Innovation Strategies for Textile Companies in Bangladesh: Development Using Quadrant Analysis Based on a Productivity Index †

Abstract

1. Introduction

2. Literature Review

2.1. Research on Textile Companies in Bangladesh

2.2. MPI Research

2.3. Research on Productivity and Efficiency in Textile Companies

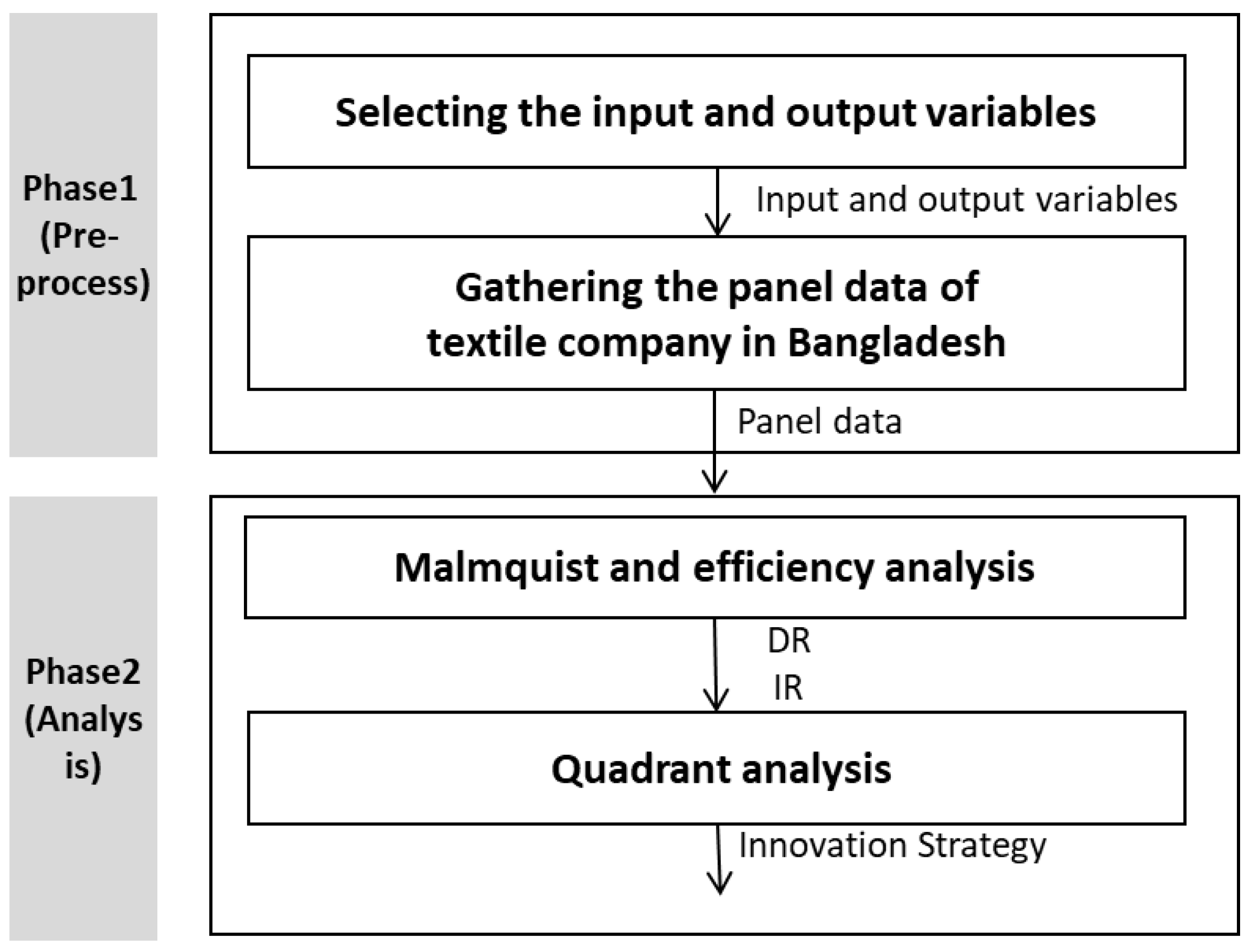

3. Research Framework

3.1. Phase 1: Preliminaries

3.2. Phase 2: Malmquist Analysis

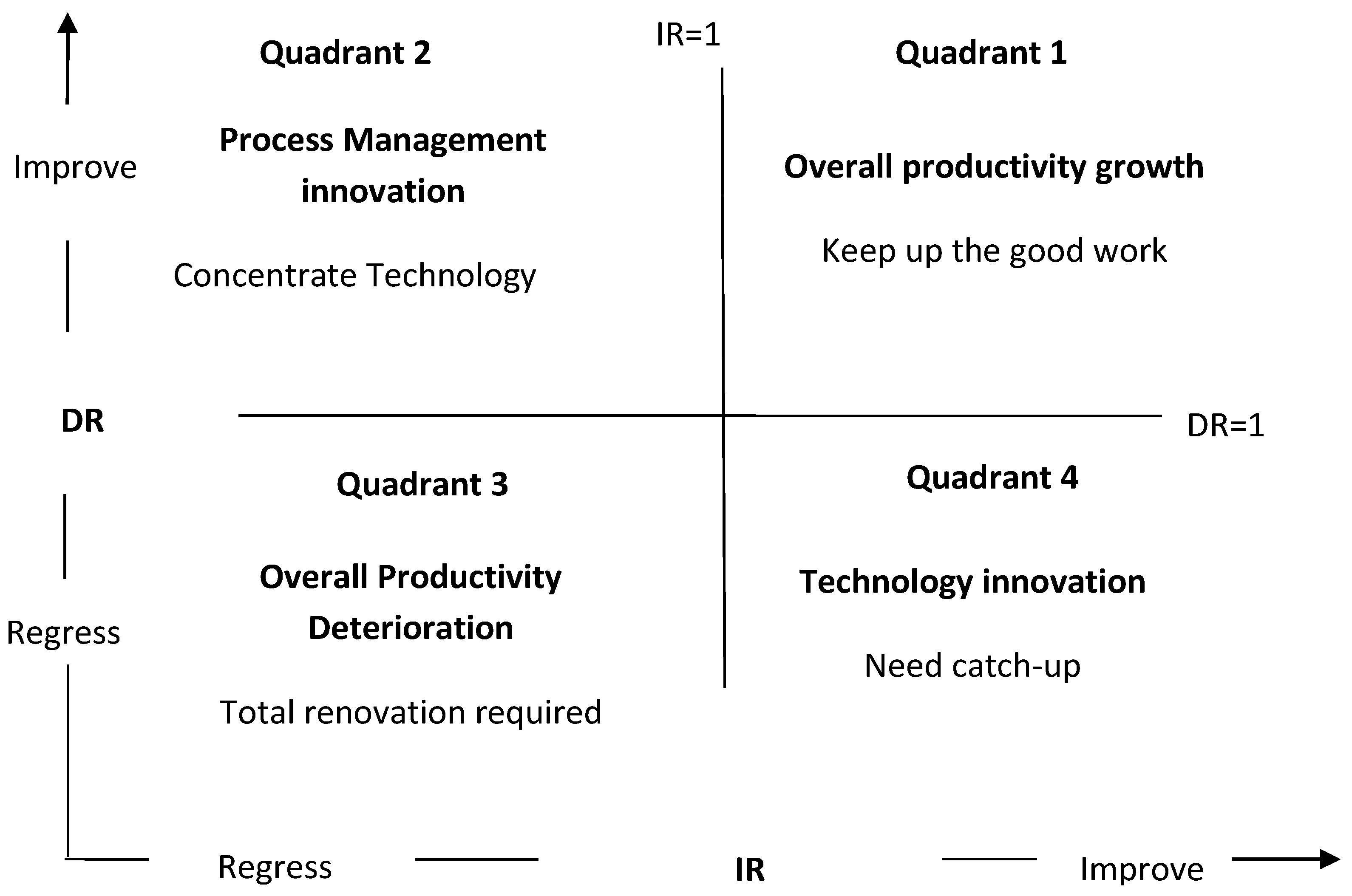

3.3. Phase 2: Quadrant Analysis

4. Results

4.1. Phase 1: Preliminary Process

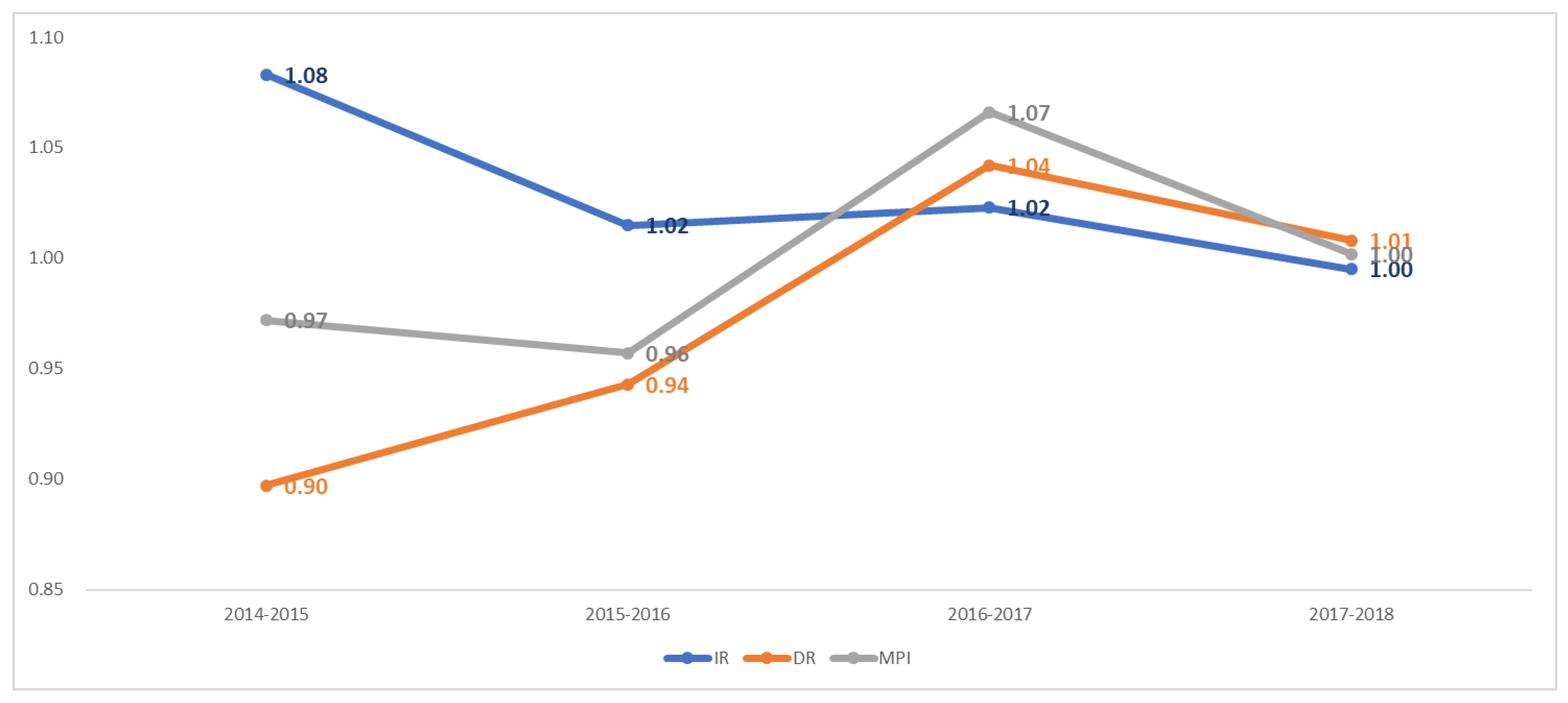

4.2. Phase 2: Malmquist Analysis

4.3. Phase 2: Quadrant Analysis of Textile Companies

5. Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A. Mean of IR, DR and MPI

| Firm | DR | IR | MPI | Quadrant |

| 1 | 1 | 0.937 | 0.937 | 2 |

| 2 | 1 | 0.936 | 0.936 | 2 |

| 3 | 0.683 | 0.982 | 0.67 | 3 |

| 4 | 1.055 | 0.977 | 1.031 | 2 |

| 5 | 0.91 | 0.95 | 0.865 | 3 |

| 6 | 0.933 | 0.955 | 0.891 | 3 |

| 7 | 1.098 | 1.009 | 1.108 | 1 |

| 8 | 1.017 | 0.993 | 1.01 | 2 |

| 9 | 0.969 | 0.972 | 0.941 | 3 |

| 10 | 1.01 | 0.971 | 0.98 | 2 |

| 11 | 1.14 | 0.957 | 1.091 | 2 |

| 12 | 1.038 | 0.987 | 1.025 | 2 |

| 13 | 0.932 | 0.992 | 0.924 | 3 |

| 14 | 1.113 | 0.995 | 1.107 | 2 |

| 15 | 0.938 | 0.955 | 0.896 | 3 |

| 16 | 1.09 | 0.984 | 1.072 | 2 |

| 17 | 1.173 | 0.969 | 1.137 | 2 |

| 18 | 0.959 | 0.984 | 0.943 | 3 |

| 19 | 1.063 | 1.063 | 1.13 | 1 |

| 20 | 1.143 | 0.939 | 1.073 | 2 |

| 21 | 1.209 | 0.941 | 1.138 | 2 |

| 22 | 0.927 | 0.944 | 0.875 | 3 |

| 23 | 1.127 | 0.973 | 1.096 | 2 |

| 24 | 1.065 | 0.965 | 1.028 | 2 |

| 25 | 1 | 0.927 | 0.927 | 2 |

| 26 | 1.056 | 0.953 | 1.006 | 2 |

| 27 | 1.087 | 0.992 | 1.078 | 2 |

| 28 | 1.081 | 0.982 | 1.061 | 2 |

| 29 | 1.331 | 0.967 | 1.288 | 2 |

| 30 | 0.806 | 0.966 | 0.778 | 3 |

| 31 | 1 | 1.079 | 1.079 | 1 |

| 32 | 1.205 | 0.939 | 1.132 | 2 |

| 33 | 1.054 | 0.953 | 1.004 | 2 |

| 34 | 1.073 | 1.001 | 1.073 | 1 |

| 35 | 1.063 | 0.958 | 1.018 | 2 |

| 36 | 0.947 | 1.011 | 0.958 | 4 |

| 37 | 0.998 | 0.969 | 0.966 | 3 |

| 38 | 0.99 | 0.969 | 0.959 | 3 |

| 39 | 1 | 0.911 | 0.911 | 2 |

| 40 | 0.962 | 0.987 | 0.95 | 3 |

| 41 | 1.182 | 0.935 | 1.105 | 2 |

| Mean | 1.028 | 0.971 | 0.998 |

Appendix B. IR, DR and MPI of DMUs

| DMUs | IR | DR | MPI | |||||||||

| 2014–2015 | 2015–2016 | 2016–2017 | 2017–2018 | 2014–2015 | 2015–2016 | 2016–2017 | 2017–2018 | 2014–2015 | 2015–2016 | 2016–2017 | 2017–2018 | |

| DMU 1 | 1.000 | 1.000 | 1.000 | 1.000 | 0.861 | 0.986 | 0.996 | 0.912 | 0.861 | 0.986 | 0.996 | 0.912 |

| DMU 2 | 1.000 | 0.931 | 0.889 | 1.208 | 0.745 | 0.899 | 1.145 | 0.999 | 0.745 | 0.837 | 1.018 | 1.207 |

| DMU 3 | 0.767 | 0.919 | 0.809 | 0.381 | 0.814 | 0.874 | 1.178 | 1.110 | 0.624 | 0.803 | 0.952 | 0.423 |

| DMU 4 | 1.222 | 1.389 | 0.758 | 0.964 | 0.900 | 0.949 | 0.987 | 1.080 | 1.099 | 1.318 | 0.749 | 1.041 |

| DMU 5 | 1.000 | 1.000 | 0.772 | 0.888 | 0.896 | 0.965 | 0.981 | 0.961 | 0.896 | 0.965 | 0.757 | 0.854 |

| DMU 6 | 1.121 | 1.234 | 0.535 | 1.024 | 0.876 | 0.954 | 1.040 | 0.958 | 0.982 | 1.178 | 0.556 | 0.980 |

| DMU 7 | 1.447 | 0.976 | 1.030 | 1.000 | 0.839 | 0.903 | 1.155 | 1.185 | 1.213 | 0.882 | 1.189 | 1.185 |

| DMU 8 | 1.037 | 1.147 | 0.806 | 1.118 | 0.916 | 1.053 | 1.104 | 0.912 | 0.949 | 1.208 | 0.889 | 1.020 |

| DMU 9 | 1.033 | 1.142 | 0.920 | 0.812 | 0.887 | 0.960 | 1.042 | 1.004 | 0.917 | 1.097 | 0.958 | 0.815 |

| DMU 10 | 1.068 | 1.031 | 1.026 | 0.920 | 0.915 | 1.015 | 0.965 | 0.993 | 0.978 | 1.046 | 0.990 | 0.913 |

| DMU 11 | 1.261 | 1.536 | 0.741 | 1.178 | 0.971 | 0.949 | 1.031 | 0.882 | 1.224 | 1.457 | 0.764 | 1.039 |

| DMU12 | 0.974 | 1.019 | 0.911 | 1.286 | 0.908 | 0.936 | 1.020 | 1.095 | 0.884 | 0.954 | 0.929 | 1.408 |

| DMU 13 | 0.908 | 0.895 | 0.949 | 0.977 | 0.901 | 0.858 | 1.111 | 1.125 | 0.818 | 0.767 | 1.055 | 1.099 |

| DMU 14 | 1.226 | 1.203 | 1.221 | 0.852 | 0.973 | 1.055 | 1.075 | 0.889 | 1.192 | 1.270 | 1.312 | 0.757 |

| DMU 15 | 1.376 | 0.756 | 1.013 | 0.735 | 0.898 | 0.983 | 0.993 | 0.948 | 1.235 | 0.743 | 1.006 | 0.696 |

| DMU 16 | 1.482 | 0.741 | 1.485 | 0.865 | 0.986 | 1.026 | 0.909 | 1.020 | 1.462 | 0.760 | 1.350 | 0.883 |

| DMU 17 | 1.259 | 1.112 | 1.089 | 1.243 | 0.856 | 0.924 | 1.076 | 1.038 | 1.077 | 1.028 | 1.172 | 1.290 |

| DMU 18 | 0.729 | 0.781 | 0.967 | 1.535 | 0.916 | 0.862 | 1.097 | 1.080 | 0.668 | 0.674 | 1.061 | 1.658 |

| DMU 19 | 1.202 | 0.915 | 1.248 | 0.930 | 0.980 | 0.866 | 1.130 | 1.333 | 1.177 | 0.792 | 1.410 | 1.240 |

| DMU 20 | 1.492 | 0.812 | 1.145 | 1.230 | 0.875 | 0.954 | 1.016 | 0.918 | 1.305 | 0.775 | 1.163 | 1.129 |

| DMU 21 | 1.216 | 0.644 | 1.465 | 1.860 | 0.868 | 0.931 | 1.021 | 0.951 | 1.055 | 0.600 | 1.496 | 1.769 |

| DMU 22 | 0.627 | 1.166 | 1.002 | 1.006 | 0.872 | 0.859 | 1.048 | 1.011 | 0.547 | 1.002 | 1.049 | 1.018 |

| DMU 23 | 0.937 | 0.884 | 1.877 | 1.036 | 0.862 | 0.962 | 1.057 | 1.022 | 0.808 | 0.851 | 1.985 | 1.059 |

| DMU 24 | 1.284 | 0.836 | 1.053 | 1.137 | 0.918 | 0.846 | 1.014 | 1.103 | 1.179 | 0.707 | 1.068 | 1.253 |

| DMU 25 | 0.656 | 1.525 | 1.000 | 1.000 | 0.686 | 0.965 | 1.234 | 0.903 | 0.450 | 1.471 | 1.234 | 0.903 |

| DMU 26 | 0.991 | 1.079 | 0.871 | 1.335 | 0.900 | 0.979 | 0.993 | 0.942 | 0.892 | 1.056 | 0.865 | 1.257 |

| DMU 27 | 0.870 | 1.077 | 1.674 | 0.889 | 0.918 | 0.908 | 1.054 | 1.103 | 0.799 | 0.978 | 1.764 | 0.981 |

| DMU 28 | 1.182 | 1.089 | 1.023 | 1.036 | 0.851 | 0.912 | 1.087 | 1.101 | 1.006 | 0.993 | 1.112 | 1.141 |

| DMU 29 | 1.560 | 0.839 | 2.285 | 1.050 | 0.883 | 0.951 | 1.085 | 0.961 | 1.378 | 0.798 | 2.478 | 1.010 |

| DMU 30 | 0.483 | 0.993 | 1.363 | 0.644 | 0.871 | 0.963 | 1.112 | 0.933 | 0.421 | 0.956 | 1.516 | 0.601 |

| DMU31 | 1.000 | 1.000 | 1.000 | 1.000 | 1.134 | 1.205 | 0.935 | 1.060 | 1.134 | 1.205 | 0.935 | 1.060 |

| DMU 32 | 1.723 | 1.030 | 1.114 | 1.066 | 0.860 | 0.960 | 1.009 | 0.935 | 1.482 | 0.989 | 1.123 | 0.996 |

| DMU 33 | 1.373 | 1.023 | 0.904 | 0.971 | 0.901 | 0.975 | 0.989 | 0.949 | 1.238 | 0.997 | 0.894 | 0.921 |

| DMU 34 | 1.324 | 1.000 | 1.000 | 1.000 | 0.992 | 0.985 | 1.056 | 0.972 | 1.313 | 0.985 | 1.056 | 0.972 |

| DMU 35 | 1.181 | 1.010 | 1.115 | 0.959 | 0.924 | 0.913 | 1.032 | 0.966 | 1.092 | 0.922 | 1.151 | 0.926 |

| DMU 36 | 0.933 | 1.031 | 1.039 | 0.805 | 0.975 | 0.834 | 1.139 | 1.130 | 0.910 | 0.860 | 1.183 | 0.909 |

| DMU 37 | 0.880 | 1.093 | 1.022 | 1.008 | 0.867 | 0.922 | 1.040 | 1.060 | 0.763 | 1.008 | 1.063 | 1.068 |

| DMU 38 | 1.000 | 1.000 | 0.886 | 1.082 | 0.890 | 0.814 | 1.049 | 1.162 | 0.890 | 0.814 | 0.929 | 1.258 |

| DMU 39 | 1.000 | 1.000 | 1.000 | 1.000 | 1.075 | 1.066 | 0.783 | 0.766 | 1.075 | 1.066 | 0.783 | 0.766 |

| DMU 40 | 1.233 | 1.039 | 0.758 | 0.883 | 0.886 | 0.902 | 1.081 | 1.097 | 1.093 | 0.937 | 0.819 | 0.969 |

| DMU 41 | 1.936 | 1.403 | 0.748 | 0.960 | 0.852 | 0.958 | 0.980 | 0.955 | 1.649 | 1.344 | 0.732 | 0.917 |

| Mean | 1.083 | 1.015 | 1.023 | 0.995 | 0.897 | 0.943 | 1.042 | 1.008 | 0.972 | 0.957 | 1.066 | 1.002 |

References

- Mondal, A.H.; Ahmad, S. Factor proportions and factor productivity changes in jute and cotton textile manufacturing industries in Bangladesh (1962/63–1977/78). Bangladesh Dev. Stud. 1984, 12, 37–63. [Google Scholar]

- World Bank. Bangladesh Development Update: Recovery and Resilience Amid Global Uncertainty; World Bank: Washington DC, USA, 2022. [Google Scholar]

- Berg, A.; Chhaparia, A.; Hedrich, S.; Magnus, K. What’s Next for Bangladesh’s Garment Industry, after a Decade of Growth? Mckinsey & Company Insights Reports; McKinsey & Company: Brussels, Belgium, 2021. [Google Scholar]

- Akter, A.; Baral, L.M.; Auntu, S.K.; Alim, M.A.; Rashed, M. Exploration of Barriers and Success Factors of Sustainability at Producer Level in Textile Industry: A Study of Bangladesh Perspective. Text. Leather Rev. 2022, 5, 430–450. [Google Scholar] [CrossRef]

- Huang, Y.; Azevedo, S.G.; Lin, T.; Cheng, C.; Lin, C. Exploring the decisive barriers to achieve circular economy: Strategies for the textile innovation in Taiwan. Sustain. Prod. Consum. 2021, 27, 1406–1423. [Google Scholar] [CrossRef]

- Rese, A.; Theresa, D.B.; Rausch, M. Success factors in sustainable textile product innovation: An empirical investigation. J. Clean. Prod. 2022, 331, 129829. [Google Scholar] [CrossRef]

- Wadho, W.; Chaudhry, A. Innovation strategies and productivity growth in developing countries: Firm-level evidence from Pakistani manufacturers. J. Asian Econ. 2022, 81, 101484. [Google Scholar] [CrossRef]

- Padilha, C.K.; Gomes, G. Innovation culture and performance in innovation of products and processes: A study in companies of textile industry. RAI Rev. Adm. Inovação 2022, 13, 285–294. [Google Scholar] [CrossRef]

- Rahman, S.; Raju, V. Impact of Supply Chain Management (SCM) in Bangladesh Textile-Clothing Industry: Comprehending the Role of Sourcing. Secialusis Ugdym. 2022, 1, 323–346. [Google Scholar]

- Shahen, M.A. The Financial Lives of the Workers: An Analysis Amid Corona Pandemic in Bangladesh. ABC J. Adv. Res. 2022, 11. in press. [Google Scholar]

- Farhana, K.; Sneha, Z.Z.; Mondol, S.; Farin, F.; Mahamude, A.S.F. Business Trend Analysis of RMG Industry in Context of Bangladesh-A Case Study. Int. J. Ind. Manag. 2022, 14, 515–528. [Google Scholar] [CrossRef]

- Hossain, M.I.; Ong, T.S.; Teh, B.H.; Said, R.M.; Siow, M.L. Nexus of Stakeholder Integration, Green Investment, Green Technology Adoption and Environmental Sustainability Practices: Evidence from Bangladesh Textile SMEs. Pertanika J. Soc. Sci. Humanit. 2022, 30, 253–281. [Google Scholar] [CrossRef]

- Raian, S.; Alia, S.; Sarker, M.; Sankaranarayanan, B.; Kabir, G.; Paul, S.; Chakrabortty, R. Assessing sustainability risks in the supply chain of the textile industry under uncertainty. Resour. Conserv. Recycl. 2022, 177, 105975. [Google Scholar] [CrossRef]

- Ahmed1, S.; Munir, M.; Hawlader, M.; Faysal, G.M.; Islam, M. Factor Analysis: The Outcome of Motivation on Employees’ Performance in Textile Sector. Hum. Resour. Manag. Res. 2022, 12, 1–5. [Google Scholar]

- Mlachila, M.; Yang, Y. The End of Textile Quotas: A Case Study of the Impact on Bangladesh; IMF Working Paper, WP/04/108; Washington, DC, USA. 2004. Available online: https://www.google.com.hk/url?sa=t&rct=j&q=&esrc=s&source=web&cd=&cad=rja&uact=8&ved=2ahUKEwj1zK_Ji9_7AhVM6qQKHXELAmIQFnoECAwQAQ&url=https%3A%2F%2Fwww.imf.org%2Fexternal%2Fpubs%2Fft%2Fwp%2F2004%2Fwp04108.pdf&usg=AOvVaw1m2nOG0ZIQ_3mju5HXMfzZ (accessed on 6 October 2022).

- Dasgupta, S. Attitudes towards Trade Unions in Bangladesh, Brazil, Hungary and Tanzania. J. Artic. Int. Labor Rev. 2002, 141, 413. [Google Scholar] [CrossRef]

- Majumder, P.P. Health Status of the Garment Workers in Bangladesh; Findings from a Survey of Employer and Employees; Bangladesh Institute of Development Studies (BIDS): Dhaka, Bangladesh, 1998. [Google Scholar]

- Chowdhury, M.A.M.; Ali, M.M.; Rahman, R. WTO, Post MFA Era and the Bangladesh RMG Sector: An Assessment of the performance and challenges. J. Inst. Bank. Bangladesh 2005, 52, 87–120. [Google Scholar]

- Raheman, A.; Afza, T.; Qayyum, A.; Bodla, M.A. Estimating Total Factor Productivity and Its Components: Evidence from Major Manufacturing Industries of Pakistan. Pak. Dev. Rev. 2008, 47, 677–694. [Google Scholar] [CrossRef]

- Wang, Y.; Zhu, Z.; Liu, Z. Evaluation of technological innovation efficiency of petroleum companies based on BCC–Malmquist index model. J. Pet. Explor. Prod. 2019, 9, 2405–2416. [Google Scholar] [CrossRef]

- Barros, C.P.; Alves, F.P. Productivity in the Tourism Industry. Int. Adv. Econ. Res. 2004, 10, 215–225. [Google Scholar] [CrossRef]

- Fulginiti, L.E.; Perrin, R.K. LDC agriculture: Nonparametric Malmquist productivity indexes. J. Dev. Econ. 1997, 53, 373–390. [Google Scholar] [CrossRef]

- Chen, Y. A non-radial Malmquist productivity index with an illustrative application to Chinese major industries. Int. J. Prod. Econ. 2003, 83, 27–35. [Google Scholar] [CrossRef]

- Liu, F.H.F.; Wang, P.H. DEA Malmquist productivity measure: Taiwanese semiconductor companies. Int. J. Prod. Econ. 2008, 112, 367–379. [Google Scholar] [CrossRef]

- Mazumdar, M.; Rajeev, M.A. Comparative Analysis of Efficiency and Productivity of the Indian Pharmaceutical Firms: A Malmquist-Meta-Frontier Approach; Institute for Social and Economic Change: Bangalore, India, 2009. [Google Scholar]

- Wang, C.N.; Chang, Y.L.; Huang, Q.H.; Wang, C.H. Assessment on intellectual capital management for Taiwanese pharmaceutical industry: Using GRA and MPI. Afr. J. Bus. Manag. 2011, 5, 2950. [Google Scholar]

- Chang, H.; Choy, H.L.; Cooper, W.W.; Ruefli, T.W. Using Malmquist Indexes to measure changes in the productivity and efficiency of US accounting firms before and after the Sarbanes–Oxley Act. Omega 2009, 37, 951–960. [Google Scholar] [CrossRef]

- Kapelko, M.; Lansink, O. Examining the relation between intangible assets and technical efficiency in the international textile and clothing industry. J. Text I 2014, 105, 491–501. [Google Scholar] [CrossRef]

- Mai, K.; Nguyen, V.; Vu, T. Analyzing productivity change in Vietnamese garment industry using global Malmquist index. J. Asian Financ. Econ. Bus. 2020, 7, 1033–1039. [Google Scholar] [CrossRef]

- Bhandari, A.K.; Ray, S.C. Technical efficiency in the Indian textiles industry: A non-parametric analysis of firmlevel data. Bull. Econ. Res. 2012, 64, 109–124. [Google Scholar] [CrossRef]

- Dhiman, D.; Sharma, M. Productivity Trends and Determinants of Indian Textile Industry: A Disaggregated Analysis Rahul. Int. J. Appl. Bus. Econ. Res. 2017, 15, 113–124. [Google Scholar]

- Zhang, Y.; Wang, T. Profitability and Productivity of the Chinese Textile Industry. China World Econ. 2010, 18, 1–21. [Google Scholar] [CrossRef]

- Lin, H.; Li, H.; Yang, C. China Agglomeration and productivity: Firm-level evidence from China’s textile industry Economic Review. China Econ. Rev. 2011, 22, 313–329. [Google Scholar] [CrossRef]

- Cooper, W.W.; Seiford, L.M.; Zhu, J. Handbook on Data Envelopment Analysis. In Chapter 1: Data Envelopment Analysis; Springer: Berlin/Heidelberg, Germany, 2011; pp. 1–39. [Google Scholar] [CrossRef]

- Coelli, T.J.; Rao DS, P.; O’Donnell, C.J.; Battese, G.E. An Introduction to Efficiency and Productivity Analysis; Springer: New York, NY, USA, 2005. [Google Scholar]

- Barros, C.P. Evaluating the Efficiency of a Small Hotel Chain with a Malmquist Productivity Index. Int. J. Tour. Res. 2005, 7, 173–184. [Google Scholar] [CrossRef]

- Lee, H.; Park, Y.; Choi, H. Comparative Evaluation of Performance of National R&D Programs with Heterogeneous Objectives: A DEA approach. Eur. J. Oper. Res. 2009, 196, 847–855. [Google Scholar]

- Piesse, J.; Thirtle, C. A stochastic frontier approach to firm level efficiency, technological change and productivity during early transition in Hungary. J. Comp. Econ. 2000, 28, 473–501. [Google Scholar] [CrossRef]

- Wu, Z.; Yeung, G.; Mok, V.; Han, Z. Firm-specific knowledge and technical efficiency of watch and clock manufacturing firms in China. Int. J. Prod. Econ. 2007, 107, 317–332. [Google Scholar] [CrossRef]

- Kapelko, M.; Lansink, O. An international comparison of productivity change in the textile and clothing industry: A bootstrapped Malmquist index approach Magdalena. Empir. Econ. 2015, 48, 1499–1523. [Google Scholar] [CrossRef]

- Abran, A.; Buglion, L. A multidimensional performance model for consolidating Balanced Scorecards. Adv. Eng. Softw. 2003, 34, 339–349. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jewel, S.; Hong, J.; Im, C. Innovation Strategies for Textile Companies in Bangladesh: Development Using Quadrant Analysis Based on a Productivity Index. Sustainability 2022, 14, 16329. https://doi.org/10.3390/su142416329

Jewel S, Hong J, Im C. Innovation Strategies for Textile Companies in Bangladesh: Development Using Quadrant Analysis Based on a Productivity Index. Sustainability. 2022; 14(24):16329. https://doi.org/10.3390/su142416329

Chicago/Turabian StyleJewel, Sarker, Jongyi Hong, and Chaechang Im. 2022. "Innovation Strategies for Textile Companies in Bangladesh: Development Using Quadrant Analysis Based on a Productivity Index" Sustainability 14, no. 24: 16329. https://doi.org/10.3390/su142416329

APA StyleJewel, S., Hong, J., & Im, C. (2022). Innovation Strategies for Textile Companies in Bangladesh: Development Using Quadrant Analysis Based on a Productivity Index. Sustainability, 14(24), 16329. https://doi.org/10.3390/su142416329