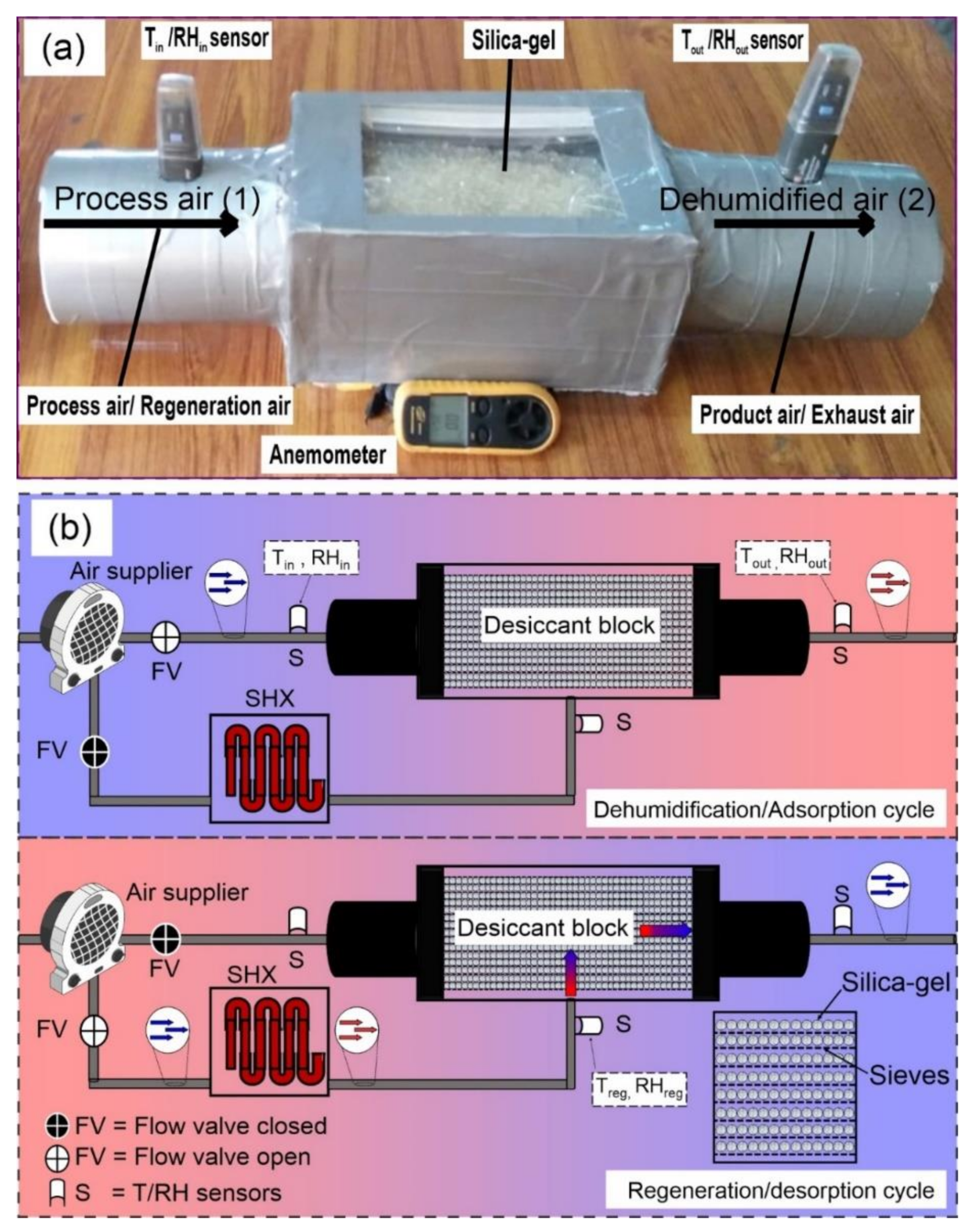

3.1. Experimental Setup

3.2. Data Reduction

3.3. Uncertainty Analysis

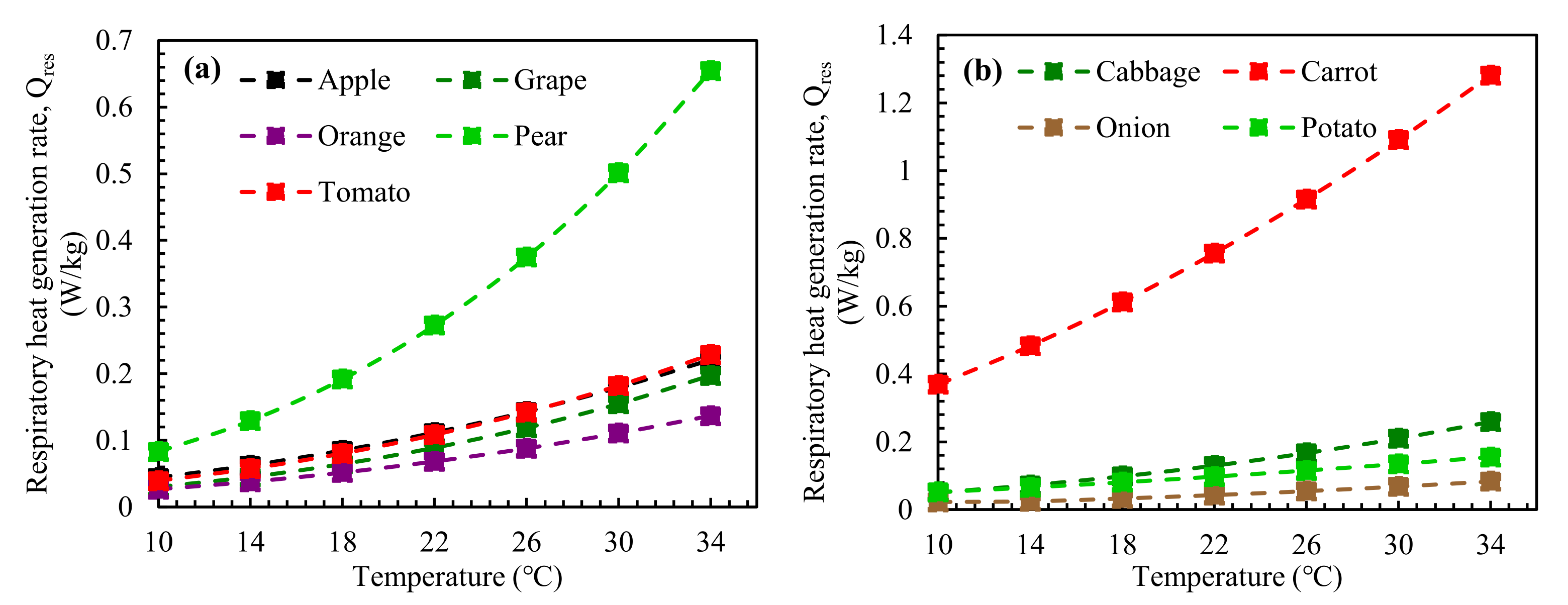

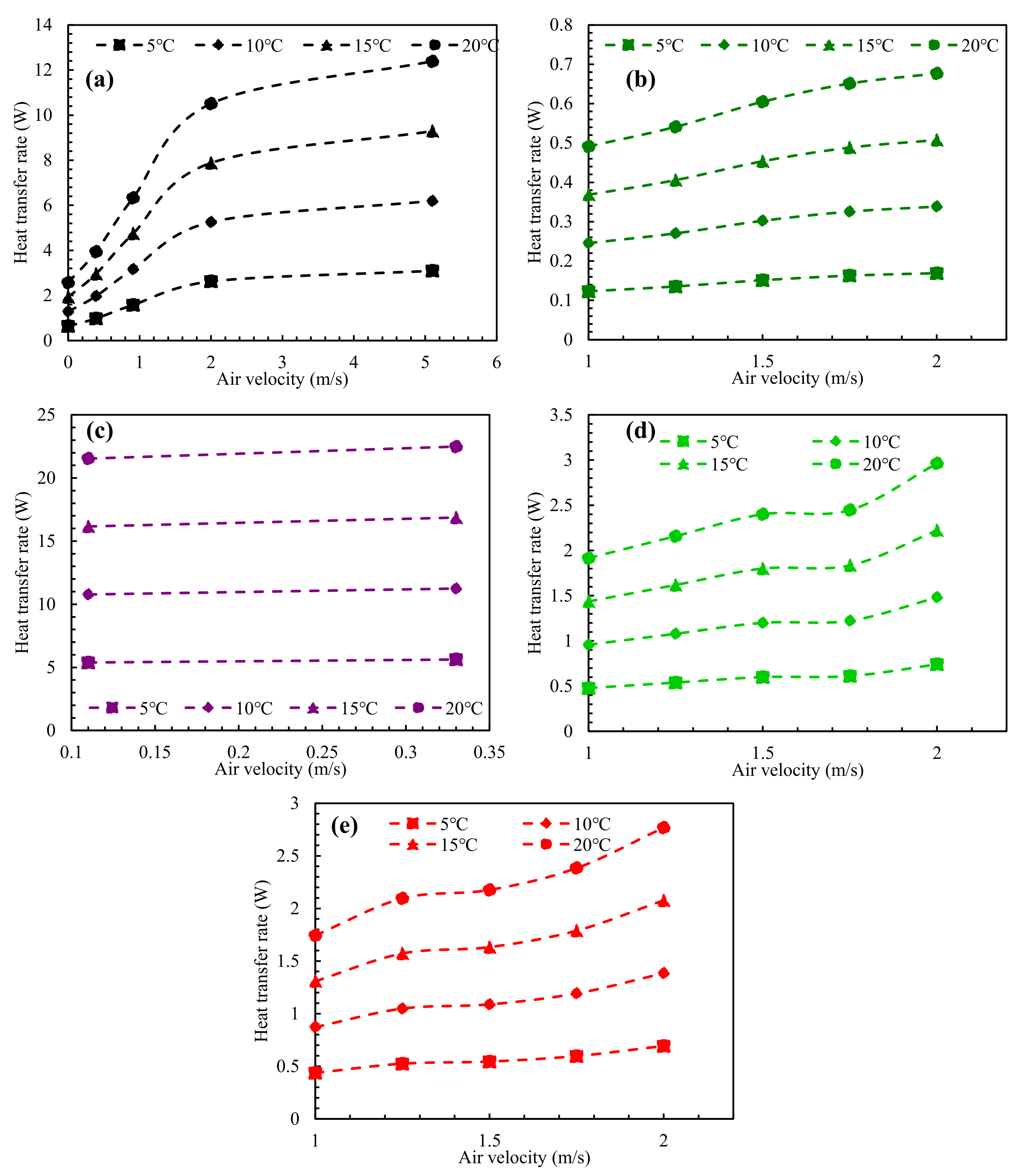

3.4. Heat Load Calculations for Agricultural Storage Application

4. Results and Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| AC | air-conditioning |

| surface area of product (m2) | |

| COP | coefficient of performance |

| specific heat capacity of air (kJ/kg K) | |

| DAC | desiccant air-conditioning |

| pressure drop (kPa) | |

| EC | evaporative cooling |

| respiratory coefficient (-) | |

| respiratory coefficient (-) | |

| air enthalpy (kJ/kg) | |

| surface heat transfer coefficient (W/m2 °C) | |

| LHR | latent heat ratio (LHR) |

| M-DAC | Maisotsenko-Cycle integrated desiccant air-conditioning |

| MEC | Maisotsenko-Cycle evaporative cooling |

| mass flow rate (kg/s) | |

| – | independent variables |

| cooling potential (kJ kg) | |

| total heat consumption (kW) | |

| latent heat consumption (kW) | |

| sensible heat consumption (kW) | |

| electricity consumption by fan (kW) | |

| cooling potential (kJ/kg) | |

| respiratory heat generation rate (W/kg) | |

| heat transfer rate (W) | |

| S-DAC | standalone desiccant air-conditioning |

| SHX | sensible heat exchanger |

| ambient air temperature (°C) | |

| surface temperature of product (°C) | |

| volume flow rate (m3/s) | |

| humidity ratio (g/kg-DA) | |

| adsorption/dehumidification potential (g/kg-DA) | |

| desorption/regeneration potential (g/kg-DA) | |

| temperature gradient (°C) | |

| – | uncertainty in independent variables |

| total uncertainty (%) | |

| efficiency of fan (%) | |

| effectiveness of sensible heat exchanger (-) | |

| latent heat of vaporization (kJ/kg) | |

| Subscripts | |

| ads | adsorption |

| DB | dry bulb |

| des | desorption |

| in | inlet condition |

| out | outlet condition |

Appendix A

References

- Noya, I.; González-García, S.; Bacenetti, J.; Fiala, M.; Moreira, M.T. Environmental Impacts of the Cultivation-Phase Associated with Agricultural Crops for Feed Production. J. Clean. Prod. 2018, 172, 3721–3733. [Google Scholar] [CrossRef]

- Abbas, M.; Maqsood, W.; Ijaz, M.; Hashim, M.Y. Post-Harvest Losses in Fruits and Vegetables in Pakistan. Available online: https://agrihunt.com/articles/pak-agri-outlook/post-harvest-losses-in-fruits-and-vegetables-in-pakistan/ (accessed on 9 June 2021).

- Ishaq, M.; Sultan, M.; Aleem, M.; Bilal, M.; Ullah, H.S.; Mahmood, M.H.; Miyazaki, T. Desiccant Dehumidification System for Storage of Fruits and Vegetables. In Energy-Efficient Systems for Agricultural Applications; Sultan, M.M.T., Ed.; Springer: Cham, Switzerland, 2022; pp. 65–83. [Google Scholar] [CrossRef]

- Ishaq, M.; Aleem, M.; Ashraf, H.; Hafiz, S.U.; Sultan, M. Study on Desiccant Dehumidification System Using Experiments and Steady-State Model. In Proceedings of the International Exchange and Innovation Conference on Engineering & Sciences (IEICES), Fukoka, Japan, 22—23 October 2020; Volume 6, pp. 92–97. [Google Scholar]

- FAO; CIHEAM. Mediterra 2016: Zero Waste in the Mediterranean. In Natural Resources, Food and Knowledge; International Centre of Advanced Mediterranean Agronomic Studies (CHIEAM); FAO; Presses de Sciences PO: Paris, France, 2016. [Google Scholar]

- Brasil, I.M.; Siddiqui, M.W. Chapter 1—Postharvest Quality of Fruits and Vegetables: An Overview; Siddiqui, M.W., Ed.; Academic Press: Amsterdam, The Netherlands, 2018; pp. 1–40. [Google Scholar]

- Sultan, M.; El-Sharkawy, I.I.; Miyazaki, T.; Saha, B.B.; Koyama, S. An Overview of Solid Desiccant Dehumidification and Air Conditioning Systems. Renew. Sustain. Energy Rev. 2015, 46, 16–29. [Google Scholar] [CrossRef]

- Mahmood, M.H.; Sultan, M.; Miyazaki, T. Significance of Temperature and Humidity Control for Agricultural Products Storage: Overview of Conventional and Advanced Options. Int. J. Food Eng. 2019, 15, 20190063. [Google Scholar] [CrossRef]

- Mahmood, M.H.; Sultan, M.; Miyazaki, T.; Koyama, S.; Maisotsenko, V.S. Overview of the Maisotsenko Cycle—A Way towards Dew Point Evaporative Cooling. Renew. Sustain. Energy Rev. 2016, 66, 537–555. [Google Scholar] [CrossRef]

- Pandelidis, D.; Anisimov, S. Numerical Analysis of the Heat and Mass Transfer Processes in Selected M-Cycle Heat Exchangers for the Dew Point Evaporative Cooling. Energy Convers. Manag. 2015, 90, 62–83. [Google Scholar] [CrossRef]

- Asfahan, H.M.; Sajjad, U.; Sultan, M.; Hussain, I.; Hamid, K.; Ali, M.; Wang, C.-C.; Shamshiri, R.R.; Khan, M.U. Artificial Intelligence for the Prediction of the Thermal Performance of Evaporative Cooling Systems. Energies 2021, 14, 3946. [Google Scholar] [CrossRef]

- Pandelidis, D.; Anisimov, S.; Worek, W.M. Performance Study of the Maisotsenko Cycle Heat Exchangers in Different Air-Conditioning Applications. Int. J. Heat Mass Transf. 2015, 81, 207–221. [Google Scholar] [CrossRef]

- Caliskan, H.; Hepbasli, A.; Dincer, I.; Maisotsenko, V. Thermodynamic Performance Assessment of a Novel Air Cooling Cycle: Maisotsenko Cycle. Int. J. Refrig. 2011, 34, 980–990. [Google Scholar] [CrossRef]

- Zhan, C.; Duan, Z.; Zhao, X.; Smith, S.; Jin, H.; Riffat, S. Comparative Study of the Performance of the M-Cycle Counter-Flow and Cross-Flow Heat Exchangers for Indirect Evaporative Cooling—Paving the Path toward Sustainable Cooling of Buildings. Energy 2011, 36, 6790–6805. [Google Scholar] [CrossRef]

- Chua, K.J.; Chou, S.K.; Yang, W.M.; Yan, J. Achieving Better Energy-Efficient Air Conditioning—A Review of Technologies and Strategies. Appl. Energy 2013, 104, 87–104. [Google Scholar] [CrossRef]

- Lal Basediya, A.; Samuel, D.V.K.; Beera, V. Evaporative Cooling System for Storage of Fruits and Vegetables—A Review. J. Food Sci. Technol. 2013, 50, 429–442. [Google Scholar] [CrossRef] [PubMed]

- Sultan, M.; Miyazaki, T. Energy-Efficient Air-Conditioning Systems for Nonhuman Applications. In Refrigeration; Ekren, O., Ed.; InTech: London, UK, 2017; pp. 97–117. [Google Scholar]

- Sultan, M.; Miyazaki, T.; Koyama, S.; Khan, Z.M. Performance Evaluation of Hydrophilic Organic Polymer Sorbents for Desiccant Air-Conditioning Applications. Adsorpt. Sci. Technol. 2018, 36, 311–326. [Google Scholar] [CrossRef]

- Kashif, M.; Sultan, M.; Khan, Z.M. Alternative Air-Conditioning Options for Developing Countries. Eur. J. Eng. Res. Sci. 2017, 2, 76. [Google Scholar] [CrossRef][Green Version]

- Sultan, M.; Miyazaki, T.; Koyama, S. Optimization of Adsorption Isotherm Types for Desiccant Air-Conditioning Applications. Renew. Energy 2018, 121, 441–450. [Google Scholar] [CrossRef]

- Xue, B.; Tahara, K.; Nakashima, K.; Noda, A.; Oktariani, E.; Wijayanta, A.T.; Nakaso, K.; Fukai, J. Numerical Simulation for Steam Generation Process in a Novel Zeolite–Water Adsorption Heat Pump. J. Chem. Eng. Japan 2012, 45, 408–416. [Google Scholar] [CrossRef]

- Xue, B.; Ye, S.; Zhang, L.; Wei, X.; Nakaso, K.; Fukai, J. High-Temperature Steam Generation from Low-Grade Waste Heat from an Adsorptive Heat Transformer with Composite Zeolite-13X/CaCl2. Energy Convers. Manag. 2019, 186, 93–102. [Google Scholar] [CrossRef]

- Oktariani, E.; Tahara, K.; Nakashima, K.; Noda, A.; Xue, B.; Wijayanta, A.T.; Nakaso, K.; Fukai, J. Experimental Investigation on the Adsorption Process for Steam Generation Using a Zeolite–Water System. J. Chem. Eng. Japan 2012, 45, 355–362. [Google Scholar] [CrossRef]

- Niu, X.; Xiao, F.; Ge, G. Performance Analysis of Liquid Desiccant Based Air-Conditioning System under Variable Fresh Air Ratios. Energy Build. 2010, 42, 2457–2464. [Google Scholar] [CrossRef]

- Jia, C.X.; Dai, Y.J.; Wu, J.Y.; Wang, R.Z. Analysis on a Hybrid Desiccant Air-Conditioning System. Appl. Therm. Eng. 2006, 26, 2393–2400. [Google Scholar] [CrossRef]

- Bassuoni, M.M. Experimental Performance Study of a Proposed Desiccant Based Air Conditioning System. J. Adv. Res. 2014, 5, 87–95. [Google Scholar] [CrossRef][Green Version]

- Qi, R.; Lu, L.; Huang, Y. Parameter Analysis and Optimization of the Energy and Economic Performance of Solar-Assisted Liquid Desiccant Cooling System under Different Climate Conditions. Energy Convers. Manag. 2015, 106, 1387–1395. [Google Scholar] [CrossRef]

- Qi, R.; Lu, L. Energy Consumption and Optimization of Internally Cooled/Heated Liquid Desiccant Air-Conditioning System: A Case Study in Hong Kong. Energy 2014, 73, 801–808. [Google Scholar] [CrossRef]

- Luo, Y.; Shao, S.; Xu, H.; Tian, C.; Yang, H. Experimental and Theoretical Research of a Fin-Tube Type Internally-Cooled Liquid Desiccant Dehumidifier. Appl. Energy 2014, 133, 127–134. [Google Scholar] [CrossRef]

- Mahmood, M.H.; Sultan, M.; Miyazaki, T. Solid Desiccant Dehumidification-Based Air-Conditioning System for Agricultural Storage Application: Theory and Experiments. Proc. Inst. Mech. Eng. Part A J. Power Energy 2020, 234, 534–547. [Google Scholar] [CrossRef]

- Mahmood, M.H.; Sultan, M.; Miyazaki, T. Experimental Evaluation of Desiccant Dehumidification and Air-Conditioning System for Energy-Efficient Storage of Dried Fruits. Build. Serv. Eng. Res. Technol. 2020, 41, 454–465. [Google Scholar] [CrossRef]

- Hussain, G.; Sultan, M.; Aleem, M. Study on Solid Desiccant Dehumidification Cooling System for the Storage of Fruits and Vegetables. In Proceedings of the International Exchange and Innovation Conference on Engineering & Sciences (IEICES), Fukoka, Japan, 21 October 2021; Volume 7, pp. 295–301. [Google Scholar]

- Ashraf, H.; Sultan, M.; Shamshiri, R.R.; Abbas, F.; Farooq, M.; Sajjad, U.; Md-Tahir, H.; Mahmood, M.H.; Ahmad, F.; Taseer, Y.R.; et al. Dynamic Evaluation of Desiccant Dehumidification Evaporative Cooling Options for Greenhouse Air-Conditioning Application in Multan (Pakistan). Energies 2021, 14, 1097. [Google Scholar] [CrossRef]

- Sultan, M.; Miyazaki, T.; Saha, B.B.; Koyama, S. Steady-State Investigation of Water Vapor Adsorption for Thermally Driven Adsorption Based Greenhouse Air-Conditioning System. Renew. Energy 2016, 86, 785–795. [Google Scholar] [CrossRef]

- Niaz, H.; Sultan, M.; Khan, A.A.; Miyazaki, T.; Feng, Y.; Khan, Z.M.; Niaz, Y.; Mahmood, M.H.; Ali, I.; Imran, M.A. Study on Evaporative Cooling Assisted Desiccant Air Conditioning System for Livestock Application in Pakistan. Fresenius Environ. Bull. 2019, 28, 8623–8633. [Google Scholar]

- Kashif, M.; Niaz, H.; Sultan, M.; Miyazaki, T.; Feng, Y.; Usman, M.; Shahzad, M.W.; Niaz, Y.; Waqas, M.M.; Ali, I. Study on Desiccant and Evaporative Cooling Systems for Livestock Thermal Comfort: Theory and Experiments. Energies 2020, 13, 2675. [Google Scholar] [CrossRef]

- Aleem, M.; Sultan, M.; Mahmood, M.H.; Miyazaki, T. Desiccant Dehumidification Cooling System for Poultry Houses in Multan (Pakistan) BT—Energy-Efficient Systems for Agricultural Applications; Sultan, M., Miyazaki, T., Eds.; Springer International Publishing: Cham, Switzerland, 2022; pp. 19–42. [Google Scholar] [CrossRef]

- Aleem, M.; Hussain, G.; Sultan, M.; Miyazaki, T. Lab-Scale Study of Desiccant Dehumidification System for Poultry Shed Air-Conditioning in Pakistan. In Proceedings of the International Exchange and Innovation Conference on Engineering & Sciences (IEICES), Fukoka, Japan, 22—23 October 2020; Volume 6, pp. 85–91. [Google Scholar]

- Aleem, M.; Sultan, M. Towards the Development of Energy-Efficient Poultry Air Conditioning System. Available online: https://www.researchgate.net/publication/354138144_Towards_the_development_of_energy-efficient_poultry_air_conditioning_system (accessed on 9 June 2021).

- Sultan, M.; Aleem, M.; Miyazaki, T. Energy-Efficient Humidity Pump System for Poultry Houses. In Synergy Development in Renewables Assisted Multi-Carrier Systems; Amidpour, M., Ebadollahi, M., Jabari, F., Kolahi, M.R., Ghaebi, H., Eds.; Springer: Cham, Switzerland, 2022. [Google Scholar] [CrossRef]

- Xu, C.-J.; Guo, D.-P.; Yuan, J.; Yuan, G.-F.; Wang, Q.-M. Changes in Glucoraphanin Content and Quinone Reductase Activity in Broccoli (Brassica oleracea var. italica) Florets during Cooling and Controlled Atmosphere Storage. Postharvest Biol. Technol. 2006, 42, 176–184. [Google Scholar] [CrossRef]

- Nampan, K.; Techavuthiporn, C.; Kanlayanarat, S. Hydrocooling Improves Quality and Storage Life of “Rong-Rein” Rambutan (Nephellium lappaceum L.) Fruit. Acta Hortic. 2006, 712, 763–769. [Google Scholar] [CrossRef]

- Nunes, M.C.N.; Émond, J.P.; Brecht, J.K. Predicting Shelf Life and Quality of Raspberries under Different Storage Temperatures. Acta Hortic. 2003, 628, 599–606. [Google Scholar] [CrossRef]

- Paull, R.E. Effect of Temperature and Relative Humidity on Fresh Commodity Quality. Postharvest Biol. Technol. 1999, 15, 263–277. [Google Scholar] [CrossRef]

- Nunes, M.C.D.N. Impact of Environmental Conditions on Fruit and Vegetable Quality. Stewart Postharvest Rev. 2008, 4, 1–14. [Google Scholar] [CrossRef]

- ASHRAE. Handbook of Fundamentals; American Society of Heating, Refrigerating and Air-Conditioning Engineers, Inc.: Atlanta, GA, USA, 2017. [Google Scholar]

- Arah, I.K.; Amaglo, H.; Kumah, E.K.; Ofori, H. Preharvest and Postharvest Factors Affecting the Quality and Shelf Life of Harvested Tomatoes: A Mini Review. Int. J. Agron. 2015, 2015. [Google Scholar] [CrossRef]

- Mahajan, P.V.; Rodrigues, F.A.S.; Motel, A.; Leonhard, A. Development of a Moisture Absorber for Packaging of Fresh Mushrooms (Agaricus bisporous). Postharvest Biol. Technol. 2008, 48, 408–414. [Google Scholar] [CrossRef]

- ASHRAE. Handbook of Heating, Ventilation, and Air-Conditioning Application; American Society of Heating, Refrigerating and Air-Conditioning Engineers, Inc.: Atlanta, GA, USA, 2019. [Google Scholar]

- Gross, K.C.; Wang, C.Y.; Mikal, S. The Commercial Storage of Fruits, Vegetables, and Florist and Nursery Stocks, 66th ed.; Kenneth, C.G., Wang, C.Y., Mikal, S., Eds.; United States Department of Agriculture, Agricultural Research Service: Washington, DC, USA, 2016.

- Sultan, M.; El-Sharkawy, I.I.; Miyazaki, T.; Saha, B.B.; Koyama, S.; Maruyama, T.; Maeda, S.; Nakamura, T. Water Vapor Sorption Kinetics of Polymer Based Sorbents: Theory and Experiments. Appl. Therm. Eng. 2016, 106, 192–202. [Google Scholar] [CrossRef]

- Sultan, M.; El-Sharkawy, I.I.; Miyazaki, T.; Saha, B.B.; Koyama, S.; Maruyama, T.; Maeda, S.; Nakamura, T. Insights of Water Vapor Sorption onto Polymer Based Sorbents. Adsorption 2015, 21, 205–215. [Google Scholar] [CrossRef]

- Aleem, M.; Hussain, G.; Sultan, M.; Miyazaki, T.; Mahmood, M.H.; Sabir, M.I.; Nasir, A.; Shabir, F.; Khan, Z.M. Experimental Investigation of Desiccant Dehumidification Cooling System for Climatic Conditions of Multan (Pakistan). Energies 2020, 13, 5530. [Google Scholar] [CrossRef]

- Sultan, M.; Miyazaki, T.; Niaz, H.; Shabir, F.; Ashraf, S.; Khan, Z.M.; Mahmood, M.H.; Raza, H.M.U. Thermodynamic Assessment of Solar Chimney Based Air-Conditioning System for Agricultural and Livestock Applications. In Proceedings of the 4th International Conference on Energy, Environment and Sustainable Development 2016 (EESD-2016), Jamshoro, Pakistan, 1–3 November 2016; Volume 2016, pp. 1–9. [Google Scholar]

- Islam, M.R.; Alan, S.W.L.; Chua, K.J. Studying the Heat and Mass Transfer Process of Liquid Desiccant for Dehumidification and Cooling. Appl. Energy 2018, 221, 334–347. [Google Scholar] [CrossRef]

- Esen, H.; Inalli, M.; Esen, M. Technoeconomic Appraisal of a Ground Source Heat Pump System for a Heating Season in Eastern Turkey. Energy Convers. Manag. 2006, 47, 1281–1297. [Google Scholar] [CrossRef]

- Holman, J.P. Experimental Methods for Engineers; McGraw-Hill: New York, NY, USA, 2012. [Google Scholar]

- Hepbasli, A.; Akdemir, O. Energy and Exergy Analysis of a Ground Source (Geothermal) Heat Pump System. Energy Convers. Manag. 2004, 45, 737–753. [Google Scholar] [CrossRef]

- Becker, B.R.; Fricke, B.A. Simulation of Moisture Loss and Heat Loads in Refrigerated Storage of Fruits and Vegetables. New Dev. Refrig. Food Saf. Qual. 1996, 6, 210–221. [Google Scholar]

- ASHRAE, ASHRAE Handbook—Refrigeration; American Society of Heating, Refrigerating, and Air-Conditioning Engineers, Inc.: Atlanta, GA, USA, 2014.

- Rafiee, S.; Keyhani, A.; Tabatabaeefar, A. Some Physical Properties of Apple Cv. ‘Golab’. Available online: https://cigrjournal.org/index.php/Ejounral/article/view/1124/1167 (accessed on 9 June 2021).

- Dincer, I. Development of New Effective Nusselt-Reynolds Correlations for Air-Cooling of Spherical and Cylindrical Products. Int. J. Heat Mass Transf. 1994, 37, 2781–2787. [Google Scholar] [CrossRef]

- Zhang, Y.; Keller, M. Grape Berry Transpiration Is Determined by Vapor Pressure Deficit, Cuticular Conductance, and Berry Size. Am. J. Enol. Vitic. 2015, 66, 454–462. [Google Scholar] [CrossRef]

- Topuz, A.; Topakci, M.; Canakci, M.; Akinci, I.; Ozdemir, F. Physical and Nutritional Properties of Four Orange Varieties. J. Food Eng. 2005, 66, 519–523. [Google Scholar] [CrossRef]

- Bennett, A.H.; Soule, J.; Yost, G.E. Temperature Response of Florida Citrus to Forced-Air Precooling. ASHRAE J. 1966, 4, 48–54. [Google Scholar]

- Babic, L.; Matic-Kekic, S.; Dedovic, N.; Babic, M.; Pavkov, I. Surface Area and Volume Modeling of the Williams Pear (Pyrus communis). Int. J. Food Prop. 2012, 15, 880–890. [Google Scholar] [CrossRef]

- Beuchat, L.R.; Farber, J.N.; Garrett, E.H.; Harris, L.J.; Parish, M.E.; Suslow, T.V.; Busta, F.F. Standardization of a Method to Determine the Efficacy of Sanitizers in Inactivating Human Pathogenic Microorganisms on Raw Fruits and Vegetables. Compr. Rev. Food Sci. Food Saf. 2003, 2, 174–178. [Google Scholar] [CrossRef]

- Phungamngoen, C.; Rittisak, S. Surface Characteristics of Leafy Vegetables and Their Effects on Salmonella Attachment. E3S Web Conf. 2020, 141, 1–5. [Google Scholar] [CrossRef]

- Parashar, V.; Trivedi, S.K.; Haleem, A. Heat Transfer Parameterization towards Enhancing Shelf Life of Vegetables in Low Cost Cold Chain with FACCC. Int. J. Innov. Technol. Explor. Eng. 2020, 9, 822–829. [Google Scholar] [CrossRef]

- Jahanbakhshi, A.; Abbaspour-Gilandeh, Y.; Gundoshmian, T.M. Determination of Physical and Mechanical Properties of Carrot in Order to Reduce Waste during Harvesting and Post-Harvesting. Food Sci. Nutr. 2018, 6, 1898–1903. [Google Scholar] [CrossRef] [PubMed]

- Chang, S.Y.; Toledo, R.T. Simultaneous Determination of Thermal Diffusivity and Heat Transfer Coefficient during Sterilization of Carrot Dices in a Packed Bed. J. Food Sci. 1990, 55, 199–205. [Google Scholar] [CrossRef]

- Kaveri, G.; Thirupathi, V. Studies on Geometrical and Physical Properties of CO4 Onion Bulb (Allium cepa Lvar. Aggregatum Don.). Int. J. Rec. Sci. Res. 2015, 6, 2897–2902. [Google Scholar]

- Gamea, G.R.; Abd El-Maksoud, M.A.; Abd El-Gawad, A.M. Physical Characteristics and Chemical Properties of Potato Tubers Under Different Storage Systems. Misr J. Agric. Eng. 2009, 26, 385–408. [Google Scholar] [CrossRef]

| Parameters | Symbol | Value | Unit |

|---|---|---|---|

| Parameters related to desiccant unit | |||

| Width | W | 0.145 | m |

| Length | L | 0.220 | m |

| Height | H | 0.045 | m |

| Total silica gel | 1.22 | kg | |

| Parameters related to silica gel | |||

| Molar mass | M | 60.08 | g/kg |

| Bulk density | 919.5 | kg/m3 | |

| Specific heat capacity | Cp | 0.85 | kJ/kg·K |

| Specific surface area | SSA | 750–850 | m2/g |

| Pore size | φ | 2–2.6 | nm |

| Heat of adsorption | Δh | 2800 | kJ/kg |

| Thermal conduction | k | 0.175 | W/m·K |

| Parameter | Symbol | Value |

|---|---|---|

| Temperature | ±2.6% | |

| Relative humidity | RH | ±5.1% |

| Pressure | P | ±1.6% |

| Velocity | V | ±3.4% |

| Humidity ratio | X | ±1.6% |

| Enthalpy | h | ±2.9% |

| Cooling potential | ±5.1% | |

| Coefficient of performance | ±2.7% | |

| Sensible heat | ±2.2% | |

| Latent heat | ±5.4% | |

| Latent heat ratio | LHR | ±5.37% |

| Product | Respiration Coefficients | |

|---|---|---|

| Fruits | ||

| Apple | 5.687 × 10−4 | 2.5977 |

| Grape | 7.056 × 10−5 | 3.033 |

| Orange | 2.8050 × 10−4 | 2.6840 |

| Pear | 6.3614 × 10−5 | 3.2037 |

| Tomato | 2.0074 × 10−4 | 2.8350 |

| Vegetables | ||

| Cabbage | 6.0803 × 10−4 | 2.6183 |

| Carrot | 0.050018 | 1.7926 |

| Onion | 3.668 × 10−4 | 2.538 |

| Potato | 0.01709 | 1.769 |

| Product | Air Velocity (m/s) | Surface Heat Transfer Coeff., (W/m2 °C) | Surface Area,

(m2) | Reference |

|---|---|---|---|---|

| Fruits | ||||

| Apple | 0 | 11.1 | 0.0116 | [60,61] |

| 0.39 | 17 | |||

| 0.91 | 27.3 | |||

| 2 | 45.3 | |||

| 5.1 | 53.4 | |||

| Grape | 1 | 30.7 | 0.0008 | [60,62,63] |

| 1.25 | 33.8 | |||

| 1.5 | 37.8 | |||

| 1.75 | 40.7 | |||

| 2 | 42.3 | |||

| Orange | 0.11 | 66.4 | 0.01622 | [60,64,65] |

| 0.33 | 69.3 | |||

| Pear | 1 | 12.6 | 0.007598 | [60,62,66] |

| 1.25 | 14.2 | |||

| 1.5 | 15.8 | |||

| 1.75 | 16.1 | |||

| 2 | 19.5 | |||

| Tomato | 1 | 10.9 | 0.008 | [60,62,67] |

| 1.25 | 13.1 | |||

| 1.5 | 13.6 | |||

| 1.75 | 14.9 | |||

| 2 | 17.3 | |||

| Vegetables | ||||

| Cabbage | 0.431 | 53.8033 | 0.000415 | [68,69] |

| Carrot | 0.0158 | 547 | 0.007758 | [70,71] |

| Onion | 0.431 | 54.6125 | 0.001404 | [61,72] |

| Potato | 0.431 | 39.0599 | 0.000134 | [69,73] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hussain, G.; Aleem, M.; Sultan, M.; Sajjad, U.; Ibrahim, S.M.; Shamshiri, R.R.; Farooq, M.; Usman Khan, M.; Bilal, M. Evaluating Evaporative Cooling Assisted Solid Desiccant Dehumidification System for Agricultural Storage Application. Sustainability 2022, 14, 1479. https://doi.org/10.3390/su14031479

Hussain G, Aleem M, Sultan M, Sajjad U, Ibrahim SM, Shamshiri RR, Farooq M, Usman Khan M, Bilal M. Evaluating Evaporative Cooling Assisted Solid Desiccant Dehumidification System for Agricultural Storage Application. Sustainability. 2022; 14(3):1479. https://doi.org/10.3390/su14031479

Chicago/Turabian StyleHussain, Ghulam, Muhammad Aleem, Muhammad Sultan, Uzair Sajjad, Sobhy M. Ibrahim, Redmond R. Shamshiri, Muhammad Farooq, Muhammad Usman Khan, and Muhammad Bilal. 2022. "Evaluating Evaporative Cooling Assisted Solid Desiccant Dehumidification System for Agricultural Storage Application" Sustainability 14, no. 3: 1479. https://doi.org/10.3390/su14031479

APA StyleHussain, G., Aleem, M., Sultan, M., Sajjad, U., Ibrahim, S. M., Shamshiri, R. R., Farooq, M., Usman Khan, M., & Bilal, M. (2022). Evaluating Evaporative Cooling Assisted Solid Desiccant Dehumidification System for Agricultural Storage Application. Sustainability, 14(3), 1479. https://doi.org/10.3390/su14031479