Reuse and Retrofitting Strategies for a Net Zero Carbon Building in Milan: An Analytic Evaluation

Abstract

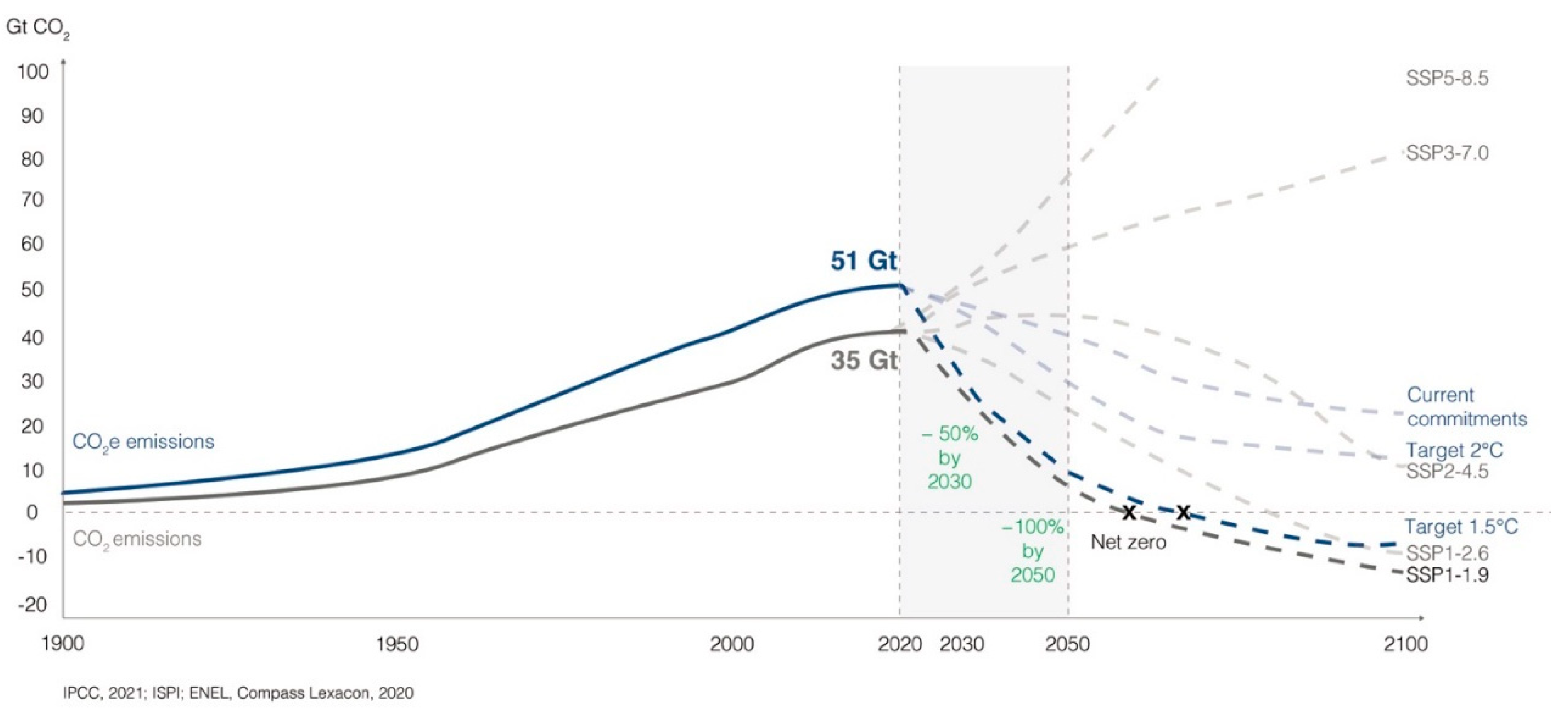

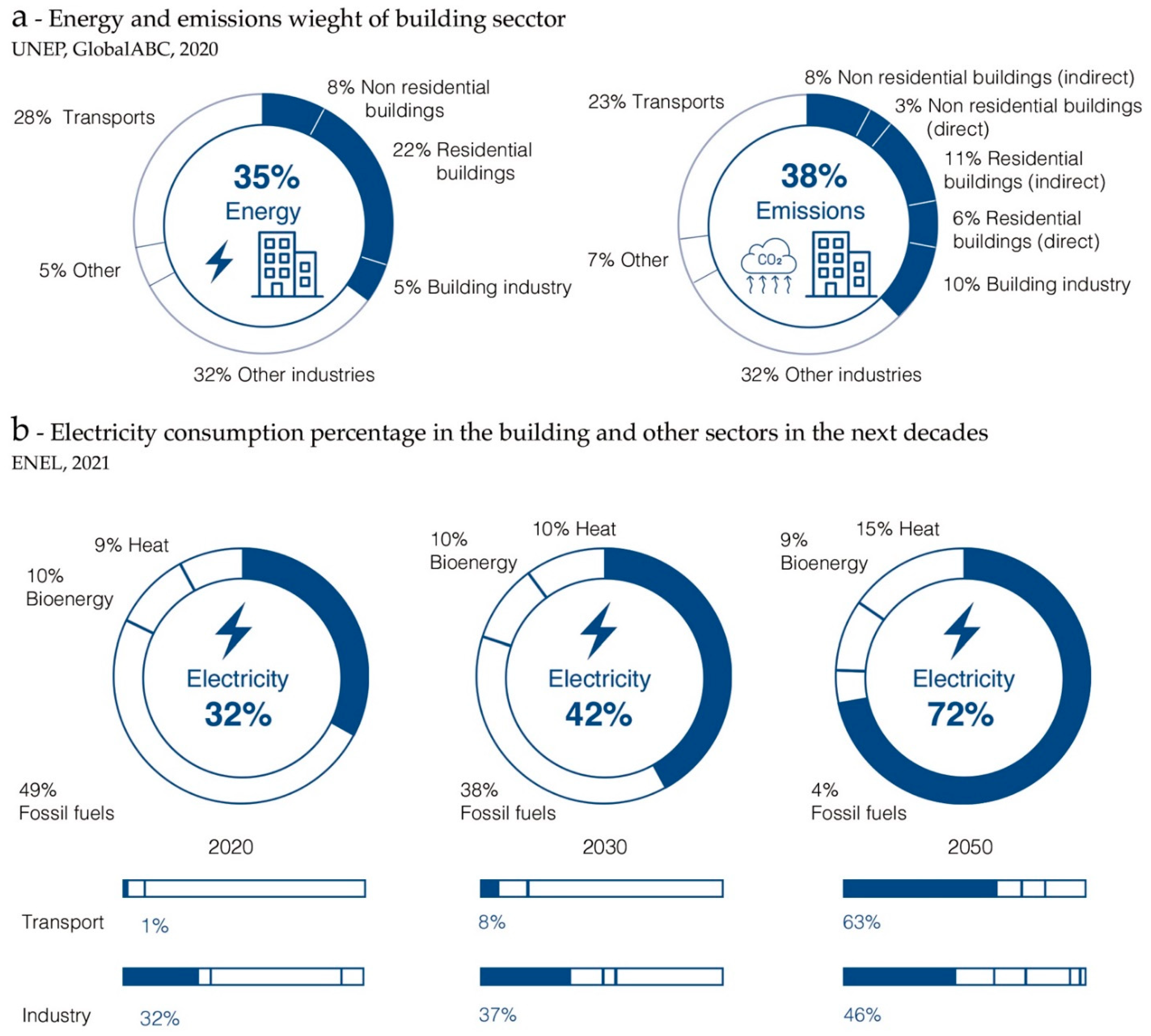

1. Introduction

2. Materials and Methods

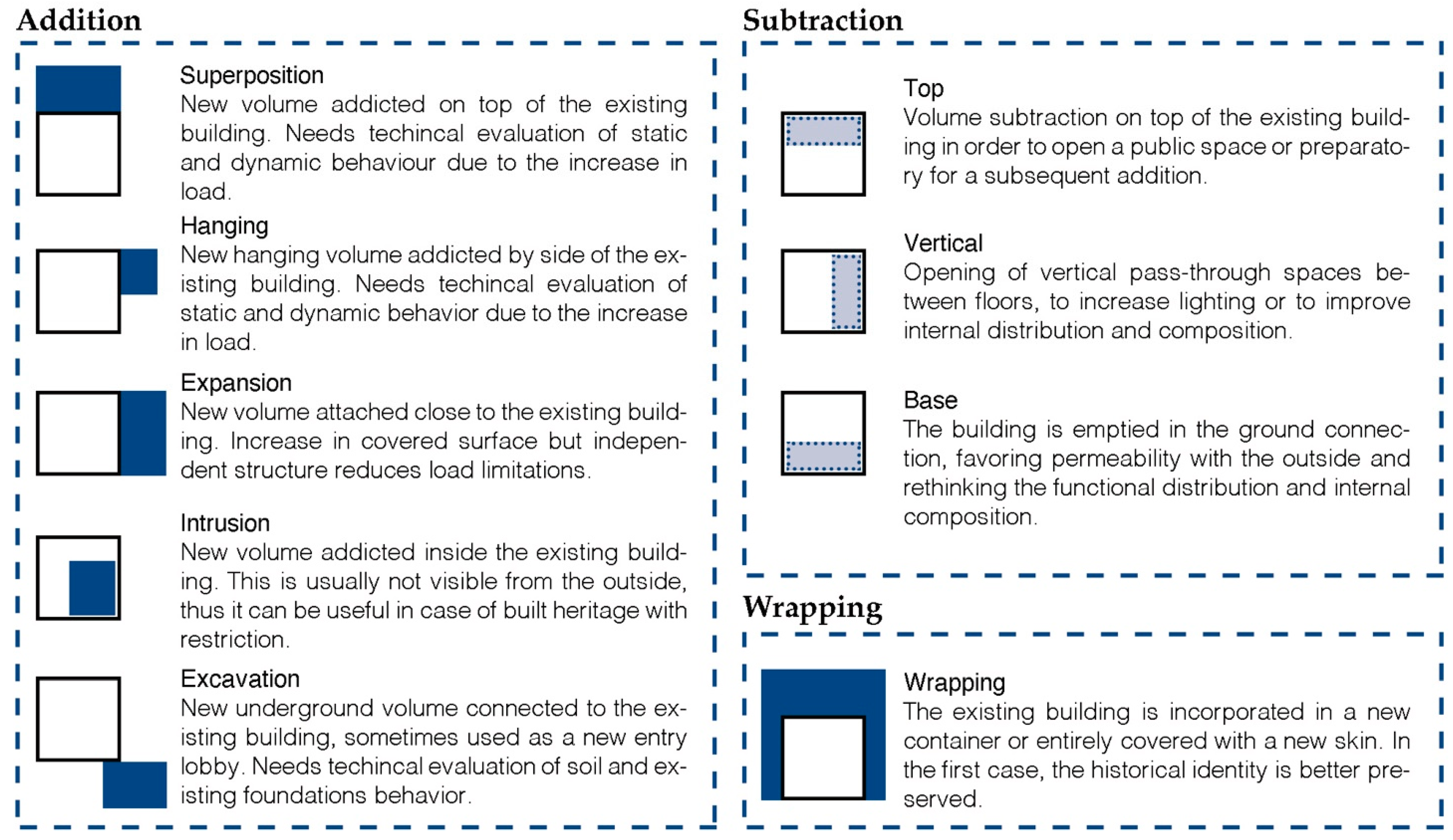

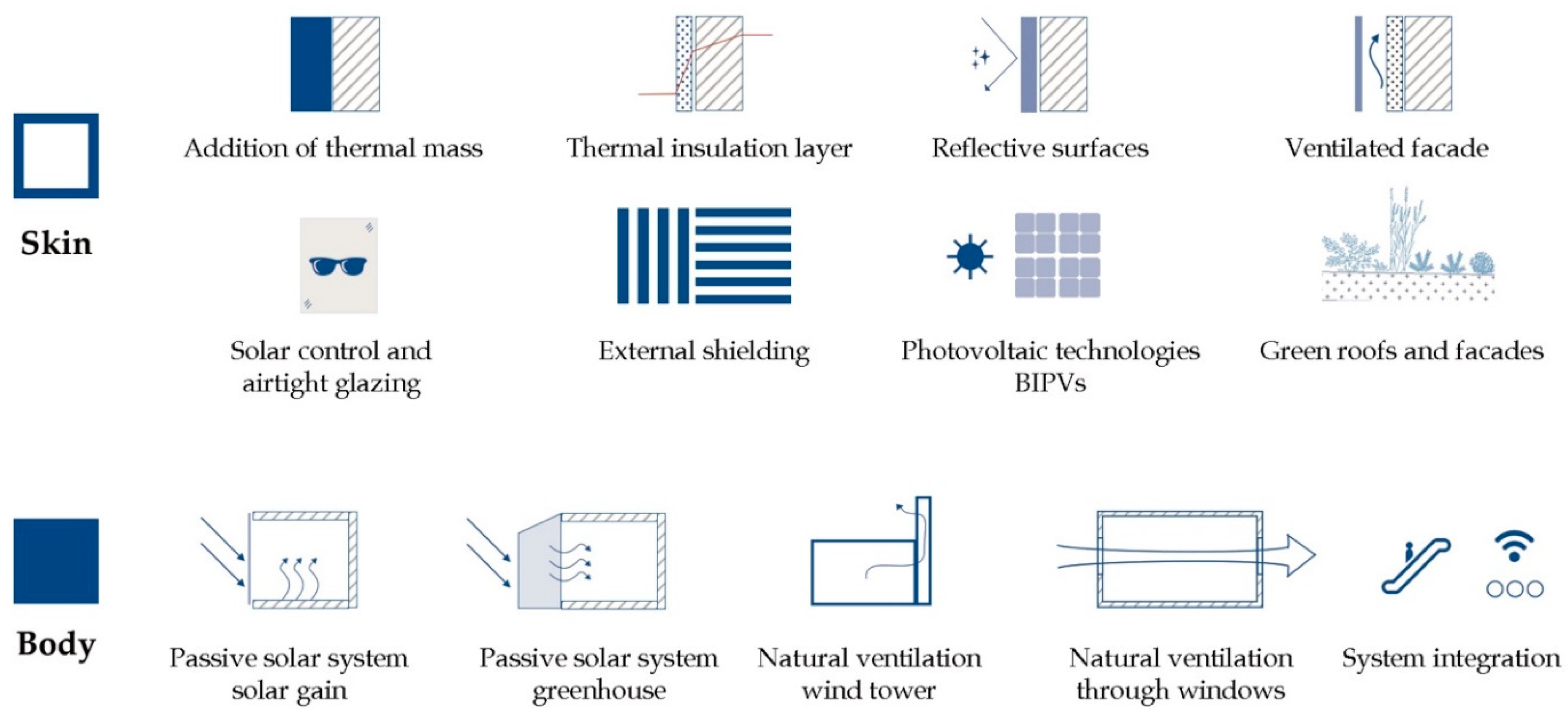

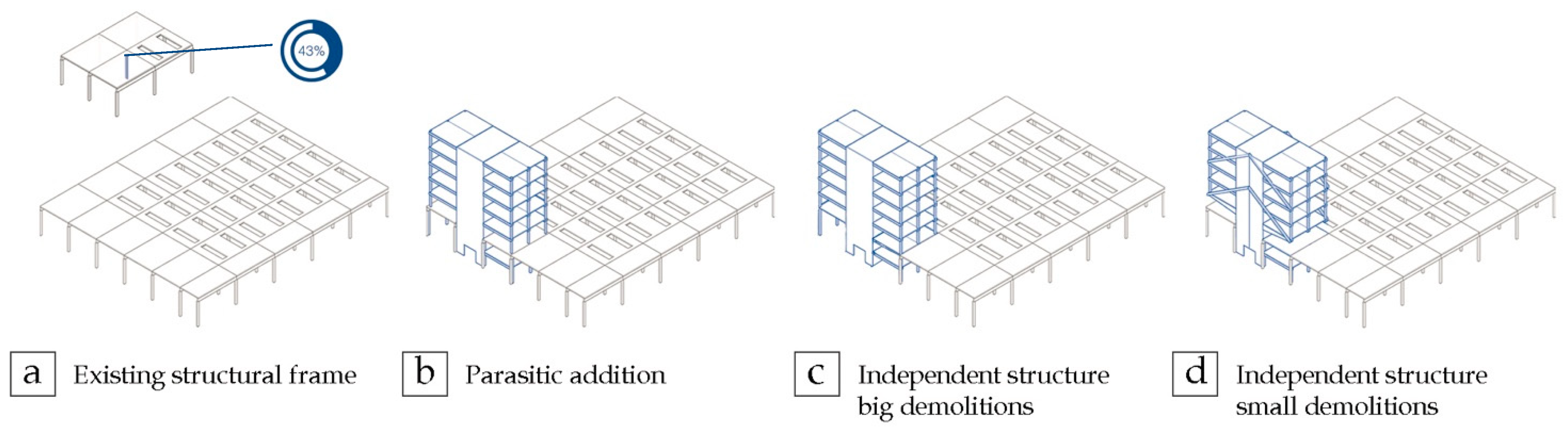

2.1. Reuse and Retrofit Strategies

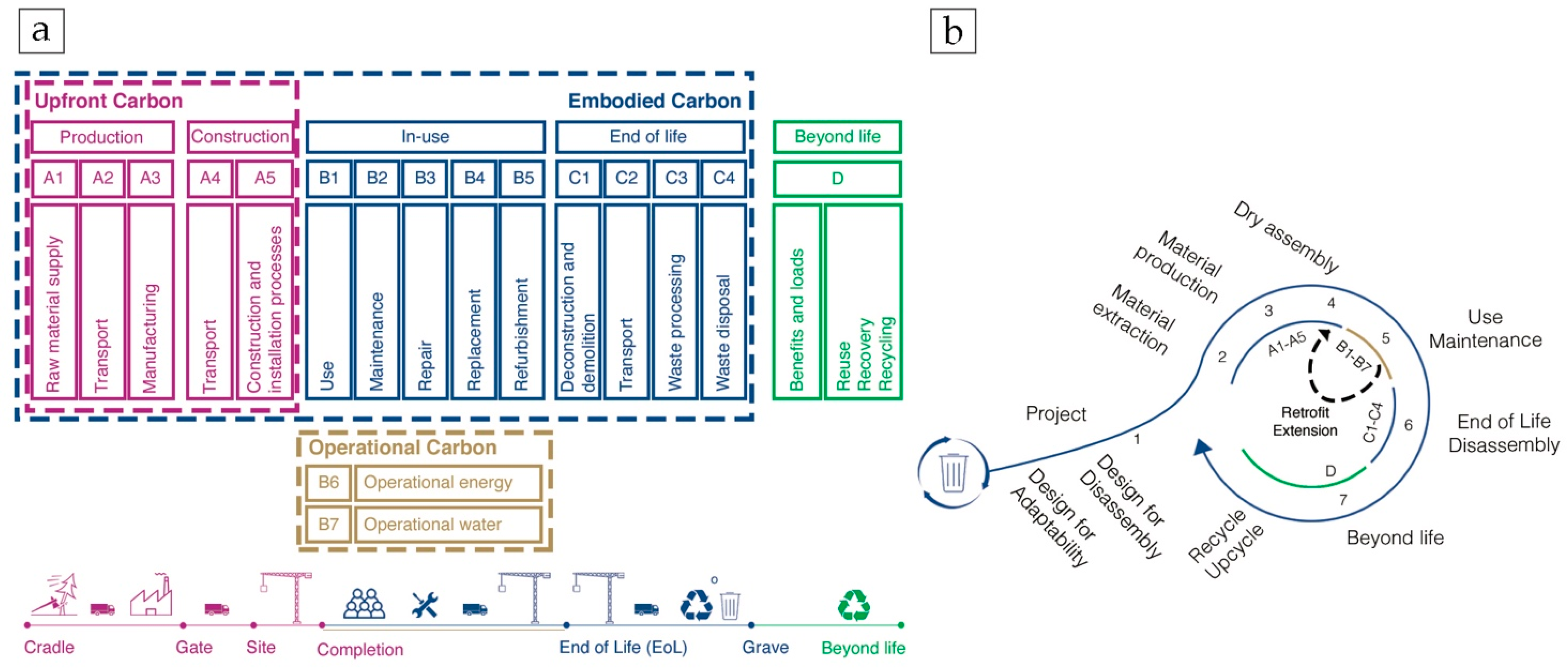

2.2. Carbon Emissions Assessment

2.3. Net Zero Carbon Buildings Strategies

- Pay-per-pollute: the cost of offsetting emissions is proportional to the emissions produced; therefore, the adoption of good emission reduction practices is encouraged for economic reasons.

- Encourage transparency: making public the data on detected and not estimated greenhouse gas emissions generates a virtuous cycle that drives efficiency, also raising public awareness on the issue.

- Encourage action in the present to be able to tighten the links in the future: starting with a net zero carbon approach for the operational and construction part helps in the task of evaluating the entire life cycle in the future, when the buildings are decommissioned, when there will be more knowledge about it [13].

2.4. Negative Carbon Contributions

2.5. LCA Software Implementation

2.6. Existing Building Description and Evaluation of Reuse Capability

3. Results

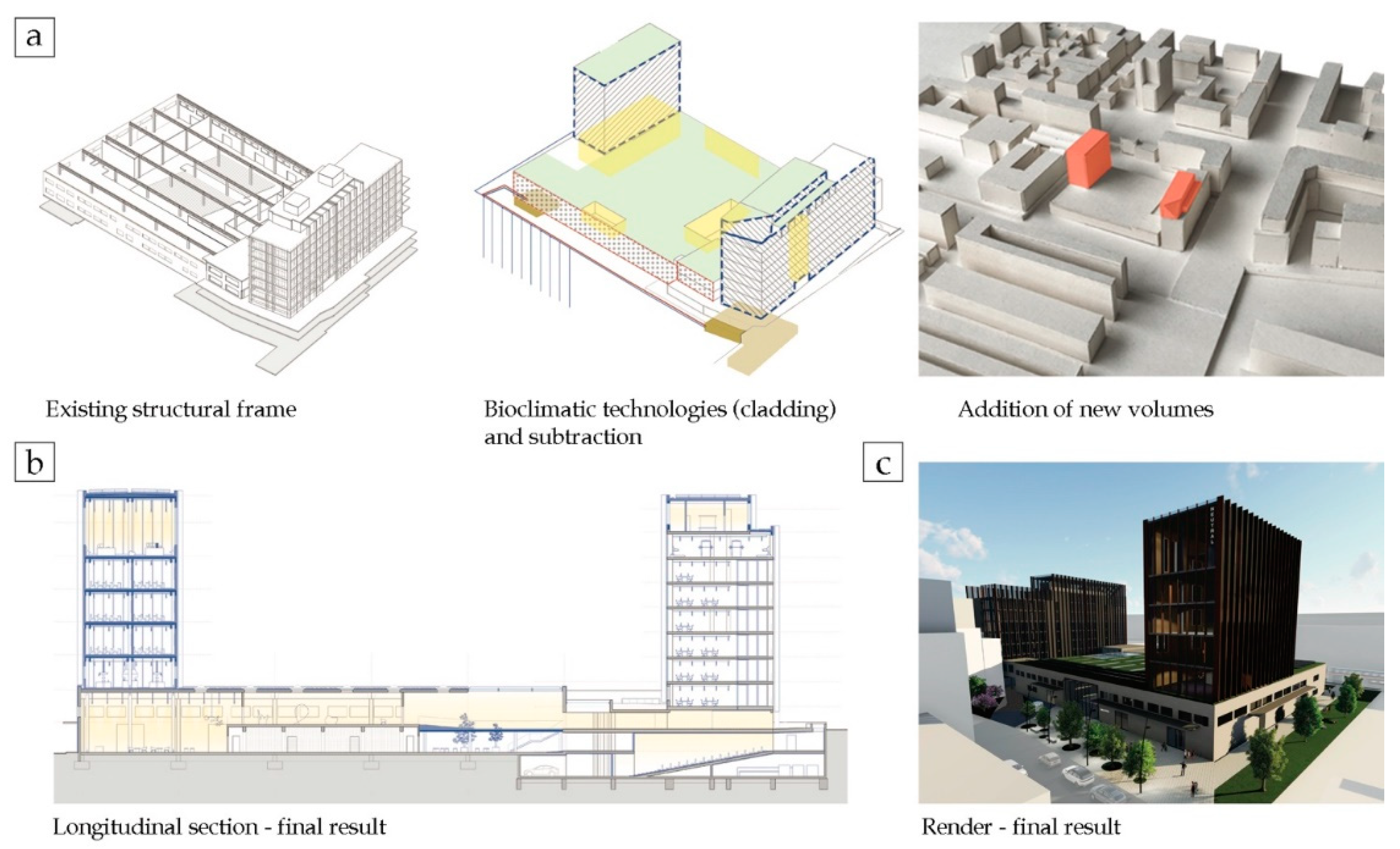

3.1. Ripamonti 42 Building Reuse: Design Process

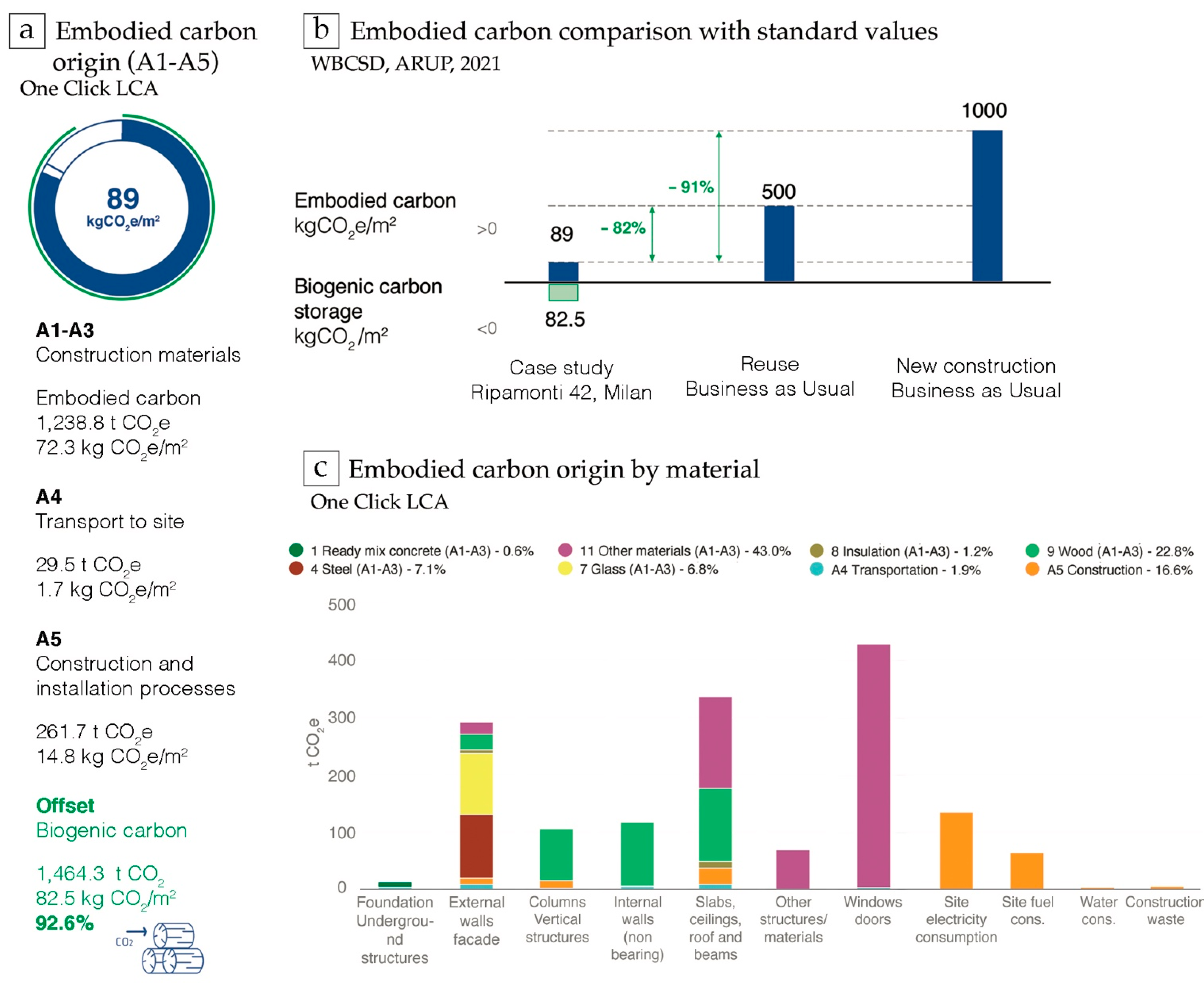

3.2. Analytical Discussion on Embodied Carbon Results Obtained with the Software

3.3. Net Zero Carbon Buildings: Adopted Strategies

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviation

| BIM | Building Information Modeling |

| BOQ | Bill of Quantities |

| C&DW | Construction and Demolition Waste |

| DT | Digital Twin |

| EoL | End of Life |

| EPD | Environmental Product Declaration |

| GFA | Gross Floor Area |

| LCA | Life Cycle Assessment |

| NZCB | Net Zero Carbon Buildings |

| nZEB | nearly Zero Energy Buildings |

| WLCA | Whole Life Carbon Assessment |

Appendix A

| Embodied Carbon Report—Construction Materials and Construction Site Operations—One Click LCA Planetary Italy | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| A—Construction materials | Quantity | Unit | km | Transport Mode | Waste (%) | GWP [kgCO2e/unit] | Biogenic CO2 [kgCO2/unit] | |||

| 1. Foundations | 16 t CO2e—1% | |||||||||

| Foundations, subsoil, basements and retaining walls | ||||||||||

| Ready-mix concrete, normal strength C28/35 60% GGBS content | 86.85 | m3 | 100 | Concrete mixer truck | 4 | 153.89 | 1.01 | |||

| Reinforcement steel (rebar), 80% recycled content | 0.60 | t | 50 | Trailer combination, 40 ton, 100% fill | 5 | 920.00 | 0.00 | |||

| Formwork panel from EPS for crawl s space (Aircrab H35) | 143 | m2 | 50 | Large delivery truck, 9 ton, 50% fill | 4 | 8.00 | 0.00 | |||

| PVC waterproofing membrane, 1.5 mm (Mapelan plus) | 154 | m2 | 1.5 | mm | 50 | Large delivery truck, 9 ton, 100% fill | 10 | 4.76 | 0.00 | |

| 2. Vertical structures and facades | 515 t CO2e—33% | |||||||||

| External walls and facades | ||||||||||

| Natural cork insulation panel, λ = 0.043 W/mK (LIS srl) | 5.950 | m2 | 100 | mm | 350 | Large delivery truck, 9 ton, 100% fill | 8 | 0.87 | 30.43 | |

| Float glass, single pane, generic | 5.500 | m2 | 6 | mm | 100 | Large delivery truck, 9 ton, 100% fill | 1 | 12.25 | 0.00 | |

| Aluminium frame windows, U = 1.0 W/m2K (Metra) | 93 | m2 | 100 | Trailer combination, 40 ton, 50% fill | None | 159.00 | 0.00 | |||

| Solid wood panels, 493 kg/m3, 9% moisture content (Nordpan) | 108 | m3 | 500 | Large delivery truck, 9 ton, 100% fill | 18 | 256.83 | 903.83 | |||

| Sandstone cladding, natural, 20 mm, (Casone group) | 43 | m3 | 60 | Large delivery truck, 9 ton, 50% fill | 5 | 151.47 | 0.00 | |||

| Steel sheets, generic, 90% recycled content S235 | 12.50 | m3 | 50 | Trailer combination, 40 ton, 100% fill | 3 | 4783.32 | 0.00 | |||

| Pillars, columns, structural walls | ||||||||||

| Glued laminated timber (Glulam), 464 kg/m3, 12% moisture (Rubner) | 37.60 | m3 | 400 | Trailer combination, 40 ton, 100% fill | 17 | 204.67 | 850.67 | |||

| Cross laminated timber (CLT), 461 kg/m3, 11% moisture (Rubner) | 390 | m3 | 100 | Trailer combination, 40 ton, 100% fill | 17 | 181.17 | 845.17 | |||

| Timber frame external wall element, U = 0.16 W/m2K (Lapwall) | 1.032 | m2 | 500 | Trailer combination, 40 ton, 100% fill | None | 13.00 | 23.90 | |||

| Internal walls and non-structural elements | ||||||||||

| Timber frame external wall element, U = 0.16 W/m2K (Lapwall) | 5.287 | m2 | 400 | Trailer combination, 40 ton, 100% fill | None | 21.20 | 17.30 | |||

| 3. Horizontal structures: beams, slabs, roofs | 337 t CO2e—21% | |||||||||

| Slabs, ceilings, beams and roofs | ||||||||||

| Cross laminated timber (CLT), 461 kg/m3, 11% moisture (Rubner) | 626 | m3 | 100 | Trailer combination, 40 ton, 100% fill | 17 | 181.17 | 845.17 | |||

| Glued laminated timber (Glulam), 464 kg/m3, 12% moisture (Rubner) | 69.50 | m3 | 400 | Trailer combination, 40 ton, 100% fill | 17 | 204.67 | 850.67 | |||

| NHL (natural hydraulic lime) based floor screed (Domus VR opus-c) | 2.600 | m2 | 80 | mm | 100 | Large delivery truck, 9 ton, 100% fill | 13 | 149.53 | 0.00 | |

| Natural cork insulation panel, lambda = 0.043 W/mK (LIS srl) | 5.847 | m2 | 100 | mm | 350 | Trailer combination, 40 ton, 100% fill | 8 | 0.87 | 30.43 | |

| Wet sand (Gruppo Bassanetti) | 321 | ton | 40 | Dumper truck, 19 ton, 100% fill | None | 0.00 | 0.00 | |||

| Wood-alu frame window, triple-glazed, U = 1.0 W/m2K (Pihla group) | 500 | m2 | 100 | Delivery van, 1.2 ton, 100% fill | None | 118.81 | 24.33 | |||

| Aluminium frame windows, U = 1.0 W/m2K (Metra) | 350 | m2 | 100 | Trailer combination, 40 ton, 100% fill | None | 159.00 | 0.00 | |||

| Bitumen-polymer membrane roofing, 2 layer (EWA) | 3.450 | m2 | 5 | mm | 90 | Trailer combination, 40 ton, 100% fill | 10 | 5.45 | 0.00 | |

| EPS insulation, L = 0.036 W/mK, 36 mm (Rexpol) | 3.450 | m2 | 90 | Trailer combination, 40 ton, 100% fill | 4 | 1.95 | 0.00 | |||

| 4. Other structures and materials | 499 t CO2e—32% | |||||||||

| Other structures and materials | ||||||||||

| Elevator, 630 kg capacity, for passenger use (Monospace 500 DX-Kone) | 8 | unit | 320 | Large delivery truck, 9 ton, 100% fill | None | 8529.84 | 23.17 | |||

| Windows and doors | ||||||||||

| Wood-alu frame window, triple-glazed, U = 1.0 W/m2K (Pihla group) | 3.180 | m2 | 100 | Delivery van, 1.2 ton, 100% fill | None | 118.81 | 24.33 | |||

| Aluminium frame windows, U = 1.0 W/m2K (Metra) | 80 | m2 | 100 | Large delivery truck, 9 ton, 100% fill | None | 159.00 | 0.00 | |||

| MDF hollow-core door, veneered, (Abet Laminam) | 346 | unit | 100 | Trailer combination, 40 ton, 100% fill | None | 102.70 | 10.09 | |||

| B—Construction site operations | Quantity | unit | CO2e | km | Transport mode | Waste (%) | GWP [kgCO2/unità] | |||

| 1. Construction site scenarios | ||||||||||

| 2. Energy use on the site | 200 t CO2e—13% | |||||||||

| Site electricity consumption | ||||||||||

| Electricity, Italy | 267.000 | kWh | 135 t—9% | 15 kWh/m2 | 0.51 | |||||

| Site district heating consumption | ||||||||||

| Site fuel consumption | ||||||||||

| Diesel | 20.000 | L | 65 t—4% | 3.24 | ||||||

| Machine hours | ||||||||||

| 3. Materials use on the site (that do not constitute part of the asset) | ||||||||||

| Material use | ||||||||||

| 4. Water use on the site | 3 t CO2e | |||||||||

| Water consumption | ||||||||||

| Tap water, clean and wastewater | 5.000 | m3 | 3.5 t—0.2% | 0.69 | ||||||

| 5. Waste generated on the site | 5 t CO2e | |||||||||

| Construction waste | ||||||||||

| Inert waste landfilling | 450 | ton | 4.8 t—0.3% | 0 | Trailer combination, 40 ton, 100% fill | None | 0.01 | |||

| 6. Additional trips for the transport to the construction site | 0.51 t CO2e | |||||||||

| Additional transportation | ||||||||||

| Transported mass | 346 | ton | 0.51 t—~0% | 20 | Dumper truck, 19 ton, 100% fill | None | ||||

References

- Gates, B. Clima, Come Evitare Un Disastro; La nave di Teseo: Milan, Italy, 2021; pp. 11–38. [Google Scholar]

- Intergovernmental Panel on Climate Changes (IPCC), Summary for Policymakers. Climate Change 2021: The Physical Science Basis. Contribution of Working Group I to the Sixth Assessment Report of the Intergovernmental Panel on Climate Change; Masson-Delmotte, V., Zhai, P., Pirani, A., Eds.; Cambridge University Press: Cambridge, UK; New York, NY, USA, 2007; pp. 3–32. [Google Scholar] [CrossRef]

- Compass Lexacon; Enerdata; ENEL Foundation. Sustainable Paths for EU Increased Climate and Energy Ambition, Final Report; ENEL Foundation: Rome, Italy, 2020. [Google Scholar]

- Istituto Per Gli Studi di Politica Internazionale (ISPI): Andamento Delle Emissioni Globali in Tre Scenari. Available online: https://www.ispionline.it/it/pubblicazione/fact-checking-i-cambiamenti-climatici-10-grafici-32170 (accessed on 6 October 2022).

- United Nations (UN). Declaration of the United Nations Conference on the Human Environment; UN: Stockholm, Sweden, 1972. [Google Scholar]

- Chou, J.R. A Scoping Review of Ontologies Relevant to Design Strategies in Response to the UN Sustainable Development Goals (SDGs). Sustainability 2021, 13, 10012. [Google Scholar] [CrossRef]

- United Nations General Assembly (UNGA). Transforming Our World: The 2030 Agenda for Sustainable Development; United Nations General Assembly: New York, NY, USA, 2015. [Google Scholar]

- United Nations (UN). Paris Agreement; UN: Paris, France, 2015; pp. 2–4. [Google Scholar]

- International Energy Agency (IEA). Net Zero by 2050. A Roadmap for the Global Energy Sector, Summary for Policymakers; IEA: Paris, France, 2021; pp. 4–5. [Google Scholar]

- United Nations Environment Programme (UNEP); Global Alliance for Buildings and Construction (GlobalABC). 2020 Global Status Report for Buildings and Construction: Towards a Zero-Emissions, Efficient and Resilient Buildings and Construction Sector; UNEP: Nairobi, Kenya, 2020; p. 10. [Google Scholar]

- United Nations Framework Convention on Climate Change (UNFCCC). Climate Action Pathway, Human Settlements; UNFCCC: Bonn, Germany, 2021; pp. 2–6. [Google Scholar]

- International Energy Agency (IEA). The Critical Role of the Buildings. In Perspectives for the Clean Energy Transition; IEA: Paris, France, 2017; p. 39. [Google Scholar]

- UK Green Building Council (UKGBC). Net Zero Carbon Buildings: A Framework Definition; UKGBC: London, UK, 2019. [Google Scholar]

- Besana, D.; Greco, A.; Morandotti, M. Resilienza e sostenibilità per il riuso del patrimonio costruito. TECHNE 2018, 15, 184–192. [Google Scholar] [CrossRef]

- Hill, S.; Dalzell, A.; Allwood, M. Net Zero Carbon Buildings: Three Steps to Take Now; ARUP: London, UK, 2020; pp. 7–13. Available online: https://www.arup.com/perspectives/publications/research/section/net-zero-carbon-buildings-three-steps-to-take-now (accessed on 6 October 2022).

- Greco, A.; Besana, D.; Giacometti, V.; Mericco, M.; Lombardi, S.; Borlini, A.; Turino, R.; Ruggeri, C. The Transformation of Healthcare Buildings: The Challenges of the University of Pavia for Urban Regeneration. Sustainability 2022, 14, 1517. [Google Scholar] [CrossRef]

- Governo Italiano. Piano Nazionale di Ripresa e Resilienza—Italia Domani; Governo: Rome, Italy, 2021; pp. 143–146.

- Davies, J. Designing for new uses, standards and requirements in the twenty-first century. In Sustainable Retrofitting of Commercial Buildings: Cool Climates; Burton, S., Ed.; Routledge: New York, NY, USA, 2015; pp. 10–11. [Google Scholar]

- Wong, L. Adaptive Reuse: Extending the Lives of Buildings; Birkhäuser: Basel, Switzerland, 2017; pp. 197–201. [Google Scholar]

- AD Classics: Le Grand Louvre/I.M.Pei. Available online: https://www.archdaily.com/88705/ad-classics-le-grande-louvre-i-m-pei (accessed on 12 August 2022).

- Department of Islamic Arts at Musèe du Louvre by Mario Bellini and Rudy Ricciotti. Available online: https://www.dezeen.com/2012/09/24/department-of-islamic-arts-at-louvre-by-mario-bellini-and-rudy-ricciotti/ (accessed on 6 October 2022).

- Grecchi, M.; Malighetti, L.E. Ripensare il Costruito: Il Progetto di Recupero e Rifunzionalizzazione Degli Edifici; Maggioli Editore: Santarcangelo di Romagna, Italy, 2010; pp. 289–300. [Google Scholar]

- Gething, B. Resilience to a changing climate. In Sustainable Retrofitting of Commercial Buildings: Cool Climates; Burton, S., Ed.; Routledge: New York, NY, USA, 2015; pp. 47–49. [Google Scholar]

- La Roche, P.M. Carbon-Neutral Architectural Design; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar]

- D’Olimpio, D. Il Retrofitting Energetico e Bioclimatico Nella Riqualificazione Edilizia; Legislazione Tecnica: Rome, Italy, 2017. [Google Scholar]

- Martín-Chivelet, N.; Kapsis, K.; Wilson, H.R.; Delisle, V.; Yang, R.; Olivieri, L.; Polo, J.; Eisenlohr, J.; Roy, B.; Maturi, L.; et al. Building-Integrated Photovoltaic (BIPV) products and systems: A review of energy-related behavior. Energy Build. 2022, 226, 111998. [Google Scholar] [CrossRef]

- Satola, D.; Balouktsi, M.; Lützkendorf, M.; Wiberg, A.H.; Gustavsen, A. How to define (net) zero greenhouses gas emissions buildings: The results of an international survey as part of IEA EBC annex 72. Build. Environ. 2021, 192, 107619. [Google Scholar] [CrossRef]

- Lützkendorf, T.; Foliente, G.; Balouktsi, M.; Wiberg, A.H. Net-zero buildings: Incorporating embodied impact. Build. Res. Inf. 2015, 43, 62–81. [Google Scholar] [CrossRef]

- World Business Council for Sustainable Development (WBCSD); ARUP. Net-Zero Buildings. Where Do We stand? WBCSD: Geneva, Switzerland, 2021; pp. 3–5. [Google Scholar]

- Finch, P.; Hirigoyen, J. Foreword. In Targeting Zero: Whole Life and Embodied Carbon Strategies for Design Professionals; Sturgis, S., Ed.; RIBA Publishing: London, UK, 2019. [Google Scholar]

- Institution of Structural Engineers (ISTRUCTE). How to Calculate Embodied Carbon; ISTRUCTE: London, UK, 2020; pp. 1–2. [Google Scholar]

- 3XN. Building a Circular Future; 3XN: Copenhagen, Denmark, 2019. [Google Scholar]

- Costanzo, E.; Basili, R.; Hugony, F.; Misceo, M.; Pallottelli, R.; Zanghirella, F.; Labia, N. Osservatorio Degli Edifici a Energia Quasi Zero (nZEB) in Italia; ENEA: Rome, Italy, 2019; pp. 21–22. [Google Scholar]

- De Wolf, C. Low Carbon Pathways for Structural Design: Embodied Life Cycle Impacts of Building Structures. Ph.D. Thesis, Massachusetts Institute of Technology, Cambridge, MA, USA, June 2017. [Google Scholar]

- Tsikos, M.; Devlin, G. Life—Cycle Assessment & Data. In Proceedings of the One Click LCA Summer School 2022, attended online. Helsinki, Finland, 31 May 2022. [Google Scholar]

- Cheshire, D. The Handbook to Building a Circular Economy; RIBA Publishing: London, UK, 2021. [Google Scholar]

- Violano, A. Oltre la Materia: La sperimentazione di bio-based grown materials dai miceli. TECHNE 2018, 16, 299–307. [Google Scholar] [CrossRef]

- Ellen MacArthur Foundation. Towards a Circular Economy: Business Rationale for an Accelerated Transition; Ellen MacArthur Foundation: London, UK, 2015; Available online: https://emf.thirdlight.com/link/ip2fh05h21it-6nvypm/@/preview/1?o (accessed on 14 November 2022).

- Clark, D. What Colour Is Your Building? Measuring and Reducing the Energy and Carbon Footprint of Buildings; RIBA Publishing: London, UK, 2019. [Google Scholar]

- Backer, N. Retrofitting for comfort. In Sustainable Retrofitting of Commercial Buildings: Cool Climates; Burton, S., Ed.; Routledge: New York, NY, USA, 2015; pp. 120–122. [Google Scholar]

- Giles-Corti, B.; Vernez-Moudon, A.; Reis, R.; Turrell, G.; Dannenberg, A.L.; Badland, H.; Foster, S.; Lowe, M.; Sallis, J.F.; Stevenson, M.; et al. City planning and population health: A global challenge. Lancet 2016, 388, 2912–2924. [Google Scholar] [CrossRef]

- Associati, P.; Grohmann, B. INLEGNO: Cambiare Prospettiva Per Costruire il Futuro; Letteraventidue: Siracusa, Italy, 2021; pp. 8–10. [Google Scholar]

- Riahi, K.; van Vuuren, D.P.; Kriegler, E.; Edmonds, J.; Tavoni, M. The Shared Socioeconomic Pathways and their energy, land use, and greenhouse gas emissions implications: An overview. Glob. Environ. Chang. 2017, 42, 153–168. [Google Scholar] [CrossRef]

- Churkina, G.; Organschi, A.; Reyer, C.P.O.; Ruff, A.; Vinke, K.; Liu, Z.; Reck, B.K.; Graedel, T.E.; Schellnhuber, H.J. Buildings as a global carbon sink. Nat. Sustain. 2020, 3, 269–276. [Google Scholar] [CrossRef]

- Carcassi, O.B.; De Angelis, E.; Iannacone, G.; Malighetti, L.E.; Masera, G.; Pittau, F. Bio-Based Materials for the Italian Construction Industry: Buildings as Carbon Sponges. In Regeneration of the Built Environment from a Circular Economy Perspective; Della Torre, S., Cattaneo, S., Lenzi, C., Zanelli, A., Eds.; Springer: Cham, Switzerland, 2020; pp. 237–247. [Google Scholar] [CrossRef]

- Hoxha, E.; Passer, A.; Mendes Saade, M.R.; Trigaux, D.; Shuttleworth, A.; Pittau, F.; Allacker, K.; Habert, G. Biogenic carbon in buildings: A critical review of LCA methods. Build. Cities 2020, 1, 504–524. [Google Scholar] [CrossRef]

- Pittau, F.; Krause, F.; Lumia, G.; Habert, G. Fast-growing bio-based materials as an opportunity for storing carbon in exterior walls. Build. Environ. 2018, 129, 117–129. [Google Scholar] [CrossRef]

- De Wolf, C.; Pomponi, F.; Moncaster, A. Measuring embodied carbon dioxide equivalent of buildings: A review and critique of current industry practice. Energy Build. 2017, 140, 71–75. [Google Scholar] [CrossRef]

- Wastiels, L.; Decuypere, R. Identification and comparison of LCA-BIM integration strategies. IOP Conf. Ser. Earth Environ. Sci. 2019, 323, 012101. [Google Scholar] [CrossRef]

- Amini Toosi, H.; Lavagna, M.; Leonforte, F.; Del Pero, C.; Aste, N. Implementing Life Cycle Sustainability Assessment in Building and Energy Retrofit Design—An Investigation into Challenges and Opportunities. In Environmental Footprints and Eco-design of Products and Processes; Muthu, S.S., Ed.; Springer: Singapore, 2021; pp. 103–136. [Google Scholar] [CrossRef]

- Shen, K.; Ding, L.; Wang, C.C. Development of a Framework to Support Whole-Life-Cycle Net-Zero-Carbon Buildings through Integration of Building Information Modelling and Digital Twins. Buildings 2022, 12, 1747. [Google Scholar] [CrossRef]

- FS Sistemi Urbani; OUTCOMIST; Diller Scofidio + Renfro; PLP Architecture; Carlo Ratti Associati. Scalo di Porta Romana, Concorso Per il Masterplan; FS Sistemi Urbani: Milan, Italy, 2021; pp. 1–10. [Google Scholar]

- Fondazione Prada. Available online: https://www.oma.com/projects/fondazione-prada (accessed on 6 October 2022).

- Baroš, T.; Katunsky, D. Parasitic architecture. SSP J. Civ. Eng. 2020, 15, 1. [Google Scholar] [CrossRef]

- Hertzberger, H. Lezioni di Architettura; Editori Laterza: Bari, Italy, 1996. [Google Scholar]

- One Click LCA Planetary. Available online: https://www.oneclicklca.com/planetary/ (accessed on 6 October 2022).

- Dahlbo, H.; Bachér, J.; Lätinen, K.; Jouttijärvi, T.; Suoheimo, P.; Mattila, T.; Sironen, S.; Myllymaa, T.; Saramäki, K. Construction and demolition waste management—A holistic evaluation of environmental performance. J. Clean. Prod. 2015, 107, 333–341. [Google Scholar] [CrossRef]

- Stanaszek, D. Energy Performance of Commercial Buildings: Europe. In Sustainable Retrofitting of Commercial Buildings: Cool Climates; Burton, S., Ed.; Routledge: New York, NY, USA, 2015; pp. 78–79. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Besana, D.; Tirelli, D. Reuse and Retrofitting Strategies for a Net Zero Carbon Building in Milan: An Analytic Evaluation. Sustainability 2022, 14, 16115. https://doi.org/10.3390/su142316115

Besana D, Tirelli D. Reuse and Retrofitting Strategies for a Net Zero Carbon Building in Milan: An Analytic Evaluation. Sustainability. 2022; 14(23):16115. https://doi.org/10.3390/su142316115

Chicago/Turabian StyleBesana, Daniela, and Davide Tirelli. 2022. "Reuse and Retrofitting Strategies for a Net Zero Carbon Building in Milan: An Analytic Evaluation" Sustainability 14, no. 23: 16115. https://doi.org/10.3390/su142316115

APA StyleBesana, D., & Tirelli, D. (2022). Reuse and Retrofitting Strategies for a Net Zero Carbon Building in Milan: An Analytic Evaluation. Sustainability, 14(23), 16115. https://doi.org/10.3390/su142316115