Effect Evaluation of Filling Medium Parameters on Operating and Mechanical Performances of Liquid Heavy Metal Heat Storage Tank

Abstract

Highlights

- An integrated thermal and mechanical analysis of a liquid LBE tank.

- The effects of four filling medium parameters are evaluated.

- The viability of liquid LBE for solar TES tanks is evaluated.

Abstract

1. Introduction

2. Material and Methods

2.1. Governing Equations

- (a)

- The LBE flow and heat transfer were symmetrical about the axis.

- (b)

- The solid fillers in the packing region of the tank could be considered as a continuous, homogeneous, and isotropic porous medium.

- (c)

- The liquid LBE flow in the packing region was laminar and incompressible.

- (d)

- The properties of the filling particles in the packing region were constant.

2.2. Numerical Model

3. Results

3.1. Operation Performance

3.2. Effect Evaluation Results of Filling Medium Parameters

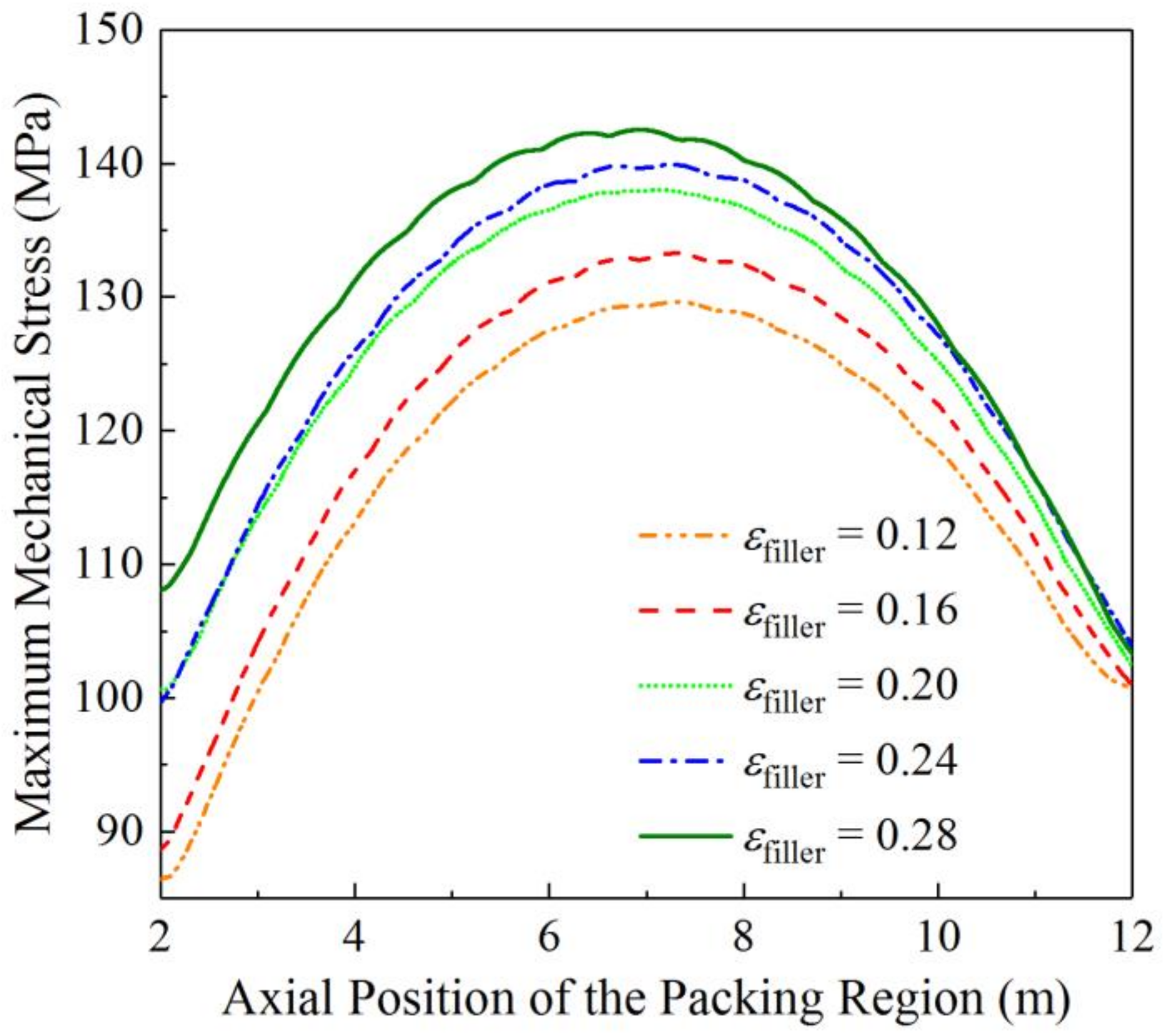

3.2.1. Effects of Porosity of the Filling Medium

3.2.2. Effects of the Thermal Conductivity of the Filling Medium

3.2.3. Effects of the Specific Heat Capacity of the Filling Medium

3.2.4. Effects of the Equivalent Diameter of the Filling Medium

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclatures

| CP | specific heat capacity | J/(kg∙K) |

| dt | thermocline thickness | m |

| D | diameter | m |

| E | elasticity modulus | Pa |

| F | inertial coefficient of the porous medium | |

| H | height | m |

| hinter | interstitial heat transfer coefficient | W/(m2∙K) |

| K | intrinsic permeability of the porous medium | m2 |

| k | thermal conductivity | W/(m∙K) |

| L | thickness of the wall layer | m |

| mass flow rate | kg/s | |

| Q | heat quantity | J |

| T | temperature | K |

| t | time | h |

| u | velocity | m/s |

| Greek symbols | ||

| α | thermal expansion coefficient | K−1 |

| εfiller | porosity of packed medium | |

| εm | mechanical strain | |

| εt | thermal strain | |

| εw | emissivity of the tank wall | |

| η | efficiency | |

| μ | viscosity | kg/(m∙s) |

| ρ | density | kg/m3 |

| σmax | maximum mechanical stress | Pa |

| Subscripts | ||

| c | cold | |

| dis | distributor | |

| discharge | discharge process | |

| eff | effective | |

| filler | filling particle | |

| fluid | heat transfer fluid | |

| h | hot | |

| in | inlet | |

| m | mechanical | |

| max | maximum | |

| min | minimum | |

| t | thermal | |

| w | tank wall | |

| Abbreviations | ||

| CF | carbon fiber | |

| CFD | computational fluid dynamics | |

| CSP | concentrated solar thermal power | |

| EG | expanded graphite | |

| HTF | heat transfer fluid | |

| LBE | lead-bismuth eutectic | |

| LHM | liquid heavy metal | |

| MMS | maximum mechanical stress | |

| PA | palmitic acid | |

| SPS | solar power system | |

| TES | thermal energy storage | |

References

- Wang, G.; Pang, S.; Jiang, T. A brief review of liquid heat transfer materials used in concentrated solar power systems and thermal energy storage devices of concentrated solar power systems. Eng. Rep. 2022, 2022, e12576. [Google Scholar] [CrossRef]

- Yang, Z.; Garimella, S.V. Molten-salt thermal energy storage in thermoclines under different environmental boundary conditions. Appl. Energy 2010, 87, 3322–3329. [Google Scholar] [CrossRef]

- Fernández-Torrijos, M.; Sobrino, C.; Almendros-Ibáñez, J. Simplified model of a dual-media molten-salt thermocline tank with a multiple layer wall. Sol. Energy 2017, 151, 146–161. [Google Scholar] [CrossRef]

- EL Sihy, E.S.; Liao, Z.; Xu, C.; Du, X. Dynamic characteristics of solid packed-bed thermocline tank using molten-salt as a heat transfer fluid. Int. J. Heat Mass Transf. 2021, 165, 120677. [Google Scholar] [CrossRef]

- Sun, B.; Liu, Z.; Ji, X.; Gao, L.; Che, D. Thermal energy storage characteristics of packed bed encapsulating spherical capsules with composite phase change materials. Appl. Therm. Eng. 2021, 201, 117659. [Google Scholar] [CrossRef]

- Zwierzchowski, R.; Wołowicz, M. Energy and Exergy Analysis of Sensible Thermal Energy Storage—Hot Water Tank for a Large CHP Plant in Poland. Energies 2020, 13, 4842. [Google Scholar] [CrossRef]

- Grötzbach, G. Challenges in low-Prandtl number heat transfer simulation and modelling. Nucl. Eng. Des. 2013, 264, 41–55. [Google Scholar] [CrossRef]

- Thiele, R.; Anglart, H. Numerical modeling of forced-convection heat transfer to lead–bismuth eutectic flowing in vertical annuli. Nucl. Eng. Des. 2013, 254, 111–119. [Google Scholar] [CrossRef]

- Wang, G. A Review of Recent Numerical and Experimental Research Progress on CDA Safety Analysis of LBE-/Lead-cooled Fast Reactors. Ann. Nucl. Energy 2017, 110, 1139–1147. [Google Scholar] [CrossRef]

- Pacio, J.; Wetzel, T. Assessment of liquid metal technology status and research paths for their use as efficient heat transfer fluids in solar central receiver systems. Sol. Energy 2013, 93, 11–22. [Google Scholar] [CrossRef]

- Laube, T.; Marocco, L.; Niedermeier, K.; Pacio, J.; Wetzel, T. Thermodynamic Analysis of High-Temperature Energy Storage Concepts Based on Liquid Metal Technology. Energy Technol. 2019, 8, 1900908. [Google Scholar] [CrossRef]

- Xu, C.; Wang, Z.; He, Y.; Li, X.; Bai, F. Sensitivity analysis of the numerical study on the thermal performance of a packed-bed molten salt thermocline thermal storage system. Appl. Energy 2012, 92, 65–75. [Google Scholar] [CrossRef]

- Wang, G.; Yu, S.; Niu, S.; Chen, Z.; Hu, P. A comprehensive parametric study on integrated thermal and mechanical performances of mol-ten-salt-based thermocline tank. Appl. Therm. Eng. 2020, 170, 115010. [Google Scholar] [CrossRef]

- Flueckiger, S.; Yang, Z.; Garimella, S.V. An integrated thermal and mechanical investigation of molten-salt thermocline energy storage. Appl. Energy 2011, 88, 2098–2105. [Google Scholar] [CrossRef]

- OECD; Nuclear Energy Agency. Handbook on Lead-Bismuth Eutectic Alloy and Lead Properties, Materials Compatibility, Thermalhydraulics and Technologies; Organisation for Economic Co-Operation and Development: Paris, France, 2015; Available online: https://publications.jrc.ec.europa.eu/repository/handle/JRC100764 (accessed on 23 August 2022).

- Pacheco, J.E.; Showalter, S.K.; Kolb, W.J. Development of a molten-salt thermocline thermal storage system for parabolic trough plants. J. Sol. Energy Eng. 2002, 124, 153–159. [Google Scholar] [CrossRef]

- Xu, C.; Li, X.; Wang, Z.; He, Y.; Bai, F. Effects of solid particle properties on the thermal performance of a packed-bed molten-salt thermocline thermal storage system. Appl. Therm. Eng. 2013, 57, 69–80. [Google Scholar] [CrossRef]

| HTFs | Advantages | Disadvantages |

|---|---|---|

| Molten salts | Strong heat storage capacity, difficult to burn, good safety, low working pressure, non-toxic | Easy to decompose, oxidation and corrosion under high temperature conditions, high melting temperature |

| Heat transfer oils | Strong fluidity, low freezing point, good heat transfer performance, low corrosiveness | Short service life, low applicable temperature, flammable |

| Liquid metals | Excellent thermal conductivity, low melting point, high boiling point, wide operating temperature range | High corrosiveness under high temperature conditions, toxicity of some metals |

| Water/steam | Low cost, innocuous, low corrosiveness, environmental protection | High temperature and pressure requirements, low heat storage capacity |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, G.; Wang, T. Effect Evaluation of Filling Medium Parameters on Operating and Mechanical Performances of Liquid Heavy Metal Heat Storage Tank. Sustainability 2022, 14, 14551. https://doi.org/10.3390/su142114551

Wang G, Wang T. Effect Evaluation of Filling Medium Parameters on Operating and Mechanical Performances of Liquid Heavy Metal Heat Storage Tank. Sustainability. 2022; 14(21):14551. https://doi.org/10.3390/su142114551

Chicago/Turabian StyleWang, Gang, and Tong Wang. 2022. "Effect Evaluation of Filling Medium Parameters on Operating and Mechanical Performances of Liquid Heavy Metal Heat Storage Tank" Sustainability 14, no. 21: 14551. https://doi.org/10.3390/su142114551

APA StyleWang, G., & Wang, T. (2022). Effect Evaluation of Filling Medium Parameters on Operating and Mechanical Performances of Liquid Heavy Metal Heat Storage Tank. Sustainability, 14(21), 14551. https://doi.org/10.3390/su142114551