Global Policy Review on Embodied Flows: Recommendations for Australian Construction Sector

Abstract

1. Introduction

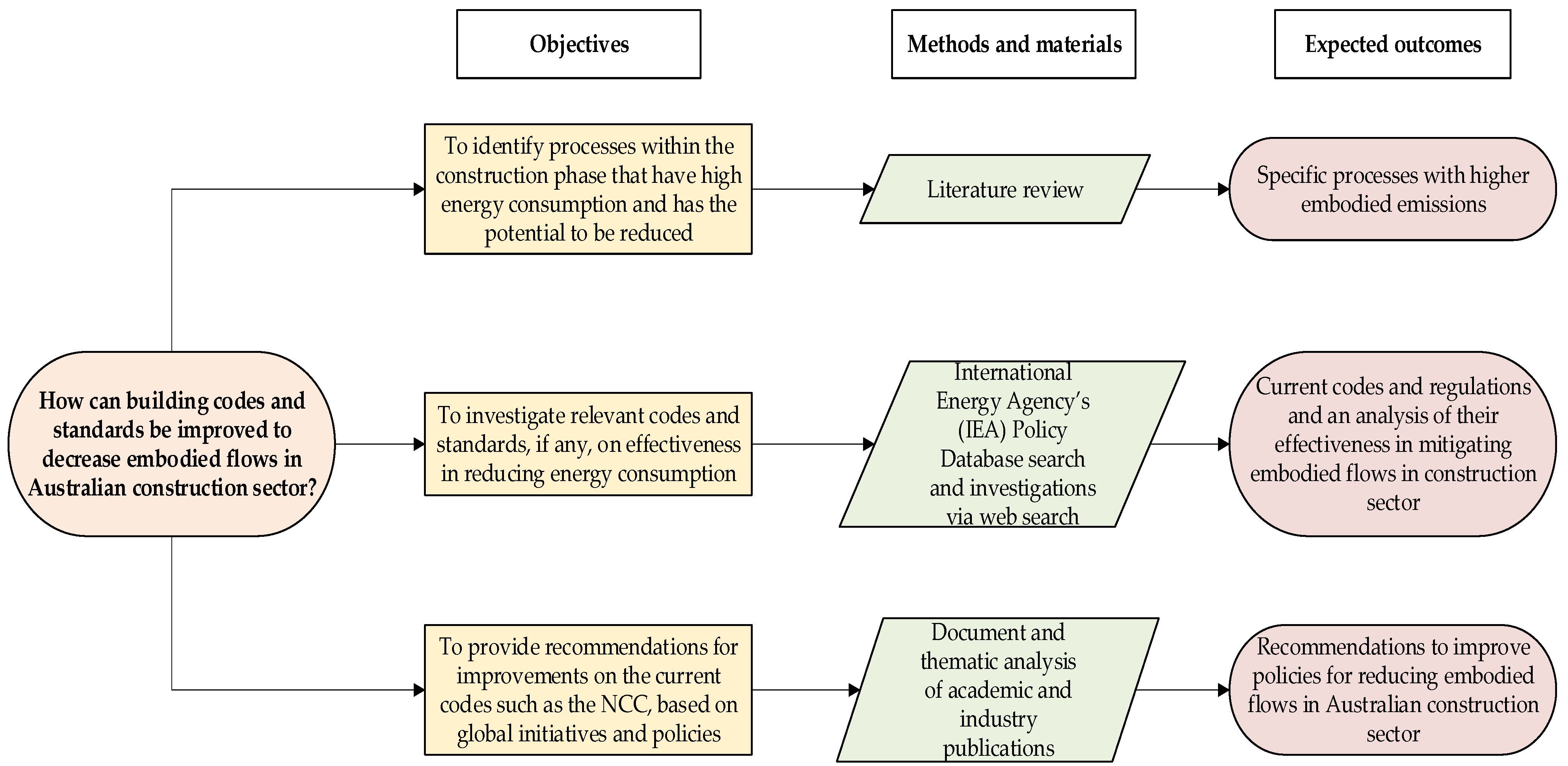

- To identify processes within the construction phase that have high energy consumption and has the potential to be reduced.

- To investigate relevant codes and standards, if any, on effectiveness in reducing energy consumption.

- To provide recommendations for improvements on the current codes, such as the NCC, based on global initiatives and policies.

2. Materials and Methods

3. Results

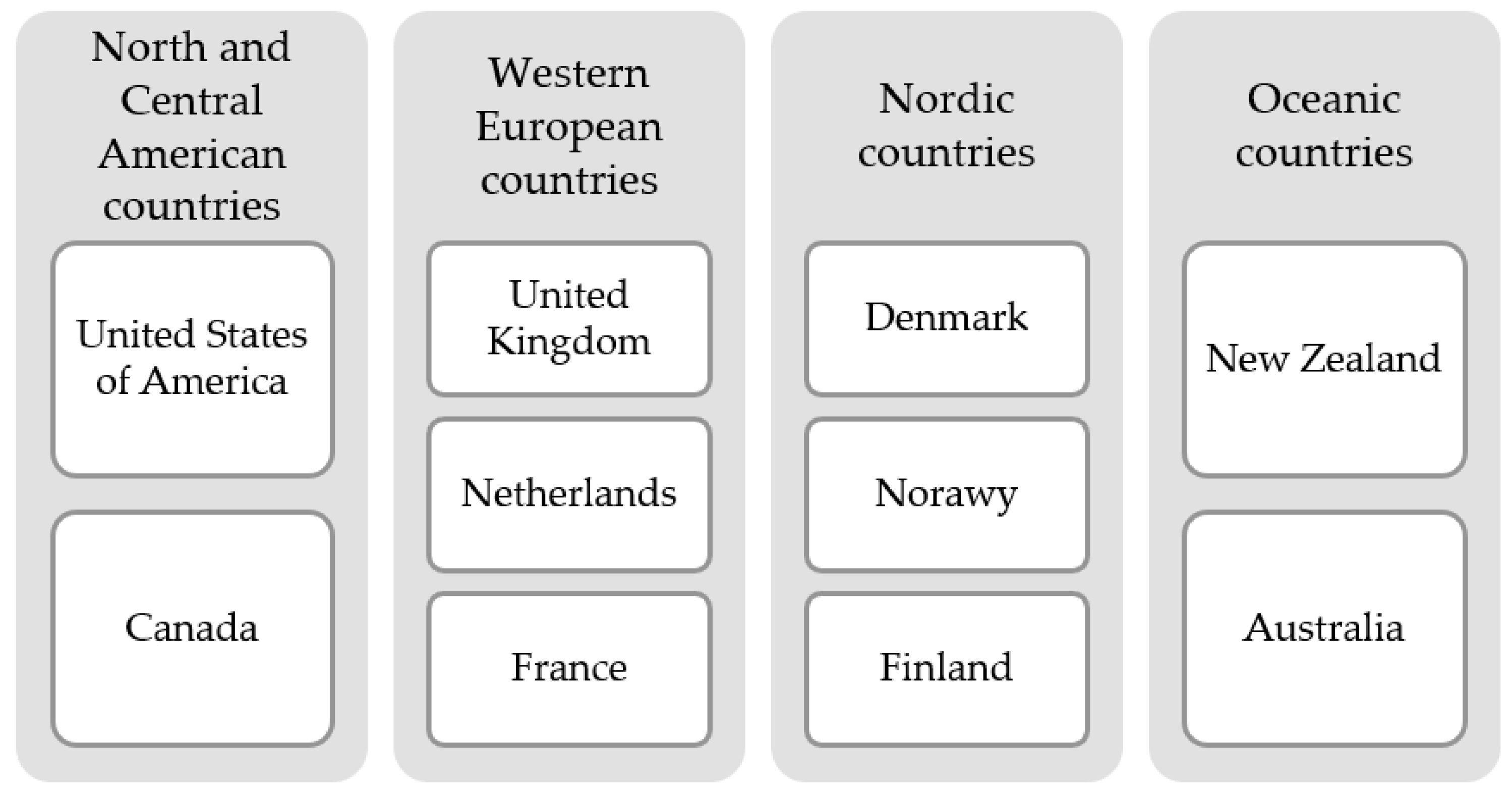

3.1. Embodied Policies in the Global Context

3.2. Canada

3.3. The United States of America

3.4. The Netherlands

3.5. France

3.6. The United Kingdom

3.7. Denmark

3.8. Norway

3.9. Finland

3.10. New Zealand

3.11. Australia

3.12. Overall Findings

4. Discussion

4.1. Embodied Policy and Built Environment Practices

4.2. Australian Built Environment and Embodied Policies

5. Conclusions and Recommendations for Policy Improvement

Author Contributions

Funding

Institutional Review Board Statement

Conflicts of Interest

References

- Lingegård, S.; Olsson, J.A.; Kadefors, A.; Uppenberg, S. Sustainable public procurement in large infrastructure projects—Policy implementation for carbon emission reductions. Sustainability 2021, 13, 11182. [Google Scholar] [CrossRef]

- Crowley, K. Fighting the future: The politics of climate policy failure in Australia (2015–2020). Wiley Interdiscip. Rev. Clim. Change 2021, 12, e725. [Google Scholar] [CrossRef]

- Lamb, W.F.; Grubb, M.; Diluiso, F.; Minx, J.C. Countries with sustained greenhouse gas emissions reductions: An analysis of trends and progress by sector. Clim. Policy 2022, 22, 1–17. [Google Scholar] [CrossRef]

- Ren, L.; Zhou, S.; Peng, T.; Ou, X. A review of CO2 emissions reduction technologies and low-carbon development in the iron and steel industry focusing on China. Renew. Sustain. Energy Rev. 2021, 143, 110846. [Google Scholar] [CrossRef]

- Wei, T.; Wu, J.; Chen, S. Keeping track of greenhouse gas emission reduction progress and targets in 167 cities worldwide. Front. Sustain. Cities 2021, 3. [Google Scholar] [CrossRef]

- Javed, S.A.; Cudjoe, D. A novel grey forecasting of greenhouse gas emissions from four industries of China and India. Sustain. Prod. Consum. 2022, 29, 777–790. [Google Scholar] [CrossRef]

- Wieser, A.A.; Scherz, M.; Passer, A.; Kreiner, H. Challenges of a healthy built environment: Air pollution in construction industry. Sustainability 2021, 13, 10469. [Google Scholar] [CrossRef]

- Miller, S.A.; Habert, G.; Myers, R.J.; Harvey, J.T. Achieving net zero greenhouse gas emissions in the cement industry via value chain mitigation strategies. ONE Earth 2021, 4, 1398–1411. [Google Scholar] [CrossRef]

- Worsley, H.; Richter, M.; Nassar, A. International Policy Review of Low Embodied Carbon Construction Materials; Materials & Embodied Carbon Leaders’ Alliance: Sydney, Australia, 2022. [Google Scholar]

- Skillington, K.; Crawford, R.H.; Warren-Myers, G.; Davidson, K. A review of existing policy for reducing embodied energy and greenhouse gas emissions of buildings. Energy Policy 2022, 168, 112920. [Google Scholar] [CrossRef]

- IPCC. Climate Change 2021 The Physical Science Basis–Summary for Policy Makers; IPCC: Geneva, Switzerland, 2021. [Google Scholar]

- Teshnizi, Z. Policy Research on Reducing the Embodied Emissions of New Buildings in Vancouver; Zera Solutions: London, UK, 2019. [Google Scholar]

- Pomponi, F.; Moncaster, A. Embodied carbon mitigation and reduction in the built environment-What does the evidence say? J. Environ. Manag. 2016, 181, 687–700. [Google Scholar] [CrossRef]

- Baptista, L.B.; Schaeffer, R.; van Soest, H.L.; Fragkos, P.; Rochedo, P.R.; van Vuuren, D.; Dewi, R.G.; Iyer, G.; Jiang, K.; Kannavou, M. Good practice policies to bridge the emissions gap in key countries. Glob. Environ. Chang. 2022, 73, 102472. [Google Scholar] [CrossRef]

- Panagiotidou, M.; Fuller, R.J. Progress in ZEBs—A review of definitions, policies and construction activity. Energy Policy 2013, 62, 196–206. [Google Scholar] [CrossRef]

- Ahmed Ali, K.; Ahmad, M.I.; Yusup, Y. Issues, impacts, and mitigations of carbon dioxide emissions in the building sector. Sustainability 2020, 12, 7427. [Google Scholar] [CrossRef]

- Langevin, J.; Harris, C.B.; Reyna, J.L. Assessing the potential to reduce US building CO2 emissions 80% by 2050. Joule 2019, 3, 2403–2424. [Google Scholar] [CrossRef]

- Lu, M.; Lai, J.H. Building energy: A review on consumptions, policies, rating schemes and standards. Energy Procedia 2019, 158, 3633–3638. [Google Scholar] [CrossRef]

- ABCB. National Construction Code; Australian Building Codes Board: Canberra, Australia, 2021. [Google Scholar]

- Hawila, A.A.W.; Pernetti, R.; Pozza, C.; Belleri, A. Plus energy building: Operational definition and assessment. Energy Build. 2022, 265, 112069. [Google Scholar] [CrossRef]

- Stephan, A.; Athanassiadis, A. Towards a more circular construction sector: Estimating and spatialising current and future non-structural material replacement flows to maintain urban building stocks. Resour. Conserv. Recycl. 2018, 129, 248–262. [Google Scholar] [CrossRef]

- Sharma, A.; Saxena, A.; Sethi, M.; Shree, V. Life cycle assessment of buildings: A review. Renew. Sustain. Energy Rev. 2011, 15, 871–875. [Google Scholar] [CrossRef]

- Mirabella, N.; Roeck, M.; Saade, M.; Spirinckx, C.; Bosmans, M.; Allacker, K.; Passer, A. Strategies to improve the energy performance of buildings: A review of their life cycle impact. Buildings 2018, 8, 105. [Google Scholar] [CrossRef]

- Omrany, H. Incorporation of Embodied Energy into Building Energy-Efficiency Codes: A Pathway to Life-Cycle Net-Zero Energy Building in Australia 2021. Available online: https://digital.library.adelaide.edu.au/dspace/handle/2440/135107 (accessed on 15 September 2022).

- Weththasinghe, K.K.; Stephan, A.; Francis, V.; Tiwari, P. Improving material selection in shopping centres through a parametric life cycle embodied flow and material cost analysis model. Renew. Sustain. Energy Rev. 2022, 165, 112530. [Google Scholar] [CrossRef]

- Dixit, M.K. Life cycle recurrent embodied energy calculation of buildings: A review. J. Clean. Prod. 2019, 209, 731–754. [Google Scholar] [CrossRef]

- Amiri, A.; Emami, N.; Ottelin, J.; Sorvari, J.; Marteinsson, B.; Heinonen, J.; Junnila, S. Embodied emissions of buildings-A forgotten factor in green building certificates. Energy Build. 2021, 241, 110962. [Google Scholar] [CrossRef]

- Röck, M.; Saade, M.R.M.; Balouktsi, M.; Rasmussen, F.N.; Birgisdottir, H.; Frischknecht, R.; Habert, G.; Lützkendorf, T.; Passer, A. Embodied GHG emissions of buildings–The hidden challenge for effective climate change mitigation. Appl. Energy 2020, 258, 114107. [Google Scholar] [CrossRef]

- USGBC. Embodied Carbon and Its Future within Climate Policy; United States Green Building Council: Washington, DC, USA, 2022. [Google Scholar]

- Minunno, R.; O’Grady, T.; Morrison, G.M.; Gruner, R.L. Investigating the embodied energy and carbon of buildings: A systematic literature review and meta-analysis of life cycle assessments. Renew. Sustain. Energy Rev. 2021, 143, 110935. [Google Scholar] [CrossRef]

- Resalati, S.; Kendrick, C.C.; Hill, C. Embodied energy data implications for optimal specification of building envelopes. Build. Res. Inf. 2020, 48, 429–445. [Google Scholar] [CrossRef]

- Jiang, L.; He, S.; Tian, X.; Zhang, B.; Zhou, H. Energy use embodied in international trade of 39 countries: Spatial transfer patterns and driving factors. Energy 2020, 195, 116988. [Google Scholar] [CrossRef]

- Guo, S.; Zheng, S.; Hu, Y.; Hong, J.; Wu, X.; Tang, M. Embodied energy use in the global construction industry. Appl. Energy 2019, 256, 113838. [Google Scholar] [CrossRef]

- Pomponi, F.; Moncaster, A. Scrutinising embodied carbon in buildings: The next performance gap made manifest. Renew. Sustain. Energy Rev. 2018, 81, 2431–2442. [Google Scholar] [CrossRef]

- Norouzi, M.; Chàfer, M.; Cabeza, L.F.; Jiménez, L.; Boer, D. Circular economy in the building and construction sector: A scientific evolution analysis. J. Build. Eng. 2021, 44, 102704. [Google Scholar] [CrossRef]

- Huang, L.; Krigsvoll, G.; Johansen, F.; Liu, Y.; Zhang, X. Carbon emission of global construction sector. Renew. Sustain. Energy Rev. 2018, 81, 1906–1916. [Google Scholar] [CrossRef]

- DCCEEW. Quarterly Update of Australia’s National Greenhouse Gas Inventory; Commonwealth of Australia: Canberra, Australia, 2021. [Google Scholar]

- WGBC. Bringing Embodied Carbon Upfront; WGBC: London, UK, 2019. [Google Scholar]

- Hou, H.; Feng, X.; Zhang, Y.; Bai, H.; Ji, Y.; Xu, H. Energy-related carbon emissions mitigation potential for the construction sector in China. Environ. Impact Assess. Rev. 2021, 89, 106599. [Google Scholar] [CrossRef]

- GBCA. Green Star Project Directory 2020. Available online: https://www.gbca.org.au/project-directory.asp (accessed on 15 September 2022).

- Heeren, N.; Hellweg, S. Tracking construction material over space and time: Prospective and geo-referenced modeling of building stocks and construction material flows. J. Ind. Ecol. 2019, 23, 253–267. [Google Scholar] [CrossRef]

- Abouhamad, M.; Abu-Hamd, M. Life Cycle Assessment Framework for Embodied Environmental Impacts of Building Construction Systems. Sustainability 2021, 13, 461. [Google Scholar] [CrossRef]

- Stephan, A. Towards a Comprehensive Energy Assessment of Residential Buildings: A Multi-Scale Life Cycle Energy Analysis Framework; Université Libre de Bruxelles & The University of Melbourne: Melbourne, Australia, 2013. [Google Scholar]

- Zari, M.P. Ecosystem services impacts as part of building materials selection criteria. Mater. Today Sustain. 2019, 3, 100010. [Google Scholar] [CrossRef]

- Krausmann, F.; Lauk, C.; Haas, W.; Wiedenhofer, D. From resource extraction to outflows of wastes and emissions: The socioeconomic metabolism of the global economy, 1900–2015. Glob. Environ. Change 2018, 52, 131–140. [Google Scholar] [CrossRef]

- Nizam, R.S.; Zhang, C.; Tian, L. A BIM based tool for assessing embodied energy for buildings. Energy Build. 2018, 170, 1–14. [Google Scholar] [CrossRef]

- Zhang, Y.; Yan, D.; Hu, S.; Guo, S. Modelling of energy consumption and carbon emission from the building construction sector in China, a process-based LCA approach. Energy Policy 2019, 134, 110949. [Google Scholar] [CrossRef]

- Fredriksson, A.; Nolz, P.C.; Seragiotto, C. A mixed method evaluation of economic and environmental considerations in construction transport planning: The case of Ostlänken. Sustain. Cities Soc. 2021, 69, 102840. [Google Scholar] [CrossRef]

- Naz, F.; Fredriksson, A.; Ivert, L.K. The Potential of Improving Construction Transport Time Efficiency—A Freight Forwarder Perspective. Sustainability 2022, 14, 10491. [Google Scholar] [CrossRef]

- Jahan, I.; Zhang, G.; Bhuiyan, M.; Navaratnam, S.; Shi, L. Experts’ Perceptions of the Management and Minimisation of Waste in the Australian Construction Industry. Sustainability 2022, 14, 11319. [Google Scholar] [CrossRef]

- Zimmermann, R.K.; Skjelmose, O.; Jensen, K.G.; Jensen, K.K.; Birgisdottir, H. (Eds.) Categorizing Building Certification Systems According to the Definition of Sustainable Building; IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2019. [Google Scholar]

- Rheude, F.; Kondrasch, J.; Röder, H.; Fröhling, M. Review of the terminology in the sustainable building sector. J. Clean. Prod. 2021, 286, 125445. [Google Scholar] [CrossRef]

- Manfren, M.; Tagliabue, L.C.; Re Cecconi, F.; Ricci, M. Long-term techno-economic performance monitoring to promote built environment decarbonisation and digital transformation—A case study. Sustainability 2022, 14, 644. [Google Scholar] [CrossRef]

- Davies, M.; Oreszczyn, T. The unintended consequences of decarbonising the built environment: A UK case study. Energy Build. 2012, 46, 80–85. [Google Scholar] [CrossRef]

- Newton, P.; Prasad, D.; Sproul, A.; White, S. Decarbonising the Built Environment: Charting the Transition; Springer: Berlin, Germany, 2019. [Google Scholar]

- Omer, M.M.; Rahman, R.A.; Almutairi, S. Construction waste recycling: Enhancement strategies and organization size. Phys. Chem. Earth Parts A/B/C 2022, 126, 103114. [Google Scholar] [CrossRef]

- Liu, J.; Yi, Y.; Wang, X. Exploring factors influencing construction waste reduction: A structural equation modeling approach. J. Clean. Prod. 2020, 276, 123185. [Google Scholar] [CrossRef]

- Duggal, S.K. Building Materials; Routledge: London, UK, 2017. [Google Scholar]

- Dixit, M.K. Embodied energy analysis of building materials: An improved IO-based hybrid method using sectoral disaggregation. Energy 2017, 124, 46–58. [Google Scholar] [CrossRef]

- Bhochhibhoya, S.; Zanetti, M.; Pierobon, F.; Gatto, P.; Maskey, R.K.; Cavalli, R. The Global Warming Potential of Building Materials: An Application of Life Cycle Analysis in Nepal. Mt. Res. Dev. 2017, 37, 47–55. [Google Scholar] [CrossRef]

- Ashe, B.; Newton, P.W.; Enker, R.; Bell, J.; Apelt, R.; Hough, R.; Davis, M. Sustainability and the Building Code of Australia; Research Project Report; Australian Cooperative Research Centre: Canberra, Australia, 2003. [Google Scholar]

- Armstrong, A.; Wright, C.; Ashe, B.; Nielsen, H. Enabling Innovation in Building Sustainability: Australia’s National Construction Code. Procedia Eng. 2017, 180, 320–330. [Google Scholar] [CrossRef]

- Research and Markets. Construction Sustainable Materials Market Growth Forecasts to 2030; Research and Markets: Canberra, Australia, 2021. [Google Scholar]

- Shooshtarian, S.; Wong, S.P.P.; Khalfan, M.; Maqsood, T.; Yang, J. (Eds.) Green construction and construction and demolition waste management in Australia. In Proceedings of the 43rd Annual Australasian University Building Educators Association Conference (AUBEA 2019), Noosa, Australia, 6–8 November 2019. [Google Scholar]

- Martek, I.; Hosseini, M.R.; Shrestha, A.; Edwards, D.J.; Durdyev, S. Barriers inhibiting the transition to sustainability within the Australian construction industry: An investigation of technical and social interactions. J. Clean. Prod. 2019, 211, 281–292. [Google Scholar] [CrossRef]

- Govindan, K.; Madan Shankar, K.; Kannan, D. Sustainable material selection for construction industry–A hybrid multi criteria decision making approach. Renew. Sustain. Energy Rev. 2016, 55, 1274–1288. [Google Scholar] [CrossRef]

- Akadiri, P.O. Understanding barriers affecting the selection of sustainable materials in building projects. J. Build. Eng. 2015, 4, 86–93. [Google Scholar] [CrossRef]

- Ireland, P.; Clausen, D. Local action that changes the world: Fresh perspectives on climate change mitigation and adaptation from Australia. In Managing Global Warming; Elsevier: Amsterdam, The Netherlands, 2019; pp. 769–782. [Google Scholar]

- Van Soest, H.L.; den Elzen, M.G.; van Vuuren, D.P. Net-zero emission targets for major emitting countries consistent with the Paris Agreement. Nat. Commun. 2021, 12, 2140. [Google Scholar] [CrossRef]

- Johnsson, F.; Karlsson, I.; Rootzén, J.; Ahlbäck, A.; Gustavsson, M. The framing of a sustainable development goals assessment in decarbonizing the construction industry–Avoiding “Greenwashing”. Renew. Sustain. Energy Rev. 2020, 131, 110029. [Google Scholar] [CrossRef] [PubMed]

- Hurlimann, A.C.; Warren-Myers, G.; Browne, G.R. Is the Australian construction industry prepared for climate change? Build. Environ. 2019, 153, 128–137. [Google Scholar] [CrossRef]

- Martin, C.; Evans, J.; Karvonen, A.; Paskaleva, K.; Yang, D.; Linjordet, T. Smart-sustainability: A new urban fix? Sustain. Cities Soc. 2019, 45, 640–648. [Google Scholar] [CrossRef]

- Moreau, V.; Vuille, F. Decoupling energy use and economic growth: Counter evidence from structural effects and embodied energy in trade. Appl. Energy 2018, 215, 54–62. [Google Scholar] [CrossRef]

- Koezjakov, A.; Urge-Vorsatz, D.; Crijns-Graus, W.; Van den Broek, M. The relationship between operational energy demand and embodied energy in Dutch residential buildings. Energy Build. 2018, 165, 233–245. [Google Scholar] [CrossRef]

- Cherian, P.; Palaniappan, S.; Menon, D.; Anumolu, M.P. Comparative study of embodied energy of affordable houses made using GFRG and conventional building technologies in India. Energy Build. 2020, 223, 110138. [Google Scholar] [CrossRef]

- Praseeda, K.; Venkatarama Reddy, B.; Mani, M. Embodied and operational energy of rural dwellings in India. Int. J. Sustain. Energy 2019, 38, 227–237. [Google Scholar] [CrossRef]

- Rakesh, K.S.; Jayasree, T.K. The Impact of Changing Trends in Material Selection on Embodied Energy of Buildings in the Context of Kerala, India. Key Eng. Mater. 2015, 666, 123–132. [Google Scholar] [CrossRef]

- Bansal, D.; Singh, R.; Sawhney, R.L. Effect of construction materials on embodied energy and cost of buildings—A case study of residential houses in India up to 60m2 of plinth area. Energy Build. 2014, 69, 260–266. [Google Scholar] [CrossRef]

- CWA. Tracking Progress to Net Zero Emissions; ClimateWorks Australia: Melbourne, Australia, 2018. [Google Scholar]

- Crawford, R.H.; Bartak, E.L.; Stephan, A.; Jensen, C.A. Evaluating the life cycle energy benefits of energy efficiency regulations for buildings. Renew. Sustain. Energy Rev. 2016, 63, 435–451. [Google Scholar] [CrossRef]

- Ürge-Vorsatz, D.; Koeppel, S.; Mirasgedis, S. Appraisal of policy instruments for reducing buildings’ CO2 emissions. Build. Res. Inf. 2007, 35, 458–477. [Google Scholar] [CrossRef]

- Howlett, M.; Cashore, B. The dependent variable problem in the study of policy change: Understanding policy change as a methodological problem. J. Comp. Policy Anal. 2009, 11, 33–46. [Google Scholar] [CrossRef]

- Maraseni, T.; Reardon-Smith, K. Meeting national emissions reduction obligations: A case study of Australia. Energies 2019, 12, 438. [Google Scholar] [CrossRef]

- CGBC. Embodied Carbon: A Primer for Buildings in Canada; Canada Green Building Council: Ottawa, ON, Canada, 2020. [Google Scholar]

- Vincent, L.; Zhang, X.; Mekis, É.; Wan, H.; Bush, E. Changes in Canada’s climate: Trends in indices based on daily temperature and precipitation data. Atmos.-Ocean 2018, 56, 332–349. [Google Scholar] [CrossRef]

- Government of Canada. Canada’s Changing Climate Report; Government of Canada: Ottawa, ON, Canada, 2020. [Google Scholar]

- Hughes, D. Canada’s Energy Sector Status, Evolution, Revenue, Employment, Production Forecasts, Emissions and Implications for Emissions Reduction; Corporate Mapping Project: Vancouver, BC, Canada, 2021. [Google Scholar]

- Hu, M.; Esram, N.W. The Status of Embodied Carbon in Building Practice and Research in the United States: A Systematic Investigation. Sustainability 2021, 13, 12961. [Google Scholar] [CrossRef]

- DGBC. Whole Life Carbon: Position Paper; Dutch Green Building Council: Den Haag, The Netherlands, 2021. [Google Scholar]

- Birgisdóttir, H. Why Building Regulations Must Incorporate Embodied Carbon. Build. Cities 2021, 1523. Available online: https://www.buildingsandcities.org/insights/commentaries/building-regulations-embodied-carbon.html (accessed on 15 September 2022).

- McGowan, M.K. Building a Foundation For Building Decarbonization. ASHRAE J. 2022, 64, 70–74. [Google Scholar]

- Anderson, J.; Moncaster, A. Embodied carbon of concrete in buildings, Part 1: Analysis of published EPD. Build. Cities 2020, 1, 198–217. [Google Scholar] [CrossRef]

- Schwarz, M.; Nakhle, C.; Knoeri, C. Innovative designs of building energy codes for building decarbonization and their implementation challenges. J. Clean. Prod. 2020, 248, 119260. [Google Scholar] [CrossRef]

- De Wolf, C.; Pomponi, F.; Moncaster, A. Measuring embodied carbon dioxide equivalent of buildings: A review and critique of current industry practice. Energy Build. 2017, 140, 68–80. [Google Scholar] [CrossRef]

- Twinn, R.; Desai, K.; Box, P. Net Zero Carbon Buildings: A Framework Definition; United Kingdom Green Building Council: London, UK, 2019. [Google Scholar]

- UKGBC. Net Zero Carbon Buildings Framework; United Kingdom Green Building Council: London, UK, 2021. [Google Scholar]

- RICS. Whole Life Carbon Assessment for the Built Environment; Royal Institute of Chartered Surveyors: London, UK, 2017. [Google Scholar]

- UK Parliament. Embodied Carbon and Retrofitting Policy under the Microscope by MPs; UK Parliament: London, UK, 2021. [Google Scholar]

- Construction Innovation Hub. Building the Foundations of a Better Future–Part Two 2020. Available online: https://constructioninnovationhub.org.uk/building-the-foundations-of-a-better-future-part-2 (accessed on 23 September 2022).

- One Click LCA. Zero Carbon Buildings with One Click LCA; One Click LCA: Helsinki, Finland, 2022; Available online: https://www.oneclicklca.com/norwegian-government-towards-zero-carbon-buildings/ (accessed on 27 September 2022).

- Sandberg, N.H.; Næss, J.S.; Brattebø, H.; Andresen, I.; Gustavsen, A. Large potentials for energy saving and greenhouse gas emission reductions from large-scale deployment of zero emission building technologies in a national building stock. Energy Policy 2021, 152, 112114. [Google Scholar] [CrossRef]

- Kristjansdottir, T.; Fjeldheim, H.; Selvig, E.; Risholt, B.D.; Time, B.; Georges, L.; Dokka, T.H.; Bourelle, J.; Bohne, R.A.; Cervenka, Z. A Norwegian ZEB-Definition Embodied Emission; SINTEF Academic Press: Trondheim, Norway, 2014. [Google Scholar]

- Kuittinen, M.; Häkkinen, T. Reduced carbon footprints of buildings: New Finnish standards and assessments. Build. Cities 2020, 1, 182–197. [Google Scholar] [CrossRef]

- Pilpola, S.; Arabzadeh, V.; Mikkola, J.; Lund, P.D. Analyzing national and local pathways to carbon-neutrality from technology, emissions, and resilience perspectives—Case of Finland. Energies 2019, 12, 949. [Google Scholar] [CrossRef]

- Karhunmaa, K. Attaining carbon neutrality in Finnish parliamentary and city council debates. Futures 2019, 109, 170–180. [Google Scholar] [CrossRef]

- MBIE. Whole-of-Life Embodied Carbon Emissions Reduction Framework; Ministry of Business, Innovation and Employment: Wellington, New Zealand, 2020. [Google Scholar]

- MBIE. Whole-of-Life Embodied Carbon Assessment: Technical Methodology; Ministry of Business, Innovation and Employment: Wellington, New Zealand, 2022. [Google Scholar]

- Bui, T.T.P.; Wilkinson, S.; Domingo, N.; MacGregor, C. Zero Carbon Building Practices in Aotearoa New Zealand. Energies 2021, 14, 4455. [Google Scholar] [CrossRef]

- Kuyper, J.; Schroeder, H.; Linnér, B.-O. The Evolution of the UNFCCC. Annu. Rev. Environ. Resour. 2018, 43, 343–368. [Google Scholar] [CrossRef]

- Wafula, J.; Talukhaba, A. (Eds.) Re-writing local authorities building control regulations to foster energy efficiency in the built environment in South Africa: The case of Ekurhuleni Metropolitan municipality. In Proceedings of the RICS Construction and Property Conference, Salford, UK, 12–13 September 2011. [Google Scholar]

- Sicignano, E.; Di Ruocco, G.; Melella, R. Mitigation Strategies for Reduction of Embodied Energy and Carbon, in the Construction Systems of Contemporary Quality Architecture. Sustainability 2019, 11, 3806. [Google Scholar] [CrossRef]

- CEFC. Australian Buildings and Infrastructure: Opportunities for Cutting Embodied Carbon; Clean Energy Finance Corporation: Canberra, Australia, 2021. [Google Scholar]

- Papadaki, D.; Nikolaou, D.A.; Assimakopoulos, M.N. Circular Environmental Impact of Recycled Building Materials and Residential Renewable Energy. Sustainability 2022, 14, 4039. [Google Scholar] [CrossRef]

- Sweet, R. Decarbonising construction: Six things the industry could do. Constr. Res. Innov. 2019, 10, 109–113. [Google Scholar] [CrossRef]

- Santamouris, M.; Vasilakopoulou, K. Present and future energy consumption of buildings: Challenges and opportunities towards decarbonisation. E-Prime-Adv. Electr. Eng. Electron. Energy 2021, 1, 100002. [Google Scholar] [CrossRef]

- IPA. Decarbonising Infrastructure; Report No.: 0648321975; Infrastructure Partnerships: Sydney, Australia, 2022. [Google Scholar]

- Dixit, M.K. Embodied energy and cost of building materials: Correlation analysis. Build. Res. Inf. 2016, 45, 508–523. [Google Scholar] [CrossRef]

- GBCA. Green Star-Design & As Built Fitout Scope: Guidance for Cold Shell, Warm Shell and Integrated Fitouts 2020. Available online: https://gbca-web.s3.amazonaws.com/media/documents/green-star-design-%26-as-built-fitout-scope-guidance-r1.pdf (accessed on 29 August 2022).

- Fonseca, L.M.; Domingues, J.P.; Dima, A.M. Mapping the sustainable development goals relationships. Sustainability 2020, 12, 3359. [Google Scholar] [CrossRef]

| National Construction Code Volumes | Scope | Description |

|---|---|---|

| Volume one—Section J: Energy Efficiency | Part J1 Building Fabric Part J3 Building Sealing Part J5 Air Conditioning and Ventilation Systems Part J6 Artificial Lighting and Power Part J7 Heated Water Supply Part J8 Facilities for Energy Monitoring | Provides the minimum performance requirements for the Australian construction industry to follow in the construction of buildings with the NCC building classification of 2 to 9. Provides three verification methods to measure compliance with JP1, the ‘NABERS Energy for Offices’ model, the Green Star rating tool, and greenhouse gas emission modelling in comparison to a reference building [19]. |

| Volume two | Part 2.6 Performance provisions—Energy efficiency Part 3.12.1 Building fabric Part 3.12.2 External glazing Part 3.12.3 Building sealing Part 3.12.4 Air movement Part 3.12.5 Services | Provides building codes for NCC building class 1 and 10 buildings. Energy efficiency performance provisions are included in Part 2.6 and codes are included in Section 3.12, where the objective is stated to “reduce greenhouse gas emissions”. Volume two provides the option of employing NatHERS to verify compliance or fulfilling the code’s specified performance solutions like R-value and glazing responsibilities to meet requirement Part 2.6 [19]. |

| Country | Human Development Index Tier (2022) | Sustainability Policy Implemented | Scope of Policy | Effectiveness | Authorizing Body |

|---|---|---|---|---|---|

| Canada | Very High (0.936 HDI) | Greening Government Strategy (2017) | Federal Government/Government Agency Operations (Construction Included) | Initial steps towards emission reductions were made; however, as of 2022, it has been found that the emission reductions were not as complete as they should have been when considering their targets. | Treasury Board of Canada Secretariat |

| The United States of America | Very High (0.921 HDI) | Buy Clean Initiative (2021) | Federal Government/Government Agency Construction Projects | A buy clean task force and embodied carbon workgroup have been launched to develop recommendations and policies, with new targeted commitments made in 2022 for the federal government to target embodied materials in its projects. | White House Federal Chief Sustainability Officer |

| Netherlands | Very High (0.941 HDI) | Bouwbesluit (2018) | New office buildings larger than 100 m squared and new residential buildings | No measures of effectiveness have been documented in research. | Ministry of the Interior and Kingdom Relations |

| France | Very High (0.903 HDI) | 1. RE2020 (2022) 2. E+/C− (2016) | 1. New residential or non-residential construction projects requiring a permit 2. Voluntary amongst French building material suppliers | 1. No measures of effectiveness have been found due to limited timeframe. 2. Environmental labelling used as an experiment for further RE2020 research that aided the regulations currently in place. | 1. Evolution of Housing, Development and Digital 2. French Federal Government |

| United Kingdom | Very High (0.929 HDI) | 1. Net Zero Carbon Certification (2019) 2. RICS Embodied Energy Assessment (2018) | 1. Builders attempting ‘Net Zero Carbon’ certification 2. RICS members submitting building reports | 1. The UKGBC in 2021 stated that they believe this certification should be used as a verification method in building policy; however, it is currently still not mandatory for building permits, which has reduced its effectiveness. 2. The large member-base of the institute allows for more awareness of embodied energy and whole life carbon, but the resulting use of the calculations do not enforce change in builders’ decisions. | 1. UK Green Building Council 2. Royal Institute of Chartered Surveyors |

| Denmark | Very High (0.948) | Sustainable Construction Strategy (2023) | All new construction from 2023 over 1000 square meters All new construction (any size) from 2025 | No measures of effectiveness have been found due to timeframe. | Danish Government |

| Norway | Very High (0.961 HDI) | 1. EPD-Norge (established 2002) 2. Norwegian Standard 3720 (2018) | 1. Over 220 companies and 1500 construction materials 2. Norway Construction Industry | 1. Has been able to increase its EPD database to effectively inform builders on material selection, as they cover over 220 companies. 2. Enforces greenhouse gas accounting effectively throughout the building industry. It is expected to be effective for creating future policy through its data. | 1. Federation of Norwegian Construction Industries 2. Directorate for Building Quality |

| Finland | Very High (0.940 HDI) | Intended Low Carbon Construction Legislation (expected by 2025) | Finland Construction Industry | No measures of effectiveness have been found due to timeframe. | Finland Ministry of Environment |

| New Zealand | Very High (0.937 HDI) | New Zealand’s First Emissions Reduction Plan (2022) | All New Zealand Industry (Construction Included) | No measures of effectiveness have been found due to timeframe. | New Zealand Government Minister of Climate |

| Australia | Very High (0.951 HDI) | National Construction Code Sustainability Standards (2019) Green Star Building Tool ‘Upfront Carbon Reductions’ | 1. Australian Construction Industry 2. Builders attempting Green Star certification | 1. Operational energy efficiency standards have been effectively applied. Embodied energy has not been implemented into the codes. 2. As it is a voluntary certification, it does not effectively enforce meaningful change in builders’ decisions. | 1. Australian Building Codes Board 2. Green Building Council Australia |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Curmi, L.; Weththasinghe, K.K.; Tariq, M.A.U.R. Global Policy Review on Embodied Flows: Recommendations for Australian Construction Sector. Sustainability 2022, 14, 14628. https://doi.org/10.3390/su142114628

Curmi L, Weththasinghe KK, Tariq MAUR. Global Policy Review on Embodied Flows: Recommendations for Australian Construction Sector. Sustainability. 2022; 14(21):14628. https://doi.org/10.3390/su142114628

Chicago/Turabian StyleCurmi, Lachlan, Kumudu Kaushalya Weththasinghe, and Muhammad Atiq Ur Rehman Tariq. 2022. "Global Policy Review on Embodied Flows: Recommendations for Australian Construction Sector" Sustainability 14, no. 21: 14628. https://doi.org/10.3390/su142114628

APA StyleCurmi, L., Weththasinghe, K. K., & Tariq, M. A. U. R. (2022). Global Policy Review on Embodied Flows: Recommendations for Australian Construction Sector. Sustainability, 14(21), 14628. https://doi.org/10.3390/su142114628