Abstract

In this study, the effect of micro-carbon fiber on the properties of concrete incorporating recycled coarse aggregate at three different levels, i.e., 0%, 50%, and 100% by volume replacement of natural coarse aggregate, was studied. Carbon fiber was incorporated at a dosage of 0.5% by volume fraction. The effect of silica fume or micro-silica on the efficacy of fiber reinforcement was also investigated. Studied parameters include important mechanical properties, such as compressive strength, splitting tensile strength, and flexural strength, and physical/quality parameters such as water absorption capacity and ultrasonic pulse velocity. The results showed that the mechanical and durability performance deteriorates with the increasing percentage of recycled coarse aggregate. Carbon fiber can significantly improve the tensile properties of recycled aggregate concrete. The combination of carbon fiber and silica fume proved to be highly useful in addressing both mechanical and durability concerns simultaneously. Concrete made with 50% recycled coarse aggregate, 8% silica fume, and 0.5% carbon fiber yielded 20% greater tensile and flexural strength compared to the control mix. Likewise, concrete containing 100% recycled coarse aggregate with silica fume and carbon fiber yielded higher tensile strength compared to the control mix. Silica fume ameliorated the bonding between fibers and matrix and improved the overall efficacy of fiber reinforcement.

1. Introduction

As a result of the urbanization and modernization of cities, a large number of existing infrastructures will be renovated, transformed, and/or demolished, causing the generation of a large amount of concrete waste (CW). Re-utilization or eco-friendly consumption of CW is a crucial problem to be addressed to save precious landfilling space and conserve natural resources. Currently, the use of CW is very limited in several countries and commonly used disposal methods include stacking and landfilling, consequently causing hazardous effects on the environment [1]. The effective mitigation of the negative impacts of CW on the environment requires future planning. The use of recycled coarse aggregate (RCA) as construction aggregate can resolve the environmental issues associated with the disposal of CW.

The use of RCA in concrete as a replacement for natural aggregate leads us towards preservation of natural resources, a circular economy, and environmental safety [2]. Various studies have investigated the effect of RCA incorporation levels on the mechanical and durability performance of concrete. Replacement levels of 30–50% of RCA do not noticeably affect the performance of concrete [3]. However, at the 100% replacement level, RCA-incorporating concrete shows a noticeable decline in mechanical and durability performance compared to 100% natural aggregate concrete (NAC) [4,5]. The degree of reduction in the mechanical performance of concrete due to the incorporation of RCA is also the dependent quality of CW. RCA-sourced, high-quality CW (high-strength, high-performance concretes) yields properties comparable to those of natural coarse aggregate (NCA), while low-quality CW (lean concretes, normal-strength concretes, lightweight concretes) yields RCA samples of inferior quality [6].

Mainly, the presence of adhered mortar makes RCA less dense and weaker compared to NCA. Normally, RCA samples comprise 30–35% old cement–sand mortar and 65–70% old natural aggregate. The former is more porous and weaker than the latter; subsequently, the performance of recycled aggregate concrete (RAC) is inferior compared to that of NAC. The drawbacks of RCA use in concrete can be controlled by using additional materials such as secondary binders, chemical admixtures, and fibers [4,7,8,9]. Mineral binders have proven more effective and eco-efficient by far in advancing the mechanical and long-term mechanical performance of RAC [10,11,12]. Silica fume (SF) was found to be more effective compared to other alternative binders (fly ash, ground steel slag, and rice husk ash) in successfully enhancing the compressive strength and splitting tensile strength of RAC [12,13]. Furthermore, with the superior filler effect and pozzolanic react-ability, SF contributes more to the mechanical performance and imperviousness of RAC than other secondary binders [12]. The bonding of porous RCA with the binder matrix is strengthened due to the filler action of SF and chemical reactions between portlandite and SF on the interface of the RCA and the binder [14,15]. SF is a waste or by-product of ferrosilicon alloys and possesses very fine and highly reactive silica; its consumption in concrete would also benefit sustainable development.

Mineral admixtures or secondary binders are used to advance the mechanical strength and durability parameters of concrete [11,16], but they do not contribute a significant change in the flexural or tensile behavior of concrete. The brittleness of plain cement concrete is a pressing issue to be resolved. Therefore, the use of fibers is being encouraged to supplement the tensile strength and post-cracking toughness of plain concrete. With the addition of a small volume fraction of fiber, RAC can yield superior tensile and flexural ductility compared to plain NAC [6,15,17]. Fibers impart special characteristics such as impact resistance, fracture toughness, and fire and freeze–thaw resistance [18,19,20,21]. They improve the tenacity, ductility, and deformability of brittle materials [22]. The efficiency of fiber is dependent on the dosage, shape, and material properties of the fibers. Among all fibers, steel fiber is most commonly used due to its wider availability and high efficiency in plain concrete. However, the use of other non-metallic (basalt, carbon, glass, etc.) and synthetic fibers (polypropylene, polyvinyl, nylon, etc.) is also being encouraged due to their high tensile strength, superior durability, and light weight.

Carbon fibers (CF) have several benefits, e.g., high tensile strength, toughness, high strength-to-weight ratio, good chemical resistance, and low thermal expansion. CF-reinforced concrete can be used for corrosion-resistant construction. The inclusion of CF improves the flexural and splitting tensile strength of high-performance concrete and delays the rupture of plain concrete [23]. The inclusion of CF also provides small improvements in the absorption resistance of concrete [23]. A companion study revealed that incorporation can improve ductility and fire resistance in reactive powder concrete [24]. The available literature implies that CF can be used as a fiber reinforcement to supplement the strength of RAC. However, systematic investigation is still needed to evaluate the engineering performance of CF-reinforced RAC.

The durability benefits of SF and ductility benefits of CF in RAC can be combined by the composite addition of SF and CF. Until now, most research has focused on the use of macro-steel fibers with secondary binders [13,25,26,27]; however, research dealing with the mechanical and durability issues of RAC by combined incorporation of micro-fibers and secondary binders is rare [15]. Thus, this research is devoted to investigating high-strength concrete incorporating RCA, CF, and SF. The aim is to develop sustainable, ductile, durable, and high-performance cementitious composite. For this purpose, high-strength concrete was produced as a control mix. RCA was incorporated at 0%, 50%, and 100% by volume replacement of NCA. With the replacement level of RCA, CF and SF were incorporated at optimum doses to modify the properties of RAC. The mechanical parameters studied in this research include compressive strength—fcm, splitting tensile strength—fct, and flexural strength—fb. To estimate the permeability-related durability, the water absorption (WA) capacity of modified mixes was evaluated. A non-destructive ultrasonic pulse velocity (UPV) test was performed to assess the quality of the concrete. The experimental results of this investigation will benefit the development of ductile, high-strength concrete using sustainable materials in the construction industry.

2. Materials and Methods

2.1. Characteristics of Constituent Materials

2.1.1. Portland Cement and Silica Fume

In the preparation of all mixes, Type I Portland cement was used as the primary binder. The characteristics of this cement meet the standard requirements of ASTM C150 [28]. It is commercially available as 53 Grade Maple Leaf cement in Pakistan.

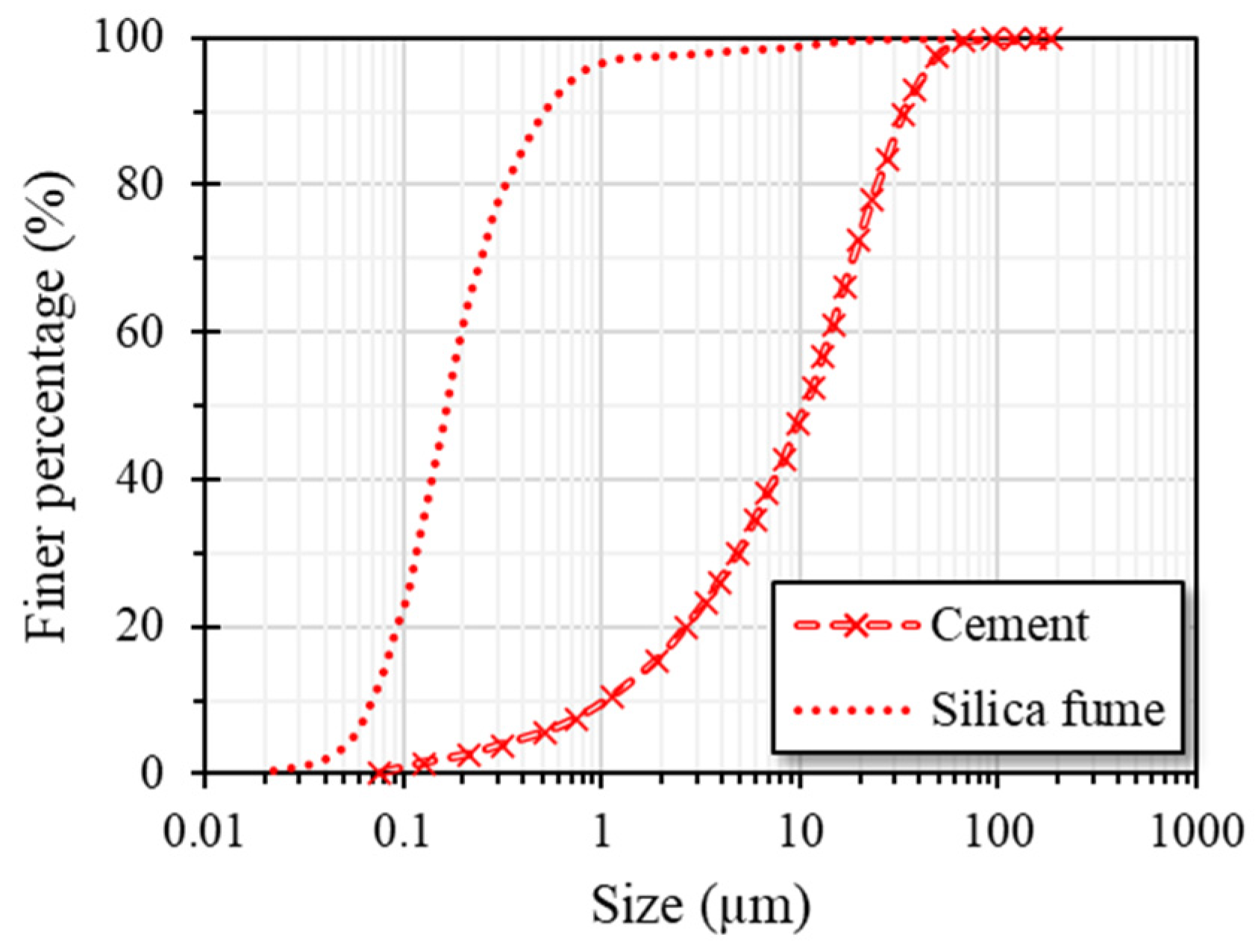

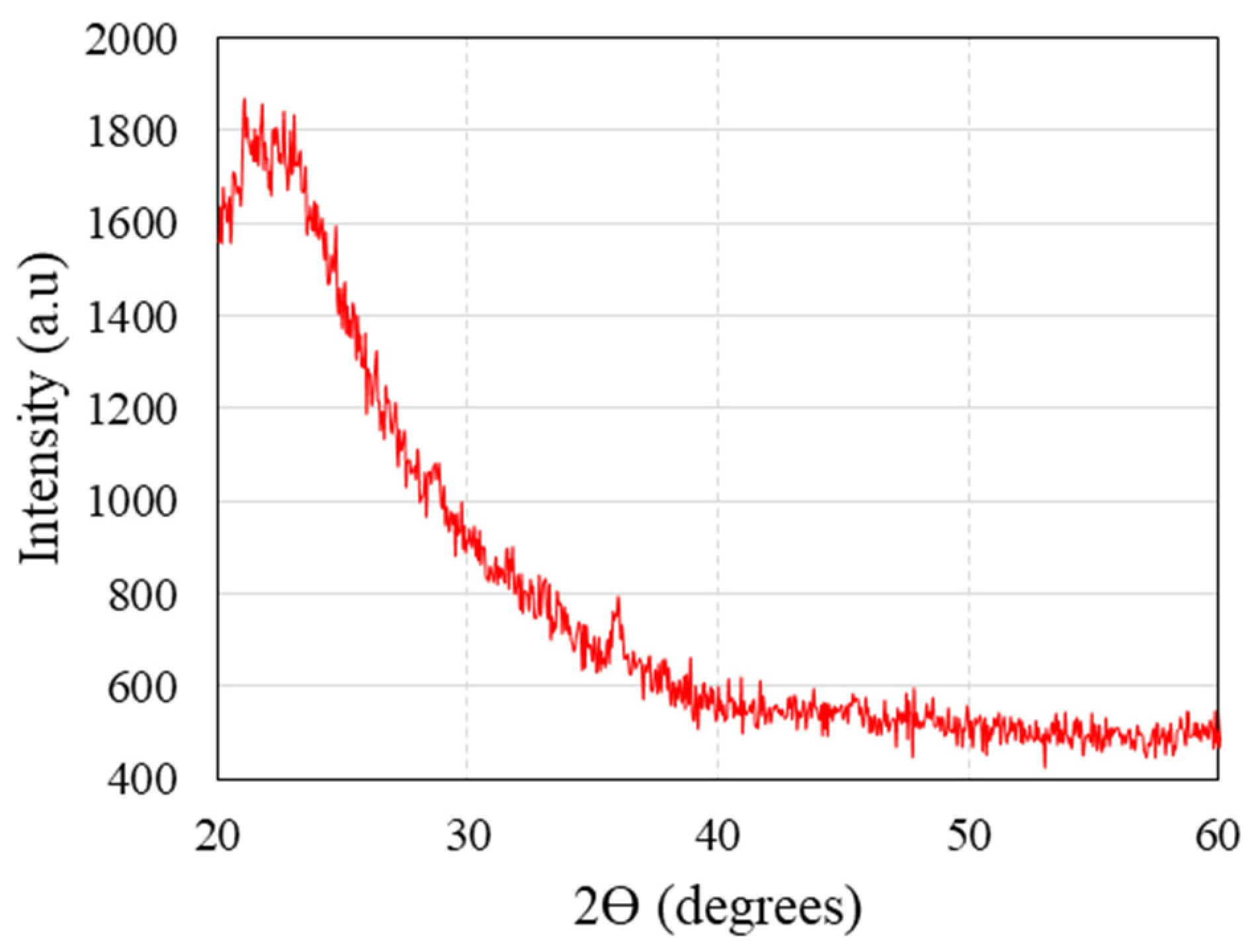

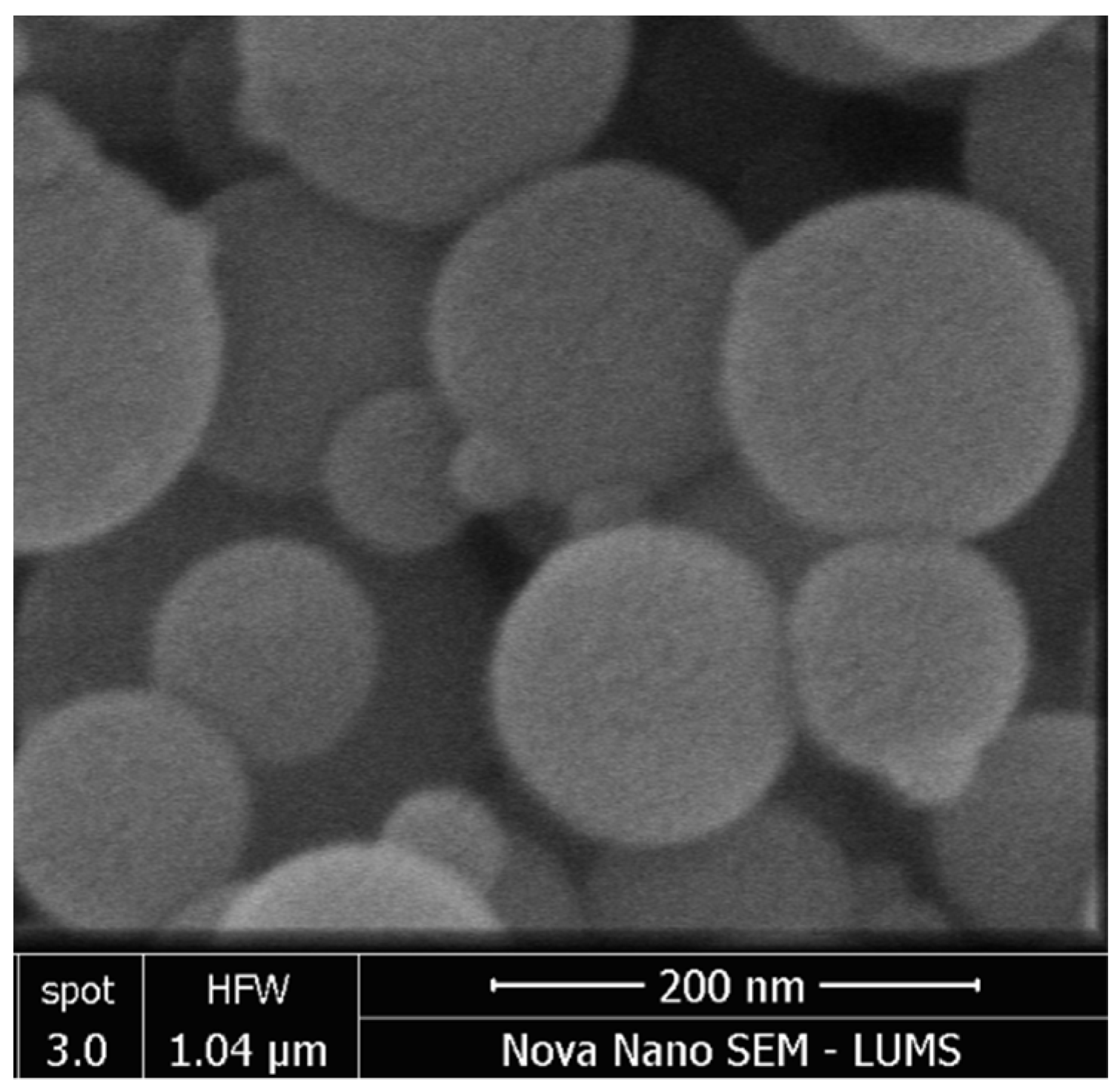

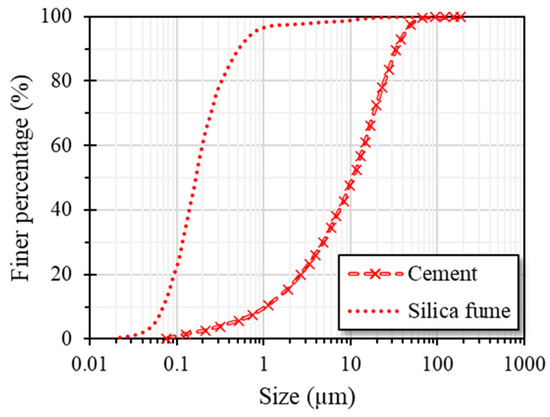

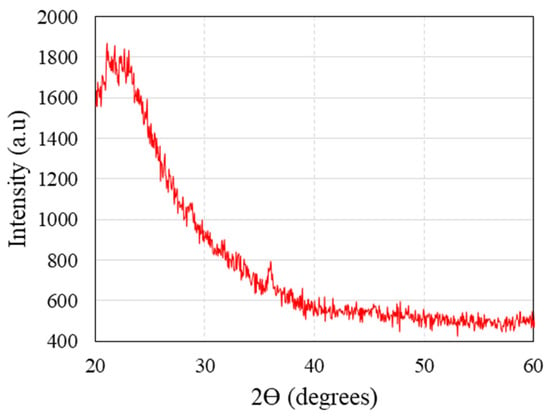

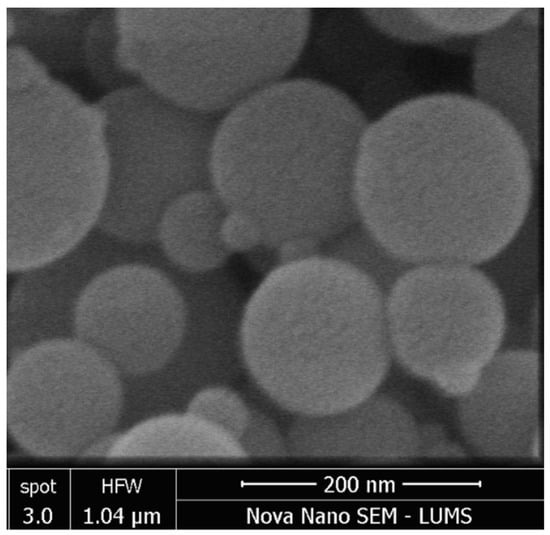

Silica fume (SF) was used as the secondary binder (by partial replacement of the primary binder). It is highly reactive and possesses a superior filling effect due to its specific surface area of around 27,000 m2/kg. SF particles are 70 times finer than Portland cement particles. Particle size distribution of both primary and secondary binders is illustrated in Figure 1. SF is almost entirely composed of silicon dioxide (SiO2). The X-ray diffraction (XRD) results revealed that ultra-fine SF shows an amorphous state, as shown in Figure 2. The XRD diffraction spectrum of the SF sample with the peak at around 2θ = 23° indicates the presence of micro-crystalline silica (a form of porous silicon) [29]. Scanning electron microscopic (SEM) images revealed that most particles in the SF sample had diameters of less than 1 micron, as shown in Figure 3. This qualified it as a ‘micro-binder’ suitable for filling the gaps between the particles of the main binder.

Figure 1.

Gradation of cement and SF.

Figure 2.

XRD analysis of SF.

Figure 3.

SEM image of SF at 200 nm resolution.

2.1.2. Natural and Recycled Aggregate

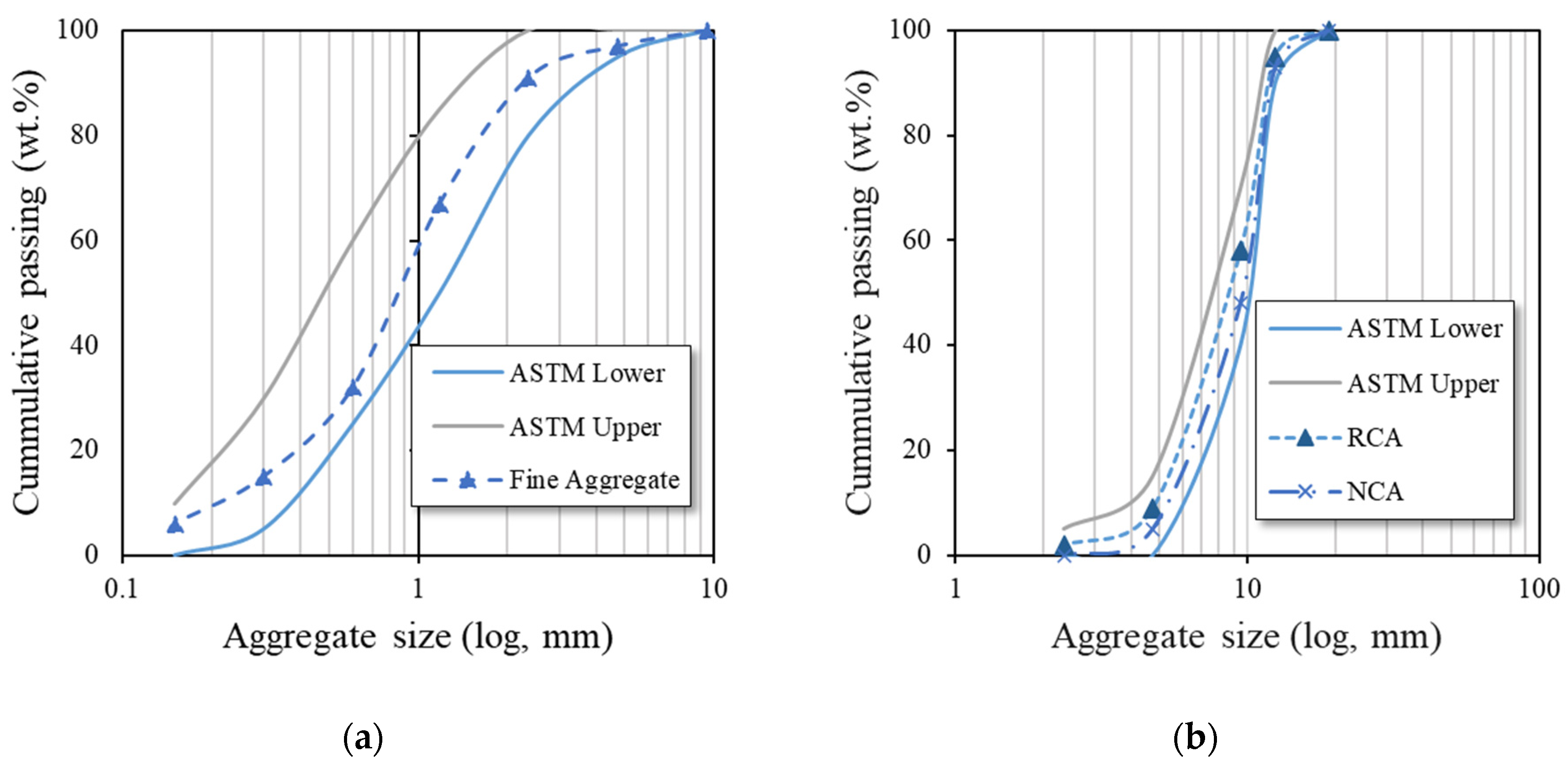

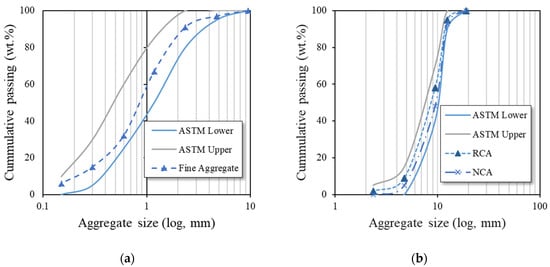

Fine aggregate was sourced from the Lawrancepur quarry in Pakistan. The fineness modulus of this siliceous sand is around 2.9. For the manufacture of fiber-reinforced concrete, the maximum size of coarse aggregate was chosen to be 12.5 mm. Dolomitic sandstone was used as NCA. Due to the non-availability of the CW recycling plant, the old concrete samples were processed by hand. The gradation or distribution of particles was kept almost the same in the samples of both RCA and NCA. Important engineering characteristics of fine and coarse aggregates are presented in Table 1. The aggregates’ gradation charts are shown in Figure 4.

Table 1.

Characteristics of aggregates.

Figure 4.

Gradation charts: (a) fine aggregate; (b) NCA and RCA.

2.1.3. Carbon Fiber

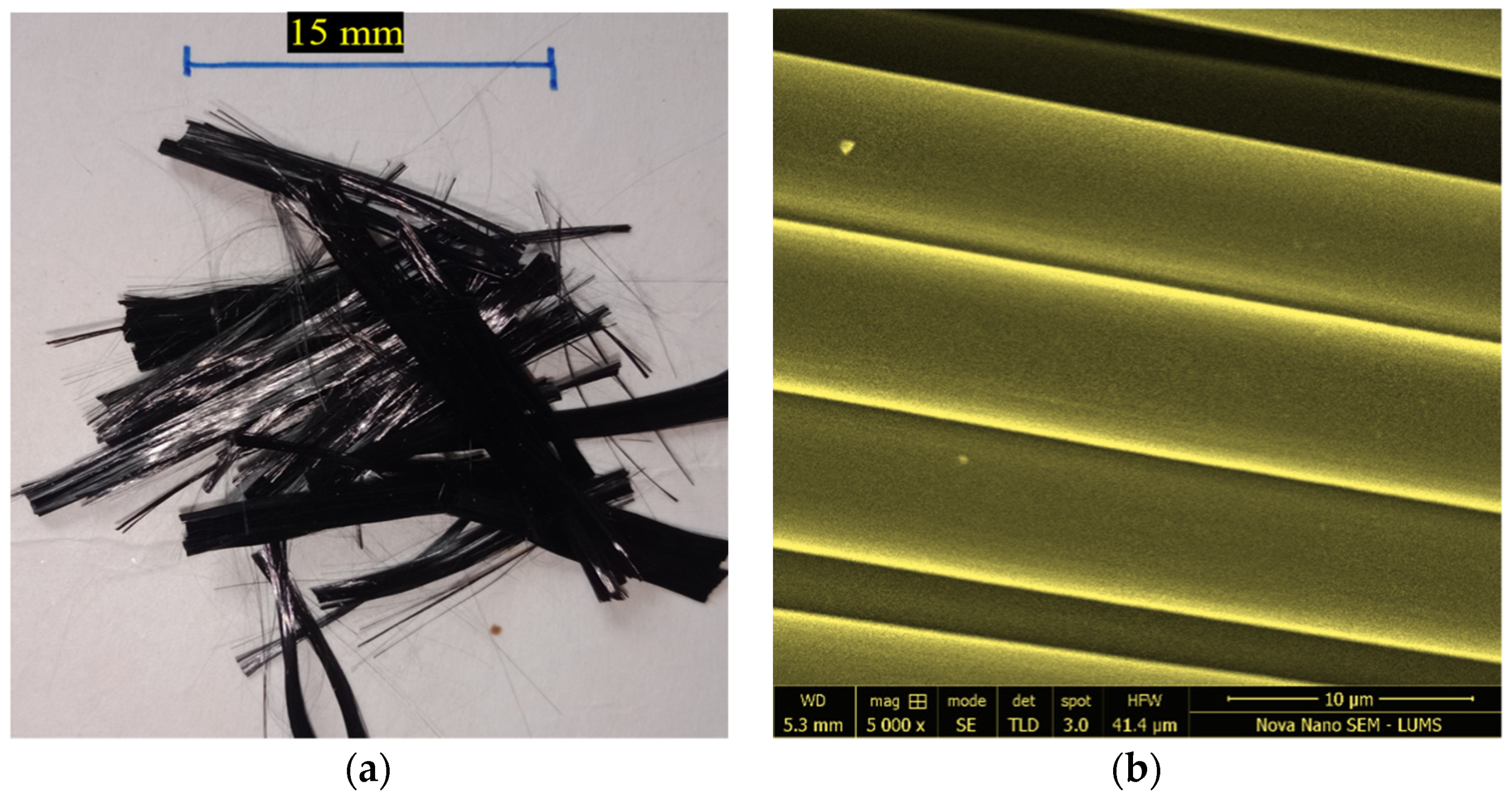

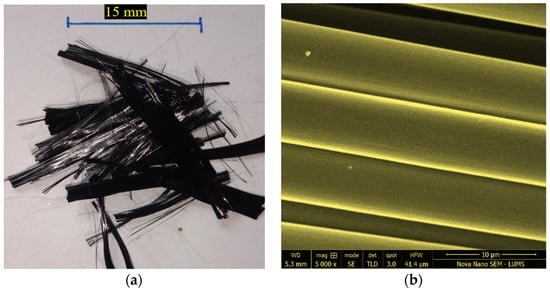

To enhance the tensile properties of RAC, CF was used as fiber reinforcement. The length and diameter of the CF were 15 mm and 7 microns, respectively. The length of the CF was decided considering the workability issues associated with longer filament lengths and the fact that shorter lengths yield insignificant effects on the ductility response of concrete [23]. Thus, a medium length of 15 mm was chosen for the CF. The tensile strength value of CF is above 3000 MPa, and it has an elastic modulus of 230 GPa. The material density of CF is 1800 kg/m3. The macro–micro overview of CF is shown in Figure 5.

Figure 5.

CF sample: (a) direct observation; (b) SEM image.

2.1.4. Tap Water and Water Reducer

The workability of all mixes in the desired range was attained using ‘Sika Viscocrete 3110’. It is a type G admixture and is designed to meet the specifications of ASTM C494 [30]. The preparation/manufacture and curing of all mixes were performed with tap water.

2.2. Characteristics of Constituent Materials

Three concrete families were designed using RCA as 0%, 50%, and 100% volumetric replacement of NCA. The first mix containing 0% RCA was designed as the control mix. The target fcm of the control mix was 65–70 MPa at 28 days, while the workability of fresh concrete was chosen for a highly flowable high-performance mix with an Abram’s cone slump value of 150–230 mm. RCA was then incorporated as 50% and a full replacement of NCA in the control mix. RCA mixes were produced with and without SF. The substitution level of SF was considered as 8% by volume replacement of the cement. Based on the literature [31,32,33], the optimum substitution level of SF lies between 5% and 10% to achieve maximum strength (Yunchao et al. [31] recommended 6% SF out of 3% SF, 6% SF, and 9% SF; Xie et al. [32] recommended 8–12% SF out of 4% SF, 8% SF, and 12% SF; Ali et al. [33] recommended 5% SF out of 5% SF and 10% SF). Thus, an intermediate percentage of 8% was chosen for SF incorporation. Similar to the selection process of SF percentage, the dosage of 0.5% CF was also selected based on maximum mechanical and durability performance according to the findings of a companion study [23] (out of 0.15% CF, 0.25% CF, 0.5% CF, 0.75% CF, and 1% CF). In the RCA incorporating mixes, CF was added as 0.5% by volume fraction with and without SF. Eventually, a total of 12 concrete mixes were produced. Complete details about the nomenclature and composition of the mixes are illustrated in Table 2. The inclusion of both CF and SF is damaging to the workability of concrete; thus, a superplasticizer or water reducer was used to maintain the workability of the fresh concrete. All 12 concrete mixes were prepared in the laboratory, as detailed by a companion study [34].

Table 2.

Proportions of concrete mixes.

2.3. Testing Techniques

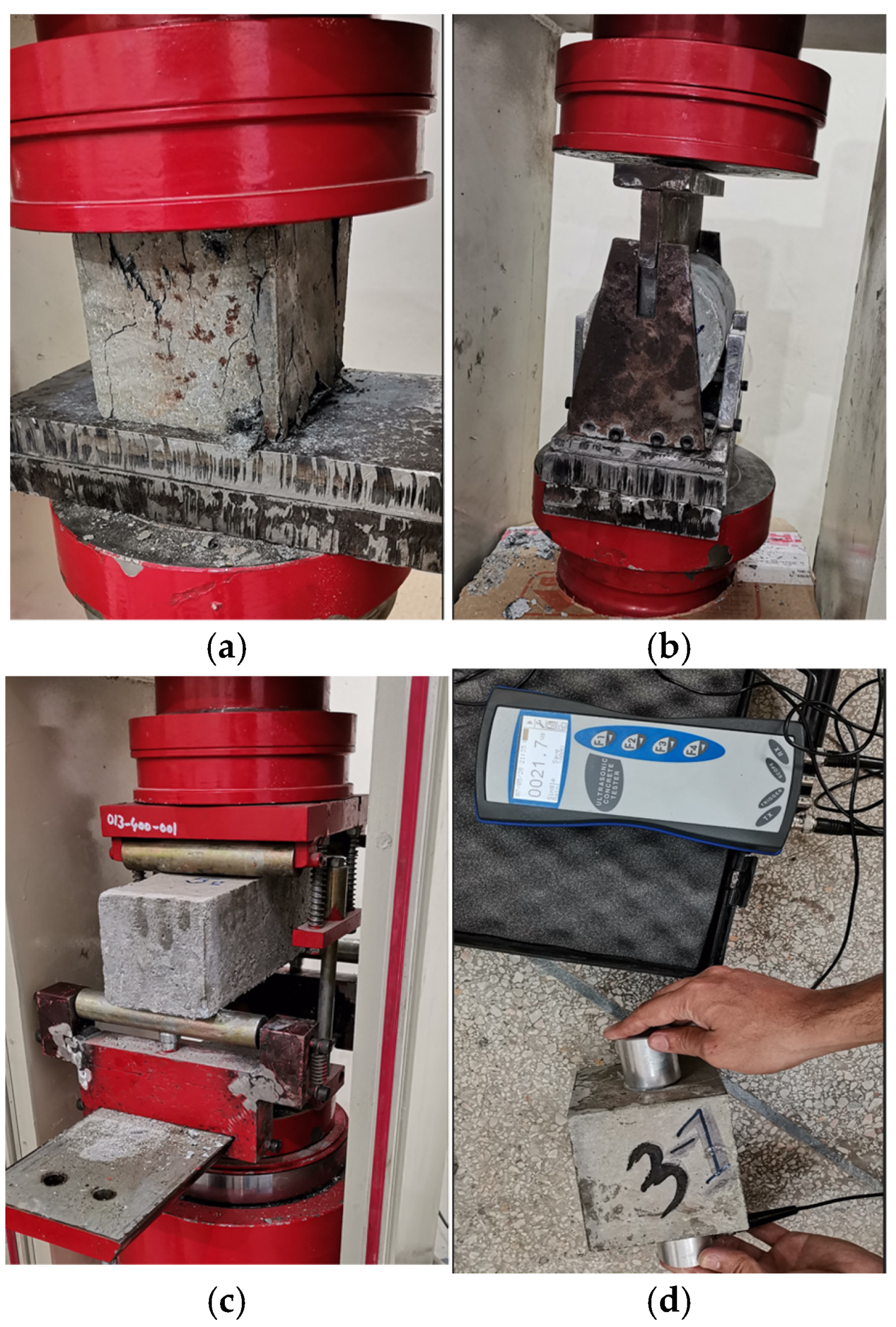

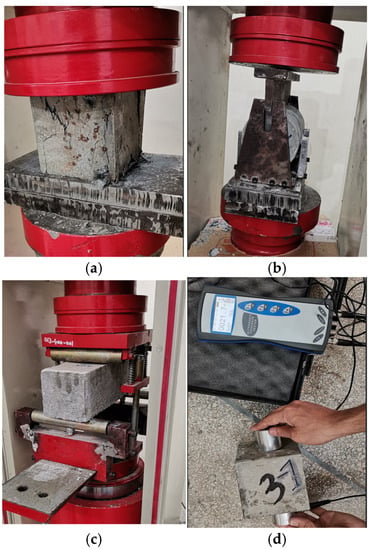

For all tests, three replicate samples of mixes were prepared, cured, and tested under the same conditions. Then, their average value is presented in this research paper with standard deviation values using error bars. All tests were conducted on samples after curing for 28 days. To evaluate the fcm of the concrete mixes, 100 mm cubic samples of the concrete were tested according to BS: EN 12390-3 [35]. The compression testing setup is shown in Figure 6a. The tensile strength of concrete is indirectly assessed by measuring the fct of concrete. For this purpose, 100 mm diameter × 200 mm height samples of concrete were subjected to splitting tensile load according to ASTM C496 [36]. The splitting tensile test setup is illustrated in Figure 6b. A third-point bending test was performed to estimate the modulus of rupture or bending strength (fcb) of the concrete samples. Prismatic specimens of 100 × 100 × 350 mm3 were tested under third-point loading according to ASTM C1609 [37]. The clear span between simple supports was 300 mm. The bending test setup is shown in Figure 6c.

Figure 6.

The overview of experimental testing: (a) compression test; (b) splitting tensile test; (c) bending test; and (d) pulse velocity test.

The durability of concrete structures is highly dependent on the voids connected to the surface of the concrete. The measure of the permeable pore volume of concrete is related to the durability assessment. Therefore, the WA capacity of all mixes was evaluated. Concrete discs of 100 mm diameter × 50 mm thickness were tested according to the ASTM C938 [38]. The percentage difference between the dried and saturated concrete samples is regarded as the WA capacity of concrete. The UPV test is a non-destructive field test to predict the strength and durability of concrete. The change in the speed of the pulse wave through a sample reveals the change in the porosity or density of concrete. The UPV test was conducted on cubic samples, as shown in Figure 6d.

3. Results and Discussion

3.1. Compressive Strength

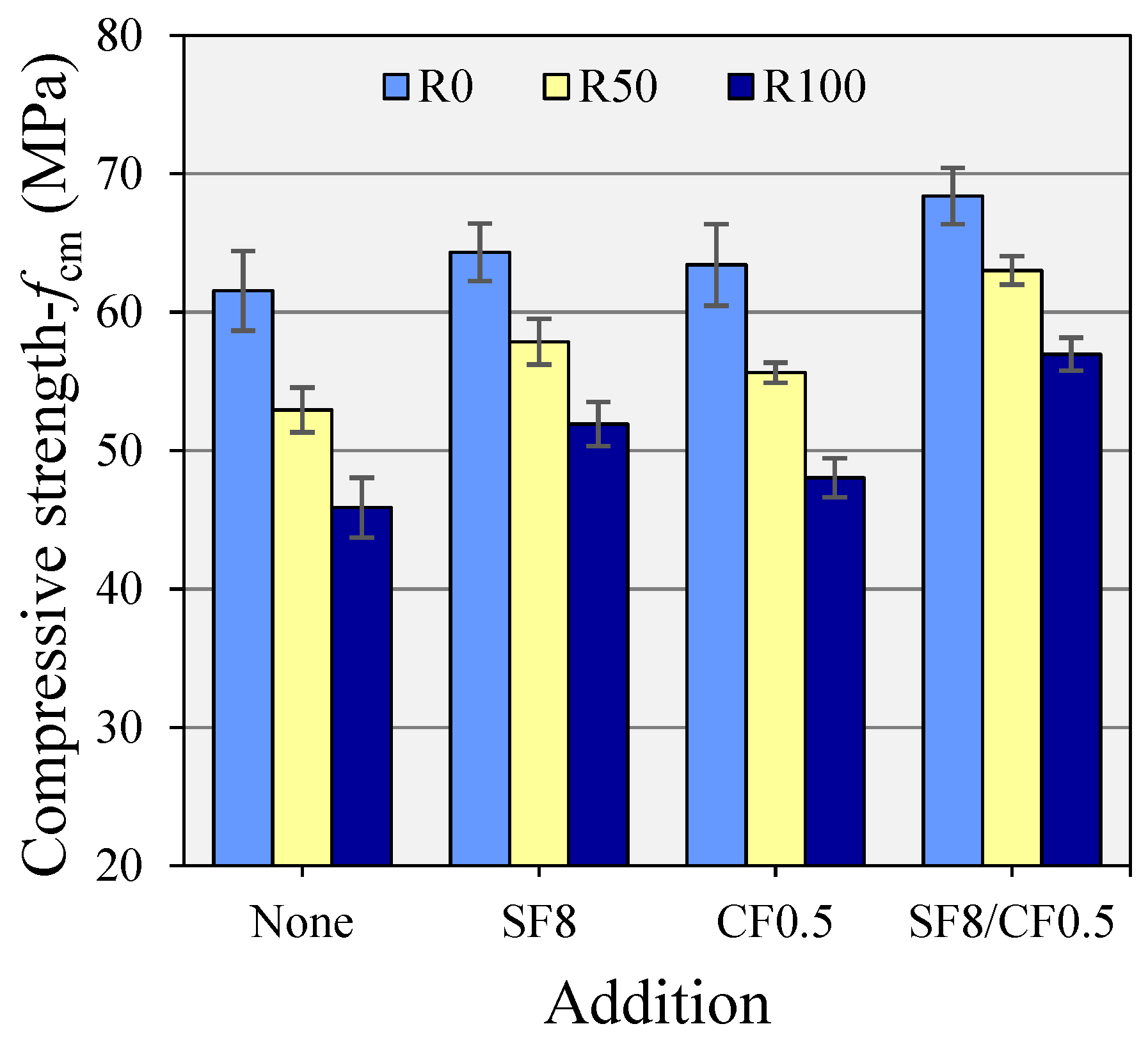

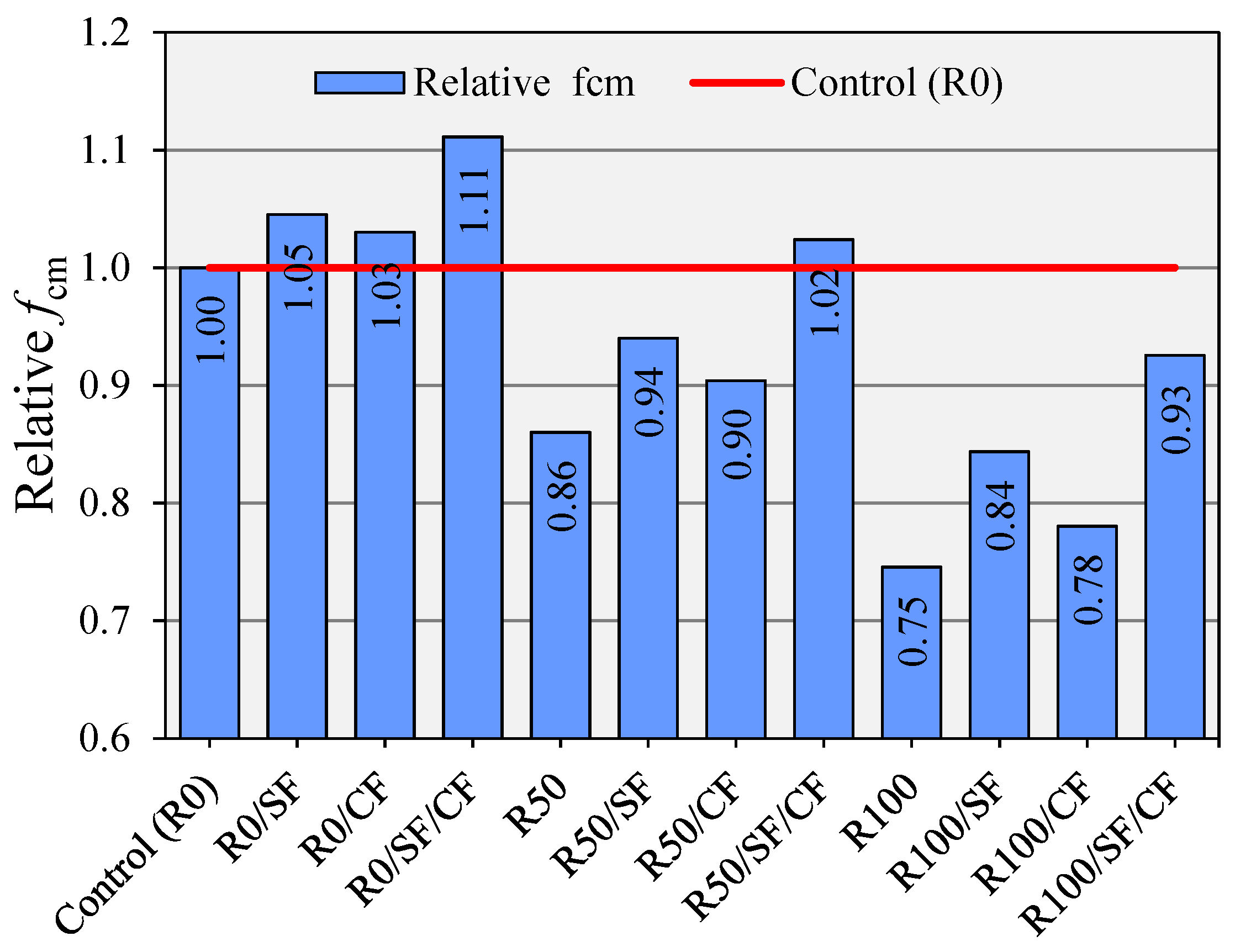

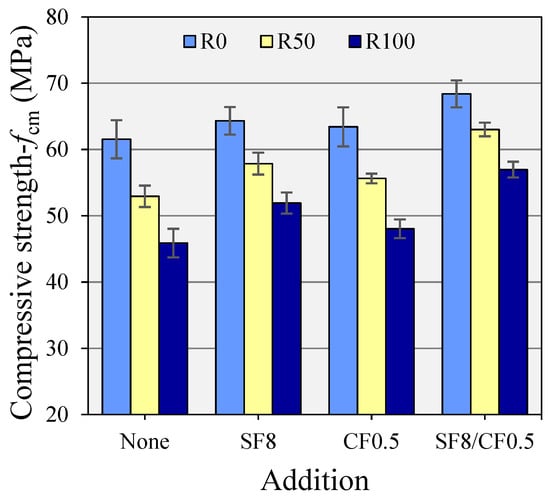

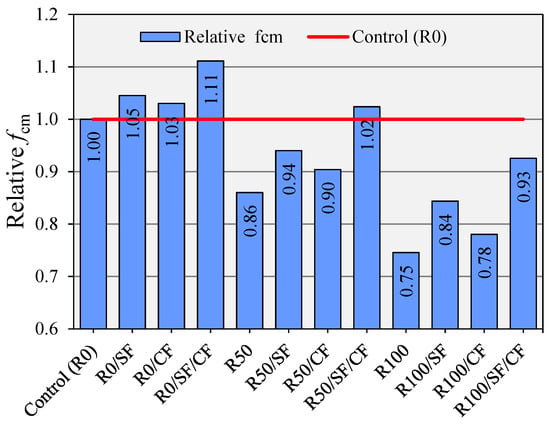

The effect of SF and CF addition on the fcm of concrete with and without RCA is shown in Figure 7. The fcm values of concrete mixes relative to the control mix are illustrated in Figure 8. It can be seen that the fcm was reduced noticeably with an increasing percentage of RCA. At 50% and full replacement of NCA with RCA, the fcm was decreased by 14% and 25%, respectively. Since RCA is more porous and weaker than NCA, it reduces the strength of the concrete. The attached mortar in RCA absorbs a high amount of water, and, thus, RAC has more voids than the NAC. The strength reduction due to RCA incorporation has been linked to the increase in porosity and voids [39].

Figure 7.

Effect of CF and SF addition on 28-day fcm of concrete with different percentages of RCA.

Figure 8.

Relative fcm of concrete mixes with SF, CF, and RCA.

The addition of SF as a partial substitution for cement caused a noticeable improvement in the fcm. For R0, the fcm was increased by 5% due to SF addition, while R50 and R100 experienced improvements of around 9% compared to the control mix. Thus, SF played an effective role in overcoming the strength deficit of RAC. It was also noted that SF addition is more useful in RCA-incorporating families. This is because the overall portlandite (CH) content in RAC is greater than in the R0 family, and the presence of RCA offers a high potential for pozzolanic reactions. This finding is in line with Dilbas et al. [7]. At the interfacial transition zones, reactions between the silica and free CH strengthen the aggregate–matrix bond [14].

A singular CF addition did not cause a noteworthy change in the fcm. A nominal improvement of 3% was observed in the fcm of all concrete families. It can be credited to the improvement in the axial stiffness of concrete due to advanced crack resistance caused by the fibers [40]. Previous studies [41,42] also reported that micro-fibers cause a minimal change in the fcm, since they are only majorly valuable for boosting the tensile strength and fracture toughness.

The combined use of CF and SF augmented the fcm of concrete by significant margins. As is shown in Figure 8, around an 11% improvement in fcm of R0 can be achieved by using 8% SF and 0.5% CF. Due to the combined use of CF and SF, R0, R50, and R100 concrete experienced 11%, 16%, and 18% improvements, respectively. It was clear that SF and CF have synergistic benefits since the benefits of their combined incorporation were marginally greater than the sum of the benefits due to their singular incorporations. R50/SF/CF showed an fcm comparable to that of the control mix.

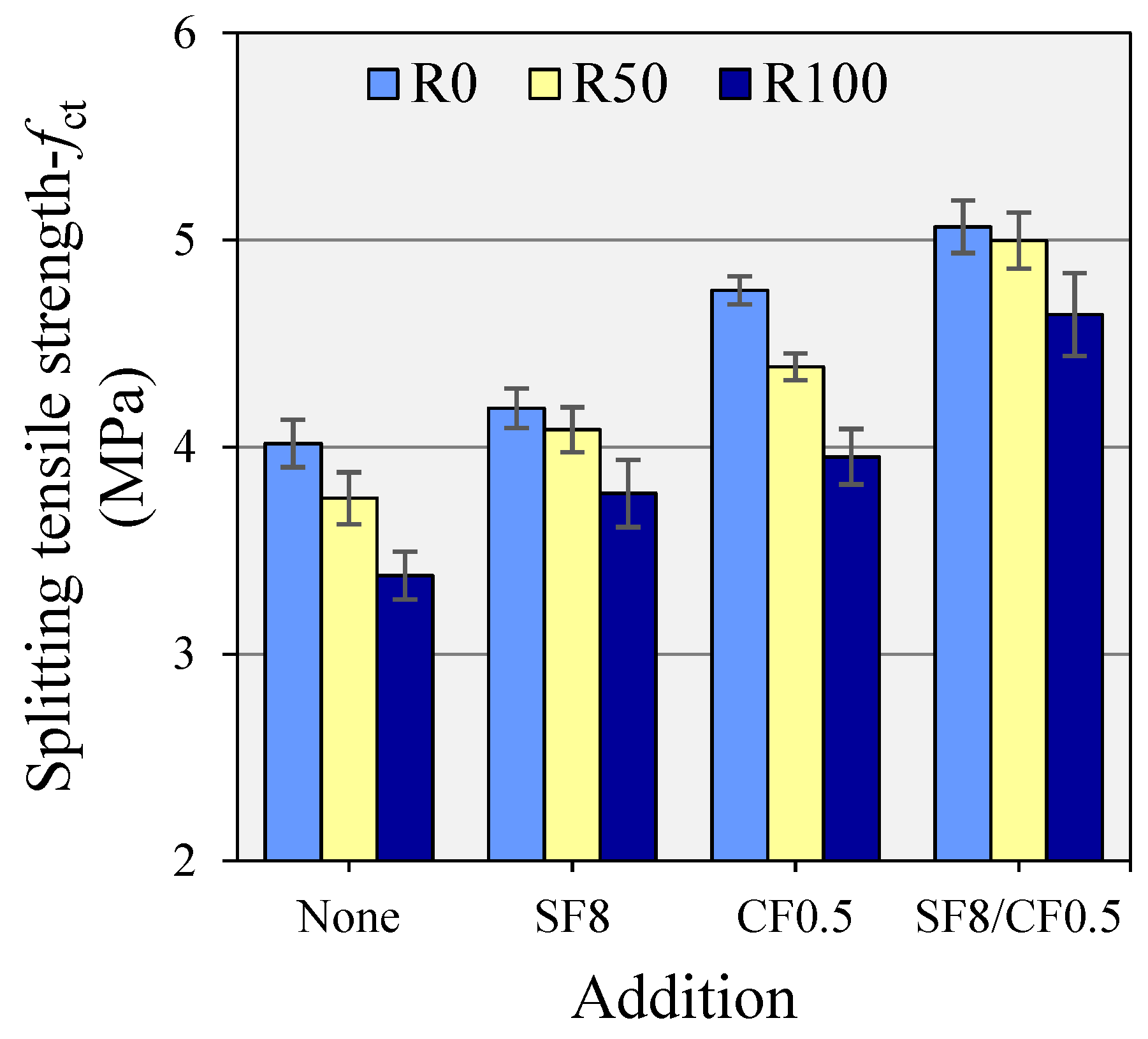

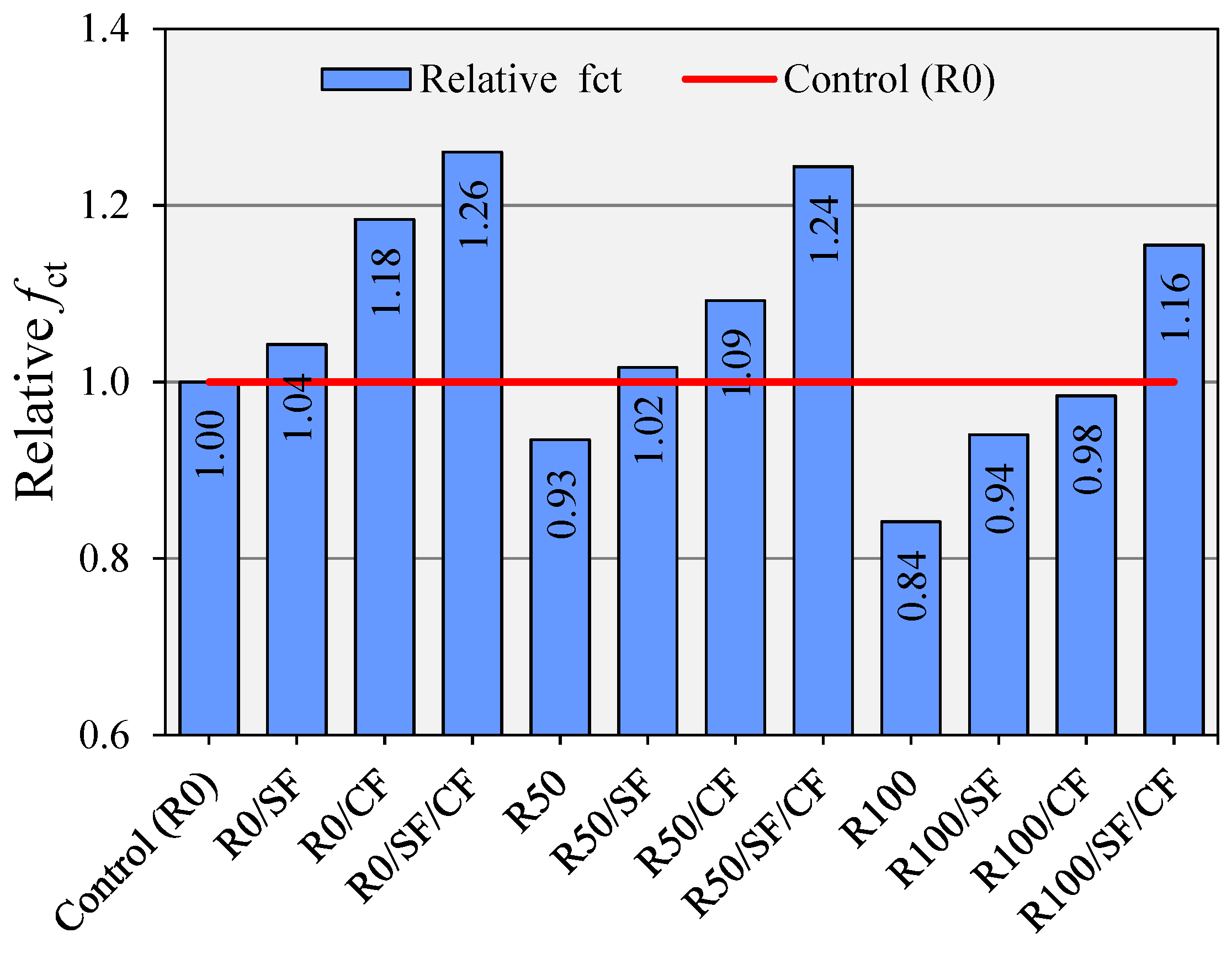

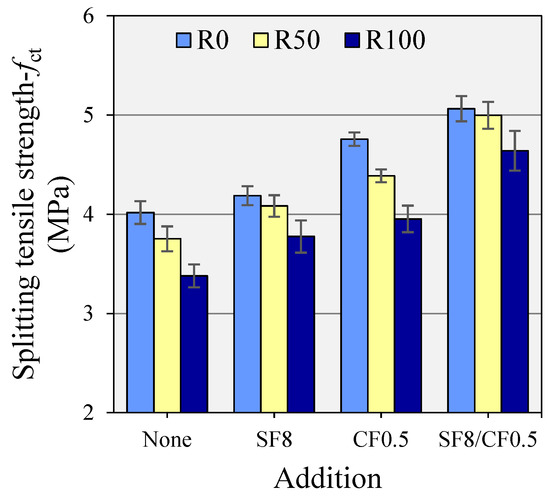

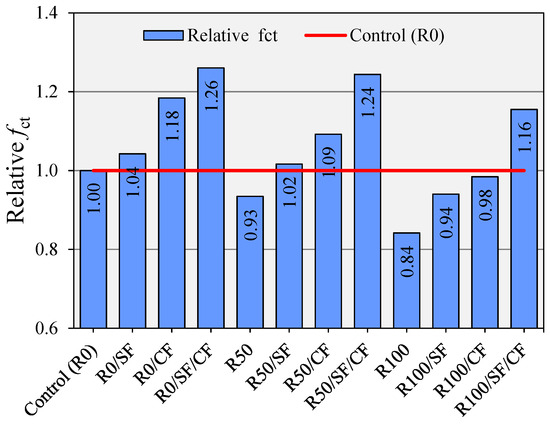

3.2. Splitting Tensile Strength

In practical engineering, fct is measured instead of direct tensile strength since it provides a simpler and easier assessment of the tensile strength of concrete. Figure 9 shows the effect of SF and CF on the fct with and without incorporation of RCA, while the fct value of all mixes relative to the control mix is shown in Figure 10. A downward trend was noticed in fct, increasing the percentage of RCA. The fct decreased by 7% and 16% at 50% and 100% RCA, respectively. These reductions in fct were anticipated due to the inherent weakness of RCA. The incorporation of SF provided minor improvements in the fct. The fct of R0, R50, and R100 was improved by 4%, 9%, and 10%, respectively, due to the inclusion of SF as an 8% replacement of cement. The pozzolanic reactions and filler effect of micro-silica particles strengthen the binder matrix. In the case of mixes incorporating RCA, the chemical reactions may also occur across the bond between silica-modified matrix and aggregates. Kurda et al. [43] systematically showed that the utilization ratio of pozzolanic binders is greater in the case of RAC than in NAC.

Figure 9.

Effect of CF and SF addition on 28-day fct of concrete with different percentages of RCA.

Figure 10.

Relative fct of concrete mixes with SF, CF, and RCA.

The incorporation of CF had an upward effect on the fct. The tensile strength was increased significantly by 18–20% with the addition of 0.5% CF. Therefore, the tensile strength deficit of RAC families was completely overwhelmed by the CF addition. Both R50 and R100 concretes attained higher tensile strengths than the control mix. This is because the use of CF increases the bonding force of concrete and enhances the fct [44]. Furthermore, the efficacy of fibers under pulling action or tension is more than under compressive forces. Fibers activate earlier under tension loads and supplement the bonding force of concrete. Raza and Qureshi [24] also found that the effect of fibers on fct is more promising than their effect on fcm.

The combined incorporation of CF and SF showed maximum improvement in fct. R0, R50, and R100 concrete experienced 26%, 31%, and 32% improvements due to the combined use of CF and SF. These results confirmed that the use of CF and SF has a synergistic effect on the fct. The surplus net gain due to the simultaneous addition of CF and SF is credited to the improvement in the bond strength of fibers. The pore refinement and growth of the extra calcium silicate hydrate (CSH) gels improve the pulling force of the cement matrix. Thus, the strengthening of the cement matrix and refinement of the pore structure improves the interfacial bond properties and causes further enhancement or synergistic effect on the macro performance.

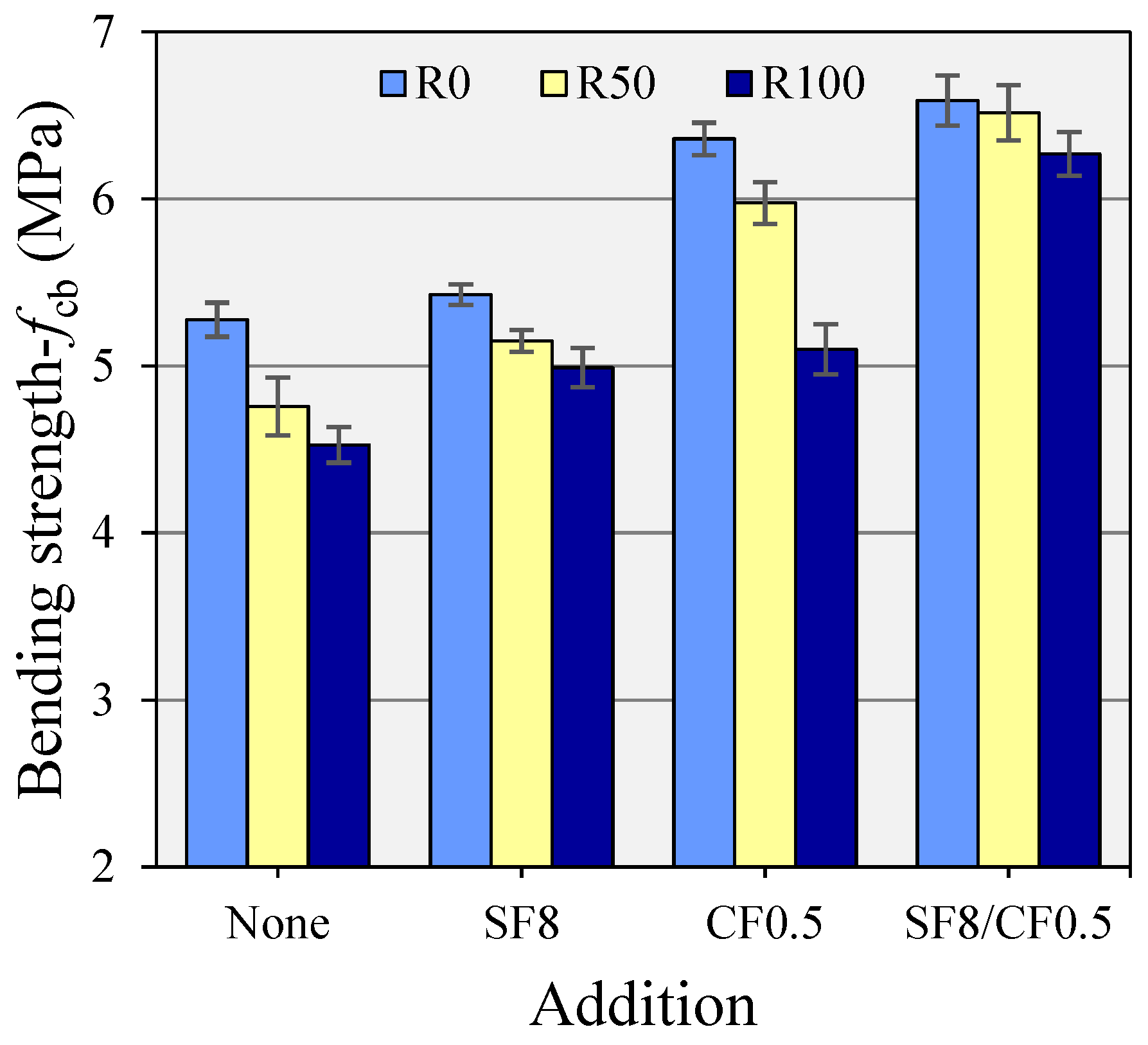

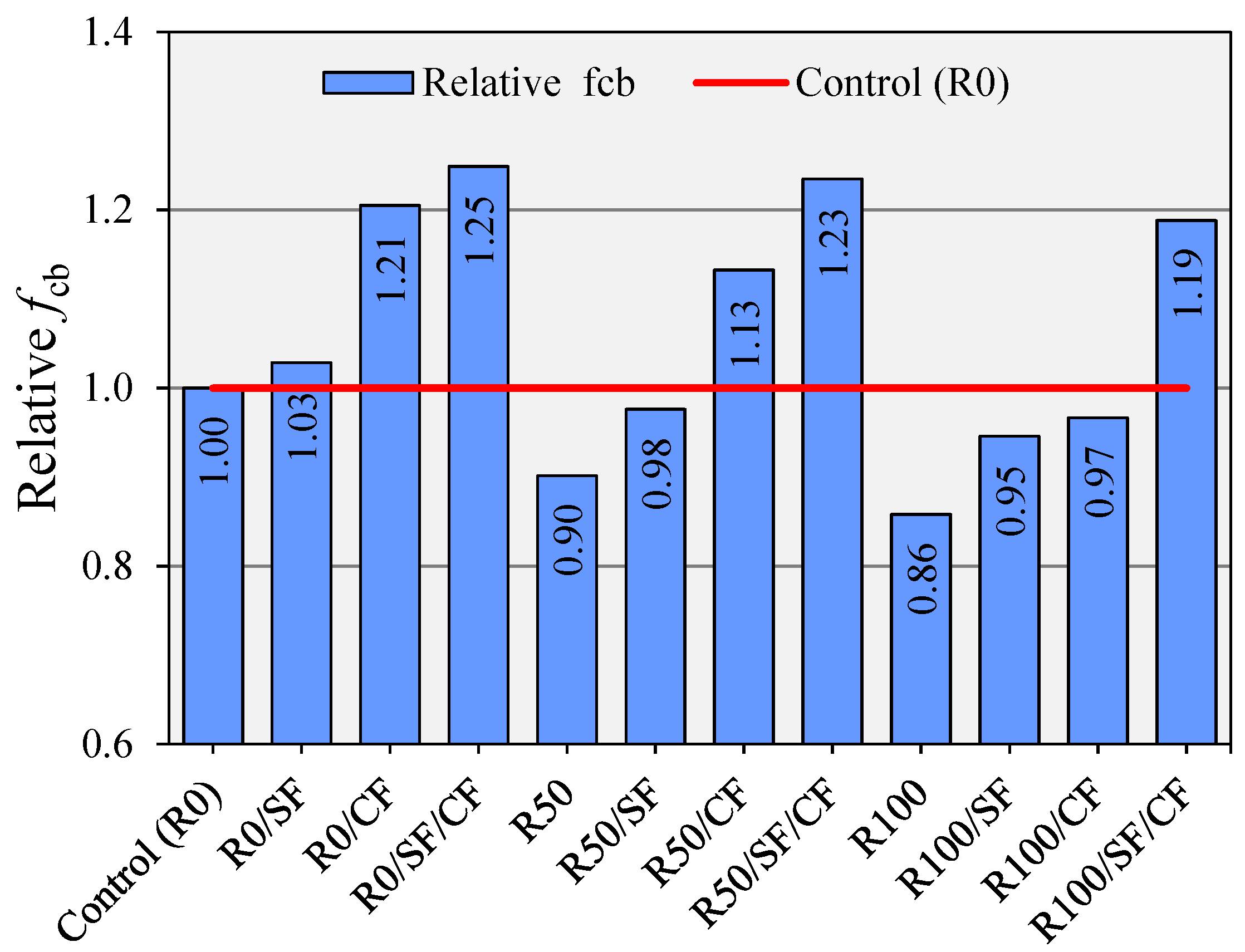

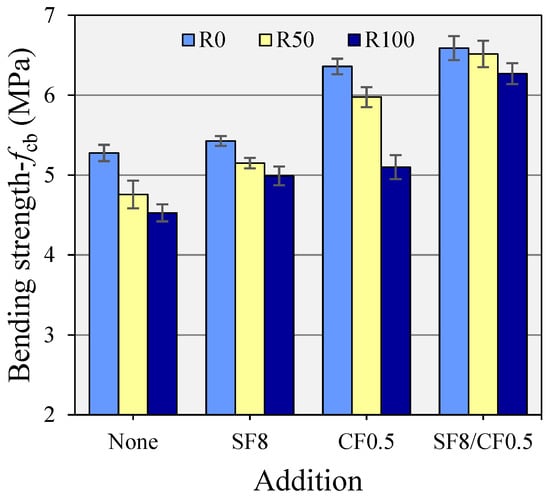

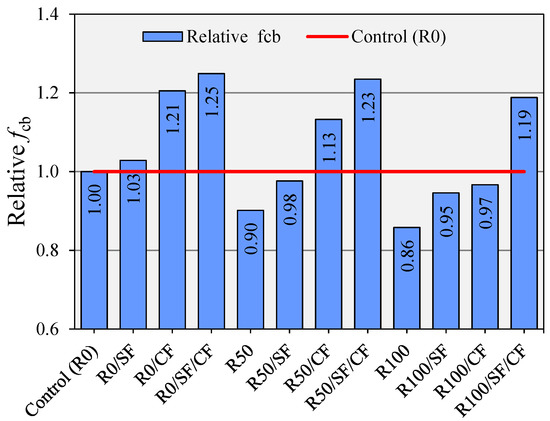

3.3. Bending Strength

Similar to fct, fcb is an indirect measure of the true tensile strength of plain and fibrous concretes. However, unlike fct, fcb can be directly used in the design of concrete elements such as tunnels, slabs, pavements, etc. Unlike fcm and fct, fcb is not a simplistic measure as it requires high-quality control and is strongly influenced by the support conditions, fiber orientations, and sample size. The effect of RCA, CF, and SF addition on fcb is illustrated in Figure 11. The fcb values of all mixes relative to the control mix are presented in Figure 12.

Figure 11.

Effect of CF and SF addition on 28-day fcb of concrete with different percentages of RCA.

Figure 12.

Relative fcb of concrete mixes with SF, CF, and RCA.

The addition of SF had a minimal effect on the fcb of R0. However, it showed phenomenal improvements of around 10% in the fcb of both R50 and R100 concretes. The net efficiency of SF was high in mixes containing RCA. This behavior was observed in the results of fct as well. The inclusion of fibers caused a remarkable increment in the fcb of all RCA families. For instance, R0, R50, and R100 experienced net improvements of 21%, 23%, and 11% due to the addition of CF, respectively. Fiber inclusion in the matrix of concrete effectively overcame the fcb deficit of R50 and R100 against the control mix.

The concurrent inclusion of SF and CF was demonstrated to be highly beneficial in boosting the fcb of all RCA families. Not only were the fcb increments of SF and CF combined by their conjunctive use, but they also caused a synergistic effect similar to that observed in other mechanical results. For instance, in R50, the singular addition of SF and CF caused net increments of 8% and 23%, respectively but their joint incorporation led to an improvement of 33%. Similarly, for the R100 concrete, the addition of SF and CF showed improvements of 9% and 11%, but their joint inclusion caused fcb to increase by 32%. The results of tensile testing (i.e., fct and fcb) showed that the individual addition of fiber in the matrix of RAC is enough to overcome the strength gap or deficit compared to plain NAC. However, the further enhancement effect on the performance of fibers can be achieved by the addition of SF.

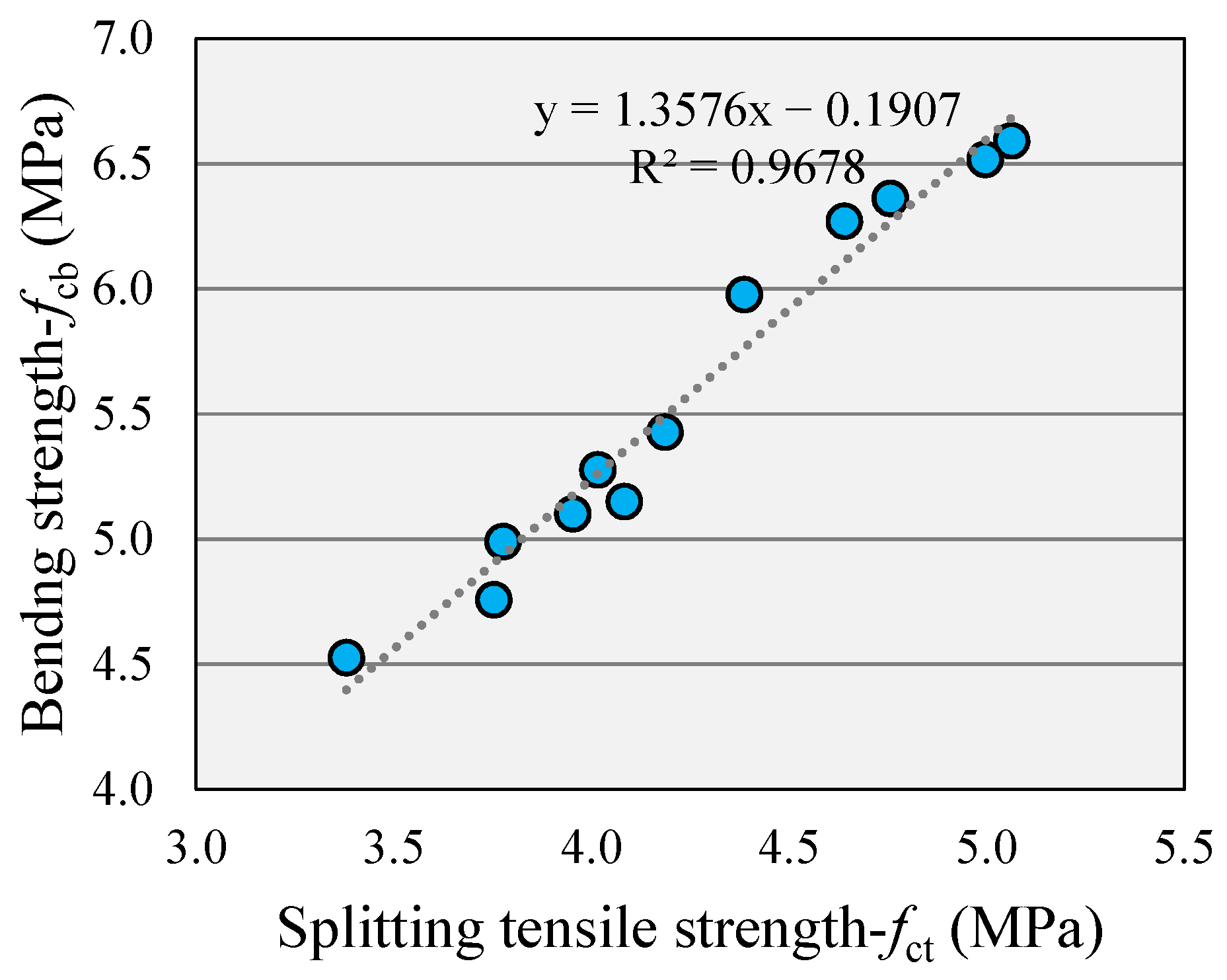

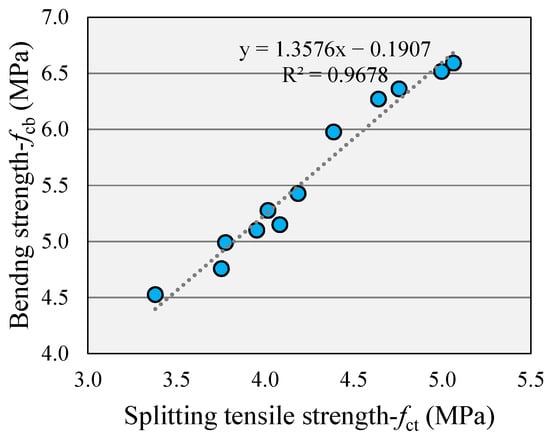

The variation in fct and fcb with the incorporation of RCA, SF, and CF almost showed a similar trend. The crack-bridging effect of fiber is highly useful for both tensile properties of concrete; therefore, the fct and fcb correlated with high accuracy, as shown in Figure 13. As we know that fcb measurement is difficult and sensitive, it can be assessed accurately from the fct.

Figure 13.

Correlation between fcb and fct.

3.4. Water Absorption

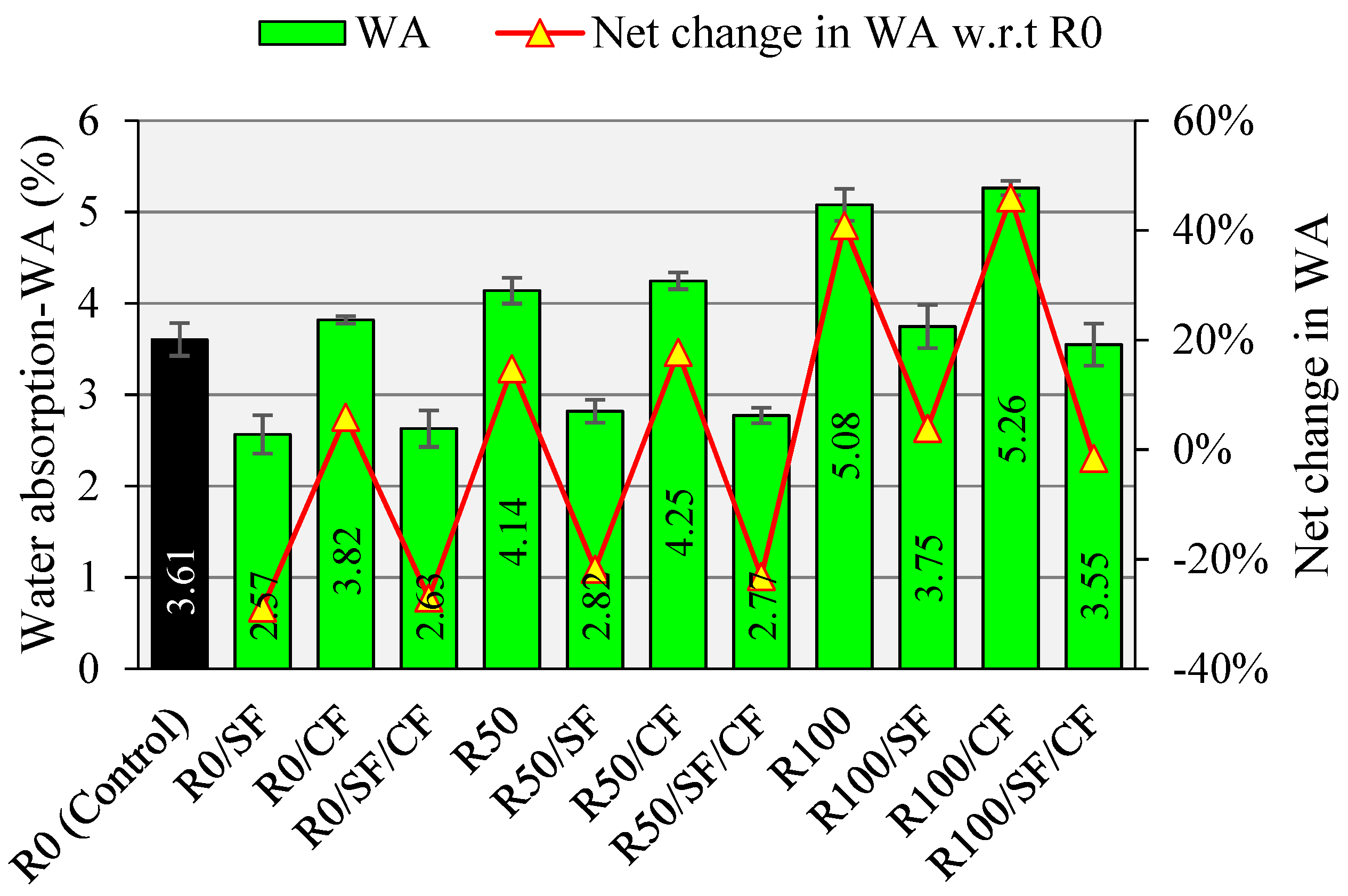

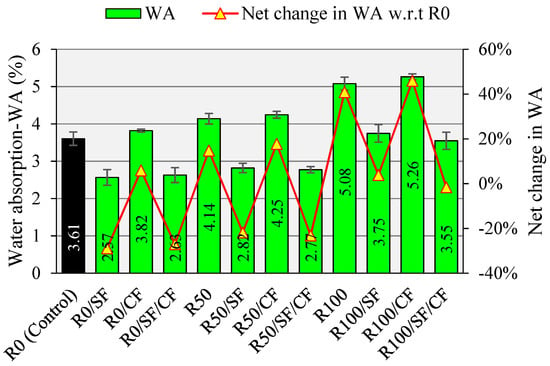

The change in the permeable porosity of concrete can be used as a durability indicator because the ingress rate of harmful chemicals is entirely dependent on the porosity of the concrete. The results of WA testing are illustrated in Figure 14. RCA incorporation is detrimental to the porosity of concrete due to the attached mortar. The pores present inside RCA increase the connectivity of micro-channels, leading to an increased value of WA. At full replacement of NCA with RCA, a 40% increase in the WA capacity of concrete was noticed. This drawback of high porosity and loosely attached mortar associated with RCA also had a detrimental effect on the mechanical properties of concrete. A secondary binder, such as SF, due to its micro size, effectively closes the spaces in the binder matrix and on the surface of RCA. The meandering effect of fine particles also slows or reduces the penetration of water inside the concrete [10,13]. The improvement in the interfacial properties of concrete results in a tremendous WA reduction.

Figure 14.

Effect of CF and SF addition on 28-day WA capacity of concrete with different percentages of RCA.

The incorporation of CF aggravates the imperviousness of concrete. The tangling effect of fiber filaments and improper compaction can lead to an increase in the size of pores and connectivity between them. The CF filaments have a high surface area; due to this reason, they can be very difficult to disperse. Thus, CF introduces voids or pores inside the cementitious matrix. At 0.5% volume of CF, the WA capacity of R0, R50, and R100 was increased by 6%, 3%, and 5%, respectively.

SF plays a vital role in managing the negative effects of both RCA and fibers. The increased CSH gel growth and pore refinement lead to better interfacial properties for both RCA and fibers. The increase in the imperviousness of the binder matrix causes a balancing effect on the pores created due to the ‘balling’ or ‘tangling’ effect of the fibers. It can be concluded that the role of SF is very crucial for suppressing the harmful effects of RCA and micro-fibers on the imperviousness of concrete. Owing to the superior filling effect of SF, R100/SF/CF yielded a WA value around 2% lower than that of the control mix, while R50/SF/CF yielded 23% less WA than the control.

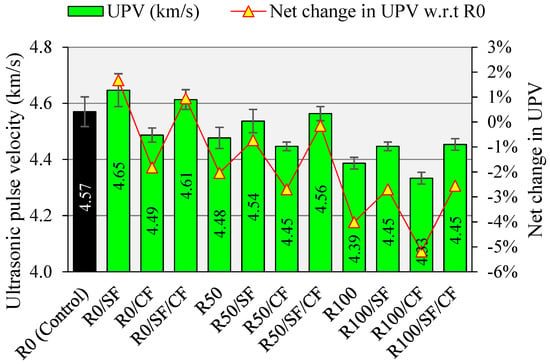

3.5. Ultrasonic Pulse Velocity

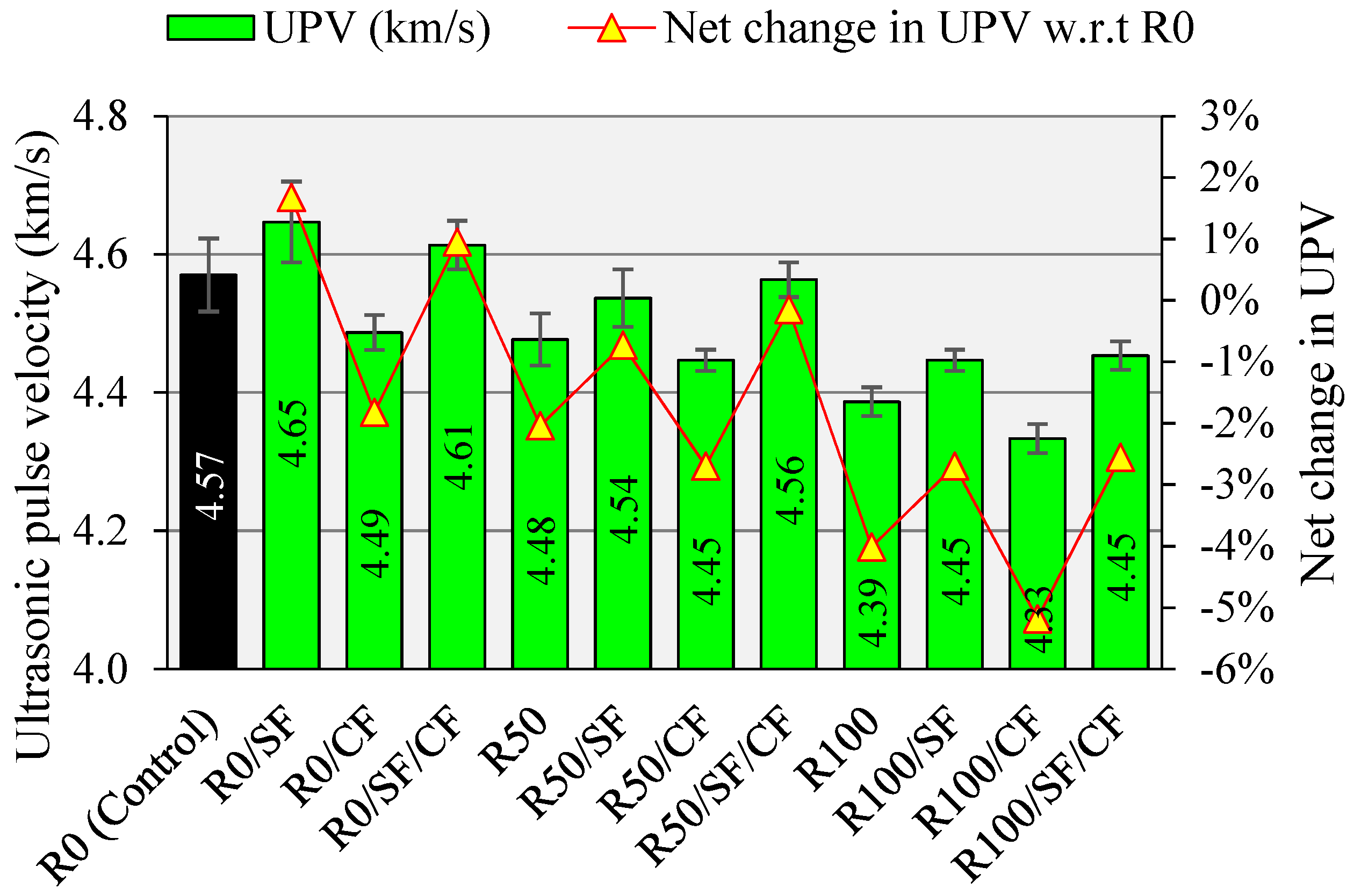

To assess the quality of concrete in the field, UPV is widely used as a non-destructive testing method. Table 3 provides the interpretation of UPV value in terms of concrete quality as per BIS: 13311 [45]. A UPV value between 3.5 and 4.5 km/s usually corresponds to normal-strength and medium-strength concretes, whereas UPV values above 4.5 km/s correspond to high-performance or high-strength concrete grades. The results of UPV testing of all mixes are illustrated in Figure 15. The control mix showed a UPV value above 4.5 km/s, which shows its excellent quality. The inclusion of SF refines the micro-structure and improves the imperviousness of concrete, which leads to further improvement in the UPV value of concrete. Unlike SF, fiber addition has a downward effect on the UPV of concrete. The increase in porosity due to fiber addition may reduce the speed of the pulse [46]. The reduction in UPV value can also be linked to the increase in heterogeneity on fiber addition. A mix containing both SF and CF attained a UPV value similar to that of the control or unmodified mix. SF balances the negative effect of micro-fibers on UPV.

Table 3.

Interpretation of UPV value.

Figure 15.

Effect of CF and SF addition on 28-day UPV of concrete with different percentages of RCA.

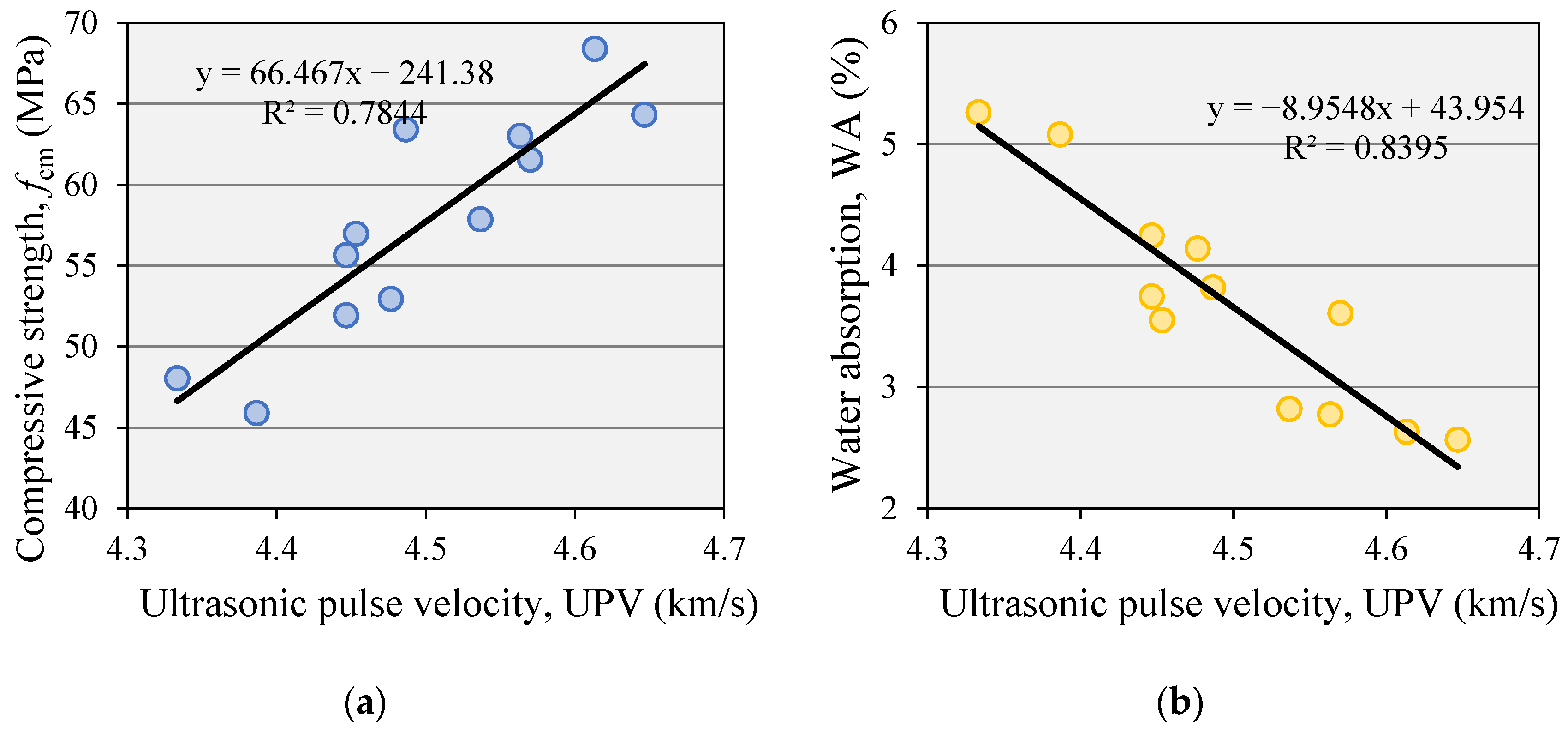

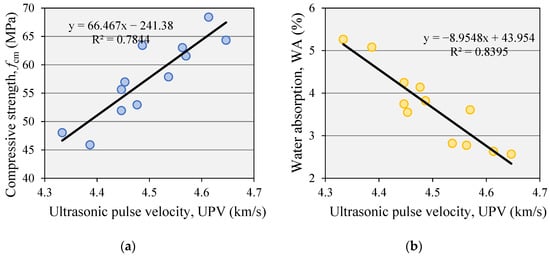

The decrease in UPV was observed due to an increase in the RCA level. The increase in the porosity and voids due to RCA addition is responsible for slowing the speed of the pulse wave. All mixes of the R100 family fell under the good quality category. SF caused a noticeable improvement in the UPV value of RAC, while CF had a declining effect on the UPV values of R0, R50, and R100 concrete. In RCA families, only R50/SF and R50/SF/CF yielded UPV values above 4.5 km/s, which falls under excellent quality. Since UPV, WA, and fcm are exclusively dependent on the density and micro-structural growth of concrete, these parameters can be correlated to UPV’s high accuracy, as shown in Figure 16. The increase in UPV due to the modification of concrete indicates an improvement in the imperviousness and fcm. For example, the increase in UPV due to SF addition can be used as an indicator of an fcm increment and a decline in WA.

Figure 16.

Correlations between (a) fcm and UPV and (b) WA and UPV.

4. Conclusions

In this research, the effect on the properties of ‘high-strength concrete’ of singular and combined incorporation of silica fume and carbon fiber was studied with three different levels of recycled coarse aggregates as a replacement for natural coarse aggregates. The following are the important findings of this research:

- The modification method using silica fume is highly effective in improving the compressive strength of recycled aggregate concrete. Concretes containing 50% and 100% recycled coarse aggregates experienced strength increments of around 9% at the addition of 8% silica fume. Carbon fiber caused nominal upgradation of 2–4% in compressive strength. At the combined use of 0.5% carbon fiber and 8% silica fume, the compressive strength of 100% recycled aggregate concrete was improved by 18%;

- The use of carbon fiber is effective in the upgradation of tensile strength. At the addition of 0.5% carbon fiber, concrete mixes made with 50% and 100% recycled aggregate experienced 16% and 14% improvements in splitting tensile strength, respectively. The combined use of silica fume and carbon fiber caused a maximum improvement of 32% in the splitting tensile strength of recycled aggregate concrete. The singular use of fiber or combined use of fiber and silica fume can overcome the tensile strength deficit of 100% recycled aggregate concrete;

- The singular addition of fiber is more useful than silica fume in upgrading the bending strength. Concretes with 50% and 100% recycled aggregates gained net improvements of 23% and 11%, respectively, due to the inclusion of 0.5% carbon fiber;

- The use of silica fume enhances the interfacial properties of aggregates and fibers; both fibers and silica cause a synergistic improvement in the tensile properties. The net effect of fiber on mechanical performance also improves with the addition of silica fume;

- Due to the addition of 0.5% carbon fiber and 8% silica fume, 100% recycled aggregate concrete achieved 19% greater bending strength than the control mix;

- Both recycled aggregate and fiber have a downward effect on the imperviousness of concrete. Thus, they can lead to a decline in the durability of concrete. The use of silica fume is highly effective in managing the negative effects of both fibers and inferior aggregates on the water absorption capacity and durability of concrete;

- The use of recycled aggregate noticeably reduces the pulse velocity; hence, the quality of concrete degrades. Fiber inclusion further has a minor but declining effect on the ultrasonic pulse velocity due to a possible increase in the porosity of concrete. Silica fume proved advantageous in refining the quality of concrete with and without recycled aggregate. Concrete made with 50% recycled coarse aggregate achieved excellent quality, with a pulse velocity value well above 4.5 km/s, owing to the filling and pozzolanic action of micro-silica.

Author Contributions

Conceptualization, S.S.R. and M.F.; methodology, B.A.; software, B.A.; validation, M.F., B.A. and M.T.A.; formal analysis, S.S.R.; investigation, Y.A.; resources, A.B.E. and S.S.R.; data curation, S.S.R.; writing—original draft preparation, S.S.R.; writing—review and editing, B.A. and M.T.A.; visualization, S.S.R.; supervision, S.S.R.; project administration, B.A. and A.B.E.; funding acquisition, Y.A. and A.B.E. All authors have read and agreed to the published version of the manuscript.

Funding

The authors extend their appreciation to the Deanship of Scientific Research at King Khalid University for funding this work through the Large Groups Project under grant number R.G.P. 2/152/43.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

The authors extend their appreciation to the Deanship of Scientific Research at King Khalid University for funding this work through the Large Groups Project under grant number R.G.P. 2/152/43.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Revilla-Cuesta, V.; Skaf, M.; Faleschini, F.; Manso, J.M.; Ortega-López, V. Self-compacting concrete manufactured with recycled concrete aggregate: An overview. J. Clean. Prod. 2020, 262, 121362. [Google Scholar] [CrossRef]

- Junaid, M.F.; ur Rehman, Z.; Kuruc, M.; Medveď, I.; Bačinskas, D.; Čurpek, J.; Čekon, M.; Ijaz, N.; Ansari, W.S. Lightweight concrete from a perspective of sustainable reuse of waste byproducts. Constr. Build. Mater. 2022, 319, 126061. [Google Scholar] [CrossRef]

- Kurda, R.; Silvestre, J.D.; de Brito, J. Life cycle assessment of concrete made with high volume of recycled concrete aggregates and fly ash. Resour. Conserv. Recycl. 2018, 139, 407–417. [Google Scholar] [CrossRef]

- Ahmadi, M.; Farzin, S.; Hassani, A.; Motamedi, M. Mechanical properties of the concrete containing recycled fibers and aggregates. Constr. Build. Mater. 2017, 144, 392–398. [Google Scholar] [CrossRef]

- Kaplan, G.; Gulcan, A.; Cagdas, B.; Bayraktar, O.Y. The impact of recycled coarse aggregates obtained from waste concretes on lightweight pervious concrete properties. Environ. Sci. Pollut. Res. 2021, 28, 17369–17394. [Google Scholar] [CrossRef]

- Afroughsabet, V.; Biolzi, L.; Ozbakkaloglu, T. Influence of double hooked-end steel fibers and slag on mechanical and durability properties of high performance recycled aggregate concrete. Compos. Struct. 2017, 181, 273–284. [Google Scholar] [CrossRef]

- Dilbas, H.; Şimşek, M.; Çakır, Ö. An investigation on mechanical and physical properties of recycled aggregate concrete (RAC) with and without silica fume. Constr. Build. Mater. 2014, 61, 50–59. [Google Scholar] [CrossRef]

- Barbudo, A.; de Brito, J.; Evangelista, L.; Bravo, M.; Agrela, F. Influence of water-reducing admixtures on the mechanical performance of recycled concrete. J. Clean. Prod. 2013, 59, 93–98. [Google Scholar] [CrossRef]

- Ali, B.; Ahmed, H.; Ali Qureshi, L.; Kurda, R.; Hafez, H.; Mohammed, H.; Raza, A. Enhancing the Hardened Properties of Recycled Concrete (RC) through Synergistic Incorporation of Fiber Reinforcement and Silica Fume. Materials 2020, 13, 4112. [Google Scholar] [CrossRef]

- Kurda, R.; Silvestre, J.D.; de Brito, J.; Ahmed, H. Optimizing recycled concrete containing high volume of fly ash in terms of the embodied energy and chloride ion resistance. J. Clean. Prod. 2018, 194, 735–750. [Google Scholar] [CrossRef]

- Kurda, R.; de Brito, J.; Silvestre, J.D. Water absorption and electrical resistivity of concrete with recycled concrete aggregates and fly ash. Cem. Concr. Compos. 2019, 95, 169–182. [Google Scholar] [CrossRef]

- Kou, S.; Poon, C.; Agrela, F. Comparisons of natural and recycled aggregate concretes prepared with the addition of different mineral admixtures. Cem. Concr. Compos. 2011, 33, 788–795. [Google Scholar] [CrossRef]

- Qureshi, L.A.; Ali, B.; Ali, A. Combined effects of supplementary cementitious materials (silica fume, GGBS, fly ash and rice husk ash) and steel fiber on the hardened properties of recycled aggregate concrete. Constr. Build. Mater. 2020, 263, 120636. [Google Scholar] [CrossRef]

- Sasanipour, H.; Aslani, F.; Taherinezhad, J. Chloride ion permeability improvement of recycled aggregate concrete using pretreated recycled aggregates by silica fume slurry. Constr. Build. Mater. 2021, 270, 121498. [Google Scholar] [CrossRef]

- Alyousef, R.; Ali, B.; Mohammed, A.; Kurda, R.; Alabduljabbar, H.; Riaz, S. Evaluation of Mechanical and Permeability Characteristics of Microfiber-Reinforced Recycled Aggregate Concrete with Different Potential Waste Mineral Admixtures. Materials 2021, 14, 5933. [Google Scholar] [CrossRef] [PubMed]

- Mangi, S.A.; Raza, M.S.; Khahro, S.H.; Qureshi, A.S.; Kumar, R. Recycling of ceramic tiles waste and marble waste in sustainable production of concrete: A review. Environ. Sci. Pollut. Res. 2022, 29, 18311–18332. [Google Scholar] [CrossRef]

- Ali, B.; Qureshi, L.A. Influence of glass fibers on mechanical and durability performance of concrete with recycled aggregates. Constr. Build. Mater. 2019, 228, 116783. [Google Scholar] [CrossRef]

- Guler, S.; Öker, B.; Akbulut, Z.F. Workability, strength and toughness properties of different types of fiber-reinforced wet-mix shotcrete. In Structures; Elsevier: Amsterdam, The Netherlands, 2021; Volume 31, pp. 781–791. [Google Scholar]

- Köksal, F.; Altun, F.; Yiǧit, I.; Şahin, Y. Combined effect of silica fume and steel fiber on the mechanical properties of high strength concretes. Constr. Build. Mater. 2008, 22, 1874–1880. [Google Scholar] [CrossRef]

- Guler, S.; Akbulut, Z.F.; Siad, H.; Lachemi, M. Effect of macro polypropylene, polyamide and steel fibers on the residual properties of SCC at ambient and elevated temperatures. Constr. Build. Mater. 2021, 289, 123154. [Google Scholar] [CrossRef]

- Guler, S.; Akbulut, Z.F. Effect of high-temperature on the behavior of single and hybrid glass and basalt fiber added geopolymer cement mortars. J. Build. Eng. 2022, 57, 104809. [Google Scholar] [CrossRef]

- Ur Rehman, Z.; Khalid, U. Optimization of COVID-19 face mask waste fibers and silica fume as a balanced mechanical ameliorator of fat clay using response surface methodology. Environ. Sci. Pollut. Res. 2022, 29, 17001–17016. [Google Scholar] [CrossRef] [PubMed]

- Raza, S.S.; Amir, M.T.; Azab, M.; Ali, B.; Abdallah, M.; El Ouni, M.H.; Elhag, A.B. Effect of micro-silica on the physical, tensile, and load-deflection characteristics of micro fiber-reinforced high-performance concrete (HPC). Case Stud. Constr. Mater. 2022, 17, e01380. [Google Scholar] [CrossRef]

- Raza, S.S.; Qureshi, L.A. Effect of carbon fiber on mechanical properties of reactive powder concrete exposed to elevated temperatures. J. Build. Eng. 2021, 42, 102503. [Google Scholar] [CrossRef]

- Mastali, M.; Dalvand, A. Use of silica fume and recycled steel fibers in self-compacting concrete (SCC). Constr. Build. Mater. 2016, 125, 196–209. [Google Scholar] [CrossRef]

- Xie, J.; Fang, C.; Lu, Z.; Li, Z.; Li, L. Effects of the addition of silica fume and rubber particles on the compressive behaviour of recycled aggregate concrete with steel fibres. J. Clean. Prod. 2018, 197, 656–667. [Google Scholar] [CrossRef]

- Nazarimofrad, E.; Shaikh, F.U.A.; Nili, M. Effects of steel fibre and silica fume on impact behaviour of recycled aggregate concrete. J. Sustain. Cem. Mater. 2017, 6, 54–68. [Google Scholar] [CrossRef]

- ASTM-C150; Standard Specification for Portland Cement. ASTM International: West Conshohocken, PA, USA, 2018.

- Wang, Y.; Xu, Z.; Wang, J.; Zhou, Z.; Du, P.; Cheng, X. Synergistic effect of nano-silica and silica fume on hydration properties of cement-based materials. J. Therm. Anal. Calorim. 2020, 140, 2225–2235. [Google Scholar] [CrossRef]

- ASTM-C494; Standard Specification for Chemical Admixtures for Concrete. AASHTO: Washington, DC, USA, 2015.

- Yunchao, T.; Zheng, C.; Wanhui, F.; Yumei, N.; Cong, L.; Jieming, C. Combined effects of nano-silica and silica fume on the mechanical behavior of recycled aggregate concrete. Nanotechnol. Rev. 2021, 10, 819–838. [Google Scholar] [CrossRef]

- Xie, J.; Zhang, Z.; Lu, Z.; Sun, M. Coupling effects of silica fume and steel-fiber on the compressive behaviour of recycled aggregate concrete after exposure to elevated temperature. Constr. Build. Mater. 2018, 184, 752–764. [Google Scholar] [CrossRef]

- Ali, B.; Kurda, R.; Herki, B.; Alyousef, R.; Mustafa, R.; Mohammed, A.; Raza, A.; Ahmed, H.; Fayyaz Ul-Haq, M. Effect of Varying Steel Fiber Content on Strength and Permeability Characteristics of High Strength Concrete with Micro Silica. Materials 2020, 13, 5739. [Google Scholar] [CrossRef]

- Farooq, M.A.; Fahad, M.; Ali, B.; ullah, S.; El Ouni, M.H.; Elhag, A.B. Influence of nylon fibers recycled from the scrap brushes on the properties of concrete: Valorization of plastic waste in concrete. Case Stud. Constr. Mater. 2022, 16, e01089. [Google Scholar] [CrossRef]

- EN-12390-3; Testing of Hardened Concrete, Part 3: Compressive Strength of Test Specimens. British Standards Institution: London, UK, 2002.

- ASTM-C496; Standard Test Method for Splitting Tensile Strength of Cylindrical Concrete Specimens. ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM-C1609; Standard Test Method for Flexural Performance of Fiber-Reinforced Concrete (Using Beam With Third-Point Loading). ASTM International: West Conshohocken, PA, USA, 2019.

- ASTM-C948 Standard; Test Method for Dry and Wet Bulk Density, Water Absorption, and Apparent Porosity of Thin Sections of Glass-Fiber Reinforced Concrete. ASTM International: West Conshohocken, PA, USA, 2016.

- Kurda, R.; de Brito, J.; Silvestre, J.D. Combined influence of recycled concrete aggregates and high contents of fly ash on concrete properties. Constr. Build. Mater. 2017, 157, 554–572. [Google Scholar] [CrossRef]

- Kazmi, S.M.S.; Munir, M.J.; Wu, Y.-F.; Patnaikuni, I.; Zhou, Y.; Xing, F. Axial stress-strain behavior of macro-synthetic fiber reinforced recycled aggregate concrete. Cem. Concr. Compos. 2019, 97, 341–356. [Google Scholar] [CrossRef]

- Khan, M.; Cao, M.; Ali, M. Effect of basalt fibers on mechanical properties of calcium carbonate whisker-steel fiber reinforced concrete. Constr. Build. Mater. 2018, 192, 742–753. [Google Scholar] [CrossRef]

- Khan, U.A.; Jahanzaib, H.M.; Khan, M.; Ali, M. Improving the tensile energy absorption of high strength natural fiber reinforced concrete with fly-ash for bridge girders. In Key Engineering Materials; Trans Tech Publications Ltd.: Wollerau, Switzerland, 2018; Volume 765, pp. 335–342. [Google Scholar]

- Kurda, R.; de Brito, J.; Silvestre, J.D. Indirect evaluation of the compressive strength of recycled aggregate concrete with high fly ash ratios. Mag. Concr. Res 2018, 70, 204–216. [Google Scholar] [CrossRef]

- Zheng, Y.; Zhuo, J.; Zhang, P.; Ma, M. Mechanical properties and meso-microscopic mechanism of basalt fiber-reinforced recycled aggregate concrete. J. Clean. Prod. 2022, 370, 133555. [Google Scholar] [CrossRef]

- BIS 13311-1; Method of Non-Destructive Testing of Concret, Part 1. Bureau of Indian Standards: Delhi, India, 1992.

- Das, C.S.; Dey, T.; Dandapat, R.; Mukharjee, B.B.; Kumar, J. Performance evaluation of polypropylene fibre reinforced recycled aggregate concrete. Constr. Build. Mater. 2018, 189, 649–659. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).