Abstract

The choice of an appropriate fuel can effectively prolong the refueling cycle of a reactor core. The Th-U cycle and U-Pu cycle are commonly used fuel breeding cycles. Oxide fuels, nitride fuels, and metal fuels are the primary candidate fuels for lead-based reactors. For fuel selection, a core model of a 60 MWt reactor was established. The results show that the breeding performance of the breeding fuel Th-232 is better than that of U-238, and the driving performance of the driving fuel Pu-239 is better than that of U-235. Therefore, PuO2-ThO2, PuN-ThN, and Pu-Th-Zr fuels may have good performance. By comparing the reactivity loss of three types of fuel, it was found that the reactivity loss of PuN-ThN fuel is the smallest. Hence, using PuN-ThN fuel as a core fuel can result in a longer refueling cycle. On this basis, PuN-ThN fuel was used in the preliminary design of the 120 MWt core physical model. It can be seen that when PuN-ThN fuel is used as the core fuel, a smaller reactivity swing (1408 pcm), smaller power peak factor, and super long refueling cycle (more than 30 years) can be obtained.

1. Introduction

Nuclear energy has the characteristics of extremely high power density, abundant resources, and zero carbon dioxide emissions [1]. Its emergence may be able to meet the needs of human beings for clean energy [2], and it is likely to become the major energy source for economic development in the future. As a new energy source, the rational use of nuclear energy is crucial to the sustainable development of the economy. At present, because little is known by the public about nuclear energy, often leading to panic, it is very important to encourage ordinary people to accept nuclear energy, which is a problem that should be solved on the road to popularizing nuclear energy [3,4]. Small reactors have several outstanding advantages: a short construction period and low construction cost; a smaller one-time investment fund; and high flexibility. Hence, research on small reactors has become popular. There are many candidate reactor types for small reactors, in which lead-based reactors are one of the most important candidates [5,6]. Due to their characteristics of inherent safety and good sustainability, they can be used not only in critical reactors, but also in subcritical reactors. Lead-based reactors can be used as excellent miniaturized high-power energy supply systems, which have critical applications in remote areas, ocean development, and the power supply of small grids [7,8,9]. In addition, they are the preferred technical solution for isotope production, thorium resource utilization, and seawater desalination.

Recently, comprehensive studies have been carried out on small lead-based reactors in Russia, China, and Japan. Furthermore, Russia already has relatively mature lead-based alloy technology, and has established lead–bismuth eutectic cooled reactors for nuclear submarines. Two typical small reactors in Russia are SVBR-100 (SVBR-100 is a lead–bismuth fast reactor with the equivalent electrical power of 100 MW), which is loaded with UO2 fuel, and BREST-300 (a 300 MWe lead-cooled fast reactor), which is loaded with U-Pu-N fuel. Both SVBR-100 and BREST-300 use lead–bismuth–eutectic (LBE) as the coolant [10,11]. The Japanese long-life, safe, simple, small, portable, proliferation-resistant reactor (LSPR) has a refueling cycle of 4200 days, and the reactor core is loaded with nitride fuels [12]. The Institute of Nuclear Energy Safety Technology proposed the conceptual design of a small modular lead–bismuth reactor with a refueling cycle of 10 years. Korea proposed the concept of a 100 MWt small modular reactor, which is a pooled fast reactor with an array of heterogeneous hexagonal cores using UO2 fuels, and with a 20-year refueling interval, without assembly reconfiguration [13]. In addition, many researchers have also studied the fuel loaded in the core of small lead-cooled reactors. Gao Yucai et al. studied the physical characteristics of the small modular fast reactor core loaded with the U-Pu-Zr fuel. Studies have shown that the decay of Pu-241 has a non-negligible effect on the burn-up reactivity swing of low-power reactors loaded with U-Pu-Zr fuel [14]. Sitdikov et al. studied the effect of the combination of MOX fuel and different coolants on reactivity in small lead-cooled fast reactors under low-power operating conditions. The results show that the combination of MOX fuel and Pb-208 has better performance than that of MOX fuel and natural lead coolant. When MOX fuel is combined with Pb-208, the core has a larger initial keff so that the fuel loading can be reduced [15]. You-Peng Zhang et al. studied the effect of axial swelling of fuel on core safety. Studies have shown that for metal fuels and oxide fuels, when a little actinide is used as the driving fuel, the axial expansion of the fuel can provide enough negative feedback so that the fuel will not be damaged, making the reactor safer [16]. Bin Liu et al. studied the effect of actinides on core lifetime. The results show that when actinides are added to PuO2-UO2 fuel, Np-237, Am-241, and Am-243 will capture neutrons during irradiation to produce Pu-238, Am-242, and Am-244 with a larger fission cross-section, which can compensate for the reactivity loss caused by the consumption of core fuel, so that the refueling cycle can be increased [17]. When He Yuan et al. studied UN fuel, they found that UN fuel has swelling and thermal decomposition problems under high-temperature conditions. In response to this problem, they proposed an annular fuel design structure. The results show that the use of annular fuel design structure can effectively reduce the core temperature of the fuel, thereby solving not only the problem of fuel swelling, but also the problem of thermal decomposition [18]. Mum et al. found that when U-10Zr fuel is loaded in a small lead-cooled reactor, if there is an air gap between the fuel and the cladding, the fuel centerline temperature can be as high as 2351 K, at which point the fuel will melt. Therefore, when the core is loaded with U-10Zr fuel, the annular fuel design is selected, where the outer surface of the fuel is in contact with the inner surface of the cladding, thereby overcoming the thermal conduction problem of the fuel gap. [19] Cho et al. designed a small lead-cooled fast reactor loaded with U-10Zr fuel, and they wanted to increase the core life without increasing the fuel enrichment of the core. Studies have found that the core life can be effectively extended under the conditions of small P/D and thick reflector [20].

From the survey, it can be found that researchers have conducted extensive research on different types of fuels. It mainly includes the following aspects: (1) the effect of nuclide properties in fuel on core performance; (2) the effect of the combination of fuel and coolant on the core initial keff; (3) the effect of fuel swelling on core safety; (4) the effect of fuel structure on core characteristics; and (5) the effect of driving fuel on core life. However, previous studies were conducted on a single type of fuel and do not compare the performance of different types of fuel for a specific problem, especially the issue of the refueling cycle. For small nuclear reactors, prolonging the refueling cycle is an important issue because extending the refueling cycle can effectively increase the safety and economics of the reactor [21]. Therefore, from the perspective of the refueling cycle, this paper compares and analyzes the main neutronic properties of different types of fuels, hoping to select a fuel with a long life.

Small reactors have many applications, such as military nuclear power, seawater desalination, and power supply in remote areas, etc. [22,23,24]. When the size of the reactor is reduced to a certain extent, it can also be used on a large vehicle or ship to achieve mobility. The most typical of these are nuclear power reactors on nuclear-powered aircraft carriers and nuclear-powered submarines, and the sustained power provided by nuclear energy can increase their ability to continue navigation by orders of magnitude. However, in order to ensure nonproliferation and nuclear security, many small reactor concepts require no on-site refueling strategy and adopt cradle-to-grave fuel services [25]. In order to achieve safety while maximizing economics, we have to consider how to prolong the life of small reactors by as much as possible. Thus, how to extend the life of small reactors is a practical problem. It is of great engineering significance to conduct research in this respect. Based on this problem, this paper takes the core fuel as the research point, and compares and analyzes the burn-up, breeding characteristics, and physical parameters of U-Pu and Th-U cycle fuel, and oxide, nitride, and metal fuel. Finally, a fuel type that meets the requirements of long life and miniaturization is selected, which can provide some reference for the design of long-life small lead-based reactors.

The structure of this paper is as follows: Section 1 mainly describes the background of nuclear energy development, the research status of small lead-based reactors, and the significance of this study; in Section 2, the parameters of the core model for fuel selection are given; in Section 3, the results are analyzed, and a fuel suitable for small lead-based reactors is preliminarily selected; in Section 4, the selected core fuel is used in a more refined core to verify the universality of the selected fuel; and in Section 5, detailed conclusions and future research directions are given.

2. Core Model and Calculation Code

2.1. Core Model

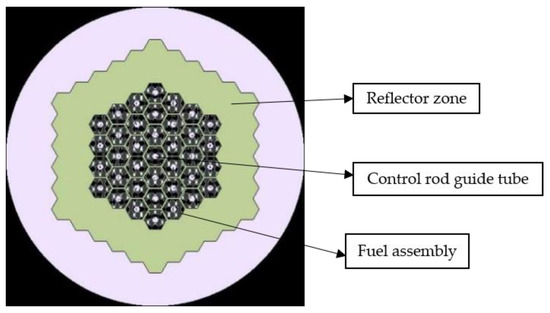

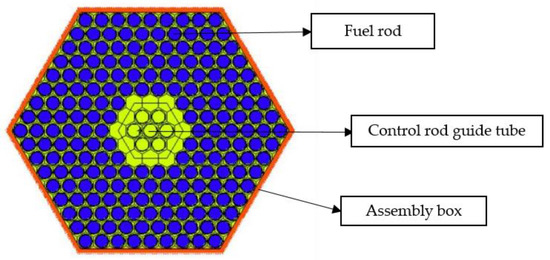

According to the engineering requirements for the selection and optimization of fuel for small lead-based reactors, this paper gives the main design parameters of the 60 MWt lead-cooled fast reactor (Table 1), referring to the EU-funded LEADER (Lead-cooled European advanced demonstration reactor) [26] and the Belgian closed hexagonal fuel assemblies [27]. The core is made of 37 fuel assemblies and 54 reflector assemblies, each of which is a hexagonal fuel assembly (control rod guide tubes are reserved in the middle). Each assembly contains 217 rod positions, of which 19 rod positions are reserved for control rod guide tubes. A total of 19 rod positions are reserved in the middle of each assembly, and they can be adjusted into different types of control assemblies according to different requirements, so that the initial excess reactivity of the core can be controlled. The active core height is 90 cm, and the equivalent core diameter is 107 cm. The x–y cross-sections of the assembly and the core are shown in Figure 1 and Figure 2. The fuel rod is composed of fuel pellets, air gaps, and cladding. Sufficient air gaps are left around the fuel rods to accommodate the released fission gas. The cladding is made of stainless steel. Using BeO as the reflector material can effectively reduce the leakage of neutrons and thus prolong the core life.

Table 1.

Design parameters of a 60 MWt lead-based reactor core.

Figure 1.

X–Y section of 60 MWt lead-based fast reactor core.

Figure 2.

Fuel assembly of the 60 MWt lead-based fast reactor.

2.2. Calculation Code

The calculation was carried out using OpenMC code developed by the Massachusetts Institute of Technology (MIT), based on the endfb7 database [28,29]. The OpenMC code is a continuous energy Monte Carlo reactor physical burn-up calculation code. The OpenMC code is exceptionally convenient in modeling and can perform burn-up calculations. Moreover, the format of the output results is very organized. For burn-up calculations, the burn step is set to 1 year. The high-temperature continuous point cross-section library was used in the calculation. The fuel, coolant, and cladding temperature were set to 1200 K, 600 K, and 900 K, respectively.

3. Fuel Selection

3.1. Selection of Breeding Fuels and Driving Fuels

By analyzing the research status of long-life lead-based reactors across the world, it is found that selecting the proper fuel type is very important to prolonging the life of the core. At present, the most commonly used fuels in the world include oxide fuels [30], nitride fuels [31], and metal fuels [32], and breeding strategies for fuel cycles in reactors mainly include the U-Pu cycle and Th-U cycle. Th-232 captures neutrons to produce U-233, which can realize the Th-U cycle; U-238 captures neutrons to produce Pu-239, which can realize the U-Pu cycle. Here, we select UO2, PuO2-ThO2, UO2-ThO2, and PuO2-UO2, for which the fuel densities are 10.36, 10.28, 10.28, and 10.28 g/cm3, respectively. This paper is to select fuel for small lead-cooled reactors, hoping to select an optimal fuel from the perspective of refueling cycle. The nuclide composition of the fuel has a great influence on the lifetime of the fuel. At present, the main breeding fuels are Th-232 and U-238, and the main driving fuels are Pu-239 and U-235. In this section, these nuclides are theoretically combined to obtain (U-235 + U-238), (U-235 + Th-232), (Pu-239 + U-235), and (Pu-239 + Th-232) combination. Oxide fuel was chosen for the type of fuel. By analyzing the properties of the four fuels, the driving fuel and breeding fuel with better performance can be obtained. On the basis of selecting the driving fuel and breeding fuel, the fuel type research can be carried out, which is the content of Section 3.2. In this section, these four fuels were selected for research, not to say that small lead-based reactors can only choose these four fuels. Oxide fuel, nitride fuel and metal fuel can all be used as fuel for small lead-cooled reactors, so it is also feasible to choose nitride fuel or metal fuel for research in this section. By selecting these four fuels in this section, the driving fuel and breeding fuel with better performance can be obtained and this is the purpose of research of this section. For these four fuels, the breeding fuel and driving fuel in each fuel are shown in Table 2. The mass fractions of four fuels are listed in Table 3. This paper is essentially a theoretical study, and many data adjustments are also theoretical adjustments. At present, there are some research foundations for lead-based reactors in the world. Some fuel composition data refer to the literature (such as Pu isotope content distribution). The fuel composition was adjusted on the basis of the literature to conduct own research. For example, the isotopes of Pu are related to each other, and the determination of the mass fraction of each nuclide is also an idealized study. When different fuels are used in the core, in order to facilitate the comparison, the initial core excess reactivity should be consistent, so that the Pu isotope fraction will be adjusted. If the initial core excess reactivity is too high, the proportion of fissile nuclides in Pu isotopes will be reduced at this time, and if the initial core excess reactivity is too low, the proportion of fissile nuclides in Pu isotopes will be increased at this time. This idea is also used for dynamic regulation of other nuclides. The range of adjustment should also refer to the actual needs of some projects. For example, in order to satisfy the requirement of non-proliferation, the content of U-235 should preferably not exceed 20% when conducting theoretical research [33,34,35].

Table 2.

Breeding fuel and driving fuel in each fuel.

Table 3.

Nuclear mass fraction of four fuels.

3.1.1. Comparison of Fuel Burn-Up Performance

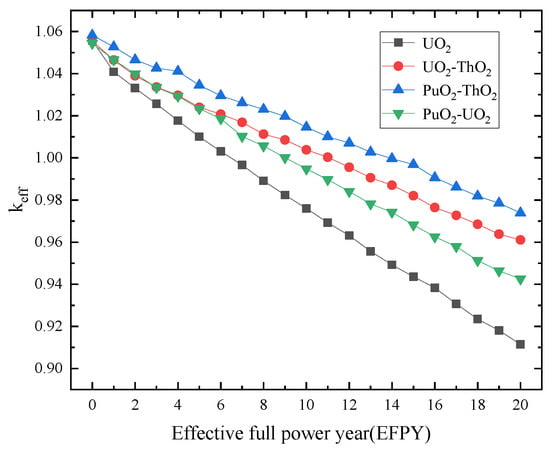

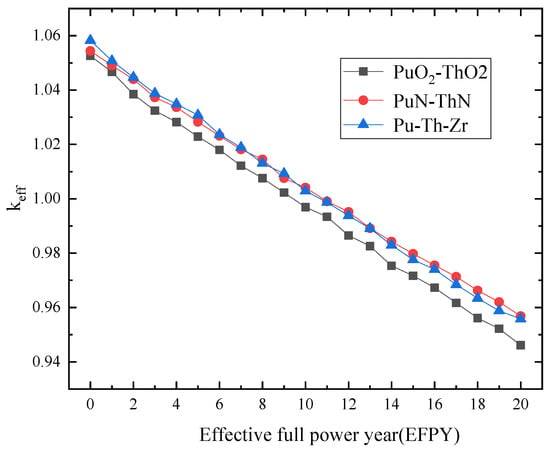

Keeping the initial excess reactivity and power density similar, and under specific energy spectrum conditions, the variation in keff with time for four kinds of fuels (UO2, PuO2-UO2, PuO2-ThO2, and UO2-ThO2) was analyzed during the full-power operation of the core for 20 years. As shown in Figure 3, under specific energy spectrum conditions (P/D is 1.3), the order of core discharge burn-up is PuO2-ThO2 > UO2-ThO2 > PuO2-UO2 > UO2, and the order of length of the core life is PuO2-ThO2 > UO2-ThO2 > PuO2-UO2 > UO2.

Figure 3.

Changes in effective multiplication factor during 20 years of full-power operation.

In order to quantitatively analyze the burn-up and breeding characteristics of the core, burn-up reactivity loss and burn-up reactivity swing are given as follows:

where keff (BOC) and keff (EOC) are the effective multiplication factor at the beginning and end of the core life.

where keff (max) and keff (min) are the maximum effective multiplication factor and the minimum effective multiplication factor during the core life, respectively.

In order to analyze the influence of the core energy spectrum on the core life, keeping the diameter of the fuel rod unchanged and obtaining different energy spectrum conditions by changing the size of P/D (1.13, 1.3, 1.4, 1.5, 1.6), the burn-up performance of four oxide fuels is calculated and analyzed under different energy spectrum conditions. With P/D increasing and the energy spectrum of core gradually softening, the core discharge burn-up of UO2 fuel remains unchanged, and the difference between the core discharge burn-up of PuO2-ThO2 and that of UO2-ThO2 gradually becomes smaller.

In addition, the fuel burn-up characteristics of the core under different energy spectrum conditions were quantitatively analyzed for each fuel. From Table 3, it can be seen that for UO2 fuel, the core keff varies little with the energy spectrum and the life of the reactor core does not change significantly. For breeding fuel PuO2-ThO2, the keff changes greatly with the energy spectrum and the core life is more significantly affected by the energy spectrum when the core is loaded with PuO2-ThO2 fuel.

From Table 4, it can also be seen that with the continuous increase in P/D, the core energy spectrum gradually softens, the fuel breeding performance gradually weakens, and the reactivity loss gradually increases. Among these effects, the reactivity loss of Th-based fuels varies significantly less with P/D than U-based fuels, indicating that Th-based fuels can achieve better breeding performance under softer energy spectrum conditions. Moreover, compared with U-235 as the driving fuel, the use of Pu-239 as the driving fuel can reduce the core reactivity loss. Therefore, in the case of five different P/D, when using PuO2-ThO2 as the core fuel, the core reactivity loss is minimal (not more than 10,100 pcm), therefore obtaining a longer core life than the other two oxide fuels.

Table 4.

Burn-Up reactivity loss of four oxide fuels under different energy spectrum conditions.

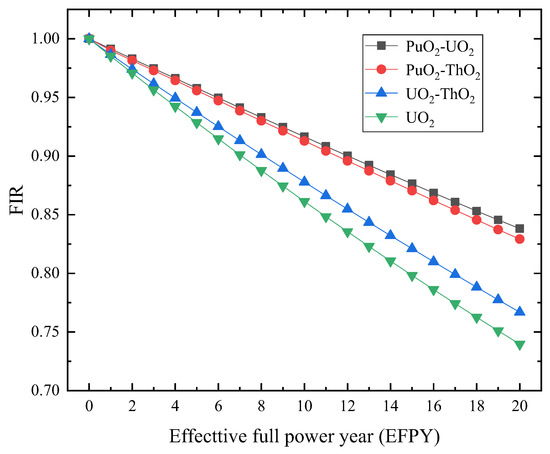

In order to further analyze the change in fissile nuclides in the reactor, this paper calculates the fissile nuclide inventory ratio of the reactor core, which is defined as follows:

where Nfissile nuclide is the amount of fissile nuclide in the reactor during operation; Nfissile nuclide(0) is the amount of fissile nuclide in the beginning of the core life; U-233, U-235, Pu-239, and Pu-241 are included when we consider the fissile inventory. This is a very effective method to compare the fission and breeding properties of the two cycles by detecting FIR.

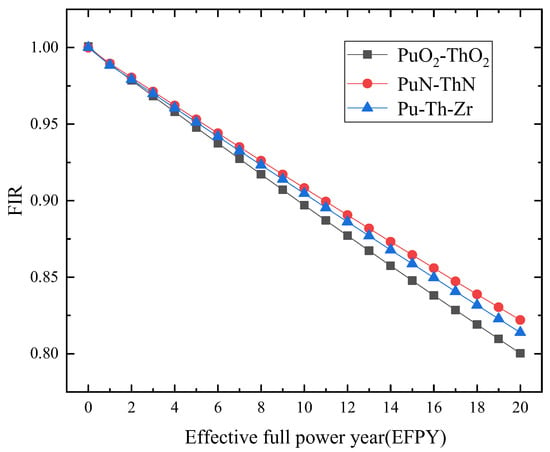

As shown in Figure 4, the order of FIR with core operation time for the four fuels analyzed is PuO2-UO2 > PuO2-ThO2 > UO2-ThO2 > UO2.

Figure 4.

Change in the FIR of four fuels with time.

The keff changes in each fuel are different, mainly because the properties of the heavy metal elements are different. In response to this problem, the microscopic cross-sectional data of Th, U, and Pu in different energy regions were searched. The specific data are shown in Table 5. The fuel burn-up performance of four fuels was compared, and the results show that under the same initial conditions, the keff of UO2 fuel decreased faster with the deepening of burn-up and the fuel burn-up reactivity loss was large, while the keff of PuO2-ThO2 fuel decreased relatively slowly and the fuel burn-up reactivity loss was relatively small. There are three main reasons for the above: (1) it can be seen from Table 5 that the effective fission neutron numbers of U-233, U-235, and Pu-239 in the fast spectrum region are 2.5, 2.3, and 2.9, with the effective fission neutron number of U-233 being slightly smaller than that of Pu-239, but the fission cross-section of U-233 in the medium- and high-energy region is much larger than that of Pu-239, such that U-233 can produce more neutrons; (2) the capture cross-section of Th-232 in the fast spectrum region is larger than that of U-238, and the fission cross-section is relatively small, such that Th-232 can produce more fission nuclides; (3) the fission cross-section of Pu-239 is slightly smaller than that of U-235, but its effective fission neutron number is much larger than that of U-235, so when Pu-239 is used as the driving fuel, fission nuclides are more prone to fission, producing more neutrons. Because the driving fuel and breeding fuel of UO2 are U-235 and U-238, the driving fuel and breeding fuel of PuO2-ThO2 fuel are Pu-239 and Th-232, respectively. Hence, the keff of UO2 fuel decreases faster, while the keff of PuO2-ThO2 fuel decreases relatively slowly. The change in keff of the other two fuels can also be explained by the above reasons.

Table 5.

Microscopic cross-section and effective fission neutron number of Th, U, and Pu nuclides.

The FIR is based on the densities of the fission nuclides U-233, U-235, Pu-239, and Pu-241. Since U-233 is more prone to fission than Pu-239, this is why PuO2-ThO2 has better breeding performance than PuO2-UO2, but PuO2-UO2 has a larger FIR; however, for UO2-ThO2 and UO2 fuels, because U-233 is more prone to fission, the FIR of UO2 fuel is larger theoretically, but the FIR of UO2 fuel is smaller than the value of UO2-ThO2. The following are the two main reasons for this: (1) the driving performance of U-235 is weaker, so the probability of causing a fission reaction in the fuel is small and the consumption of U-233 becomes slow; (2) Th-232 has a stronger breeding performance than U-238, producing more fission nuclides. Hence, the FIR of UO2 fuel is smaller than the FIR of UO2-ThO2 fuel.

3.1.2. Neutron Dynamics Parameter Analysis

The average life of delayed neutrons is approximately 13 s, which is orders of magnitude longer than the average life of prompt neutrons. Delayed neutrons extend the average life of neutrons, thereby prolonging the period of the reactor and making it possible to control the reactor. Because delayed neutrons play an essential role in reactor safety and control, the fractions of the delayed neutrons of four fuels were compared. In Table 6, the fractions of delayed neutrons of four fuels are given. The results presented in Table 6 are obtained based on the burned fuel rather than fresh fuel, and EFPY (effective full power year) for the burned fuel is 20 years. By analyzing Table 6, it can be found that the fraction of delayed neutrons of PuO2-ThO2 fuel is small (less than 0.3%), so higher requirements are placed on reactivity control and the design of control rod systems.

Table 6.

The fraction of delayed neutrons of four fuels.

The delayed neutron fraction is only related to the type of fission element; however, it can be found that the delayed neutron fraction changes with P/D. For a single U-233 fission nuclide, its delayed neutron fraction does not change with P/D. However, UO2 fuel contains fissile nuclides such as U-235, Pu-239, and Pu-241, not just U-235, and the delayed neutron fraction of Pu-239 is much smaller than the delayed neutron fraction of U-235. If the content of each nuclide in UO2 fuel changes, the final delayed neutron fraction will also change. The delayed neutron fraction given in the paper is the result of a mixture of several fission nuclides. This reason provides a good explanation of why the delayed neutron fraction varies with P/D, because when P/D changes, the initial excess reactivity will also change, but in order to make the initial excess reactivity the same under different P/D conditions, it is necessary to adjust the relative content of fission nuclides in the fuel so that the final delayed neutron fraction will change. Since each adjustment’s magnitude is minimal, the difference in the delayed neutron fraction under different P/D conditions is also very tiny. Different types of fuel contain different fission elements, but the main fission elements are U-233, U-235, Pu-239, and Pu-241. The delayed neutron fraction of U-233, U-235, Pu-239, and Pu-241 are measured to be 0.309%, 0.65%, 0.195%, and 0.554%, respectively. The main fission elements of the four fuels are shown in Table 7, and by analyzing the data in Table 7, it is easy to explain why different types of fuel have different shares of delayed neutrons. Among them, UO2 fuel has the largest delayed neutron fraction, and PuO2-ThO2 has the smallest delayed neutron fraction.

Table 7.

Fission elements of four fuels.

3.1.3. Physical Parameters of Three Fuels

The important physical parameters of PuO2, UO2, and ThO2 are listed in Table 8. Analyzing the data in Table 8 shows the following rules: (1) ThO2 fuel has better thermal properties because it has a higher melting point and thermal conductivity than the other two fuels; (2) ThO2 fuel has more stable chemical properties under high irradiation than UO2 fuel; (3) among the three fuels, the thermal expansion coefficient of ThO2 is the smallest, which enhances the storage capacity of its fission products, so it is very suitable for high-burn-up fuel; (4) Th-based fuel produces fewer ultra-uranium nuclides, thereby reducing the difficulty of nuclear waste disposal and preventing nuclear proliferation; and (5) PuO2, UO2, and ThO2 fuels have similar mechanical and thermal properties, so they can be well compatible and form a mixture of fissile and fertile materials.

Table 8.

Physical Parameters of Three Fuels.

In addition to the above advantages, Th-based fuels also have some disadvantages: (1) the fraction of delayed neutrons for PuO2-ThO2 fuels is small (below 0.3%), which poses significant challenges for reactor control; and (2) the most critical nuclide in the conversion of thorium–uranium is Pa-233, which has a large neutron absorption cross-section and a long half-life of 27.4 days. During the full-power operation and shutdown of the reactor, changes in the number of nuclides in Pa-233 and U-233 can cause a giant reactivity swing in the reactor core, which will cause some difficulties for the fuel reprocessing of the reactor.

In summary, there are many advantages to using Th-based fuels in the design of a long-life natural cycle reactor. Compared with U-based fuels, Th-based fuels have better breeding performance, so the Th-U cycle is selected as the breeding cycle. In the case of a hard energy spectrum, when using Pu-239 as the driving fuel compared with U-235 as the driving fuel, the reactivity loss will be reduced by approximately 1500 pcm. However, it is necessary to overcome the ineffective absorption of neutrons in the core and reduce the leakage of neutrons to improve the initial keff of the core, while controlling the reactivity swing caused by Pa-233. Therefore, PuO2-ThO2 fuel was selected as the core fuel for the next research step.

3.2. Selection of Oxide Fuels, Nitride Fuels, and Metal Fuels

The calculations in the previous section show that the breeding performance of the Th-U cycle is better than that of the U-Pu cycle for the small lead-based reactor. Based on the selection of the Th-U cycle, the fuel type is now selected. Different fuels have different physical properties, corrosion resistance of lead/lead–bismuth, and chemical properties. When the lead-based fast reactor is loaded with different fuel types, the loading capacity, fuel burn-up characteristics, and reactivity of the fuel are all quite different, resulting in significant differences in the physical and thermal safety performance of the reactor. Therefore, it is necessary to conduct research and analysis. At present, there are two main types of fast reactor fuel in the world: oxide and nitride ceramic fuels, and metal fuels. In this section, PuO2-ThO2, PuN-ThN, and Pu-Th-Zr fuels are selected, and their physical properties, fuel burn-up and breeding properties, and the fraction of delayed neutrons are analyzed and compared so that the performance of different types of fuel can be evaluated.

3.2.1. Parameter Comparison of Three Types of Fuel

The material properties of three types of fuel are listed in Table 9. The most widely used and mature fuel is oxide ceramic fuel, which was one of the earliest fuels used in lead-based fast reactors. Nitride ceramic fuels have the highest melting point and thermal conductivity, as well as better thermal safety characteristics and solubility of nitric acid, such that nitride fuels are recognized as good accident-resistant fuels. However, there is a lack of manufacturing experience in N purification technology, and it is currently in the research stage. Metal fuels have good thermal conductivity and corrosion resistance. The harder neutron spectrum can be obtained using metal fuel in the core. However, metal fuels have a low melting point and poor radiation stability. Moreover, highly enriched uranium is needed, which is not conducive to preventing nuclear proliferation.

Table 9.

Material properties of 3 types of fuel.

3.2.2. Comparison of Burn-Up and Breeding Performance

Figure 5 shows the reactivity loss of three types of fuel over 20 years at full core power. The order of the reactivity loss is Pu-Th-Zr > PuO2-ThO2 > PuN-ThN. There are two main reasons for the smallest reactivity loss when PuN-ThN fuel is used as core fuel: (1) PuN-ThN fuel has a higher effective density, a larger nuclear fuel loading, and a relatively small specific power; and (2) PuN-ThN fuel has relatively high proportion of heavy metals, which reduces the ineffective neutron absorption and improves the neutron economics. Figure 6 shows the variation in the FIR of three fuels with running time, and the order of FIR is as follows: PuN-ThN > Pu-Th-Zr > PuO2-ThO2. At the end of life, the decrease in FIR of Pu-Th-Zr is also tiny, mainly due to the high fuel density, low core-specific power, and hard energy spectrum, so that more fissile nuclides can be retained in the core.

Figure 5.

Burn-up reactivity loss of different types of fuel.

Figure 6.

Changes in the FIR of different types of fuel with time.

When using PuN-ThN fuel as core fuel, the reactivity loss and FIR calculation results are better than the other two fuels. It can be seen that using PuN-ThN fuel as core fuel can obtain a longer life. However, when PuN-ThN fuel is used as core fuel, the fraction of delayed neutrons is only 0.266%, which needs to be considered in the design of the control rod system in the future. Pu-Th-Zr and PuO2-ThO2 have delayed neutron fractions of 0.265% and 0.266%, respectively, which are almost the same as the delayed neutron fraction of PuN-ThN. Because the fissile elements of the three fuels are identical, the results are almost the same.

The above results indicate, for lead-based reactors, that the breeding performance of Th-232 is better than that of U-238, while the neutron economy of Pu-239 is better than that of U-235, so when the core is loaded with PuO2-ThO2, PuN-ThN, and Pu-Th-Zr, it can obtain relatively small reactivity loss and obtain a long core refueling cycle. At the same time, by comparing the reactivity loss of the three fuels, in the case of similar initial excess reactivity (the initial reactivity is about 1.05), the reactivity loss of PuN-ThN fuel is the smallest (only 9700 pcm) when the core operates at full power for 20 years and the core can obtain the longest life when loaded with PuN-ThN fuel. Compared with O and Zr elements, the N element has smaller neutron absorption cross-section in the fast spectrum and less harmful absorption for neutrons, which improves the neutron economy. At the same time, due to the high density, high melting point, and good thermal conductivity of nitride fuel, it is one of the most important candidates for the core fuel of future long life lead–bismuth reactors.

4. Application and Validation of PuN-ThN Fuel

From the comparative analysis of different fuels in Section 3, it can be seen that a relatively small reactivity loss and long core refueling cycle can be obtained when PuN-ThN fuel is loaded into the core. In order to verify the universality of PuN-ThN fuel as a candidate fuel, PuN-ThN fuel is used in the preliminary physical design of the 120 MWt lead-bismuth reactor core. In this section, the criteria and requirements for the preliminary physical design of the 120 MWt long-life lead–bismuth reactor core and the core layout scheme are first given, and then, the performance of PuN-ThN fuel is further evaluated from the perspective of core neutronics.

4.1. Design Goals and Constraints

The core physical design meets the following design goals and limitations:

- It adopts the core arrangement of 61 assemblies, the assembly size is the same as that in Section 2, and the height of the active zone is 150 cm;

- The reactor is required to produce 120 MWt;

- The core refueling cycle shall be longer than 30 years;

- The core is loaded with PuN-ThN fuel;

- The reactivity swing is less than 2000 pcm during the entire cycle;

- The assembly radial power peak factor is less than 1.4.

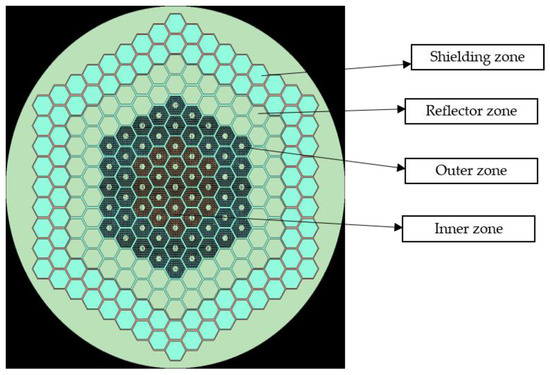

4.2. Core Scheme

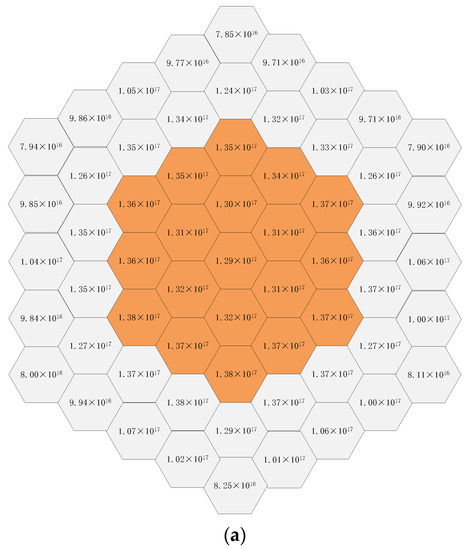

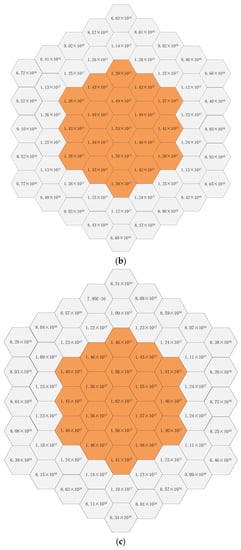

Based on the 60 MWt lead–bismuth reactor core scheme in Section 2, the preliminary design of the 120 MWt lead–bismuth reactor core scheme is carried out. The reactor core consists of 61 fuel assemblies, each of which is a hexagonal fuel assembly (with a control rod guide in the middle). Each assembly contains 217 rod positions, and the 19 rod positions in the center part of the assembly are reserved for control rod guide tubes. The overall structure and dimensions of the fuel assembly are consistent with the 60 MWt core scheme, but the height of the active zone is 150 cm and the equivalent diameter of the active zone of the core is 172.2 cm. The core layout is shown in Figure 7. The parameters of the inner and outer zone fuels are listed in Table 10.

Figure 7.

The 120 MWt core arrangement.

Table 10.

The parameters of the core fuel.

4.3. Computational Analysis of Core Neutronics

Under the design criteria and requirements in Section 4.1, one year is taken as a burn-up step to calculate the change in core excess reactivity with time, the change in core fissile nuclide inventory ratio with time, and the change in nuclide density with time. The results of power distributions and flux distributions at the beginning (0 a), middle (16 a), and end (32 a) of cycles (BOC, MOC, and EOC) are given.

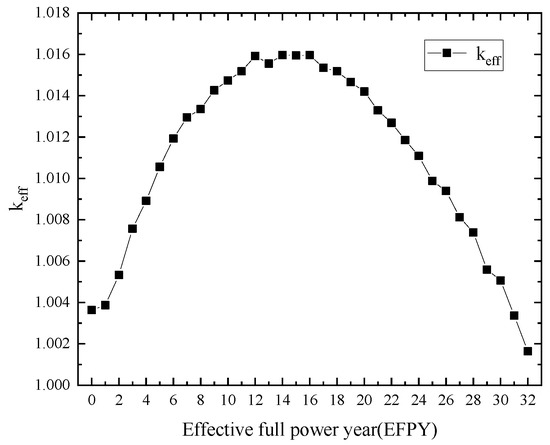

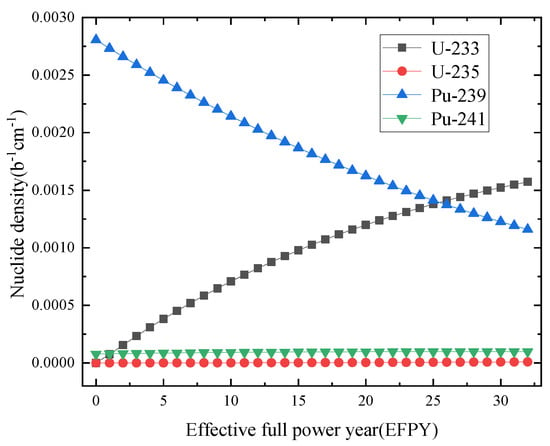

Figure 8 shows the change in the excess reactivity with time during the 32-year operation of the core. The initial reactivity of the core is 1.00363, and it can be seen from Figure 9 that the fissile nuclides Pu-239 and Pu-241 in the fuel are continuously consumed, but the Th-232 nuclide continues to multiply to produce fissile nuclide U-233. Because U-233 has a larger fission cross-section and more neutrons can be produced by U-233 fission, the excess reactivity of the core reaches a maximum of 1.01597 when it has been running for 14 years. As can be seen in Figure 8, although keff increased gradually in the early stages of reactor operation, the keff increased very slowly in the first year, mainly due to the influence of Pa-233. In the Th-U cycle, Pa-233 is the most important intermediate nuclide in the conversion process, in which the absorption cross-section is very large and the half-life is as long as 27.4 d. Since then, the Pa-233 content has reached saturation and the excess reactivity of the core increased rapidly. After 14 years, the excess reactivity of the core gradually decreased, and keff reached a minimum of 1.00164 when operating for 32 years. The main reasons for the decline in keff are as follows: (1) Pa-233 is still absorbing neutrons during the burn-up process; and (2) due to the gradual decrease in the content of Th-232 in the burn-up process, the content of U-233 produced is far from able to make up for the consumption of fissile nuclides.

Figure 8.

The change in core excess reactivity with time.

Figure 9.

The change in nuclide density with time.

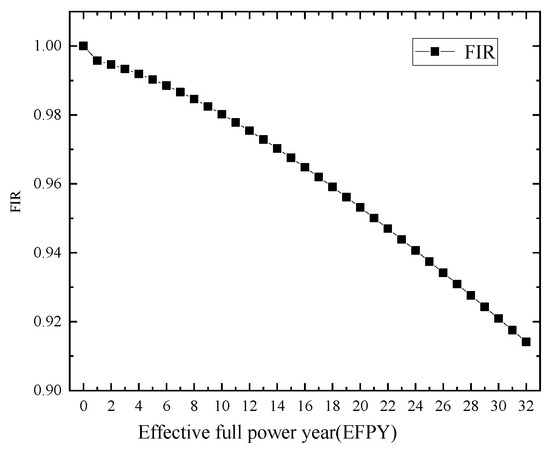

The fissile nuclides considered here are U-233, U-235, Pu-239, and Pu-241. First of all, it can be seen in Figure 9 that the Pu-239 nuclide will gradually decrease due to fission, and the stock of U-233 nuclide produced after Th-232 captures the neutron will continue to increase. At the same time, Pu-240 produces Pu-241 due to the capture of neutrons. Thus, the stock of Pu-241 nuclides increases slightly, but the overall number is minimal; the content of U-235 throughout the fuel burn-up process is very small, and the effect on the core excess reactivity is also small. In the previous 14 years, due to the high content of Th-232, the stock of U-233 nuclides increased rapidly, which gradually increased the core excess reactivity. Subsequently, due to the gradual decrease in the content of Th-232, the content of U-233 produced is far from able to make up for the consumption of fissile nuclides, so the core excess reactivity gradually decreases. However, throughout the burn-up process, the content of fissile nuclides gradually decreases relative to the content of the original breeding nuclides. Therefore, in Figure 8, it can be seen that the core excess reactivity gradually increases in the first 14 years, and then gradually decreases; in Figure 10, it can be seen that the stock of fissile nuclides in the reactor core decreased more slowly in the first 14 years, and the nuclide content in the reactor core decreased more rapidly after 14 years. Therefore, the problems reflected in Figure 8 and Figure 9 are consistent, so there is no conflict.

Figure 10.

The change in core fissile nuclide inventory with time.

At the same time, in the case that the thermal power of the core is 120 MWt, the volume power density of the core is 34.36 MW/m3 and the average line power density is 6.63 KW/m, the power distribution and the flux distribution of the core at the BOC, MOC, and EOC are calculated.

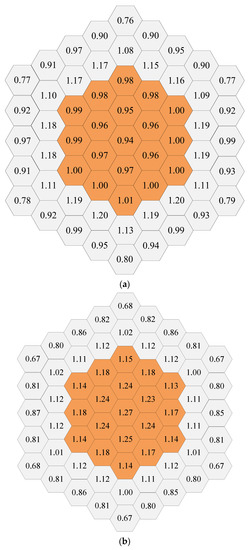

Figure 11 shows the radial power distribution of the core at the BOC, MOC, and EOC during the 32-year operation of the core, corresponding to the power peak factors of 1.20, 1.27, and 1.35, respectively. The dark zone is the inner zone and the light zone is the outer zone. Due to the high enrichment of fuel in the inner zone, it has a stronger breeding capacity. With the deepening of the burn-up degree, the inner core fissile nuclide inventory gradually increases, so the power gradually increases. Conversely, the power of the fuel assembly in the outer zone is gradually reduced. At the EOC, the maximum power peak factor gradually migrates to the central core assembly until it reaches the most central fuel assembly. The assembly radial power peak factor is less than 1.4 throughout the refueling cycle, meeting the design requirements.

Figure 11.

(a) Power distribution at BOC; (b) power distribution at MOC; and (c) power distribution at EOC.

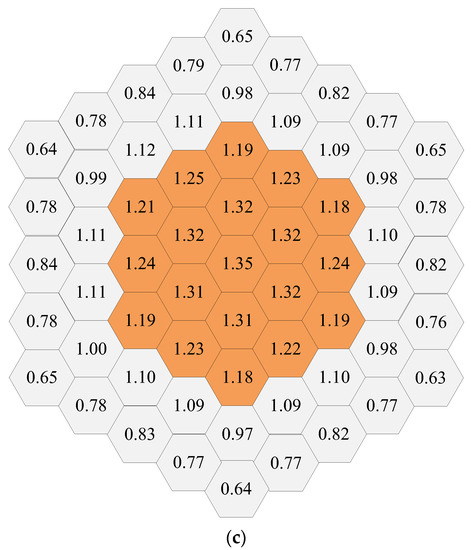

Figure 12 shows the radial flux distribution of the core at the BOC, MOC, and EOC during the 32-year operation of the core. The data of power distribution and flux distribution are interrelated, and the trend of change is the same, which more strongly illustrates the real situation regarding core operation.

Figure 12.

(a) Flux distribution at BOC; (b) flux distribution at MOC; and (c) flux distribution at EOC.

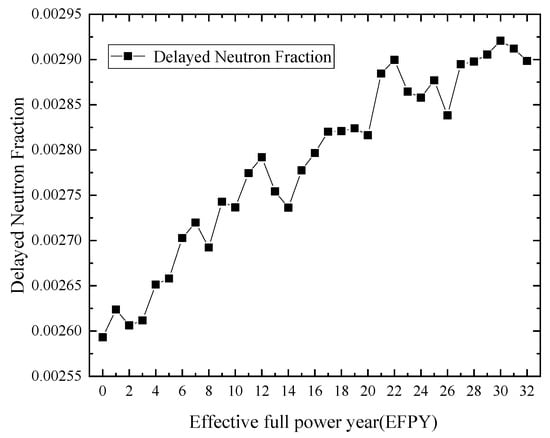

Figure 13 shows the change in the fraction of delayed neutrons over time. At the beginning of the cycle, the driving fuel is mainly Pu-239, and its fraction of delayed neutrons is relatively low. With the deepening of the core fuel burn-up, Th-232 continues to multiply to produce U-233, and the fraction of delayed neutrons in the reactor core gradually increases. However, the same problems can be found, with a lower share of slow-hair neutrons (less than 0.3%), making the reactivity control and design of control rod systems more difficult.

Figure 13.

The change in the fraction of delayed neutrons with time.

5. Conclusions

In this paper, much work has been carried out on fuel selection for a lead-based reactor, including the following steps: (1) In order to select a core fuel, a 60 MWt core model was first designed, and 19 rod positions were reserved in the middle of core assembly, which could be adjusted to different control assemblies for subsequent research as required. (2) Based on the 60 MWt core model, the fuel selection was carried out, and the most suitable core fuel for the lead-based reactor was finally selected. (3) A 120 MWt reactor model was designed, and the selected fuel was used in this reactor model, with the results being in line with expectations. In the following section, detailed conclusions will be elaborated.

For a lead-based reactor, the breeding performance of the breeding fuel Th-232 is better than that of U-238, while the neutron economy of the driving fuel Pu-239 is better than that of U-235, such that the reactor can obtain a relatively small reactivity loss (in the case of a soft spectrum, the reactivity loss is below 10,100 pcm), and a longer core refueling cycle can be obtained when the core is loaded with PuO2-ThO2, PuN-ThN, and Pu-Th-Zr. On the basis of the selection of breeding fuel and driving fuel, the selection of fuel types was carried out. By comparing the reactivity loss of PuO2-ThO2, PuN-ThN, and Pu-Th-Zr, when the initial excess reactivity is similar, the reactivity loss of PuN-ThN fuel is the smallest (when the energy spectrum is relatively soft, it is only 9700 pcm). The above results are due to the fact that the neutron absorption cross-section of N in the fast spectrum region is smaller than that of O and Zr, which is less harmful to neutron absorption and improves the neutron economy. Finally, a 120 MWt core physical model was designed using PuN-ThN fuel as the core fuel. Through the analysis, it can be seen that when PuN-ThN fuel is used as the core fuel, a smaller reactivity swing (1408 pcm) and smaller power peak factor (all less than 1.4) can be obtained, in addition to a super long refueling cycle (more than 30 years). This is a more powerful explanation of the reasonableness of PuN-ThN fuel as a candidate fuel for lead-based reactors.

Nitride fuel has the characteristics of high density, high melting point, good thermal conductivity, and good neutron economy. Therefore, using nitride fuels as the core fuel is a continuing trend in the design of core fuels for long-life lead-based reactors worldwide. The rational use of reactor core fuel is of great significance for the sustainable development of energy, so the research in this paper can be used as a reference for future research on lead-based reactors.

In this paper, a fuel suitable for small lead-based reactors is selected, and the performance of the selected fuel is verified. When the selected fuel is used in the core, it is necessary to consider the control of the reactivity of the reactor during operation, so the design of the control rod will be studied in the future.

Author Contributions

Conceptualization, G.H. and C.Y.; Methodology, G.H. and Z.C.; Software, Z.C.; Validation, G.H., J.L. and C.Y.; Formal Analysis, J.L.; Investigation, G.H.; Resources, C.Y.; Data Curation, J.L.; Writing-Original Draft Preparation, G.H.; Writing-Review & Editing, G.H.; Visualization, L.S.; Supervision, Z.C. and T.Y.; Project Administration, Z.C.; Funding Acquisition, Z.C. and T.Y. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Hunan Province Science and Technology Talent Support Project (2020TJ-N02), the National Natural Science Foundation of China (Grant No.12175101 and 12105136), Scientific Research Fund of Hunan Provincial Education Department (Grant No.19A422 and 18C0414), the Science and Technology innovation Program of Hunan Province (Grant No.2020RC4053) and Postgraduate Scientific Research Innovation Project of Hunan Province (CX20220970).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

We thank all the teachers in the NEAL group of the School of Nuclear Science and Technology of USC for their guidance and the students for their help.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Clulow, Z.; Reiner, D.M. Democracy, Economic Development and Low-Carbon Energy: When and Why Does Democratization Promote Energy Transition? Sustainability 2022, 14, 13213. [Google Scholar] [CrossRef]

- Allen, T.R.; Crawford, D.C. Lead-cooled fast reactor systems and the fuels and materials challenges. Sci. Technol. Nucl. Install. 2007, 2007, 097486. [Google Scholar] [CrossRef]

- Drace, Z.; Ojovan, M.I.; Samanta, S.K. Challenges in Planning of Integrated Nuclear Waste Management. Sustainability 2022, 14, 14204. [Google Scholar] [CrossRef]

- Yang, J.; Wang, J.; Zhang, X.; Shen, C.; Shao, Z. How Social Impressions Affect Public Acceptance of Nuclear Energy: A Case Study in China. Sustainability 2022, 14, 11190. [Google Scholar] [CrossRef]

- Wei, S.; Sun, H.; Wang, C.; Chen, R.; Tian, W.; Qiu, S.; Su, G.H. Neutronic/thermal-hydraulic design features of an improved lead-bismuth cooled small modular fast reactor. Int. J. Energy Res. 2019, 43, 3794–3805. [Google Scholar] [CrossRef]

- Wang, C.; Sun, H.; Tang, S.; Tian, W.; Qiu, S.; Su, G. Thermal-hydraulic analysis of a new conceptual heat pipe cooled small nuclear reactor system. Nucl. Eng. Technol. 2020, 52, 19–26. [Google Scholar] [CrossRef]

- Wei, S.; Wang, C.; Tian, W.; Qiu, S.; Su, G. Transient thermal-hydraulic evaluation of lead-bismuth fast reactor by coupling sub-channel and system analysis codes. Nucl. Eng. Des. 2018, 337, 228–235. [Google Scholar] [CrossRef]

- Nguyen, T.D.C.; Khandaq, M.F.; Jeong, E.; Choe, J.; Lee, D.; Fynan, D.A. MicroURANUS: Core design for long-cycle lead-bismuth-cooled fast reactor for marine applications. Int. J. Energy Res. 2021, 45, 12426–12448. [Google Scholar] [CrossRef]

- Kwak, J.; Kim, H.R. Modelling and analysis of extra vessel electro magnetic pump for a small modular lead-bismuth fast reactor. Ann. Nucl. Energy 2021, 152, 107979. [Google Scholar] [CrossRef]

- Toshinsky, G.; Petrochenko, V. Modular lead-bismuth fast reactors in nuclear power. Sustainability 2012, 4, 2293–2316. [Google Scholar] [CrossRef]

- Hartanto, D.; Heo, W.; Kim, C.; Kim, Y. Impacts of burn-up-dependent swelling of metallic fuel on the performance of a compact breed-and-burn fast reactor. Nucl. Eng. Technol. 2016, 48, 330–338. [Google Scholar] [CrossRef][Green Version]

- Ueda, N.; Kinoshita, I.; Minato, A.; Kasai, S.; Yokoyama, T.; Maruyama, S. Sodium cooled small fast long-life reactor “4S”. Prog. Nucl. Energy 2005, 47, 222–230. [Google Scholar] [CrossRef]

- Shin, Y.H.; Choi, S.; Cho, J.; Kim, J.H.; Hwang, S., II. Advanced passive design of small modular reactor cooled by heavy liquid metal natural circulation. Prog. Nucl. Energy 2015, 83, 433–442. [Google Scholar] [CrossRef]

- Gao, Y.; Cao, L.; Yang, Y.; Zhao, Z.; Zhou, S.; Wang, S. Physical study of an ultra-long-life small modular fast reactor loaded with U-Pu-Zr fuel. Ann. Nucl. Energy 2020, 142, 107390. [Google Scholar] [CrossRef]

- Sitdikov, E.R.; Terekhova, A.M. Low-power lead-cooled fast reactor loaded with MOX-fuel. J. Phys. Conf. Ser. 2017, 781, 012007. [Google Scholar] [CrossRef]

- Zhang, Y.P.; Wallenius, J.; Gu, L.; Yang, S.; Zhao, Y.Y.; Li, J.Y.; Peng, T.J. Axial expansion for prompt safety of a small lead-cooled reactor. Ann. Nucl. Energy 2020, 147, 107733. [Google Scholar] [CrossRef]

- Liu, B.; Han, J.; Liu, F.; Sheng, J.; Li, Z. Minor actinide transmutation in the lead-cooled fast reactor. Prog. Nucl. Energy 2020, 119, 103148. [Google Scholar] [CrossRef]

- Yuan, H.; Wang, G.; Yu, R.; Tao, Y.; Wang, Z.; Guo, S.; Liu, W.; Yun, D.; Gu, L. Lead-Cooled Fast Reactor Annular UN Fuel Design and Development of Performance Analysis Program. Front. Energy Res. 2021, 9, 400. [Google Scholar] [CrossRef]

- Mum, J.W.; Kin, H.J.; Sweidan, F.B. Metallic fuel performance evaluation for micro lead cooled fast reactor. In Proceedings of the Transactions of the Korean Nuclear Society Virtual Spring Meeting, Seoul, Republic of Korea, 9–10 July 2020. [Google Scholar]

- Cho, Y.Y.; Hong, S.G. Neutronic analysis of an ultra long cycle vSMLFR (very small modular lead-cooled fast reactor). In Proceedings of the Transactions of the Korean Nuclear Society Virtual Autumn Meeting, Seoul, Republic of Korea, 21–22 October 2021. [Google Scholar]

- Mignacca, B.; Locatelli, G. Economics and finance of Small Modular Reactors: A systematic review and research agenda. Renew. Sustain. Energy Rev. 2020, 118, 109519. [Google Scholar] [CrossRef]

- Lyons, R.E.; Roulstone, A.R.M. Production learning in a small modular reactor supply chain. In Proceedings of the 2018 International Congress on Advances in Nuclear Power Plants, Charlotte, NC, USA, 8–11 April 2018. [Google Scholar]

- Herring, S.J.; Mackwell, S.; Pestak, C.; Hilser, K. Small modular fission reactors for space applications. In Proceedings of the Nuclear and Emerging Technologies for Space, American Nuclear Society Topical Meeting, Richland, WA, USA, 25–28 February 2019. [Google Scholar]

- Daniel, N.; Kim, J. A study on integrating SMRs into Uganda’s future energy system. Sustainability 2022, 14, 10033. [Google Scholar] [CrossRef]

- Wallenius, J.; Bortot, S. A small lead-cooled reactor with improved Am-burning and non-proliferation characteristics. Ann. Nucl. Energy 2018, 122, 193–200. [Google Scholar] [CrossRef]

- Grasso, G.; Petrovich, C.; Mattioli, D.; Artioli, C.; Sciora, P.; Gugiu, D.; Bandini, G.; Bubelis, E.; Mikityuk, K. The core design of ALFRED, a demonstrator for the European lead-cooled reactors. Nucl. Eng. Des. 2014, 278, 287–301. [Google Scholar] [CrossRef]

- Sobolev, V.; Malambu, E.; Abderrahim, H.A. Design of a fuel element for a lead-cooled fast reactor. J. Nucl. Mater. 2009, 385, 392–399. [Google Scholar] [CrossRef]

- Romano, P.K.; Forget, B. The OpenMC monte carlo particle transport code. Ann. Nucl. Energy 2013, 51, 274–281. [Google Scholar] [CrossRef]

- Romano, P.K.; Horelik, N.E.; Herman, B.R.; Nelson, A.G.; Forget, B.; Smith, K. OpenMC: A state-of-the-art Monte Carlo code for research and development. Ann. Nucl. Energy 2015, 82, 90–97. [Google Scholar] [CrossRef]

- Burkes, D.E.; Fielding, R.S.; Porter, D.L.; Meyer, M.K.; Makenas, B.J. A US perspective on fast reactor fuel fabrication technology and experience. Part II: Ceramic fuels. J. Nucl. Mater. 2009, 393, 1–11. [Google Scholar] [CrossRef]

- Meyer, M.K.; Fielding, R.; Gan, J. Fuel development for gas-cooled fast reactors. J. Nucl. Mater. 2007, 371, 281–287. [Google Scholar] [CrossRef]

- Hofman, G.L.; Walters, L.C.; Bauer, T.H. Metallic fast reactor fuels. Prog. Nucl. Energy 1997, 31, 83–110. [Google Scholar] [CrossRef]

- Choi, S.; Cho, J.H.; Bae, M.H.; Lim, J.; Puspitarini, D.; Jeun, J.H.; Joo, H.G.; Hwang, S., II. PASCAR: Long burning small modular reactor based on natural circulation. Nucl. Eng. Des. 2011, 241, 1486–1499. [Google Scholar] [CrossRef]

- Beliavskii, S.V.; Nesterov, V.N.; Laas, R.A.; Godovikh, A.V.; Bulakh, O.I. Effect of fuel nuclide composition on the fuel lifetime of reactor KLT-40S. Nucl. Eng. Des. 2020, 360, 110524. [Google Scholar] [CrossRef]

- Baybakov, D.F.; Godovykh, A.V.; Martynov, I.S.; Nesterov, V.N. The dependence of the nuclide composition of the fuel core loading on multiplying and breeding properties of the KLT-40S nuclear facility. Nucl. Energy Technol. 2016, 2, 183–190. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).