Optimization of the Process Parameters of Fully Mechanized Top-Coal Caving in Thick-Seam Coal Using BP Neural Networks

Abstract

:1. Introduction

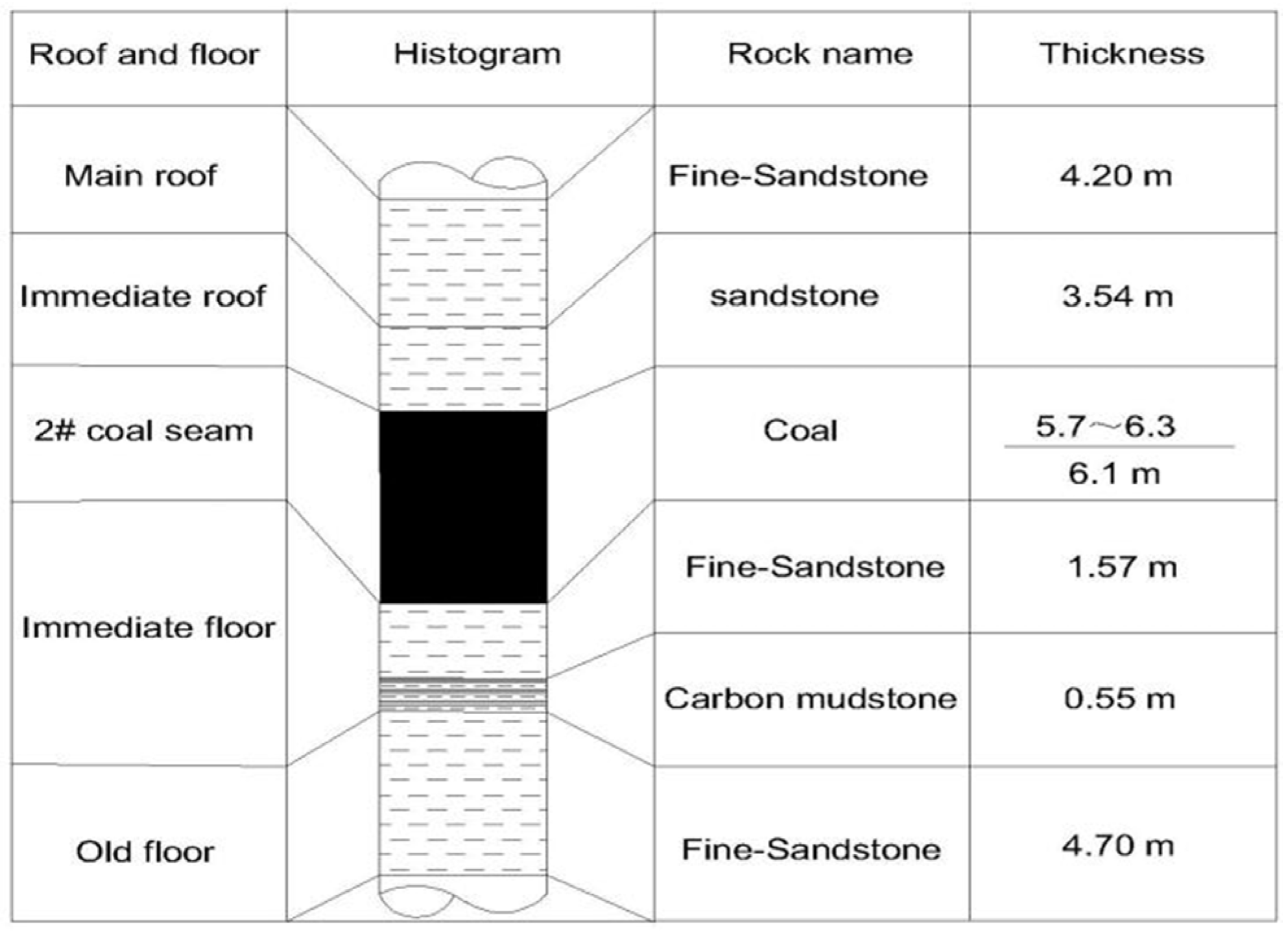

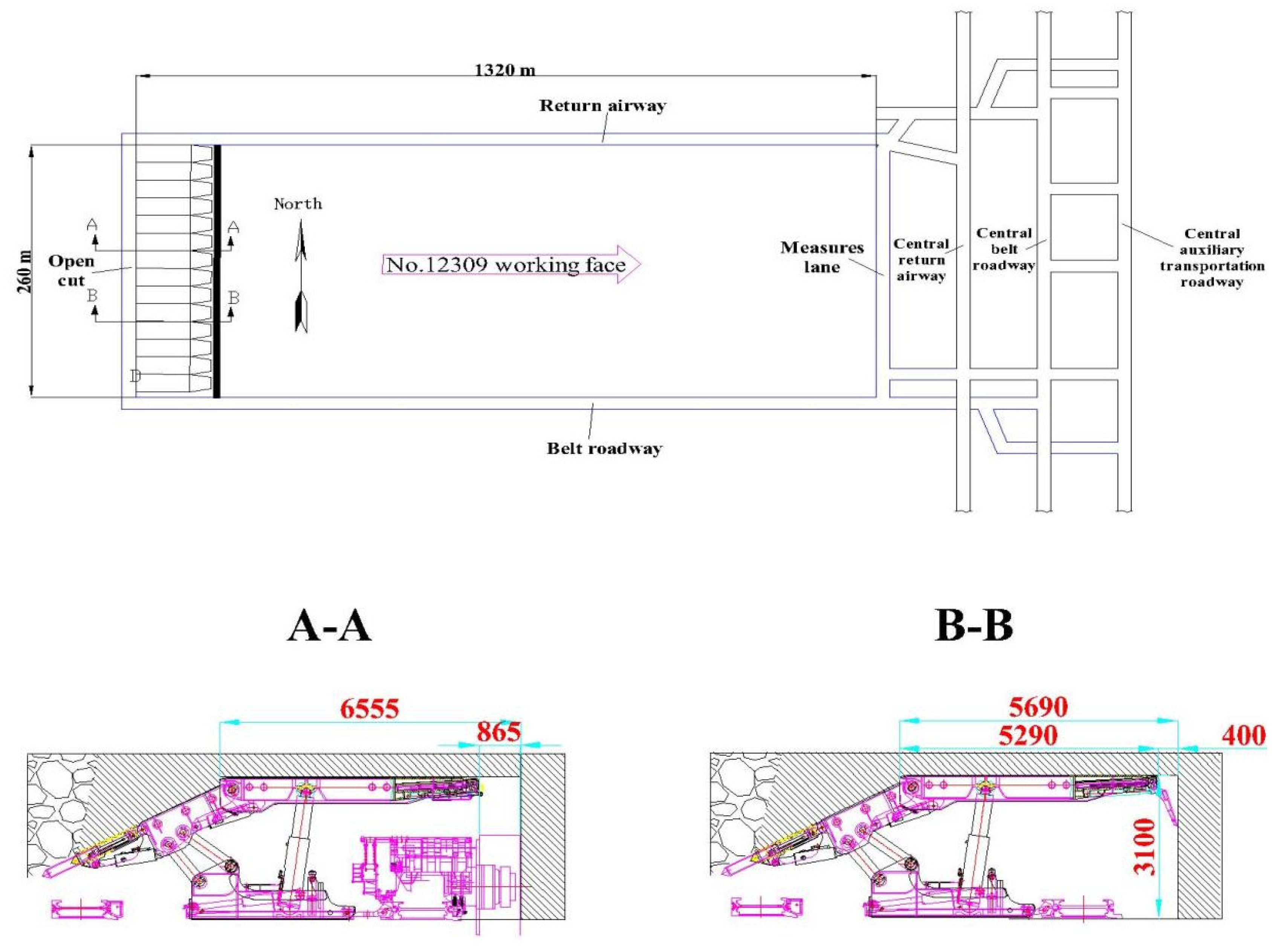

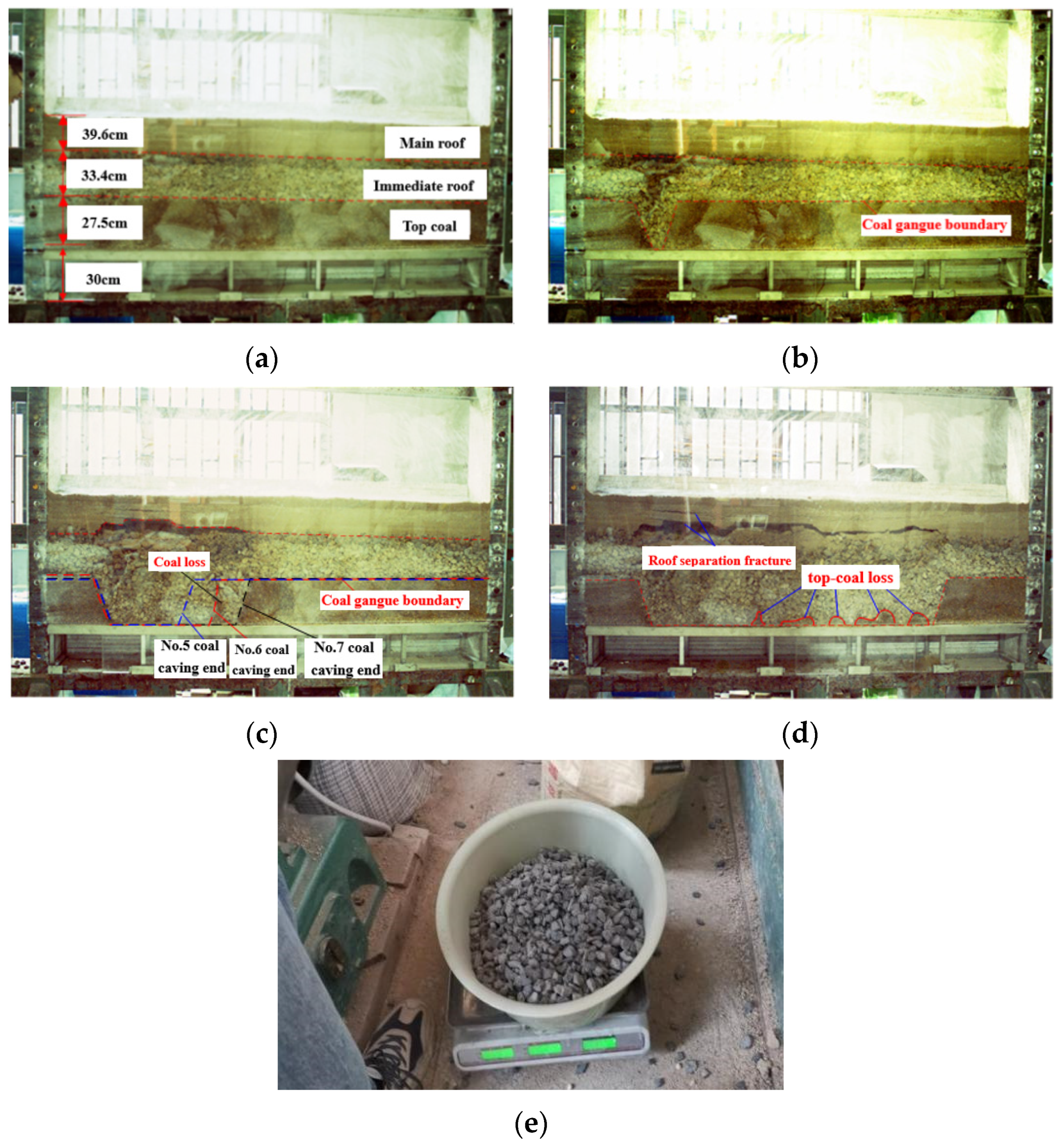

2. Engineering Background

3. Methodology

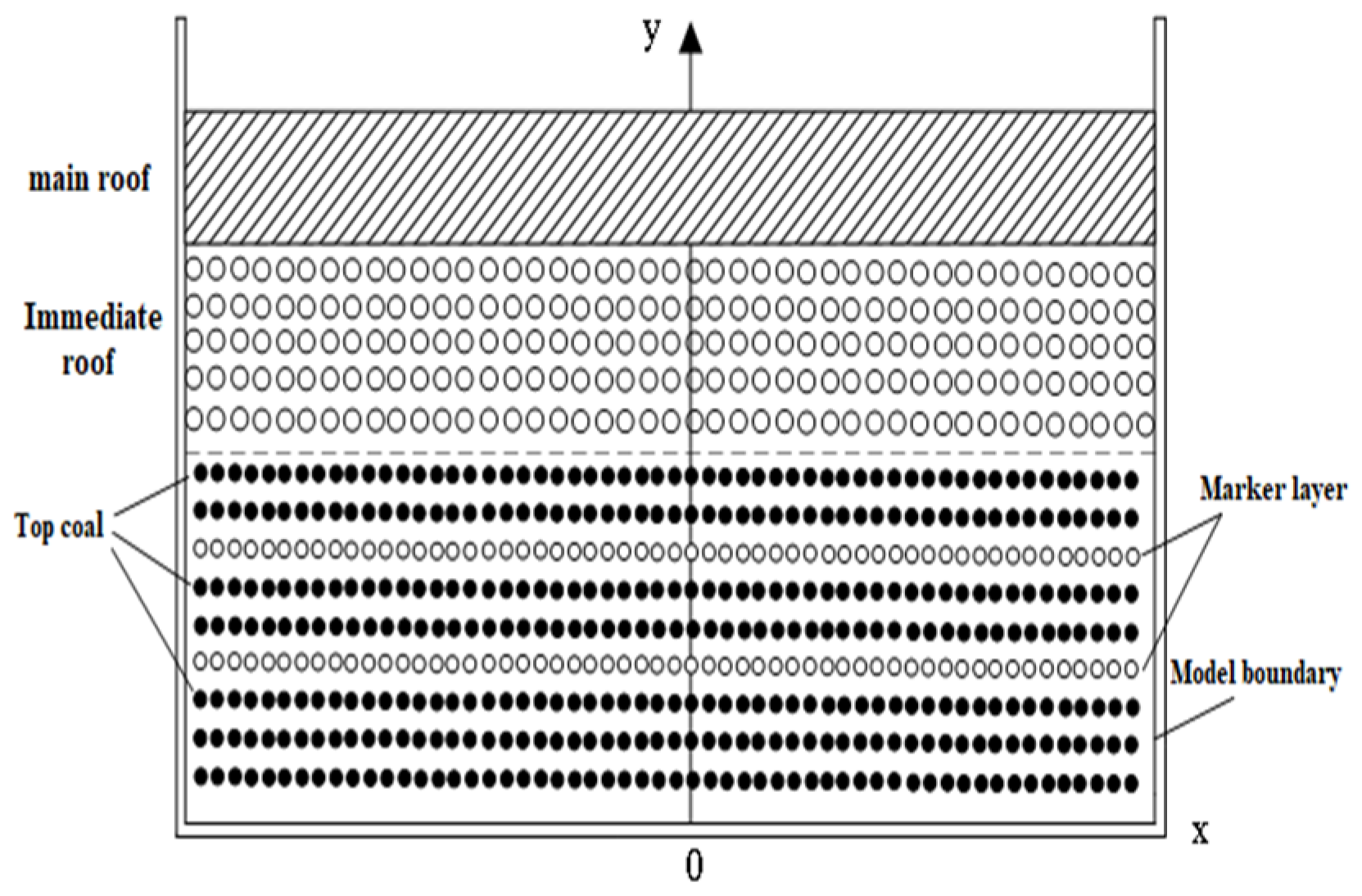

3.1. Numerical Simulation Design

3.2. Numerical Simulation Calculation

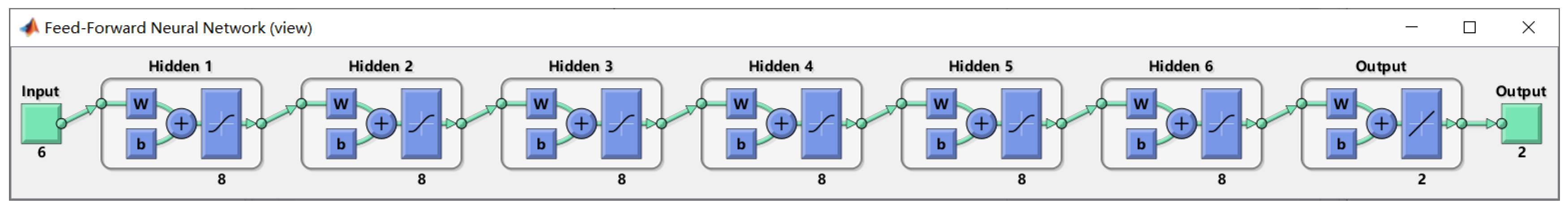

3.2.1. BP Neural Network

- Loading initialized training sample parameters, input array P and output array A, and randomly selecting 80% of the samples as the training group (P1, A1) and 20% of the samples as the test group (P2, A2).

- Defining a series of neuron parameters such as the number of neural network layers, the number of neurons per layer, the maximum number of trainings (net.trainParam.epochs) and the training target error (net.trainParam.goal).

- Using the feedforwardnet function in Matlab to establish the neuron model, and using the train function to train the input and output array of the samples, such that a corresponding network is obtained.

- Using the Sim function to calculate the error between the input data P2 of the verification group and the output A2 of the verification group in the network. According to the error condition, returning to the second step to adjust the neural network parameters and continuing to train until the error requirements are met.

- Taking the target parameters into the Sim function, calculating the output of the neural network net, the predicted results of the target parameters are obtained.

3.2.2. Cross-Validation

3.2.3. Optimized Decision

3.3. Similarity Simulation Test

4. Results and Discussion

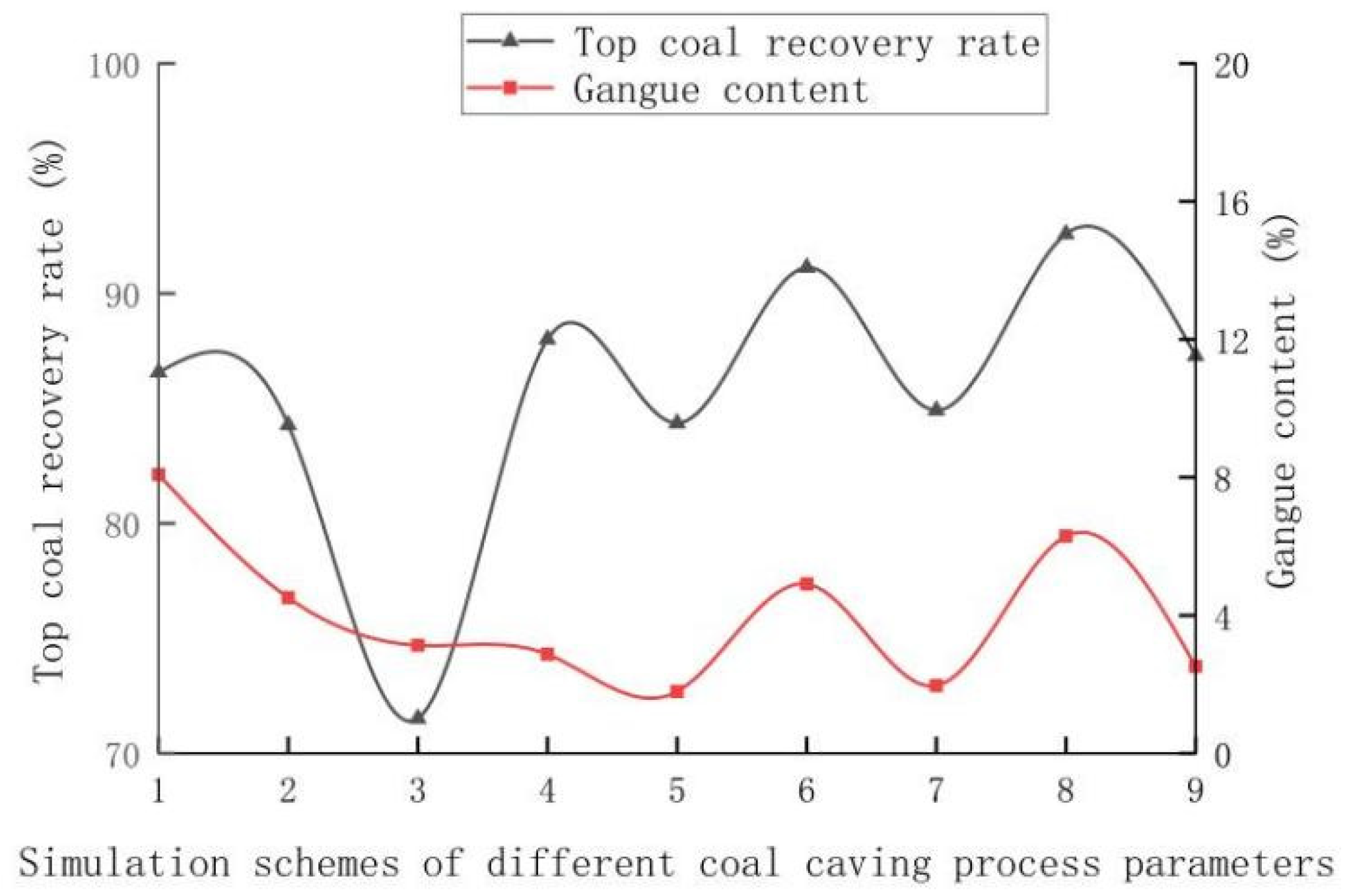

4.1. Numerical Simulation Experiment

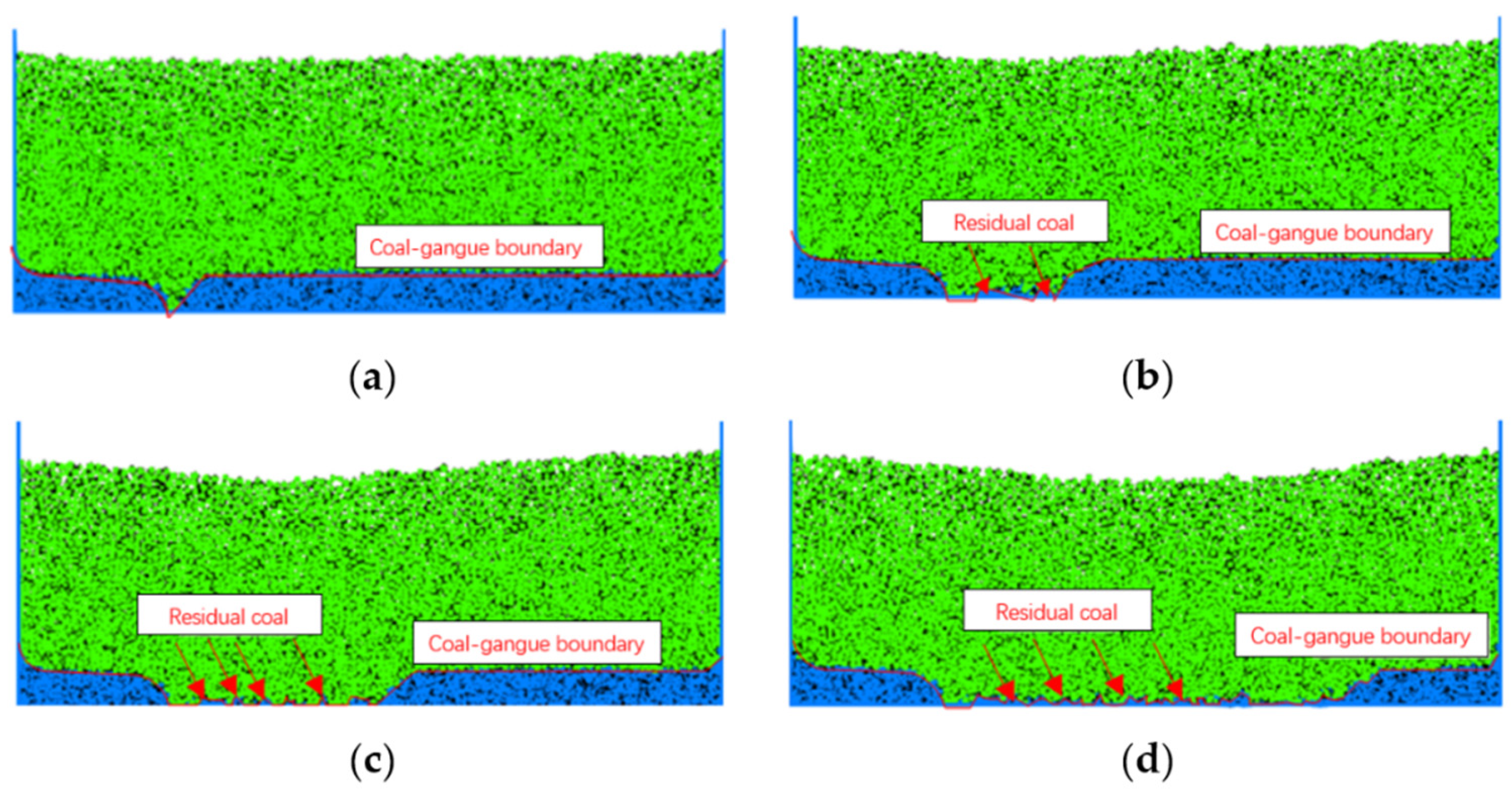

4.1.1. Coal Caving Mode

- (1)

- Sequential coal caving

- (2)

- Group interval coal caving

- (3)

- Interval return coal caving

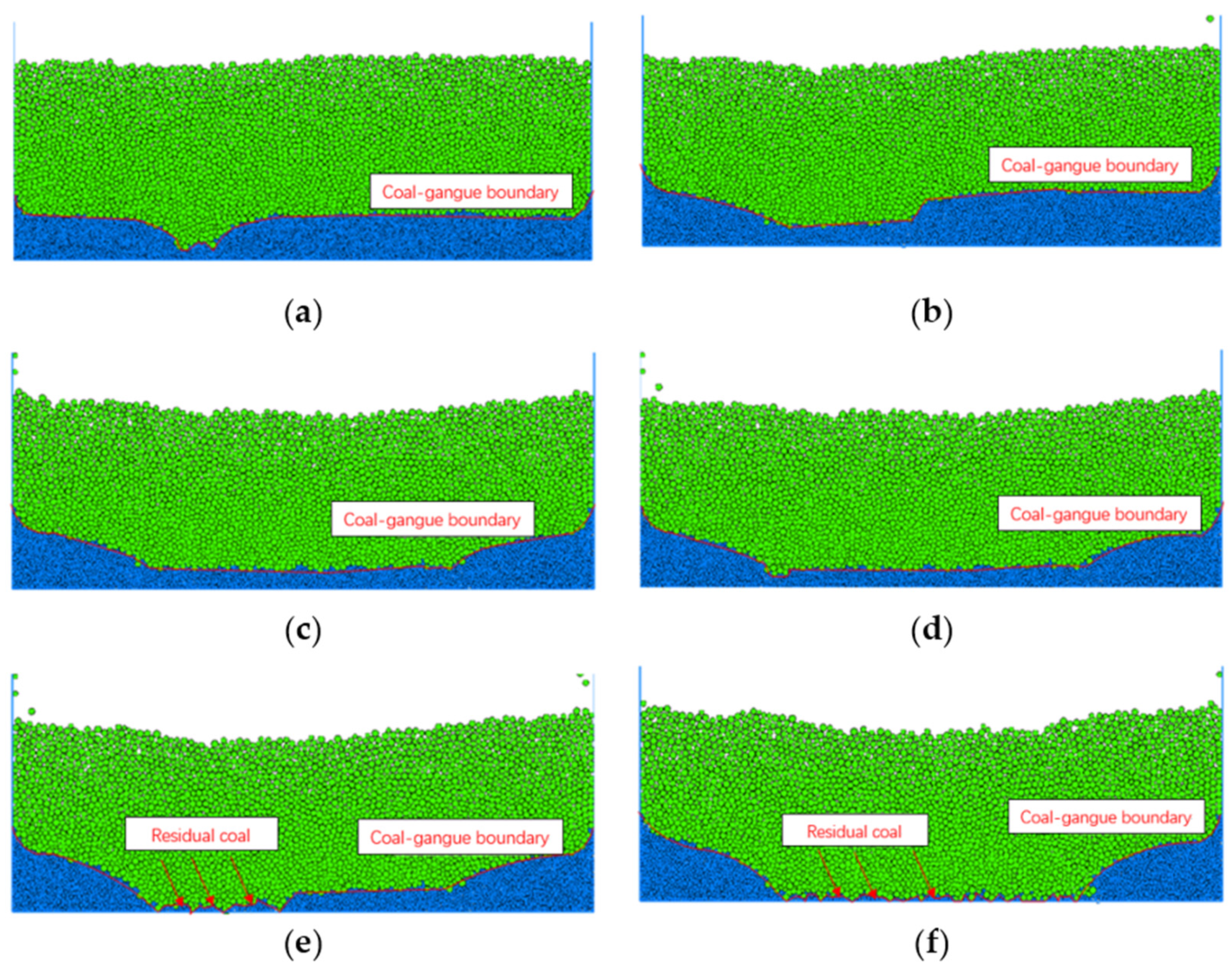

4.1.2. Coal Caving Procedure

4.2. Cross-Validation Results

4.3. Optimized Process Parameters

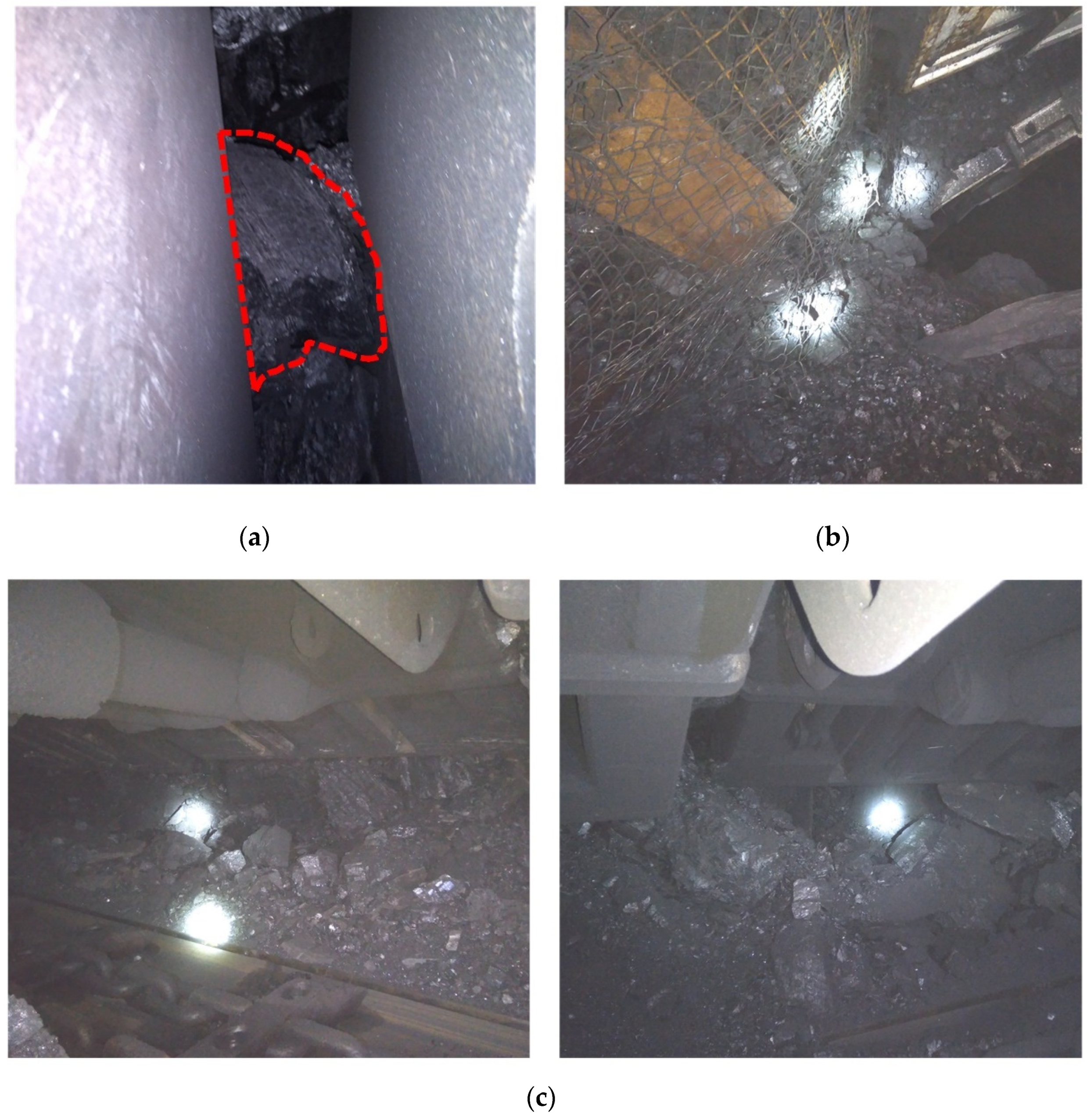

4.4. Coal Caving Effectiveness

5. Conclusions

- (1)

- For different coal caving process parameters, the top-coal recovery rates and gangue content are obviously differen, the top-coal recovery rate could be improved by appropriately increasing the gangue content, and the critical point for the gangue content should be determined according to the specific coal caving process parameters and the actual production situation.

- (2)

- In top-coal caving mining, the selection of a small caving step distance was conducive to top-coal caving.When the top-coal caving height was small, a better coal caving effect could be achieved by single-round sequential coal caving.When the top-coal caving height was large (6 m), using multiple rounds of coal caving was conducive to ensuring that the boundary between coal and gangue dropped evenly, and preventing the gangue above the coal caving support from entering the adjacent coal caving opening prematurely.

- (3)

- Through the in-lab similar simulation experiment, it was indicated that the BP neural network can be used to study the optimized decision making of mining process parameters and can obtain good results, improving the benefit of process parameter decision making, and provide the basis for realizing the intelligent mining of fully mechanized top-coal caving.

- (4)

- There are many factors affecting the top-coal recovery rate and gangue content in addition to the fully mechanized caving process parameters studied in this paper. The calculation of a relaxed ellipsoid can also be considered in future research.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Leonard, M.D.; Michaelides, E.E.; Michaelides, D.N. Substitution of coal power plants with renewable energy sources—Shift of the power demand and energy storage. Energy Convers. Manag. 2018, 164, 27–35. [Google Scholar] [CrossRef]

- Wang, J.; Yu, B.; Kang, H.; Wang, G.; Mao, D.; Liang, Y.; Jiang, P. Key technologies and equipment for a fully mechanized top-coal caving operation with a large mining height at ultra-thick coal seams. Int. J. Coal Sci. Technol. 2015, 2, 97–161. [Google Scholar] [CrossRef] [Green Version]

- Bhattacharya, M.; Rafiq, S.; Bhattacharya, S. The role of technology on the dynamics of coal consumption–economic growth: New evidence from China. Appl. Energy 2015, 154, 686–695. [Google Scholar] [CrossRef]

- Herezy, Ł.; Janik, D.; Skrzypkowski, K. Powered Roof Support—Rock Strata Interactions on the Example of an Automated Coal Plough System. Studia Geotech. Mech. 2018, 40, 46–55. [Google Scholar] [CrossRef] [Green Version]

- Wang, Z.; Zhang, G.; Zhao, L. Recognition of rock–coal interface in top coal caving through tail beam vibrations by using stacked sparse autoencoders. J. Vibroeng. 2016, 18, 4261–4275. [Google Scholar] [CrossRef]

- Wu, J.; Qin, Y.; Zhai, M. Mining safety of longwall top-coal caving in China. In Proceedings of the 8th U.S. Mine Ventilation Symposium, Rolla, MO, USA, 11–17 June 1999. [Google Scholar]

- Wang, J. Development and prospect on fully mechanized mining in Chinese coal mines. J. Coal Sci. Eng. 2014, 1, 253–260. [Google Scholar] [CrossRef] [Green Version]

- Le, T.D.; Mitra, R.; Oh, J.; Hebblewhite, B. A review of cavability evaluation in longwall top coal caving. Int. J. Min. Sci. Technol. 2017, 27, 907–915. [Google Scholar] [CrossRef]

- Yasitli, N.E.; Unver, B. 3D numerical modeling of longwall mining with top-coal caving. Int. J. Rock Mech. Min. Sci. 2005, 42, 219–235. [Google Scholar] [CrossRef]

- Alehossein, H.; Poulsen, B.A. Stress analysis of longwall top coal caving. Int. J. Rock Mech. Min. Sci. 2010, 47, 30–41. [Google Scholar] [CrossRef]

- Si, G.; Jamnikar, S.; Lazar, J.; Shi, J.Q.; Durucan, S.; Korre, A.; Zavšek, S. Monitoring and modelling of gas dynamics in multi-level longwall top coal caving of ultra-thick coal seams, part I: Borehole measurements and a conceptual model for gas emission zones. Int. J. Coal Geol. 2015, 144–145, 98–110. [Google Scholar] [CrossRef]

- Klishin, V.; Nikitenko, S.; Opruk, G. Longwall top coal caving (LTCC) mining technologies with roof softening by hydraulic fracturing method. IOP Conf. Ser. Mater. Sci. Eng. 2018, 354, 012015. [Google Scholar] [CrossRef]

- Klishin, V.I.; Fryanov, V.N.; Pavlova, L.D.; Opruk, G.Y. Modeling top coal disintegration in thick seams in longwall top coal caving. J. Min. Sci. 2019, 55, 247–256. [Google Scholar] [CrossRef]

- Ti, Z.; Li, J.; Wang, M.; Wang, K.; Jin, Z.; Tai, C. Fracture mechanism in overlying strata during longwall mining. Shock. Vib. 2021, 2021, 4764732. [Google Scholar] [CrossRef]

- Zhang, N.; Liu, C.; Wu, X.; Ren, T. Dynamic Random Arching in the Flow Field of Top-Coal Caving Mining. Energies 2018, 11, 1106. [Google Scholar] [CrossRef] [Green Version]

- Unver, B.; Yasitli, N.E. Modelling of strata movement with a special reference to caving mechanism in thick seam coal mining. Int. J. Coal Geol. 2006, 66, 227–252. [Google Scholar] [CrossRef]

- Ghosh, A.K.; Gong, Y. Improving coal recovery from longwall top coal caving. J. Mines Met. Fuels 2014, 62, 51–64. [Google Scholar]

- Klishin, V.I.; Klishin, S.V. Coal extraction from thick flat and steep beds. J. Min. Sci. 2010, 46, 149–159. [Google Scholar] [CrossRef]

- Klishin, S.V.; Klishin, V.I.; Opruk, G.Y. Modeling coal discharge in mechanized steep and thick coal mining. J. Min. Sci. 2013, 49, 932–940. [Google Scholar] [CrossRef]

- Yu, K.; Qiang, W. Application of ant colony clustering algorithm in coal mine gas accident analysis under the background of big data research. J. Intell. Fuzzy Syst. 2020, 38, 1381–1390. [Google Scholar] [CrossRef]

- Ruilin, Z.; Lowndes, I. The application of a coupled artificial neural network and fault tree analysis model to predict coal and gas outbursts. Int. J. Coal Geol. 2010, 84, 141–152. [Google Scholar] [CrossRef]

- Jiang, H.; Song, Q.; Gao, K.; Song, Q.; Zhao, X. Rule-based expert system to assess caving output ratio in top coal caving. PLoS ONE 2020, 15, e0238138. [Google Scholar] [CrossRef] [PubMed]

- Fan, S. Study of the Safety Assessment Model of Coal Mine Based on BP Neural Network. In Proceedings of the International Conference on Intelligent Computation Technology & Automation IEEE, Changsha, China, 10–11 October 2009. [Google Scholar]

- Meng, X.; Lu, P.; Wang, B. Coal mine safety warning system based on principal component method and neural network. In Proceedings of the 2017 6th Data Driven Control and Learning Systems (DDCLS) IEEE, Chongqing, China, 26–27 May 2017. [Google Scholar]

- O’Rourke, D.; Ringer, A. The impact of sustainability information on consumer decision making. J. Ind. Ecol. 2015, 20, 882–892. [Google Scholar] [CrossRef] [Green Version]

- Treichler, E.B.H.; William, D. Beyond shared decision-making: Collaboration in the age of recovery from serious mental illness. Am. J. Orthopsychiatry 2017, 87, 567–574. [Google Scholar] [CrossRef] [PubMed]

- Li, W. Consumer Decision-Making Power Based on BP Neural Network and Fuzzy Mathematical Model. Wirel. Commun. Mob. Comput. 2021, 2021, 6387633. [Google Scholar] [CrossRef]

- Joshi, Y.; Rahman, Z. Predictors of young consumer’s green purchase behavior. Manag. Environ. Qual. Int. J. 2016, 27, 452–472. [Google Scholar] [CrossRef]

- Hortaçsu, A.; Madanizadeh, S.A.; Puller, S. Power to choose? an analysis of consumer inertia in the residential electricity market. Nber Work. Pap. 2015, 9, 192–226. [Google Scholar]

- Dong, L.-J.; Tang, Z.; Li, X.-B.; Chen, Y.-C.; Xue, J.-C. Discrimination of mining microseismic events and blasts using convolutional neural networks and original waveform. J. Cent. South Univ. 2020, 27, 3078–3089. [Google Scholar] [CrossRef]

- Dong, L.; Zhou, Y.; Deng, S.; Wang, M.; Sun, D. Evaluation methods of man-machine-environment system for clean and safe production in phosphorus mines: A case study. J. Cent. South Univ. 2021, 28, 3856–3870. [Google Scholar] [CrossRef]

| Contact Type | Constitutive Model | Firc | dp_Nratio | dp_Sratio | kn | ks |

|---|---|---|---|---|---|---|

| Immediate roof | Liner | 0.5 | 0.3 | 0.3 | 4 × 108 | 4 × 108 |

| Top coal | 0.4 | 0.3 | 0.3 | 3 × 108 | 3 × 108 | |

| Ball–Ball | 0.4 | 0.3 | 0.3 | 3 × 108 | 3 × 108 | |

| Ball–Facets | 0.3 | 0.3 | 0.3 | 5 × 108 | 5 × 108 |

| Rock Stratum | Unit Type | Elastic Modulus/GPa | Bulk Density/kg·m−3 | Poisson’s Ratio | Local Damping |

|---|---|---|---|---|---|

| Main roof | Zone | 15.0 | 2660 | 0.34 | / |

| Immediate roof | Ball | 13.6 | 2660 | / | 0.7 |

| Top coal | Ball | 2.3 | 1400 | / | 0.7 |

| Bottom coal | Zone | 2.3 | 1400 | 0.26 | / |

| Level | Coal Seam Thickness (m) | Caving Ratio | Number of Coal Caving Rounds | Coal Caving Sequence | Number of Coal Discharge Openings at the Same Time | Top-Coal Particle Size (m) |

|---|---|---|---|---|---|---|

| 1 | 6 | 1:1 | Single round | Sequential | Single opening | 0.15–0.3 |

| 2 | 8 | 1:1.5 | Two rounds | Group interval | Two openings | 0.25–0.4 |

| 3 | 10 | 1:2 | Three rounds | Interval return | Three openings | 0.35–0.5 |

| Scheme No | Coal Seam Thickness | Caving Ratio | Number of Coal Caving Rounds | Coal Caving Sequence | Number of Coal Discharge Openings | Top-Coal Particle Size |

|---|---|---|---|---|---|---|

| 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| 2 | 1 | 2 | 2 | 2 | 2 | 2 |

| 3 | 1 | 3 | 3 | 3 | 3 | 3 |

| 4 | 2 | 1 | 1 | 2 | 2 | 3 |

| 5 | 2 | 2 | 2 | 3 | 3 | 1 |

| 6 | 2 | 3 | 3 | 1 | 1 | 2 |

| 7 | 3 | 1 | 2 | 1 | 3 | 2 |

| 8 | 3 | 2 | 3 | 2 | 1 | 3 |

| 9 | 3 | 3 | 1 | 3 | 2 | 1 |

| 10 | 1 | 1 | 3 | 3 | 2 | 2 |

| 11 | 1 | 2 | 1 | 1 | 3 | 3 |

| 12 | 1 | 3 | 2 | 2 | 1 | 1 |

| 13 | 2 | 1 | 2 | 3 | 1 | 3 |

| 14 | 2 | 2 | 3 | 1 | 2 | 1 |

| 15 | 2 | 3 | 1 | 2 | 3 | 2 |

| 16 | 3 | 1 | 3 | 2 | 3 | 1 |

| 17 | 3 | 2 | 1 | 3 | 1 | 2 |

| 18 | 3 | 3 | 2 | 1 | 2 | 3 |

| Level | Coal Seam Thickness (m) | Caving Ratio | Coal Caving Procedure | Top-Coal Particle Size (m) |

|---|---|---|---|---|

| 1 | 6 | 1:1 | One cutting with one caving | 0.15–0.3 |

| 2 | 8 | 1:1.5 | Two cutting with one caving | 0.25–0.4 |

| 3 | 10 | 1:2 | Three cutting with one caving | 0.35–0.5 |

| Scheme No | Coal Seam Thickness | Caving Ratio | Coal Caving Procedure | Top-Coal Particle Size |

|---|---|---|---|---|

| 1 | 1 | 1 | 1 | 1 |

| 2 | 1 | 2 | 2 | 2 |

| 3 | 1 | 3 | 3 | 3 |

| 4 | 2 | 1 | 2 | 3 |

| 5 | 2 | 2 | 3 | 1 |

| 6 | 2 | 3 | 1 | 2 |

| 7 | 3 | 1 | 3 | 2 |

| 8 | 3 | 2 | 1 | 3 |

| 9 | 3 | 3 | 2 | 1 |

| Sample Parameter | Concept Description | Neural Network Assignment Range |

|---|---|---|

| Interlayer and joint fracture development degree | Interlayer thickness > 0.5 m, Joint fissure less developed | 0–0.33 |

| Interlayer thickness 0.2–0.5 m Joint fracture development general | 0.34–0.66 | |

| Interlayer thickness < 0.2 m Joint fracture development | 0.67–1.0 | |

| Roof lithology and thickness | Pressure step < 25 m Immediate roof thickness > 10 m | 0.75–1.0 |

| Pressure step 25–50 m Immediate roof thickness 5–10 m | 0.5–0.75 | |

| Pressure step 25–50 m Immediate roof thickness < 5 m | 0.25–0.49 | |

| pressure step > 50 m Immediate roof thickness < 3 m | 0–0.24 | |

| Coal caving sequence | Multi-round sequential coal caving | 0.76–1.0 |

| Interval caving coal among multi-cutting | 0.51–0.75 | |

| Single-round sequential coal caving | 0.26–0.50 | |

| Single round interval coal caving | 0–0.25 |

| Parameters | Coal Seam Thickness | Caving Ratio | Number of Coal Caving Rounds | Coal Caving Order | Number of Coal Caving Openings | Top-Coal Particle Size | Top-Coal Recovery Rate | Gangue Content |

|---|---|---|---|---|---|---|---|---|

| Input parameters | 1 | 1 | 0.5 | 0.5 | 0.5 | 0.25 | 92.48% | 2.16% |

| Actual parameters | 10 m | 1:1 | Three rounds | Three ports | Interval return coal caving | 0.15–0.3 m | / | / |

| Coal Seam Occurrence Conditions (X) | Optimized Process Parameter (Y) | ||

|---|---|---|---|

| Coal seam thickness (X1) | 6.1 m | Coal caving sequence Single-round sequential | |

| Top-coal firmness coefficient (X2) | 1.8 | ||

| Interlayer and joint fissure (X3) | 0.4 | Caving ratio | 1.09 |

| Depth of embedment (X4) | 400 m | ||

| Roof lithology and thickness (X5) | 0.4 | Coal caving step | 0.78 m |

| Top-coal dip angle (X6) | 2° | ||

| Coal Caving Opening Number | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | Sum |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Coal quantity (kg) | 2.82 | 2.82 | 2.82 | 2.82 | 2.82 | 2.82 | 2.82 | 2.82 | 2.82 | 2.82 | 2.82 | 31.02 |

| Coal output (kg) | 2.83 | 2.45 | 2.43 | 2.44 | 2.37 | 2.38 | 2.32 | 2.45 | 2.32 | 2.44 | 2.42 | 26.85 |

| Gangue output (kg) | 0.11 | 0.2 | 0.21 | 0.05 | 0.12 | 0.1 | 0.03 | 0.02 | 0.03 | 0.08 | 0.12 | 1.07 |

| Top-coal recovery rate (%) | 100.35 | 86.88 | 86.17 | 86.52 | 84.04 | 84.40 | 82.27 | 86.88 | 82.27 | 86.52 | 85.82 | 86.56 |

| Gangue content (%) | 3.90 | 7.09 | 7.45 | 1.77 | 4.98 | 4.26 | 1.06 | 0.71 | 1.06 | 2.84 | 4.26 | 3.45 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liang, M.; Hu, C.; Yu, R.; Wang, L.; Zhao, B.; Xu, Z. Optimization of the Process Parameters of Fully Mechanized Top-Coal Caving in Thick-Seam Coal Using BP Neural Networks. Sustainability 2022, 14, 1340. https://doi.org/10.3390/su14031340

Liang M, Hu C, Yu R, Wang L, Zhao B, Xu Z. Optimization of the Process Parameters of Fully Mechanized Top-Coal Caving in Thick-Seam Coal Using BP Neural Networks. Sustainability. 2022; 14(3):1340. https://doi.org/10.3390/su14031340

Chicago/Turabian StyleLiang, Minfu, Chengjun Hu, Rui Yu, Lixin Wang, Baofu Zhao, and Ziyue Xu. 2022. "Optimization of the Process Parameters of Fully Mechanized Top-Coal Caving in Thick-Seam Coal Using BP Neural Networks" Sustainability 14, no. 3: 1340. https://doi.org/10.3390/su14031340

APA StyleLiang, M., Hu, C., Yu, R., Wang, L., Zhao, B., & Xu, Z. (2022). Optimization of the Process Parameters of Fully Mechanized Top-Coal Caving in Thick-Seam Coal Using BP Neural Networks. Sustainability, 14(3), 1340. https://doi.org/10.3390/su14031340