Abstract

With growing environmental and ecological concerns, innovative energy storage systems are urgently required to develop smart grids and electric vehicles (EVs). Since their invention in the 1970s, rechargeable lithium-ion batteries (LIBs) have risen as a revolutionary innovation due to their superior benefits of high operating potential and energy density. Similarly, fuel cells, especially Proton Exchange Membrane Fuel Cells (PEMFC) and Solid-Oxide Fuel Cells (SOFC), have been developed as an energy storage system for EVs due to their compactness and high-temperature stability, respectively. Various attempts have been made to explore novel materials to enhance existing energy storage technologies. Materials design and development are significantly based on trial-and-error techniques and require substantial human effort and time. Additionally, researchers work on individual materials for specific applications. As a viewpoint, we present the available sustainable routes for electrochemical energy storage, highlighting the use of (i) green materials and processes, (ii) renewables, (iii) the circular economy approach, (iv) regulatory policies, and (v) the data driven approach to find the best materials from several databases with minimal human involvement and time. Finally, we provide an example of a high throughput and machine learning assisted approach for optimizing the properties of several sustainable carbon materials and applying them to energy storage devices. This study can prompt researchers to think, advance, and develop opportunities for future sustainable materials selection, optimization, and application in various electrochemical energy devices utilizing ML.

1. Introduction

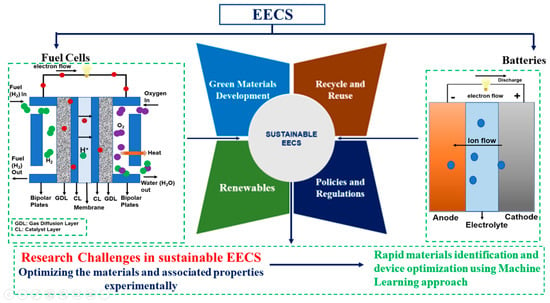

Electrochemical energy conversion and storage (EECS) technologies, batteries, and fuel cells have the potential to make a significant contribution to the energy conversion and storage sector [1]. For example, a low-carbon dioxide emission, environmentally-friendly, and cost-effective public transportation system is becoming increasingly crucial in our everyday lives [1]. Global energy consumption is rising owing to population growth and industrial expansion. Lithium-ion batteries have become a crucial enabler for energy storage and are expected to be widely used in the data center and electric vehicle sectors in the near future [2,3]. Similarly, hydrogen is an enticing replacement for carbon-based fuels [4]. Part of its attractiveness arises from the fact that it may be made from a variety of renewable resources (solar, hydro, wind). The global vehicle market is expected to approach 180 million sales by 2045, with electric battery vehicles accounting for 100 million, using fuel cells and battery technology [5]. The creation and design of innovative EECS systems aims to find suitable catalysts and membranes in fuel cells, as well as electrodes and electrolytes in batteries, with desirable properties to improve efficacy and safety [6,7]. Optimizing the interfacial and material characteristics, however, calls for significant effort in the development of high-performance organic batteries and environmentally friendly fuel cells [8]. Experimentally examining the characteristics of the available materials takes a lot of time and is difficult. Therefore, we propose that the combination of Machine Learning and EECS research can provide solutions to a number of unresolved questions about materials and associated properties. In this review, we highlight the main components and sustainable trends in EECS technologies. We also present how the use of a data-driven approach helps to advance the material identification as well as the device optimization process. Modern statistical and computational approaches may anticipate the properties of certain components in specific scenarios. Nonetheless, due to complicated electrochemical processes and thousands of material options, selecting the proper materials remains a tough step. Thus, machine learning (ML) and artificial intelligence (AI) may work together to realize trial circumstances and anticipate the optimal material choice for EECS devices. This review presents the two significant scenarios—: the sustainable methods and ML—separately, which will aid in understanding the interrelationship of distinct qualities for the selection of sustainable materials for EECS. Therefore, we connected the approaches for constructing sustainable EECS, which we separated into four aspects: (i) green materials development, (ii) a circular economy approach, (iii) renewable powering sources, and (iv) policies and regulations, followed by interrelating the sustainable aspects of materials development with ML/AI (Figure 1).

Figure 1.

Overview of the review, focusing on sustainable strategies for EECS leveraged by Machine Learning.

2. Fuel Cell Technologies

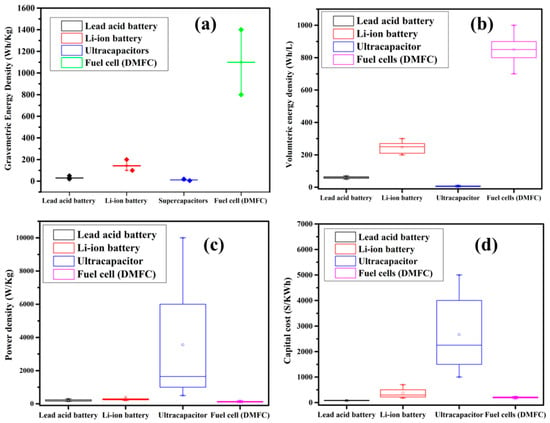

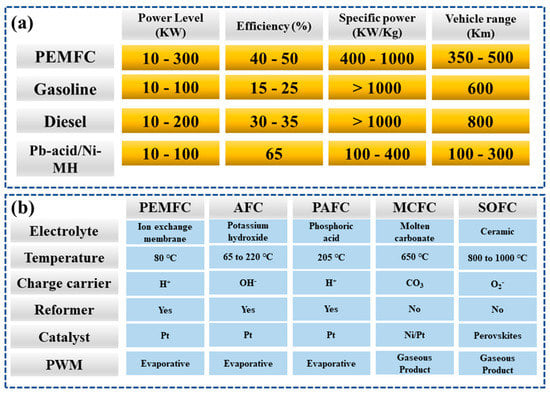

Fuel cells are one of the cleanest and most efficient routes for producing hydrogen [9]. Although gasoline, diesel, supercapacitors, and fuel cells are mostly used in portable and automotive industries, fuel cells possess higher gravimetric and volumetric energy density, as shown in Figure 2a–d, and are cleaner. Hydrogen can be created by various processes, including partial oxidation, methane pyrolysis, and plasma reforming [10]. As long as the fuel source is provided, fuel cells transform the chemical energy in the fuel and oxidant into electrical energy. Furthermore, no carbon dioxide is generated due to the absence of the combustion process, and the produced heat may be utilized for co-generation. There are six different types of fuel cells, namely, alkaline fuel cell (AFC), solid oxide fuel cell (SOFC), proton exchange membrane fuel cell (PEMFC), molten carbonate fuel cell (MCFC), phosphoric acid fuel cell (PAFC), and direct methanol fuel cell (DMFC), with characteristics shown in Figure 3a,b. Due to their operating stability and advancements, AFC, SOFC, and PEMFC have the most potential for commercialization in the near future.

Figure 2.

Comparison of power density, capital cost, and gravimetric and volumetric energy densities of Pb-acid battery, Li-ion battery, ultracapacitor and fuel cells (data obtained with references from [11,12,13,14]). (a) Gravimetric energy density; (b) Volumetric energy density; (c) Power density; (d) Capital cost.

AFCs [15] were the first developed technology employed in spacecrafts [16]. The electrolyte used in the AFCs is the solution of potassium hydroxide and water. Electrodes are mostly non-precious metals and their alloys [17]. AFCs are similar to PEMFCs, except for using an alkaline membrane instead of an acid membrane. However, it is prone to carbon dioxide toxicity (CO2) [17]. In essence, even trace amounts of CO2 in the atmosphere can substantially impact cell performance and endurance owing to carbonate production. AFCs with aqueous electrolytes can be driven in a circularity mode, allowing for electrolyte rejuvenation to lessen the impacts of carbonate production in the electrolyte. However, it creates shunt current complications [18]. Recent research on AFCs addresses some of the challenges in AFCs, including high temperature operability, water management, membrane conductivity, etc. [15]. Recently, AFCs were created with a polymer membrane as the electrolyte with hydrophobic backbone, with functional hydroxide ions separating the anode and cathode; these are known as alkaline anion exchange membrane fuel cells (AEMFC) [19]. The exchange membrane’s electrochemical and mechanical characteristics are critical for the design of effective AEMFCs [20]. Improvements in the mechanical characteristics of the polymer membrane, such as elasticity and tensile strength, enhance fuel cell performance. However, when the temperature rises, tensile strength falls, and as porosity rises, conductivity falls, presuming the microstructural characteristics stay constant [21].

Figure 3.

Comparison between different fuel cells and their characteristics (data adapted from [9,22,23]). (a) Comparison of power level, efficiency, specific power and mileage for PEMFC, batteries and conventional fuels (b) Comparison of working characteristics for different fuel cells.

Although numerous materials such as carbon-polymer matrices and Fe7C3-CNT composites enhance AEMFCs’ performance [24], there are still a lot of opportunities for identifying the correct type of material, its proportion, additives and properties for standardization, and commercial usage. Membranes in fuel cells influence friction, swelling, water absorption, ion transport, and ion diffusion (surface hopping) [17]. The main function of the membrane is to transport hydroxide ions and block electron crossover between the electrodes. The membrane consists of a hydrophobic backbone to which hydrophilic functional groups are attached, and it conducts ions via the interaction between the positive hydrophilic and OH− anions. The length of the hydrophobic backbone is proportional to the length of the ion transfer channel formed. For instance, if there are more ions, they get aggregated into a cluster and facilitate interconnected transfer channels. Furthermore, increasing the ion exchange group increases the ionic conductivity of the electrolyte, resulting in increased water absorption, which is troublesome. Hydrophilic polymers have higher ion exchange groups but also higher water uptake [25]. On the other hand, hydrophobic polymers have fewer ion exchange groups but also lower water uptake [17]. The main problem with the membrane materials is keeping the water uptake in control. Increased water absorption causes membrane swelling and, as a result, loss of mechanical characteristics. Water uptake depends on the temperature, elasticity, and hydrophobicity of the membrane, presence of conducting functional groups, and membrane pretreatment. Water management is simpler in AEMFCs, as they transport water from cathode to anode by electroosmosis. Recently, quaternary ammonia compounds, imidazole, pyridine, and guanidine have been used as a membrane material [26]. Quaternary ammonium side groups with multiple cation chains in particular increase ionic conductivity with less water uptake. Further, cross linked polymers such as hydroxypropyltrimethyl ammonium chloride, iodomethane, and pyridine carboxaldehyde are also used in membranes. Patil et al. used a dual hydroxide co-polymer membrane consisting of quinuclidinum and piperidinium cations on polyethersulfone (QP-PES), which is compatible with NaOH electrolytes [27]. The water uptake and swelling slightly increased for Q-PES and QP-PES membranes with a rise in temperature from 25 °C to 80 °C owing to the alkyl hydrophobic spacer preventing the membrane from absorbing water. Also, the QP-PES membrane had a hydroxide conductivity of 0.06 S/cm, higher than conventional quaternary compounds, and lower activation energy (16.42 kJ/mol) for ion transport [27].

Considering the commercial aspects, AEMFCs are cheaper and easier to manufacture. Recent developments in bipolar plates and anion exchange membranes including liquid urea solutions and metal amine complexes have led to better performance efficiency [28,29]. The disadvantage is that AEMFCs are not suitable for high temperature applications and have membrane conductivity and swelling issues. The solution is to identify the best polymer exchange material suitable for both high hydroxide conductivity and low swelling.

SOFC operates at high temperatures (1000 °C) without the need for precious metal catalysts and employs a non-porous ceramic electrolyte (Pt). SOFCs are also resistant to sulfur, can be made from any fuel source, and are not harmed by carbon monoxide [30]. Higher thermal shielding and cooling systems, on the other hand, are required to retain heat and safeguard against mishaps. The creation of low-cost materials with high durability at cell operating temperatures is the key technological challenge for this technology. Scientists are now investigating the possibility of building lower-temperature SOFCs that operate at or below 700 °C, have fewer durability issues, and are less expensive [31]. Ammonia, being lighter than air, has recently been used as a fuel for generating hydrogen via SOFC. The fuel gets oxidized at the anode, and oxygen gets reduced at the cathode. At first, oxygen gas enters via the cathode and reacts with the free electrons, generating charged ions. These charged ions transfer via the electrolyte to the anode and react with the fuel, releasing electrons externally. The interface and the electrode materials strongly influence the cell performance [31]. Co-ionic ceramic electrolytes like BaCeO3, LaMnO3, and Ba(Ce1−xTix)1−yYyO3−δ lead to higher oxygen vacancies [32]. Rare earth materials are suitable for high temperature fuel cells. For instance, europium doping in La2-xNiO4+δ improves the oxygen transport and reduces the activation energy for ion transport. Lenka et al. compared Ca, Ba, and Sr doped Nd2NiO4+δ as cathodes in SOFCs and found that Ca improved the power density (188 mW cm−2) [33]. Lower-temperature SOFCs have not yet equaled the efficiency of higher-temperature systems, and materials for this lower temperature range are currently being developed. Nanomaterials with high surface area and quantum size effects used as a thin film electrolyte can enhance the ionic conductivity and interfacial reaction kinetics at low temperatures. In this regard, artificial intelligence can help accelerate new material discovery for SOFCs [33].

Proton exchange membrane fuel cells (PEMFC) are operable from 70 °C to 250 °C. Low-temperature PEMFCs require pure fuel and suffer from catalytic poisoning and reduced oxygen transport [34]. High-temperature PEMFCs have improved reaction kinetics and performance. However, corrosion, mechanical failure of catalyst and membranes, and water management are still issues. Designing catalysts requires a lot of consideration for their intrinsic properties [21]. Generally, Pt-based catalysts are utilized in PEMFC; however, scientists are currently concentrating on developing inexpensive, higher-performing catalysts based on Ru, Ir, carbon, and metal oxide nanostructures. In Pt-based catalysts, the oxygen reduction process (ORR) typically generates H2O through a four-electron route [34,35]. Concerns such homogeneous dispersion, bulk loading of catalysts, and the expensive price of Pt must be addressed. Pt catalysts supported on graphene, wrapped by CNT, attached to metal alloys, and compositing with nanomaterials are the most recent progress made based on research [35]. Wrapping polymers such as polyvinyl pyrrolidone (PVP) and poly [2,2′-(2,5-pyridine)-5,5′-bibenzimidazole] (para-PyPBI) on the Pt or Ru catalysts has proven to have enhanced H+ conductivity [35]. Further, non-platinum group metals like carbon-based nanomaterials have also shown progressive catalytic behavior for ORR [36,37].

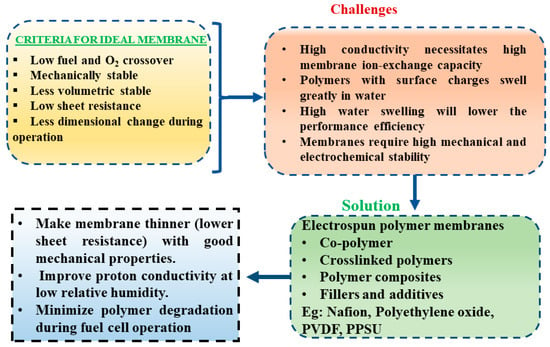

The proton exchange membrane, which is present in between the anode catalyst layer and cathode catalyst layer, plays a vital role [38]. The anode catalyst layer undergoes a hydrogen oxidation reaction (HOR), and the cathode catalysts undergo ORR, generating heat and water [38]. The PEM membrane should have high H+ conductivity to reduce the voltage loss and improve the power density [38,39]. Sulfonated hydrocarbon polymers, perfluorinated sulfonic acid polymers, phosphoric acid, and acid base membranes are the main materials researched so far. Metal organic frameworks (MOFs) like ZIF-8, ZIF-67, and MIL-101 are becoming attractive for their use as catalysts and gas diffusion layers in fuel cells [40,41]. An ideal membrane should be mechanically stable, thin, conductive, and undergo fewer dimensional changes during hydration and dehydration [42]. However, in general, highly conductive polymers have increased water uptake due to hydrophilic side groups, which reduces the device performance [42,43]. Utilizing cross-linked polymers, blends, and composites using electrospinning is the key solution for altering the membrane properties suitable for fuel cells, as summarized in Figure 4.

Figure 4.

Criteria, challenges, and opportunities in generating ideal membranes for fuel cells (data adapted from [44,45]).

Similarly, the pursuit of the “green” battery has been the focus of various initiatives over the past few years. The present experimental agenda includes the substitution of ecologically dubious metals like Li and Cd with more ecologically friendly sustainable compounds like Mn, Fe, carbon, Ti, and Si [46,47,48,49,50]. The best method to overcome conventional batteries’ technological and financial limitations is to use organic or polymer compounds rather than metals or metal oxides [51]. However, fluorinated salts (LiTFSI) are corrosive and should be avoided. Instead, eco-friendly 4,5-dicyano-1,2,3-triazolate (DCTA) and PVDF-based polymer electrolytes are used [52,53]. Metal usage relies on available metal reserves, but hereafter, it may be possible to synthesize alternate green materials like polymers and carbon from organic components in a natural way from renewable resources [46,47,52]. Furthermore, green electrodes can also offer superior processability and flexibility, leading quickly to flexible electronics [54,55]. However, completely organic batteries exhibit poorer performance characteristics and can only sustain low temperature operations [56,57]. Fully organic Li-ion batteries, for instance, which have an OCV less than 2 V and a capacity less than 100 mAh g−1, can perform better with morphological and structural tuning. Organic polymer gel and composite electrolytes based on polyethylene oxide and polycarbonates are already known [51]. The procress of making complete organic batteries relies on making high performing organic electrodes [58]. Organic electrodes are classified based on the reaction type, i.e., donating electrons (P-type) or accepting electrons (N-type) [58,59,60]. It is necessary to select and optimize suitable organic electrodes for the organic batteries [56,58,59,60,61].

Exploring the membrane materials, catalysts, and diffusion layers in fuel cells experimentally with thousands of different compositions and optimizing control parameters will be time-consuming [62,63,64]. Similarly, developing green materials for batteries and optimizing the material composition based on performance traits require immense effort and are challenging [58,64]. This review addresses these challenges with a beneficial opinion for future directions. Some of the most important sustainability needs for EECS systems are covered prior to presenting the AI-based solution [65].

3. Routes for Sustainable EECS

The significance of material selection, the circular economy, renewable energy sources, and existing and potential future strategies for sustainable EECS are all covered in this section [60].

3.1. “Green” Material Development for EECS

The term “green” refers to low toxic and environmentally benign EECS materials. There are six important factors to be considered while designing a sustainable material for an EECS device, namely (Figure 5): (i) abundance, (ii) toxicity and carbon emission, (iii) cost, (iv) safety, (v) recyclability, and (vi) electrochemical performance [58,59].

Figure 5.

Criteria for green materials selection (data adapted from [66,67]).

Aside from these considerations, choosing materials for eco-friendly EECS or emerging technologies involves assessing various additional chemical and commercial factors [6]. The most-used Li-ion batteries for energy storage contain Li, Ni, Cu, Co, and F as the main components. The predicted shortage of elements Li and Co has driven scientists to consider alternative metals as electrode materials, such as titanium, iron, and manganese [68]. Fe, Si, Mn, Ti, and carbon have been most studied, since these materials can be produced from biomass and biowaste [68,69]. For example, P, Na, H, S, O, K, Ca, Mg, Mn, Ti, and Fe can be used in batteries since they can be recycled and are ecologically more beneficial than Li, Co, Ni, and Cu. Sustainable metal-sulfur and metal-air batteries are made possible by employing low-toxicity, abundant materials such as sulfur and oxygen as cathodes [70,71]. Sulfur is cheap (USD 100 to 300 per ton), plentiful (500 parts per million in the lithosphere) and generated at a pace of 60 million tons per year [72]. Sulfate salts and O2 are typically used as cathode materials in alkali metal-ion batteries [73]. However, O2 must be separated from other air constituents, which is costly and necessitates a complex device construction. Phosphorus is another abundant, open-source element that is less harmful and does not pose a potential shortage issue [74]. These materials can be utilized as “green” alternatives, and the above reasons justify the huge investments in metal-air and metal-sulfur technology. Furthermore, the correct choice of transition metal cations, such as PO43− in LiFePO4 (LFP), is presently the most desirable electrode material for Li-ion batteries in terms of safety and sustainability [74]. Currently, companies like Tesla are using carbon nanostructures in LFP pioneered by Michel Armand et al. to beat the theoretical capacity (170 mAh g−1) of LFP in Li-ion batteries [75]. Switching from the previous choice of electrode-electrolyte materials to Na-ion batteries, which are identical to Li-ion batteries, might be another option for developing cleaner batteries. The same applies to Li-supercapacitors and fuel cells. While considering fuel cells, three significant issues with commercialization need to be addressed: production cost, technology standardization, and safety [76]. Integrated fuel cells and battery storage also lead to a spectrum of opportunities. Together, batteries and fuel cells can revolutionize the transportation sector by eliminating CO2 emissions. These innovations provide a significant chance to switch the carbon dioxide polluted world to a sustainable, green, and secure one centered on hydrogen throughout the whole spectrum of electricity usage. The difficulties are tremendous, necessitating scientific discoveries, significant technology improvements, and ongoing socioeconomic commitment [77].

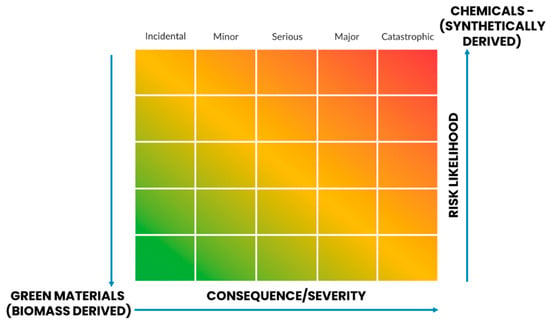

Mimicking nature and its tremendous combinations is becoming increasingly popular in energy conversion and storage technologies. Organic materials and their related chemistry solutions offer the benefit of developing novel electrodes and low dimensional structures with improved physicochemical characteristics that are safer (Figure 6) [78]. Porous carbon derived from biomass has been found to provide excellent ion diffusion characteristics in battery systems [79]. A few other examples are fish scale lamellae, shrimp skin, lotus petal, and crab shell structure, containing essential salts and biopolymers, which increases the mobility of ions in electrolytes while effectively inhibiting the agglomeration of nanoparticles [80,81,82,83]. The Bouligand structure of a crab shell serves as an effective host, allowing transfer of sulfur in Li-S batteries [84,85]. Several researchers have identified farm crops and leftovers as a critical source of sustainable carbon-based electrodes for fuel cells [77,86]. Some agro-based sources used to produce carbon are waste sugarcane baggage, paddy waste, sawdust, rice husks, coconut shells, vegetables, and floral waste [80,87,88,89,90,91]. In addition to agricultural waste, textile and plastic waste are also burned at high temperatures to produce carbon nanostructures for electrodes [80,87,88,92]. Using pyrolysis, the waste tier is converted into pyro char, pyro oil, and porous carbon compounds, which are utilized as additives for electrodes in energy storage devices [93]. It is worth noting that agro/biomass/waste-derived carbon comes in various allotropes, including graphene, diamond, fullerenes, nanorods, and nanotubes, all of which may be used to make highly polarizable electrode materials [88,92]. For a very long time, biomass has been used as a precursor for the creation of innovative carbon-based nanostructures since it is abundant, sustainable, inexpensive, and ecologically beneficial [94]. More significantly, biomass materials frequently show a wide variety of nanostructures, making them excellent candidates to serve as precursors for creating the anticipated carbon compounds with distinctive structures [94,95,96]. For instance, a certain quantity of N, O, and S obtained from polysaccharides, proteins, and other organic molecules in the biomass resource category may often form self-doping carbon compounds with improved electrochemical characteristics [94]. Low temperature pyrolysis, hydrothermal carbonization, and template synthesis are mostly used for extracting a higher content of carbon from biomass [94]. Further, 1D carbon nanofiber and CNT have better transport properties than diamond, graphite, and 3D structures [86,97]. The electronic conductivity of the resultant carbon electrodes, on the other hand, is substantially determined by the features of the feedstock (for instance, size and morphology) and the synthesis routes used (e.g., activation, hybridization, and annealing) [66,98]. Furthermore, carbon might exist in both the anode or cathode due to its amphoteric nature and varying electrochemical characteristics. The selection of feedstocks and synthesis routes is vital for optimizing the end product’s characteristics [66]. Significantly, the synthesis process must not be polluting, as it serves no purpose to produce greener materials using an ecologically detrimental synthesis approach. Low-temperature synthesis (less than 180 °C) procedures should be used instead of high-temperature (400 to 1000 °C) synthesis protocols, unless solar heat is used [97]. The low-temperature processes preserve the intrinsic structure and properties, save money, and do not emit toxic fumes [99]. For example, Si and Si-phosphates can be prepared at ~200 °C rather than using high temperature (700–900 °C) ceramic methods [100,101]. Wet chemical synthesis methods such as sonochemical, hydrothermal, solvothermal, and microwave assisted techniques with temperatures below 300 °C have been recently employed for preparing electrode materials with customized morphologies [97,98]. In fact, the use of less hazardous microorganisms for electrode synthesis is gaining popularity due to its low cost [99]. Biomineralization with bacteria for mineral precipitations has long been acknowledged and practiced in the field of microbiology. The same can be applied for preparing electrodes in EECS. One example is the preparation of V2O5 and nanotubes for the Si anode using tobacco mosaic virus (TMV) as bio-template [102]. The major limitation of this technique is reduced cycle numbers and performance compared to commercial batteries. Compositing or doping chemically synthesized materials with microbe derived elements and tailoring their morphology could help in optimizing the electrochemical characteristics [46,103].

Figure 6.

Risk assessment between biomass and chemically derived materials for EECS [67].

3.2. Circular EECS Economy—Reuse, Recycle and Refurbish

Lead (Pb) acid batteries are widely used, have a high recycling efficiency (>90%), and account for 86% of worldwide secondary battery recycling, with this figure predicted to climb by 2025 [104]. Lead-based items are recognized easily, collectible, and able to recycle all of the regularly employed metals; further, lead has the most remarkable end of life (EoL) recycling rate. Fully used Pb acid cells are well-managed in developed countries such as in Europe and the USA through effective retail strategies and transportation by super-efficient initiatives with higher requirements for labor training and technological standards [104]. Pb acid batteries widely demonstrate a readily accessible battery circular economy due to their ample recycling possibilities and the fact that they are manufactured from reused components. Nevertheless, Pb acid batteries are recovered in unstructured or substandard processes in many other countries, resulting in significant Pb leaks into the ecosystem and high levels of toxic exposure in society [105]. The most used pyrometallurgical and hydrometallurgical techniques have several shortcomings, mostly owing to technical and atmospheric considerations [106]. There is an immense desire to develop innovative techniques to extract Pb from worn or entirely used Pb acid batteries due to rising metal extraction costs and the severe health implications of lead levels from increased lead particle air emissions. Hydrometallurgical lead recycling involves acidic solution reduction and wet processing techniques to recover Pb salt in the lead paste [106]. Conversely, a new family of liquids known as deep eutectic solvents (DESs) has begun to evolve, demonstrating significant solubility of Pb salts yet possessing few related risks [107]. New procedures have been researched in recent years, including the atomic calcination method, direct membrane electrolysis, and electrokinetic separation, and they have shown significant cost reductions over traditional recycling processes while significantly minimizing auxiliary contamination [108]. The thermal decomposition approach allows for more significant self-sustaining lead recovery, while the electrowinning method reduces the number of stages in the recycling method [109].

Like Pb acid batteries, Li-ion battery components must be discarded or recycled safely. LiCoO2, LiFePO4, and LiMnO4 are the most used cathodes in Li-ion batteries. When these cathodes react with acids or bases, heavy metals are produced, which, if not properly disposed of, might damage the environment by raising the pH level [106]. Similarly, anode material like graphite produces CO when ignited. Electrolytes such as LiPF6 and LiBF4 in ethylene carbonate or propylene carbonate are corrosive and toxic, and release CO upon combustion [106]. Supercapacitor components disposal is unsafe in the same way that battery materials are. While hydrogen–oxygen fuel cells are a greener technology that does not generate CO2, a few catalysts used to speed up the electrochemical process are hazardous and may release CO2 indirectly. Similarly, when phosphoric acid fuel cells are burned, they produce phosphoric oxide and hazardous gases. Still, many EECS devices are burnt after they get disposed, which will contaminate the environment with a lot of debris or microscopic particles. Some EECS devices are deposited in the land alongside solid waste generated trash, perhaps necessitating stringent impermeable actions; otherwise, major degradation of the topsoil is highly likely. Another common practice involves crushing discarded primary cells and combining them with cement in a specific ratio before using the mixed concrete to pave roads or combine with construction materials. There are a variety of procedures for separating and refining EECS components, including solvent extraction, leaching, curing, and wet recovery; however, due to the high amounts of dust and toxic chemicals released, these approaches have a significant impact on the atmosphere in the outlying towns [110]. To control these harmful outflows into the air, a shift towards biometallurgy is required. Battery metal extraction using bacteria and their metabolites via bioleaching, biosorption, and bioaccumulation is still being perfected, but studies suggest that it is both eco-friendly and cost effective. For example, Thiobacillus ferrooxidans bacteria was used for extracting Fe ions and Co2+ from spent batteries involving a series of biochemical process like bioleaching [111]. The Fe3+/Fe2+ couples influence the redox potential, which is a significant factor in bioleaching. The redox potentials can be controlled by adjusting the O2 supply or using reductants [111].

Leaching agents are a combination of oxidants and strong acids. Bioleaching is a viable strategy that incorporates redox, acid, and secondary metabolite processes, reported by several researchers. Acid or proteins in microbes are used for the conversion of insoluble metal species into soluble forms. The microorganisms acquire energy by puncturing and collapsing LIB waste during this process. For instance, with sulfur as the energy source, Thiobacillus thiooxidans produces sulfuric acid, which helps to dissolve metals from electrodes [112]. The biologically active acids work similarly to the chemical leaching process. At first, the biogenic acids dissolve into protons, which target the metallic oxygen surfaces, followed by leaching of metal from the parent component, forming H+ ions, O2, and H2O [112]. Limitations of this technique include the varying pH and solid-to-liquid ratio (pulp density), which inhibits the microbe’s efficiency at bioleaching. Bioleaching of battery components by mesophilic bacteria requires an acidic pH (~1 to 3) and temperature (30 to 35 °C) [112]. The fluctuation in pH, which affects the microbe’s ability to bioleach, is one of the limitations of this approach. Due to the obvious alkaline characteristics of wasted EECS and hazardous chemicals, the effectiveness of bioleaching reduces dramatically when the solid concentration is higher than liquid (i.e., pulp density is higher). Pulp density employed so far for bacterial bioleaching of battery metals is ~10% [111]. Another non-contact leaching technique is the redoxolysis process, which can occur even if no bacteria are present in proximity to the metal ores. Extracellular biofilms grow during redoxolysis, aiding the attachment of bacteria to metal surfaces and the transmission of electrons between bacteria and minerals [113]. Maintaining particle sizes below 100 nm will help reduce shear stress and the mass transfer area for successful bioleaching [113]. The common microbes used for bioleaching of battery materials are A. ferrooxidans, A. thiooxidans, and Leptospirillum ferrooxidans. Like bacteria, fungi such as Penicillium chrysogenum and Penicillium simplicissimum are also used for bioleaching of LIBs [114]. The advantage of fungal bioleaching is that there is no acidic pH requirement, as the process takes place at neutral or alkaline pH and minimal pulp density (~2%) [114]. However, this process requires primary carbon nutrients, which can be taken from food or agro wastes to supplement the leaching process. The overall kinetics and speed of leaching can be enhanced by adjusting the temperature, redox potential, growth nutrients, O2 supply, and pH [114].

Sustainable clean batteries are created using organic electrode and electrolyte materials. There has been a significant increase in the development of organic electrode materials for batteries being regarded as delivering completely ecological and clean energy production. It is not the goal of this review to provide a thorough analysis of organic materials for batteries. From a utility-oriented design perspective, developments in carbonyl-based polymers, composites, and flexible electrodes are discussed. Compounds that undergo reduction reactions such as 1,2-diones, vinylene carbonates, PEO-based, aromatic carbonates, and phenenthraquinones are utilized to provide solid intrinsic characteristics like ionic conductivity in batteries [115,116,117,118,119]. However, the repeatability and recycling of organic electrolytes are challenging. When utilized for a prolonged time, the aging electrolytes in spent batteries diffuse across the entire electrode structure and might even get trapped. The electrolyte is maintained with constant cycling to create solid electrolyte interphases (SEI) on the surface of the electrode, which results in complex byproducts in the solution [106]. Most scientific studies and industrial battery recycling processes typically concentrate on cathode reprocessing and overlook the opportunities for leaking and overused electrolytes due to the intricate aspect of formulation and distribution, resulting in unfathomable loss and toxicity [106]. The flammability of organic electrolytes is also well recognized. This problem is solved by aqueous electrolytes. In comparison to organic electrolytes, one kind, water in salt electrolytes, has a larger electrochemical window and better ionic conductivity [7]. This may be a good substitute for risk-free batteries. Solid electrolytes are gradually becoming recognized as a potential replacement. Solid state batteries provide benefits, such as safety and the prevention of dendritic growth, in spite of their allegedly poorer conductivity [106,120,121,122].

The type and material of the cathode used affects battery energy density significantly, and cathodes often cost 25% of the price of the batteries [74]. Because it has a large energy density, cobalt is one material that is frequently utilized as the cathode in LIBs. Its maximum temperature is constrained, and thermal runaway is a possibility. Because it is a heavy metal, disposing of batteries raises a lot of environmental issues. Companies like Tesla are refocusing on LiFePO4 and Mn to create cobalt-free batteries [74]. Due to its abundance and significant redox potential, sulfur is a preferred cathode material. Due to its poor conductivity on its own, sulfur is frequently combined with other conductive substances, such as graphene and CNT, to address this problem. Nevertheless, a considerable volume expansion issue due to the shuttling effect also exists. Air has also been investigated as a cathode alternative when paired with other materials [73,81,123,124,125,126]. The air cathode consists of three layers: (i) gas diffusion layer, (ii) conductive, and (iii) catalyst layer. The concept underlying this is to employ atmospheric air’s oxygen in the chemical reaction. Air has a large theoretical capacity, similar to sulfur [81]. The shortcomings of air vary depending on the material it is partnered with. The volumetric capacity of the cell is often inversely correlated with the total surface area of the electrode. Pore size has been discovered to be significantly crucial in air batteries, though, as the metal oxide compounds precipitate and can block smaller pores [81]. Na-ion batteries, Mg-ion batteries and Zn-ion batteries are currently being researched and have high theoretical capacity; however, anodic corrosion is challenging to deal with. Additionally, the dendrite structures are a serious problem because of unstable SEI [115,127,128,129,130]. This can also happen in other battery compositions, but because Mg and Zn are ionically insulating, the anode can no longer generate or absorb ions, therefore leaving the cell worthless. In this case, a less reactive anode–electrolyte combination might be more useful [128,129,130].

3.3. Waste to Energy Materials

Municipal solid waste, agricultural and food waste, industrial waste, and hazardous waste are the four basic categories of waste produced. Each waste’s risk evaluation, processing, and conversion processes are unique. Municipal solid wastes are anticipated to grow to 3.40 billion tons by 2050, and carbon from MSW is likely to be employed increasingly in batteries [131]. Carbon-based compounds are generated from municipal solid waste, food, and agricultural waste using thermochemical or biochemical conversion. These carbon structures are often utilized in batteries. The conversion methods involve pyrolysis, gasification, and incineration, which all require high temperature and may release toxic gases depending on the feedstock. Flue gas treatment plants with multiple filters possibly reduce the toxicity of the emitted gas. Further, the coarse carbon soot and ash are used in the cement industry as a secondary raw material [132].

Industries account for nearly 21% of all waste produced globally. Because of the shutdown of industries, 5.88 million metric tons of solid garbage were created during the pandemic in 2020, which was less than in previous years [133]. Concurrently, it is vital to discover a feasible utilization for this waste while also avoiding contamination. As a result, the use of industrial waste utilized in EECS will be discussed in the subsequent section.

Disposed tire waste.

Landfills are created due to the accumulation of waste tires, leading to the loss of precious land space. In addition, because they contain vulcanized rubber, sulfur, antiozonants, and antioxidants, the tires are non-biodegradable. Various techniques such as crumbling, re-treading, grinding, gasification, and pyrolysis have recently been used for recycling tires. Pyrolysis has fewer environmental effects and ideal efficiency owing to the lack of oxygen and a decomposition temperature below 400 °C [134]. Further, pyrolysis of tires yields pyro oil, pyro char, and pyro gas. Activated carbon was derived from pyro char by chemical activation processes and used as electrocatalysts, electrodes in supercapacitors, LIBs, and fuel cells because of the high electrical conductivity, surface area, porosity, and delocalized π electrons. Zhao et al. used steam-based activation for modifying pyro char, suitable for supercapacitor electrodes [135]. Naskar et al. employed pyrolysis to obtain carbon from rubber tires and demonstrated its usage in LIBs with a reversible capacity and coulombic efficiency of 390 mAh g−1 and ~100% [136]. Sharma et al. used tire-derived carbon in LIBs and reported a specific capacity of ~880 mAh g−1 after 100 cycles with 80% capacity retention [137].

Karthikeyan et al. prepared MWCNT using a ferrocene catalyst and hydrocarbon tire oil via spray pyrolysis. The precursor (hydrocarbon oil) flow was maintained at 20 mL min−1 at 950 °C. This waste tire oil may be turned into precious carbon nanotubes for use in a variety of applications such as batteries, solar cells, and EMI shielding [138].

Printed circuit board waste.

Metals like tin, Cu, and Fe can be recovered from waste printed circuit boards (PCB) via hydrometallurgy, mechanical separation, and activation processes. Gao et al. used zeolite as a catalyst for separating useful metals from pyrolysis products. The group designed a tubular furnace, gas collector, condenser, stainless steel reactor, and a heat controller for performing the extraction process. The recovered metals can possibly be used in batteries after several acid and filtering steps [139]. Similarly, using acid and proton activation processes, Cu- and Co-based metals can be recovered from waste PCBs [140]. Not only may the lost components in PCBs be recovered, but so can the spent water used to manufacture PCBs, which includes Cu2+, Zn2+, and Pb. Zn ions may be removed from water using a Di(2-ethylhexyl) phosphoric acid (D2EHPA) polymer, retaining Cu ions in the solution. According to an ion-exchange isotherm, the D2EHPA XAD-4 resin shows better Zn ion selectivity than the Cu ion [141]. Carbonaceous materials are recovered from waste PCBs when processed at a temperature of ~1300 °C in argon (inert) atmosphere [142].

Red mud and rust waste.

Red mud is a kind of manufacturing alkaline waste with 50% Fe-based oxides produced during the processing of bauxite ore. The bauxite leftovers are generated in massive quantities every year, and there have been several massive environmental catastrophes relating to red mud. Gourav et al. studied the electrochemical performance of mechanically processed red mud as an electrode in a supercapacitor. The obtained red mud waste was ground into fine powders of various sizes using a ball mill. The red mud was composed of Fe2O3, SiO2, Al2O3, trace amounts of TiO2, and Mn, Mg, and Na oxides. The ball-milled red mud was then used as electrode material in a supercapacitor. The highest specific capacitance was 72 Fg−1 at a scan rate of 200 mV s−1. The effect of both capacitive and intramolecular mechanisms determines the overall energy stored in electrodes. In fact, the storage process was revealed to be diffusion controlled [143]. An iron-air battery has just been redesigned for long-term energy storage. It can work as a reversible rust battery, absorbing oxygen from the air during discharge, converting metallic iron to rust, and vice versa during charging. The development of a clean recycling method from scrap rusts to marketable electrodes using ammonium bicarbonate was also reported in LIBs with LiFePO4 cathodes. [144,145].

Leather waste.

The leather manufacturing industry produces untanned and tanned leather waste in vast amounts. This leather waste was employed as a precursor for the chemical activation of porous carbon electrode architectures via the addition of KOH and heat treatment. Niketha et al. prepared carbon material for supercapacitor electrodes from waste leather via carbonization and KOH activation. It was revealed that the increase in activation temperature increased the surface area and porosity, leading to enhanced N2 adsorption. The electrodes are made up of 95 wt% carbon recovered from waste leather and 5 wt% nafion (to improve ionic conductivity), all of which are coated in nickel foam. Ag/AgCl and platinum were used as a reference and counter electrode. The overall specific capacitance achieved was 1960 Fg−1 in 1 M KCl electrolyte [146]. Similarly, many researchers recovered porous carbon from leather waste, activated with KOH and used in supercapacitors [147]. Interestingly, Soni et al. prepared low-cost Fe–N–C based catalysts as an alternate to Pt catalysts in alkaline fuel cells and Zn air battery systems. The waste footwear leather was pyrolyzed with FeCl3 at 900 °C to obtain N, S, and Fe combined porous carbon. The fuel cell with this porous carbon cathode showed a power density of 50 mW cm−2 and OCV of 0.92 V. Similarly, the Zn air battery with the prepared porous carbon exhibited a power density of 174 mW cm−2 [148]. These findings suggest that leather scrap may be used in electrochemical energy storage systems, which reveals significant improvements in cell performance comparable to commercial carbons.

Silica and steel waste.

Quartz and silicon containing materials are frequently used in modern manufacturing. While a vast volume of silicon waste is produced each year, recycling it for value-added applications has remained unproductive [149]. Wu et al. used block Si and quartz sand waste andrefined it to prepare Si/SiO2 composite anodes for LIBs. Initially, the Si waste was ground and heated to 650 °C to remove organic moieties, followed by HCl and HF etching to remove surface impurities. After multiple washes and filtration, the obtained Si/SiO2 composite was used as an anode material for LIBs. The prepared anode exhibited a capacity of ~993 mAh g−1 after 400 cycles with complete capacity retention. The high capacity is because of prelithiated Si/SiO2 compounds, which allow the whole cell to have an increased energy density (459.4 Wh kg−1) over conventional graphite electrodes [149].

3.4. Underpinning Renewables for EECS

Solar power has the most possibility to satisfy future power consumption demand, achieving emissions reduction objectives among the various renewable energy technologies accessible. According to Creutzig et al., solar has the potential to offset 30–50% of the world’s electricity consumption by 2050, owing to a considerable decrease in renewable energy setup’s initial investment over the years and predicted developments in the upcoming years due to science and technology progressions [150]. On the other hand, these energy-generating methods are changeable and necessitate flexible substrates for effective interaction with the developing grid system. Integration of power grids, renewables, and a transmission network with low carbon emissions might be viable alternatives to compensate for the existing energy demand. Solar and fuel cell/batteries integration are critical options for a sustainable future. Solar–hydrogen hybrid systems involving photovoltaic powered electrolysis used for hydrogen production have lots of scope in the future. Unfortunately, solar generation hybrid system efficiency is a poor match for the effectiveness of hydrogen derived from fossil fuels. For instance, a recently developed proton exchange membrane electrolyzer with solar power had an efficiency of 31%. However, the authors highlight the commercial scalability, infrastructure, and cost difficulties of developing such hybrid systems [151].

3.5. Policies and Regulations

Administrators and policymakers have already begun to examine the adverse effects of GHG and have taken measures to mitigate them (SGD goals). Several nations committed to achieving zero CO2 emission targets by 2050 at the UN Climate Action Summit in 2019. These are lofty ambitions, and achieving them will need a significant energy renaissance.

Hydrogen is one of the key solutions for the energy crisis and for creating a sustainable market. Recently, 13 international organizations formed a council for hydrogen energy for the following reasons:

- (i)

- Several feedstocks and techniques may be used to manufacture hydrogen, with varied prices.

- (ii)

- Hydrogen may be utilized in a variety of applications.

- (iii)

- Fuel cells can offer several benefits to the entire electricity requirement of countries.

- (iv)

- Hydrogen technology may be expensive, but there are several inexpensive supplementary approaches that have been recently developed.

The UK’s 2017 white paper summarizes the possibilities and challenges of using hydrogen as fuel. The demand for hydrogen is predicted to grow on a worldwide scale by 2070, with transportation, industries, and energy being the primary consumers [152].

The European Commission’s (EC) strategy has developed different ways to improve hydrogen energy production and investments. They also support the development of green hydrogen [153]. The New Green Deal was initiated by the EC in three phases: 2020 to 2025, 2025 to 2030, and 2030 to 2050. Some of the initiatives are:

- (i)

- Minimizing the expenses associated with producing hydrogen using industrial technologies that emit less carbon dioxide.

- (ii)

- Making use of every available collaboration with practical facilities that already exist to spread hydrogen’s possibilities logistically.

- (iii)

- Lowering the cost of producing renewable power, which includes lowering the price of producing hydrogen thanks to manufacturing methods using minimal carbon dioxide emissions.

- (iv)

- Maturing green hydrogen technology and making it viable in the long term (beyond 2030).

- (v)

- Subsidizing blue hydrogen investments via pilot projects andnational and EU funding.

- (vi)

- Reducing the cost of electrolyzers and membranes.

The International Hydrogen Council had 81 companies as members in 2021, up from 13 in 2017. The Council’s goals are to pinpoint the current obstacles that must be solved with the aid of the governments and to develop the practical application of hydrogen in several required fields [152,153,154]. The assessment of cost-effective improvements, both current and future, as well as a more accurate price for both green and blue hydrogen, should be the main emphasis of future development. Subsidies of up to USD 61 million, USD 466 million, and USD 100 million, respectively, were allotted for the construction of hydrogen fueling stations in Japan, Germany, and California [153]. Fuel distributors may be encouraged to establish a long-term hydrogen fueling infrastructure through rules and incentives for low-carbon hydrogen generation. The Hydrogen Program Plan, published by the United States Department of Energy in 2020, offers policy direction for developing, implementing, and validating hydrogen production and associated technologies while eliminating regulatory and commercial impediments and achieving diverse commercial routes.

4. Proposed Perspective

In the last decades, computational chemistry and calculations such as Monte Carlo techniques, first principles calculations, molecular dynamics, molecular simulations, and quantum mechanics were used to predict the properties of new materials and design [155]. DFT calculations and computational tools have resulted in the creation of several databases such as the Inorganic Crystal Structure Database (ICSD), Materials Project, MaterialGo, Electronic Structure Project, Harvard Clean Energy Project, and Open Quantum Materials Database [156]. However, owing to the increased need for coding and poor scalability of computations, there are still numerous obstacles in identifying adequate descriptors or models, limiting their efficacy in studying complicated real components. Furthermore, substantial volumes of material data files are frequently overlooked in databases. As a result, it is critical to speed material discovery by developing a new study design.

Artificial intelligence (AI) is a recently used tool for material discovery. Furthermore, data science has become a research hotspot, integrating AI with big data [157]. Further, data visualization tools, Power BI, and presentation tools play a vital role in analyzing the collected data and branching. Machine learning (ML), an essential component of AI, can discover mathematical laws hidden in large amounts of data to create consistent, repeatable values and outcomes [157]. ML may also connect tiny and big temporal and dimension scales. It ensures incredible precision by being able to forecast different materials or attributes quickly. ML methods such as deep neural networks, support vector machines (SVM), partial least squares regression (PLS), logistic regression (LR), and random forest (RF) can be used to predict the EECS material attributes [157]. The developed ML model should consist of descriptive, predictive, and prescriptive AI in order to extract information from available data sources, analyze and predict the pattern, and provide improvement criteria, respectively [157,158].

The development of ML for rechargeable batteries has been considerably aided by the research studies listed below. The cohesive energy and diffusion barrier of an olivine-type LiMXO4 were predicted in 2014 by Jalem et al. [159] by combining density functional theory (DFT) with the partial least squares (PLS) algorithm. Using the DFT and PLS approaches, they chose 15 solid electrolyte combinations for lithium-ion batteries and then used Bayesian optimization to determine which compounds were the best conductors. With only 30% of the total DFT-based assessments, the approach can, 90% of the time, locate the perfect combination. Based on their ability to avoid metal dendrites in the Li anode, Ahmad et al. [160] performed a computational evaluation of more than 12,000 inorganic solids in 2018. Twenty interfaces with six solid electrolytes were predicted by ML models to be resistant to dendrites. In order to construct a high-performance solid electrolyte interphase, Arghya et al. [161] combined semi-supervised procedural deep learning models with laboratory testing in 2019. ML is an appropriate computational approach for rechargeable battery materials because it can more rapidly and precisely discover the structure connections of these materials. Each potential characteristic set is evaluated using a trained machine learning model, such as Support Vector Machine (SVM) or Artificial Neural Networks (ANN). Several potential feature subgroups are kept and used to construct the list of feature subsets until the chosen feature subset satisfies the repetition end conditions. Wu et al. [162] chose 23 key descriptors containing essential characteristics like impurity level. With a root mean square error (RMSE) of 0.15 eV, a Gaussian kernels ridge regression (GKRR) model was created to forecast FCC solute transport barriers. Recently, the LSSVM model was utilized to predict the electrical properties of a ternary mixture at different temperatures and atmospheric pressure, with 179 samples, which had an R2 of 0.999. According to relevant research, the average melting point has the biggest influence on the electrical conductivity of the ternary combination [163].

Recently, Chenmali et al. used deep feedforward neural networks for estimating the state of charge (SOC). They used DNN, which can bypass fillers and map the current, voltage, and temperature-varied SOC. The DNN may train itself with additional parameters using learning techniques like gradient descent [164]. Similarly, battery degradation performance was predicted using a Gaussian regression ML model with the help of impedance spectroscopy. Regarding fuel cells, Zhongliang et al. [165] used Fisher discriminant analysis (FDA) to identify individual cell voltages of PEMFC. Similarly, SVM and ANN were also used to determine the catalyst’s activity, voltage, and redox characteristics [166]. Although SOFCs and PEMFCs have significant variances, the diagnostic approach and the electrochemical issues are indicative [167]. For ML-based techniques, the system’s physical properties and scientific relationships are not essential [168]. Since the state of health (SOH) of a fuel cell system may be determined by identifying patterns from simple sensor inputs, machine learning (ML) can be a useful option for real-time application in SOH evaluation [169]. The essential problem, from the laboratory concept to the industrial application of ML-based techniques, is how to achieve high accuracy using inexpensive sensors, followed by the reliability and resilience of the diagnostic model [169].

However, all these studies used theoretical data sets and minimal experimental measurements. In real-time scenarios, a much bigger training set is necessary. The gap between the laboratory and industry is because of the changes in material properties and device performance when operated on a large scale [170]. Previously, Chellappan et al. reported high-throughput solution processable hybrid materials, supported by ML optimization, and identified the suitable hybrid materials for high electrical conductivity [158]. The group proposed a high-throughput semi-automated synthesis and electrical testing method for identifying the best hybrid materials with the ML algorithm. This platform uses Bayesian optimization for focused data sampling, which was then applied to generate the best material for organic photovoltaics. The same concept can be applied in batteries and fuel cells [158].

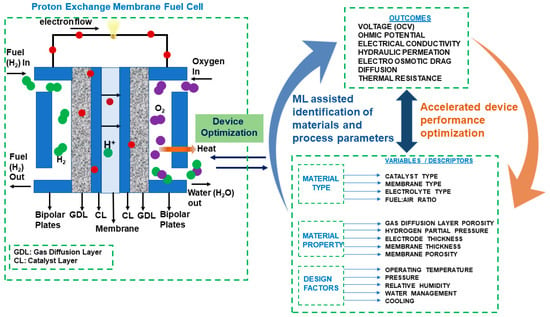

As an example, the key design prototype for optimizing materials in PEMFC and battery cathodes is illustrated [158]. The initial step in ML design is to assess the descriptors. The descriptors for fuel cells used here are membrane thickness, catalyst type, membrane porosity, and hydrogen partial pressure [171,172]. Many additional characteristics, such as fuel-to-oxygen ratio, feed materials, temperature, etc., might also be considered depending on the case condition [171]. The next step is to assign the target properties relative to the descriptors, as shown in Figure 7, such as voltage (OCV), Ohmic potential, and electrical conductivity. The third step is the hardest, as it involves mathematical optimization and screening [172]. The screening strategy involves generating all conceivable target properties in the model space, followed by material testing utilizing high throughput (HT) materials development, and then optimizing using the created ML models [172]. In our proposed HT design [158], we recommend employing ML enabled thickness estimation to measure surface thickness, cyclic voltammetry to analyze electrocatalytic performance, a surface probe analyzer to detect pore size, and a pressure sensor to monitor hydrogen pressure [173]. The datasets gathered during the design of HT experiments will be utilized for ML model construction and validation (Step 4). Because closed-loop ML is more exact and accurate than open-loop ML, forecasted data sets will be integrated into the input process following the loop iteration (Step 5) [158,174].

Figure 7.

Fuel cell materials and performance optimization by ML (concept adapted from [158]).

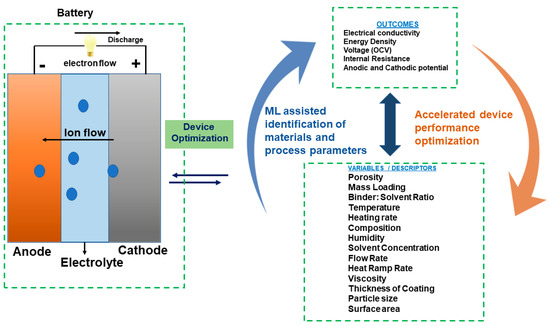

Like the design of experiments for fuel cells, a prototype with different descriptors for selecting cathodes in a battery is shown in Figure 8 [175,176,177,178]. The descriptors used here are porosity, mass loading, binder-to-solvent ratio, and composited material properties. The outcomes are electrical conductivity and voltage (OCV). Other descriptors and outcomes are stated in Figure 8.

Figure 8.

Battery materials and performance optimization by ML (concept adapted from [158]).

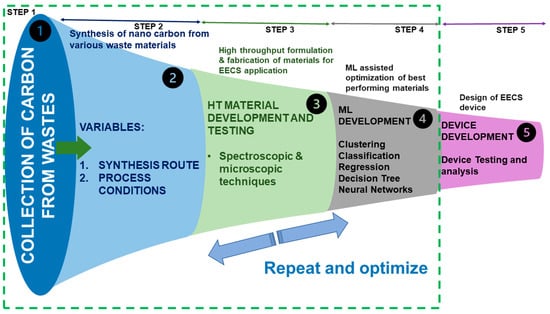

As various research has demonstrated the simplicity with which carbon compounds may be extracted from trash, we propose a perspective to investigate their qualities and performance using machine learning [179]. It is important to value both sustainability and performance, which is possible with carbon materials, and it is one of the viable options. As an example, a methodology for utilizing waste resources and involving both experimental and theoretical datasets for machine learning is described [158,179]. Machine learning (ML) leverages real-world insights gained from raw data to solve complex problems fast. There are several publications and research work about sustainability and recycling, but there is no standard set of protocols to follow. Thus, we propose to use machine learning algorithms to predict the best recycled materials compatible with fuel cells and batteries from both available data sets and experimental data, allowing computers to uncover a variety of deep insights while being specifically educated on various opportunities and developing a standard protocol [158,170]. ML is growing rapidly, fueled mostly by advances in processing technology and accelerated materials development. For instance, we have illustrated a development protocol for an alternative sustainable, low-cost/high-performance electrochemical energy storage device suitable for commercial use, which will involve optimizing several interdependent material parameters and operating conditions using high throughput accelerated materials fabrication and machine learning. The overall proposed workflow is shown in Figure 9 [158,169,180].

Figure 9.

Solution flow using HT and ML methods for optimizing the best energy materials and methods derived from carbon waste (data and concept adapted from [158,179]).

Initially, the process parameters, descriptors, and outcomes should be identified. There are five steps, of which Step 1 to Step 4 undergo closed-loop repetition until convergence.

Step 1 is to collect and segregate carbon resources.

Step 2 is to identify and optimize the morphological and surface features using synthesis methods.

Step 3 is to utilize high throughput experiments for analyzing the spectral and microscopic features of thousands of samples.

Step 4 is to use the ML algorithm to study the traits and pattern, with closed-loop optimization from Step 1 to Step 4.

Once the suitable and promising material is identified, Step 5 is to build and test the EECS device.

Researchers claim it is easier to do reverse materials design; that is, to use ML for identifying materials with datasets as a first step and then optimize using experimental studies. From our viewpoint, the AI technologies are not completely reliable for new material discoveries with available databases in the field of EECS. For instance, the performance of LiFePO4 cathodes in LIBs significantly varies from 90 to 170 mAh g−1, and yet different work that reports the same method of preparation, mass loading, and similar particle sizes shows that the performance characteristics are not analogous to each other. The realm of applying ML to EECS technology is new and started only a decade ago; therefore, complete reliance on databases has the possibility for definitive errors. Further, if the first step of reverse materials design is itself an error, the process of continuing the assessment remains ineffective.

Bayesian optimization and sampling algorithms are specifically suited for small materials science problems where data is collected in a high throughput fashion, which is perfectly suited to the viewpoint. The Bayesian optimization (BO) algorithm explores the relationship between the input process parameters and the measured material descriptors. The application of ML to these advanced algorithms in a closed loop will allow us to map the correlation between the input process variables and the output material characteristics. This will accelerate the identification of optimal process conditions to fabricate the most suitable EECS electrodes with higher electrical conductivity and mechanical stability.

We also suggest involving descriptive AI, which analyzes the target properties’ underlying ability to construct an exact data model, enhancing the integrity of data sets. A well-organized digital twin can generate varied data (e.g., malfunctions, inconsistencies, data under specific circumstances) that are seldom encountered in the actual world. Trustworthy data increase the complexity of training datasets, which empowers the AI system and increases the reliability and scalability of ML techniques.

The fundamental feature is the digital twin, which is utilized to perform initial training and test the impacts of ML-based refinements. The suggested architecture eliminates the hazards of error and/or inaccurate suggestions by retraining the AI engine on the digital twin by experimental datasets rather than only relying on theoretical datasets. Furthermore, because the training dataset is limited, it is not guaranteed that developing early findings acquired in the framework will convert to a correct implementation due to technical intricacy. As a result, the high-fidelity digital twin is utilized to assess the AI engine’s proposed operations in preparation, evaluating risk and estimating efficacy.

5. Conclusions

Computational chemistry has matured as a method for supplementing and assisting a series of experiments for the prediction and development of novel materials and databases. Although it has been generally projected that machine learning will enhance and revolutionize the EECS sector, realistic implementation remains a challenge. It is difficult to analyze all real-time problems due to complex non-linear features and insufficient datasets. To overcome these issues, it is critical to develop established standard algorithms that are applicable to all systems. Experiment datasets for real-time applications may be easily created using a high throughput synthesis and characterization platform. We insist on the use of sustainable materials and processes in EECS systems, particularly in terms of materials recycling and transforming waste to energy materials. Perhaps electrospun fibers and nanomaterials are advantages owing to their tunable properties. For instance, carbon compounds generated from waste with varied characteristics can be used as a sustainable resource for EECS. Nevertheless, various processes and parameter controls exist for creating and determining the best-performing materials. Standardization of methodologies is, therefore, necessary to provide opportunities in the EECS commercial market. As a result, accelerated material synthesis and characterizing platforms with machine learning might aid in the identification of the most sustainable materials and processes.

Author Contributions

B.R.: Formal analysis, Conceptualization, Writing—Original Draft, Review &=and Editing; R.P.R.: Conceptualization, Writing—Original Draft, Review and Editing; V.C.: Conceptualization, Review and Editing, Supervision; S.R.: Conceptualization, Review and Editing, Supervision. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Data Availability Statement

Data will be made available upon request.

Acknowledgments

B.R. acknowledges A-STAR-SINGA (SING-2021-02-0819), offered by Agency for Science, Technology and Research (A*STAR) Singapore. B.R. and V.C. acknowledge funding from the Accelerated Materials Development for Manufacturing Program at A*STAR via the AME Programmatic Fund by the Agency for Science, Technology and Research under Grant No. A1898b0043.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Cano, Z.P.; Banham, D.; Ye, S.; Hintennach, A.; Lu, J.; Fowler, M.; Chen, Z. Batteries and Fuel Cells for Emerging Electric Vehicle Markets. Nat. Energy 2018, 3, 279–289. [Google Scholar] [CrossRef]

- Mohamed, N.; Allam, N.K. Recent Advances in the Design of Cathode Materials for Li-Ion Batteries. RSC Adv. 2020, 10, 21662–21685. [Google Scholar] [CrossRef] [PubMed]

- Brindha, R.; Ajith, S.S.R.; Nandhini, M.; Selvam, M.; Subannajui, K.; Khotmungkhun, K.; Sakthipandi, K. Evaluation of Anticorrosive Behaviour of ZnO Nanotetra-Pods on a AZ91-Grade Mg Alloy. Bull. Mater. Sci. 2019, 42, 221. [Google Scholar] [CrossRef]

- Zhang, X.; Shen, J.X.; Turiansky, M.E.; van de Walle, C.G. Minimizing Hydrogen Vacancies to Enable Highly Efficient Hybrid Perovskites. Nat. Mater. 2021, 20, 971–976. [Google Scholar] [CrossRef] [PubMed]

- Global EV Outlook 2021—Analysis—IEA. Available online: https://www.iea.org/reports/global-ev-outlook-2021 (accessed on 29 July 2022).

- Ramasubramanian, B.; Reddy, M.V.; Zaghib, K.; Armand, M.; Ramakrishna, S. Growth Mechanism of Micro/Nano Metal Dendrites and Cumulative Strategies for Countering Its Impacts in Metal Ion Batteries: A Review. Nanomaterials 2021, 11, 2476. [Google Scholar] [CrossRef] [PubMed]

- Kumar, K.K.; Brindha, R.; Nandhini, M.; Selvam, M.; Saminathan, K.; Sakthipandi, K. Water-Suspended Graphene as Electrolyte Additive in Zinc-Air Alkaline Battery System. Ionics 2019, 25, 1699–1706. [Google Scholar] [CrossRef]

- Wu, Y.; Ghalkhani, M.; Afshar, E.A.; Karimi, F.; Xia, C.; van Le, Q.; Vasseghian, Y. Recent Progress in Biomass-Derived Nanoelectrocatalysts for the Sustainable Energy Development. Fuel 2022, 323, 124349. [Google Scholar] [CrossRef]

- Dodds, P.E.; Staffell, I.; Hawkes, A.D.; Li, F.; Grünewald, P.; McDowall, W.; Ekins, P. Hydrogen and Fuel Cell Technologies for Heating: A Review. Int. J. Hydrogen Energy 2015, 40, 2065–2083. [Google Scholar] [CrossRef]

- Wang, Y.; Diaz, D.F.R.; Chen, K.S.; Wang, Z.; Adroher, X.C. Materials, Technological Status, and Fundamentals of PEM Fuel Cells—A Review. Mater. Today 2020, 32, 178–203. [Google Scholar] [CrossRef]

- Hameer, S.; van Niekerk, J.L. A Review of Large-Scale Electrical Energy Storage. Int. J. Energy Res. 2015, 39, 1179–1195. [Google Scholar] [CrossRef]

- Smdani, G.; Islam, M.R.; Yahaya, A.N.A.; Safie, S.I.B. Performance Evaluation of Advanced Energy Storage Systems: A Review. Energy Environ. 2022. [Google Scholar] [CrossRef]

- Whittingham, M.S. History, Evolution, and Future Status of Energy Storage. Proc. IEEE 2012, 100, 1518–1534. [Google Scholar] [CrossRef]

- Khaligh, A.; Li, Z. Battery, Ultracapacitor, Fuel Cell, and Hybrid Energy Storage Systems for Electric, Hybrid Electric, Fuel Cell, and Plug-in Hybrid Electric Vehicles: State of the Art. IEEE Trans. Veh. Technol. 2010, 59, 2806–2814. [Google Scholar] [CrossRef]

- Vijayakumar, V.; Nam, S.Y. Recent Advancements in Applications of Alkaline Anion Exchange Membranes for Polymer Electrolyte Fuel Cells. J. Ind. Eng. Chem. 2019, 70, 70–86. [Google Scholar] [CrossRef]

- Markgraf, S.; Hörenz, M.; Schmiel, T.; Jehle, W.; Lucas, J.; Henn, N. Alkaline Fuel Cells Running at Elevated Temperature for Regenerative Fuel Cell System Applications in Spacecrafts. J. Power Source 2012, 201, 236–242. [Google Scholar] [CrossRef]

- Ferriday, T.B.; Middleton, P.H. Alkaline Fuel Cell Technology—A Review. Int. J. Hydrogen Energy 2021, 46, 18489–18510. [Google Scholar] [CrossRef]

- Chen, D.; Zou, Y.; Shi, W.; Serbin, S.; You, H. Proton Exchange Membrane Fuel Cells Using New Cathode Field Designs of Multi-Inlet Shunt Intake Design. Int. J. Energy Res. 2021, 45, 9948–9960. [Google Scholar] [CrossRef]

- Son, T.Y.; Kim, D.J.; Vijayakumar, V.; Kim, K.; Kim, D.S.; Nam, S.Y. Anion Exchange Membrane Using Poly(Ether Ether Ketone) Containing Imidazolium for Anion Exchange Membrane Fuel Cell (AEMFC). J. Ind. Eng. Chem. 2020, 89, 175–182. [Google Scholar] [CrossRef]

- Zhang, S.; Zhu, X.; Jin, C. Development of a High-Performance Anion Exchange Membrane Using Poly(Isatin Biphenylene) with Flexible Heterocyclic Quaternary Ammonium Cations for Alkaline Fuel Cells. J. Mater. Chem. A 2019, 7, 6883–6893. [Google Scholar] [CrossRef]

- Kimura, T.; Matsumoto, A.; Inukai, J.; Miyatake, K. Highly Anion Conductive Polymers: How Do Hexafluoroisopropylidene Groups Affect Membrane Properties and Alkaline Fuel Cell Performance? ACS Appl. Energy Mater. 2020, 3, 469–477. [Google Scholar] [CrossRef]

- O’Hayre, R.; Cha, S.-W.; Colella, W.; Prinz, F.B.; Fuel Cell Fundamentals. Prinz—Google Books. Available online: https://books.google.com.sg/books?hl=en&lr=&id=O2JYCwAAQBAJ&oi=fnd&pg=PR11&dq=hydrogen+fuel+cells+types&ots=RRDRTTJZpk&sig=lxVfE_wQSLaJV-Mvh4JnnJhUoi8&redir_esc=y#v=onepage&q=hydrogen%20fuel%20cells%20types&f=false (accessed on 3 November 2022).

- Alaswad, A.; Baroutaji, A.; Achour, H.; Carton, J.; Al Makky, A.; Olabi, A.G. Developments in Fuel Cell Technologies in the Transport Sector. Int. J. Hydrogen Energy 2016, 41, 16499–16508. [Google Scholar] [CrossRef]

- Chai, L.; Hu, Z.; Wang, X.; Zhang, L.; Li, T.T.; Hu, Y.; Pan, J.; Qian, J.; Huang, S. Fe7C3 Nanoparticles with in Situ Grown CNT on Nitrogen Doped Hollow Carbon Cube with Greatly Enhanced Conductivity and ORR Performance for Alkaline Fuel Cell. Carbon 2021, 174, 531–539. [Google Scholar] [CrossRef]

- Mandal, M.; Huang, G.; Hassan, N.U.; Peng, X.; Gu, T.; Brooks-Starks, A.H.; Bahar, B.; Mustain, W.E.; Kohl, P.A. The Importance of Water Transport in High Conductivity and High-Power Alkaline Fuel Cells. J. Electrochem. Soc. 2020, 167, 054501. [Google Scholar] [CrossRef]

- Wang, X.; Sheng, W.; Shen, Y.; Liu, L.; Dai, S.; Li, N. N-Cyclic Quaternary Ammonium-Functionalized Anion Exchange Membrane with Improved Alkaline Stability Enabled by Aryl-Ether Free Polymer Backbones for Alkaline Fuel Cells. J. Memb. Sci. 2019, 587, 117135. [Google Scholar] [CrossRef]

- Patil, S.S.; Madhura, V.; Kammakakam, I.; Swamy, M.H.; Patil, K.S.; Lai, Z.; HN, A.R. Quinuclidinium-Piperidinium Based Dual Hydroxide Anion Exchange Membranes as Highly Conductive and Stable Electrolyte Materials for Alkaline Fuel Cell Applications. Electrochim. Acta 2022, 426, 140826. [Google Scholar] [CrossRef]

- Yoon, J.; Lee, D.; Lee, Y.N.; Yoon, Y.S.; Kim, D.J. Solid Solution Palladium-Nickel Bimetallic Anode Catalysts by Co-Sputtering for Direct Urea Fuel Cells (DUFC). J. Power Source 2019, 431, 259–264. [Google Scholar] [CrossRef]

- Pothaya, S.; Regalbuto, J.R.; Monnier, J.R.; Punyawudho, K. Preparation of Pt/Graphene Catalysts for Polymer Electrolyte Membrane Fuel Cells by Strong Electrostatic Adsorption Technique. Int. J. Hydrogen Energy 2019, 44, 26361–26372. [Google Scholar] [CrossRef]

- Radenahmad, N.; Azad, A.T.; Saghir, M.; Taweekun, J.; Bakar, M.S.A.; Reza, M.S.; Azad, A.K. A Review on Biomass Derived Syngas for SOFC Based Combined Heat and Power Application. Renew. Sustain. Energy Rev. 2020, 119, 109560. [Google Scholar] [CrossRef]

- Zhang, W.; Hu, Y.H. Recent Progress in Design and Fabrication of SOFC Cathodes for Efficient Catalytic Oxygen Reduction. Catal. Today 2022, 374. [Google Scholar] [CrossRef]

- Pasierb, P.; Drożdż-Cieśla, E.; Gajerski, R.; Łabuś, S.; Komornicki, S.; Rękas, M. Chemical Stability of Ba(Ce1−xTix)1−yYyO3 Proton-Conducting Solid Electrolytes. J. Therm. Anal. Calorim. 2009, 96, 475–480. [Google Scholar] [CrossRef]

- Lenka, R.K.; Patro, P.K.; Patel, V.; Muhmood, L.; Mahata, T. Comparative Investigation on the Functional Properties of Alkaline Earth Metal (Ca, Ba, Sr) Doped Nd2NiO4+δ Oxygen Electrode Material for SOFC Applications. J. Alloys Compd. 2021, 860, 158490. [Google Scholar] [CrossRef]

- Lee, F.C.; Ismail, M.S.; Ingham, D.B.; Hughes, K.J.; Ma, L.; Lyth, S.M.; Pourkashanian, M. Alternative Architectures and Materials for PEMFC Gas Diffusion Layers: A Review and Outlook. Renew. Sustain. Energy Rev. 2022, 166, 112640. [Google Scholar] [CrossRef]

- Belenov, S.; Alekseenko, A.; Pavlets, A.; Nevelskaya, A.; Danilenko, M. Architecture Evolution of Different Nanoparticles Types: Relationship between the Structure and Functional Properties of Catalysts for PEMFC. Catalysts 2022, 12, 638. [Google Scholar] [CrossRef]

- Manojkumar, K.; Kandeeban, R.; Brindha, R.; Sangeetha, V.; Saminathan, K. Non-Precious Metal-Based Integrated Electrodes for Overall Alkaline Water Splitting. J. Indian Chem. Soc. 2022, 99, 100775. [Google Scholar] [CrossRef]

- Rajagopalan, K.; Ramasubramanian, B.; Manojkumar, K.; Ramakrishna, S.; Marappan, P.; Saminathan, R.K. Organo-Metallic Electrolyte Additive for Regulating Hydrogen Evolution and Self-Discharge in Mg–Air Aqueous Battery. New J. Chem. 2022, 46, 19950–19962. [Google Scholar] [CrossRef]

- Ott, S.; Du, F.; Luna, M.L.; Dao, T.A.; Cuenya, B.R.; Orfanidi, A.; Strasser, P. Understanding the Performance Increase of Catalysts Supported on N-Functionalized Carbon in PEMFC Catalyst Layers. J. Electrochem. Soc. 2022, 169, 054520. [Google Scholar] [CrossRef]

- Ungan, H.; Yurtcan, A.B. PEMFC Catalyst Layer Modification with the Addition of Different Amounts of PDMS Polymer in Order to Improve Water Management. Int. J. Energy Res. 2019, 43, 5946–5958. [Google Scholar] [CrossRef]

- Zhu, L.; Li, Y.; Zhao, J.; Liu, J.; Wang, L.; Lei, J.; Xue, R. Enhanced Proton Conductivity of Nafion Membrane Induced by Incorporation of MOF-Anchored 3D Microspheres: A Superior and Promising Membrane for Fuel Cell Applications. Chem. Commun. 2022, 58, 2906–2909. [Google Scholar] [CrossRef]

- Xie, X.; Shang, L.; Xiong, X.; Shi, R.; Zhang, T. Fe Single-Atom Catalysts on MOF-5 Derived Carbon for Efficient Oxygen Reduction Reaction in Proton Exchange Membrane Fuel Cells. Adv. Energy Mater. 2022, 12, 2102688. [Google Scholar] [CrossRef]

- Lim, B.H.; Majlan, E.H.; Tajuddin, A.; Husaini, T.; Daud, W.R.W.; Radzuan, N.A.M.; Haque, M.A. Comparison of Catalyst-Coated Membranes and Catalyst-Coated Substrate for PEMFC Membrane Electrode Assembly: A Review. Chin. J. Chem. Eng. 2021, 33, 1–16. [Google Scholar] [CrossRef]

- Balogun, E.O.; Hussain, N.; Chamier, J.; Barendse, P. Performance and Durability Studies of Perfluorosulfonic Acid Ionomers as Binders in PEMFC Catalyst Layers Using Electrochemical Impedance Spectroscopy. Int. J. Hydrogen Energy 2019, 44, 32219–32230. [Google Scholar] [CrossRef]

- Kravos, A.; Ritzberger, D.; Tavčar, G.; Hametner, C.; Jakubek, S.; Katrašnik, T. Thermodynamically Consistent Reduced Dimensionality Electrochemical Model for Proton Exchange Membrane Fuel Cell Performance Modelling and Control. J. Power Source 2020, 454, 227930. [Google Scholar] [CrossRef]