Quantitative Study on the Life-Cycle Carbon Emissions of a Nearly Zero Energy Building in the Severe Cold Zones of China

Abstract

:1. Introduction

2. Research Contents

3. Research Methods

3.1. Life Cycle Assessment and Carbon Emission Calculation Standards

3.2. Case Study

4. Carbon Emission Calculation Results and Analysis

4.1. Carbon Emissions in the Production and Transportation Stages of Construction Materials

4.1.1. Building Materials Production Stage

4.1.2. Building Materials Transportation Stage

4.2. Carbon Emissions in the Operation Stage

4.3. Carbon Emissions during Construction and Demolition

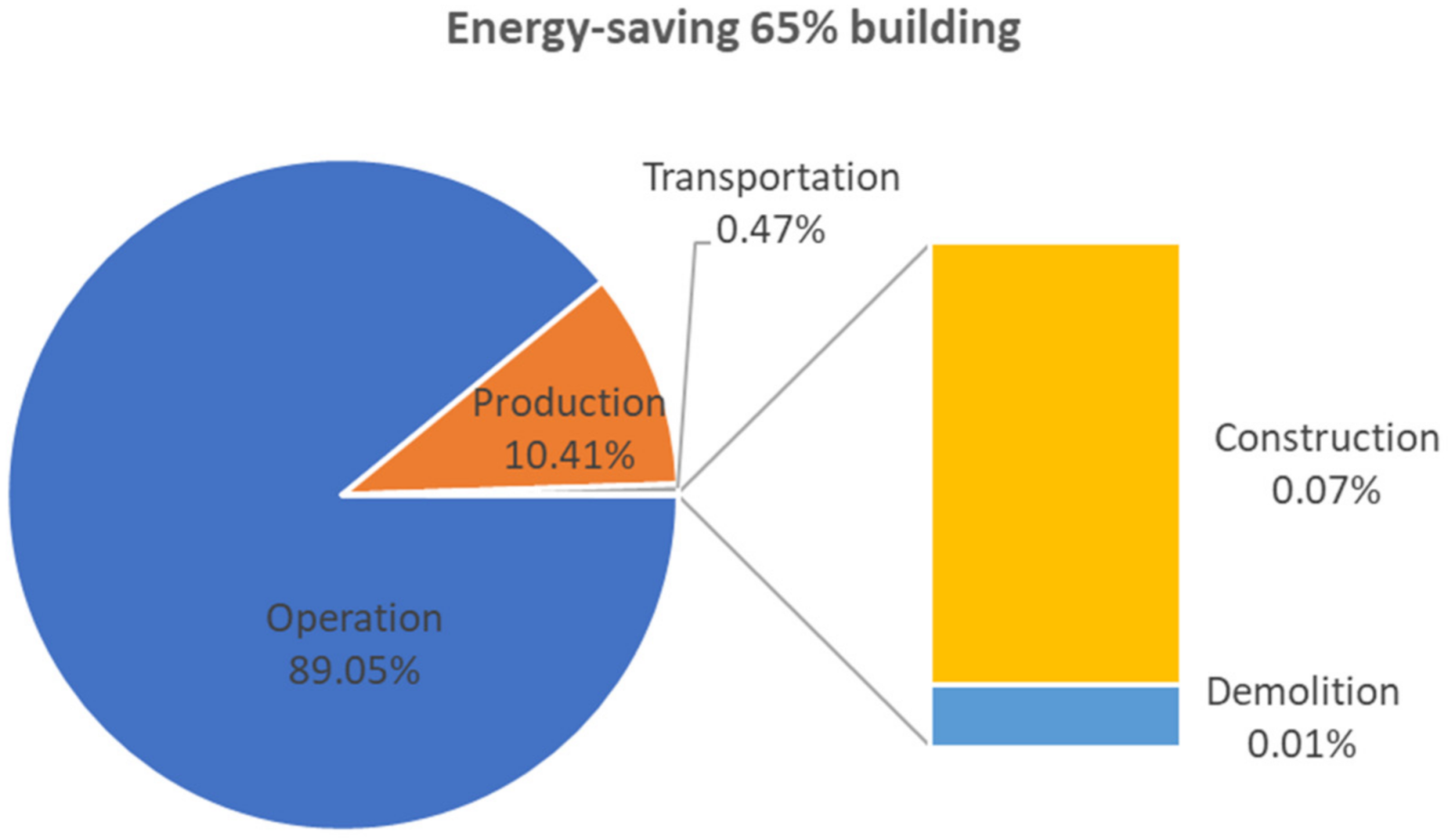

4.4. Total Carbon Emissions in the Whole Life Cycle

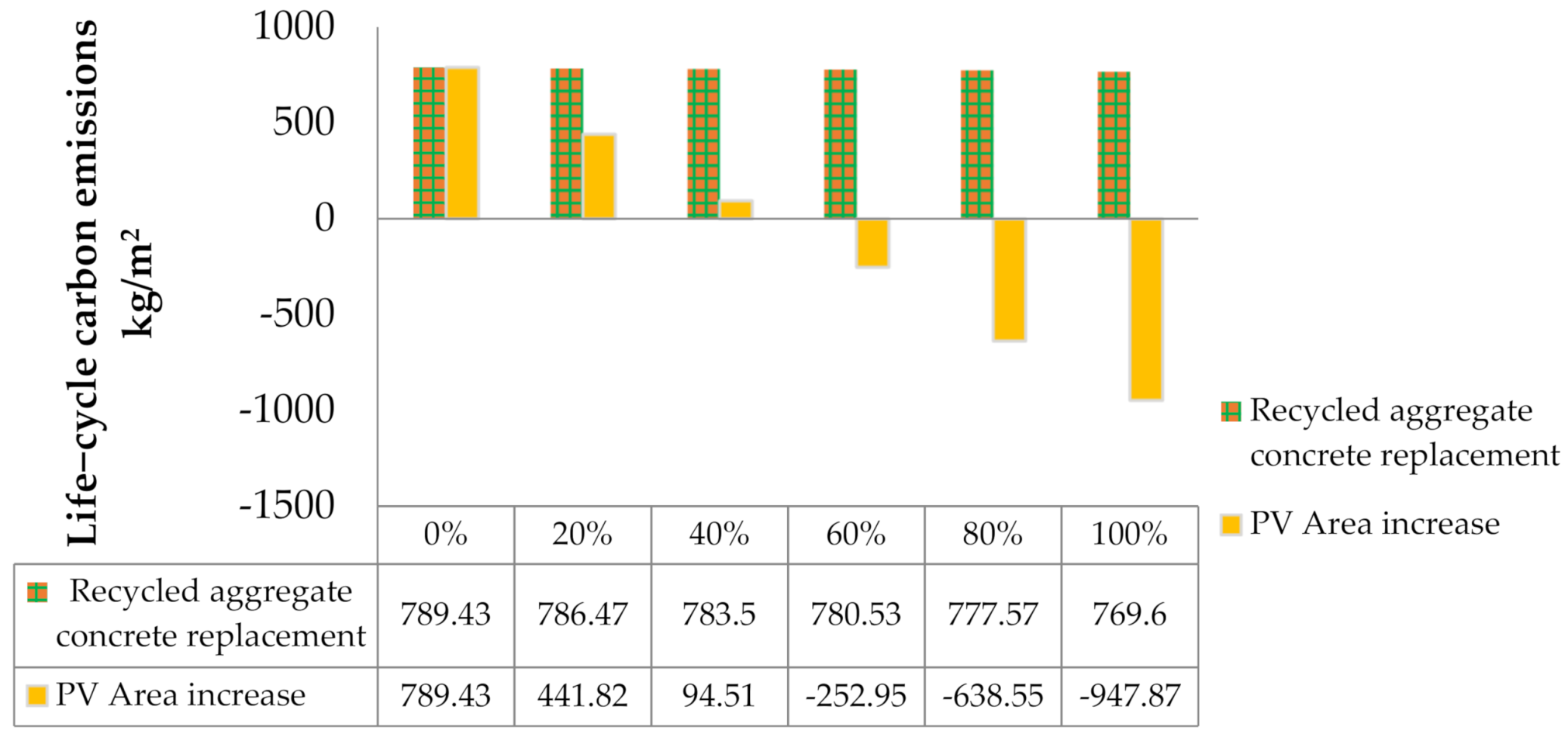

5. Carbon Reduction Potential Analysis

5.1. Analysis of the Influencing Parameters

5.1.1. Adopt a Timber Structure

5.1.2. Adopt Low-Carbon Building Materials

5.1.3. Increase the Area of Photovoltaic Panels

5.2. Sensitivity Analysis

5.3. Analysis of Results

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

References

- IEA. Global Status Report for Buildings and Construction; IEA: Paris, France, 2019.

- THUBERC. 2020 Annual Report on China Building Energy Efficiency; China Architecture & Building Press: Beijing, China, 2020. [Google Scholar]

- Yang, X.Y.; Zhang, S.; Wang, K. Quantitative study of life cycle carbon emissions from 7 timber buildings in China. Int. J. Life Cycle Assess. 2021, 26, 1721–1734. [Google Scholar] [CrossRef]

- Intergovernmental Panel for Climate Change (IPCC). Summary for Policymakers, Climate Change; IPCC WG1 Fourth Assessment Report; Cambridge University Press: Cambridge, UK, 2007. [Google Scholar]

- Erhorn., H.; Erhornkluttig, H. The path towards 2020: Nearly zero-energy buildings. Rehva J. 2012, 49, 12–15. [Google Scholar]

- IEA. Global Status Report for Buildings and Construction; IEA: Paris, France, 2013.

- Qiu, L.U. German passive and ultra-low-energy building technology system. Eco-City Green Build. 2015, 1, 29–36. [Google Scholar]

- German Government. German Energy Saving Act 2009 (EnEG 2009); German Government: Berlin, Germany, 2009.

- MINERGIE®: The Swiss Standard for Comfort, Efficiency and Value Preservation [R]. 2017. Available online: https://www.minergie.ch/media/20170906_flyer_minergie_allgemein_en_rgb.pdf (accessed on 6 September 2017).

- Bao, L.; He, Y. Low Energy Consumption for the Future Building: Analysis on “MINERGIE”—Swiss Sustainable Building standard. Eco-City Green Build. 2010, 4, 50–53. [Google Scholar]

- zHome: Setting a National Net Zero Energy and Green Building Precedent[R]. Available online: https://www.builtgreen.net/docs/librariesprovider2/resources/zhome-white-paper.pdf (accessed on 19 November 2021).

- Li, H.; Zhang, S. Japan Zero Energy Building Development Status. Build. Sci. 2017, 33, 142–148. [Google Scholar]

- Kamimura, T. KI Building Renewal towards ZEB: Outline of 50% Energy Savings and Lighting Plan (Trend of net Zero Energy Building and Energy Saving by Lighting). J. Illum. Eng. Inst. Jpn. 2014, 98, 265–268. [Google Scholar] [CrossRef] [Green Version]

- Lee, M.-J. Planning and Implementation of Korea’s first Zero Energy Housing Complex. Rev. Archit. Build. Sci. 2014, 58, 47–53. [Google Scholar]

- Li, Y.; Zhang, S.; Xu, W. Study of Zero Energy Building Development in Korea. Build. Sci. 2016, 32, 171–177. [Google Scholar] [CrossRef]

- Kim, Y.; Yu, K.H. Study on the Certification Policy of Zero-Energy Buildings in Korea. Sustainability 2020, 12, 5172. [Google Scholar] [CrossRef]

- Zhang, S.; Wang, K.; Lv, Y.J.; Xu, W. Research and Practice of Nearly Zero Energy Building Evaluation. Build. Sci. 2020, 17, 61–67. [Google Scholar]

- Marszal, A.J.; Heiselberg, P.; Bourrelle, J.S.; Musall, E.; Voss, K.; Sartori, I.; Napolitano, A. Zero energy building-a review of definitions and calculation methodologies. Energy Build. 2011, 43, 971–979. [Google Scholar] [CrossRef]

- The State Council Information Office of the People’s Republic of China. Energy in China’s New Era; The People’s Daily 12-22(010): Beijing, China, 2020.

- Zhang, S.; Lv, Y.J.; Xu, W. Research on the Energy Criteria and Technology Path of 64 Ultra-low Energy Building Best Practices. Build. Sci. 2020, 36, 7–13. [Google Scholar]

- Xu, W.; Yang, X.Y.; Zhang, S.C. Key Issues and Solutions for the Development of Near-Zero Energy Buildings in China. Build. Sci. 2020, 34, 165–173. [Google Scholar]

- Sartori, I.; Hestnes, A.G. Energy use in the life cycle of conventional and low-energy buildings: A review article. Energy Build. 2007, 39, 249–257. [Google Scholar] [CrossRef]

- Ramesh, T.; Prakash, R.; Shukla, K.K. Life cycle energy analysis of buildings: An overview. Energy Build. 2010, 42, 1592–1600. [Google Scholar] [CrossRef]

- Blengini, G.A.; Di Carlo, T. The changing role of life cycle phases, subsystems and materials in the LCA of low energy buildings. Energy Build. 2010, 42, 869–880. [Google Scholar] [CrossRef]

- D’Agostino, D.; Mazzarella, L. Data on energy consumption and Nearly zero energy buildings (NZEBs) in Europe. Data Brief 2018, 21, 2470–2474. [Google Scholar] [CrossRef] [PubMed]

- Verbeeck, G.; Hens, H. Life cycle inventory of buildings: A contribution analysis. Build. Environ. 2010, 45, 964–967. [Google Scholar] [CrossRef]

- Citherlet, S.; Defaux, T. Energy and environmental comparison of three variants of a family house during its whole life span. Build. Environ. 2007, 42, 591–598. [Google Scholar] [CrossRef]

- Kristjansdottir, T.F.; Good, C.S.; Inman, M.R.; Schlanbusch, R.D.; Andresen, I. Embodied greenhouse gas emissions from PV systems in Norwegian residential Zero Emission Pilot Buildings. Sol. Energy 2016, 133, 155–171. [Google Scholar] [CrossRef]

- De Wolf, C.; Pomponi, F.; Moncaster, A. Measuring embodied carbon dioxide equivalent of buildings: A review and critique of current industry practice. Energy Build. 2017, 140, 68–80. [Google Scholar] [CrossRef]

- Cabeza, L.F.; Barreneche, C.; Miro, L. Affordable construction towards sustainable buildings: Review on embodied energy in building material´s Ferna. Curr. Opin. Environ. Sustain. 2013, 5, 229–238. [Google Scholar] [CrossRef]

- Kristjansdottir, T.F.; Heeren, N.; Andresen, I.; Brattebø, H. Comparative emission analysis of low-energy and zero-emission buildings. Build. Res. Inf. 2017, 46, 367–382. [Google Scholar] [CrossRef]

- European Committee for Standardization. EN 15978; Sustainability of Construction Works—Assessment of Environmental Performance of Buildings—Calculation Method. European Committee for Standardization: Brussels, Belgium, 2011.

- Georges, L.; Haase, M.; Wiberg Houlihan, A.A.M.; Kristjansdottir, T.F.; Risholt, B. Life cycle emissions analysis of two nZEB concepts, Build. Res. Inf. 2015, 43, 82–93. [Google Scholar]

- Cao, X.D.; Dai, X.L.; Liu, J.J. Building energy-consumption status worldwide and the state-of-the-art technologies for zero-energy buildings during the past decade. Energy Build. 2016, 128, 198–213. [Google Scholar] [CrossRef]

- Wiberg, A.H.; Hofmeister, T.B.; Kristjansdottir, T.; Time, B. Life cycle GHG Emissions from a wooden load-bearing alterntive for a ZEB office concept. In Expanding Boundaries: Systems Tinking in the Built Enviroment; Ulster University: Belfast, UK, 2016; pp. 454–458. [Google Scholar]

- Lim, B.; Boileau, P.; Bonduki, Y.; Van Amstel, A.R.; Janssen, L.H.; Olivier, J.G.; Kroeze, C. Improving the quality of national greenhouse gas inventories. Environ. Sci. Policy 1999, 2, 335–346. [Google Scholar] [CrossRef]

- Paleari, M.; Lavagna, M.; Campioli, A. The assessment of the relevance of building components and life phases for the environmental profile of nearly zero-energy buildings: Life cycle assessment of a multifamily building in Italy. Int. J. Life Cycle Assess. 2016, 21, 1667–1690. [Google Scholar] [CrossRef]

- Cabeza, L.F.; Chàfer, M. Technological options and strategies towards zero energy buildings contributing to climate change mitigation: A systematic review. Energy Build. 2020, 219, 110009. [Google Scholar] [CrossRef]

- MoHURD. GB/T 51366-2019; Calculation Standard for Building Carbon Emissions. China Architecture & Building Press: Beijing, China, 2019.

- Marique, A.-F.; Rossi, B. Cradle-to-grave life-cycle assessment within the built environment: Comparison between the refurbishment and the complete reconstruction of an office building in Belgium. J. Environ. Manag. 2018, 224, 396–405. [Google Scholar] [CrossRef] [Green Version]

- Lin, Y.; Yang, W.; Hao, X.L.; Yu, C.X. Building integrated renewable energy. Energy Explor. Exploit. 2021, 39, 603–607. [Google Scholar] [CrossRef]

- International Energy Agency. Solar Heating & Cooling Program IEA/SHC 2000 Overview: Solar Combi Systems; IEA: Paris, France, 2000.

- MoHURD. GB/T 51350-2019; Technical Standard for Nearly Zero Energy Buildings. China Architecture & Building Press: Beijing, China, 2019.

- CECA. T/CABEE 003-2019; Evaluation Standard for Nearly Zero Energy Buildings. China Architecture & Building Press: Beijing, China, 2019.

- Zhao, Y.Q.; Hou, X.Y.; Tang, S.S.; Deng, J.Y.; Yang, X. Economic Analysis and Carbon Emissions of Near-Zero Energy Buildings Based on Lifetime. Build. Energy Effic. 2020, 48, 126–130. [Google Scholar]

- Ding, G.K.C. Life cycle energy assessment of Australian secondary schools. Build. Res. Inf. 2007, 35, 487–500. [Google Scholar] [CrossRef]

- Suh, S.W.; Tomar, S.; Leighton, M.; Kneifel, J. Environmental performance of green building code and certification systems. Environ. Sci. Technol. 2014, 48, 2551–2560. [Google Scholar] [CrossRef] [Green Version]

- Sadineni, S.B.; France, T.M.; Boehm, R.F. Economic feasibility of energy efficiency measures in residential buildings. Renew. Energy 2011, 36, 2925–2931. [Google Scholar] [CrossRef]

- Cabeza, L.F.; Barreneche, C.; Miró, L.; Morera, J.M.; Bartolí, E.; Fernandez, A.I. Low carbon and low embodied energy materials in buildings: A review. Renew. Sustain. Energy Rev. 2013, 23, 536–542. [Google Scholar] [CrossRef]

- Reddy, B.V.V. Sustainable materials for low carbon buildings. Int. J. Low-Carbon Technol. 2009, 4, 175–181. [Google Scholar] [CrossRef] [Green Version]

- Thormark, C. The effect of material choice on the total energy need and recycling potential of a building. Build. Environ. 2006, 41, 1019–1026. [Google Scholar] [CrossRef]

- Habert, G.; Roussel, N. Study of two concrete mix-design strategies to reach carbon mitigation objectives. Cem. Concr. Compos. 2009, 31, 397–402. [Google Scholar] [CrossRef]

- Buchanan, A.H.; Levine, S.B. Wood-based building materials and atmospheric carbon emissions. Environ. Sci. Policy 1999, 2, 427–437. [Google Scholar] [CrossRef]

- Cabeza, L.F.; Boquera, L.; Chàfer, M.; Vérez, D. Embodied energy and embodied carbon of structural building materials: Worldwide progress and barriers through literature map analysis. Energy Build. 2021, 231, 1146–1158. [Google Scholar] [CrossRef]

- Gong, X.; Nie, Z.; Wang, Z.; Cui, S.; Gao, F.; Zuo, T. Life cycle energy consumption and carbon dioxide emission of residential building designs in Beijing: A comparative study. J. Ind. Ecol. 2012, 16, 576–587. [Google Scholar] [CrossRef]

- Teng, J.Y.; Wu, X.G.; Qin, Y.W.; Hou, T.M.; Zhang, L.M. Assessing incremental cost-efficiency of eco-footprint saving measures for school buildings: The case of the Inner Mongolia region in China. Eng. Econ. 2016, 61, 244–261. [Google Scholar] [CrossRef]

- Zhou, X.; Yan, J.W.; Zhu, J.W.; Cai, P.P. Survey of energy consumption and energy conservation measures for colleges and universities in Guangdong province. Energy Build. 2013, 66, 112–118. [Google Scholar] [CrossRef]

- Wu, P.; Xia, B.; Zhao, X. The importance of use and end of-life phases to the life cycle greenhouse gas (GHG) emissions of concrete—A review. Renew. Sustain. Energy Rev. 2014, 37, 360–369. [Google Scholar] [CrossRef] [Green Version]

| Description | Numerical Values |

|---|---|

| Total floors | 2 |

| Total construction area (m2) | 1180 |

| Heating volume (m3) | 3150 |

| External wall area (m2) | 592 |

| Roof area (m2) | 425 |

| Window and exterior door area (m2) | 92.4 |

| Building Envelopes | Structural Parameters | Value W/m2K |

|---|---|---|

| External wall | 190 mm block + 140 mm Expanded Polystyrene (EPS) insulation board + 80 mm rock wool + 50 mm thermal insulation mortar + 12 mm inorganic resin decoration panel | 0.1 |

| Ground | 40 mm fine aggregate concrete + 80 mm concrete cushion + Insulation of extruded board with 50 mm thickness in 2000 mm wide range around external wall + 80 mm gravel filled with cement mortar | 0.1 |

| Roof | 300 mm Expanded Polystyrene (EPS) insulation board + 200 mm reinforced concrete roof panel | 0.1 |

| Window | The frame is a combination of imported solid wood and thermal insulation materialsThree-glass two-cavity double low-E argon-filled hollow glass | 0.8 |

| Renewable Energy Systems | Equipment and Specifications | Quantities | Nominal Parameter |

|---|---|---|---|

| PV power generation system | Polycrystalline silicon photovoltaic panels/LN240(30)-3-250 | 112 pieces | 28 kW |

| Solar Thermal System | Heat pipe solar collector/Z-QB/20-58 | 48 groups | 158.4 m2 |

| Breeze power generation system | Breeze force generator set/CXF-600 Wdn150 | 4 sets | 2.4 kW |

| Ground Source Heat Pump System | Capacity with cooling 62.5 kW and heating 46.5 kW | 1 set | 62.5 kW/46.5 kW |

| Project | Numerical Number | Standard Requirements | Whether to Meet the Requirements |

|---|---|---|---|

| Comprehensive building energy efficiency rate (%) | 163.70 | ≥60% | Satisfy |

| Renewable Energy Utilization Rate (%) | 135.01 | ≥10% | Satisfy |

| Ontology of Architecture Energy Conservation rate (%) | 82.85 | ≥10% | Satisfy |

| Ventilation rate N50 | 0.60 | ≤1.0 | Satisfy |

| Building Type | Design Standards | Data Acquisition | Calculation Basis |

|---|---|---|---|

| 65% Energy-saving building | “Design Standard for Energy Efficiency of Public Buildings (Energy-Saving 65%)” (DB22/JT 149-2016) | The 65% energy-saving building was simulated using eQUEST software (San Francisco, USA; the software version used is 3.6.5), and data collection was extracted from the building information model (BIM) available in the project | Standard for building carbon emission calculation (GB/T 51366-2019) |

| nZEB | “Technical Standard for Nearly zero Energy Buildings“(GB/T51350-2019) | Invoices paid by builders, quantities of construction operations and consumed materials in construction site reports, and design drawings obtained, and energy consumption data collected by energy monitoring platforms |

| Building Types | Building Materials | Carbon Emission Factors | Consumption of Building Materials | Sub-Items Carbon Emissions kg CO2/m2 | Subtotal of Carbon Emissions kg CO2/m2 |

|---|---|---|---|---|---|

| 65% Energy-saving building | Concrete | 320 kg CO2/m3 | 1258 m3 | 341.15 | 595.33 |

| Reinforcement | 2617 kg CO2/t | 109 t | 241.74 | ||

| Polystyrene | 4.487 kg CO2/kg | 1325 kg | 5.04 | ||

| Low-E glass | 1071 kg CO2/t | 0.38 t | 0.34 | ||

| Alloy window Frame | 253.7 kg CO2/m2 | 32.8 m2 | 7.06 | ||

| nZEB | Concrete | 320 kg CO2/m3 | 1258 m3 | 341.15 | 596.98 |

| Reinforcement | 2617 kg CO2/t | 109 t | 241.74 | ||

| Polystyrene | 4.487 kg CO2/kg | 2484 kg | 9.45 | ||

| Low-E glass | 1071 kg CO2/t | 0.56 t | 0.51 | ||

| Wood window frame | 147 kg CO2/m2 | 32.8 m2 | 4.09 | ||

| PV photovoltaic panels | 2 kg CO2/kW | 28 kW | 0.05 |

| Transport Stage | Sub-Items | Basis |

|---|---|---|

| The transportation of building materials from the place of production to the site of construction | Mining and processing of energy consumed during the transportation of building materials | Calculation |

| Production of transportation vehicles | The influence of incomplete basic data is small and can be ignored | |

| Construction of infrastructure such as transportation roads |

| Building Types | Building Materials | Transport Weight t | Transportation Distance km | Sub-Items Carbon Emissions kg CO2/m2 | Subtotal of Carbon Emissions kg CO2/m2 |

|---|---|---|---|---|---|

| 65% Energy-saving building | Concrete | 3019 | 40 | 18.32 | 26.74 |

| reinforcement | 109 | 500 | 8.27 | ||

| Polystyrene | 1.33 | 500 | 0.10 | ||

| Low-E glass | 0.38 | 500 | 0.03 | ||

| alloy window Frame | 0.26 | 500 | 0.02 | ||

| nZEB | Concrete | 3019 | 40 | 18.32 | 27.04 |

| reinforcement | 109 | 500 | 8.27 | ||

| Polystyrene | 2.48 | 500 | 0.19 | ||

| Low-E glass | 0.56 | 500 | 0.04 | ||

| wood window frame | 0.98 | 500 | 0.07 | ||

| PV photovoltaic panels | 1.96 | 500 | 0.15 |

| Building Type | Heating | Refrigeration | Outdoor Air | Lighting | PV Power | Energy Consumption |

|---|---|---|---|---|---|---|

| 65% Energy-saving building | 45.06 | 16.15 | 21.71 | 11.59 | 0.00 | 94.51 |

| nZEB | 16.08 | 9.28 | 4.56 | 6.34 | 31.71 | 4.56 |

| Building Type | Energy Consumption Convert to Carbon Emissions kg CO2/m2a | Green Space Carbon Sin kg CO2/m2a | Annual Carbon Emissions kg CO2/m2a | Whole Life Cycle Carbon Emissions kg CO2/m2 |

|---|---|---|---|---|

| 65% Energy-saving building | 103.64 | 1.78 | 101.86 | 5093.22 |

| nZEB | 5.00 | 1.78 | 3.22 | 161.02 |

| Various Stages | Energy-Saving 65% Building | nZEB | ||

|---|---|---|---|---|

| Carbon Missions kg CO2/m2 | Proportion | Carbon Missions kg CO2/m2 | Proportion | |

| Building materials production | 595.33 | 10.41% | 596.98 | 75.62% |

| Building materials transportation | 26.74 | 0.47% | 27.04 | 3.43% |

| Operation | 5093.22 | 89.05% | 161.02 | 20.40% |

| Construction | 3.99 | 0.07% | 3.99 | 0.51% |

| Demolition | 0.4 | 0.01% | 0.4 | 0.05% |

| Total | 5719.68 | 100.00% | 789.43 | 100.00% |

| Building Types | Building Materials | Carbon Emission Factors kg CO2/m2 | Quantity of Work | Carbon Emissions kg CO2/m2 | Subtotal of Carbon Emissions kg CO2/m2 |

|---|---|---|---|---|---|

| Timber building | Northeast fir Northeast larch | −374.41 kg CO2/m3 −32.25 kg CO2/m3 | 776 m3 | −246.22 −21.21 | Northeast fir timber structure −56.23 Northeast larch timber structure 168.78 |

| Concrete | 320 kg CO2/m3 | 436 m3 | 118.24 | ||

| Reinforcement | 2617 kg CO2/t | 26 t | 57.66 | ||

| Polystyrene | 4.487 kg CO2/kg | 2484 kg | 9.45 | ||

| Low-E glass | 1071 kg CO2/t | 0.56 t | 0.51 | ||

| wood window frame | 147 kg CO2/m2 | 32.8 m2 | 4.09 | ||

| PV panels | 2 t/kW | 28 kW | 0.05 |

| Sensitive Parameters | ||||||||

|---|---|---|---|---|---|---|---|---|

| PV power increments | 33.6 | 5.6 | 0.2 | 441.82 | −347.61 | −0.319 | −1.595 | −1.603 |

| 39.2 | 11.2 | 0.4 | 94.51 | −694.92 | −0.638 | −1.594 | ||

| 44.8 | 16.8 | 0.6 | −252.95 | −1042.38 | −0.956 | −1.594 | ||

| 50.4 | 22.4 | 0.8 | −638.55 | −1427.98 | −1.31 | −1.638 | ||

| 56 | 28 | 1 | −947.87 | −1737.3 | −1.594 | −1.594 | ||

| Recycled concrete replacement rate | 0.2 | 0.2 | 0.2 | 786.47 | −2.96 | −0.004 | −0.019 | −0.020 |

| 0.4 | 0.4 | 0.4 | 783.50 | −5.93 | −0.008 | −0.019 | ||

| 0.6 | 0.6 | 0.6 | 780.53 | −8.9 | −0.011 | −0.019 | ||

| 0.8 | 0.8 | 0.8 | 777.57 | −11.86 | −0.015 | −0.019 | ||

| 1 | 1 | 1 | 769.60 | −19.83 | −0.025 | −0.025 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Yang, X.; Hou, Q.; Tao, J.; Dong, J. Quantitative Study on the Life-Cycle Carbon Emissions of a Nearly Zero Energy Building in the Severe Cold Zones of China. Sustainability 2022, 14, 1448. https://doi.org/10.3390/su14031448

Wang Y, Yang X, Hou Q, Tao J, Dong J. Quantitative Study on the Life-Cycle Carbon Emissions of a Nearly Zero Energy Building in the Severe Cold Zones of China. Sustainability. 2022; 14(3):1448. https://doi.org/10.3390/su14031448

Chicago/Turabian StyleWang, Yangyang, Xinyan Yang, Qingying Hou, Jin Tao, and Jiankai Dong. 2022. "Quantitative Study on the Life-Cycle Carbon Emissions of a Nearly Zero Energy Building in the Severe Cold Zones of China" Sustainability 14, no. 3: 1448. https://doi.org/10.3390/su14031448

APA StyleWang, Y., Yang, X., Hou, Q., Tao, J., & Dong, J. (2022). Quantitative Study on the Life-Cycle Carbon Emissions of a Nearly Zero Energy Building in the Severe Cold Zones of China. Sustainability, 14(3), 1448. https://doi.org/10.3390/su14031448