1. Introduction

Securing a proper drinking water supply has become a serious challenge that faces billions of people in many regions all over the world, especially in arid regions that lack fresh water sources. Therefore, saline and brackish water desalination are extensively used to compensate for the lack of natural potable water resources. Among various desalination technologies, solar desalination is considered a sustainable avenue to secure fresh water, primarily in remote areas far from the electricity grid. In particular, solar stills employ a simple and less expensive technique in terms of fabrication, operation, and maintenance to convert saline and brackish water to potable water by the utilization of solar energy. In addition, depending on the heat source to evaporate saline water, solar stills are classified as passive or active. Passive solar stills utilize only solar irradiation to evaporate saline water while active solar stills use other heat sources in addition to solar irradiation. Hundreds of passive-solar-still designs are reported in the literature. These include single-slope [

1] and double-slope stills [

2], pyramid-shaped solar stills [

3], spherical solar stills [

4], diffusion solar stills [

5], tubular solar stills [

6], wick solar stills [

7], stepped solar stills [

8], and weir-type solar stills [

9]. A review of the effect of several design modifications on the performance of solar stills can be found in Katekar and Deshmukh [

10].

Single-slope basin solar stills are the simplest and the cheapest design among different types of passive solar stills. Enhancing the daily distillate and the efficiency of single-slope basin stills has been the motive of exhaustive research work in the literature. For example, Omara et al. [

11] investigated the effect of increasing the surface area of the absorber, and hence the evaporation rate of saline water, by using finned and corrugated saline water trays. It was found that the productivity increased by 40% in finned solar stills and by 21% in corrugated solar stills. Dumka et al. [

12] placed 144 hollow plastic balls covered with a jute cloth on the saline water surface in the basin, which increased the water productivity of the still by 64%. Essa et al. [

13] used corrugated rotating discs with wick material to increase the evaporation surface area and the surface area exposed to solar radiation in single-slope stills. This modification improved the distillate of the still by 124%.

Elevated temperatures of the still components increase the thermal losses from the still to the ambient surroundings and negatively affect its productivity. Lowering the temperatures of the still components, especially during peak hours, can significantly enhance the performance of the still. This can be achieved by storing part of the incident energy in sensible or latent heat storage materials. In this context, Mevada et al. [

14] added different sensible heat storage materials to the basin of a single-slope still. The study showed an increase of 76% in the daily distillate yield of the still. In addition, different phase change materials (PCMs) such as paraffin wax, palmitic acid, lauric acid, and capric acid have been used for storing energy from the base during sun hours and reusing them in distillation after sunset. Katekar and Deshmukh [

15] concluded that paraffin wax is the best PCM to be used in basin stills as it increases their productivity by 180%.

The evaporation rate of saline water depends on the temperature difference between the evaporation area (the basin) and the condensation area (the glass top). To maximize this temperature difference, the glass temperature has to be maintained as low as possible. This has been achieved in multiple ways such as the cooling of the glass cover by air or water flow, by the use of an external fan [

16], or by integrating an internal or external condenser into the still [

17]. In this context, Kumar et. al. [

18] improved both the evaporation and condensation rates in single-slope stills by the use of a rotating shaft with five blades, which was immersed in the saline water and an exhaust fan that drove the water vapor to an external condenser. These modifications enhanced the daily distillate by 39.49%. Somwanshi and Tiwari [

19] studied the effect of cooling the glass cover of single-slope stills by the flow of cooled water from the tank of an evaporative air cooler. This increased the annual yield of the still by 41.3% in warm and humid climates and by 56.5% in dry and hot climates. Ahmed and Alfaylakawi [

20] evaluated the influence of cooling the outside surface of the glass cover by the use of a water sprinkler on productivity of single-slope stills. The still productivity increased by 15.7% for cooling intervals of 20 min and by 31.8% for cooling intervals of 10 min.

The latent heat of condensation in basin solar stills is typically lost to the ambient surroundings through the glass cover. This heat loss, although big, is inevitable for distillate production. However, in multi-effect solar stills, the latent heat of condensation is recovered in heating of saline water in the next effect. Various designs for multi-effect stills have been reported in the literature such as single-slope double-basin solar stills [

21], single-slope double-basin solar stills with wick piles of jute cloth in the basin [

22], single-slope double-basin solar stills with Al

2O

3 nanoparticles in the basin [

23], single-slope double-basin solar stills with wick fins and hollow fins in the basin [

24], double-basin solar stills with double-slope cover for the upper basin and single-slope cover for the lower basin [

25], and single-slope triple-basin solar stills with corrugated basin, sensible energy storage material, and evacuated heat pipes [

26].

Nevertheless, in double-basin solar stills, the majority of the solar energy is absorbed in the upper basin and only a small portion of solar energy is received by the lower basin. This limits the temperature difference between the saline water in each basin and the glass top directly above it and, hence, limits the yield of each basin. In addition, the heating of the saline water in each basin causes the accumulation of salts and deposits on the base of that basin, which, in turn, obstructs the penetration of solar energy to the lower one.

In this manuscript, the condensation energy in single-slope basin stills is utilized as the driving thermal energy for an auxiliary humidification–dehumidification distillation process. Specifically, the glass cover of a single-slope basin solar still was replaced by a double glass air heater where the latent heat of condensation in the still was recovered by the flowing air through the glass air heater. The heated air was then humidified by saline water spray inside a humidifier and then fresh water was extracted from the air inside a water-cooled dehumidifier. Finally, the air was circulated back to the glass air heater by an air blower. In addition, in order to recover the latent heat of condensation inside the dehumidifier, the heated water exiting from the dehumidifier was utilized in the humidification of the air in the humidifier. The resultant solar still-humidification–dehumidification (SS-HDH) distiller was tested under the weather conditions of Sakaka (29.9° N, 39.3° E), Saudi Arabia, side by side with a single-slope basin still of the same basin area.

A detailed description of the fabricated SS-HDH distiller and the instruments used in measuring the experimental results are shown in the

Section 2. The mathematical equations for the energy analysis of the SS-HDH and the separate still are included in the

Section 3. The measured results and their analysis are illustrated in the

Section 4. Finally, the main findings of the study are highlighted in the

Section 5.

2. Experimental Setup

A scheme of the SS-HDH distiller is shown in

Figure 1 and the actual setup is shown in

Figure 2. The SS-HDH distiller consists of (i) a single-slope basin-type solar still that has a blackened basin made of 3 mm galvanized steel sheet and sized 1 m × 0.5 m × 0.1 m, (ii) an air heater that consists of a 5 cm depth glass channel that replaces the regular glass top of the still and tilts 30° on the horizontal plane, (iii) a humidifier where saline water is sprayed over the heated air, and (iv) a dehumidifier that contains a cooper coil with saline water flows inside the coil. Heated water exiting the dehumidifier is sprayed inside the humidifier over the flowing air to recover the condensation energy of the dehumidifier. The basin and the sides of the still were insulated by a 5 cm thick extruded polystyrene insulation board. The walls of the humidifier and the dehumidifier, and the connecting pipes were also insulated by a flexible insulation sheet to minimize thermal losses to the ambient surroundings. Air is circulated through the HDH cycle by the use of an air blower. In addition, a separate single-slope basin-type solar still that was identical to the basin in the SS-HDH distiller was constructed and tested side by side with the SS-HDH distiller where both stills were oriented in the south direction.

Temperatures within the SS-HDH distiller and the separate still, and the ambient temperature were measured by K-type thermocouples with a measuring range of −50 to 400 °C, an accuracy of ±1 °C, and an error of 2%. Thermocouples were placed at the inlet and exit of the glass air heater, the humidifier, and the dehumidifier, on the outer surfaces of the glass top and glass air heater, underneath the still basin, and underneath basin insulation. The locations of the thermocouples are illustrated in

Figure 1. A radiation shield was used in measuring the outer surface of the glass cover in order to minimize the influence of incident solar irradiation on its measured temperature. The incident solar intensity was measured by a digital pyranometer that measures from 0 to 3999 W/m

2 with an accuracy of ±10 W/m

2 and an error of 3%. Ambient wind and airflow velocities inside the HDH cycle were measured by a digital anemometer that has a measuring range of 0.1 to 30 m/s, an accuracy of ±0.1 m/s, and an error of 1%. Water distillate productions of both the SS-HDH distiller and the separate solar still were measured by a 1000 mL measuring jar with a resolution of 10 mL.

4. Results and Discussion

The SS-HDH distiller and the separate solar still were tested side by side on the same day and under the same weather conditions. In order to ensure the accuracy of the measured results, the test was carried out on three consecutive days to minimize the influence of the changes in weather conditions. The results were consistent with small deviations due to the unavoidable variation in the weather conditions.

Figure 3 shows the measured weather conditions on March 19th from 8 am to 5 pm at Sakaka (29.9° N, 39.3° E), Saudi Arabia along with their best-fitting trend lines. The incident solar radiation reached its peak value of about 900 W/m

2 by midday while the highest measured ambient temperature was about 34 °C, which took place two hours after midday. In addition, the wind speed continuously fluctuated during the day between its minimum recorded value of 1.5 m/s and its maximum recorded value of 3.5 m/s.

Figure 4 shows a comparison between measured temperatures within the still of the SS-HDH distiller and those within the separate solar still. Throughout the day the glass cover temperature in the SS-HDH distiller was about 5 °C lower than that in the separate still. This was primarily because of the cooling effect of the circulating air of the HDH cycle. However, the basin temperature in the SS-HDH distiller was about 10 °C higher than that in the separate still, which can be attributed to the reduction in the heat losses from the glass to the ambience in the SS-HDH distiller. In addition, the temperature of the basin insulation was very much the same in both the SS-HDH distiller and the separate still, which indicates that the heat losses from the basin to the ambient surroundings were almost equal in both the SS-HDH distiller and the separate still.

Figure 5 illustrates the heating process of the circulated air within the double glass heater in the SS-HDH distiller as compared to the measured ambient temperature. Throughout the day the circulated air temperature at the inlet of the heater was about 10–15 °C higher than the ambient air temperature. This implies the advantage of using a closed-air HDH cycle versus an open-air cycle. In addition, the air temperature difference between the inlet and the exit of the glass heater increased gradually during the day and then decreased in the afternoon. This was caused by the variation in the solar intensity during the day. The biggest temperature difference between the inlet and the exit was about 10 °C, which was recorded about one hour after midday.

The hourly temperature variation of the circulated air at the humidifier inlet and exit during the day is shown in

Figure 6. The circulated air was cooled inside the humidifier due to utilizing its heat content in evaporating the sprayed saline water. The air temperature difference across the humidifier increased during the day until noon and then decreased in the afternoon. The reduction in the air temperature refers to the evaporated amount of the sprayed saline water inside the humidifier. The difference between the circulated air temperature at the exit of the humidifier and the sprayed saline water temperature refers to the efficiency of the humidification process. The larger the temperature difference between the exiting air and the saline water, the more far the exiting air is from reaching the water-vapor saturation state.

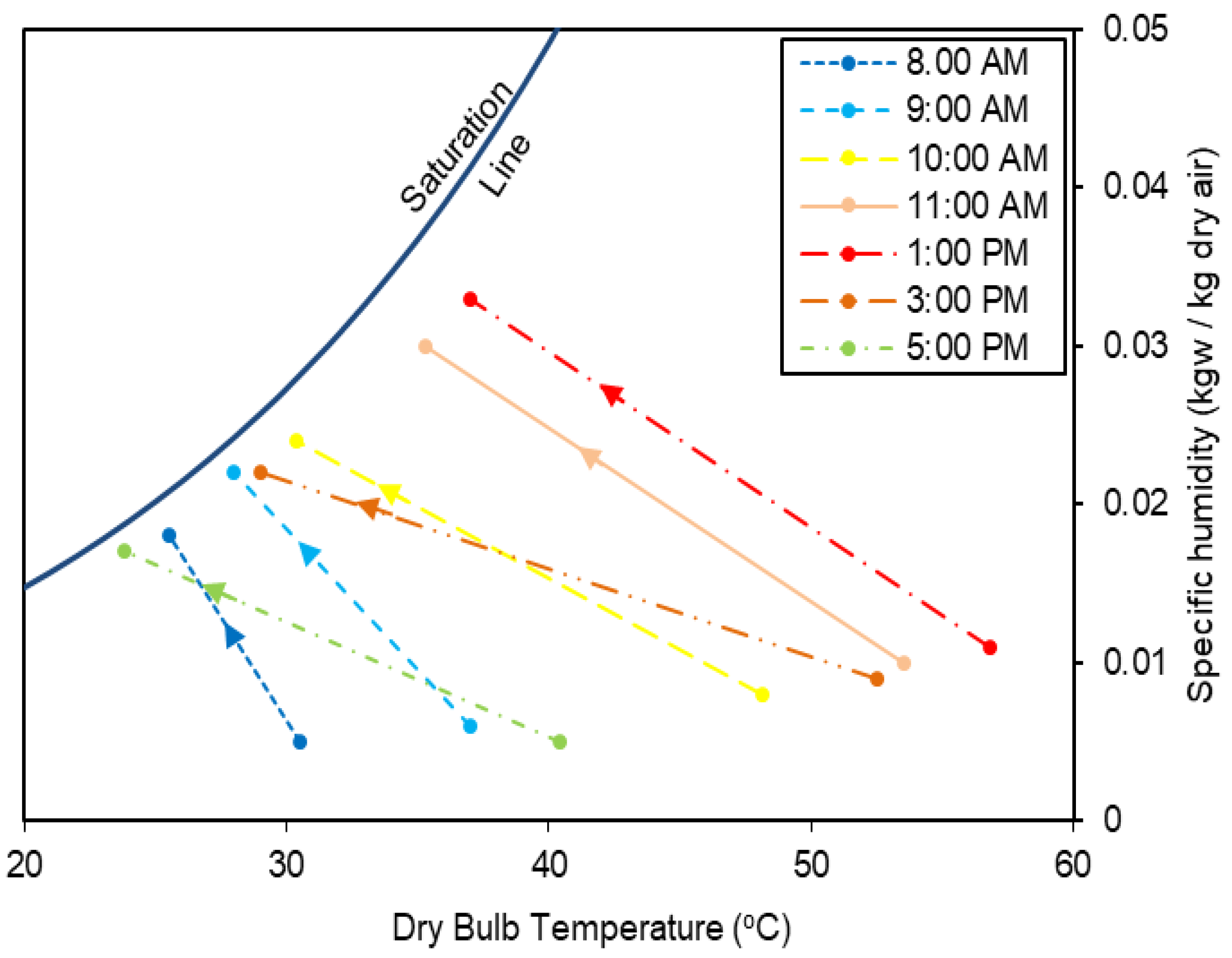

Figure 7 shows a psychometric chart that illustrates the humidification process of the circulated air. The reduction in the circulated air dry-bulb temperature (on the

x-axis of the chart) shows the cooling down of the air while the increase in the specific humidity of the circulated air (on the

y-axis of the chart) shows the increase in the moisture content of the air. It can be seen that the temperature and moisture content of the air increased from the morning to midday and then decreased in the afternoon, which is consistent with the results shown in

Figure 6.

The hourly variation in the circulated air temperature inside the dehumidifier during the day is shown in

Figure 8. The reduction in the air temperature between the exit and the inlet of the dehumidifier, similar to other trends, increased in the morning towards midday and then decreased in the afternoon. In addition, the temperature difference between the circulated air exit and the cooling water inlet refers to the efficiency of the cooling process of the circulated air through the dehumidifier.

Figure 9 shows the hourly change in the psychometric properties of the circulated air during the dehumidification process. The cooling and dehumidification process that the circulated air underwent is represented by the reduction in both the dry-bulb temperature (on the

x-axis) and the specific humidity of the circulated air (on the

y-axis). In addition, the reduction in the air temperature and specific humidity through the dehumidifier increased gradually from morning to noon and then decreased towards sunset.

The measured hourly fresh water distillate from both the still and HDH cycle in the SS-HDH distiller is presented in

Figure 10 and is compared to that from the separate still. The fresh water production from the separate solar still is much larger than that from the still in the SS-HDH distiller. This can be attributed to the reduction in the solar irradiation received by the saline water in the basin of the SS-HDH distiller due to the existence of the glass air heater, which, in turn, reduced the evaporation of the saline water. Furthermore, although the existence of the glass air heater helped in recovering part of the condensation energy of the water inside the still, it stood as an obstacle to the release of the condensation energy to the ambience, and hence, reduced the daily distillate of the still. On the other hand, the fresh water production from the HDH cycle was much less than the production of the still of the SS-HDH distiller or the separate still.

Figure 11 shows the accumulative distillates of the separate solar still, the still in the SS-HDH distiller, the HDH cycle, and the accumulative distillate of the SS-HDH distiller, which is the accumulative sum of the distillates of the HDH cycle and the still in the SS-HDH distiller. The accumulative distillate of the separate still was about 0.25 L more than the distillate of the still in the SS-HDH distiller. However, the total distillate produced by the HDH process was about 1.25 L, which outbalanced the reduction in the productivity of the still in the SS-HDH distiller. Hence, the total fresh water production of the SS-HDH distiller was about 2.75 L, which was about 1 L higher than that produced by the separate still.

According to the measured results that were discussed earlier, the daily total solar energy incident on each of the SS-HDH distiller and the separate still was about 7956 kJ, the total energy gains of the SS-HDH distiller and the separate still were 6215 kJ and 3955 kJ, respectively. Therefore, the daily thermal efficiencies of the SS-HDH distiller and the separate still were 78% and 49.7%, respectively.

Figure 12 compares between the overall thermal efficiencies of the SS-HDH distiller and the separate still. It is worth mentioning that during the day, the temperature increase within the separate still caused a corresponding increase in the thermal losses from the still to the ambient surroundings and, hence, reduced the overall thermal efficiency of the still. On the other side, the utilization of the thermal losses from the still in the SS-HDH distiller in producing extra fresh water by the HDH cycle added up to the overall thermal efficiency of the SS-HDH distiller. Furthermore,

Table 1 compares the findings of the present study to those of other studies, which explored the influence of various approaches to cooling the glass cover of single-slope single-basin stills.