Environmental Life Cycle Assessment of a Novel Cultivated Meat Burger Patty in the United States

Abstract

:1. Introduction

2. Methods and Materials

2.1. Goal and Scope

2.1.1. System Boundaries

2.1.2. Functional Unit

2.1.3. Impact Assessment

2.2. Comparison Studies

2.3. Life Cycle Inventory Analysis

2.3.1. Data Collection Procedure

2.3.2. Fat and Muscle Cell Production

- Salts: Eighteen compounds (e.g., calcium chloride, ferrous sulfate, sodium chloride, and potassium chloride) were classified as salts. Among the 18 compounds, 12 compounds were included in the database. Six compounds (i.e., ferric nitrate, magnesium chloride, zinc sulfate, sodium pyruvate, hypoxanthine sodium, thymidine) were replaced with other compounds. The following compounds have been produced in a similar process or have a similar supply chain with the replaced compounds [24,36,37,38]:

- -

- Ferric nitrate (Fe(NO3)3·9H2O): Iron sulfate.

- -

- Magnesium chloride (MgCl2): Magnesium sulfate.

- -

- Zinc sulfate (ZnSO4·H2O): Manganese sulfate.

- -

- Sodium pyruvate (NaC3H3O3): Sodium phosphate.

- -

- Hypoxanthine sodium (NaC5H3N4O): Sodium phosphate.

- -

- Thymidine (C10H14N2O5): Glucose.

- Amino acids: Among the 21 compounds in the group of amino acids, only six compounds (i.e., glutamine, glycine, lysine HCl, threonine, tryptophan, and valine) are included in the database. We replaced other compounds using lysine and threonine since these compounds are produced using similar processes with lysine and threonine as follows [24,36,39,40]:

- -

- Lysine (C6H14N2O2·HCl): Arginine HCl, cysteine.HCl·H2O, histidine.HCl·H2O, methionine, phenylalanine, tyrosine.2Na·2H2O.

- -

- Threonine (C4H9NO3): Alanine, asparagine, aspartic acid, cysteine, glutamic acid, isoleucine, leucine, proline, and serine.

- Vitamins: There were no life cycle data for 11 vitamins in the database. Thus, the compounds were replaced by glutamine and lysine since the biotechnological production processes (i.e., fermentation and microbial/enzymatic transformation) are constructed for the commercial production of vitamins and related compounds, and the vitamin production process is similar to the other fermentation processes [41,42]:

- -

- Lysine (C6H14N2O2·HCl): Biotin, folic acid, riboflavin, and vitamin B12.

- -

- Glutamine (C5H10N2O3): D-calcium pantothenate, choline chloride, i-inositol, pyridoxal.HCl, pyridoxine.HCl, and thiamine.HCl.

- Lipids: We assumed that two compounds were synthesized in the process, from soybean oil to fatty acid. Using the process input and output data, we incorporated two compounds in the OpenLCA [24].

- Others: Twelve compounds (e.g., D-glucose, FBS, and water) were categorized as others in this study. Among these, four compounds (i.e., D-glucose, water, sodium selenite, and ascorbic acid) were included in the databases (i.e., Agribalyse and USLCI). One compound, HEPES, requires a negligible amount for fat and muscle cell cultivation; thus, it did not make the replacing strategy. As discussed in the vitamin categories, hormones (i.e., insulin, transferrin, FGF-2, and AlbuMAX Ⅱ) and putrecine.2HCl were replaced using lysine [41].

- Utilities: A heating source (i.e., steam) is required for fat and muscle cell cultivation in a high-temperature short-time sterilizer [43]. The consumed heat in the process was converted to the amount of natural gas from the Artemys food. The required amount of natural gas was incorporated into OpenLCA. Electricity, which is utilized for mixing and cell cultivation, was supplied from the energy grid. The life cycle data for electricity were based on the U.S. average data in the Ecoinvent database.

2.3.3. Novel Burger Production

3. Results and Discussion

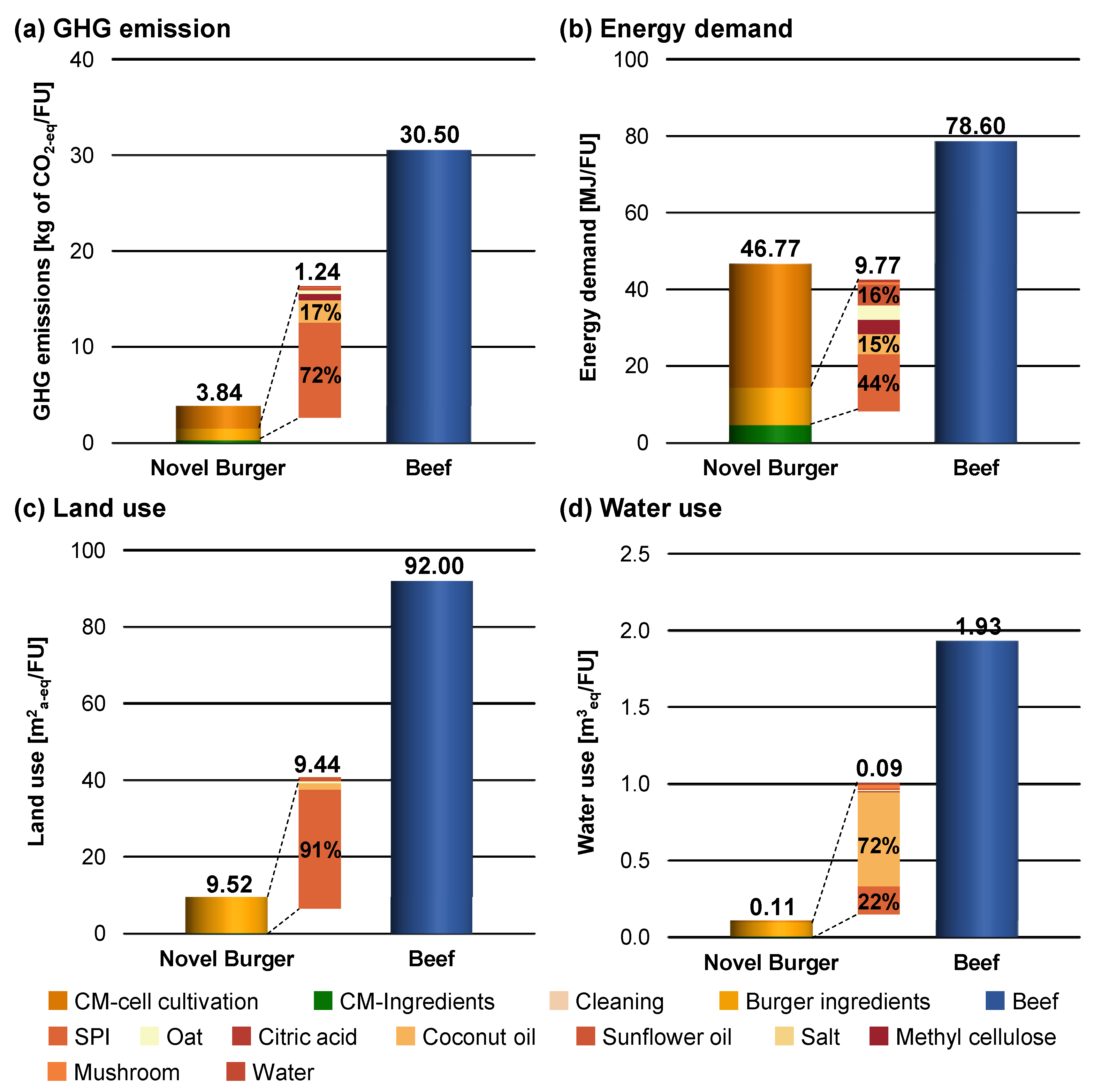

3.1. Life Cycle Impacts

3.2. Uncertainty Analysis

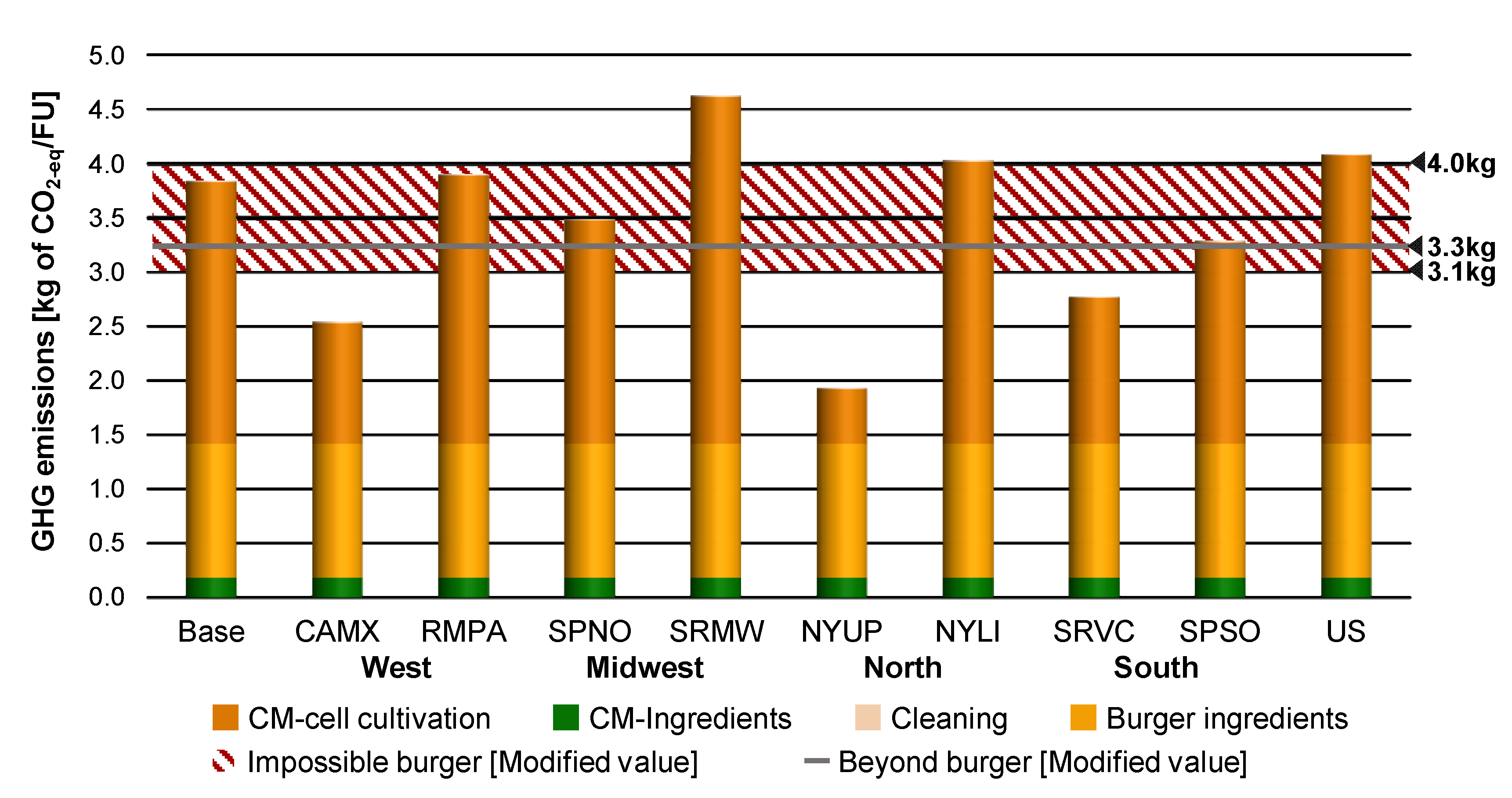

3.3. Spatial Analysis: Effect of Facility Location

3.4. Sensitivity Analysis

4. Conclusions

- Like other alternative meat and burgers, SCiFi Foods’ novel burger is environmentally better than traditional beef. GHG emissions, land use, and water use were less than 15% of the beef patty. Moreover, the energy use of the novel burger was 44% lower than that of the beef patty.

- Through the uncertainty analysis, the LCIA results of the novel burger were comparatively more reliable than the traditional meat for assessing the real-life impact by comparing the COV. Using the sensitivity analysis and case study, the LCIA results can be enhanced for the novel burger and can be further improved through technological innovation.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Drouillard, J.S. Current Situation and Future Trends for Beef Production in the United States of America—A Review. Asian-Australas. J. Anim. Sci. 2018, 31, 1007. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Tilman, D.; Clark, M. Global Diets Link Environmental Sustainability and Human Health. Nature 2014, 515, 518–522. [Google Scholar] [CrossRef] [PubMed]

- Heller, M.C.; Willits-Smith, A.; Meyer, R.; Keoleian, G.A.; Rose, D. Greenhouse Gas Emissions and Energy use Associated with Production of Individual Self-Selected US Diets. Environ. Res. Lett. 2018, 13, 044004. [Google Scholar] [CrossRef]

- Eshel, G.; Shepon, A.; Makov, T.; Milo, R. Land, Irrigation Water, Greenhouse Gas, and Reactive Nitrogen Burdens of Meat, Eggs, and Dairy Production in the United States. Proc. Natl. Acad. Sci. USA 2014, 111, 11996–12001. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bhat, Z.F.; Bhat, H.; Kumar, S. Cultured Meat—A Humane Meat Production System. In Principles of Tissue Engineering; Elsevier: Amsterdam, The Netherlands, 2020; pp. 1369–1388. [Google Scholar]

- Savadogo, P.; Sawadogo, L.; Tiveau, D. Effects of Grazing Intensity and Prescribed Fire on Soil Physical and Hydrological Properties and Pasture Yield in the Savanna Woodlands of Burkina Faso. Agric. Ecosyst. Environ. 2007, 118, 80–92. [Google Scholar] [CrossRef]

- Asner, G.P.; Elmore, A.J.; Olander, L.P.; Martin, R.E.; Harris, A.T. Grazing Systems, Ecosystem Responses, and Global Change. Annu. Rev. Environ. Resour. 2004, 29, 261–299. [Google Scholar] [CrossRef]

- De Haan, C.; Steinfeld, H.; Blackburn, H. Livestock and the Environment: Finding A Balance; Food and Agriculture Organization of the United Nations; US Agency for International Development and World Bank: Washington, DC, USA, 1997. [Google Scholar]

- Machovina, B.; Feeley, K.J.; Ripple, W.J. Biodiversity Conservation: The Key is Reducing Meat Consumption. Sci. Total Environ. 2015, 536, 419–431. [Google Scholar] [CrossRef]

- Morell, V. Meat-Eaters may Speed Worldwide Species Extinction, Study Warns. Science 2015, 11. [Google Scholar] [CrossRef]

- Pagotto, M.; Halog, A.; Costa, D.F.A.; Lu, T. A Sustainability Assessment Framework for the Australian Food Industry: Integrating Life Cycle Sustainability Assessment and Circular Economy. In Life Cycle Sustainability Assessment (LCSA); Springer: Berlin/Heidelberg, Germany, 2021; pp. 15–42. [Google Scholar]

- Marinescu, V.; Fox, B.; Cristea, D.; Roventa-Frumusani, D.; Marinache, R.; Branea, S. Talking about Sustainability: How the Media Construct the Public’s Understanding of Sustainable Food in Romania. Sustainability 2021, 13, 4609. [Google Scholar] [CrossRef]

- Urban, R.A.; Bakshi, B.R. 1, 3-Propanediol from Fossils Versus Biomass: A Life Cycle Evaluation of Emissions and Ecological Resources. Ind. Eng. Chem. Res. 2009, 48, 8068–8082. [Google Scholar] [CrossRef]

- Chang, Y.; Sproesser, G.; Neugebauer, S.; Wolf, K.; Scheumann, R.; Pittner, A.; Rethmeier, M.; Finkbeiner, M. Environmental and Social Life Cycle Assessment of Welding Technologies. Procedia Cirp. 2015, 26, 293–298. [Google Scholar] [CrossRef] [Green Version]

- Neugebauer, S.; Forin, S.; Finkbeiner, M. From Life Cycle Costing to Economic Life Cycle Assessment—Introducing an Economic Impact Pathway. Sustainability 2016, 8, 428. [Google Scholar] [CrossRef] [Green Version]

- Thonemann, N.; Schulte, A.; Maga, D. How to Conduct Prospective Life Cycle Assessment for Emerging Technologies? A Systematic Review and Methodological Guidance. Sustainability 2020, 12, 1192. [Google Scholar] [CrossRef] [Green Version]

- Notarnicola, B.; Sala, S.; Anton, A.; McLaren, S.J.; Saouter, E.; Sonesson, U. The Role of Life Cycle Assessment in Supporting Sustainable Agri-Food Systems: A Review of the Challenges. J. Clean. Prod. 2017, 140, 399–409. [Google Scholar] [CrossRef]

- Halloran, A.; Roos, N.; Eilenberg, J.; Cerutti, A.; Bruun, S. Life Cycle Assessment of Edible Insects for Food Protein: A Review. Agron. Sustain. Dev. 2016, 36, 57. [Google Scholar] [CrossRef] [Green Version]

- Hallström, E.; Carlsson-Kanyama, A.; Börjesson, P. Environmental Impact of Dietary Change: A Systematic Review. J. Clean. Prod. 2015, 91, 1–11. [Google Scholar] [CrossRef]

- Bryngelsson, D.; Wirsenius, S.; Hedenus, F.; Sonesson, U. How can the EU Climate Targets be Met? A Combined Analysis of Technological and Demand-Side Changes in Food and Agriculture. Food Policy 2016, 59, 152–164. [Google Scholar] [CrossRef] [Green Version]

- Wood, P.; Tavan, M. A Review of the Alternative Protein Industry. Curr. Opin. Food Sci. 2022, 47, 100869. [Google Scholar] [CrossRef]

- He, J.; Evans, N.M.; Liu, H.; Shao, S. A Review of Research on Plant-based Meat Alternatives: Driving Forces, History, Manufacturing, and Consumer Attitudes. Compr. Rev. Food Sci. Food Saf. 2020, 19, 2639–2656. [Google Scholar] [CrossRef]

- Listrat, A.; Lebret, B.; Louveau, I.; Astruc, T.; Bonnet, M.; Lefaucheur, L.; Picard, B.; Bugeon, J. How Muscle Structure and Composition Influence Meat and Flesh Quality. Sci. World J. 2016, 2016, 3182746. [Google Scholar] [CrossRef]

- Mattick, C.S.; Landis, A.E.; Allenby, B.R.; Genovese, N.J. Anticipatory Life Cycle Analysis of in Vitro Biomass Cultivation for Cultured Meat Production in the United States. Environ. Sci. Technol. 2015, 49, 11941–11949. [Google Scholar] [CrossRef] [PubMed]

- Smetana, S.; Schmitt, E.; Mathys, A. Sustainable use of Hermetia Illucens Insect Biomass for Feed and Food: Attributional and Consequential Life Cycle Assessment. Resour. Conserv. Recycl. 2019, 144, 285–296. [Google Scholar] [CrossRef]

- Khan, S.; Loyola, C.; Dettling, J.; Hester, J.; Moses, R. Comparative Environmental LCA of the Impossible Burger with Conventional Ground Beef Burger; Impossible Foods; Quantis: Lausanne, Switzerland, 2019. [Google Scholar]

- Heller, M.C.; Keoleian, G.A. Beyond Meat’s beyond Burger Life Cycle Assessment: A Detailed Comparison between a Plant-Based and an Animal-Based Protein Source. 2018. Available online: https://css.umich.edu/sites/default/files/publication/CSS18-10.pdf (accessed on 28 November 2022).

- Hadi, J.; Brightwell, G. Safety of Alternative Proteins: Technological, Environmental and Regulatory Aspects of Cultured Meat, Plant-Based Meat, Insect Protein and Single-Cell Protein. Foods 2021, 10, 1226. [Google Scholar] [CrossRef] [PubMed]

- Kustar, A.; Patino-Echeverri, D. A Review of Environmental Life Cycle Assessments of Diets: Plant-Based Solutions are Truly Sustainable, Even in the Form of Fast Foods. Sustainability 2021, 13, 9926. [Google Scholar] [CrossRef]

- Calderón, L.A.; Iglesias, L.; Laca, A.; Herrero, M.; Díaz, M. The Utility of Life Cycle Assessment in the Ready Meal Food Industry. Resour. Conserv. Recycl. 2010, 54, 1196–1207. [Google Scholar] [CrossRef]

- Turconi, R.; Boldrin, A.; Astrup, T. Life Cycle Assessment (LCA) of Electricity Generation Technologies: Overview, Comparability and Limitations. Renew. Sustain. Energy Rev. 2013, 28, 555–565. [Google Scholar] [CrossRef] [Green Version]

- Stoessel, F.; Juraske, R.; Pfister, S.; Hellweg, S. Life Cycle Inventory and Carbon and Water Foodprint of Fruits and Vegetables: Application to a Swiss Retailer. Environ. Sci. Technol. 2012, 46, 3253–3262. [Google Scholar] [CrossRef]

- Abyar, H.; Younesi, H.; Nowrouzi, M. Life Cycle Assessment of A2O Bioreactor for Meat Processing Wastewater Treatment: An Endeavor Toward the Achievement of Environmental Sustainable Development. J. Clean. Prod. 2020, 257, 120575. [Google Scholar] [CrossRef]

- Tuomisto, H.L.; Teixeira de Mattos, M.J. Environmental Impacts of Cultured Meat Production. Environ. Sci. Technol. 2011, 45, 6117–6123. [Google Scholar] [CrossRef]

- Smetana, S.; Mathys, A.; Knoch, A.; Heinz, V. Meat Alternatives: Life Cycle Assessment of most Known Meat Substitutes. Int. J. Life Cycle Assess. 2015, 20, 1254–1267. [Google Scholar] [CrossRef]

- Dunn, J.B.; Adom, F.; Sather, N.; Han, J.; Snyder, S.; He, C.; Gong, J.; Yue, D.; You, F. Life-Cycle Analysis of Bioproducts and Their Conventional Counterparts in GREET; Argonne National Lab (ANL): Argonne, IL, USA, 2015. [Google Scholar]

- Jin, D.; Liu, S.; Xu, L.; Ye, H. Study of a Cleaner Extraction of Pyruvic Acid from Fermentation Broth. Afr. J. Biotechnol. 2011, 10, 14083–14089. [Google Scholar]

- Causey, T.B.; Shanmugam, K.T.; Yomano, L.P.; Ingram, L.O. Engineering Escherichia Coli for Efficient Conversion of Glucose to Pyruvate. Proc. Natl. Acad. Sci. USA 2004, 101, 2235–2240. [Google Scholar] [CrossRef] [Green Version]

- Sung, Y.H.; Lim, S.W.; Chung, J.Y.; Lee, G. Yeast Hydrolysate as a Low-Cost Additive to Serum-Free Medium for the Production of Human Thrombopoietin in Suspension Cultures of Chinese Hamster Ovary Cells. Appl. Microbiol. Biotechnol. 2004, 63, 527–536. [Google Scholar] [CrossRef]

- Li, J.; Ma, C.; Ma, Y.; Li, Y.; Zhou, W.; Xu, P. Medium Optimization by Combination of Response Surface Methodology and Desirability Function: An Application in Glutamine Production. Appl. Microbiol. Biotechnol. 2007, 74, 563–571. [Google Scholar] [CrossRef]

- Survase, S.A.; Bajaj, I.B.; Singhal, R.S. Biotechnological Production of Vitamins. Food Technol. Biotechnol. 2006, 44, 381–396. [Google Scholar]

- Shimizu, S. Vitamins and Related Compounds: Microbial Production. Biotechnol. Set 2001, 318–340. [Google Scholar]

- Maroulis, Z.B.; Saravacos, G.D. Food Process Design; CRC Press: Boca Raton, FL, USA, 2003. [Google Scholar]

- Smetana, S.; Profeta, A.; Voigt, R.; Kircher, C.; Heinz, V. Meat Substitution in Burgers: Nutritional Scoring, Sensorial Testing, and Life Cycle Assessment. Future Foods 2021, 4, 100042. [Google Scholar] [CrossRef]

- Heusala, H.; Sinkko, T.; Sözer, N.; Hytönen, E.; Mogensen, L.; Knudsen, M.T. Carbon Footprint and Land use of Oat and Faba Bean Protein Concentrates using a Life Cycle Assessment Approach. J. Clean. Prod. 2020, 242, 118376. [Google Scholar] [CrossRef]

- Berardy, A.; Costello, C.; Seager, T.P. Life Cycle Assessment of Soy Protein Isolate. In Proceedings of the International Symposium on Sustainable Systems and Tchnologies, Pittsburgh, PA, USA, 18–20 May 2015; Sustainable Conoscente Network: Tempe, AZ, USA, 2015; Volume 3. [Google Scholar]

- Brewer, M.S. Reducing the Fat Content in Ground Beef without Sacrificing Quality: A Review. Meat Sci. 2012, 91, 385–395. [Google Scholar] [CrossRef]

- Wei, W.; Larrey-Lassalle, P.; Faure, T.; Dumoulin, N.; Roux, P.; Mathias, J. Using the Reliability Theory for Assessing the Decision Confidence Probability for Comparative Life Cycle Assessments. Environ. Sci. Technol. 2016, 50, 2272–2280. [Google Scholar] [CrossRef]

- Beausang, C.; McDonnell, K.; Murphy, F. Assessing the Environmental Sustainability of Grass Silage and Cattle Slurry for Biogas Production. J. Clean. Prod. 2021, 298, 126838. [Google Scholar] [CrossRef]

- Igos, E.; Benetto, E.; Meyer, R.; Baustert, P.; Othoniel, B. How to Treat Uncertainties in Life Cycle Assessment Studies? Int. J. Life Cycle Assess. 2019, 24, 794–807. [Google Scholar] [CrossRef]

- Ask.OpenLCA. Negative Water Use. Available online: https://ask.openlca.org/1949/certain-processes-ecoinvent-modelled-with-negative-output (accessed on 9 April 2022).

- Sultana, M.N.; Uddin, M.M.; Ridoutt, B.G.; Peters, K.J. Comparison of Water use in Global Milk Production for Different Typical Farms. Agric. Syst. 2014, 129, 9–21. [Google Scholar] [CrossRef]

- Kiss, B.; Kácsor, E.; Szalay, Z. Environmental Assessment of Future Electricity mix–Linking an Hourly Economic Model with LCA. J. Clean. Prod. 2020, 264, 121536. [Google Scholar] [CrossRef]

- Jaggai, C.; Imkaraaz, Z.; Samm, K.; Pounder, A.; Koylass, N.; Chakrabarti, D.P.; Guo, M.; Ward, K. Towards Greater Sustainable Development within Current Mega-Methanol (MM) Production. Green Chem. 2020, 22, 4279–4294. [Google Scholar] [CrossRef]

- United States Environmental Protection Agency (USEPA). Emissions & Generation Resource Integrated Database (eGRID). Available online: https://www.epa.gov/egrid (accessed on 18 March 2022).

- Liu, X.; Jin, J.; Wang, G.; Herbert, S.J. Soybean Yield Physiology and Development of High-Yielding Practices in Northeast China. Field Crops Res. 2008, 105, 157–171. [Google Scholar] [CrossRef]

- Arena, N.; Lee, J.; Clift, R. Life Cycle Assessment of Activated Carbon Production from Coconut Shells. J. Clean. Prod. 2016, 125, 68–77. [Google Scholar] [CrossRef]

| Tuomisto and Mattos (2011) [34] | Mattick et al. (2015) [24] | Smetana et al. (2015) [35] | Beyond Meat (2017) [27] | Impossible Foods (2019) [26] | This Study | |

|---|---|---|---|---|---|---|

| Functional Unit | 1 ton of cultivated meat | 1 kg of Chinese hamster ovary biomass | 1 kg of protein-concentrated meal | 4 oz of Beyond burger | 4 oz of Impossible burger | 1 kg of novel burger |

| System boundaries | Cradle-to-gate | Cradle-to-gate | Cradle-to-gate | Cradle-to-distribution | Cradle-to-gate | Cradle-to-gate |

| Life cycle inventory | European Life Cycle (ELCD) V2.0 and calculation | US LCI, Ecoinvent V2.0, European Life Cycle (ELCD) V2.0 | Agri-footprint and Ecoinvent V3.1 | Ecoinvent V3.0 and Agrifootprint V3.0 | Ecoinvent V3.3, World Food Lifecycle Database V3.1 | Ecoinvent V3.8 and Agribalyse V3.0.1 |

| LCIA method | ||||||

| GHG emission | ISO14000 | CML 2001 | Impact 2002+ | IPCC 2007 | Impact 2002+ | CML-IA |

| Energy use | ISO14000 | Cumulative energy demand | Impact 2002+ | Cumulative energy demand | - | Cumulative energy demand |

| Land use | ISO14000 | Ecological footprint | Impact 2002+ | Calculation | Impact 2002+ | ReCiPe 2016 midpoint (E) |

| Water use | ISO14000 | - | Impact 2002+ | Calculation | Impact 2002+ | ReCiPe 2016 midpoint (E) |

| USCLI | Ecoinvent V3.8 | ELCD V3.0 | Agri-Footprint V5.0 | Agribalyse V3.0.1 | |

|---|---|---|---|---|---|

| Compounds (62) | 6 | 18 | 2 | 2 | 20 |

| Salts (16) | 5 | 12 | 1 | 1 | 12 |

| Amino acids (21) | 0 | 3 | 0 | 0 | 6 |

| Vitamins (11) | 0 | 0 | 0 | 0 | 0 |

| Lipids (2) | 0 | 0 | 0 | 0 | 1 |

| Others (12) | 1 | 3 | 1 | 1 | 2 |

| Utilities (Heat & Elec.) | O | O | O | O | O |

| Substances | [wt%] |

|---|---|

| Water | 50.5 |

| Cultivated meat | 16.9 |

| Soy protein isolate | 10.0 |

| Coconut oil | 7.0 |

| Mushrooms | 5.3 |

| Sunflower oil | 5.0 |

| Oat | 2.0 |

| Methylcellulose | 1.5 |

| Potato starch | 1.5 |

| Salt | 0.2 |

| Citric acid | 0.2 |

| GHG Emissions | Energy Demand | Water Use | Land Use | |

|---|---|---|---|---|

| Novel burger | 6.8% | 4.6% | 14.9% | 130.0% |

| Beef burger | 10.3% | 12.2% | 40.0% | 29.2% |

| −25% | Base Line | +25% | |

|---|---|---|---|

| Motor yield [%] | 45/53 | 60/70 | 75/88 |

| Soybean cultivation yield [kg/m2] | 0.045 | 0.059 | 0.074 |

| Coconut cultivation yield [kg/m2] | 0.107 | 0.143 | 0.179 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, S.; Beier, A.; Schreyer, H.B.; Bakshi, B.R. Environmental Life Cycle Assessment of a Novel Cultivated Meat Burger Patty in the United States. Sustainability 2022, 14, 16133. https://doi.org/10.3390/su142316133

Kim S, Beier A, Schreyer HB, Bakshi BR. Environmental Life Cycle Assessment of a Novel Cultivated Meat Burger Patty in the United States. Sustainability. 2022; 14(23):16133. https://doi.org/10.3390/su142316133

Chicago/Turabian StyleKim, Sunghoon, Adam Beier, H. Brett Schreyer, and Bhavik R. Bakshi. 2022. "Environmental Life Cycle Assessment of a Novel Cultivated Meat Burger Patty in the United States" Sustainability 14, no. 23: 16133. https://doi.org/10.3390/su142316133