Characteristics of Roof Collapse of Mining Tunnels in the Fault Fracture Zone and Distribution of the Boundary Force of the Accumulation Body

Abstract

1. Introduction

2. Characteristics of Collapse Accumulation in Fault Fracture Zone

2.1. Physical Characteristics of Accumulation Body

- (1)

- The accumulated rock blocks have unclear edges and corners, and the size of each direction is equivalent. Based on this, it is concluded that the collapse of the mining tunnel section in the fault fracture zone is dominated by fragment filling.

- (2)

- Under the action of gravity and falling impact from other collapsed blocks, the accumulated rock mass has realized passive adjustment, showing a self-organized chimeric state.

- (3)

- In the extension direction along the axis of the mining tunnel, the farther away from the accumulation body, the larger its fragmentation is, showing a certain sorting property.

2.2. Mechanical Characteristics of Accumulation Body Boundary

- (1)

- The walls on both sides of the tunnel only restrict the accumulation body and do not exert active force. Therefore, it is inferred that the passive resistance, which only plays a limiting role, originates from the slope slip effect in the accumulation process of the accumulation body.

- (2)

- According to the roof collapse arch theory, the fragment filling above the tunnel top forms a natural roof collapse equilibrium arch in the process of seeking a new mechanical balance, which achieves temporary stability, stopping the roof’s collapse. It can be seen from this that the collapse amount of the fault fracture zone should be limited. At the same time, if a rescue channel is formed in the accumulation body, the overlying load is the weight of the accumulation body above it.

- (3)

- Since the acting force of the walls on both sides of the tunnel on the accumulation body is a passive resistance that only plays a limiting role, and the accumulation body as a whole is in a scattered accumulation state, the surrounding original rock stress has little effect on the accumulation body.

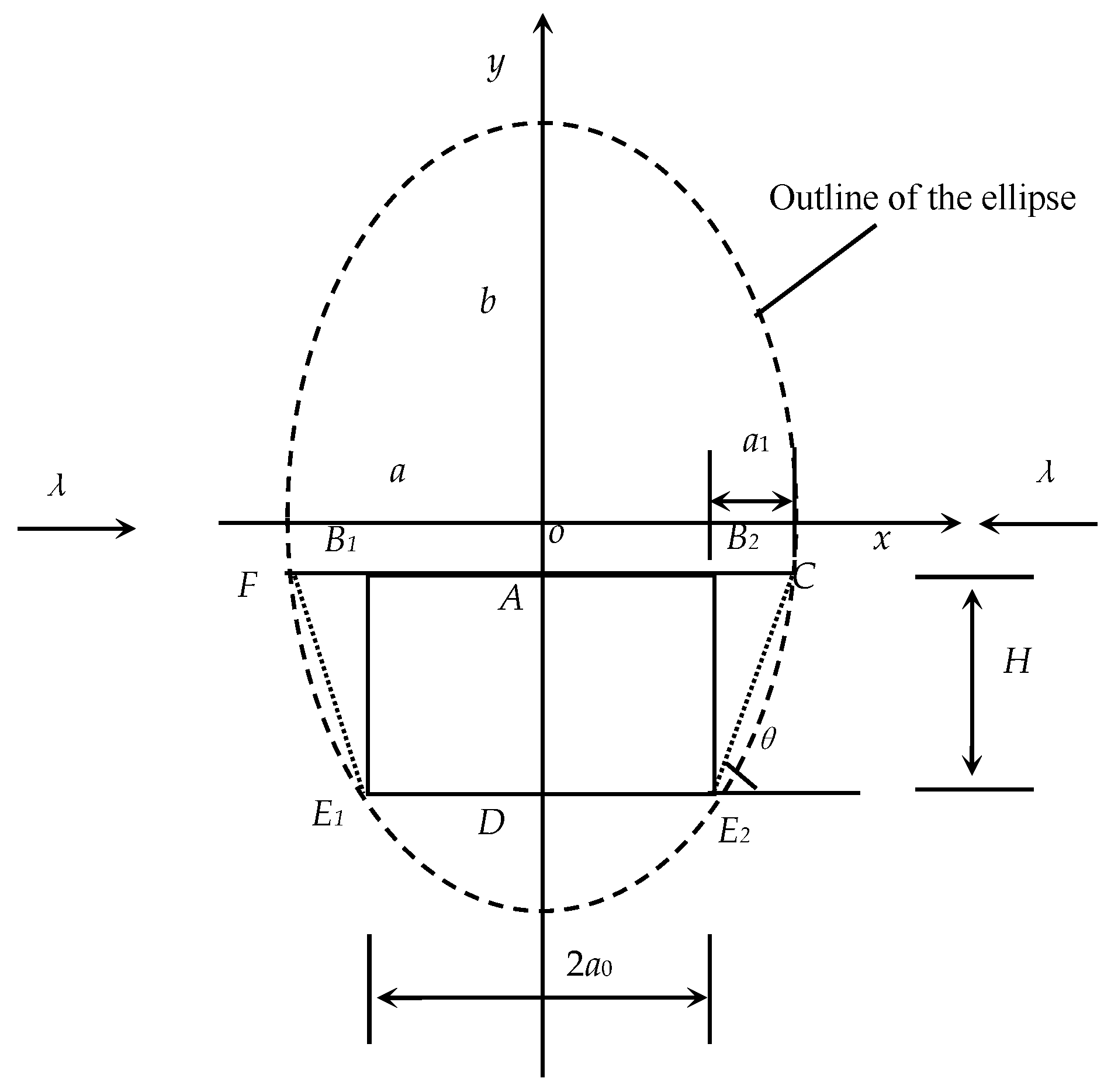

3. Collapse Characteristics of Fault Fracture Zone

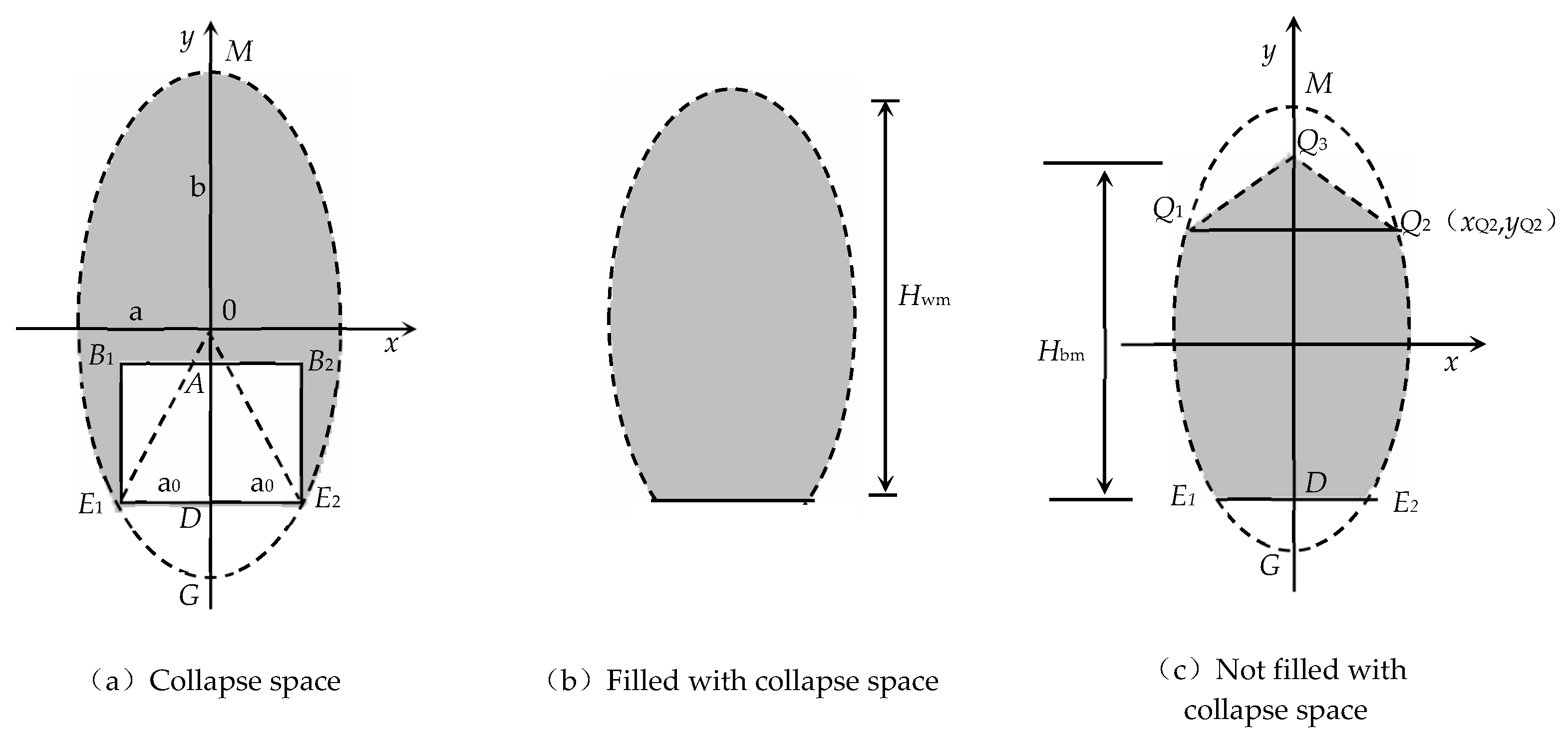

4. Height of the Collapse Accumulation Body

- (1)

- If the accumulation body fills the whole space, as shown in Figure 3b, the following conditions shall be met:

- (2)

- If the accumulation body cannot fill the whole space, the following conditions shall be met:

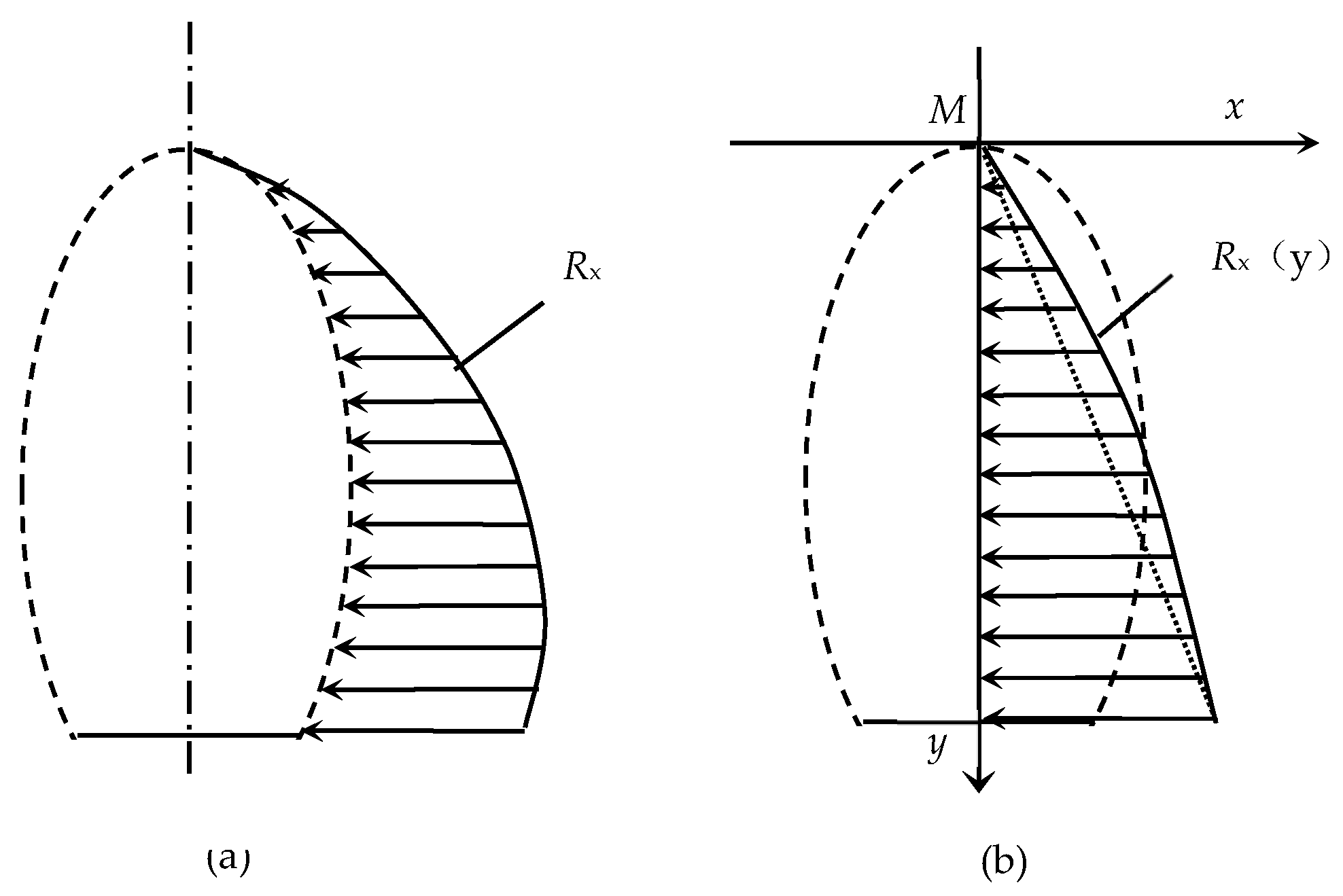

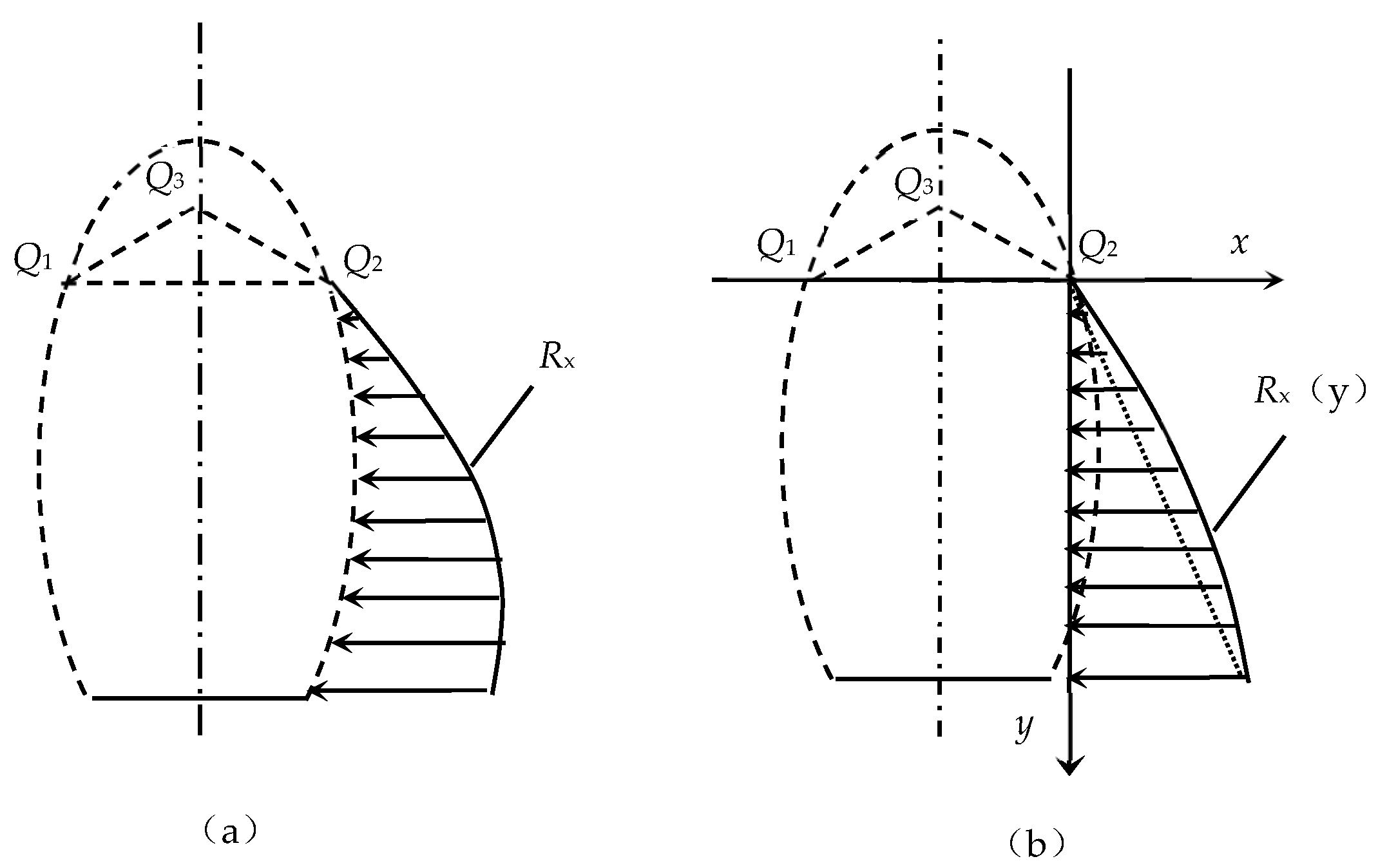

5. Horizontal Forces at the Accumulation Body Boundaries

5.1. Collapse Space Is Fully Filled

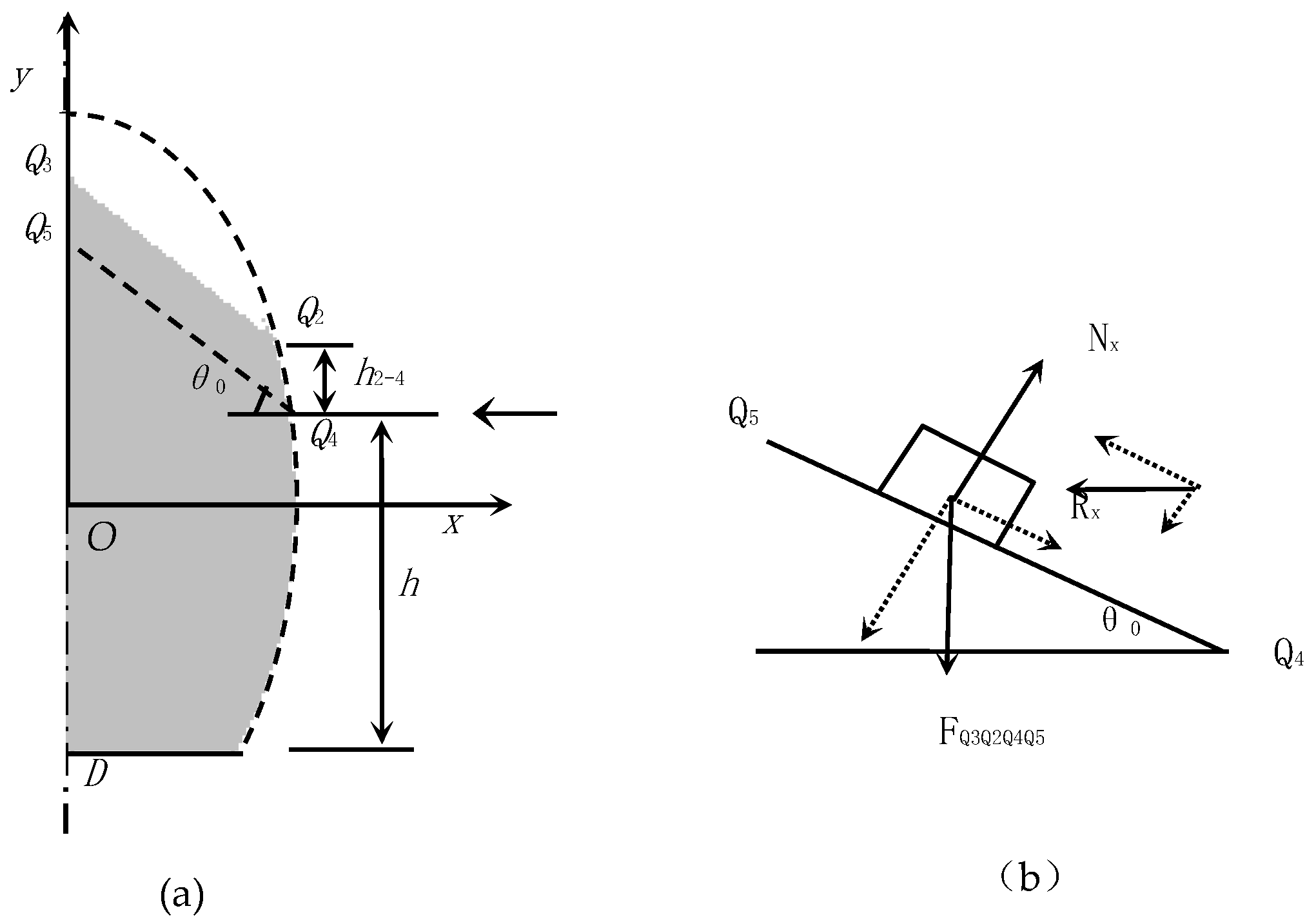

5.2. Collapse Space Is Not Fully Filled

6. Conclusions

- (1)

- The accumulation process of the accumulation body in the fault fracture zone is a self-organized mosaic process, and the accumulation process only suffers passive resistance due to the slope slip effect. At the same time, the overall instability outline of the fault fracture zone is elliptical, and the overlying load on the rescue channel to be excavated in the accumulation body is limited.

- (2)

- The relationship between the maximum lateral instability width and the maximum collapse height of the broken zone of a mining tunnel’s surrounding rock and the height and width of the original tunnel, the lateral stress coefficient, and the internal friction angle of the fragment filling is obtained. The collapse height is also related to the natural accumulation angle of the accumulation body when the collapse space is not filled.

- (3)

- It is concluded that under the two conditions of whether the collapse space is filled or not, the lateral force at the boundary of the accumulation body depends on the distance to the floor of the mining tunnel, the volume weight of the accumulation body, the natural accumulation angle of the accumulation body, the size of the tunnel, the lateral stress coefficient in the cross-section direction of the tunnel, and the internal friction angle of the fragment filling body in the fracture zone. Its distribution is in a curve relationship with the burial depth in the accumulation body.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yi, E. Prevention of rock burst by protective seam mining in high-depth strata: A case study. Vibroeng. Procedia 2018, 19, 110–115. [Google Scholar] [CrossRef]

- Yonts, B. Analysis of Underground Coal Mine Structures Subjected to Dynamic Events; University of Kentucky: Lexington KY, USA, 2018. [Google Scholar]

- Zhang, G.-H.; Li, W.-C.; Chen, G.; Hao, C.-B.; Zhang, D.-P. Simulation study on rescue channel position and section shape selection for accumulation body of collapse-collapse. J. Heilongjiang Univ. Sci. Technol. 2017, 27, 1–7. [Google Scholar]

- Chen, G.; Teng, P.; Duan, H.; Zhang, G.; Li, T. Characteristics of Collapse Accumulation Body in Roadway and Numerical Simulation of Rescue Channel Excavation. Geotech. Geol. Eng. 2022, 40, 1121–1133. [Google Scholar] [CrossRef]

- Li, Z.; Zhang, H.; Jiang, Z.; Feng, G.-R.; Cui, J.-Q.; Ma, J.-K. Research on failure criteria and collapse height of roadway roof strata based on energy accumulation and dissipation characteristics. Energy Sci. Eng. 2021, 9, 2461–2473. [Google Scholar] [CrossRef]

- Song, D.; He, X.; Wang, E.; Li, Z.; Wei, M.; Mu, H. A dynamic ejection coal burst model for coalmine roadway collapse. Int. J. Min. Sci. Technol. 2019, 29, 557–564. [Google Scholar] [CrossRef]

- Feng, X.; Ding, Z.; Hu, Q.; Zhao, X.; Ali, M.; Banquando, J.T. Orthogonal numerical analysis of deformation and failure characteristics of deep roadway in coal mines: A case study. Mineral 2022, 12, 185. [Google Scholar] [CrossRef]

- Protasov, M.I.; Gadylshin, K.G.; Tcheverda, V.A.; Pravduhin, A.P. 3D diffraction imaging of fault and fracture zones via image spectral decomposition of partial images. Geophys. Prospect. 2019, 67, 1256–1270. [Google Scholar] [CrossRef]

- Wang, K.; Wang, L.; Ren, B. Failure mechanism analysis and support technology for roadway tunnel in fault fracture zone: A case study. Energies 2021, 14, 3767. [Google Scholar] [CrossRef]

- Ding, Z.; Feng, X.; Wang, E.; Wei, Q.; Zhao, Q.; Hu, Q. Acoustic emission response and evolution of precracked coal in the meta-instability stage under graded loading. Eng. Geol. 2022, 312, 106930. [Google Scholar] [CrossRef]

- Zheng, C.; Zheng, J.; Peng, X.; Zhou, L. Study on Failure Characteristics and Rock Burst Mechanism of Roadway Roof under Cyclic Dynamic Load. Shock Vib. 2021, 2021, 7074350. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, M.; Xi, C. Tunnel Collapse Mechanism and Its Control Strategy in Fault Fracture Zone. Shock Vib. 2021, 2021, 9988676. [Google Scholar] [CrossRef]

- McKeighan, C. Analyzing deformation within a normal fault transfer zone using SFM 3D modeling. Proc. Keck Geol. Consort. 2019, 32. [Google Scholar] [CrossRef]

- Wu, T.; Chuanbo, Z.; Nan, J.; Yuqing, X.; Zhu, B. Study on the mechanical cumulative damage model of slope fault fracture zone under the cumulative effect of blasting vibration. Period. Polytech. Civ. Eng. 2020, 64, 845–858. [Google Scholar] [CrossRef]

- Takahashi, M.; Van den Ende, M.P.A.; Niemeijer, A.R.; Spiers, C.J. Shear localization in a mature mylonitic rock analog during fast slip. Geochem. Geophys. Geosystems 2017, 18, 513–530. [Google Scholar] [CrossRef]

- Feng, X.; Ding, Z.; Ju, Y.; Zhang, Q.; Ali, M. “Double Peak” of Dynamic Strengths and Acoustic Emission Responses of Coal Masses Under Dynamic Loading. Nat. Resour. Res. 2022, 31, 1705–1720. [Google Scholar] [CrossRef]

- Bahaaddini, M. Effect of boundary condition on the shear behaviour of rock joints in the direct shear test. Rock Mech. Rock Eng. 2017, 50, 1141–1155. [Google Scholar] [CrossRef]

- Hao, C.-B.; Yu, H.-J.; Zhang, G.H.; Pu, W.L. Caving forms of roadway deposit underground geological fault fracture zone. J. Heilongjiang Univ. Sci. Technol. 2016, 26, 251–255. [Google Scholar]

- Saadat, M.; Taheri, A. Effect of contributing parameters on the behaviour of a bolted rock joint subjected to combined pull-and-shear loading: A DEM approach. Rock Mech. Rock Eng. 2020, 53, 383–409. [Google Scholar] [CrossRef]

- Saadat, M.; Taheri, A. A cohesive grain based model to simulate shear behaviour of rock joints with asperity damage in polycrystalline rock. Comput. Geotech. 2020, 117, 103254. [Google Scholar] [CrossRef]

- Fan, L.; Liu, S. A conceptual model to characterize and model compaction behavior and permeability evolution of broken rock mass in coal mine gobs. Int. J. Coal Geol. 2017, 172, 60–70. [Google Scholar] [CrossRef]

- Zhang, C.; Li, H.; Tian, X. The research and application of support technology in high stress broken surrounding rock roadway. Mine Eng. 2016, 4, 57–63. [Google Scholar] [CrossRef]

- Wang, P.; Feng, T.; Zhu, Y.; Yu, W. Experimental study on secondary bearing mechanism of weakly cemented broken rock mass. J. Vibroeng. 2019, 21, 2228–2241. [Google Scholar] [CrossRef]

- Peng, W.; Zhu, H.; Wang, Q.; Peng, G. Study on safety control of large-section roadway with high stress and broken surrounding rock. Adv. Civ. Eng. 2021, 2021, 6686208. [Google Scholar] [CrossRef]

- Watabe, Y.; Sassa, S.; Kaneko, T.; Nakata, Y. Mechanical characteristics of undisturbed coral gravel soils: The intergranular void ratio as a common governing parameter. Soils Found. 2017, 57, 760–775. [Google Scholar] [CrossRef]

- Li, B.; Wang, X.; Liu, Z.; Li, T. Study on multi-field catastrophe evolution laws of water inrush from concealed karst cave in roadway excavation: A case of Jiyuan coal mine. Geomat. Nat. Hazards Risk 2021, 12, 222–243. [Google Scholar] [CrossRef]

- Zhou, Q.; Gao, Q.; Xu, H.-T. Study on setting angle of bolt forepoling in surrounding fractured rock. J. China Coal Soc. 2009, 34, 1594–1598. [Google Scholar]

- Zhang, G.-H.; Yu, H.-J.; Hao, C.-B. Resistance force distribution law of collapse caving accumulation body’s boundary in fault fracture zone. J. Min. Saf. Eng. 2018, 35, 532–537. [Google Scholar]

- Zheng, K.-C.; Ding, W.-Q.; Jin, W. Formation law of pressure arch of circular TBM tunnel based on model test and FEM. J. China Coal Soc. 2015, 40, 1270–1275. [Google Scholar]

- Zhang, G.-H.; Li, F.-Y. Mine Surrounding Rock Control and Disaster Prevention; China University of Mining and Technology Press: Beijing, China, 2009. [Google Scholar]

- Zhang, G.-H. The theory-count about space between bolters support laneway’s side. J. China Coal Soc. 2006, 31, 433–436. [Google Scholar]

- YU, Y.-X.; Hong, X.; CHEN, F.-F. Study on load transmission mechanism and limit equilibrium zone of coal wall in extraction opening. J. China Coal Soc. 2012, 37, 1630–1636. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, G.; Liu, M.; Qin, T.; Wang, L.; Duan, Y.; Li, Z. Characteristics of Roof Collapse of Mining Tunnels in the Fault Fracture Zone and Distribution of the Boundary Force of the Accumulation Body. Sustainability 2022, 14, 16811. https://doi.org/10.3390/su142416811

Zhang G, Liu M, Qin T, Wang L, Duan Y, Li Z. Characteristics of Roof Collapse of Mining Tunnels in the Fault Fracture Zone and Distribution of the Boundary Force of the Accumulation Body. Sustainability. 2022; 14(24):16811. https://doi.org/10.3390/su142416811

Chicago/Turabian StyleZhang, Guohua, Mengsen Liu, Tao Qin, Lei Wang, Yanwei Duan, and Zibo Li. 2022. "Characteristics of Roof Collapse of Mining Tunnels in the Fault Fracture Zone and Distribution of the Boundary Force of the Accumulation Body" Sustainability 14, no. 24: 16811. https://doi.org/10.3390/su142416811

APA StyleZhang, G., Liu, M., Qin, T., Wang, L., Duan, Y., & Li, Z. (2022). Characteristics of Roof Collapse of Mining Tunnels in the Fault Fracture Zone and Distribution of the Boundary Force of the Accumulation Body. Sustainability, 14(24), 16811. https://doi.org/10.3390/su142416811