The Effect of Nano-Silica and Nano-Alumina with Polypropylene Fiber on the Chemical Resistance of Alkali-Activated Mortar

Abstract

1. Introduction

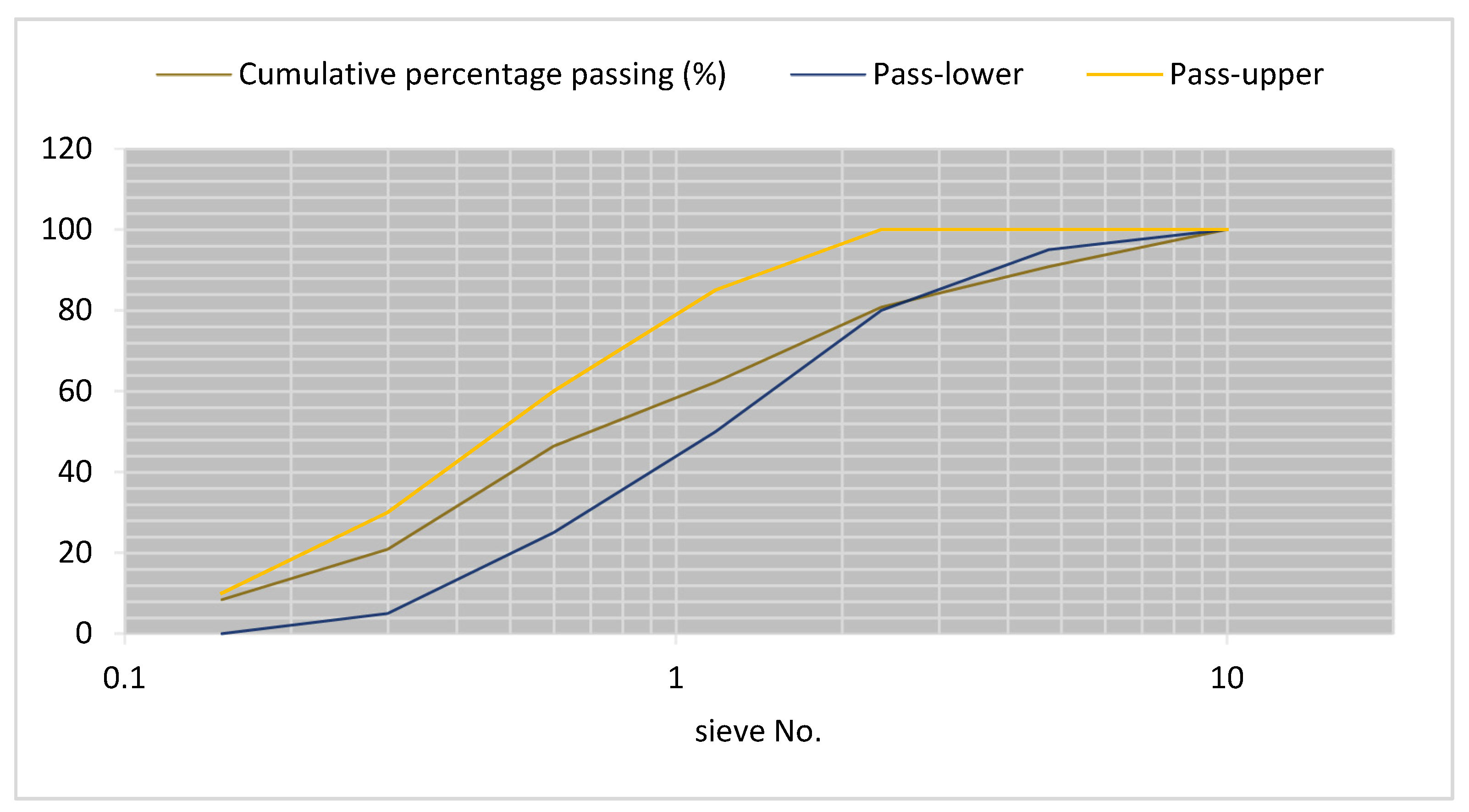

2. Materials

3. Methods and Mix Design

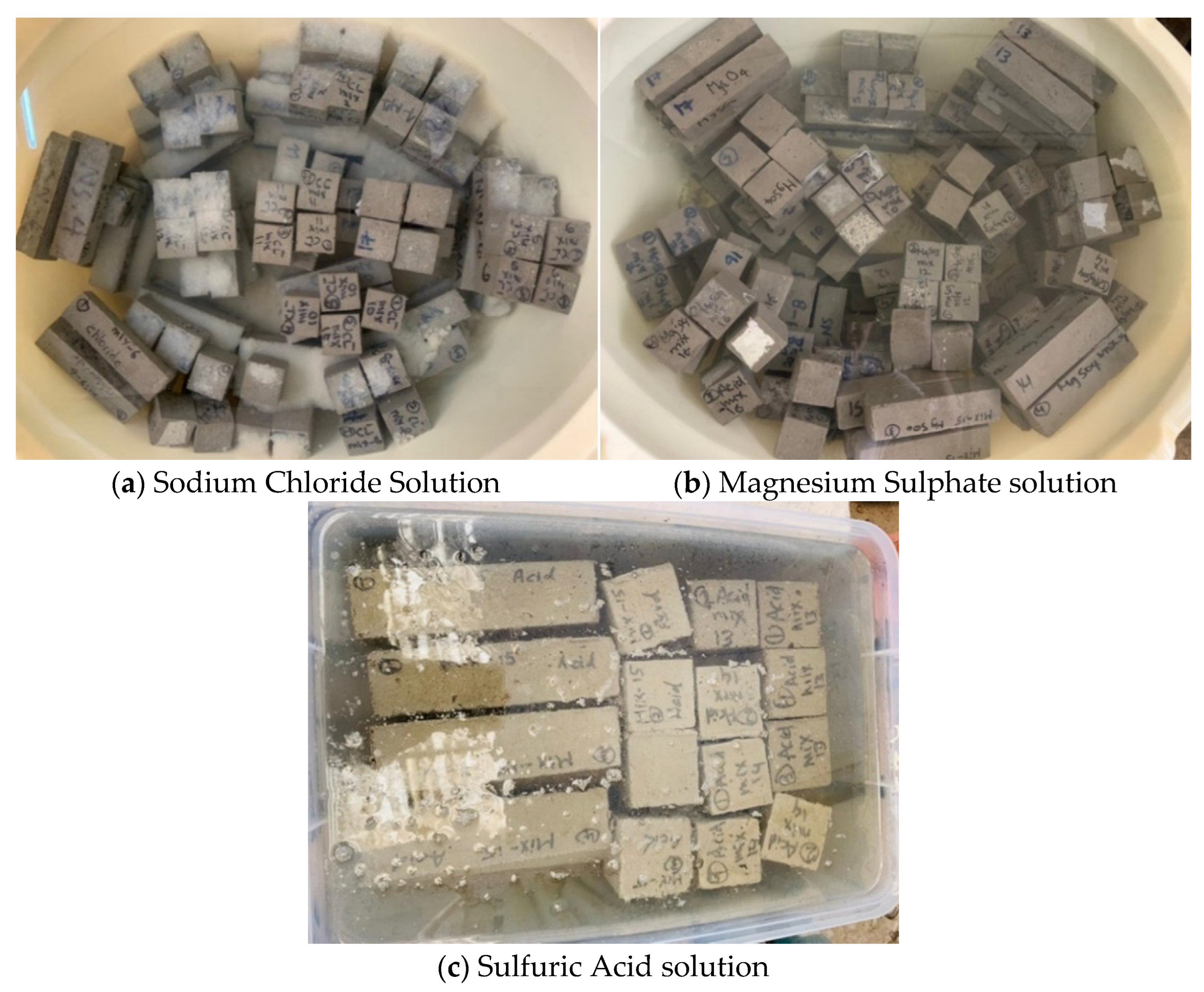

4. Specimen Preparing and Curing

5. Testing Procedure

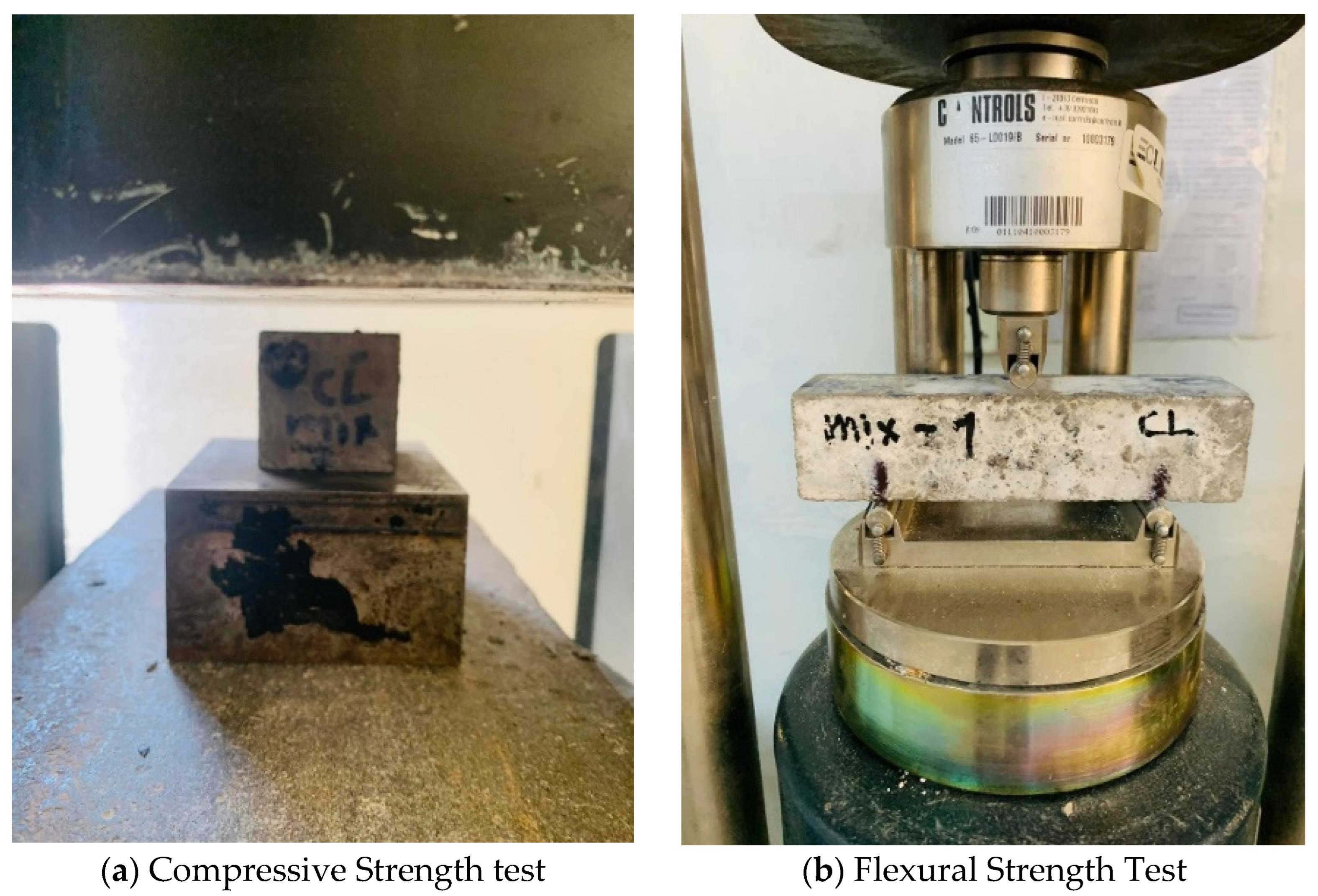

5.1. Compressive Strength Test

5.2. Flexural Strength Test

6. Result and Discussion

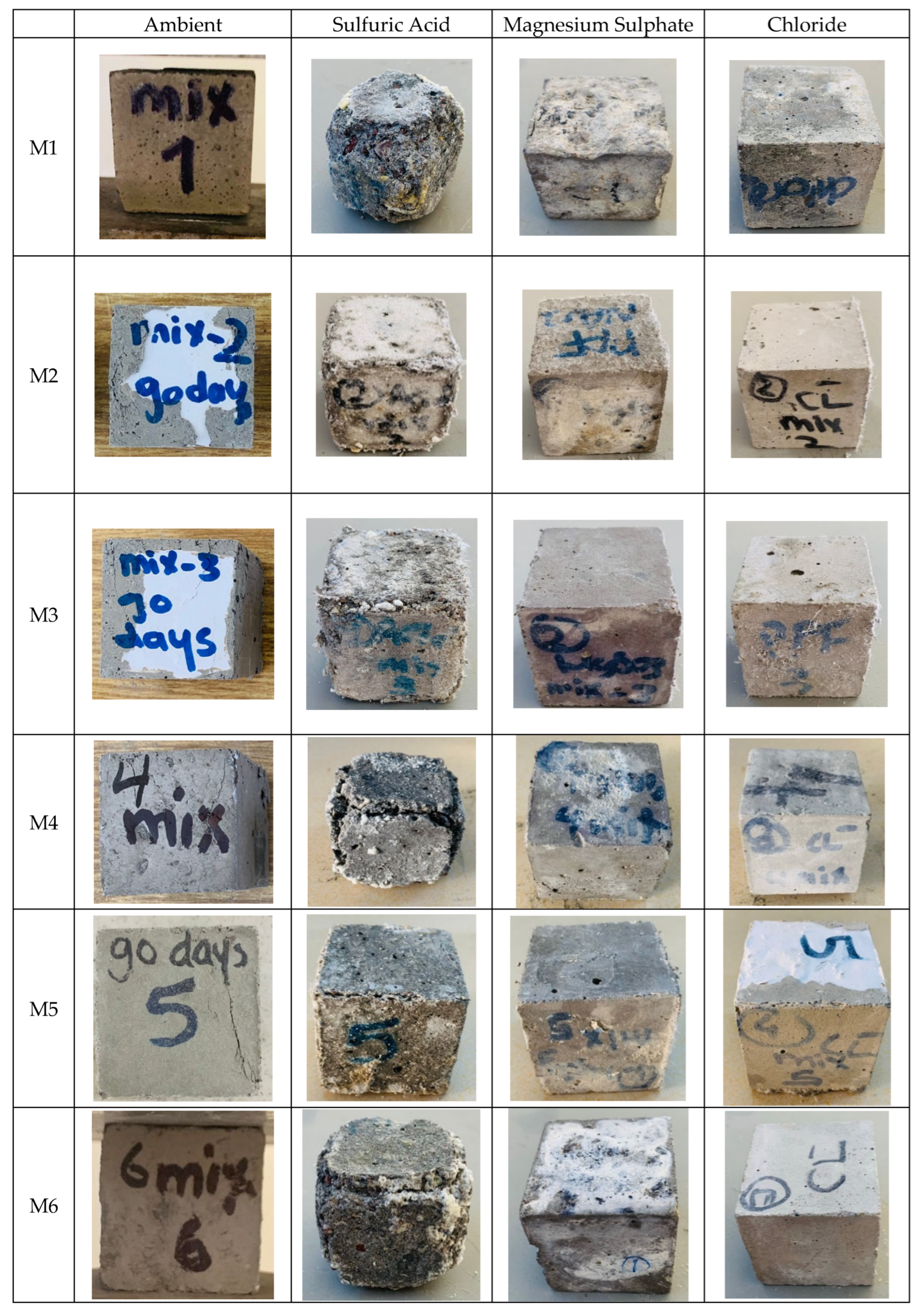

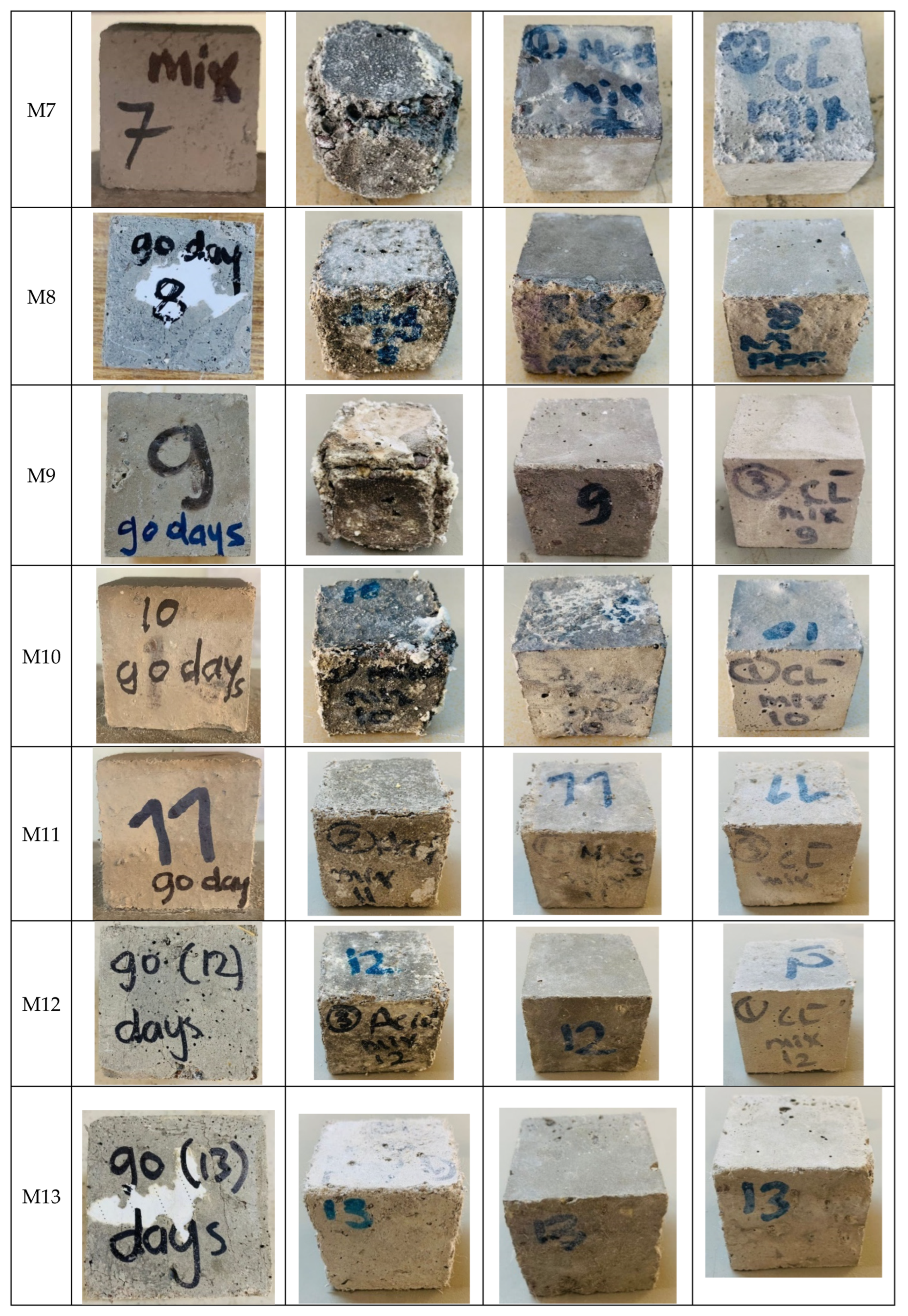

6.1. Visual Inspection

6.1.1. Sulfuric Acid Attack

6.1.2. Magnesium Sulphate Attack

6.1.3. Sodium Chloride Attack

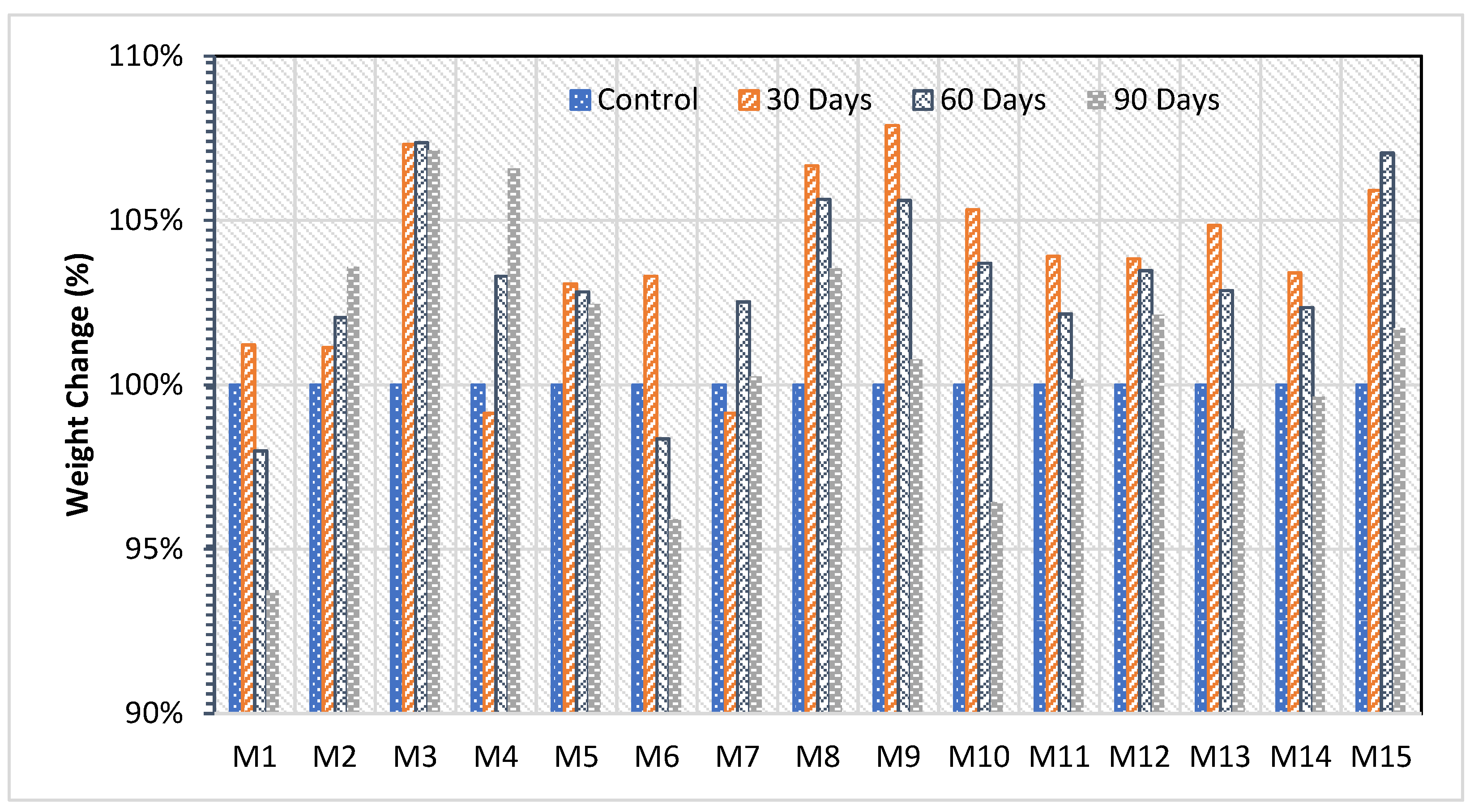

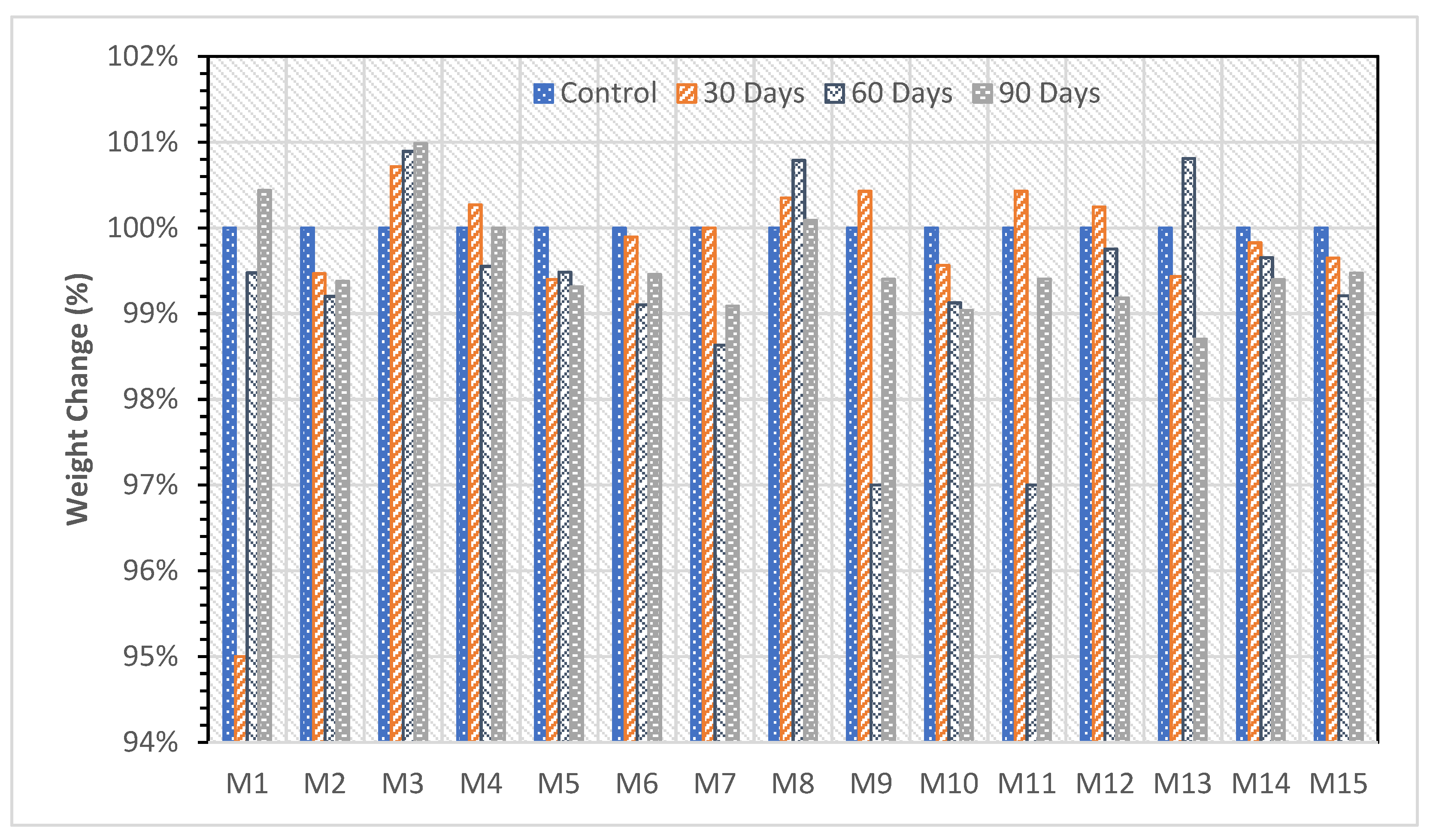

6.2. Weight Change

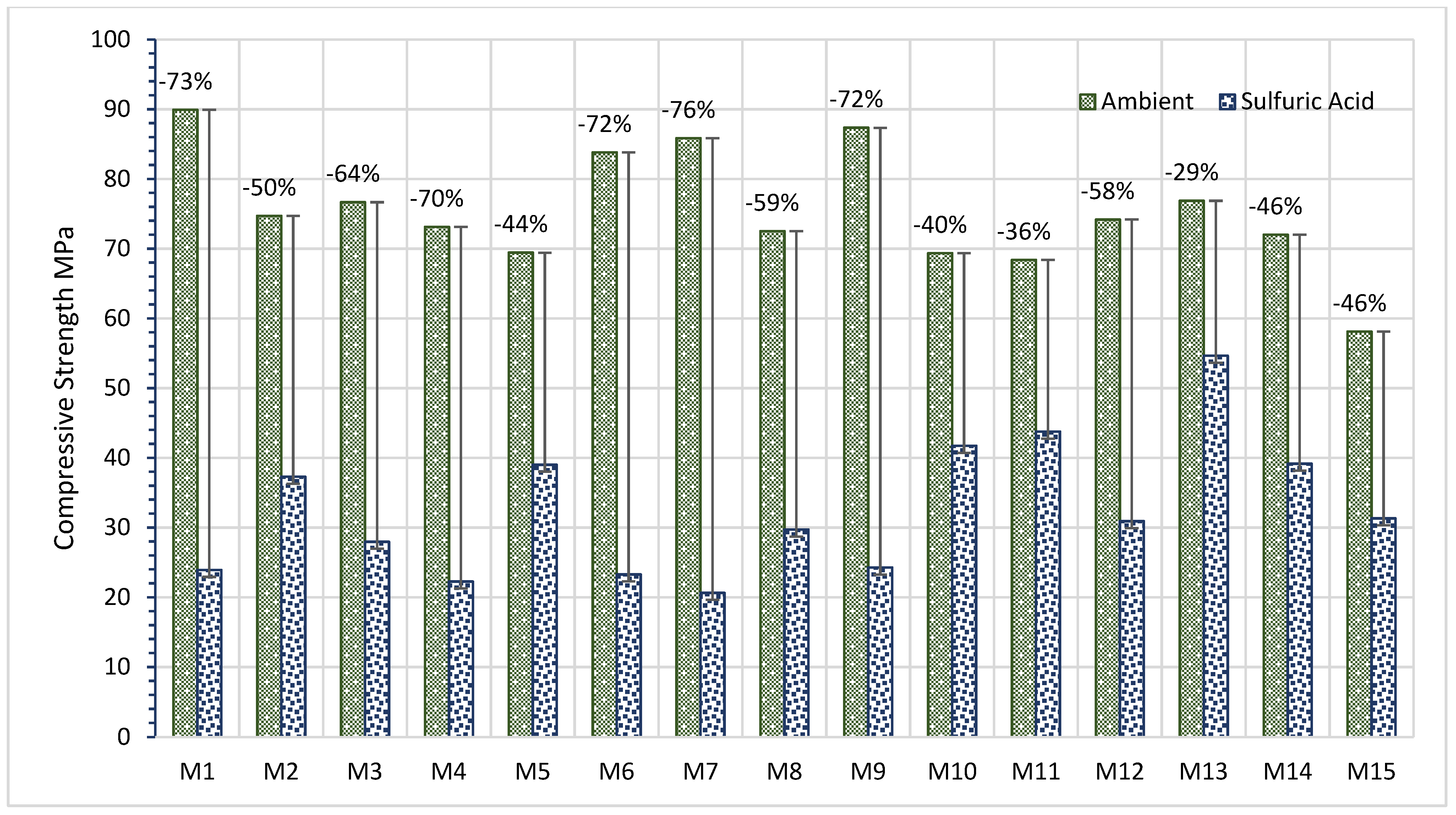

6.3. Sulfuric Acid Attack

6.3.1. Compressive Strength

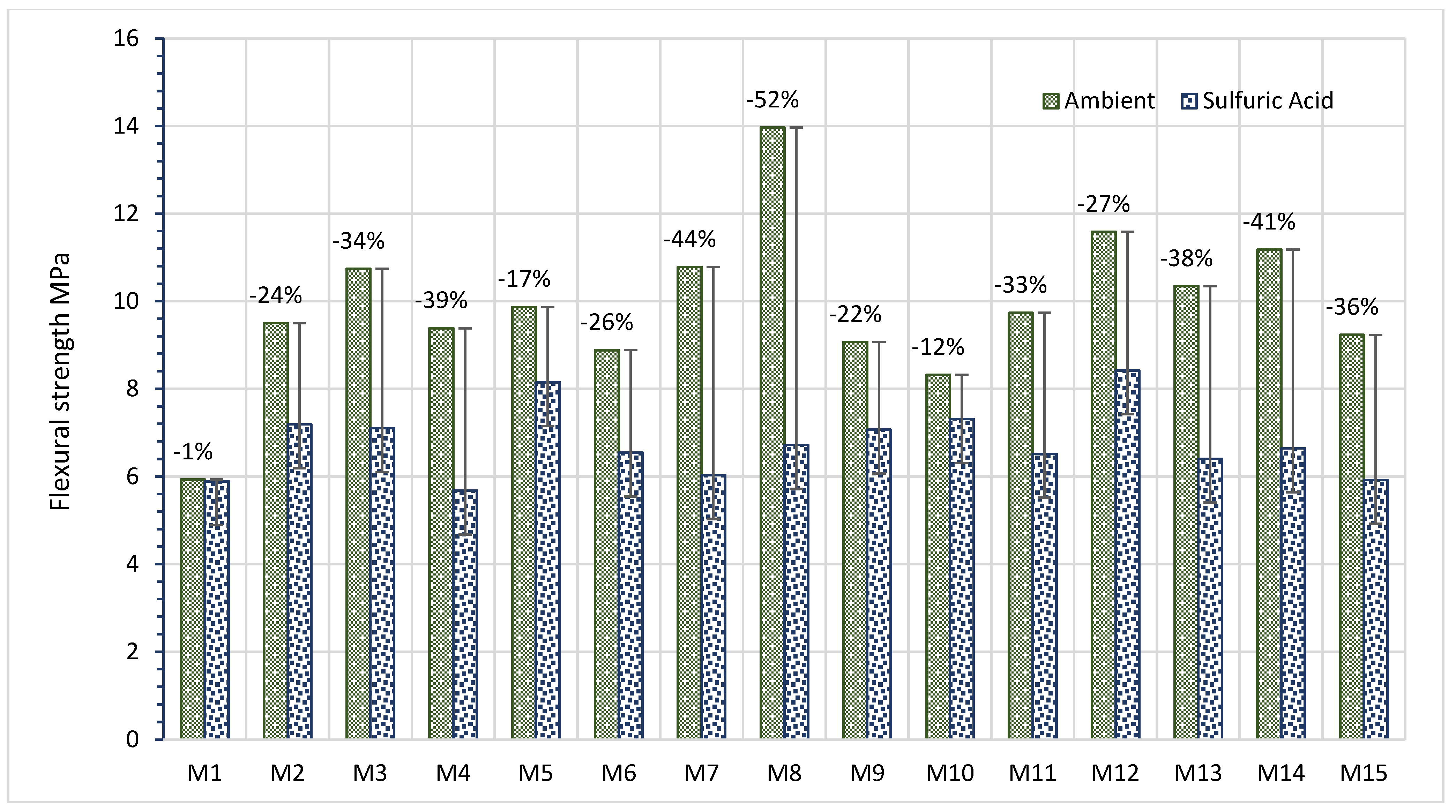

6.3.2. Flexural Strength

6.4. Magnesium Sulphate Attack

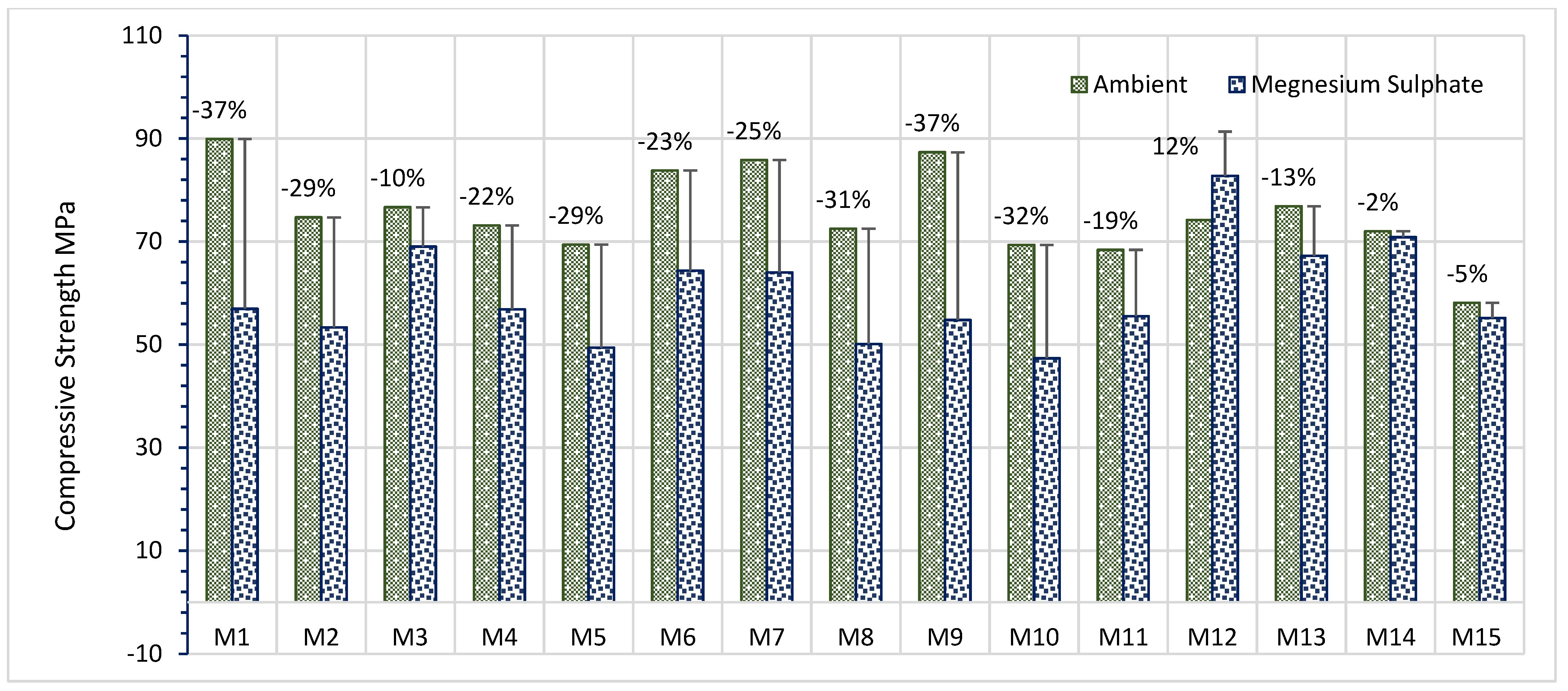

6.4.1. Compressive Strength

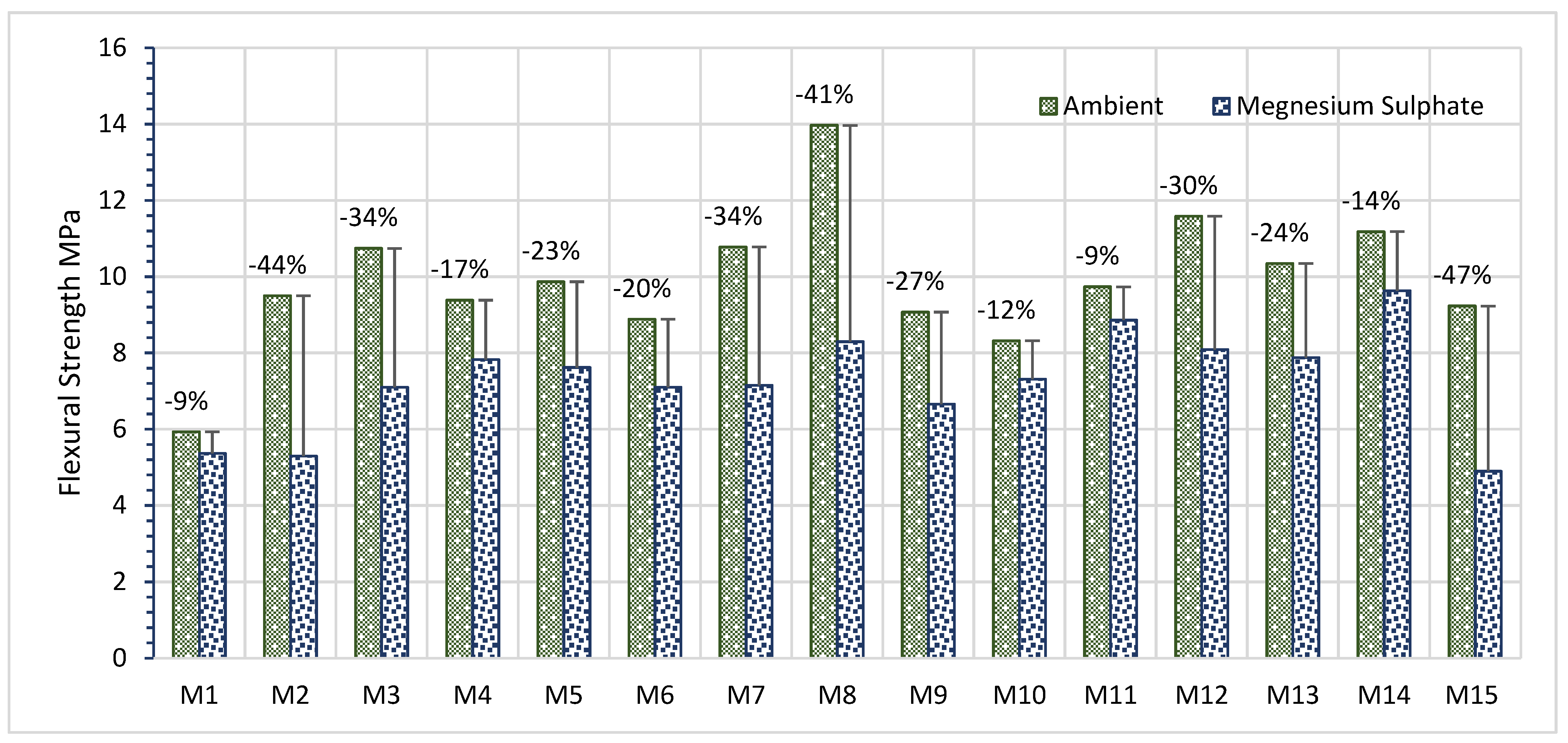

6.4.2. Flexural Strength

6.5. Sodium Chloride Attack

6.5.1. Compressive Strength

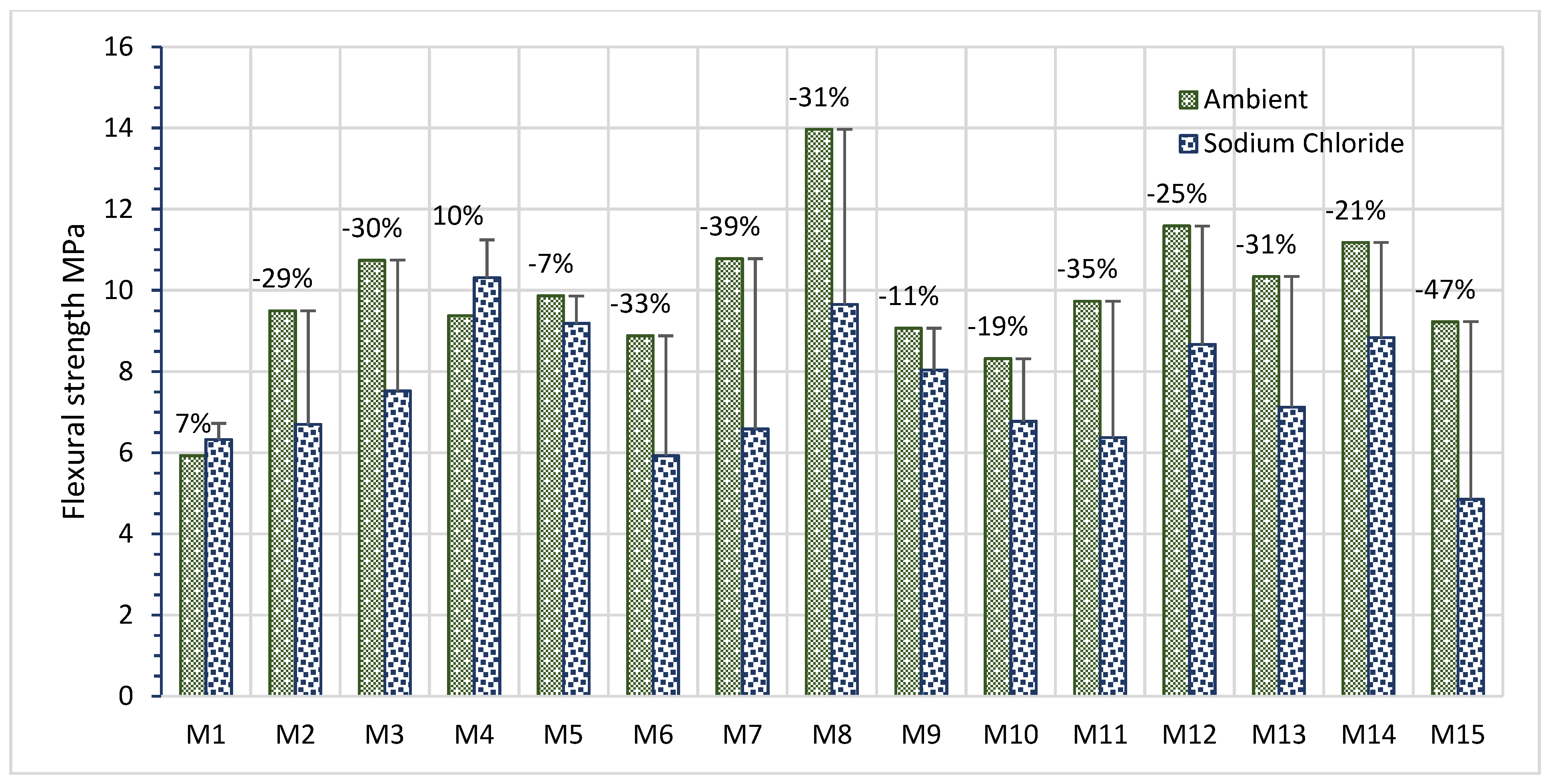

6.5.2. Flexural Strength

7. Conclusions

- Visual examination revealed that AAM specimens exposed to magnesium sulfate and chloride had moderate surface erosion, but those exposed to sulfuric acid had severe surface erosion. Furthermore, AAM specimens retained their original conditions in the presence of magnesium sulfate and chloride, despite the fact that the color of the specimens changed. Even after a short duration of chemical exposure, the beneficial effect of nano materials on the durability performance of AAM can be clearly seen. In addition, the PPF exhibits superior influence in chemical solutions.

- The weight loss of AAM specimens after exposure to chemical solutions. At 30 days exposed to magnesium sulphate solution, the specimens decreased by approximately −4.8% for specimens containing 2% NA (M1) and −0.8% for specimens containing 2% NS (M6). However, the weight of the specimens exposed to chloride solution were reduced slightly; however, when PPF was added, the weight of the specimens increased in the chloride solution.

- For all AAM specimens, the chemical environments of sulfuric acid, magnesium sulfate, seawater environments led to lower compressive strength and flexural strength. Sulfuric acid was observed to be the most hazardous environments.

- Mechanical strength tests (compressive and flexural) revealed that specimens exposed to chloride performed marginally better than those exposed to sulfuric acid and magnesium sulfate. Specimens in the same solution contained PPF performed better than specimens without PPF.

- When AAM exposed to sulfuric acid, the specimen includes 2% NA and the specimen presence nanomaterials and PPF) demonstrated the minimum mechanical strength degradation. In terms of flexural strength, M8 performed the lowest, whereas M1 performed the best.

- Polypropylene fiber specimens are resistant to magnesium sulphate, and specimens including both nano materials, nano silica and nano alumina, with 1% polypropylene fiber, performed better than samples containing 0.5% polypropylene fiber. Moreover, specimens containing 2% NA slightly decrease approximately 1% and M8 decrease about 52%. It also demonstrates that polypropylene fiber has greater strength and ductility.

- The better performance of AAM specimens exposed to chloride solution is M12, which is the compressive strength of samples containing 2% NA and 1% nano silica with 0.5% polypropylene fiber. Additionally, 1% PPF M3 slightly increasing in compressive strength by 5% and 3% after 90 days of curing in chloride solution. Polypropylene fiber samples perform worse than nanomaterial samples, however the difference is reducing; samples contain 2% NA (M1) and 1% NA and 1% NS (M4) The flexural strength increases marginally during the 90-day curing period of lifted samples in sodium chloride.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Neeraj, M.; Aashish, S.; Aman, M. Green Concrete: An Innovative Approach to Sustainable Development. Int. J. Adv. Eng. Sci. Approach 2015, 2349–3607. [Google Scholar]

- Lahoti, M.; Tan, K.H.; Yang, E.-H. A Critical Review of Geopolymer Properties for Structural Fire-Resistance Applications. Constr. Build. Mater. 2019, 221, 514–526. [Google Scholar] [CrossRef]

- Singh, B.; Ishwarya, G.; Gupta, M.; Bhattacharyya, S.K. Geopolymer Concrete: A Review of Some Recent Developments. Constr. Build. Mater. 2015, 85, 78–90. [Google Scholar] [CrossRef]

- Davidovits, J. Properties of Geopolymer Cements. In Proceedings of the First International Conference on Alkaline Cements and Concretes, Kiev, Ukraine, 11–14 October 1994; Volume 1, pp. 131–149. [Google Scholar]

- Law, D.W.; Adam, A.A.; Molyneaux, T.K.; Patnaikuni, I.; Wardhono, A. Long Term Durability Properties of Class F Fly Ash Geopolymer Concrete. Mater. Struct. 2015, 48, 721–731. [Google Scholar] [CrossRef]

- Prud’Homme, E.; Michaud, P.; Joussein, E.; Peyratout, C.; Smith, A.; Rossignol, S. In Situ Inorganic Foams Prepared from Various Clays at Low Temperature. Appl. Clay Sci. 2011, 51, 15–22. [Google Scholar] [CrossRef]

- Robayo-Salazar, R.; Mejía-Arcila, J.; de Gutiérrez, R.M.; Martínez, E. Life Cycle Assessment (LCA) of an Alkali-Activated Binary Concrete Based on Natural Volcanic Pozzolan: A Comparative Analysis to OPC Concrete. Constr. Build. Mater. 2018, 176, 103–111. [Google Scholar] [CrossRef]

- Syed, M.; GuhaRay, A.; Garg, A. Performance Evaluation of Lime, Cement and Alkali-Activated Binder in Fiber-Reinforced Expansive Subgrade Soil: A Comparative Study. J. Test. Eval. 2021, 51. [Google Scholar] [CrossRef]

- Turner, L.K.; Collins, F.G. Carbon Dioxide Equivalent (CO2-e) Emissions: A Comparison between Geopolymer and OPC Cement Concrete. Constr. Build. Mater. 2013, 43, 125–130. [Google Scholar] [CrossRef]

- Ashfaq, M.; Moghal, A.A.B. Cost and Carbon Footprint Analysis of Flyash Utilization in Earthworks. Int. J. Geosynth. Gr. Eng. 2022, 8, 21. [Google Scholar] [CrossRef]

- Bakharev, T. Geopolymeric Materials Prepared Using Class F Fly Ash and Elevated Temperature Curing. Cem. Concr. Res. 2005, 35, 1224–1232. [Google Scholar] [CrossRef]

- He, P.; Jia, D.; Lin, T.; Wang, M.; Zhou, Y. Effects of High-Temperature Heat Treatment on the Mechanical Properties of Unidirectional Carbon Fiber Reinforced Geopolymer Composites. Ceram. Int. 2010, 36, 1447–1453. [Google Scholar] [CrossRef]

- Aulia, T.B. Effects of Polypropylene Fibers on the Properties of High-Strength Concretes; Institutes Massivbau Baustoffechnologi, Universität Leipzig: Leipzig, Germany, 2002; p. 7. [Google Scholar]

- Davidovits, J. High-Alkali Cements for 21st Century Concretes. Spec. Publ. 1994, 144, 383–398. [Google Scholar]

- Amran, Y.H.M.; Alyousef, R.; Alabduljabbar, H.; El-Zeadani, M. Clean Production and Properties of Geopolymer Concrete; A Review. J. Clean. Prod. 2020, 251, 119679. [Google Scholar] [CrossRef]

- Zhang, P.; Wang, K.; Li, Q.; Wang, J.; Ling, Y. Fabrication and Engineering Properties of Concretes Based on Geopolymers/Alkali-Activated Binders-A Review. J. Clean. Prod. 2020, 258, 120896. [Google Scholar] [CrossRef]

- Ahmaruzzaman, M. A Review on the Utilization of Fly Ash. Prog. Energy Combust. Sci. 2010, 36, 327–363. [Google Scholar] [CrossRef]

- Albitar, M.; Ali, M.S.M.; Visintin, P.; Drechsler, M. Durability Evaluation of Geopolymer and Conventional Concretes. Constr. Build. Mater. 2017, 136, 374–385. [Google Scholar] [CrossRef]

- Vafaei, M.; Allahverdi, A.; Dong, P.; Bassim, N. Acid Attack on Geopolymer Cement Mortar Based on Waste-Glass Powder and Calcium Aluminate Cement at Mild Concentration. Constr. Build. Mater. 2018, 193, 363–372. [Google Scholar] [CrossRef]

- Fernando, P.-T.; João, C.-G.; Said, J. Durability and Environmental Performance of Alkali-Activated Tungsten Mine Waste Mud Mortars. J. Mater. Civ. Eng. 2010, 22, 897–904. [Google Scholar] [CrossRef]

- Bakharev, T.; Sanjayan, J.G.; Cheng, Y.-B. Resistance of Alkali-Activated Slag Concrete to Acid Attack. Cem. Concr. Res. 2003, 33, 1607–1611. [Google Scholar] [CrossRef]

- Aydın, S.; Yazıcı, H.; Yiğiter, H.; Baradan, B. Sulfuric Acid Resistance of High-Volume Fly Ash Concrete. Build. Environ. 2007, 42, 717–721. [Google Scholar] [CrossRef]

- Chindaprasirt, P.; Rattanasak, U. Improvement of Durability of Cement Pipe with High Calcium Fly Ash Geopolymer Covering. Constr. Build. Mater. 2016, 112, 956–961. [Google Scholar] [CrossRef]

- Mehta, P.K. Sulfate attack on concrete separating myths from reality. Concr. Int. 2000, 8, 57–61. [Google Scholar]

- Irassar, E.F.; Di Maio, A.; Batic, O.R. Sulfate Attack on Concrete with Mineral Admixtures. Cem. Concr. Res. 1996, 26, 113–123. [Google Scholar] [CrossRef]

- Bakharev, T. Durability of Geopolymer Materials in Sodium and Magnesium Sulfate Solutions. Cem. Concr. Res. 2005, 35, 1233–1246. [Google Scholar] [CrossRef]

- Sumajouw, M.; Rangan, B.V. Low-Calcium Fly Ash-Based Geopolymer Concrete: Reinforced Beams and Columns; Curtin University of Technology: Perth, Australia, 2006; Available online: http://hdl.handle.net/20.500.11937/23928 (accessed on 2 October 2022).

- Valencia Saavedra, W.G.; Angulo, D.E.; de Gutiérrez, R. Fly Ash Slag Geopolymer Concrete: Resistance to Sodium and Magnesium Sulfate Attack. J. Mater. Civ. Eng. 2016, 28, 4016148. [Google Scholar] [CrossRef]

- Puertas, F.; Gutierrez, R.D.; Fernández-Jiménez, A.; Delvasto, S.; Maldonado, J. Alkaline Cement Mortars. Chemical Resistance to Sulfate and Seawater Attack. Mater. Constr. 2002, 52, 55–71. [Google Scholar] [CrossRef]

- Stanish, K.; Hooton, R.D.; Thomas, M.D.A. The Rapid Migration Test, An Alternative to AASHTO T 277; HPC Bridge Views; National Concrete Bridge Council: Skokie, IL, USA, 2005. [Google Scholar]

- Elakneswaran, Y.; Nawa, T.; Kurumisawa, K. Influence of Surface Charge on Ingress of Chloride Ion in Hardened Pastes. Mater. Struct. 2009, 42, 83–93. [Google Scholar] [CrossRef]

- Behfarnia, K.; Rostami, M. An Assessment on Parameters Affecting the Carbonation of Alkali-Activated Slag Concrete. J. Clean. Prod. 2017, 157, 1–9. [Google Scholar] [CrossRef]

- Thokchom, S.; Ghosh, P.; Ghosh, S. Effect of Water Absorption, Porosity and Sorptivity on Durability of Geopolymer Mortars. ARPN J. Eng. Appl. Sci. 2009, 4, 28–32. [Google Scholar]

- Alzeebaree, R.; Çevik, A.; Nematollahi, B.; Sanjayan, J.; Mohammedameen, A.; Gül\csan, M.E. Mechanical Properties and Durability of Unconfined and Confined Geopolymer Concrete with Fiber Reinforced Polymers Exposed to Sulfuric Acid. Constr. Build. Mater. 2019, 215, 1015–1032. [Google Scholar] [CrossRef]

- Stefanidou, M.; Tsardaka, E.-C.; Pavlidou, E. Influence of Nano-Silica and Nano-Alumina in Lime-Pozzolan and Lime-Metakaolin Binders. Mater. Today Proc. 2017, 4, 6908–6922. [Google Scholar] [CrossRef]

- Moutaoukil, G.; Alehyen, S.; Sobrados, I.; Fadil, M.; Taibi, M. Optimization of Compressive Strength of Fly Ash-Based Geopolymers Using Central Composite Design. Bull. Mater. Sci. 2021, 44, 138. [Google Scholar] [CrossRef]

- Mosaberpanah, M.A.; Eren, O. Statistical Flexural Toughness Modeling of Ultra High Performance Concrete Using Response Surface Method. Comput. Concr. 2016, 17, 477–488. [Google Scholar] [CrossRef]

- Dheyaaldin, M.H.; Mosaberpanah, M.A.; Alzeebaree, R. Shrinkage Behavior and Mechanical Properties of Alkali Activated Mortar Incorporating Nanomaterials and Polypropylene Fiber. Ceram. Int. 2022, 48, 23159–23171. [Google Scholar] [CrossRef]

- Gülşan, M.E.; Alzeebaree, R.; Rasheed, A.A.; Niş, A.; Kurtoğlu, A.E. Development of Fly Ash/Slag Based Self-Compacting Geopolymer Concrete Using Nano-Silica and Steel Fiber. Constr. Build. Mater. 2019, 211, 271–283. [Google Scholar] [CrossRef]

- Assaedi, H.; Shaikh, F.U.A.; Low, I.M. Effect of Nanoclay on Durability and Mechanical Properties of Flax Fabric Reinforced Geopolymer Composites. J. Asian Ceram. Soc. 2017, 5, 62–70. [Google Scholar] [CrossRef]

- Singh, B.; Rahman, M.R.; Paswan, R.; Bhattacharyya, S.K. Effect of Activator Concentration on the Strength, ITZ and Drying Shrinkage of Fly Ash/Slag Geopolymer Concrete. Constr. Build. Mater. 2016, 118, 171–179. [Google Scholar] [CrossRef]

- Saini, G.; Vattipalli, U. Assessing Properties of Alkali Activated GGBS Based Self-Compacting Geopolymer Concrete Using Nano-Silica. Case Stud. Constr. Mater. 2020, 12, e00352. [Google Scholar] [CrossRef]

- Riahi, S.; Nazari, A. The Effects of Nanoparticles on Early Age Compressive Strength of Ash-Based Geopolymers. Ceram. Int. 2012, 38, 4467–4476. [Google Scholar] [CrossRef]

- Çevik, A.; Alzeebaree, R.; Humur, G.; Niş, A.; Gülşan, M.E. Effect of Nano-Silica on the Chemical Durability and Mechanical Performance of Fly Ash Based Geopolymer Concrete. Ceram. Int. 2018, 44, 12253–12264. [Google Scholar] [CrossRef]

- ASTM C267-01; Standard Test Methods for Chemical Resistance of Mortars, Grouts and Monolithic Surfacing and Polymer Concretes. ASTM International: West Conshohocken, PA, USA, 2020.

- ASTM C109/C109M-20; Standard Test Method for Compressive Strength of Hydraulic Cement Mortars (Using 2-in. or Cube Specimens). WASTM International: West Conshohocken, PA, USA, 2016; pp. 1–10.

- BS EN 196-1:2015; British Standard Methods of Testing Cement—Part 1 Determination of Strength. BSI: London, UK, 2015.

- Karthik, A.; Sudalaimani, K.; Vijayakumar, C.T. Durability Study on Coal Fly Ash-Blast Furnace Slag Geopolymer Concretes with Bio-Additives. Ceram. Int. 2017, 43, 11935–11943. [Google Scholar] [CrossRef]

- Parande, A.K.; Ramsamy, P.L.; Ethirajan, S.; Rao, C.R.K.; Palanisamy, N. Deterioration of Reinforced Concrete in Sewer Environments. Inst. Civ. Eng. Proc. Munic. Eng. 2006, 159, 11–20. [Google Scholar] [CrossRef]

- Gutberlet, T.; Hilbig, H.; Beddoe, R.E. Acid Attack on Hydrated Cement- Effect of Mineral Acids on the Degradation Process. Cem. Concr. Res. 2015, 74, 35–43. [Google Scholar] [CrossRef]

- Chindaprasirt, P.; Rattanasak, U.; Taebuanhuad, S. Resistance to Acid and Sulfate Solutions of Microwave-Assisted High Calcium Fly Ash Geopolymer. Mater. Struct. 2013, 46, 375–381. [Google Scholar] [CrossRef]

- Song, X.J.; Marosszeky, M.; Brungs, M.; Munn, R. Durability of Fly Ash Based Geopolymer Concrete against Sulphuric Acid Attack. In Proceedings of the International Conference on Durability of Building Materials and Components, Lyon, France, 17–20 April 2005; Volume 10. [Google Scholar]

- Castel, A.; Foster, S.J. Bond Strength between Blended Slag and Class F Fly Ash Geopolymer Concrete with Steel Reinforcement. Cem. Concr. Res. 2015, 72, 48–53. [Google Scholar] [CrossRef]

- Hussein, T.A.; Dheyaaldin, M.H.; Mosaberpanah, M.A.; Ahmed, Y.M.; Mohammed, H.A.; Omer, R.R.; Hamid, S.M.; Alzeebaree, R. Chemical resistance of alkali-activated mortar with nano silica and polypropylene fiber. Constr. Build. Mater. 2023, 363, 129847. [Google Scholar] [CrossRef]

| Component | CaO | SiO2 | Al2O3 | Fe2O3 | MgO | TiO2 | SO3 | K2O | P2O3 | Mn2O3 | Na2O | SrO | LoI | SSA | Particle Size | Density |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| FA% | 15.48 | 48.43 | 17.15 | 11.96 | 1.35 | 2.68 | 0.82 | 0.41 | 0.4 | 0.17 | 0.0019 | 0.2 | 1.47 | 360 | 45 µ | <2.6 g/cm3 |

| GGBS% | 47.75 | 28.17 | 8.6 | 0.42 | 3.89 | 0.94 | 1.45 | 0.29 | 0.06 | 0.47 | 0.02 | 0.076 | 0.2 | 419 | - | 2.9 g/cm3 |

| Mix No. | Mixes | NS | NA | PPF | FA kg/m3 | GGBS kg/m3 | S.H kg/m3 | S. S kg/m3 | F. Agg kg/m3 | SP kg/m3 | E.W kg/m3 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| M1 | NA%2 | −1 | 1 | −1 | 343 | 343 | 100 | 250 | 1033.5 | 21 | 33.35 |

| M2 | NA%2-PPF%1 | −1 | 1 | 1 | 343 | 343 | 100 | 250 | 1033.5 | 21 | 33.35 |

| M3 | PPF%1 | −1 | −1 | 1 | 350 | 350 | 100 | 250 | 1033.5 | 21 | 33.35 |

| M4 | NA%2-NA%2 | 1 | 1 | −1 | 336 | 336 | 100 | 250 | 1033.5 | 21 | 33.35 |

| M5 | NS%2-NA%2-PPF%1 | 1 | 1 | 1 | 336 | 336 | 100 | 250 | 1033.5 | 21 | 33.35 |

| M6 | NS%2 | 1 | −1 | −1 | 343 | 343 | 100 | 250 | 1033.5 | 21 | 33.35 |

| M7 | Control | −1 | −1 | −1 | 350 | 350 | 100 | 250 | 1033.5 | 21 | 33.35 |

| M8 | NS%2-PPF%1 | 1 | −1 | 1 | 343 | 343 | 100 | 250 | 1033.5 | 21 | 33.35 |

| M9 | NS%1-NA%1 | 0 | 0 | −1 | 343 | 343 | 100 | 250 | 1033.5 | 21 | 33.35 |

| M10 | NS%1-NA%2-PPF%0.5 | 0 | 1 | 0 | 339.5 | 339.5 | 100 | 250 | 1033.5 | 21 | 33.35 |

| M11 | NS%1-NA%1-PPF%1 | 0 | 0 | 1 | 343 | 343 | 100 | 250 | 1033.5 | 21 | 33.35 |

| M12 | NS%1-PPF%0.5 | 0 | −1 | 0 | 346.5 | 346.5 | 100 | 250 | 1033.5 | 21 | 33.35 |

| M13 | NA%1-PPF%0.5 | −1 | 0 | 0 | 346.5 | 346.5 | 100 | 250 | 1033.5 | 21 | 33.35 |

| M14 | NS%2-NA%1-PPF%0.5 | 1 | 0 | 0 | 339.5 | 339.5 | 100 | 250 | 1033.5 | 21 | 33.35 |

| M15 | NS%1-NA%1-PPF%0.5 | 0 | 0 | 0 | 343 | 343 | 100 | 250 | 1033.5 | 21 | 33.35 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dheyaaldin, M.H.; Mosaberpanah, M.A.; Alzeebaree, R. The Effect of Nano-Silica and Nano-Alumina with Polypropylene Fiber on the Chemical Resistance of Alkali-Activated Mortar. Sustainability 2022, 14, 16688. https://doi.org/10.3390/su142416688

Dheyaaldin MH, Mosaberpanah MA, Alzeebaree R. The Effect of Nano-Silica and Nano-Alumina with Polypropylene Fiber on the Chemical Resistance of Alkali-Activated Mortar. Sustainability. 2022; 14(24):16688. https://doi.org/10.3390/su142416688

Chicago/Turabian StyleDheyaaldin, Mahmood Hunar, Mohammad Ali Mosaberpanah, and Radhwan Alzeebaree. 2022. "The Effect of Nano-Silica and Nano-Alumina with Polypropylene Fiber on the Chemical Resistance of Alkali-Activated Mortar" Sustainability 14, no. 24: 16688. https://doi.org/10.3390/su142416688

APA StyleDheyaaldin, M. H., Mosaberpanah, M. A., & Alzeebaree, R. (2022). The Effect of Nano-Silica and Nano-Alumina with Polypropylene Fiber on the Chemical Resistance of Alkali-Activated Mortar. Sustainability, 14(24), 16688. https://doi.org/10.3390/su142416688