Abstract

In the era of Industry 4.0, Quality 4.0 (Q4.0) relates to quality management. To that end, it focuses on digital technologies that integrate social and technical resources and offer the best possible product and service to its customers. Few real-world studies have been done on the social and technical aspects of Q4.0. Thus, the purpose of this study is to investigate empirically the impact of social and technical Q4.0 on I4.0 technologies and circular economy practices (CEP) in small- and medium-sized (SME) manufacturing enterprises. A framework based on the resource-based view (RBV) theory is developed and empirically validated by an online questionnaire of 189 Malaysian SME manufacturing enterprises. In contrast to the other existent QM investigations, which made use of structural equation modelling (SEM), this study performed an analysis in two stages. First, the Q4.0 practices that significantly influence I4.0 technologies and CEP are identified using the SEM approach. Second, the significant predictors obtained from SEM are ranked according to their relative importance using the artificial neural network (ANN) technique. The findings indicate that social and technical Q4.0 practices have improved I4.0 technologies and CEP. The findings also highlight the role performed by technical Q4.0 practices as a mediator between social Q4.0 practices, I4.0 technologies, and CEP. The findings of ANN highlight that the role of social and technical Q4.0 are crucial to the successful deployment of I4.0 technologies and CEP in manufacturing companies. The purpose of the current research is to shed light on the importance of Q4.0 multidimensions, hence contributing to theory application, especially given the scarcity of multidimensional perspectives of Q4.0 literature. In essence, the SEM-ANN methodology adds something new to the bodies of literature on Q4.0, I4.0, and CEP. As an outcome of the research, organisations can develop innovative strategies to adopt Q4.0 by gaining a better understanding of the elements that contribute to effective Q4.0 implementation in the digital transformation era.

1. Introduction

In the digital realm, Industry 4.0 technologies (IT4.0) are reshaping the traditional business landscape. Furthermore, it pushes organizations to make changes in their operational models to achieve sustainability and strategic growth [1]. To remain competitive in today’s world, advanced technologies require organizations to change constantly to sustain market dominance and competitiveness [2]. Maintaining this is very challenging for all organizations worldwide, especially small and medium enterprises (SMEs). To answer this question, organizations tend to focus on quality management [3].

In the past century, quality management has undergone several changes. In the fourth industrial revolution (I4.0), it is again ready for another round of change. During the second industrial revolution, the concept of quality was linked with inspection and statistical quality control (SQC) [4]. In this era, the primary focus was on production and it ignored the people-related factors. In the third industrial revolution, quality assurance, total quality control (TQC), and total quality management (TQM) gained popularity [2,4]. Again, in this era, production-related factors gained dominance. During various industrial revolutions, different quality-related concepts find a home under the umbrella of quality management. However, TQM has gained popularity and still gains customer satisfaction from its inception. Ali and Johl [5] argued that TQM is not solely focused on the system, it also includes people and social aspects. Therefore, TQM represents a holistic framework that includes all the aspects related to people and systems. Calvo-Mora et al. [6] argued that the successful application of TQM is based upon a balanced combination of social and technical management factors, as both factors are required to achieve organizational objectives. In the prior literature, people-related factors represent social TQM practices, and process and production-related factors represent technical TQM practices [7,8].

The fourth industrial revolution has challenged quality practices to adapt new methodologies that would align with present industrial growth [9,10]. In this context, there exist several models and conceptual frameworks, especially on Quality 4.0, for instance Fonseca et al.’s [11] model of the European Foundation for Quality Management (EFQM 2020), the LNS Research Quality 4.0 framework by Jacob [12], Lim’s [13] framework combining information and operational technology through digital transformation, and Sader et al.’s [14] fourth industrial revolution framework in TQM context. However, the major challenge is how an organization can shift from its present quality strategy to modern quality that is in line with current IR4.0.

Theoretical foundations shed light on several significant pieces of research around Quality 4.0. Maganga et al. [10] performed an empirical study to access the respondents’ perceptions and awareness of quality 4.0 in the Tanzanian manufacturing industries. Escobar et al. [15] performed a case study approach to examine how the quality 4.0 initiative improves conventional quality control methods. Maganga et al. [16] conducted a review study to identify the enablers and readiness factors for quality 4.0. Mtotywa [17] performed a quantitative study to develop a Quality 4.0 maturity index. The exploratory study of Nguyen et al. [18] identifies the key factors of TQM 4.0/Quality 4.0. Prashar [19] performed a review study to identify future research opportunities based on morphological analysis. Finally, the review work of Thekkoote [20] identifies the vital factors of Quality 4.0 implementation. However, much of the research up to now has been reviewed and conceived in nature. Furthermore, there are empirical studies on Quality 4.0 practices, and it is probably unclear how manufacturing firms implement quality 4.0, particularly in emerging economies. Thus, this study aims to bridge this gap by proposing a framework for manufacturing firms and empirically examining it.

RO1: To examine the role of quality 4.0 practices to promote Industry 4.0 technologies.

RO2: To analyze the role of Quality 4.0 practices to promote circular economy practices in manufacturing firms.

RO3: To examine the importance of Quality 4.0 social and technical factors to promote IT4.0 and CEP.

The remaining sections of this article are structured as follows. The following section provided a review of the prior research conducted within the scope of the current investigation, which will then be followed by the formulation of a theoretical framework and hypotheses. The analysis of the data will be presented in the following part, which will then be followed by a discussion of the findings. Finally, the research’s contributions, limitations, and future directions are discussed.

2. Literature Review

2.1. Multidimensional View of Quality 4.0

Wilkinson [21] is recognized as being the first to divide quality practices into social and technical dimensions. Technical quality practices incorporate production techniques including product design, processes, and procedures, whereas social quality practices reflect a social system that includes human resource management and enhancing customer awareness [22,23]. This research utilized this categorization to build the multidimensional perspective of quality 4.0 by drawing from the work of prior research studies [22,24,25,26].

Prior research has tried to distinguish between the social and technical dimensions of quality management. The social quality factors are concerned with behavioral qualities and, more broadly, with human resources, social, and organisational cultures [22,26]. Contrarily, technical quality practices are those related to management that are primarily focused on the production process and techniques [27]. Researchers have broadened the overall perspective on QM key variables over the decades, however, there remains debate among quality researchers [28]. Theoretically, to attain greater performance, quality researchers should adopt both factors [2]. According to Zeng et al. [22], the quality management system in general includes the integration of social and technical resources. On the technical end of the spectrum are design methods such as PM, ADC, and TU, while the social end is represented by TMS, CC, and TL, which focus on human factors. Furthermore, Sony and Naik [29] argued that the combination of social and technical quality factors is crucial for the proper implementation of I4.0.

2.2. Quality 4.0

Based on Crosby’s definition, “Quality is meeting the requirements and expectations in services or products that were committed to” [30]. According to CQI [31], quality is the persistent goal of achieving excellence, ensuring that everything an organization does is not only suitable for its intended purpose but also continues to improve. The application of digital technologies has initiated a new era of quality, which is known as Quality 4.0 [15]. According to Maganga et al. [10] Quality, 4.0 is a part of I4.0 that strives to enhance quality through efficient technologies and advanced analytics. According to Zonnenshain et al. [32], Quality 4.0 combines cutting-edge technologies with traditional quality management practices to achieve unprecedented levels of efficiency, effectiveness, and creativity in business operations. Chiarini and Kumar [9] revealed that the Quality 4.0 concept aligns quality management practices and procedures with the growing I4.0 capabilities. Different researchers explain Quality 4.0 from a different perspective. However, Quality 4.0 is not all about technologies, it arises from the integration of people, processes, and technology [1,9,33]. Furthermore, Murugesan [34] argued that Quality 4.0 does not replace the existing quality practices. It is mostly centered around identifying gaps among these existing practices and digitally transforming them. Additionally, Murugesan [34], from LNS research, affirmed that Quality 4.0 is a continuous process that requires significant commitments from all stakeholders, requires a considerable period, and financial assets.

2.3. Quality 4.0 Practices

In recent years, there has been an increasing amount of literature on Quality 4.0 practices. In previous studies, different factors are related to Quality 4.0 practices. For instance, Ali and Johl [5,23] considered the critical success factors for Quality 4.0 are top management, customer-centeredness, training and learning, process management, and quality information and analysis. Likewise, Mtotywa [17] argued that top management support, Quality 4.0 vision and strategy, customer-centeredness, and Quality 4.0 training and learning are essential factors for Quality 4.0. Thekoote [20] stated that Quality 4.0 consists of leadership, training, and organizational culture. Dias et al. [8] argued that Quality 4.0 consist of leadership, employee skills, and cybernetics. Sony et al. [29] affirmed that Quality 4.0 consists of big data, leadership, training, organization culture, and top management support. The empirical research of Kaswan et al. (2021) argued that management-related issues must be addressed before implementing sustainable practices. In the same vein, Kaswan et al. (2022) argued that productivity-related indicators are more important in sustainable performance in the manufacturing industry (Rathi et al., 2022). On the other hand, Nguyen et al. [18] argued that Quality 4.0/TQM 4.0 consist of social and technical factors. The social factors consist of top management, quality culture, and employee skills, whereas technical factors consist of automatic data collection, smart quality control and assurance, and smart products. Likewise, Ali and Johl [1,2] argued that Quality 4.0 is divided into social (soft), and technical (hard) practices. The social factors consist of top management commitment, customer focus, and employee training and learning. The technical factors consist of the quality of big data and analysis, process management, product design, and continuous improvement. Based on past studies, Quality 4.0 practices are divided into social and technical factors. Table 1 shows the Quality 4.0 social and technical factors.

Table 1.

List of Quality 4.0 practices.

2.4. Quality Management, Industry 4.0, and Circular Economy

I4.0 is encouraged in the current global economy by both social and technical factors. Literature from the past stated that to support an organization implement I4.0, a holistic and integrated approach that includes both social and technical factors is required [3,5,27]. Quality management, as stated by Manz and Stewart [44], combines social and technical processes to ensure the sustainability of a business and its employees. In quality management literature, social factors are practices that involve people, and technical factors are practices that involve processes and technology [2,18]. In addition, researchers stated that QM in I4.0 might be viewed as combining social and technical variables [35,39]. Past research has demonstrated that quality practices aligning with I4.0, which enables firms to improve their efficiency, performance, and business strategies [35,37,39]. According to current research, social and technical quality practices are crucial for SMEs to apply I4.0 practices [4,7,8,33].

Industry 4.0 can solve complex business, social, and environmental problems [45]. Recently, the scholarly world showed great interest in understanding the role of I4.0 to achieve circular economy practices. The qualitative work of Bag et al. [46] proposed that I4.0 and CE have a positive relationship. The review study of Sahu et al. [47] argued that I4.0 technologies help to promote circular economy integration that ultimately helps to achieve firm performance. Likewise, Kumar et al. [48] affirmed that I4.0 technologies help to overcome adoption barriers that ultimately help to achieve CE practices. The empirical study of Khan et al. [49] affirmed that I4.0 technology has a positive association with CE practices to achieve firm performance. Finally, Cezarino et al. [50] argued that I4.0 technologies use resources more effectively and efficiently, consequently, energy consumption will be minimized. Moreover, digitalization creates opportunities for sustainable manufacturing in the firm’s value chain. Although the prior literature highlights the possible relationship between quality management, I4.0, and circular economy practices, there is still a paucity of empirical studies. Rathi et al. (2022) argued that SMEs are still struggling to implement CE in I4.0. They further argued that there is no roadmap. Thus, this study will address this knowledge gap.

3. Theoretical Framework and Hypothesis Development

3.1. Resource-Based View (RBV) Theory

According to Wernerfelt [51], organizational resources combined uniquely can provide a sustainable competitive advantage. The theory of RBV postulates that an organization’s resources (tangible and intangible) are retained for a long period of time and distributed differently between companies in the industry [52]. The resources that are important, rare, unique, and non-substitutable provide a long-term advantage for the firms in the industry [53]. The RBV literature suggests that organisational capabilities are higher-order constructs that depend on resource bundling [54]. Grant [55] argues further that capabilities are created when resources are integrated and utilized together. Researchers in the Industry 4.0 domain have argued that adopting I4.0 technologies is a capability that explains how businesses may take advantage of technological advancements to boost their own efficiency and effectiveness [56,57].

3.2. Relationship between Quality 4.0, IT4.0, and CEP

In the prior literature, social factors are important for achieving circular economy practices. Kamasak [58] argues that social factors offer economic benefits to an organization that cannot be easily replicated and acquired and should have a higher impact on firm competitive advantages. In this digital age, cyber-physical systems programming and maintenance are some of the skills that are becoming more important. Furthermore, more focus should be given to creativity and critical thinking skills [59]. Therefore, the organization needs to focus on learning and knowledge sharing [60]. Staff must be trained on safety issues because automatic machines/robots operating on the shop floor are relatively new and can cause accidents [46].

H1:

There is a positive relationship that exists between Quality 4.0 social factors and circular economy practices.

From a theoretical standpoint, the interaction between social and technical Quality 4.0 practices is articulated by the synchronized alignment of social and technical components. Although technical elements are vital, focusing solely on them may not result in a sustainable competitive advantage because competitors can quickly imitate and adopt it. Social Q4.0 practices, on the other hand, are difficult to imitate because they rely on intangible human factors. Therefore, in order to acquire long-term competitive advantages, it is necessary to engage in both social and technical Q4.0 activities.

According to the available research, a competitive business can recognize the significance of social factors in advancing technical quality practices. For example, Calvo-Mora et al. [6] discovered that leadership and people management are required for technical quality 4.0 methods to attain improved performance. Sciarelli et al. [26] research confirmed the positive relationship between social quality management techniques and technical practices. According to Khan and Naeem [61], social quality factors have a positive effect on technical attributes. Social practices support technical practices in manufacturing organizations, as indicated by Tar et al. [6]. Nasaj and Al Marri [62] concluded that social factors largely predict technical factors. Therefore, the following hypothesis has been proposed.

H2:

There is a positive relationship existing between Quality 4.0 social and technical factors.

In the current business world, quality management facilitates I4.0 business excellence. From a theoretical standpoint, Sony and Naik [29] asserted that social (TMS, education, and training) and technical (automated data management and process management) factors are the most important for I4.0 implementation. According to Thekkoote [20], a strong commitment from top management helps with resource distribution and encourages workers to adopt quality practices in I4.0. Babatunde’s [27] exploratory research matched I4.0’s ramifications and competencies to social and technical practices. The results demonstrated the significance of social and technical QM practices for I4.0. Sureshchandar [36] also emphasized the importance of top-level management and leadership in a successful I4.0 implementation. Antony, McDermott, and Sony [35] stated that for organizations to be ready for I4.0, their workers need to learn new skills and recieve new training. According to Dubey and Gunasekaran [63], investing in training helps firms gain a competitive advantage. A rising corpus of research acknowledges the importance of training and education in obtaining I4.0 implementations [64]. According to Khin and Hung Kee [4], the alignment of HRM with I4.0 is anticipated to facilitate teamwork and learning. According to Stentoft et al. [57], I4.0 is driven by factors including business strategy, consumer demand, data availability, and cutting-edge technologies. Sony and Naik [29] review article states that TMS, employee adaptability, strategy, IT products and services, and the degree of digitization are essential components of I4.0. In addition, they suggested that these variables are connected. Consequently, an organization deploying I4.0 should consider these elements in their totality. Strategy, leadership, operations, and technology are crucial components for I4.0 preparedness in manufacturing SMEs [65]. Based on the literature and theoretical arguments mentioned above, the following hypotheses have been proposed.

H3:

There is a positive relationship existing between Quality 4.0 technical factors and Industry 4.0 technologies (IT4.0).

H4:

There is a positive relationship existing between Quality 4.0 social factors and IT4.0.

Prior literature indicates that the relationship between I4.0 technologies and CE can be valuable for an organization [46]. The relationship between these two concepts has been explained in detail by Massaro et al. [66]. For instance, the adoption of I4.0 technologies is closely connected to the production system with a reduction in the inputs exploited with a consequent improvement in the quality of life and efficiency in the use of resources. However, the uses of I4.0 technologies not only reduce resources but also the capabilities to manage information through new technologies.

H5:

There is a positive relationship existing between IT4.0 and circular economy practices.

H6:

There is a positive relationship existing between Quality 4.0 technical factors and circular economy practices.

3.3. Mediating Role of Quality 4.0 Technical Factors

The theoretical stance underscores the interdependence of social and technical quality management practices. Prior research has shown that social quality practices impact organisational performance through technical quality practices [33]. Technical QM was investigated by Calvo-Mora et al. [6] as a potential mediator between social QM and outcome determinants. In the same way, Zeng, Zhang, Matsui, and Zhao [22] analyzed how technical quality practices act as a mediator between social quality practices and innovation performance in manufacturing firms. The mediation influence of QM technical aspects between social QM practices and performance results were examined by Calvo-Mora et al. [6]. The outcomes of the structural model validated the mediating role of technical QM practices in Spanish manufacturing firms. Khan and Naeem [61] asserted that technical quality practices mediate the relationship between social quality practices and outcome variables in the emerging economy. The role of technical QM as a mediator between social quality dimensions and outcome variables was also investigated by Gambi et al. [67]. Nasaj and Al Marri [62] investigated the significance of technical quality dimensions as a mediator between social quality factors and business results. Following the preceding discussion, the following hypotheses have been put forward.

H7a:

Quality 4.0 technical factors have a mediating role between social factors and CEP.

H7b:

Quality 4.0 technical factors have a mediating role between social factors and IT4.0.

3.4. Mediating Role of Industry 4.0 Technologies

Over the past few decades, industry 4.0 technologies transform the firm social and technical landscape. IT4.0 pushes organizations to rethink their operations and make changes accordingly. Prior literature highlights the mediating role of industry 4.0 technologies to achieve sustainable performance [60,68,69]. Torrent-Sellens et al. [60] performed a panel data analysis to affirm the mediating role of IT4.0 between environmental assets and sustainability performance (economic and social) in Spanish manufacturing firms. The empirical results highlight that I4.0 technologies played a partial mediation role among study variables. Likewise, Jayashree et al. [70] concluded that I4.0 technologies have a mediating role between organizational social and technical resources and sustainability in Malaysian manufacturing SMEs. Another study by Jayashree et al. [68] affirmed the mediating role of I4.0 implementation between firm social and technical resources and TBL of sustainability in Malaysian manufacturing SMEs. Finally, the empirical study of Gadekar et al. [69] affirmed the mediation role of I4.0 adoption between I4.0 drivers and sustainable performance in Indian manufacturing firms. Based on the above literature support, the following hypothesis has been developed.

H8:

IT4.0 has a mediating role between Q4.0 social factors and CEP.

4. Material and Methods

Research methodology explains how samples were selected and information was gathered. In addition, the constructs and statistical tests that were utilized to determine how Quality 4.0 influenced IT4.0 and circular economy practices (CEP) are discussed.

4.1. Sampling and Data Collection

The study population was sampled through an online survey. According to Wright [71], conducting surveys online enables researchers to access niche communities while also saving money and time. Tanner [72] emphasizes the major contribution of digital technology to survey methods to reach respondents with limited time and resources. The study population consists of small, medium, and large manufacturing firms in Malaysia. The criteria for the selection of manufacturing firms are based on full-time employees. Based on Malaysian SME Corporation [73], a firm having 5–74 employees is regarded as small, 75 ≤ 200 employees as medium, and above 200 is regarded as a large firm. The sample frame was based on the Federation of Malaysian Manufacturers (FMM) list 2019. The sampled data was collected through simple random sampling. Before performing the actual survey, the pretesting and pilot testing steps were performed. In pretesting, face and content-related validities are essential, and can only be determined by academic and industry experts. Before actual data collection, six experts (academic and industry) were invited to validate the items of each variable. A pilot study was undertaken on a small sample size (N = 38) and analyzed through SPSS. The results indicate that all the constructs achieve the minimum reliability and validity threshold. Moreover, ethical considerations were considered throughout the data collection. More than 670 emails were sent, and 189 final questionnaires were received for further analysis with a response rate of 28.20%. The data was analyzed using the partial least square structural equation modeling method (PLS-SEM) technique. This technique is useful to analyze multiple relationships and is less stringent on normality assumptions (Hair et al., 2019). The respondent demographic statistics are shown in Table 2.

Table 2.

Demographic statistics.

4.2. Measures

In this research, the questionnaire was adapted from past studies. The social Q4.0 practices are divided into top management support (TMS), customer-centric (CC), and team learning (TL). The technical Q4.0 practices are divided into automatic data collection (ADC), process management (PM), and technology utilization (TU). The items related to Q4.0 practices are adapted from Ali and Johl [1,2], Sila [74], and Rahman and Bullock [25]. Six items of Industry 4.0 technologies have been adapted from Stentoft et al. [57] and Ali and Johl [1]. The four items of CEP are adapted from Beg et al. [46]. All items are measured on a seven-item Likert scale.

5. Data Analysis

5.1. Descriptive Statistics and Common Method Bias

This section highlights the descriptive statistics of the study. It consists of mean, standard deviation (SD), skewness, and kurtosis. As recommended by George and Mallery [75], the threshold limit of skewness and kurtosis was ±2. Table 3 shows the descriptive analysis. From Table 3, all the study constructs have mean values above 4.0, except Tl (3.904) and ADC (3.634). Based on Table 3, the social factors such as TMS have mean value 4.0 with SD 1.917, CC has mean value 4.579 with SD 1.768, and TL has mean value 3.904 with SD 1.893. On the other hand, the descriptive statistics of technical factors are presented in Table 3: ADC (3.634, 1.909), PM (4.023, 2.010), and TU (4.100, 1.860). Finally, the IT4.0 has mean value 4.010 with SD 1.98, and CEP has mean value 4.00 with SD 1.789. Furthermore, the common method bias (CMB) was performed to examine the bias in the dataset. To resolve the CMB issue, both procedural and statistical remedies were adopted [76]. Harman’s single-factor test was conducted from a statistical perspective. The analysis indicated that the variance of a single factor was less than 50%. It indicates that CMB is not an issue. According to Kock [77] and Kock and Lynn [78], the CMB cannot be a problem in PLS-SEM, if the variance inflation factor (VIF) value obtained through the full collinearity test is less than 3.3. The full collinearity analysis indicates that the VIF value of all study variables is less than 3.3. Hence, CMB is not an issue.

Table 3.

Descriptive Statistics.

5.2. Assessment of Measurement Model

5.2.1. Reliability and Convergent Validity

Following the recommendation by Hair et al. [79], the assessment of the measurement model consists of reliability and validity (convergent and discriminant). In terms of reliability, composite reliability (CR) was used to measure the data reliability.

As Hair et al. [79] suggest, CR values less than 0.70 are considered to be good. Concerning convergent validity, item loading and average variance extracted (AVE) are very important [80]. Hair et al. [81] assert that an item with a loading of 0.708 is good. However, if the loading is between 0.4 and 0.7 and the AVE is less than 0.5, the constructs can be retained. In addition, AVE’s threshold value is greater and equal to 0.5.

Table 4 shows the reliability and convergent validity. Moreover, Table 4 shows the item’s loading. In terms of loading, all the items achieve the threshold values. Table 4 also highlights the reliability values of TMS (0.928), CC (0.900), TL (0.913), PM (0.931), ADC (0.912), TU (0.911), IT (0.946), and CEP (0.864). Moreover, Table 4 shows the convergent validity (AVE)

Table 4.

Reliability and Convergent Validity.

5.2.2. Discriminant Validity

Fornell–Larker, cross-loading, and heterotrait–monotrait (HTMT) are the three methods for assessing discriminant validity described in the PLS-SEM literature. Forell–Larker and cross-loading methods have been recently questioned by Henseler et al. [82] for their inability to identify discriminant validity in PLS-SEM. Therefore, the HTMT technique was followed to measure discriminant validity. Acceptable HTMT values are less than 0.90 for related variables and less than 0.85 for distinct variables [81]. All of the latent variables’ discriminant validity (HTMT) are shown in Table 5, and all constructs satisfy the threshold limit (0.85) [83].

Table 5.

Discriminant validity (HTMT).

5.3. Assessment of Structural Model

The association between exogenous and endogenous variables was evaluated in the structural model assessment, as recommended by Hair et al. [81]. In this research, Quality 4.0 readiness constructs are divided into social (TMS, CC, and TL) and technical (PM, ADC, and TU) factors. As recommended by Hair et al. [79], a two-stage approach was adopted to measure the higher-order analysis. Sarstedt et al. [84] stated that more than eighty percent of studies adopted a two-stage approach for higher-order analysis.

Table 6 shows the hypothesized relationship and effect size between study variables. Based on the analysis, the association between social factors and CEP (β = 0.334, f2 = 0.059, p < 0.05) is positive and significant. Hence, H1 has been accepted. Likewise, the statistical analysis highlight that the relationship between social factors and technical factors (β = 0.744, f2 = 1.241, p < 0.05) is significant and positive. Thus, H2 has been accepted. Furthermore, the empirical results indicated that technical factors have a positive and significant relationship with IT4.0 (β = 0.203, f2 = 0.027, p < 0.05). Hence, H3 has been accepted. Moreover, the results highlight that social factors and IT4.0 (β = 0.7396, f2 = 0.103, p < 0.05) have a positive and significant association. Therefore, H4 was supported and accepted. The analysis also indicated that the association between IT4.0 and CEP (β = 0.126, f2 = 0.014, p < 0.05) has been positive and significant. Thus, H5 has been accepted. Finally, the relationship between technical factors and CEP (β = 0.246, f2 = 0.034, p < 0.05) has been positive and significant. Hence, H6 has been accepted.

Table 6.

Structural model and effect size.

5.4. Mediation Analysis

The previous literature divided mediation analysis into implicit and explicit approaches [85]. Traditional analyses, such as the Baron and Kenny technique and the test of joint significance, are commonly used to depict implicit procedures. However, no inferential test for the indirect effect was carried out by implicit analysis procedures. Conversely, explicit mediation techniques, such as the Sobel test, distribution of product method, bootstrapping method, and Monte Carlo simulation method, largely concentrate on the indirect effect [85].

A two-step process was used in accordance with Cepeda Carrión et al. [86] and Nitzl et al.’s [87] recommendations. In the first step, the researcher used 5000 resamples to assess the importance of indirect effects. To determine the significance between constructs, p-values were applied. The second step identified the nature of the effect and/or its mediation. The variance accounted for (VAF) ratio was utilized to compute the full and partial mediation. The general guideline is that there is no mediation if the VAF is less than 20%, partial mediation if the VAF is between 20% and 80%, and full mediation if the VAF is larger than 80%. Both steps were shown in Table 7.

Table 7.

Mediation analysis.

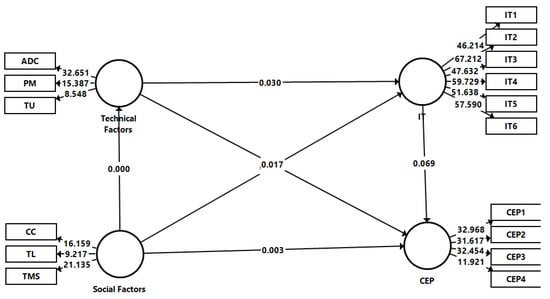

In the first step, the indirect relationships among study variables have been examined. The results indicate that SF→TF→CEP (β = 0.183, p = 0.023), SF→TF→IT4.0 (β = 0.151, p = 0.034), and SF→IT4.0→CEP (β = 0.500, p = 0.055) have positive and significant relationships. The second step indicates that TF partially mediates the association between SF and CEP having a VAF value of 35%. Similarly, TF partially mediates the relationship between SF and IT4.0 having a VAF value of 28%. Surprisingly, IT4.0 has not performed a mediating role between SF and CEP because the VAF value is less than 20%. Finally, Figure 1 shows the PLS diagram of the hypothesized model.

Figure 1.

PLS Diagram of the hypothesized model.

5.5. Predictive Relevance and R2

Table 8 shows the coefficient of determination (R2) and predictive relevance (Q2). As recommended by Cohen [88], the value of R2 is categorized into three; 0.02 is considered small, 0.13 is considered medium/moderate, and 0.26 is considered large. The results of Table 8 indicate that TF (0.554) and IT 4.0 (0.318) have a large effect. On the other hand, a Q2 value greater than zero (Q2 < 0) indicates good predictive relevance [81,83]. Table 8 indicates that the Q2 value for all endogenous variables is greater than zero.

Table 8.

Predictive relevance (Q2) and coefficient of determination (R2).

5.6. Artificial Neural Network (ANN) Analysis

This section outlines the rationale for using artificial neural networks (ANN) and illustrates the outcomes. The linear relationship between exogenous and endogenous variables is explained by structural equation modeling (SEM) and multiple regression analysis (MRA). However, both techniques are deemed insufficient for explaining the complicated nature of the decision-making process [89]. In addition, the compensating assumption underlies both SEM and MRA, which implies that if one or more exogenous components in the framework are reduced, this can be offset by an increase in another [90]. However, in this study, the Q4.0 practices are non-compensable and critical for IT4.0 and CEP. For instance, a decrease in TMS cannot be compensated with an increase in CC and TL as the exogenous constructs are distinctive in conceptualization and definitions. To overcome this issue and capture the linear and non-linear correlations within a non-compensatory framework, ANN is used in tandem with PLS-SEM [2]. Furthermore, the use of two-stage SEM-ANN represents a novel methodological improvement. Given the benefits and acceptability of the ANN approach, this study employs it to evaluate the relationship between each predictor and dependent variables.

The input, hidden, and output layers make up the architecture of the ANN technique. Based on the existing literature, a feed-forward-back-propagation algorithm with a multi-layer perceptron was applied [2,90]. In the same way as Ali and Johl [2], 90% of the samples were used for training and 10% for testing. Ali and Johl [2] stated that a ten-fold cross-validation method was used to reduce the chance of over-fitting and determined the root mean square of errors (RMSE). Sensitivity analysis is seen to be pivotal in the ANN approach. It helps to analyze the predictive power of each input neuron.

Table 9 shows the RMSE values when IT4.0 and CEP are dependent variables. Table 10 illustrates the sensitivity analysis when IT4.0 is the dependent variable. The results indicate that quality 4.0 readiness factors are important to promote IT4.0. The most prominent factors are TL (100%), CC (96%), ADC (81%), TU (42%), TMS (41%), and PM (34%). Table 11 shows the sensitivity analysis when CEP is a dependent variable. The ANN outcome indicated that Q4.0 readiness and IT 4.0 and important factors to achieve CEP. The most prominent factor is TL (100%), followed by TU (87%), TMS (87%), PM (80%), CC (71%), ADC (70%), and IT4.0 (51%).

Table 9.

RMSE values.

Table 10.

Sensitivity analysis (IT as dependent variable).

Table 11.

Sensitivity analysis (CEP as dependent variable).

6. Discussion of Findings

The purpose of this research is to investigate the role of Quality 4.0 social and technical factors to promote Industry 4.0 technologies and circular economy practices. Furthermore, this study also examines the mediating role of Quality 4.0 technical factors and Industry 4.0 technologies between quality social and circular economy practices. To achieve the study objectives, eight research hypotheses have been developed and empirically analyzed through the PLS-SEM technique. After that, the artificial neural network (ANN) technique was applied to identify the important Quality 4.0 factors for IT4.0 and CEP.

The findings of the first hypothesis affirmed that the social factors of Quality 4.0 have a positive relationship with circular economy practices (H1). This study’s finding is consistent with past literature. Sawe et al. [91] argued that people-driven factors (top management and training) are considered the most important factors for circular economy practices in SMEs. Due to current developments in technology, there has been increasing growth in resources overutilization. Sawe et al. [91] argued that manufacturing organization need to be able to adopt CEP, enabling it to reduce resource overuse, and minimize waste, while promoting reuse, remanufacturing, and reduce strategies [60]. In other words, organization social factors (top management and employees) should be able to stimulate environmentally friendly and efficient products [59,60]. Similarly, Jabbour et al. [92] concluded that both human and organizational factors are important to implement circular economy practices in emerging economies. Finally, Chowdhury et al. [93] argued that organizational factors (leadership) are essential to promote circular economy practices in SME manufacturing. Therefore, H1 has been accepted.

The findings of the second hypothesis affirmed that the Quality 4.0 social factors have a significant and positive relationship with technical factors (H2). The study findings are in line with past literature. Ali and Johl [2,33] concluded that social QM factors significantly affect technical QM practices. Similarly, Zeng et al. [22] affirmed that social QM practices have a positive and significant relationship with technical QM practices. Thus, H2 has been accepted. The prior literature argued that the key to quality performance in digital era is not solely lies on technical factors like process management, and data and analysis, but in social or intangible factors [3,33]. Moreover, Nguyen et al. [18] argued that both social and technical Q4.0 are important to achieve organizational flexibility, adaptability, and sustainability. They further argued that both quality factors must be jointly optimized in the digital era [29].

The findings of the third and fourth research hypotheses stated that Quality 4.0 practices have a positive relationship with Industry 4.0 technologies (H3 & H4). The findings are in line with previous research studies. Ali and Johl [1] affirmed that both social and technical factors have a positive and significant relationship with I4.0 technologies. Furthermore, Cresnar et al. [56] and Sony et al. [37] argued that Quality 4.0 helps to promote I4.0 technologies in manufacturing firms. Therefore, H3 and H4 have been accepted. In the digital era, technology transformed the traditional quality practices into Q4.0 [33] which includes people (social) and process and technology (technical). Most quality researchers agree that Q4.0 is closely aligned with I4.0, which will help organizations to achieve higher performance, efficiency, and improved business model [3,29,33,37].

The findings of the fifth and sixth hypotheses affirmed that IT4.0 and quality 4.0 technical factors have a positive relationship with CEP (H5 and H6). The findings are consistent with past literature. Khan et al. [49] concluded that IT4.0 has a positive relationship with CEP in Ecuadorian manufacturing firms. The results are also supported by several past studies [92]. Thus, H5 and H6 have been accepted. Previous literature argued that I4.0 technology play a vital role in upgrading the sustainability domain, which benefits organizations through greater information sharing and visibility [49]. The real-time sharing of data with greater accuracy is a revolutionary contribution of I4.0 technology, which significantly reduce the carbon footprints on their operations [45,47].

The outcomes of the seventh research hypothesis stated the mediating role of Q4.0 technical factors between social factors and IT4.0 and CEP. The results of both hypotheses are supported by past studies. Ali and Johl [2] concluded the technical Q4.0 factors have a mediating role between social and industry 4.0. Likewise, Ali and Johl [33] affirmed the mediating role of technical QM factors between social and sustainable performance in Malaysian manufacturing SMEs. Therefore, H7 was accepted.

The findings of the eighth research hypothesis indicated that IT4.0 has no mediation role between Q4.0 social factors and CEP. The study findings are consistent with the past literature. Kumar and Bhatia [94] argued that IT4.0 has no mediating role between human factors and performance in Indian manufacturing firms. Jayashree et al. [70] concluded that I4.0 technologies have no mediating role between stakeholders and sustainability. Therefore, H8 has been rejected.

Finally, the ANN analysis indicated that social factors (TL and CC) are important predictors of Industry 4.0 practices in manufacturing firms. Moreover, the ANN results highlight that both social and technical factors are essential for circular economy practices [95]. The ANN study of Kashif et al. [2] affirmed that both social and technical factors are essential to promote Industry 4.0 readiness in SME manufacturing. Moreover, Lim et al. [13] argued that social factors are important to achieve sustainable performance.

7. Conclusions

7.1. Theoretical Contributions

Theoretically, this study contributes to the growing body of literature on the interplay between Q4.0, I4.0, and the circular economy, by highlighting the diverse impacts of social and technical Q4.0 practices on IT4.0 and CEP in the SME sector. This increases the generalizability of conclusions that have already been validated in larger companies. Second, Quality 4.0’s multidimensional approach has proven to be important and useful because it allows for different paths through social and technical practices that affect IT4.0 and CEP. These results also demonstrate the mediating role that technical Quality 4.0 plays between social factors and IT4.0 and CEP. In other words, when good leaders are in place and human resources are managed efficiently, an organization’s performance improves significantly. Third, this research gives us a reliable model based on practical research that proves the theoretical connections between Quality 4.0 practices, IT4.0, and CEP [96]. As the survey concludes, a lack of consensus exists over which technologies are necessary for different types of firms, making it difficult for small- and medium-sized enterprises to advance to the next level.

7.2. Practical Implications

Overall, this research helps us learn more about how social and technical Quality 4.0 practices influence IT4.0 and CEP in small- and medium-sized manufacturing enterprises (SMEs). Therefore, it could be used as a guide for SMEs. Based on what this research found, there are certain aspects that SME owners and managers might also consider. First, evidence from this empirical study showed that social Quality 4.0 practices have a big effect on technical quality 4.0 practices. This means that owners and managers should put management and employee-related social practices at the top of their list of priorities when putting I4.0 technologies into place. Second, the fact that social Q4.0 is so important to technical Q4.0 shows how much Q4.0 practices depend on each other and how important it is to use the RBV approach to manage them. Managers therefore must first lay the groundwork for quality by focusing on social practices before starting any project to improve quality [97,98]. Last, academics are also influenced by the practical implications. In terms of I4.0, past studies have shown how important digital education is. Academics should use these results to update their teaching and curriculum methods and put more focus on digital resources.

7.3. Limitations and Future Research Directions

It can be beneficial to discuss the findings, the limitations, and the possible future initiatives. First, the analysis shows that there is still a gap between what SMEs know about I4.0 and what they do. This gap is partly caused by reactive investments in technology. In the future, studies could look at how the success of SMEs is linked to both reactive and proactive ways of adapting to I4.0 technology. Second, this research focused on manufacturing SMEs. It is not possible to generalize these findings to other service sectors. In the future, it will be possible to generalize the findings more precisely by conducting comparative research [99]. Third, the data originates from a single person’s responses to a survey form. The use of a single perspective in a study could be seen as constrained. Therefore, in order to get more accurate results, future studies will look into this phenomenon by surveying multiple people within each company. Future studies could also look at how internal factors (organisational culture, learning, and strategic convergence) and external factors (regulatory conditions, technology turbulence, and the level of competition) might affect the proposed framework [100]. These things can be looked at as moderators, which could lead to more interesting results. Finally, the current study was performed in small and medium industries. The prior literature argued that the implementation of I4.0 technologies is based on contextual factors like firm size (small and medium). In future studies, the role of firm size (small and medium) may be taken as a moderator to get more exciting results.

Author Contributions

Conceptualization, Z.H. and A.S.; methodology, A.S.; software, Z.H.; validation, A.S. and Y.D.K.; formal analysis, Z.H.; investigation, A.S.; resources, Y.D.K.; data curation, Z.H.; writing—original draft preparation, Z.H.; writing—review and editing, A.S.; visualization, Y.D.K.; supervision, A.S.; project administration, Y.D.K.; funding acquisition, Z.H. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Acknowledgments

We are thankful for the help and guidance provided by all authors and Kashif Ali from Universiti Teknologi PETRONAS; without their assistance it would have been impossible to achieve such a research goal.

Conflicts of Interest

The authors declare no conflict of interest. The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

References

- Ali, K.; Johl, S.K. Impact of total quality management on industry 4.0 readiness and practices: Does firm size matter? Int. J. Comput. Integr. Manuf. 2022, 1–23. [Google Scholar] [CrossRef]

- Ali, K.; Johl, S.K.; Muneer, A.; Alwadain, A.; Ali, R.F. Soft and Hard Total Quality Management Practices Promote Industry 4.0 Readiness: A SEM-Neural Network Approach. Sustainability 2022, 14, 11917. [Google Scholar] [CrossRef]

- Broday, E.E. The Evolution of Quality: From Inspection to Quality 4.0. Int. J. Qual. Serv. Sci. 2022. ahead-of-print. [Google Scholar]

- Khin, S.; Kee, D.M.H. Identifying the Driving and Moderating Factors of Malaysian Smes’ Readiness for Industry 4.0. Int. J. Comput. Integr. Manuf. 2022, 35, 1–19. [Google Scholar] [CrossRef]

- Ali, K.; Johl, S.K. Soft and Hard Tqm Practices: Future Research Agenda for Industry 4.0. Total Qual. Manag. Bus. Excell. 2021, 33, 1625–1655. [Google Scholar] [CrossRef]

- Calvo-Mora, A.; Picón, A.; Ruiz, C.; Cauzo, L. The Relationships between Soft-Hard Tqm Factors and Key Business Results. Int. J. Oper. Prod. Manag. 2013, 34, 115–143. [Google Scholar] [CrossRef]

- Tarí, J.J.; Claver-Cortés, E.; García-Fernández, M. How Quality Management Can Enhance Performance? A Model of Relationships Mediated by Innovation. Prod. Plan. Control. 2021, 1–17. [Google Scholar] [CrossRef]

- Dias, A.M.; Carvalho, A.M.; Sampaio, P. Quality 4.0: Literature Review Analysis, Definition and Impacts of the Digital Transformation Process on Quality. Int. J. Qual. Reliab. Manag. 2021. ahead-of-print. [Google Scholar]

- Chiarini, A.; Kumar, M. What Is Quality 4.0? An Exploratory Sequential Mixed Methods Study of Italian Manufacturing Companies. Int. J. Prod. Res. 2021, 60, 4890–4910. [Google Scholar] [CrossRef]

- Maganga, D.P.; Taifa, I.W. Quality 4.0 Transition Framework for Tanzanian Manufacturing Industries. TQM J. 2022. ahead-of-print. [Google Scholar]

- Fonseca, L.; Amaral, A.; Oliveira, J. Quality 4.0: The EFQM 2020 model and industry 4.0 relationships and implications. Sustainability 2021, 13, 3107. [Google Scholar] [CrossRef]

- Jacob, D. Quality 4.0 Impact and Strategy Handbook. 2017. Available online: https://www.lnsresearch.com (accessed on 30 June 2022).

- Lim, A.; Lee, V.H.; Foo, P.Y.; Ooi, K.B.; Tan, G.W.-H. Unfolding the Impact of Supply Chain Quality Management Practices on Sustainability Performance: An Artificial Neural Network Approach. Supply Chain. Manag. Int. J. 2021, 27, 611–624. [Google Scholar] [CrossRef]

- Sader, S.; Husti, I.; Daroczi, M. A review of quality 4.0: Definitions, features, technologies, applications, and challenges. Total Qual. Manag. Bus. Excell. 2022, 33, 1164–1182. [Google Scholar] [CrossRef]

- Escobar, C.A.; Macias, D.; McGovern, M.; Hernandez-de-Menendez, M.; Morales-Menendez, R. Quality 4.0–an evolution of Six Sigma DMAIC. Int. J. Lean Six Sigma 2022, 13, 1200–1238. [Google Scholar] [CrossRef]

- Maganga, D.P.; Taifa, I.W.R. Quality 4.0 conceptualisation: An emerging quality management concept for manufacturing industries. TQM J. 2022. ahead-of-print. [Google Scholar]

- Mtotywa, M.M. Developing a Quality 4.0 Maturity Index for Improved Business Operational Efficiency and Performance. Qual. Innov. Prosper. 2022, 26, 101–127. [Google Scholar] [CrossRef]

- Van Nguyen, T.A.; Tucek, D.; Pham, N.T. Indicators for Tqm 4.0 Model: Delphi Method and Analytic Hierarchy Process (Ahp) Analysis. Total Qual. Manag. Bus. Excell. 2022, 1–15. [Google Scholar] [CrossRef]

- Prashar, A. Quality management in industry 4.0 environment: A morphological analysis and research agenda. Int. J. Qual. Reliab. Manag. 2022. ahead-of-print. [Google Scholar]

- Thekkoote, R. Enabler toward Successful Implementation of Quality 4.0 Indigital Transformation Era: A comprehensive Review and future research Agenda. Int. J. Qual. Reliab. Manag. 2022. ahead-of-print. [Google Scholar]

- Wilkinson, A. The Other Side of Quality: ‘Soft’ Issues and the Human Resource Dimension. Total Qual. Manag. 1992, 3, 323–330. [Google Scholar] [CrossRef]

- Zeng, J.; Zhang, W.; Matsui, Y.; Zhao, X. The impact of organizational context on hard and soft quality management and innovation performance. Int. J. Prod. Econ. 2017, 185, 240–251. [Google Scholar] [CrossRef]

- Ali, K.; Johl, S.K. Critical Success Factors of Total Quality Management Practices Using Pareto Analysis. Int. J. Product. Qual. Manag. 2021, 36, 353–381. [Google Scholar] [CrossRef]

- Flynn, B.B.; Schroeder, R.G.; Sakakibara, S. The Impact of Quality Management Practices on Performance and Competitive Advantage. Decis. Sci. 1995, 26, 659–691. [Google Scholar] [CrossRef]

- Rahman, S.U.; Bullock, P. Soft Tqm, Hard Tqm, and Organisational Performance Relationships: An Empirical Investigation. Omega 2005, 33, 73–83. [Google Scholar] [CrossRef]

- Sciarelli, M.; Gheith, M.H.; Tani, M. The relationship between soft and hard quality management practices, innovation and organizational performance in higher education. TQM J. 2020, 32, 1349–1372. [Google Scholar] [CrossRef]

- Babatunde, O.K. Mapping the implications and competencies for Industry 4.0 to hard and soft total quality management. TQM J. 2020, 33, 896–914. [Google Scholar] [CrossRef]

- Georgiev, S.; Ohtaki, S. Critical success factors for TQM implementation among manufacturing SMEs. Benchmarking Int. J. 2019, 27, 473–498. [Google Scholar] [CrossRef]

- Sony, M.; Naik, S. Industry 4.0 integration with socio-technical systems theory: A systematic review and proposed theoretical model. Technol. Soc. 2020, 61, 101248. [Google Scholar] [CrossRef]

- Connell, S. What Do We Mean by ‘Quality’? Quality in Mind, 13 October 2017. Available online: Asq.org/blog/2013/01/what-do-we-mean-by-quality (accessed on 30 June 2022).

- Johns, E. What Is Quality? CQI|IRCA, 25 June 2020. Available online: www.quality.org/what-quality (accessed on 30 June 2022).

- Zonnenshain, A.; Kenett, R.S. Quality 4.0—The Challenging Future of Quality Engineering. Qual. Eng. 2020, 32, 614–626. [Google Scholar] [CrossRef]

- Ali, K.; Johl, S.K. Impact of Total Quality Management on SMEs Sustainable Performance in the Context of Industry 4.0. In Proceedings of the International Conference on Emerging Technologies and Intelligent Systems, Al Buraimi, Oman, 25–26 June 2021; Springer: Berlin/Heidelberg, Germany, 2021; pp. 608–620. [Google Scholar]

- Murugesan, V. What Is Quality 4.0? And What It Isn’t. Available online: blog.lnsresearch.com/what-is-quality-4.0-and-what-it-isnt (accessed on 9 October 2022).

- Antony, J.; Sony, M.; Furterer, S.; McDermott, O.; Pepper, M. Quality 4.0 and Its Impact on Organizational Performance: An Integrative Viewpoint. TQM J. 2021. ahead-of-print. [Google Scholar]

- Sureshchandar, G.S. Quality 4.0–Understanding the Criticality of the Dimensions Using the Analytic Hierarchy Process (Ahp) Technique. Int. J. Qual. Reliab. Manag. 2022, 39, 1336–1367. [Google Scholar] [CrossRef]

- Sony, M.; Antony, J.; Douglas, J.A.; McDermott, O. Motivations, Barriers and Readiness Factors for Quality 4.0 Implementation: An Exploratory Study. TQM J. 2021, 33, 1502–1515. [Google Scholar] [CrossRef]

- Carvalho, A.V.; Enrique, D.V.; Chouchene, A.; Charrua-Santos, F. Quality 4.0: An overview. Procedia Comput. Sci. 2021, 181, 341–346. [Google Scholar] [CrossRef]

- Antony, J.; McDermott, O.; Sony, M. Quality 4.0 Conceptualisation and Theoretical Understanding: A Global Exploratory Qualitative Study. TQM J. 2021. ahead-of-print. [Google Scholar]

- Yadav, N.; Shankar, R.; Singh, S.P. Critical Success Factors for Lean Six Sigma in Quality 4.0. Int. J. Qual. Serv. Sci. 2021, 13, 123–156. [Google Scholar] [CrossRef]

- Javaid, M.; Haleem, A.; Singh, R.P.; Suman, R. Significance of Quality 4.0 towards comprehensive enhancement in manufacturing sector. Sens. Int. 2021, 2, 100109. [Google Scholar] [CrossRef]

- Elibal, K.; Özceylan, E. Comparing industry 4.0 maturity models in the perspective of TQM principles using Fuzzy MCDM methods. Technol. Forecast. Soc. Change 2021, 175, 121379. [Google Scholar] [CrossRef]

- Glogovac, M.; Ruso, J.; Maricic, M. ISO 9004 maturity model for quality in industry 4.0. Total Qual. Manag. Bus. Excel. 2020, 33, 529–547. [Google Scholar] [CrossRef]

- Manz, C.C.; Stewart, G.L. Attaining Flexible Stability by Integrating Total Quality Management and Socio-Technical Systems Theory. Organ. Sci. 1997, 8, 59–70. [Google Scholar] [CrossRef]

- Ćwiklicki, M.; Wojnarowska, M. Circular economy and industry 4.0: One-way or two-way relationships? Eng. Econ. 2020, 31, 387–397. [Google Scholar] [CrossRef]

- Bag, S.; Pretorius, J.H.C.; Gupta, S.; Dwivedi, Y.K. Role of institutional pressures and resources in the adoption of big data analytics powered artificial intelligence, sustainable manufacturing practices and circular economy capabilities. Technol. Forecast. Soc. Change 2021, 163, 120420. [Google Scholar] [CrossRef]

- Sahu, A.; Agrawa, S.; Kumar, G. Integrating Industry 4.0 and circular economy: A review. J. Enterp. Inf. Manag. 2021, 35, 3. [Google Scholar] [CrossRef]

- Kumar, P.; Singh, R.K.; Kumar, V. Managing supply chains for sustainable operations in the era of industry 4.0 and circular economy: Analysis of barriers. Resour. Conserv. Recycl. 2021, 164, 105215. [Google Scholar] [CrossRef]

- Khan, S.A.R.; Razzaq, A.; Yu, Z.; Miller, S. Industry 4.0 and circular economy practices: A new era business strategies for environmental sustainability. Bus. Strategy Environ. 2021, 30, 4001–4014. [Google Scholar] [CrossRef]

- Cezarino, L.O.; Liboni, L.B.; Stefanelli, N.O.; Oliveira, B.G.; Stocco, L.C. Diving into emerging economies bottleneck: Industry 4.0 and implications for circular economy. Manag. Decis. 2019, 59, 1841–1862. [Google Scholar] [CrossRef]

- Wernerfelt, B. A resource-based view of the firm. Strateg. Manag. J. 1984, 5, 171–180. [Google Scholar] [CrossRef]

- Barney, J. Firm resources and sustained competitive advantage. J. Manag. 1991, 17, 99–120. [Google Scholar] [CrossRef]

- Jakhar, S.K.; Mangla, S.K.; Luthra, S.; Sarpong, S.K. When stakeholder pressure drives the circular economy: Measuring the mediating role of innovation capabilities. Manag. Decis. 2018, 57, 4. [Google Scholar] [CrossRef]

- Dubey, R.; Gunasekaran, A.; Childe, S.J.; Blome, C.; Papadopoulos, T. Big data and predictive analytics and manufacturing performance: Integrating institutional theory, resource-based view and big data culture. Br. J. Manag. 2019, 30, 341–361. [Google Scholar] [CrossRef]

- Grant, R.M. The resource-based theory of competitive advantage: Implications for strategy formulation. Calif. Manag. Rev. 1991, 33, 114–135. [Google Scholar] [CrossRef]

- Črešnar, R.; Potočan, V.; Nedelko, Z. Speeding up the Implementation of Industry 4.0 with Management Tools: Empirical Investigations in Manufacturing Organizations. Sensors 2020, 20, 3469. [Google Scholar] [CrossRef] [PubMed]

- Stentoft, J.; Wickstrøm, K.A.; Philipsen, K.; Haug, A. Drivers and Barriers for Industry 4.0 Readiness and Practice: Empirical Evidence from Small and Medium-Sized Manufacturers. Prod. Plan. Control. 2021, 32, 811–828. [Google Scholar] [CrossRef]

- Kamasak, R. The contribution of tangible and intangible resources, and capabilities to a firm’s profitability and market performance. Eur. J. Manag. Bus. Econ. 2017, 26, 2. [Google Scholar] [CrossRef]

- Jerman, A.; Bach, M.P.; Aleksić, A. Transformation towards smart factory system: Examining new job profiles and competencies. Syst. Res. Behav. Sci. 2020, 37, 388–402. [Google Scholar] [CrossRef]

- Torrent-Sellens, J.; Ficapal-Cusí, P.; Enache-Zegheru, M. Boosting environmental management: The mediating role of Industry 4.0 between environmental assets and economic and social firm performance. Bus. Strategy Environ. 2022, online. [Google Scholar] [CrossRef]

- Khan, B.A.; Naeem, H. Measuring the Impact of Soft and Hard Quality Practices on Service Innovation and Organisational Performance. Total Qual. Manag. Bus. Excell. 2016, 29, 1402–1426. [Google Scholar] [CrossRef]

- Nasaj, M.I.; Al Marri, K. The Influence of Soft and Hard Quality Management on Innovation Performance in UAE Service Sector. In Proceedings of the II International Triple Helix Summit, Cape Town, South Africa, 9–11 September 2019; Springer: Berlin/Heidelberg, Germany, 2019; pp. 307–321. [Google Scholar] [CrossRef]

- Dubey, R.; Gunasekaran, A. Exploring Soft Tqm Dimensions and Their Impact on Firm Performance: Some Exploratory Empirical Results. Int. J. Prod. Res. 2014, 53, 371–382. [Google Scholar] [CrossRef]

- Ali, K.; Johl, S.K. Entrepreneurial Competencies Needed to Improve Innovation Performance in Industry 4.0: An Artificial Neural Network Approach; CRC Press: Boca Raton, FL, USA, 2022; pp. 1–19. [Google Scholar] [CrossRef]

- Mittal, S.; Khan, M.A.; Romero, D.; Wuest, T. A Critical Review of Smart Manufacturing & Industry 4.0 Maturity Models: Implications for Small and Medium-Sized Enterprises (Smes). J. Manuf. Syst. 2018, 49, 194–214. [Google Scholar]

- Massaro, M.; Secinaro, S.; Mas, F.D.; Brescia, V.; Calandra, D. Industry 4.0 and circular economy: An exploratory analysis of academic and practitioners’ perspectives. Bus. Strategy Environ. 2021, 30, 1213–1231. [Google Scholar] [CrossRef]

- Nascimento, G.L.D.; Lizarelli, F.L.; Rosa, A.R.; Boer, H. The Impact of Quality Management Practices on Innovation: An Empirical Research Study of Brazilian Manufacturing Companies. Benchmarking Int. J. 2020, 28, 1059–1082. [Google Scholar]

- Jayashree, S.; Reza, M.N.H.; Malarvizhi, C.A.N.; Mohiuddin, M. Industry 4.0 implementation and Triple Bottom Line sustainability: An empirical study on small and medium manufacturing firms. Heliyon 2021, 7, e07753. [Google Scholar] [CrossRef] [PubMed]

- Rimalini, G.; Sarkar, B.; Gadekar, A. Investigating the relationship among Industry 4.0 drivers, adoption, risks reduction, and sustainable organizational performance in manufacturing industries: An empirical study. Sustain. Prod. Consum. 2022, 31, 670–692. [Google Scholar]

- Jayashree, S.; Reza, M.N.H.; Malarvizhi, C.A.N.; Gunasekaran, A.; Rauf, A. Testing an adoption model for Industry 4.0 and sustainability: A Malaysian scenario. Sustain. Prod. Consum. 2022, 31, 313–330. [Google Scholar] [CrossRef]

- Wright, K.B. Researching Internet-based populations: Advantages and disadvantages of online survey research, online questionnaire authoring software packages, and web survey services. J. Comput.-Mediat. Commun. 2005, 10, JCMC1034. [Google Scholar] [CrossRef]

- Tanner, K. Chapter 6–Survey Designs. In Research Methods, 2nd ed.; Williamson, K., Johanson, G., Eds.; Chandos Publishing: Amsterdam, The Netherlands, 2018; pp. 159–192. [Google Scholar]

- SME Corporation Malaysia. Guideline for SME Definition. National Entrepreneur and SME Development Council, Jan. 2013. Available online: www.smecorp.gov.my/images/pdf/2022/Guideline_on_SME_Definition_Updated_September_2020_Final.pdf (accessed on 9 October 2022).

- Sila, I. Investigating Changes in Tqm’s Effects on Corporate Social Performance and Financial Performance over Time. Total Qual. Manag. Bus. Excell. 2018, 31, 210–229. [Google Scholar] [CrossRef]

- Darren, G.; Mallery, P. Spss for Windows Step by Step: A Simple Guide and Reference 17.0 Update, 10th ed.; Pearson: Boston, MA, USA, 2010. [Google Scholar]

- Podsakoff, N.P. Common Method Biases in Behavioral Research: A Critical Review of the Literature and Recommended Remedies. J. Appl. Psychol. 2003, 88, 879. [Google Scholar] [CrossRef]

- Ned, K.; Lynn, G. Lateral Collinearity and Misleading Results in Variance-Based Sem: An Illustration and Recommendations. J. Assoc. Inf. Syst. 2012, 13, 7. [Google Scholar]

- Kock, N. Common Method Bias in Pls-Sem: A Full Collinearity Assessment Approach. Int. J. e-Collab. 2015, 11, 1–10. [Google Scholar] [CrossRef]

- Hair, J.F.; Page, M.; Brunsveld, N. Essentials of Business Research Methods; Routledge: Oxfordshire, UK, 2019. [Google Scholar]

- Hair, J.F.; Black, W.C.; Babin, B.J.; Anderson, R.E. Multivariate Data Analysis, 7th ed.; Prentice Hall: Upper Saddle River, NJ, USA, 2010. [Google Scholar]

- Hair, J.F.; Sarstedt, M.; Ringle, C.M. Rethinking Some of the Rethinking of Partial Least Squares. Eur. J. Mark. 2019, 53, 566–584. [Google Scholar] [CrossRef]

- Jörg, H.; Ringle, C.M.; Sarstedt, M. Testing Measurement Invariance of Composites Using Partial Least Squares. Int. Mark. Rev. 2016, 33, 405–431. [Google Scholar]

- Ali, R.F.; Dominic, P.D.D.; Ali, K. Organizational Governance, Social Bonds and Information Security Policy Compliance: A Perspective towards Oil and Gas Employees. Sustainability 2020, 12, 8576. [Google Scholar] [CrossRef]

- Sarstedt, M.; Hair, J.F.; Cheah, J.H.; Becker, J.; Ringle, C.M. How to specify, estimate, and validate higher-order constructs in PLS-SEM. Australas. Mark. J. 2019, 27, 197–211. [Google Scholar] [CrossRef]

- Rasoolimanesh, S.M.; Wang, M.; Roldán, J.L.; Kunasekaran, P. Are we in right path for mediation analysis? Reviewing the literature and proposing robust guidelines. J. Hosp. Tour. Manag. 2021, 48, 395–405. [Google Scholar] [CrossRef]

- Carrión, G.C.; Henseler, J.; Ringle, C.M.; Roldán, J.L. Prediction-oriented modeling in business research by means of PLS path modeling: Introduction to a JBR special section. J. Bus. Res. 2016, 69, 4545–4551. [Google Scholar] [CrossRef]

- Christian, N.; Roldan, J.L.; Cepeda, G. Mediation analysis in partial least squares path modeling: Helping researchers discuss more sophisticated models. Ind. Manag. Data Syst. 2016, 116, 9. [Google Scholar]

- Jacob, C. Statistical Power Analysis for the Behavioral Sciences; Lawrence Erlbaum Associates: Hillsdale, NJ, USA, 1988; pp. 20–26. [Google Scholar]

- Francisco, L.C.; Marinković, V.; Kalinić, Z. A Sem-Neural Network Approach for Predicting Antecedents of M-Commerce Acceptance. Int. J. Inf. Manag. 2017, 37, 14–24. [Google Scholar]

- Wan, W.L.; Leong, L.Y.; Hew, J.J.; Tan, G.W.H.; Ooi, K.B. Time to Seize the Digital Evolution: Adoption of Blockchain in Operations and Supply Chain Management among Malaysian Smes. Int. J. Inf. Manag. 2020, 52, 101997. [Google Scholar]

- Sawe, F.B.; Kumar, A.; Garza-Reyes, J.A.; Agrawal, R. Assessing people-driven factors for circular economy practices in small and medium-sized enterprise supply chains: Business strategies and environmental perspectives. Bus. Strat. Environ. 2021, 30, 2951–2965. [Google Scholar] [CrossRef]

- Jabbour, C.J.C.; Sarkis, J.; Jabbour, A.B.L.D.S.; Renwick, D.W.S.; Singh, S.K.; Grebinevych, O.; Kruglianskas, I.; Filho, M.G. Who is in charge? A review and a research agenda on the ‘human side’ of the circular economy. J. Clean. Prod. 2019, 222, 793–801. [Google Scholar] [CrossRef]

- Chowdhury, S.; Dey, P.K.; Rodríguez-Espíndola, O.; Parkes, G.; Tuyet, N.T.A.; Long, D.D.; Ha, T.P. Impact of Organisational Factors on the Circular Economy Practices and Sustainable Performance of Small and Medium-sized Enterprises in Vietnam. J. Bus. Res. 2022, 147, 362–378. [Google Scholar] [CrossRef]

- Saurabh, K.; Bhatia, M.S. Environmental dynamism, industry 4.0 and performance: Mediating role of organizational and technological factors. Ind. Mark. Manag. 2021, 95, 54–64. [Google Scholar]

- Kaswan, M.S.; Rathi, R.; Reyes, J.A.G.; Antony, J. Exploration and investigation of green lean six sigma adoption barriers for manufacturing sustainability. IEEE Trans. Eng. Manag. 2021, 1–15. [Google Scholar] [CrossRef]

- Kaswan, M.S.; Rathi, R.; Garza-Reyes, J.A.; Antony, J. Green lean six sigma sustainability–oriented project selection and implementation framework for manufacturing industry. Int. J. Lean Six Sigma 2022. ahead-of-print. [Google Scholar]

- Rathi, R.; Sabale, D.B.; Antony, J.; Kaswan, M.S.; Jayaraman, R. An Analysis of Circular Economy Deployment in Developing Nations’ Manufacturing Sector: A Systematic State-of-the-Art Review. Sustainability 2022, 14, 11354. [Google Scholar] [CrossRef]

- Rathi, R.; Kaswan, M.S.; Garza-Reyes, J.A.; Antony, J.; Cross, J. Green Lean Six Sigma for improving manufacturing sustainability: Framework development and validation. J. Clean. Prod. 2022, 345, 131130. [Google Scholar] [CrossRef]

- Ali, R.F.; Dominic, P.D.D.; Ali, S.E.A.; Rehman, M.; Sohail, A. Information Security Behavior and Information Security Policy Compliance: A Systematic Literature Review for Identifying the Transformation Process from Noncompliance to Compliance. Appl. Sci. 2021, 11, 3383. [Google Scholar] [CrossRef]

- Dong, K.; Ali, R.F.; Dominic, P.D.D.; Ali, S.E.A. The Effect of Organizational Information Security Climate on Information Security Policy Compliance: The Mediating Effect of Social Bonding towards Healthcare Nurses. Sustainability 2021, 13, 2800. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).