Unfolding the Impact of Quality 4.0 Practices on Industry 4.0 and Circular Economy Practices: A Hybrid SEM-ANN Approach

Abstract

1. Introduction

2. Literature Review

2.1. Multidimensional View of Quality 4.0

2.2. Quality 4.0

2.3. Quality 4.0 Practices

2.4. Quality Management, Industry 4.0, and Circular Economy

3. Theoretical Framework and Hypothesis Development

3.1. Resource-Based View (RBV) Theory

3.2. Relationship between Quality 4.0, IT4.0, and CEP

3.3. Mediating Role of Quality 4.0 Technical Factors

3.4. Mediating Role of Industry 4.0 Technologies

4. Material and Methods

4.1. Sampling and Data Collection

4.2. Measures

5. Data Analysis

5.1. Descriptive Statistics and Common Method Bias

5.2. Assessment of Measurement Model

5.2.1. Reliability and Convergent Validity

5.2.2. Discriminant Validity

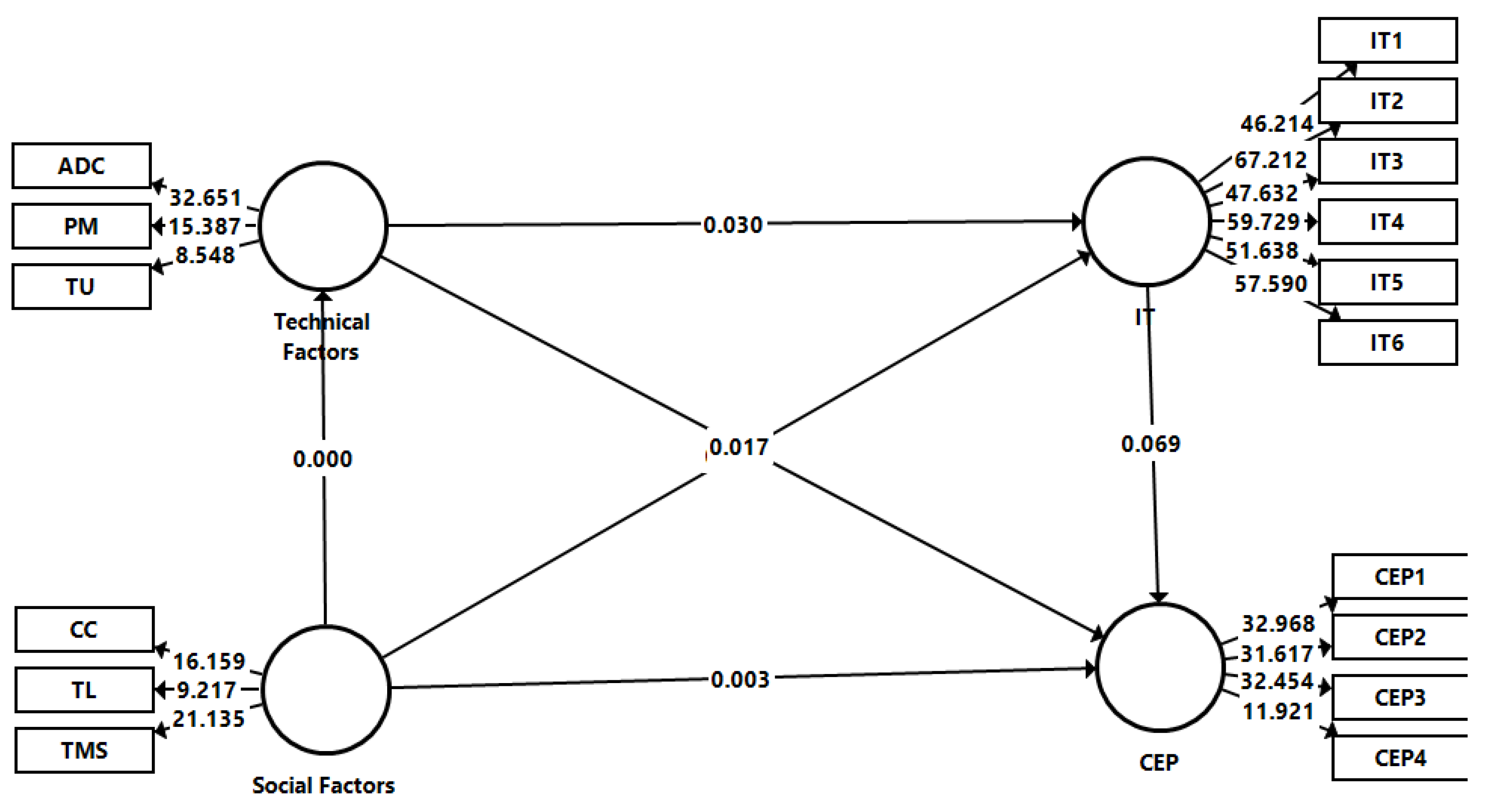

5.3. Assessment of Structural Model

5.4. Mediation Analysis

5.5. Predictive Relevance and R2

5.6. Artificial Neural Network (ANN) Analysis

6. Discussion of Findings

7. Conclusions

7.1. Theoretical Contributions

7.2. Practical Implications

7.3. Limitations and Future Research Directions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Ali, K.; Johl, S.K. Impact of total quality management on industry 4.0 readiness and practices: Does firm size matter? Int. J. Comput. Integr. Manuf. 2022, 1–23. [Google Scholar] [CrossRef]

- Ali, K.; Johl, S.K.; Muneer, A.; Alwadain, A.; Ali, R.F. Soft and Hard Total Quality Management Practices Promote Industry 4.0 Readiness: A SEM-Neural Network Approach. Sustainability 2022, 14, 11917. [Google Scholar] [CrossRef]

- Broday, E.E. The Evolution of Quality: From Inspection to Quality 4.0. Int. J. Qual. Serv. Sci. 2022. ahead-of-print. [Google Scholar]

- Khin, S.; Kee, D.M.H. Identifying the Driving and Moderating Factors of Malaysian Smes’ Readiness for Industry 4.0. Int. J. Comput. Integr. Manuf. 2022, 35, 1–19. [Google Scholar] [CrossRef]

- Ali, K.; Johl, S.K. Soft and Hard Tqm Practices: Future Research Agenda for Industry 4.0. Total Qual. Manag. Bus. Excell. 2021, 33, 1625–1655. [Google Scholar] [CrossRef]

- Calvo-Mora, A.; Picón, A.; Ruiz, C.; Cauzo, L. The Relationships between Soft-Hard Tqm Factors and Key Business Results. Int. J. Oper. Prod. Manag. 2013, 34, 115–143. [Google Scholar] [CrossRef]

- Tarí, J.J.; Claver-Cortés, E.; García-Fernández, M. How Quality Management Can Enhance Performance? A Model of Relationships Mediated by Innovation. Prod. Plan. Control. 2021, 1–17. [Google Scholar] [CrossRef]

- Dias, A.M.; Carvalho, A.M.; Sampaio, P. Quality 4.0: Literature Review Analysis, Definition and Impacts of the Digital Transformation Process on Quality. Int. J. Qual. Reliab. Manag. 2021. ahead-of-print. [Google Scholar]

- Chiarini, A.; Kumar, M. What Is Quality 4.0? An Exploratory Sequential Mixed Methods Study of Italian Manufacturing Companies. Int. J. Prod. Res. 2021, 60, 4890–4910. [Google Scholar] [CrossRef]

- Maganga, D.P.; Taifa, I.W. Quality 4.0 Transition Framework for Tanzanian Manufacturing Industries. TQM J. 2022. ahead-of-print. [Google Scholar]

- Fonseca, L.; Amaral, A.; Oliveira, J. Quality 4.0: The EFQM 2020 model and industry 4.0 relationships and implications. Sustainability 2021, 13, 3107. [Google Scholar] [CrossRef]

- Jacob, D. Quality 4.0 Impact and Strategy Handbook. 2017. Available online: https://www.lnsresearch.com (accessed on 30 June 2022).

- Lim, A.; Lee, V.H.; Foo, P.Y.; Ooi, K.B.; Tan, G.W.-H. Unfolding the Impact of Supply Chain Quality Management Practices on Sustainability Performance: An Artificial Neural Network Approach. Supply Chain. Manag. Int. J. 2021, 27, 611–624. [Google Scholar] [CrossRef]

- Sader, S.; Husti, I.; Daroczi, M. A review of quality 4.0: Definitions, features, technologies, applications, and challenges. Total Qual. Manag. Bus. Excell. 2022, 33, 1164–1182. [Google Scholar] [CrossRef]

- Escobar, C.A.; Macias, D.; McGovern, M.; Hernandez-de-Menendez, M.; Morales-Menendez, R. Quality 4.0–an evolution of Six Sigma DMAIC. Int. J. Lean Six Sigma 2022, 13, 1200–1238. [Google Scholar] [CrossRef]

- Maganga, D.P.; Taifa, I.W.R. Quality 4.0 conceptualisation: An emerging quality management concept for manufacturing industries. TQM J. 2022. ahead-of-print. [Google Scholar]

- Mtotywa, M.M. Developing a Quality 4.0 Maturity Index for Improved Business Operational Efficiency and Performance. Qual. Innov. Prosper. 2022, 26, 101–127. [Google Scholar] [CrossRef]

- Van Nguyen, T.A.; Tucek, D.; Pham, N.T. Indicators for Tqm 4.0 Model: Delphi Method and Analytic Hierarchy Process (Ahp) Analysis. Total Qual. Manag. Bus. Excell. 2022, 1–15. [Google Scholar] [CrossRef]

- Prashar, A. Quality management in industry 4.0 environment: A morphological analysis and research agenda. Int. J. Qual. Reliab. Manag. 2022. ahead-of-print. [Google Scholar]

- Thekkoote, R. Enabler toward Successful Implementation of Quality 4.0 Indigital Transformation Era: A comprehensive Review and future research Agenda. Int. J. Qual. Reliab. Manag. 2022. ahead-of-print. [Google Scholar]

- Wilkinson, A. The Other Side of Quality: ‘Soft’ Issues and the Human Resource Dimension. Total Qual. Manag. 1992, 3, 323–330. [Google Scholar] [CrossRef]

- Zeng, J.; Zhang, W.; Matsui, Y.; Zhao, X. The impact of organizational context on hard and soft quality management and innovation performance. Int. J. Prod. Econ. 2017, 185, 240–251. [Google Scholar] [CrossRef]

- Ali, K.; Johl, S.K. Critical Success Factors of Total Quality Management Practices Using Pareto Analysis. Int. J. Product. Qual. Manag. 2021, 36, 353–381. [Google Scholar] [CrossRef]

- Flynn, B.B.; Schroeder, R.G.; Sakakibara, S. The Impact of Quality Management Practices on Performance and Competitive Advantage. Decis. Sci. 1995, 26, 659–691. [Google Scholar] [CrossRef]

- Rahman, S.U.; Bullock, P. Soft Tqm, Hard Tqm, and Organisational Performance Relationships: An Empirical Investigation. Omega 2005, 33, 73–83. [Google Scholar] [CrossRef]

- Sciarelli, M.; Gheith, M.H.; Tani, M. The relationship between soft and hard quality management practices, innovation and organizational performance in higher education. TQM J. 2020, 32, 1349–1372. [Google Scholar] [CrossRef]

- Babatunde, O.K. Mapping the implications and competencies for Industry 4.0 to hard and soft total quality management. TQM J. 2020, 33, 896–914. [Google Scholar] [CrossRef]

- Georgiev, S.; Ohtaki, S. Critical success factors for TQM implementation among manufacturing SMEs. Benchmarking Int. J. 2019, 27, 473–498. [Google Scholar] [CrossRef]

- Sony, M.; Naik, S. Industry 4.0 integration with socio-technical systems theory: A systematic review and proposed theoretical model. Technol. Soc. 2020, 61, 101248. [Google Scholar] [CrossRef]

- Connell, S. What Do We Mean by ‘Quality’? Quality in Mind, 13 October 2017. Available online: Asq.org/blog/2013/01/what-do-we-mean-by-quality (accessed on 30 June 2022).

- Johns, E. What Is Quality? CQI|IRCA, 25 June 2020. Available online: www.quality.org/what-quality (accessed on 30 June 2022).

- Zonnenshain, A.; Kenett, R.S. Quality 4.0—The Challenging Future of Quality Engineering. Qual. Eng. 2020, 32, 614–626. [Google Scholar] [CrossRef]

- Ali, K.; Johl, S.K. Impact of Total Quality Management on SMEs Sustainable Performance in the Context of Industry 4.0. In Proceedings of the International Conference on Emerging Technologies and Intelligent Systems, Al Buraimi, Oman, 25–26 June 2021; Springer: Berlin/Heidelberg, Germany, 2021; pp. 608–620. [Google Scholar]

- Murugesan, V. What Is Quality 4.0? And What It Isn’t. Available online: blog.lnsresearch.com/what-is-quality-4.0-and-what-it-isnt (accessed on 9 October 2022).

- Antony, J.; Sony, M.; Furterer, S.; McDermott, O.; Pepper, M. Quality 4.0 and Its Impact on Organizational Performance: An Integrative Viewpoint. TQM J. 2021. ahead-of-print. [Google Scholar]

- Sureshchandar, G.S. Quality 4.0–Understanding the Criticality of the Dimensions Using the Analytic Hierarchy Process (Ahp) Technique. Int. J. Qual. Reliab. Manag. 2022, 39, 1336–1367. [Google Scholar] [CrossRef]

- Sony, M.; Antony, J.; Douglas, J.A.; McDermott, O. Motivations, Barriers and Readiness Factors for Quality 4.0 Implementation: An Exploratory Study. TQM J. 2021, 33, 1502–1515. [Google Scholar] [CrossRef]

- Carvalho, A.V.; Enrique, D.V.; Chouchene, A.; Charrua-Santos, F. Quality 4.0: An overview. Procedia Comput. Sci. 2021, 181, 341–346. [Google Scholar] [CrossRef]

- Antony, J.; McDermott, O.; Sony, M. Quality 4.0 Conceptualisation and Theoretical Understanding: A Global Exploratory Qualitative Study. TQM J. 2021. ahead-of-print. [Google Scholar]

- Yadav, N.; Shankar, R.; Singh, S.P. Critical Success Factors for Lean Six Sigma in Quality 4.0. Int. J. Qual. Serv. Sci. 2021, 13, 123–156. [Google Scholar] [CrossRef]

- Javaid, M.; Haleem, A.; Singh, R.P.; Suman, R. Significance of Quality 4.0 towards comprehensive enhancement in manufacturing sector. Sens. Int. 2021, 2, 100109. [Google Scholar] [CrossRef]

- Elibal, K.; Özceylan, E. Comparing industry 4.0 maturity models in the perspective of TQM principles using Fuzzy MCDM methods. Technol. Forecast. Soc. Change 2021, 175, 121379. [Google Scholar] [CrossRef]

- Glogovac, M.; Ruso, J.; Maricic, M. ISO 9004 maturity model for quality in industry 4.0. Total Qual. Manag. Bus. Excel. 2020, 33, 529–547. [Google Scholar] [CrossRef]

- Manz, C.C.; Stewart, G.L. Attaining Flexible Stability by Integrating Total Quality Management and Socio-Technical Systems Theory. Organ. Sci. 1997, 8, 59–70. [Google Scholar] [CrossRef]

- Ćwiklicki, M.; Wojnarowska, M. Circular economy and industry 4.0: One-way or two-way relationships? Eng. Econ. 2020, 31, 387–397. [Google Scholar] [CrossRef]

- Bag, S.; Pretorius, J.H.C.; Gupta, S.; Dwivedi, Y.K. Role of institutional pressures and resources in the adoption of big data analytics powered artificial intelligence, sustainable manufacturing practices and circular economy capabilities. Technol. Forecast. Soc. Change 2021, 163, 120420. [Google Scholar] [CrossRef]

- Sahu, A.; Agrawa, S.; Kumar, G. Integrating Industry 4.0 and circular economy: A review. J. Enterp. Inf. Manag. 2021, 35, 3. [Google Scholar] [CrossRef]

- Kumar, P.; Singh, R.K.; Kumar, V. Managing supply chains for sustainable operations in the era of industry 4.0 and circular economy: Analysis of barriers. Resour. Conserv. Recycl. 2021, 164, 105215. [Google Scholar] [CrossRef]

- Khan, S.A.R.; Razzaq, A.; Yu, Z.; Miller, S. Industry 4.0 and circular economy practices: A new era business strategies for environmental sustainability. Bus. Strategy Environ. 2021, 30, 4001–4014. [Google Scholar] [CrossRef]

- Cezarino, L.O.; Liboni, L.B.; Stefanelli, N.O.; Oliveira, B.G.; Stocco, L.C. Diving into emerging economies bottleneck: Industry 4.0 and implications for circular economy. Manag. Decis. 2019, 59, 1841–1862. [Google Scholar] [CrossRef]

- Wernerfelt, B. A resource-based view of the firm. Strateg. Manag. J. 1984, 5, 171–180. [Google Scholar] [CrossRef]

- Barney, J. Firm resources and sustained competitive advantage. J. Manag. 1991, 17, 99–120. [Google Scholar] [CrossRef]

- Jakhar, S.K.; Mangla, S.K.; Luthra, S.; Sarpong, S.K. When stakeholder pressure drives the circular economy: Measuring the mediating role of innovation capabilities. Manag. Decis. 2018, 57, 4. [Google Scholar] [CrossRef]

- Dubey, R.; Gunasekaran, A.; Childe, S.J.; Blome, C.; Papadopoulos, T. Big data and predictive analytics and manufacturing performance: Integrating institutional theory, resource-based view and big data culture. Br. J. Manag. 2019, 30, 341–361. [Google Scholar] [CrossRef]

- Grant, R.M. The resource-based theory of competitive advantage: Implications for strategy formulation. Calif. Manag. Rev. 1991, 33, 114–135. [Google Scholar] [CrossRef]

- Črešnar, R.; Potočan, V.; Nedelko, Z. Speeding up the Implementation of Industry 4.0 with Management Tools: Empirical Investigations in Manufacturing Organizations. Sensors 2020, 20, 3469. [Google Scholar] [CrossRef] [PubMed]

- Stentoft, J.; Wickstrøm, K.A.; Philipsen, K.; Haug, A. Drivers and Barriers for Industry 4.0 Readiness and Practice: Empirical Evidence from Small and Medium-Sized Manufacturers. Prod. Plan. Control. 2021, 32, 811–828. [Google Scholar] [CrossRef]

- Kamasak, R. The contribution of tangible and intangible resources, and capabilities to a firm’s profitability and market performance. Eur. J. Manag. Bus. Econ. 2017, 26, 2. [Google Scholar] [CrossRef]

- Jerman, A.; Bach, M.P.; Aleksić, A. Transformation towards smart factory system: Examining new job profiles and competencies. Syst. Res. Behav. Sci. 2020, 37, 388–402. [Google Scholar] [CrossRef]

- Torrent-Sellens, J.; Ficapal-Cusí, P.; Enache-Zegheru, M. Boosting environmental management: The mediating role of Industry 4.0 between environmental assets and economic and social firm performance. Bus. Strategy Environ. 2022, online. [Google Scholar] [CrossRef]

- Khan, B.A.; Naeem, H. Measuring the Impact of Soft and Hard Quality Practices on Service Innovation and Organisational Performance. Total Qual. Manag. Bus. Excell. 2016, 29, 1402–1426. [Google Scholar] [CrossRef]

- Nasaj, M.I.; Al Marri, K. The Influence of Soft and Hard Quality Management on Innovation Performance in UAE Service Sector. In Proceedings of the II International Triple Helix Summit, Cape Town, South Africa, 9–11 September 2019; Springer: Berlin/Heidelberg, Germany, 2019; pp. 307–321. [Google Scholar] [CrossRef]

- Dubey, R.; Gunasekaran, A. Exploring Soft Tqm Dimensions and Their Impact on Firm Performance: Some Exploratory Empirical Results. Int. J. Prod. Res. 2014, 53, 371–382. [Google Scholar] [CrossRef]

- Ali, K.; Johl, S.K. Entrepreneurial Competencies Needed to Improve Innovation Performance in Industry 4.0: An Artificial Neural Network Approach; CRC Press: Boca Raton, FL, USA, 2022; pp. 1–19. [Google Scholar] [CrossRef]

- Mittal, S.; Khan, M.A.; Romero, D.; Wuest, T. A Critical Review of Smart Manufacturing & Industry 4.0 Maturity Models: Implications for Small and Medium-Sized Enterprises (Smes). J. Manuf. Syst. 2018, 49, 194–214. [Google Scholar]

- Massaro, M.; Secinaro, S.; Mas, F.D.; Brescia, V.; Calandra, D. Industry 4.0 and circular economy: An exploratory analysis of academic and practitioners’ perspectives. Bus. Strategy Environ. 2021, 30, 1213–1231. [Google Scholar] [CrossRef]

- Nascimento, G.L.D.; Lizarelli, F.L.; Rosa, A.R.; Boer, H. The Impact of Quality Management Practices on Innovation: An Empirical Research Study of Brazilian Manufacturing Companies. Benchmarking Int. J. 2020, 28, 1059–1082. [Google Scholar]

- Jayashree, S.; Reza, M.N.H.; Malarvizhi, C.A.N.; Mohiuddin, M. Industry 4.0 implementation and Triple Bottom Line sustainability: An empirical study on small and medium manufacturing firms. Heliyon 2021, 7, e07753. [Google Scholar] [CrossRef] [PubMed]

- Rimalini, G.; Sarkar, B.; Gadekar, A. Investigating the relationship among Industry 4.0 drivers, adoption, risks reduction, and sustainable organizational performance in manufacturing industries: An empirical study. Sustain. Prod. Consum. 2022, 31, 670–692. [Google Scholar]

- Jayashree, S.; Reza, M.N.H.; Malarvizhi, C.A.N.; Gunasekaran, A.; Rauf, A. Testing an adoption model for Industry 4.0 and sustainability: A Malaysian scenario. Sustain. Prod. Consum. 2022, 31, 313–330. [Google Scholar] [CrossRef]

- Wright, K.B. Researching Internet-based populations: Advantages and disadvantages of online survey research, online questionnaire authoring software packages, and web survey services. J. Comput.-Mediat. Commun. 2005, 10, JCMC1034. [Google Scholar] [CrossRef]

- Tanner, K. Chapter 6–Survey Designs. In Research Methods, 2nd ed.; Williamson, K., Johanson, G., Eds.; Chandos Publishing: Amsterdam, The Netherlands, 2018; pp. 159–192. [Google Scholar]

- SME Corporation Malaysia. Guideline for SME Definition. National Entrepreneur and SME Development Council, Jan. 2013. Available online: www.smecorp.gov.my/images/pdf/2022/Guideline_on_SME_Definition_Updated_September_2020_Final.pdf (accessed on 9 October 2022).

- Sila, I. Investigating Changes in Tqm’s Effects on Corporate Social Performance and Financial Performance over Time. Total Qual. Manag. Bus. Excell. 2018, 31, 210–229. [Google Scholar] [CrossRef]

- Darren, G.; Mallery, P. Spss for Windows Step by Step: A Simple Guide and Reference 17.0 Update, 10th ed.; Pearson: Boston, MA, USA, 2010. [Google Scholar]

- Podsakoff, N.P. Common Method Biases in Behavioral Research: A Critical Review of the Literature and Recommended Remedies. J. Appl. Psychol. 2003, 88, 879. [Google Scholar] [CrossRef]

- Ned, K.; Lynn, G. Lateral Collinearity and Misleading Results in Variance-Based Sem: An Illustration and Recommendations. J. Assoc. Inf. Syst. 2012, 13, 7. [Google Scholar]

- Kock, N. Common Method Bias in Pls-Sem: A Full Collinearity Assessment Approach. Int. J. e-Collab. 2015, 11, 1–10. [Google Scholar] [CrossRef]

- Hair, J.F.; Page, M.; Brunsveld, N. Essentials of Business Research Methods; Routledge: Oxfordshire, UK, 2019. [Google Scholar]

- Hair, J.F.; Black, W.C.; Babin, B.J.; Anderson, R.E. Multivariate Data Analysis, 7th ed.; Prentice Hall: Upper Saddle River, NJ, USA, 2010. [Google Scholar]

- Hair, J.F.; Sarstedt, M.; Ringle, C.M. Rethinking Some of the Rethinking of Partial Least Squares. Eur. J. Mark. 2019, 53, 566–584. [Google Scholar] [CrossRef]

- Jörg, H.; Ringle, C.M.; Sarstedt, M. Testing Measurement Invariance of Composites Using Partial Least Squares. Int. Mark. Rev. 2016, 33, 405–431. [Google Scholar]

- Ali, R.F.; Dominic, P.D.D.; Ali, K. Organizational Governance, Social Bonds and Information Security Policy Compliance: A Perspective towards Oil and Gas Employees. Sustainability 2020, 12, 8576. [Google Scholar] [CrossRef]

- Sarstedt, M.; Hair, J.F.; Cheah, J.H.; Becker, J.; Ringle, C.M. How to specify, estimate, and validate higher-order constructs in PLS-SEM. Australas. Mark. J. 2019, 27, 197–211. [Google Scholar] [CrossRef]

- Rasoolimanesh, S.M.; Wang, M.; Roldán, J.L.; Kunasekaran, P. Are we in right path for mediation analysis? Reviewing the literature and proposing robust guidelines. J. Hosp. Tour. Manag. 2021, 48, 395–405. [Google Scholar] [CrossRef]

- Carrión, G.C.; Henseler, J.; Ringle, C.M.; Roldán, J.L. Prediction-oriented modeling in business research by means of PLS path modeling: Introduction to a JBR special section. J. Bus. Res. 2016, 69, 4545–4551. [Google Scholar] [CrossRef]

- Christian, N.; Roldan, J.L.; Cepeda, G. Mediation analysis in partial least squares path modeling: Helping researchers discuss more sophisticated models. Ind. Manag. Data Syst. 2016, 116, 9. [Google Scholar]

- Jacob, C. Statistical Power Analysis for the Behavioral Sciences; Lawrence Erlbaum Associates: Hillsdale, NJ, USA, 1988; pp. 20–26. [Google Scholar]

- Francisco, L.C.; Marinković, V.; Kalinić, Z. A Sem-Neural Network Approach for Predicting Antecedents of M-Commerce Acceptance. Int. J. Inf. Manag. 2017, 37, 14–24. [Google Scholar]

- Wan, W.L.; Leong, L.Y.; Hew, J.J.; Tan, G.W.H.; Ooi, K.B. Time to Seize the Digital Evolution: Adoption of Blockchain in Operations and Supply Chain Management among Malaysian Smes. Int. J. Inf. Manag. 2020, 52, 101997. [Google Scholar]

- Sawe, F.B.; Kumar, A.; Garza-Reyes, J.A.; Agrawal, R. Assessing people-driven factors for circular economy practices in small and medium-sized enterprise supply chains: Business strategies and environmental perspectives. Bus. Strat. Environ. 2021, 30, 2951–2965. [Google Scholar] [CrossRef]

- Jabbour, C.J.C.; Sarkis, J.; Jabbour, A.B.L.D.S.; Renwick, D.W.S.; Singh, S.K.; Grebinevych, O.; Kruglianskas, I.; Filho, M.G. Who is in charge? A review and a research agenda on the ‘human side’ of the circular economy. J. Clean. Prod. 2019, 222, 793–801. [Google Scholar] [CrossRef]

- Chowdhury, S.; Dey, P.K.; Rodríguez-Espíndola, O.; Parkes, G.; Tuyet, N.T.A.; Long, D.D.; Ha, T.P. Impact of Organisational Factors on the Circular Economy Practices and Sustainable Performance of Small and Medium-sized Enterprises in Vietnam. J. Bus. Res. 2022, 147, 362–378. [Google Scholar] [CrossRef]

- Saurabh, K.; Bhatia, M.S. Environmental dynamism, industry 4.0 and performance: Mediating role of organizational and technological factors. Ind. Mark. Manag. 2021, 95, 54–64. [Google Scholar]

- Kaswan, M.S.; Rathi, R.; Reyes, J.A.G.; Antony, J. Exploration and investigation of green lean six sigma adoption barriers for manufacturing sustainability. IEEE Trans. Eng. Manag. 2021, 1–15. [Google Scholar] [CrossRef]

- Kaswan, M.S.; Rathi, R.; Garza-Reyes, J.A.; Antony, J. Green lean six sigma sustainability–oriented project selection and implementation framework for manufacturing industry. Int. J. Lean Six Sigma 2022. ahead-of-print. [Google Scholar]

- Rathi, R.; Sabale, D.B.; Antony, J.; Kaswan, M.S.; Jayaraman, R. An Analysis of Circular Economy Deployment in Developing Nations’ Manufacturing Sector: A Systematic State-of-the-Art Review. Sustainability 2022, 14, 11354. [Google Scholar] [CrossRef]

- Rathi, R.; Kaswan, M.S.; Garza-Reyes, J.A.; Antony, J.; Cross, J. Green Lean Six Sigma for improving manufacturing sustainability: Framework development and validation. J. Clean. Prod. 2022, 345, 131130. [Google Scholar] [CrossRef]

- Ali, R.F.; Dominic, P.D.D.; Ali, S.E.A.; Rehman, M.; Sohail, A. Information Security Behavior and Information Security Policy Compliance: A Systematic Literature Review for Identifying the Transformation Process from Noncompliance to Compliance. Appl. Sci. 2021, 11, 3383. [Google Scholar] [CrossRef]

- Dong, K.; Ali, R.F.; Dominic, P.D.D.; Ali, S.E.A. The Effect of Organizational Information Security Climate on Information Security Policy Compliance: The Mediating Effect of Social Bonding towards Healthcare Nurses. Sustainability 2021, 13, 2800. [Google Scholar] [CrossRef]

| Quality 4.0 | References |

|---|---|

| Social factors | |

| Top management support (TMC) | [5,9,10,18,29,35,36,37,38,39] |

| Customer centeredness (CC) | [2,5,16,35,36,38] |

| Training and learning (TL) | [1,2,20,29,37,39] |

| Technical factors | |

| Automatic data collection (ADC) | [9,14,18,40,41] |

| Process management (PM) | [19,38,42,43] |

| Technology utilization (TU) | [9,14,37,40,41] |

| Constructs | Item | Frequency | Percentage (%) |

|---|---|---|---|

| Gender | Male | 102 | 53.97 |

| Female | 87 | 46.03 | |

| Firm age | Less than 5-years | 53 | 28.04 |

| 5–10 years | 77 | 40.74 | |

| More than 10 years | 59 | 31.22 | |

| Industry type | Electrical and Electronics | 65 | 34.4 |

| Machinery and Hardware | 41 | 21.69 | |

| Food | 29 | 15.34 | |

| Rubber and Plastic | 33 | 17.46 | |

| Other | 21 | 11.11 |

| Constructs | Mean | SD | Skewness | Kurtosis |

|---|---|---|---|---|

| TMS | 4.0000 | 1.91786 | 0.027 | −1.308 |

| CC | 4.5794 | 1.76823 | −0.310 | −1.012 |

| TL | 3.9048 | 1.89314 | 0.097 | −1.271 |

| ADC | 3.6349 | 1.90926 | 0.269 | −1.214 |

| PM | 4.0238 | 2.01014 | −0.059 | −1.373 |

| TU | 4.1005 | 1.86098 | −0.001 | −1.218 |

| IT4.0 | 4.0106 | 1.98730 | −0.009 | −1.342 |

| CEP | 4.0026 | 1.78982 | −0.037 | −1.070 |

| Constructs | Items | Loadings | VIF | CR | AVE |

|---|---|---|---|---|---|

| Top management support (TMS) | TMS1 | 0.876 | 2.452 | 0.928 | 0.764 |

| TMS2 | 0.867 | 2.433 | |||

| TMS3 | 0.875 | 2.561 | |||

| TMS4 | 0.878 | 2.624 | |||

| Customer-centeredness (CC) | CC1 | 0.746 | 1.691 | 0.900 | 0.601 |

| CC2 | 0.779 | 1.879 | |||

| CC3 | 0.776 | 1.911 | |||

| CC4 | 0.816 | 2.064 | |||

| CC5 | 0.777 | 1.874 | |||

| CC6 | 0.756 | 1.772 | |||

| Training and learning (TL) | TL1 | 0.896 | 2.012 | 0.913 | 0.778 |

| TL2 | 0.881 | 2.341 | |||

| TL3 | 0.869 | 2.219 | |||

| Process management (PM) | PM1 | 0.841 | 2.313 | 0.931 | 0.730 |

| PM2 | 0.846 | 2.384 | |||

| PM3 | 0.839 | 2.345 | |||

| PM4 | 0.878 | 2.881 | |||

| PM5 | 0.867 | 2.574 | |||

| Automatic data collection (ADC) | ADC1 | 0.708 | 1.669 | 0.912 | 0.566 |

| ADC2 | 0.711 | 1.625 | |||

| ADC3 | 0.757 | 1.900 | |||

| ADC4 | 0.724 | 1.694 | |||

| ADC5 | 0.715 | 1.725 | |||

| ADC6 | 0.755 | 1.837 | |||

| ADC7 | 0.786 | 2.011 | |||

| ADC8 | 0.854 | 2.655 | |||

| Technology utilization (TU) | TU1 | 0.794 | 2.024 | 0.911 | 0.672 |

| TU2 | 0.804 | 2.002 | |||

| TU3 | 0.833 | 2.172 | |||

| TU4 | 0.850 | 2.185 | |||

| TU5 | 0.816 | 2.237 | |||

| I4.0 Technologies | IT1 | 0.849 | 2.654 | 0.946 | 0.745 |

| IT2 | 0.868 | 2.910 | |||

| IT3 | 0.858 | 2.844 | |||

| IT4 | 0.879 | 2.964 | |||

| IT5 | 0.862 | 2.863 | |||

| IT6 | 0.863 | 2.722 | |||

| Circular economy practices | CEP1 | 0.809 | 1.671 | 0.864 | 0.616 |

| CEP2 | 0.847 | 1.854 | |||

| CEP3 | 0.796 | 1.680 | |||

| CEP4 | 0.677 | 1.312 |

| Constructs | TMS (1) | CC (2) | TL (3) | PM (4) | ADC (5) | TU (6) | IT (7) | CEP (8) |

|---|---|---|---|---|---|---|---|---|

| TMS (1) | ||||||||

| CC (2) | 0.354 | |||||||

| TL (3) | 0.339 | 0.360 | ||||||

| PM (4) | 0.539 | 0.727 | 0.325 | |||||

| ADC (5) | 0.728 | 0.373 | 0.400 | 0.471 | ||||

| TU (6) | 0.511 | 0.232 | 0.098 | 0.238 | 0.541 | |||

| IT (7) | 0.308 | 0.551 | 0.486 | 0.414 | 0.482 | 0.320 | ||

| CEP (8) | 0.468 | 0.339 | 0.351 | 0.458 | 0.336 | 0.364 | 0.208 |

| Relation | β-Value | t-Value | f2 | p-Value | Decision |

|---|---|---|---|---|---|

| H1: Social factors → CEP | 0.334 | 3.230 | 0.059 | 0.001 | Accepted |

| H2: Social factors → Technical Factors | 0.744 | 23.173 | 1.241 | 0.000 | Accepted |

| H3: Technical factors → IT4.0 | 0.203 | 1.954 | 0.027 | 0.028 | Accepted |

| H4: Social factors → IT4.0 | 0.396 | 4.354 | 0.103 | 0.000 | Accepted |

| H5: IT 4.0 → CEP | 0.126 | 1.696 | 0.014 | 0.048 | Accepted |

| H6: Technical factors →CEP | 0.246 | 2.085 | 0.034 | 0.021 | Accepted |

| Relationship | β | p-Value | axb | VAF | Decision | ||

|---|---|---|---|---|---|---|---|

| Step-1 | SF→TF→CEP | 0.183 | 0.023 | ||||

| SF→TF→IT4.0 | 0.151 | 0.034 | |||||

| SF→IT4.0→CEP | 0.500 | 0.055 | |||||

| Step-2 | H7a | Path a: SF→TF | 0.744 | 0.000 | 0.183 | 35% | Partial Mediation |

| Path b: TF → CEP | 0.246 | 0.017 | |||||

| Path C: SF→ CEP | 0.334 | 0.003 | |||||

| H7b | Path a: SF→TF | 0.744 | 0.000 | 0.151 | 28% | Partial Mediation | |

| Path b: TF → IT4.0 | 0.203 | 0.030 | |||||

| Path C: SF→ IT4.0 | 0.396 | 0.000 | |||||

| H8 | Path a: SF→IT4.0 | 0.396 | 0.000 | 0.050 | 13% | No Mediation | |

| Path b: IT4.0 → CEP | 0.126 | 0.069 | |||||

| Path C: SF→ CEP | 0.334 | 0.003 | |||||

| Constructs | R2 | Q2 |

|---|---|---|

| Technical Factors | 0.554 | 0.304 |

| IT 4.0 | 0.318 | 0.231 |

| CEP | 0.234 | 0.136 |

| RMSE Values (IT as Dependent Variable) | RMSE Values (CEP as Dependent Variable) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Training | Testing | Total Samples | Training | Testing | Total Samples | ||||

| N | RMSE | N | RMSE | N | RMSE | N | RMSE | ||

| 168 | 0.620 | 21 | 0.438 | 189 | 169 | 0.644 | 20 | 0.642 | 189 |

| 173 | 0.645 | 16 | 0.527 | 189 | 170 | 0.645 | 19 | 0.642 | 189 |

| 168 | 0.579 | 21 | 0.585 | 189 | 171 | 0.685 | 18 | 0.753 | 189 |

| 167 | 0.601 | 22 | 0.378 | 189 | 161 | 0.619 | 28 | 0.564 | 189 |

| 171 | 0.558 | 18 | 0.510 | 189 | 169 | 0.622 | 20 | 0.684 | 189 |

| 172 | 0.654 | 17 | 0.584 | 189 | 165 | 0.665 | 24 | 0.531 | 189 |

| 169 | 0.569 | 20 | 0.584 | 189 | 165 | 0.629 | 24 | 0.657 | 189 |

| 171 | 0.518 | 18 | 0.421 | 189 | 176 | 0.678 | 13 | 0.752 | 189 |

| 166 | 0.597 | 23 | 0.696 | 189 | 166 | 0.640 | 23 | 0.642 | 189 |

| 171 | 0.577 | 18 | 0.521 | 189 | 170 | 0.631 | 19 | 0.678 | 189 |

| Mean | 0.592 | 0.524 | Mean | 0.646 | 0.654 | ||||

| S.D | 0.041 | 0.094 | S.D | 0.023 | 0.070 | ||||

| Neural Network (NN) | TMS | CC | TL | ADC | PM | TU |

|---|---|---|---|---|---|---|

| 1st | 0.359 | 1.000 | 0.806 | 0.648 | 0.340 | 0.137 |

| 2nd | 0.811 | 1.000 | 0.962 | 0.350 | 0.517 | 0.501 |

| 3rd | 0.069 | 0.799 | 1.000 | 0.872 | 0.063 | 0.047 |

| 4th | 0.121 | 1.000 | 0.873 | 0.632 | 0.183 | 0.118 |

| 5th | 0.272 | 1.000 | 0.967 | 0.677 | 0.130 | 0.344 |

| 6th | 0.850 | 0.692 | 1.000 | 0.393 | 0.311 | 0.390 |

| 7th | 0.342 | 0.661 | 0.749 | 1.000 | 0.141 | 0.345 |

| 8th | 0.518 | 1.000 | 0.858 | 0.799 | 0.652 | 0.667 |

| 9th | 0.124 | 0.302 | 1.000 | 0.746 | 0.566 | 0.803 |

| 10th | 0.162 | 1.000 | 0.561 | 0.991 | 0.067 | 0.367 |

| Mean importance | 0.363 | 0.845 | 0.878 | 0.711 | 0.297 | 0.372 |

| Normalized importance | 41% | 96% | 100% | 81% | 34% | 42% |

| Neural Network (NN) | TMS | CC | TL | ADC | PM | TU | IT |

|---|---|---|---|---|---|---|---|

| 1st | 0.477 | 0.683 | 0.487 | 0.934 | 1.000 | 0.837 | 0.046 |

| 2nd | 1.000 | 0.122 | 0.697 | 0.725 | 0.257 | 0.660 | 0.594 |

| 3rd | 0.561 | 1.000 | 0.959 | 0.667 | 0.127 | 0.421 | 0.557 |

| 4th | 0.671 | 0.347 | 1.000 | 0.197 | 0.862 | 0.978 | 0.642 |

| 5th | 1.000 | 0.406 | 0.926 | 0.367 | 0.694 | 0.964 | 0.401 |

| 6th | 1.000 | 0.263 | 0.978 | 0.458 | 0.457 | 0.364 | 0.350 |

| 7th | 0.842 | 1.000 | 0.849 | 0.778 | 0.966 | 0.898 | 0.715 |

| 8th | 1.000 | 0.637 | 0.714 | 0.467 | 0.867 | 0.448 | 0.535 |

| 9th | 0.799 | 0.634 | 1.000 | 0.419 | 0.769 | 0.914 | 0.321 |

| 10th | 0.127 | 0.979 | 0.966 | 0.961 | 0.871 | 1.000 | 0.247 |

| Mean importance | 0.748 | 0.607 | 0.858 | 0.597 | 0.687 | 0.748 | 0.441 |

| Normalized importance | 87% | 71% | 100% | 70% | 80% | 87% | 51% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, Z.; Shahzadi, A.; Khan, Y.D. Unfolding the Impact of Quality 4.0 Practices on Industry 4.0 and Circular Economy Practices: A Hybrid SEM-ANN Approach. Sustainability 2022, 14, 15495. https://doi.org/10.3390/su142315495

Huang Z, Shahzadi A, Khan YD. Unfolding the Impact of Quality 4.0 Practices on Industry 4.0 and Circular Economy Practices: A Hybrid SEM-ANN Approach. Sustainability. 2022; 14(23):15495. https://doi.org/10.3390/su142315495

Chicago/Turabian StyleHuang, Zengjian, Amna Shahzadi, and Yaser Daanial Khan. 2022. "Unfolding the Impact of Quality 4.0 Practices on Industry 4.0 and Circular Economy Practices: A Hybrid SEM-ANN Approach" Sustainability 14, no. 23: 15495. https://doi.org/10.3390/su142315495

APA StyleHuang, Z., Shahzadi, A., & Khan, Y. D. (2022). Unfolding the Impact of Quality 4.0 Practices on Industry 4.0 and Circular Economy Practices: A Hybrid SEM-ANN Approach. Sustainability, 14(23), 15495. https://doi.org/10.3390/su142315495