Upgrading Anaerobic Sludge Digestion by Using an Oil Refinery By-Product

Abstract

1. Introduction

2. Materials and Methods

2.1. Substrate

2.2. Inoculum

2.3. Conductive Material

2.4. Analytical Methods

2.5. Experimental Setups

2.6. Statistical Analysis

3. Results and Discussion

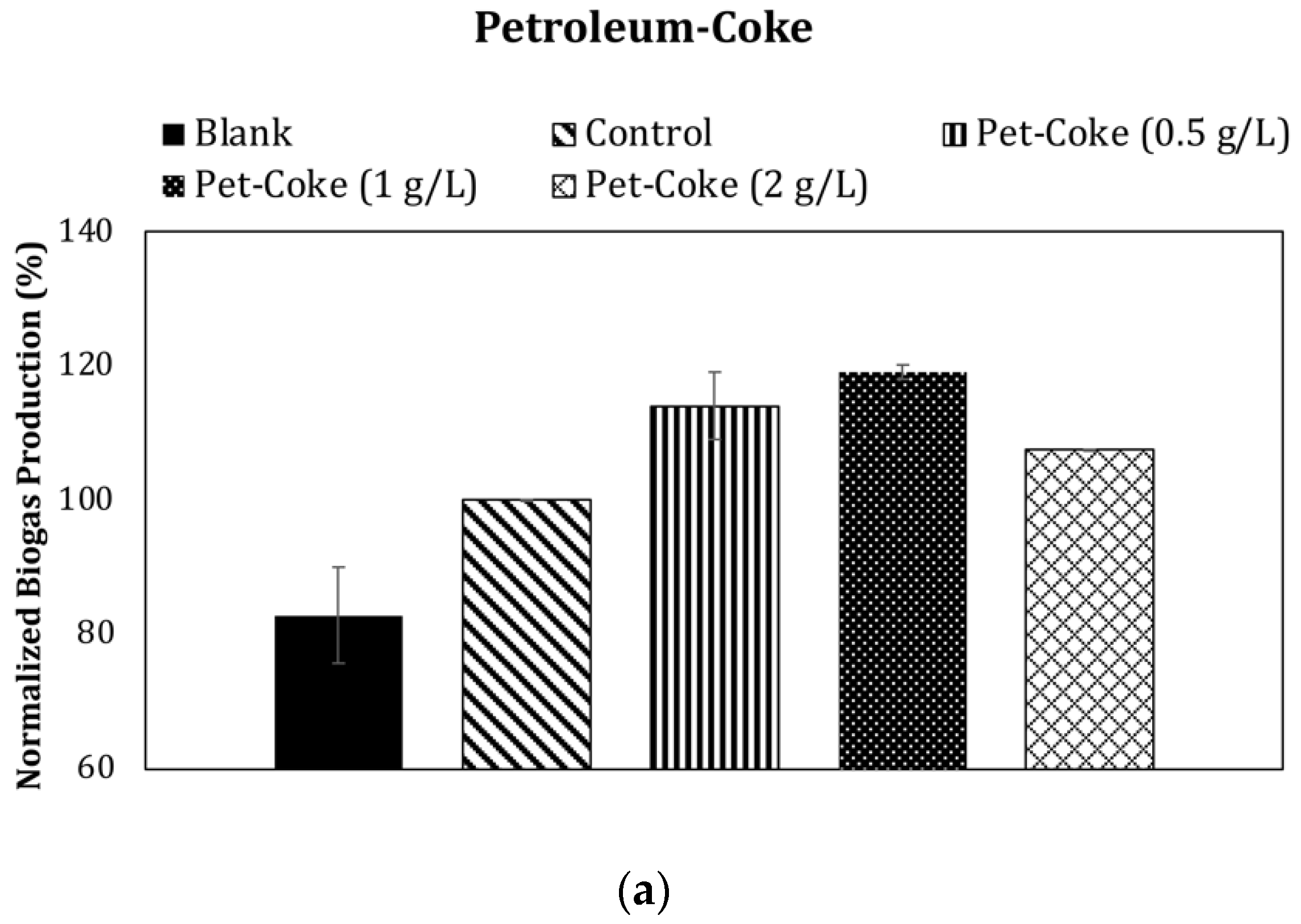

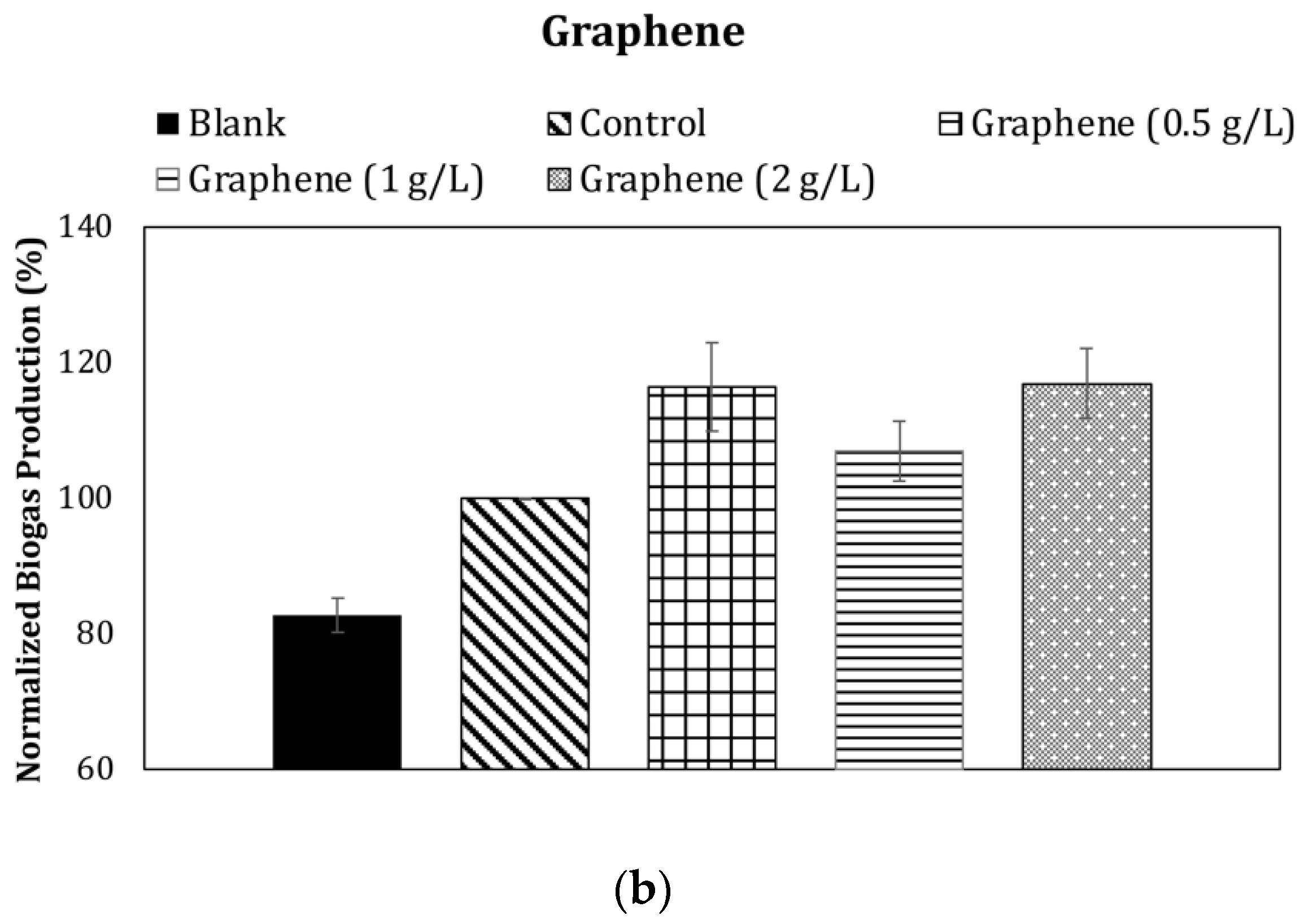

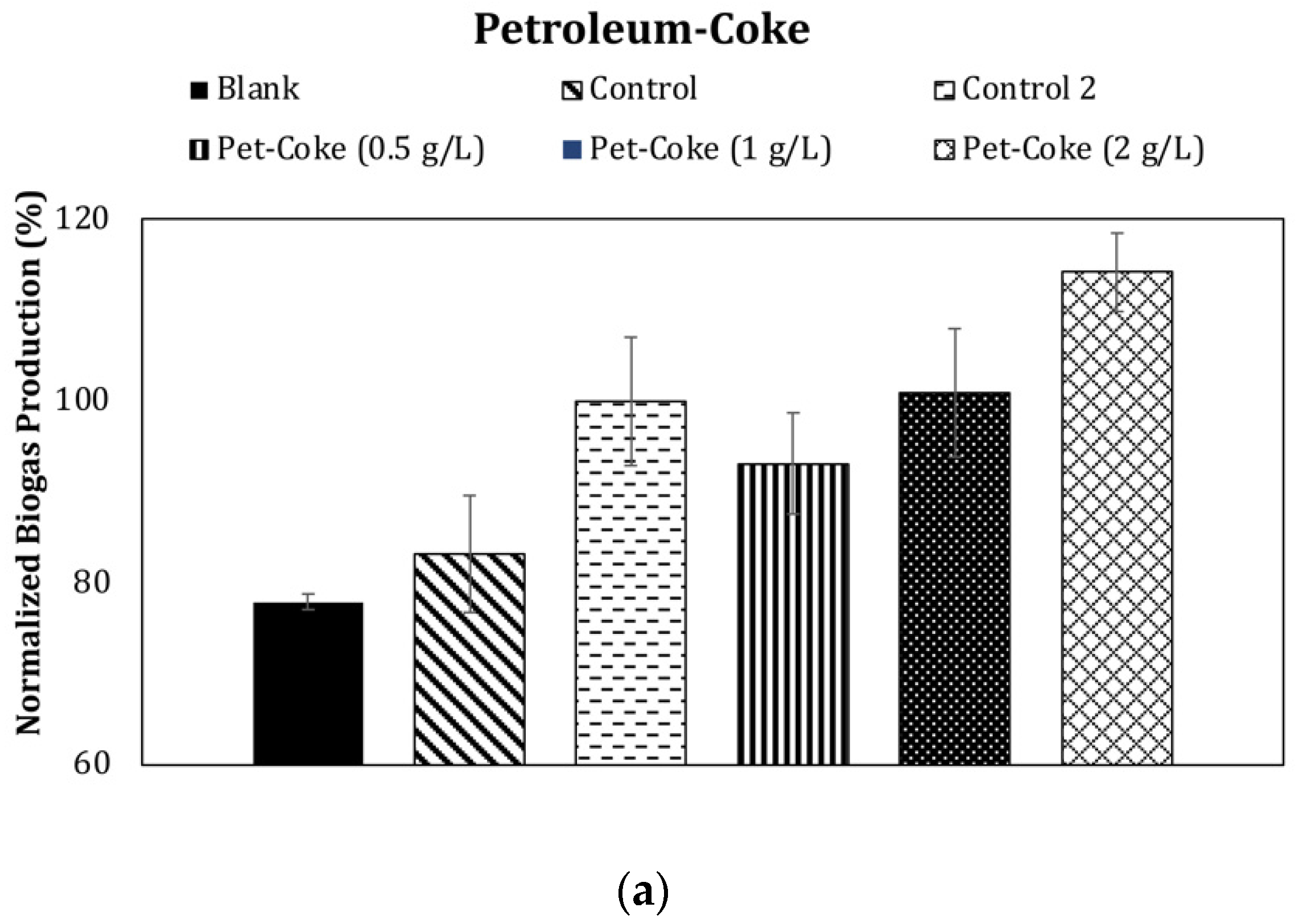

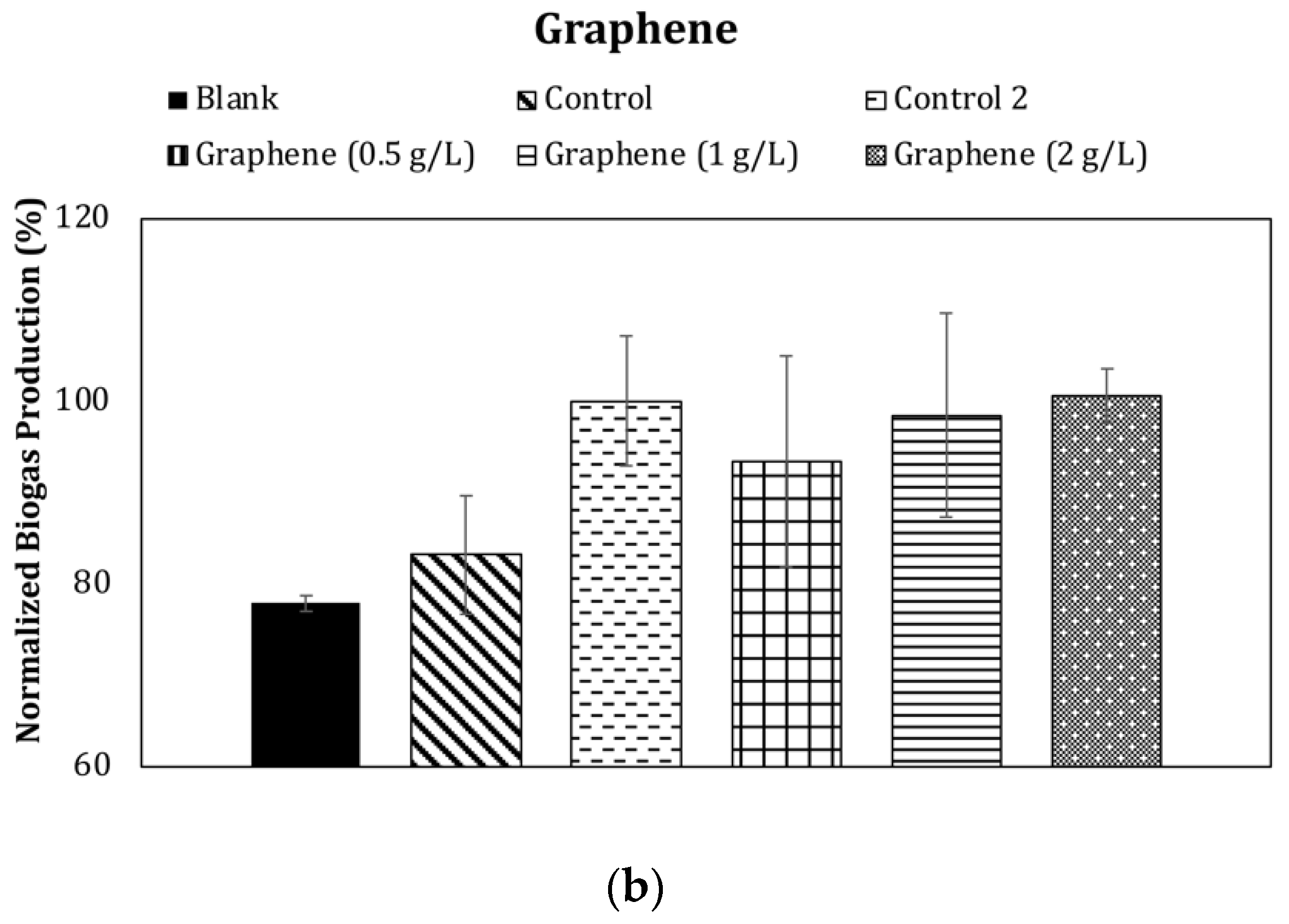

3.1. Effect of Petroleum Coke and Graphene on Biogas Production

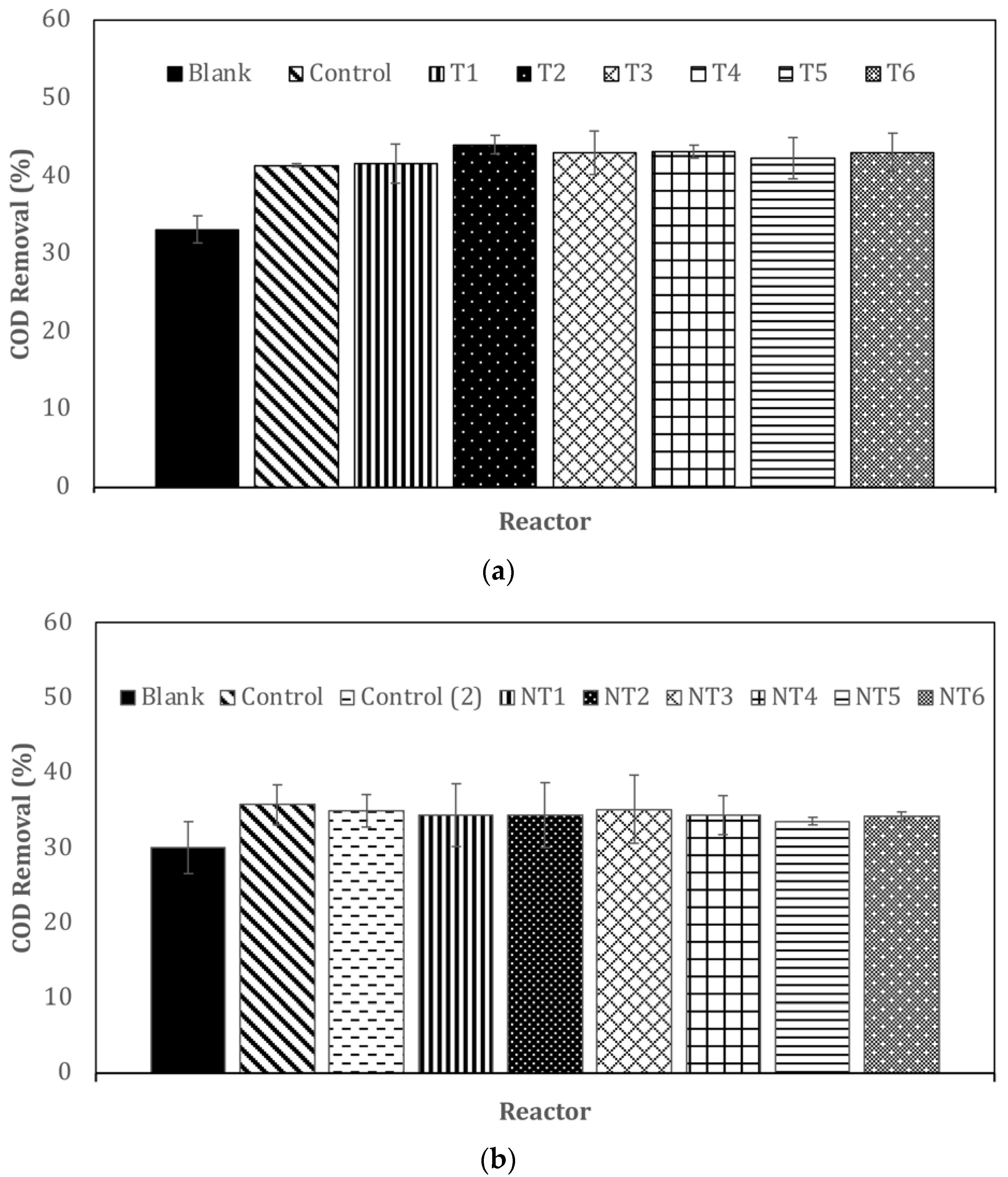

3.2. COD Removal

3.3. pH Variation and Organic Matter Removal

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

Abbreviations

| AD | Anaerobic digestion |

| COD | Chemical oxygen demand |

| BOD | Biological oxygen demand |

| CMs | Conductive materials |

| GAC | Granular activated carbon |

| DIET | Direct interspecies electron transfer |

| Ni | Nickel |

| Co | Cobalt |

| Mo | Molybdenum |

| Fe | Iron |

| Se | Selenium |

| W | Tungsten |

| Zn | Zinc |

| Cu | Copper |

| Mn | Manganese |

| TS | Total solids |

| VS | Volatile solids |

| TN | Total Nitrogen |

| TP | Total Phosphorus |

| TUDCP | Tulsa Delayed Coker Project |

| GC | Gas chromatograph |

| FID | Flame ionization detector |

References

- Anukam, A.; Mohammadi, A.; Naqvi, M.; Granström, K. A Review of the Chemistry of Anaerobic Digestion: Methods of Accelerating and Optimizing Process Efficiency. Processes 2019, 7, 504. [Google Scholar] [CrossRef]

- Li, Y.; Park, S.Y.; Zhu, J. Solid-State Anaerobic Digestion for Methane Production from Organic Waste. Renew. Sustain. Energy Rev. 2011, 15, 821–826. [Google Scholar] [CrossRef]

- Kumar, M.; Dutta, S.; You, S.; Luo, G.; Zhang, S.; Show, P.L.; Sawarkar, A.D.; Singh, L.; Tsang, D.C.W. A Critical Review on Biochar for Enhancing Biogas Production from Anaerobic Digestion of Food Waste and Sludge. J. Clean. Prod. 2021, 305, 127143. [Google Scholar] [CrossRef]

- Vasco-Correa, J.; Khanal, S.; Manandhar, A.; Shah, A. Anaerobic Digestion for Bioenergy Production: Global Status, Environmental and Techno-Economic Implications, and Government Policies. Bioresour. Technol. 2018, 247, 1015–1026. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Zhao, W.; Zhang, H.; Wang, Z.; Fan, C.; Zang, L. Recent Achievements in Enhancing Anaerobic Digestion with Carbon- Based Functional Materials. Bioresour. Technol. 2018, 266, 555–567. [Google Scholar] [CrossRef]

- Park, J.H.; Park, J.H.; Lee, S.H.; Jung, S.P.; Kim, S.H. Enhancing Anaerobic Digestion for Rural Wastewater Treatment with Granular Activated Carbon (GAC) Supplementation. Bioresour. Technol. 2020, 315, 123890. [Google Scholar] [CrossRef]

- Gökçek, Ö.B.; Muratçobanoğlu, F.; Muratçobanoğlu, H.; Uçar, D.; Mert, R.A.; Yıldırım, B.; Zan, R.; Demirel, S. The Effect of Reduced Graphene Oxide Addition on Methane Production from Municipal Organic Solid Waste. J. Chem. Technol. Biotechnol. 2021, 96, 2845–2851. [Google Scholar] [CrossRef]

- Qi, Q.; Sun, C.; Cristhian, C.; Zhang, T.; Zhang, J.; Tian, H.; He, Y.; Tong, Y.W. Enhancement of Methanogenic Performance by Gasification Biochar on Anaerobic Digestion. Bioresour. Technol. 2021, 330, 124993. [Google Scholar] [CrossRef]

- Barua, S.; Zakaria, B.S.; Dhar, B.R. Enhanced Methanogenic Co-Degradation of Propionate and Butyrate by Anaerobic Microbiome Enriched on Conductive Carbon Fibers. Bioresour. Technol. 2018, 266, 259–266. [Google Scholar] [CrossRef]

- Feng, D.; Xia, A.; Huang, Y.; Zhu, X.; Zhu, X.; Liao, Q. Effects of Carbon Cloth on Anaerobic Digestion of High Concentration Organic Wastewater under Various Mixing Conditions. J. Hazard. Mater. 2022, 423, 127100. [Google Scholar] [CrossRef]

- Lei, Y.; Wei, L.; Liu, T.; Xiao, Y.; Dang, Y.; Sun, D.; Holmes, D.E. Magnetite Enhances Anaerobic Digestion and Methanogenesis of Fresh Leachate from a Municipal Solid Waste Incineration Plant. Chem. Eng. J. 2018, 348, 992–999. [Google Scholar] [CrossRef]

- Li, L.L.; Tong, Z.H.; Fang, C.Y.; Chu, J.; Yu, H.Q. Response of Anaerobic Granular Sludge to Single-Wall Carbon Nanotube Exposure. Water Res. 2015, 70, 1–8. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Zhang, Y.; Li, Z.; Zhao, Z.; Quan, X.; Zhao, Z. Adding Granular Activated Carbon into Anaerobic Sludge Digestion to Promote Methane Production and Sludge Decomposition. J. Clean. Prod. 2017, 149, 1101–1108. [Google Scholar] [CrossRef]

- Liu, F.; Rotaru, A.E.; Shrestha, P.M.; Malvankar, N.S.; Nevin, K.P.; Lovley, D.R. Promoting Direct Interspecies Electron Transfer with Activated Carbon. Energy Environ. Sci. 2012, 5, 8982–8989. [Google Scholar] [CrossRef]

- Tian, T.; Qiao, S.; Li, X.; Zhang, M.; Zhou, J. Nano-Graphene Induced Positive Effects on Methanogenesis in Anaerobic Digestion. Bioresour. Technol. 2017, 224, 41–47. [Google Scholar] [CrossRef]

- Capson-Tojo, G.; Moscoviz, R.; Ruiz, D.; Santa-Catalina, G.; Trably, E.; Rouez, M.; Crest, M.; Steyer, J.P.; Bernet, N.; Delgenès, J.P.; et al. Addition of Granular Activated Carbon and Trace Elements to Favor Volatile Fatty Acid Consumption during Anaerobic Digestion of Food Waste. Bioresour. Technol. 2018, 260, 157–168. [Google Scholar] [CrossRef] [PubMed]

- Baek, G.; Kim, J.; Kim, J.; Lee, C. Role and Potential of Direct Interspecies Electron Transfer in Anaerobic Digestion. Energies 2018, 11, 107. [Google Scholar] [CrossRef]

- ElMekawy, A.; Hegab, H.M.; Losic, D.; Saint, C.P.; Pant, D. Applications of Graphene in Microbial Fuel Cells: The Gap between Promise and Reality. Renew. Sustain. Energy Rev. 2017, 72, 1389–1403. [Google Scholar] [CrossRef]

- Nguyen, H.N.; Castro-Wallace, S.L.; Rodrigues, D.F. Acute Toxicity of Graphene Nanoplatelets on Biological Wastewater Treatment Process. Environ. Sci. Nano 2017, 4, 160–169. [Google Scholar] [CrossRef]

- Lei, Y.; Sun, D.; Dang, Y.; Chen, H.; Zhao, Z.; Zhang, Y.; Holmes, D.E. Stimulation of Methanogenesis in Anaerobic Digesters Treating Leachate from a Municipal Solid Waste Incineration Plant with Carbon Cloth. Bioresour. Technol. 2016, 222, 270–276. [Google Scholar] [CrossRef] [PubMed]

- Lin, R.; Cheng, J.; Zhang, J.; Zhou, J.; Cen, K.; Murphy, J.D. Boosting Biomethane Yield and Production Rate with Graphene: The Potential of Direct Interspecies Electron Transfer in Anaerobic Digestion. Bioresour. Technol. 2017, 239, 345–352. [Google Scholar] [CrossRef]

- Dourson, M.L.; Chinkin, L.R.; MacIntosh, D.L.; Finn, J.A.; Brown, K.W.; Reid, S.B.; Martinez, J.M. A Case Study of Potential Human Health Impacts from Petroleum Coke Transfer Facilities. J. Air Waste Manag. Assoc. 2016, 66, 1061–1076. [Google Scholar] [CrossRef][Green Version]

- Boateng, A.A. Rotary Kilns: Transport Phenomena and Transport Processes, 2nd ed.; Butterworth-Heinemann: Oxford, UK, 2015. [Google Scholar]

- Tillman, D.; Duong, D.; Harding, N.S. Solid Fuel Blending; Elsevier: Amsterdam, The Netherlands, 2012. [Google Scholar]

- Ramírez Zamora, R.M.; Schouwenaars, R.; Durán Moreno, A.; Buitrón, G. Production of Activated Carbon from Petroleum Coke and Its Application in Water Treatment for the Removal of Metals and Phenol. Water Sci. Technol. 2000, 42, 119–126. [Google Scholar] [CrossRef]

- Sakkour, A.; Al-Abdullah, A. Adsorption of Some Toxic Heavy Metals from Aqueous Solutions by Activated Petroleum Coke. Am. J. Eng. Res. 2018, 7, 245–252. [Google Scholar]

- Akturk, A.S.; Demirer, G.N. Petroleum Coke Supplementation Improves Biogas Production from Food Waste at a Level Comparable to Commercial Carbon-Based Conductive Materials. Bioenergy Res. 2022, 15, 1482–1490. [Google Scholar] [CrossRef]

- Rodak, B.W.; Freitas, D.S.; de Oliveira Lima, G.J.E.; Reis, A.R.; dos Schulze, J.; Guilherme, L.R.G. Beneficial Use of Ni-Rich Petroleum Coke Ashes: Product Characterization and Effects on Soil Properties and Plant Growth. J. Clean. Prod. 2018, 198, 785–796. [Google Scholar] [CrossRef]

- Matheri, A.N.; Belaid, M.; Seodigeng, T.; Ngila, J.C. The Role of Trace Elements on Anaerobic Co-Digestion in Biogas Production. In Proceedings of the Lecture Notes in Engineering and Computer Science, London, UK, 29 June–1 July 2016; Volume 2224. [Google Scholar]

- Scherer, P.; Lippert, H.; Wolff, G. Composition of the Major Elements and Trace Elements of 10 Methanogenic Bacteria Determined by Inductively Coupled Plasma Emission Spectrometry. Biol. Trace Elem. Res. 1983, 5, 149–163. [Google Scholar] [CrossRef]

- Glass, J.B.; Orphan, V.J. Trace Metal Requirements for Microbial Enzymes Involved in the Production and Consumption of Methane and Nitrous Oxide. Front. Microbiol. 2012, 3, 61. [Google Scholar] [CrossRef] [PubMed]

- Romero-Güiza, M.S.; Vila, J.; Mata-Alvarez, J.; Chimenos, J.M.; Astals, S. The Role of Additives on Anaerobic Digestion: A Review. Renew. Sustain. Energy Rev. 2016, 58, 1486–1499. [Google Scholar] [CrossRef]

- Voelklein, M.A.; O’ Shea, R.; Jacob, A.; Murphy, J.D. Role of Trace Elements in Single and Two-Stage Digestion of Food Waste at High Organic Loading Rates. Energy 2017, 121, 185–192. [Google Scholar] [CrossRef]

- Sinan Akturk, A.; Demirer, G.N. Improved Food Waste Stabilization and Valorization by Anaerobic Digestion through Supplementation of Conductive Materials and Trace Elements. Sustainability 2020, 12, 5222. [Google Scholar] [CrossRef]

- Pourrezaei, P.; Alpatova, A.; Khosravi, K.; Drzewicz, P.; Chen, Y.; Chelme-Ayala, P.; Gamal El-Din, M. Removal of Organic Compounds and Trace Metals from Oil Sands Process-Affected Water Using Zero Valent Iron Enhanced by Petroleum Coke. J. Environ. Manag. 2014, 139, 50–58. [Google Scholar] [CrossRef]

- Jean, M.; Desnoyer, C.; Tranchant, A.; Messina, R. Electrochemical and Structural Studies of Petroleum Coke in Carbonate-Based Electrolytes. J. Electrochem. Soc. 1995, 142, 2122. [Google Scholar] [CrossRef]

- Cai, W.; Li, K.; Jiang, K.; Lv, D.; Liu, Y.Q.; Wang, D.; Wang, X.; Lai, C. Utilization of High-sulfur-Containing Petroleum Coke for Making Sulfur-Doped Porous Carbon Composite Material and Its Application in Supercapacitors. Diam. Relat. Mater. 2021, 116, 108380. [Google Scholar] [CrossRef]

- APHA. Standard Methods for the Examination of Water and Wastewater. In Standard Methods; American Public Health Association (APHA): Washington, DC, USA, 2005; ISBN 9780875532356. [Google Scholar]

- Boshagh, F.; Rostami, K. A Review of Measurement Methods of Biological Hydrogen. Int. J. Hydrogen Energy 2020, 45, 24424–24452. [Google Scholar] [CrossRef]

- Lim, S.J.; Fox, P. Biochemical Methane Potential (BMP) Test for Thickened Sludge Using Anaerobic Granular Sludge at Different Inoculum/Substrate Ratios. Biotechnol. Bioprocess Eng. 2013, 18, 306–312. [Google Scholar] [CrossRef]

- Ross, A.; Willson, V.L. Basic and Advanced Statistical Tests; Brill: Leiden, The Netherlands, 2017. [Google Scholar]

- Wheeler, A.J.; Ganji, A.R.; Krishnan, V.V.; Thurow, B.S. Introduction to Engineering Experimentation; Pearson: London, UK, 2010. [Google Scholar]

- Posten, H.O. The Robustness of the One-Sample t-Test over the Pearson System. J. Stat. Comput. Simul. 1979, 9, 133–149. [Google Scholar] [CrossRef]

- Andrade, C. The P Value and Statistical Significance: Misunderstandings, Explanations, Challenges, and Alternatives. Indian J. Psychol. Med. 2019, 41, 210–215. [Google Scholar] [CrossRef]

- Wu, B.; Lin, R.; Kang, X.; Deng, C.; Xia, A.; Dobson, A.D.W.; Murphy, J.D. Graphene Addition to Digestion of Thin Stillage Can Alleviate Acidic Shock and Improve Biomethane Production. ACS Sustain. Chem. Eng. 2020, 8, 13248–13260. [Google Scholar] [CrossRef]

- Lin, R.; Deng, C.; Cheng, J.; Xia, A.; Lens, P.N.L.; Jackson, S.A.; Dobson, A.D.W.; Murphy, J.D. Graphene Facilitates Biomethane Production from Protein-Derived Glycine in Anaerobic Digestion. iScience 2018, 10, 158–170. [Google Scholar] [CrossRef] [PubMed]

- Ünşar, E.K.; Çığgın, A.S.; Erdem, A.; Perendeci, N.A. Long and Short Term Impacts of CuO, Ag and CeO2 Nanoparticles on Anaerobic Digestion of Municipal Waste Activated Sludge. Environ. Sci. Process. Impacts 2016, 18, 277–288. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, Y.; Yang, Y.; Quan, X.; Zhao, Z. Potentially Direct Interspecies Electron Transfer of Methanogenesis for Syntrophic Metabolism under Sulfate Reducing Conditions with Stainless Steel. Bioresour. Technol. 2017, 234, 303–309. [Google Scholar] [CrossRef]

- de Mes, T.; Stams, A.; Reith, J.; Zeeman, G. Methane Production by Anaerobic Digestion of Wastewater and Solid Wastes. Bio-Methane Bio-Hydrog. 2003, 58–102. Available online: https://www.ircwash.org/sites/default/files/Reith-2003-Bio.pdf#page=59 (accessed on 6 October 2022).

- Zwietering, M.H.; Jongenburger, I.; Rombouts, F.M.; Van’t Riet, K. Modeling of the Bacterial Growth Curve. Appl. Environ. Microbiol. 1990, 56, 1875–1881. [Google Scholar] [CrossRef]

- Grosser, A.; Neczaj, E. Enhancement of Biogas Production from Sewage Sludge by Addition of Grease Trap Sludge. Energy Convers. Manag. 2016, 125, 301–308. [Google Scholar] [CrossRef]

- Choong, Y.Y.; Norli, I.; Abdullah, A.Z.; Yhaya, M.F. Impacts of Trace Element Supplementation on the Performance of Anaerobic Digestion Process: A Critical Review. Bioresour. Technol. 2016, 209, 369–379. [Google Scholar] [CrossRef]

- Feng, Q.; Song, Y.C.; Kim, D.H.; Kim, M.S.; Kim, D.H. Influence of the Temperature and Hydraulic Retention Time in Bioelectrochemical Anaerobic Digestion of Sewage Sludge. Int. J. Hydrogen Energy 2019, 44, 2170–2179. [Google Scholar] [CrossRef]

- Dinh, N.T.; Le, N.H. The Performance of an Anaerobic Digester Treating Bio-Sludge Generated from a Municipal Wastewater Treatment Plant in a Pilot Scale. Chem. Eng. Trans. 2020, 78, 541–546. [Google Scholar] [CrossRef]

- Dastyar, W.; Mirsoleimani Azizi, S.M.; Meshref, M.N.A.; Dhar, B.R. Powdered Activated Carbon Amendment in Percolate Tank Enhances High-Solids Anaerobic Digestion of Organic Fraction of Municipal Solid Waste. Process Saf. Environ. Prot. 2021, 151, 63–70. [Google Scholar] [CrossRef]

| Parameter | Substrate | Inoculum |

|---|---|---|

| COD (mg/L) | 33,940 ± 315 | 41,660 ± 1082 |

| TS (mg/L) | 26,067 ± 306 | 44,267 ± 416 |

| VS (mg/L) | 17,467 ± 416 | 33,800 ± 200 |

| Total Nitrogen (TN) (mg/L) | 2073 ± 77 | 3737 ± 107 |

| Total Phosphorus (TP) (mg/L) | 1285 ± 18 | 1134 ± 37 |

| Analysis | Content (%) |

|---|---|

| Carbon | 87.5 |

| Hydrogen | 3.4 |

| Nitrogen | 1.4 |

| H2O | 0.50 |

| Volatile Matter | 10.02 |

| Sulphur | 6.1 |

| Ash | 0.03 |

| First Setup: Without Trace Metal Supplementation | ||||||

| Reactor | Substrate (mL) | Inoculum (mL) | Trace Metals | Alkalinity | Graphene (g/L) | Petroleum Coke (g/L) |

| Blank | 116 | 0 | − | − | 0 | 0 |

| Control | 116 | 20 | − | − | 0 | 0 |

| T1 | 116 | 20 | − | − | 0 | 0.5 |

| T2 | 116 | 20 | − | − | 0 | 1 |

| T3 | 116 | 20 | − | − | 0 | 2 |

| T4 | 116 | 20 | − | − | 0.5 | 0 |

| T5 | 116 | 20 | − | − | 1 | 0 |

| T6 | 116 | 20 | − | − | 2 | 0 |

| Second Setup: With Trace Metal Supplemetation | ||||||

| Reactor | Substrate (mL) | Inoculum (mL) | Trace Metals | Alkalinity | Graphene (g/L) | Petroleum coke (g/L) |

| Blank | 58 | 0 | − | + | 0 | 0 |

| Control | 58 | 10 | − | + | 0 | 0 |

| Control 2 | 58 | 10 | + | + | 0 | 0 |

| NT1 | 58 | 10 | + | + | 0 | 0.5 |

| NT2 | 58 | 10 | + | + | 0 | 1 |

| NT3 | 58 | 10 | + | + | 0 | 2 |

| NT4 | 58 | 10 | + | + | 0.5 | 0 |

| NT5 | 58 | 10 | + | + | 1 | 0 |

| NT6 | 58 | 10 | + | + | 2 | 0 |

| Without Trace Metal Supplementation | ||||

| Rmax (mL/h) | Pmax (mL) | λ (h) | R2 | |

| Petroleum coke (1 g/L) | 3.61 | 354.7 | 172.8 | 0.987 |

| Graphene (2 g/L) | 3.64 | 348.3 | 172.8 | 0.986 |

| With Trace Metal Supplementation | ||||

| Rmax (mL/h) | Pmax (mL) | λ (h) | R2 | |

| Petroleum coke (2 g/L) | 1.025 | 121.7 | 46.08 | 0.989 |

| Graphene (2 g/L) | 1.42 | 107.2 | 46.08 | 0.919 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alimohammadi, M.; Demirer, G.N. Upgrading Anaerobic Sludge Digestion by Using an Oil Refinery By-Product. Sustainability 2022, 14, 15693. https://doi.org/10.3390/su142315693

Alimohammadi M, Demirer GN. Upgrading Anaerobic Sludge Digestion by Using an Oil Refinery By-Product. Sustainability. 2022; 14(23):15693. https://doi.org/10.3390/su142315693

Chicago/Turabian StyleAlimohammadi, Mahsa, and Goksel N. Demirer. 2022. "Upgrading Anaerobic Sludge Digestion by Using an Oil Refinery By-Product" Sustainability 14, no. 23: 15693. https://doi.org/10.3390/su142315693

APA StyleAlimohammadi, M., & Demirer, G. N. (2022). Upgrading Anaerobic Sludge Digestion by Using an Oil Refinery By-Product. Sustainability, 14(23), 15693. https://doi.org/10.3390/su142315693