The Flexural Performance of BFRP-Reinforced UHPC Beams Compared to Steel and GFRP-Reinforced Beams

Abstract

1. Introduction

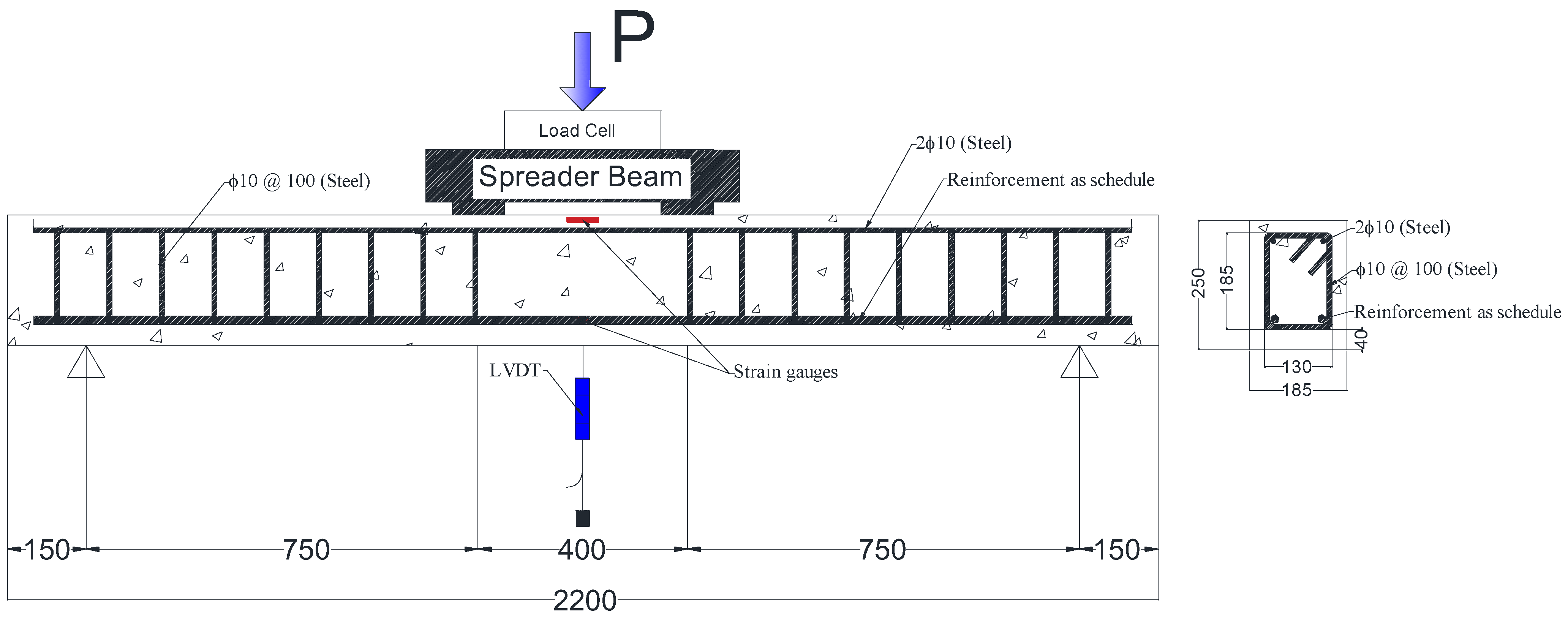

2. Materials and Methods

3. Experimental Results

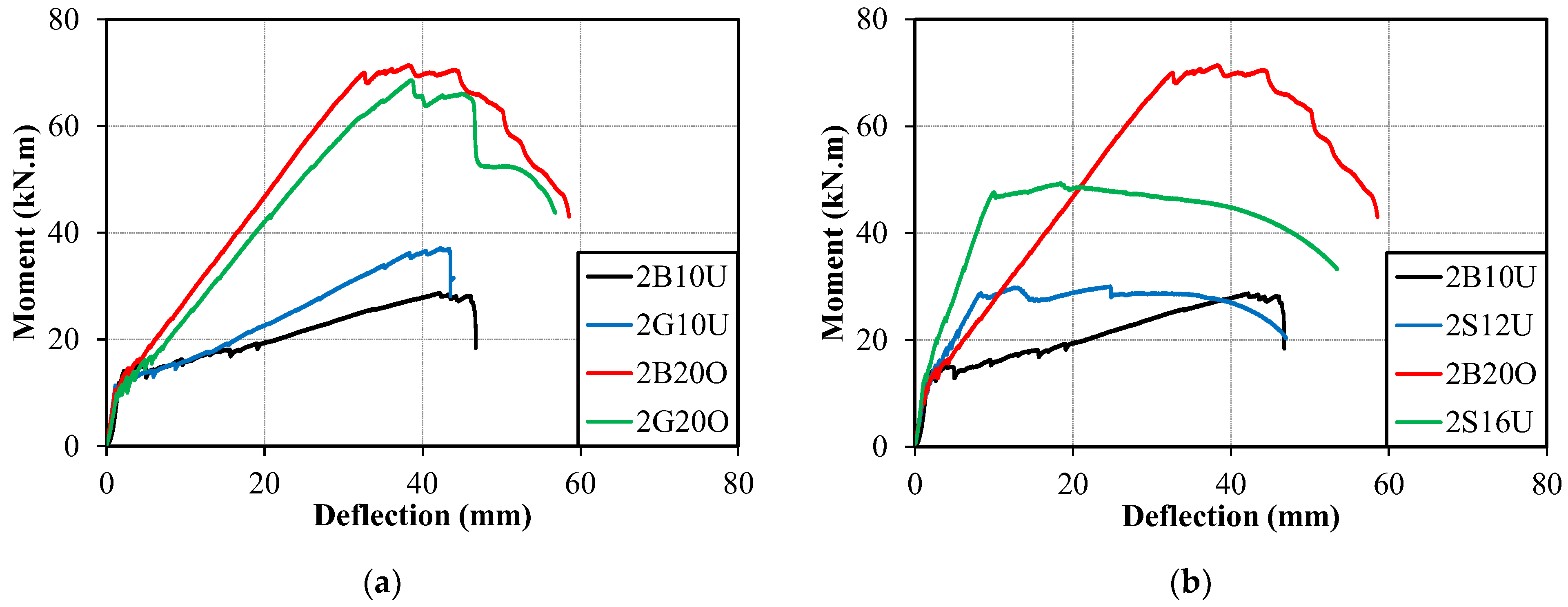

3.1. Moment vs. Deflection Relationship

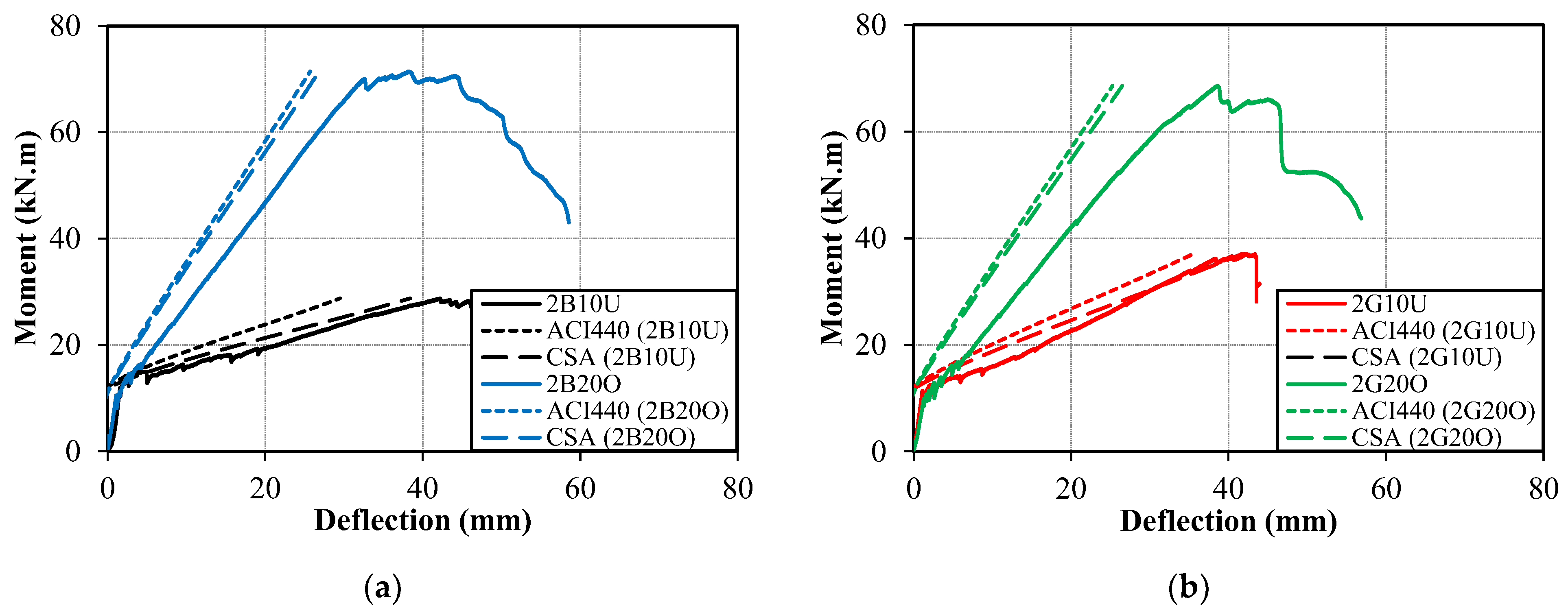

3.1.1. BFRP vs. GFRP-Reinforced Beams

3.1.2. BFRP vs. Steel Reinforced Beams

3.2. Moment-Strain Relationship

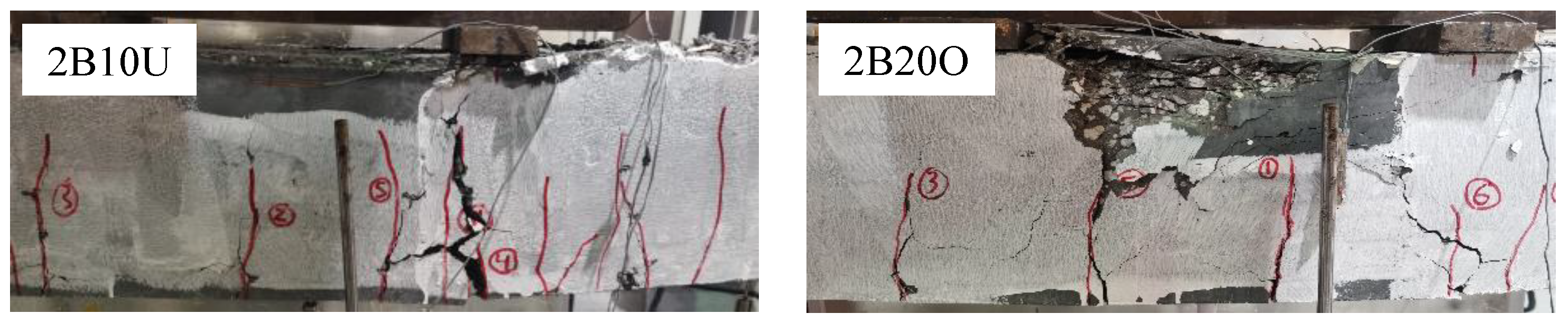

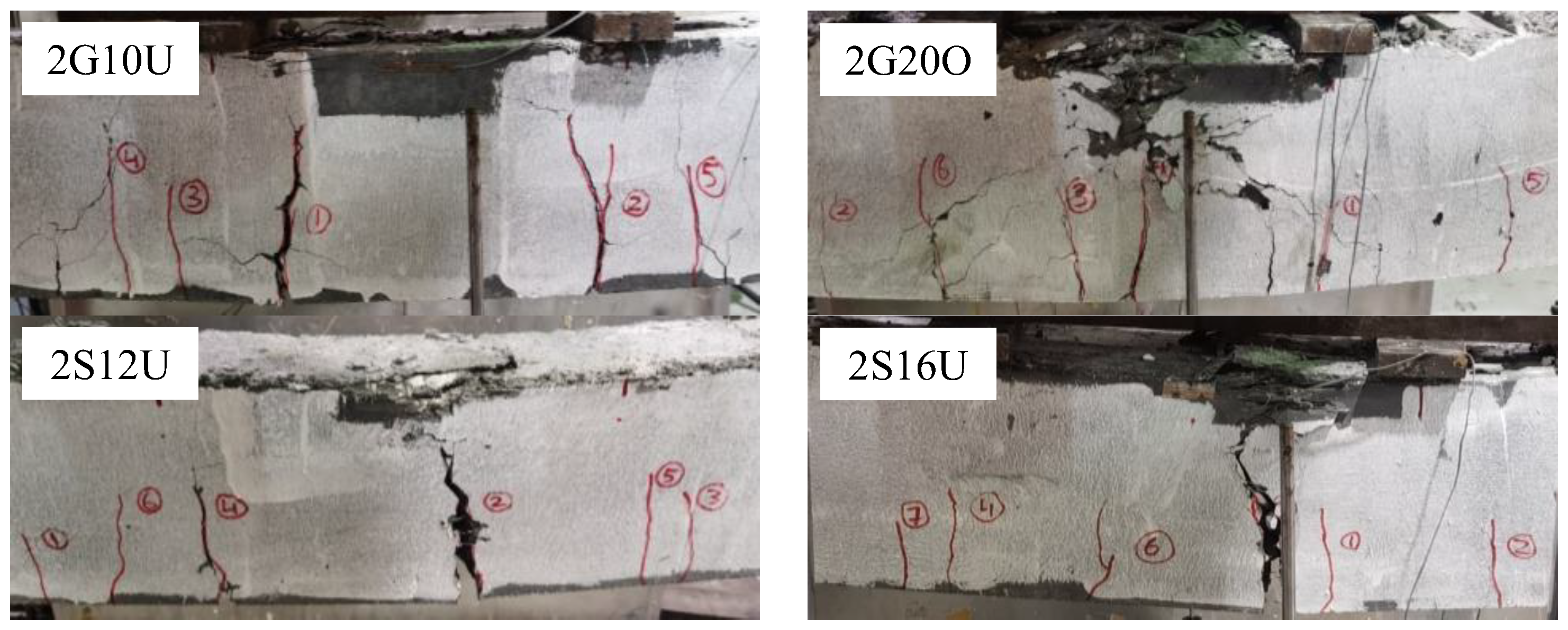

3.3. Failure Modes

4. Analytical Results

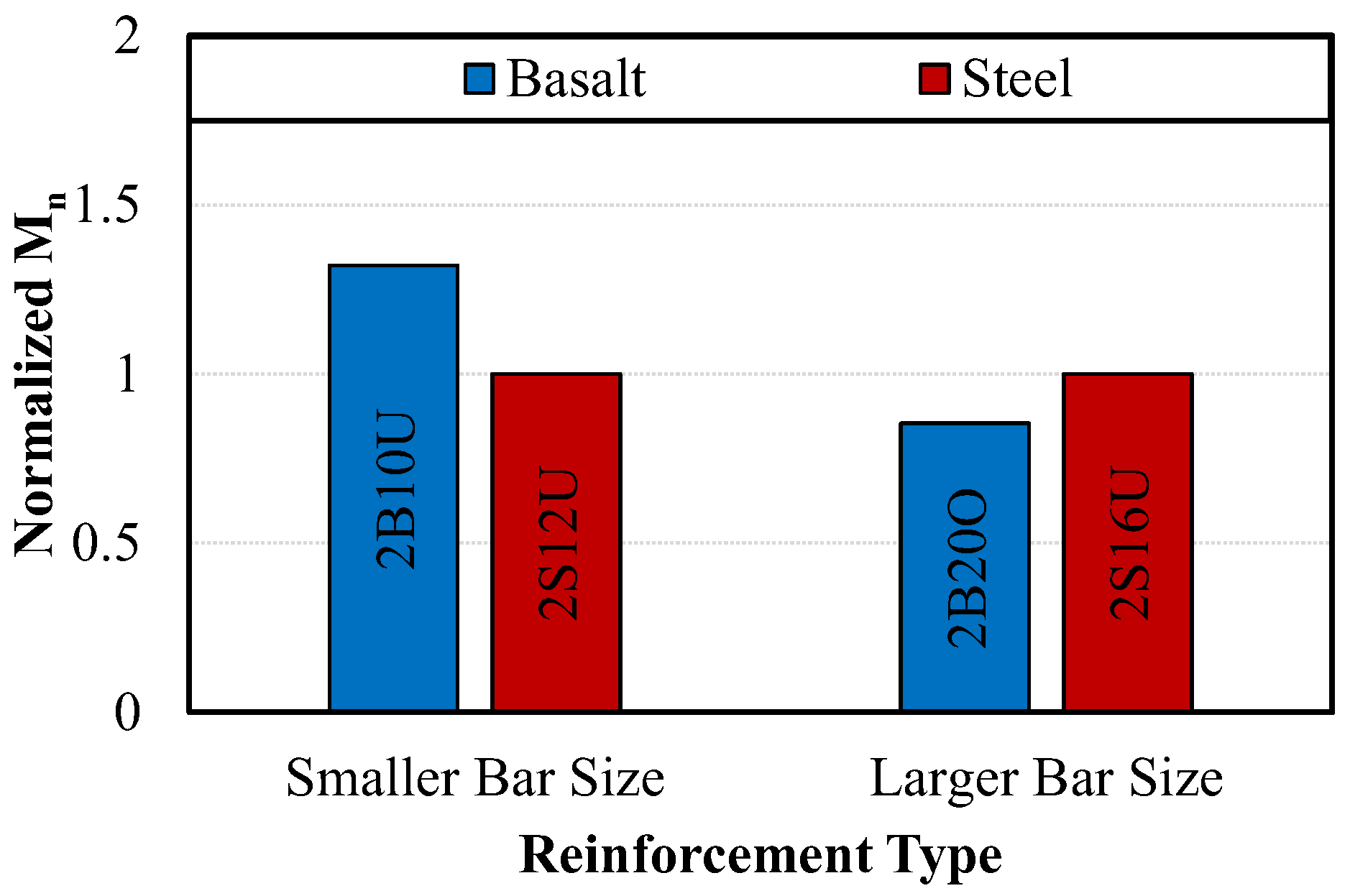

4.1. Flexural Capacity

4.2. Deflection

5. Conclusions

- The UHPC beams reinforced with BFRP bars exhibited a typical bilinear behavior between the moment and deflections/strains. The overall behavior of BFRP-reinforced beams was very similar to that of the GFRP-reinforced beams. Once the cracking moment was exceeded, the BFRP- and GFRP-reinforced beams experienced a reduction in the bending stiffness, which was governed by the modulus of elasticity and amount of the reinforcement. On the other hand, steel-reinforced beams experienced a gradual reduction in stiffness until yielding.

- For lower reinforcement ratios, the UHPC beams reinforced with BFRP bars reported a 23% decrease in the flexural capacity compared to the GFRP-reinforced beams, while a 4% increase in flexural capacity was recorded by the BFRP-reinforced beams over the GFRP-reinforced beams when a larger reinforcement ratio was utilized.

- Based on normalized results with respect to reinforcement ratio between BFRP- and steel-reinforced beams, a clear dominance can be seen in favor of the BFRP-reinforced beams. This is attributed to the higher tensile strength of the BFRP reinforcement as compared to the yield strength of the steel. However, when a higher reinforcement ratio is used the BFRP-reinforced beam was defined by concrete failure and had a slightly lower moment capacity than the steel-reinforced beam.

- The observed mode of failure of all beams followed the behavior of the beams as designed, in which over-reinforced beams failed by concrete crushing and under-reinforced beams failed by FRP rupture or steel yielding. Relying on concrete crushing of over-reinforced FRP beams resulted in an enhanced ductility of the UHPC beams. On the other hand, the under-reinforced FRP beams exhibited a linear moment-deflection curve until failure, which was brittle as a result of the rupture of FRP reinforcement.

- Relying on concrete having high compressive strength resulted in better utilization of the FRP reinforcement, as evidenced by the utilized strain in the longitudinal FRP reinforcement. The strain values ranged between 1.8 and 2.2% when the ultimate load of the beams was reached, which corresponds to 70–85% of the ultimate strain of FRP bars.

- Overall, the ACI 440.1R code equations reasonably predicted the nominal flexural capacity of BFRP-reinforced beams. In addition, both the ACI 440.1R and CSA S806 well predicted the cracking moments of the UHPC beams.

- On average, the CSA S806 estimated the deflection values of the UHPC BFRP-reinforced beams better than the ACI 440.1R. However, the midspan deflection was significantly under-estimated by both codes when compared to the actual experimental values. This shows that the ACI 440.1R and CSA S806 formulations for the midspan deflection of UHPC beams need further improvement.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hammond, G.P.; Jones, C.I. Embodied energy and carbon in construction materials. Proc. Inst. Civ. Eng. Energy 2008, 161, 87–98. [Google Scholar] [CrossRef]

- Purnell, P. The carbon footprint of reinforced concrete. Adv. Cem. Res. 2013, 25, 362–368. [Google Scholar] [CrossRef]

- ACI Committee 440. Guide for the Design and Construction of Structural Concrete Reinforced with Fiber-Reinforced Polymer (FRP) Bars; ACI 440.1R-15; American Concrete Institute: Farmington Hills, MI, USA, 2015. [Google Scholar]

- Canadian Standard Association. Design and Construction of Building Structures with Fibre-Reinforced Polymers; CSA-S806-12; CSA: Mississauga, ON, Canada, 2012. [Google Scholar]

- El-Nemr, B.A.; Ahmed, E.A.; Benmokrane, B. Flexural Behavior and Serviceability of Normal- and High-Strength Concrete Beams Reinforced with Glass Fiber-Reinforced Polymer Bars. ACI Struct. J. 2013, 110. [Google Scholar] [CrossRef]

- Abdelkarim, O.I.; Ahmed, E.A.; Mohamed, H.M.; Benmokrane, B. Flexural strength and serviceability evaluation of concrete beams reinforced with deformed GFRP bars. Eng. Struct. 2019, 186, 282–296. [Google Scholar] [CrossRef]

- El-Nemr, A.; Ahmed, E.A.; El-Safty, A.; Benmokrane, B. Evaluation of the flexural strength and serviceability of concrete beams reinforced with different types of GFRP bars. Eng. Struct. 2018, 173, 606–619. [Google Scholar] [CrossRef]

- Abed, F.; Alhafiz, A.R. Effect of basalt fibers on the flexural behavior of concrete beams reinforced with BFRP bars. Compos. Struct. 2019, 215, 23–34. [Google Scholar] [CrossRef]

- Alkhraisha, H.; Mhanna, H.; Tello, N.; Abed, F. Serviceability and Flexural Behavior of Concrete Beams Reinforced with Basalt Fiber-Reinforced Polymer (BFRP) Bars Exposed to Harsh Conditions. Polymers 2020, 12, 2110. [Google Scholar] [CrossRef]

- Adam, M.; Said, M.; Mahmoud, A.A.; Shanour, A.S. Analytical and experimental flexural behavior of concrete beams reinforced with glass fiber reinforced polymers bars. Constr. Build. Mater. 2015, 84, 354–366. [Google Scholar] [CrossRef]

- Abed, F.; Al-Mimar, M.; Ahmed, S. Performance of BFRP RC beams using high strength concrete. Compos. Part C Open Access 2021, 4, 100107. [Google Scholar] [CrossRef]

- Xie, Y.; Zhuo, K.; Rashid, K.; Deng, J.; Zhang, F. Flexural Performance of BFRP Bar Reinforced High-Strength Concrete Beam. In Proceedings of the International Conference on Fibre-Reinforced Polymer (FRP) Composites in Civil Engineering, Istanbul, Turkey, 8–10 December 2021; pp. 111–120. [Google Scholar]

- Rashid, M.A.; Mansur, M.A.; Paramasivam, P. Behavior of Aramid Fiber-Reinforced Polymer Reinforced High Strength Concrete Beams under Bending. J. Compos. Constr. 2005, 9, 117–127. [Google Scholar] [CrossRef]

- Erfan, A.M.; Hassan, H.E.; Hatab, K.M.; El-Sayed, T.A. The flexural behavior of nano concrete and high strength concrete using GFRP. Constr. Build. Mater. 2020, 247, 118664. [Google Scholar] [CrossRef]

- El Refai, A.; Abed, F. Concrete Contribution to Shear Strength of Beams Reinforced with Basalt Fiber-Reinforced Bars. J. Compos. Constr. 2016, 20. [Google Scholar] [CrossRef]

- Abed, F.; Sabbagh, M.K.; Karzad, A.S. Effect of basalt microfibers on the shear response of short concrete beams reinforced with BFRP bars. Compos. Struct. 2021, 269, 114029. [Google Scholar] [CrossRef]

- Abed, F.; El Refai, A.; Abdalla, S. Experimental and finite element investigation of the shear performance of BFRP-RC short beams. Structures 2019, 20, 689–701. [Google Scholar] [CrossRef]

- Al-Hamrani, A.; Alnahhal, W.; Elahtem, A. Shear behavior of green concrete beams reinforced with basalt FRP bars and stirrups. Compos. Struct. 2021, 277, 114619. [Google Scholar] [CrossRef]

- Al-Hamrani, A.; Alnahhal, W. Shear behavior of basalt FRC beams reinforced with basalt FRP bars and glass FRP stirrups: Experimental and analytical investigations. Eng. Struct. 2021, 242, 112612. [Google Scholar] [CrossRef]

- Yoo, D.-Y.; Banthia, N.; Yoon, Y.-S. Predicting service deflection of ultra-high-performance fiber-reinforced concrete beams reinforced with GFRP bars. Compos. Part B Eng. 2016, 99, 381–397. [Google Scholar] [CrossRef]

- Abbas, E.M.; Ge, Y.; Zhang, Z.; Chen, Y.; Ashour, A.; Ge, W.; Tang, R.; Yang, Z.; Khailah, E.Y.; Yao, S.; et al. Flexural behavior of UHPC beam reinforced with steel-FRP composite bars. Case Stud. Constr. Mater. 2022, 16, e01110. [Google Scholar] [CrossRef]

- Goldston, M.; Remennikov, A.; Sheikh, M.N. Flexural behaviour of GFRP-reinforced high strength and ultra high strength concrete beams. Constr. Build. Mater. 2017, 131, 606–617. [Google Scholar] [CrossRef]

- Zhao, J.; Pan, H.; Wang, Z.; Li, G. Experimental and Theoretical Study on Flexural Behavior of GFRP- and CFRP-Reinforced Concrete Beams after High-Temperature Exposure. Polymers 2022, 14, 4002. [Google Scholar] [CrossRef] [PubMed]

- Abed, M.A.; Anagreh, A.; Tošić, N.; Alkhabbaz, O.; Alshwaiki, M.E.; Černý, R. Structural Performance of Lightweight Aggregate Concrete Reinforced by Glass or Basalt Fiber Reinforced Polymer Bars. Polymers 2022, 14, 2142. [Google Scholar] [CrossRef] [PubMed]

- Al Rifai, M.; El-Hassan, H.; El-Maaddawy, T.; Abed, F. Durability of basalt FRP reinforcing bars in alkaline solution and moist concrete environments. Constr. Build. Mater. 2020, 243, 118258. [Google Scholar] [CrossRef]

- ACI 318 Committee. Building Code Requirements for Structural Concrete and Commentary, 1st ed.; American Concrete Institute: Farmington Hills, MI, USA, 2019. [Google Scholar]

| Beam ID | Bar Type | Bar Diameter (mm) | ρf (%) | ρf/ρfb |

|---|---|---|---|---|

| 2B10U | BFRP | 10 | 0.42 | 0.66 |

| 2B20O | BFRP | 20 | 1.78 | 2.07 |

| 2G10U | GFRP | 10 | 0.50 | 0.65 |

| 2G20O | GFRP | 20 | 1.76 | 1.53 |

| 2S12U | Steel | 12 | 0.58 | 0.11 |

| 2S16U | Steel | 16 | 1.05 | 0.19 |

| Bar Type | Bar Diameter (mm) | Bar Area (mm2) | Ultimate Strength (MPa) | Modulus of Elasticity (GPa) | Photo |

|---|---|---|---|---|---|

| BFRP | 10 | 80.1 | 1028.7 | 42.8 |  |

| BFRP | 20 | 328.1 | 913 | 45.9 |  |

| GFRP | 10 | 94.1 | 960 | 43.1 |  |

| GFRP | 20 | 325.3 | 779 | 46.1 |  |

| Steel | 12 | 110.3 * | 575 | 200 |  |

| Steel | 16 | 195.8 * | 568 | 200 |  |

| Material | Proportion |

|---|---|

| Cement | 700 kg/m3 |

| Water | 140 kg/m3 |

| 20 mm aggregate | 560 kg/m3 |

| 10 mm aggregate | 365 kg/m3 |

| Washed sand | 450 kg/m3 |

| Dune sand | 305 kg/m3 |

| Micro silica | 150 kg/m3 |

| Superplasticizer | 10 l/m3 |

| Beam | Experimental | Experimental/Predicted | Failure Mode | ||||

|---|---|---|---|---|---|---|---|

| Mn (kN·m) | δ (mm) | Mcr (kN·m) | Mcr (ACI) | Mcr (CSA) | Mn (ACI) | ||

| 2B10U | 28.73 | 46.40 | 11.71 | 0.93 | 0.97 | 0.88 | TC |

| 2B20O | 71.41 | 44.57 | 11.13 | 0.89 | 0.92 | 0.93 | CC |

| 2G10U | 37.12 | 43.32 | 11.43 | 0.91 | 0.94 | 1.05 | TC |

| 2G20O | 68.60 | 46.38 | 10.78 | 0.86 | 0.89 | 0.91 | CC |

| 2S12U | 30.05 | 24.73 | 12.44 | 0.99 | 1.03 | 1.18 | TC |

| 2S16U | 49.37 | 19.06 | 13.49 | 1.08 | 1.11 | 1.13 | TC |

| Average | - | - | - | 0.94 | 0.98 | 1.01 | - |

| Stand. Dev. | - | - | - | 0.07 | 0.07 | 0.11 | - |

| Beam | Measured Deflection (mm) | Predicted Deflection (mm) | |||

|---|---|---|---|---|---|

| ACI 440 | CSA S806 | ACI 440 | CSA S806 | ||

| 2B10U | 43.32 | 35.56 | 41.78 | 1.22 | 1.04 |

| 2B20O | 38.51 | 25.25 | 26.48 | 1.53 | 1.45 |

| 2G10U | 46.40 | 29.48 | 38.39 | 1.57 | 1.21 |

| 2G20O | 38.32 | 25.70 | 26.85 | 1.49 | 1.43 |

| Average | - | - | - | 1.45 | 1.28 |

| Standard Deviation | - | - | - | 0.14 | 0.17 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alhoubi, Y.; Mahaini, Z.; Abed, F. The Flexural Performance of BFRP-Reinforced UHPC Beams Compared to Steel and GFRP-Reinforced Beams. Sustainability 2022, 14, 15139. https://doi.org/10.3390/su142215139

Alhoubi Y, Mahaini Z, Abed F. The Flexural Performance of BFRP-Reinforced UHPC Beams Compared to Steel and GFRP-Reinforced Beams. Sustainability. 2022; 14(22):15139. https://doi.org/10.3390/su142215139

Chicago/Turabian StyleAlhoubi, Yazan, Zin Mahaini, and Farid Abed. 2022. "The Flexural Performance of BFRP-Reinforced UHPC Beams Compared to Steel and GFRP-Reinforced Beams" Sustainability 14, no. 22: 15139. https://doi.org/10.3390/su142215139

APA StyleAlhoubi, Y., Mahaini, Z., & Abed, F. (2022). The Flexural Performance of BFRP-Reinforced UHPC Beams Compared to Steel and GFRP-Reinforced Beams. Sustainability, 14(22), 15139. https://doi.org/10.3390/su142215139