Abstract

The global demand for plastic is expected to double in the next 20 years. The increasing demand for Single-Use Plastic Products (SUPPs) has become one of the main environmental problems in many developing countries, including Sri Lanka, through direct and indirect means, in the way of excessive consumption and the pollution of the environment through waste generation. In this way, there is a pressing need to accelerate the sustainability evaluation, comparison, impact mitigation and policy recommendation of SUPPs to address the environmental impacts and sustainable development. Therefore, this study aims to quantify and compare the environmental impacts of SUPPs for policy decision making in Sri Lanka using life cycle assessment (LCA) techniques. Accordingly, the most popular and widely used single-use plastic products, which are under consideration for regulation in Sri Lanka, and their possible alternatives, are considered for this LCA study. The results reveal that SUPPs produced using polystyrene (PS), polypropylene (PP), low-density polyethylene (LDPE), high-density polyethylene (HDPE), and polyethylene terephthalate (PET) have a significant contribution in all life cycle stages, in terms of global warming potential (GWP) and endpoint impact categories. However, the outcomes of the study reveal that the net GWP impact of SUPPs that have recycling practice at the end of life shows better performance compared to incineration and landfill. In addition, the polylactic acid- (PLA)-based products also show a significant impact on mid- and end-point GWP impact categories. Remarkably, the midpoint analysis of PLA-based products and their alternatives emphasized that PLA production was the most impactful for most of the midpoint impact categories due to PLA resin production, which contributes significantly to all impact categories. In particular, for the pesticide bottles with the preferred end-of-life option of incineration, the HDPE indicates a 7.6% lower GWP compared to PET. For reusable steel cutlery, the largest GWP-associated life cycle stage is the user phase (97.5%), which includes cleaning the cutlery. However, the overall reduction in GWP in the use of steel, considering the best (PS with recycling) and worst (PS with incineration) case scenarios, with single-use items are 0.01 and 0.05 kg CO2 (eq), respectively. In the case of pesticide bottles, with the preferred end-of-life option being incineration, the HDPE indicates a 7.6% lower GWP compared to PET. the study reveals that conducting LCA will facilitate scientific decision making for policy interventions related to SUPPs and their processes. Notably, the study shows that, at present, the capability of conducting LCA studies to evaluate the sustainability performance of SUPPs in Sri Lanka is limited due to the lack of life cycle inventory (LCI) data availability on SUPPs and relevant waste management practices in Sri Lanka.

1. Introduction

Over the last few decades, environmental issues, such as global warming, pollution, and depletion of resources, have attracted much attention around the world., noting with concern that the high and rapidly increasing levels of plastic pollution represent a serious environmental problem on a global scale, negatively impacting the environmental, as well as social and economic dimensions of sustainable development [1].

In particular, the severe environmental threat of plastic pollution has caused growing global concern. In that respect, the global demand for plastic is expected to double in the next 20 years [2]. Plastics are the most widely used materials for single-use applications and packaging purposes due to their appealing characteristics, such as being lightweight, transparent, and flexible, with good mechanical and barrier properties, relatively low cost of production, chemical inertness, and relative convenience in fabrication, and handling and hygiene [3,4,5]. Therefore, the manufacturing and usage of plastic and its waste have steadily increased over the past 30 years and pose several threats to humans, resources, and to the ecosystem [6].

Single-use plastic products (SUPPs) are one of the most consumed items, globally, and much debate has evolved around their environmental impact. The most common single-use plastic waste products are straws, yogurt cups, mega bottles, lunch sheets, milk packets, meal boxes, polyethylene bags, sachet packets, and wrappers [7], which need to be managed in an environmentally sound manner. Therefore, it is crucial to accelerate the sustainability evaluation, comparison and impact mitigation of single-use plastic to address the global challenges of climate change and sustainable development [8].

Sri Lanka annually imports a considerable amount of plastic raw materials and finished products. A major portion of these end up as “Consumer Plastic Waste”, causing serious environmental issues. It is estimated that approximately 160,000 MT of plastics products and raw materials are imported to Sri Lanka per annum, with an annual average growth rate of around 10–12% [7,9]; within this figure, 30% have been exported as finished products, and the remainder are used locally [10]. Sri Lanka has over 400 companies engaged in plastic processing. The main polymers used for producing single-use plastics are high-density polyethylene (HDPE), low-density polyethylene (LDPE), polyethylene terephthalate (PET), polypropylene (PP), and polystyrene (PS) [7]. Many of these SUPPs end up in municipal solid waste (MSW) due to the lack of technical and financial capacities of local governments to manage them, and due to the irresponsible behavior of consumers [11]. Of the MSW generated, only one-third is collected for processing, and the rest are either open-dumped [12] or open-burned [11]. This has become a national burden.

There are many initiatives being implemented both globally and nationally to address plastic pollution, especially the single use of plastics. According to the United Nations Environment Programme (UNEP) and the World Resources Institute (WRI), 127 countries have already reviewed and adopted some form of legislation to regulate plastic bags, while 27 countries have enacted some form of law to ban single-use plastics, either in specific products (e.g., plates, cups, straws, packaging) or materials (e.g., polystyrene), or at the production level [13]. In Sri Lanka, the government developed the National Action Plan on Plastic Waste Management in 2021 [11] and introduced several gazette orders to ban some single-use plastic product-packaging and selected product categories that fall into SUPPs [8]. As these decisions led to many socio-economic issues, and al there are some doubts about the true environmental gain of these decisions, it is timely to investigate the overall picture of actual environmental gains, as some instances of alternatives to SUPPs will have more negative impacts on the environment. However, it is not easy to capture the complete picture of actual environmental impact or gain by concentrating on only one aspect of the products, such as the manufacturing phase, usage, or disposal. This study will be only possible if the total life cycle of the products is investigated for their environmental impacts. In order to convince the consumers of the complete picture of products’ environmental sustainability, it is important to inculcate life cycle thinking (LCT) among them. LCT is about going beyond the traditional focus on the production site and manufacturing processes to include environmental, social and economic impacts of a product, over its entire life cycle [14], as well as their alternatives, which also need to be investigated from a life cycle perspective. Life cycle assessment (LCA) is a quantitative tool designed for the purpose of assessing the environmental impacts of products and services across their entire life cycle, including raw material extraction, manufacturing, transportation, use and end-of-life [15]. The fourth and fifth United Nations Environment Assemblies (UNEA4 [16] and UNEA5.2 [17], respectively) encouraged member states to address SUPP’s pollution by taking actions, such as promoting the identification and development of environmentally friendly alternatives to SUPPs and considering the full-life-cycle implications of those alternatives [18]. To further assist this process, the United Nations Life Cycle Initiative (UNEP-LCI) is creating a meta-analysis of SUPPs and alternative LCA studies. In the meantime, the limitations of the present LCA, assessing the end-of-life impacts of mismanaged plastics [19] and the lack of life cycle inventory (LCI) data, especially in developing countries, hinder the application of LCA to evidence-based policymaking. At present, the capability of conducting LCA studies in Sri Lanka is limited due to the lack of LCI data availability on a national scale, and foreign background databases available in the LCA software do not include specific data for the Sri Lankan context [20]. Although there is wide availability of data related to the major products and processes in Sri Lanka, these available data are in different formats and used for different objectives than the LCA. Although the government and other related constitutional bodies have acknowledged the importance of the LCA approach to achieve sustainable development goals for the country, an effective policy has not yet been established to mainstream the LCI database at national level. Accumulation of the available data, in a usable form and in a national database, will be essential for promoting LCT and LCA approaches in Sri Lanka, as well as in the decision-making process for implementing sustainable development practices.

Therefore, this research aims to evaluate the environmental performance of SUPPs and their possible alternatives for policy-making and recommendations in Sri Lanka, using LCA techniques, while considering the limitations of LCA. Accordingly, this study aims to quantify the environmental impacts of eight selected SUPPs and their possible alternatives, using LCA techniques. The selected SUPPs are: cutlery (fork/spoon), cotton buds, Joss-Stick wrappers, cloth wick wrappers, pesticide bottles, grocery bags, straws and, water bottles. Further, SimaPro 8.3.0.0 software, IPCC 2013 Global warming potential (GWP) 100a V1.03/Characterization, ReCiPe Midpoint (H) V1.13/Normalization, and ReCiPe Endpoint (H) V1.13/Weighting perspective model approaches were used for the assessment and comparison of the environmental performance of the eight selected SUPPs and their possible alternatives.

2. Materials and Methods

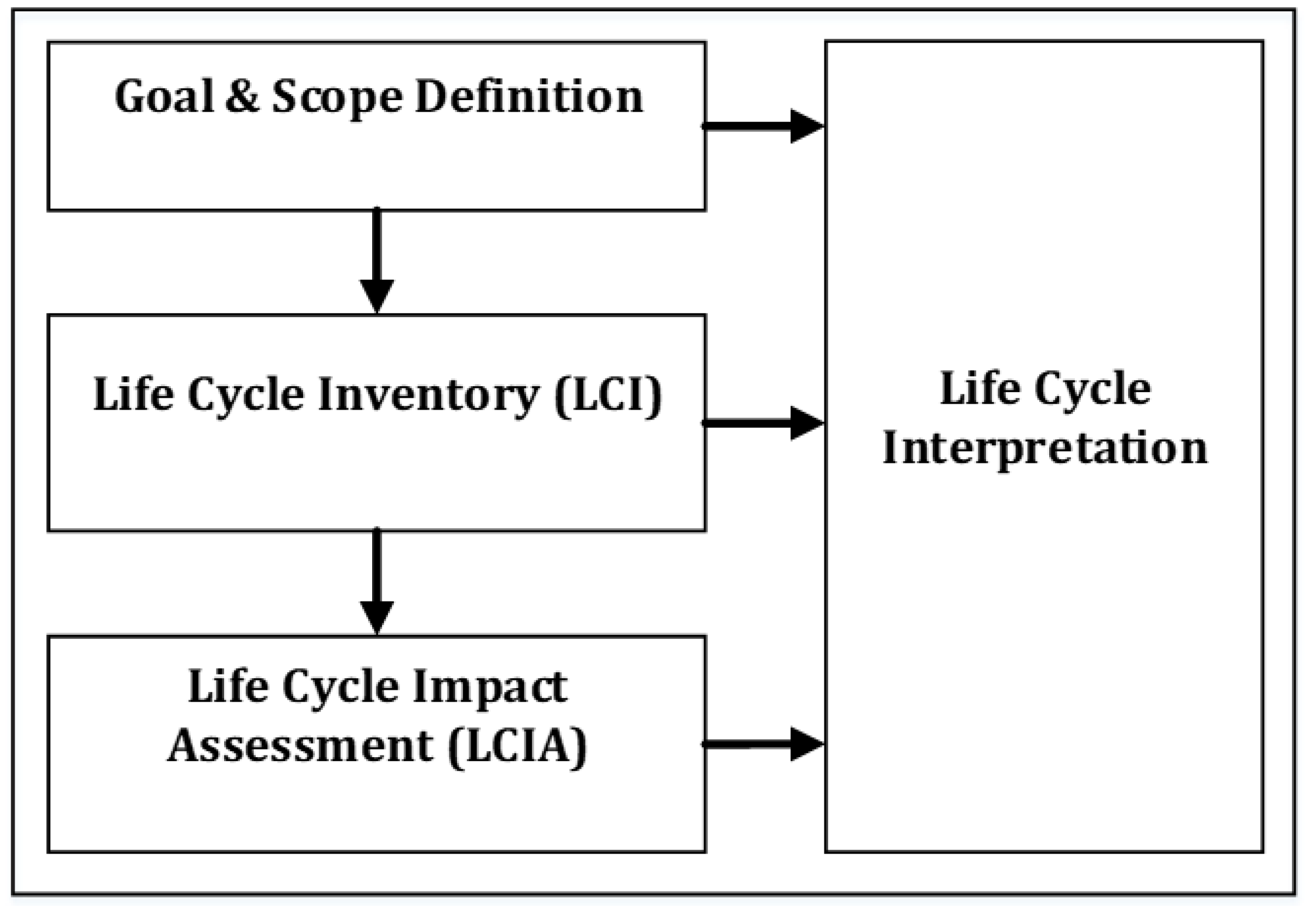

This study is structured by goal and scope definition, life cycle inventory analysis, life cycle impact assessment and life cycle interpretation according to ISO 14040 [21] and 14044 [22].

2.1. LCA Methodology—ISO 14040/14044

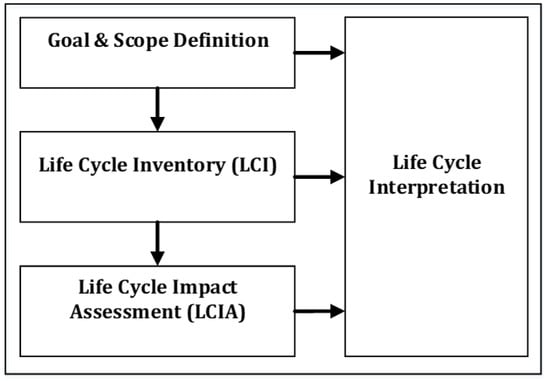

The LCA is a useful tool that is a structured, comprehensive and internationally standardized method used for the identification of environmental hotspots throughout the product life cycle [23]. It quantifies the relevant emissions, consumption of resources and energy, and environmental impacts associated with the product, process, or system. The LCA is, therefore, a vital and robust decision support tool, complementing other methods which are equally necessary to help effectively and efficiently make consumption and production more sustainable [24]. Moreover, LCA brings a holistic perspective to decision-making and has gained acceptance as a decision-making tool in industry, procurement and policymaking. The standardized LCA methodological framework was developed and established by ISO 14040 and ISO 14044 [21,22]. Figure 1 shows the ISO methodological framework of LCA.

Figure 1.

LCA methodology framework—ISO14040.

According to the ISO 14040 (2006) [21,22], LCA comprises four main stages as described below:

- Goal and scope definition: The goal and scope phase defines the purpose of the study, the intended use of the results, and what should be included.

- Life cycle inventory (LCI): The life cycle inventory phase involves the compilation and quantification of inputs and outputs for a product throughout its life cycle.

- Life cycle impact assessment (LCIA): The life cycle impact assessment phase is aimed at understanding and evaluating the magnitude and significance of the potential environmental impacts of a product system, throughout the life cycle of the product.

- Interpretation of results: The life cycle assessment phase, in which the findings of either the inventory analysis or the impact assessment, or both, is evaluated in relation to the defined goal and scope to reach conclusions and provide recommendations.

2.2. Goal and Scope Definition

This study aims to quantify the environmental impacts of SUPPs in order to provide recommendations for policy-making in Sri Lanka, using LCA techniques. Accordingly, the most popular and widely used SUPPs and their possible alternatives in Sri Lanka are considered for the LCA study and policy recommendations. The selected SUPPs and their alternatives are listed below, in Table 1. The eight SUPPs were selected from the list of stepwise banning items, regulated by the Ministry of Environment (MOE), Sri Lanka. The overall Sri Lankan regulating list includes 16 SUPP gazette items [24], an additional list of four supp items [25], and two non-SUPPs items [26]. The list of all the items is given in the supplementary document, Table S1. The eight selected items are a result of our communication with MOE, Sri Lanka; the central environmental authority, Sri Lanka; and a pre-data availability study for the SUPPs and the potential alternatives proposed by the local experts. PLA was targeted as an important alternative, as it has better mechanical strength, durability, and transparency, compared to other bio-degradable plastics. PLA is widely used for single-use and short-lifetime packaging products, such as food packaging and single-use products [27]. In addition to its mechanical properties, another reason for selecting PLA is that the manufacturing process that turns PLA into single-use packaging is almost identical to other fossil fuel-based plastics. Notably, the development of the properties of current PLA has the potential for commercialization, while also solving the problems related to its fragility in packaging applications [28].

Table 1.

Selected SUPPs and their potential alternatives are considered in this study.

2.2.1. Goal, Functional Unit (FU), and System Boundaries

The LCA system’s definition and functional unit for all of the selected SUPPs in this study are presented in this section. The LCA system’s definition of this study is presented in Table 2. For the multiple-use (reusable) alternatives, the time of reuse is considered to be 200 times. All unit processes of SUPPs were considered in the system boundary. The required infrastructure and equipment to execute these unit processes were not included in the analysis. Moreover, this study considered the raw material import; transportation from import to the manufacturing plant and from manufacturing to the consumer; and transportation to the recycling plant, landfill, and incineration.

Table 2.

System definition of selected SUPPs and their possible alternatives.

2.2.2. General Data and Assumptions

Detailed analysis was conducted in order to prepare life cycle inventories of respective products, based on the system boundaries already defined in the four main stages of the life cycles of each product category. Materials of each product have been identified and further details of material compositions are currently being investigated, before finalizing the LCIs. T sources of data were commercial LCI databases, public LCI databases, measured data, data from peer-reviewed literature [29,30,31], data from reports of public bodies, and data from manufacturers. The alternatives for the selected SUPPs were selected by considering the social acceptance, adaptability to change, and the manufacturing process by material substitution. In their respective manufacturing processes, PP, PE, PS, and PLA-based products undergo the same process of injection molding, using SimaPro.

Phase-related information, such as water and detergent consumption for the washing of the metal cutlery (fork/spoon) and the aluminium water bottle, was taken from the literature [29,30]. Accordingly, the water and detergent consumption for washing during the use phase is assumed as 0.4 L and 1 g for metal cutlery (fork/spoon), and 0.25 L and 1 g, for the aluminium water bottles(for 200 times washing). In addition, the average weight of the aluminium water bottles and of the labels for PET water bottles were taken from the literature [30,31].The weight of the aluminum water bottle and label for the PET water bottle were assumed as 105.9 g of aluminum and 0.37 g of PE, respectively. The end-of-life phase of each product category was taken based on the potential and possible scenario of Sri Lankan waste management practices. This study worked with the assumption that waste from all single-use items is either 100% recycled or put into landfill and incinerated. End-of-life process data were primarily taken from SimaPro software.

All the transportation distances were calculated based on assumptions, and were not measured. Transportation distances from overseas to Sri Lanka were assumed based on the import countries, particularly China, India, and UAE. The local transportation, to the factory and to the consumer, is estimated at 50 km and 150 km, respectively. The municipal transportation from consumers to recycling plants, landfill, and incinerations are assumed as 40 km, 20 km, and 80 km, respectively. Detailed information is provided in the supplementary Table S2.

2.3. Life-Cycle Inventory

Life cycle inventory considers the collection of data for all relevant inputs (energy and material) and outputs (emissions and wastes) along the life cycle. These data are then set concerning the FU defined in the goal and scope definition. The data collection for the life cycle inventory preparation involved information related to the pre-manufacturing, production, transportation, and disposal associated with the SUPPs. The data relating to SUPPs at different stages along the life cycle have been collected through field surveys, observations, and personal interviews. When it comes to alternative products, respective life cycle phases related to activity data have been estimated and collected from equivalent manufacturing processes.

2.4. Life Cycle Impact Assessment

The life cycle impact assessment is the stage in which the size and significance of potential impacts are determined and assessed in an LCA study, with a defined system boundary. In this study, the LCA analysis was performed for the determined system boundary, and global warming potential (GWP), ReCiPe Midpoint and Endpoint were examined. LCA analysis is performed using SimaPro 8.3.0.0 software. The secondary data used in the model has been obtained from the existing ecoinvent database 3.0 in SimaPro 8.3.0.0 software. IPCC 2013 GWP 100a V1.03 method indicates the effects of climate change as a result of greenhouse gas (GHG) emissions. The ReCiPe midpoint impact categories provide more reliable results due to the wide range of indicators provided and the endpoint method indicates the extent of adverse impacts in categories such as human health, ecosystem quality, and resources.

2.5. Sri Lankan Situation of SUPPs Regulating Process

The background of Sri Lanka’s national legislation related to plastic pollution and the SUPPs regulating process was studied through communication with MOE, Sri Lanka; the central environmental authority (CEA), Sri Lanka; and from referral to the published documents by the relevant authorities.

3. Results

3.1. Life Cycle Inventory

The life cycle inventory involves “the quantification and compilation of inputs and outputs” related to SUPPs, throughout their life cycle. Inputs to the product systems include materials and energy, while outputs include emissions to air, water and soil. The life cycle inventory related to the products and their process was identified and compiled for each SUPP, based on the FUs described in Section 2.2.1. The life cycle inventory summary of all of the SUPPs for their respective FU of this study is presented in Supplementary Table S2. This summarized LCI data was used to model and assess the impact through the SimaPro software.

3.2. Life Cycle Impact of SUPPs and Alternative Products

In this study, the LCA analysis was performed for the determined system boundary, and GWP, ReCiPe Midpoint, and Endpoint were all examined. LCA analyses were performed using SimaPro 8.3.0.0 software. The results of the impact assessment and comparison of the SUPPs are presented in this section.

3.2.1. Cutlery (Fork/Spoon)

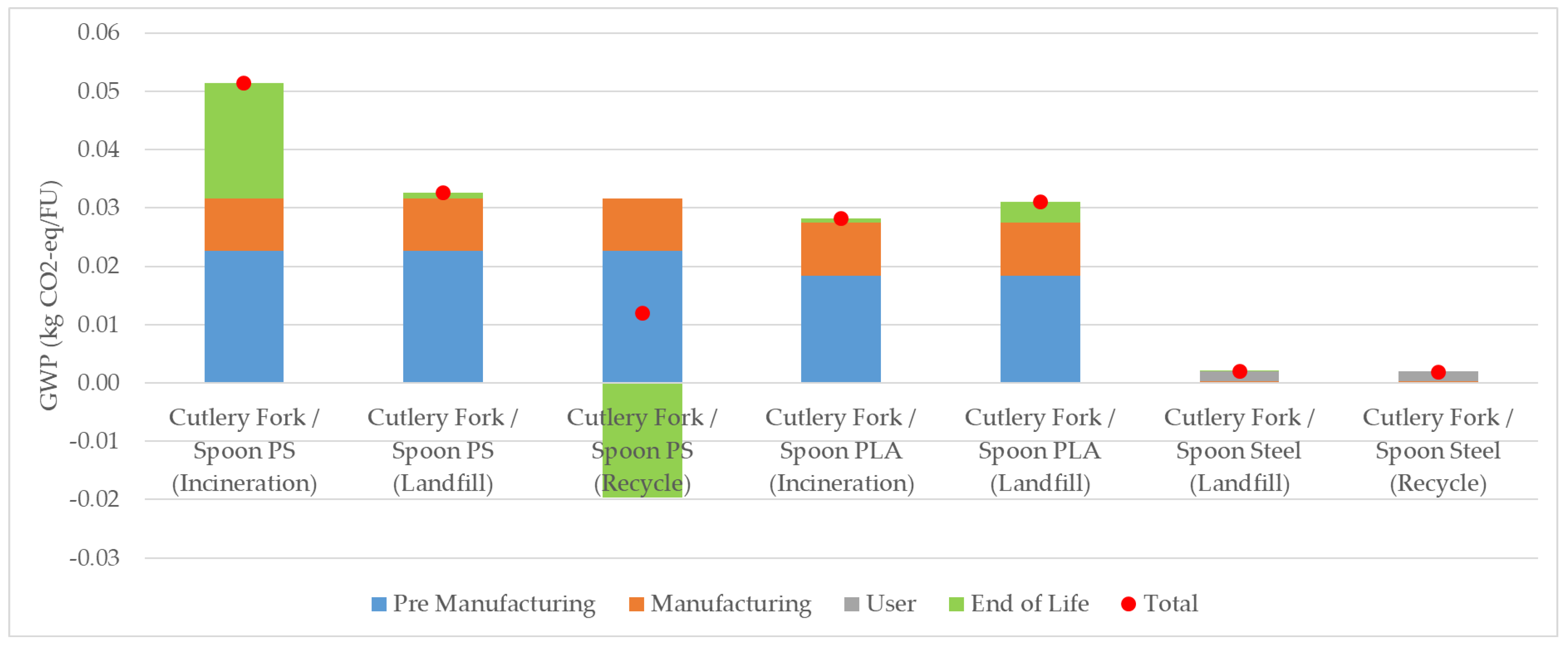

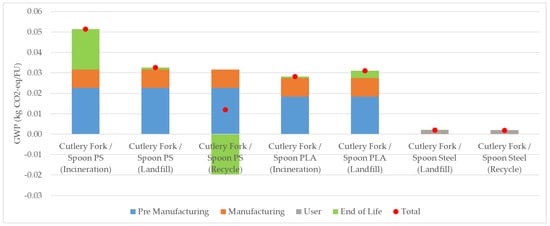

Figure 2 shows the contribution of climate change impact emissions from the life cycle stages of cutlery (fork/spoon) made of PS, PLA and Steel. Results show that the total GWP impact of PS cutlery is 0.0514 kg CO2 (eq) for 100% incineration; 0.032 kg CO2 (eq) for 100% landfill; and 0.0119 kg CO2 (eq) for 100% recycling. The GWP impact of PLA cutlery is shown to be 0.0280 kg CO2 (eq) for 100% incineration, and 0.0310 kg CO2 (eq) for 100% landfill. In addition, it depicts that the GWP of steel cutlery is 0.002 kg CO2 (eq) for 100% landfill and 0.0018 kg CO2 (eq) for 100% recycling.

Figure 2.

Comparison of global warming potential for cutlery (fork/spoon).

The results highlighted that the PS- and PLA-based cutlery (fork/spoon)were the least environmentally sound products in terms of GWP, while for the single-use steel cutlery (fork/spoon), the environmental performance was tenfold lower than its alternatives. Therefore, promoting metal cutlery will be advantageous for the significant reduction of GWP. The results for the PS and PLA cutleries reveal that the pre-manufacturing phase had a significant contribution to GWP, and its contribution to the total impacts of the system was around 50%. Notably, the net GWP impact of cutlery with recycling practice as its end of life shows a better performance, and can be considered as a possible potential alternative.

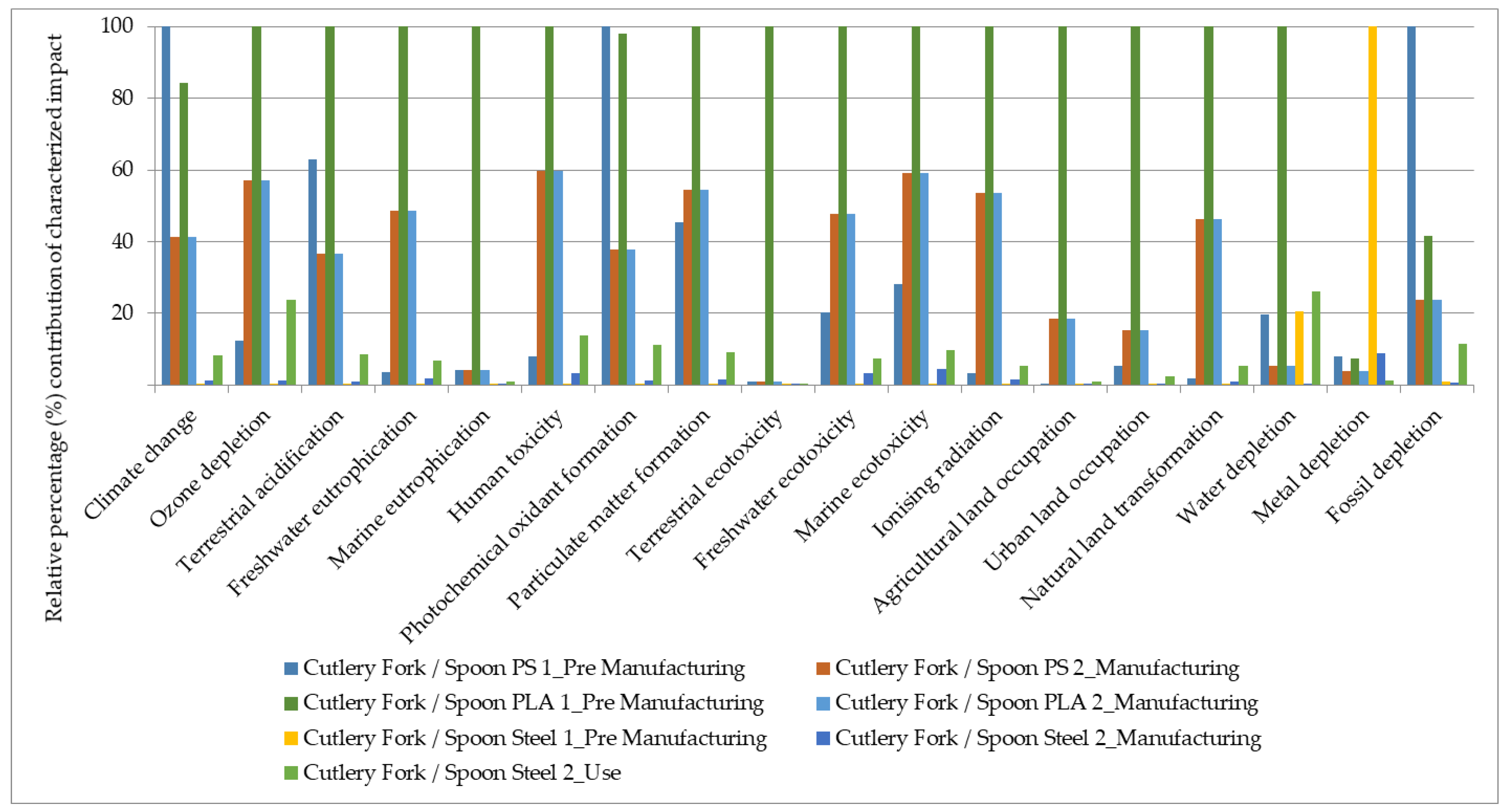

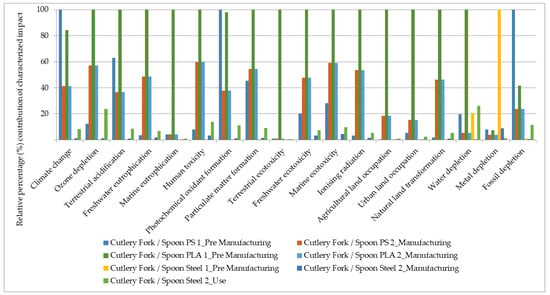

Figure 3 describes the ReCiPe midpoint analysis of all three cutlery (fork/spoon) alternatives: PS, PLA, and steel. Only pre-manufacturing and manufacturing phases prior to midpoint comparison are considered. The midpoint analysis of the cutlery (fork/spoon) highlighted that PLA production was the most impactful for all midpoint impact categories, with the exception of climate change, photochemical oxidant formation, metal depletion, and fossil depletion. PS production plays a significant role in climate change, photochemical oxidant formation and fossil depletion, while metal depletion is affected by steel production.

Figure 3.

Comparison of ReCiPe Midpoint Characterization of Cutlery (fork/spoon).

Notably, PLA production generally has higher impacts than the others due to PLA resin production, which contributes significantly to all impact categories. In particular, considerable GHG emissions occur during the corn production phase and are caused by a large amount of fertilizer and herbicides, which are generally used in corn cultivation [4]. Due to the various crop-based PLA production, it is difficult to quantify the exact impacts of PLA-based products, since crop inputs (i.e., pesticides, fertilizers, field activities) generally differ and therefore have different effects on GWP [30].

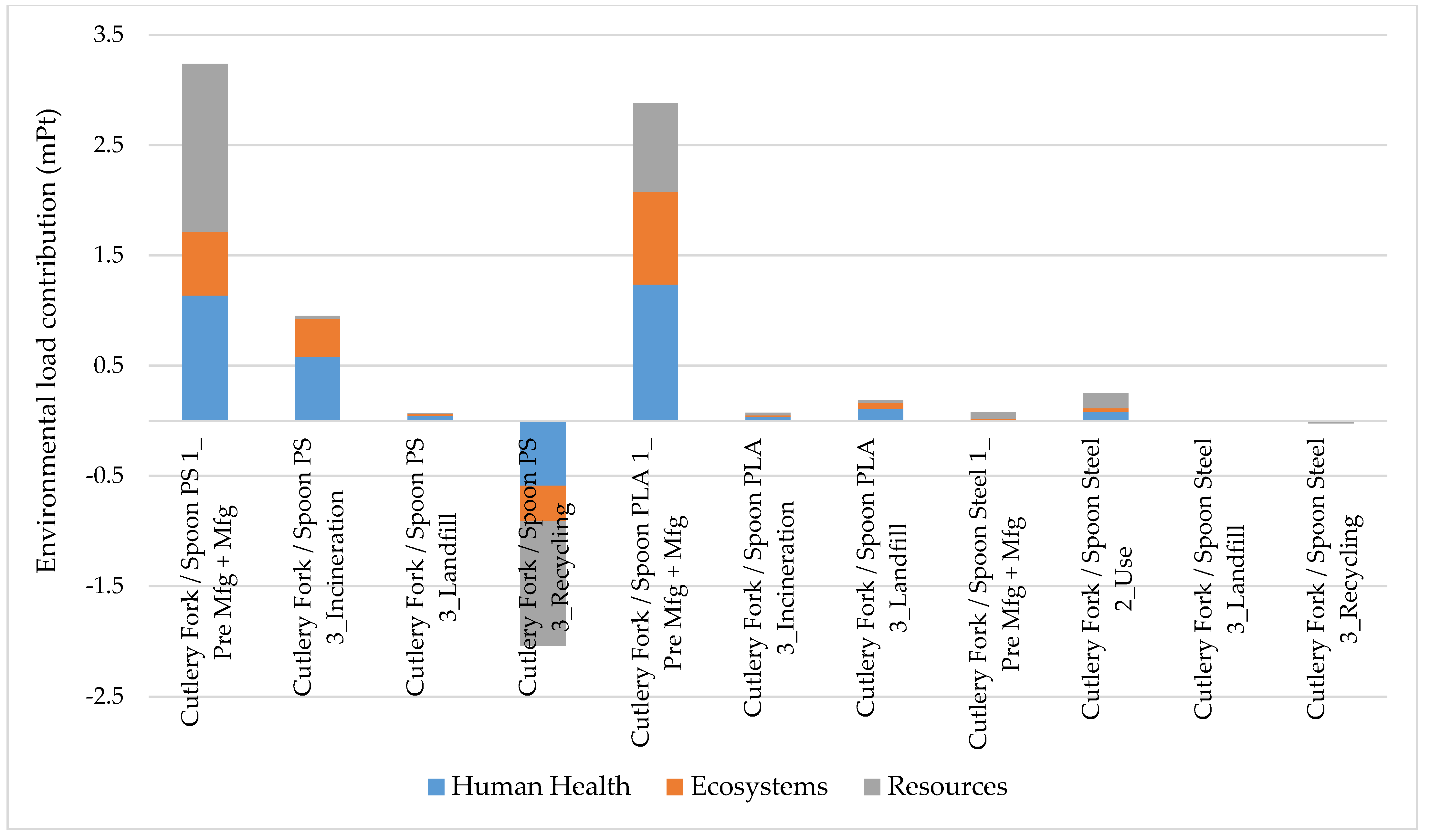

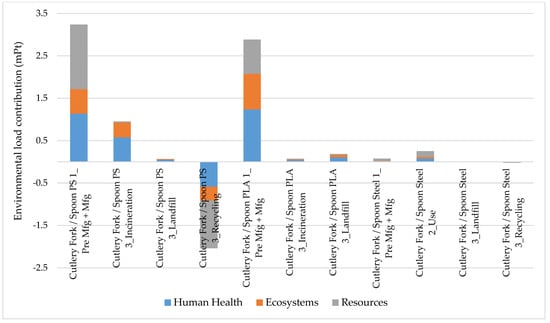

Figure 4 depicts the ReCiPe endpoint assessment of single score comparison for the PS, PLA and metal cutlery (fork/ knife). According to the endpoint single score results, all three impact categories (human health, ecosystem, and resources) were significantly affected by the pre-manufacturing and manufacturing phases of PS and PLA cutlery (fork/spoon). It is essential to consider that the recycling of PS cutlery shows a positive impact on the environment and should be promoted in waste management practice.

Figure 4.

Comparison of ReCiPe Endpoint Single Score of Cutlery fork/spoon.

Based on the LCIA results, it could be concluded that using steel cutlery is environmentally friendly, when compared to PS and PLA cutlery, in terms of GWP and mid- and end-point impact analysis. Although steel cutlery (fork/spoon) only considers 200 reusable cycles for the comparison, it can usually be used for an extended life of more than 200 cycles, which gives a better sustainable solution and substitution than the other types of cutlery (fork/spoon). When comparing PS and PLA, it can be concluded that the PS-based cutlery (fork/spoon) can be used if the end-of-life practice is recycling.

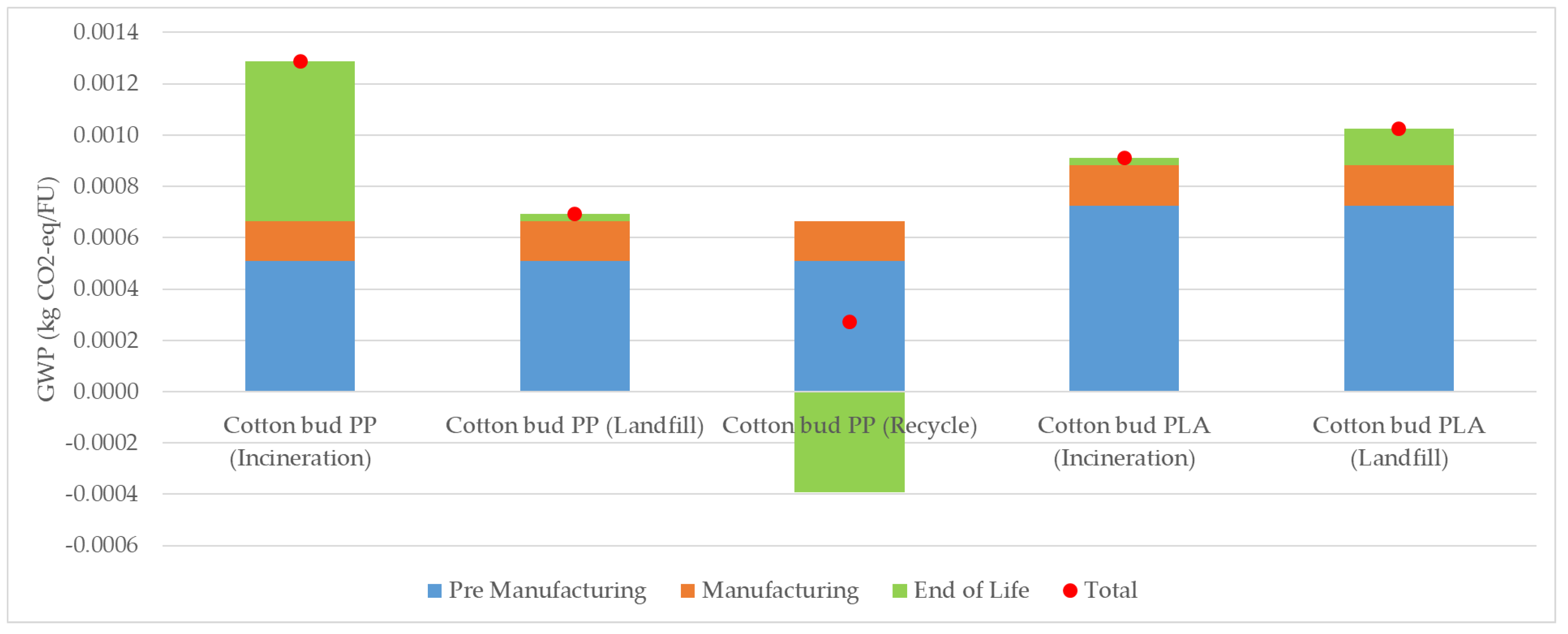

3.2.2. Cotton Bud

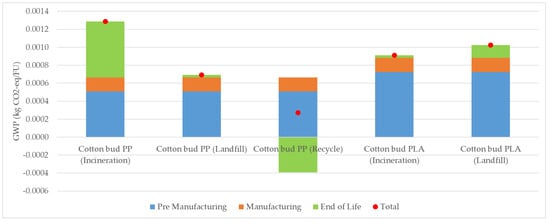

Figure 5 displays the contribution of GWP impact of the different life cycle stages of PP and PLA cotton buds. It reveals that the total GWP impact of PP cotton buds is 0.0013 kg CO2 (eq) for 100% incineration, 0.0007 kg CO2 (eq) for 100% landfill and 0.00027 kg CO2 (eq) for 100% recycling. The GWP impact of PLA cotton buds is shown to be 0.0009 kg CO2 (eq) for 100% incineration, and 0.001 kg CO2 (eq) for 100% landfill. The results emphasized that the PP and PLA-based cotton bud were of almost equal environmental impact in creating products, in terms of GWP, while for the PP cotton bud with recycling practice, the impact was the best option in comparison to the other scenarios and PLA cotton buds. Therefore, promoting PP cotton buds with a recycling approach at the end of life will be an advantage for the significant GWP reduction. Figures S1 and S2, in the supplementary document, provides the ReCiPe midpoint impacts assessment information for the cotton buds. With the exception of the fossil fuel (which is a raw material for PP), the other impacts are comparatively higher for the PLA due to the pre-manufacturing stage associated with environmental burdens.

Figure 5.

Comparison of global warming potential for Cotton bud.

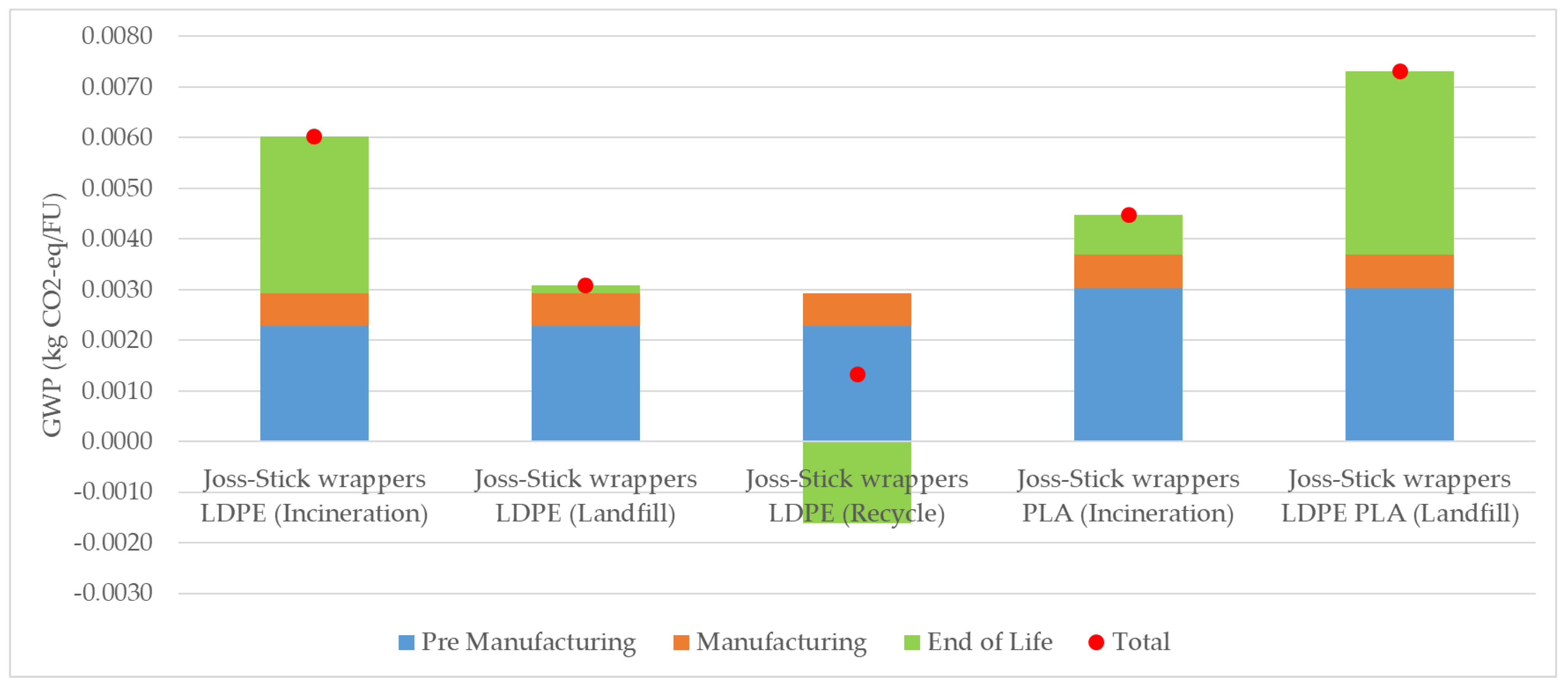

3.2.3. Joss-Stick Wrappers

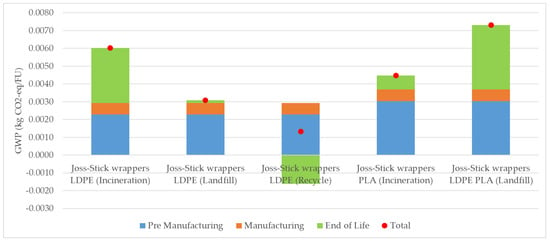

Figure 6 displays the comparison of the GWP impact of the different life cycle stages of LDPE and PLA Joss-Stick wrappers. It demonstrates that the total GWP impact of LDPE Joss-Stick wrappers is 0.006 kg CO2 (eq) for 100% incineration, 0.003 kg CO2 (eq) for 100% landfill and 0.0013 kg CO2 (eq) for 100% recycling. The GWP impact of PLA Joss-Stick wrappers is shown to be 0.0038 kg CO2 (eq) for 100% incineration, and 0.0015 kg CO2 (eq) for 100% landfill. The results highlighted that the LDPE and PLA-based Joss-Stick wrappers were of an approximately equal environmental impact in terms of GWP, while for the LDPE Joss-Stick wrappers with recycling method, the impact was comparatively better than the other scenarios and PLA Joss-Stick wrappers. However, the GWP of LDPE Joss-Stick wrappers with incineration plays a significant role in the environmental damage compared to the other alternatives. Therefore, promoting LDPE Joss-Stick wrappers with a recycling approach at the end of life will be an advantage for the substantial GWP reduction. Figures S3 and S4 in the supplementary document provide the ReCiPe midpoint impacts assessment information for the Joss-Stick wrappers. With the exception of the fossil fuel (which is a raw material for LDPE), the other impacts are comparatively higher for the PLA due to the pre-manufacturing stage associated with environmental burdens.

Figure 6.

Comparison of global warming potential for Joss-Stick wrappers.

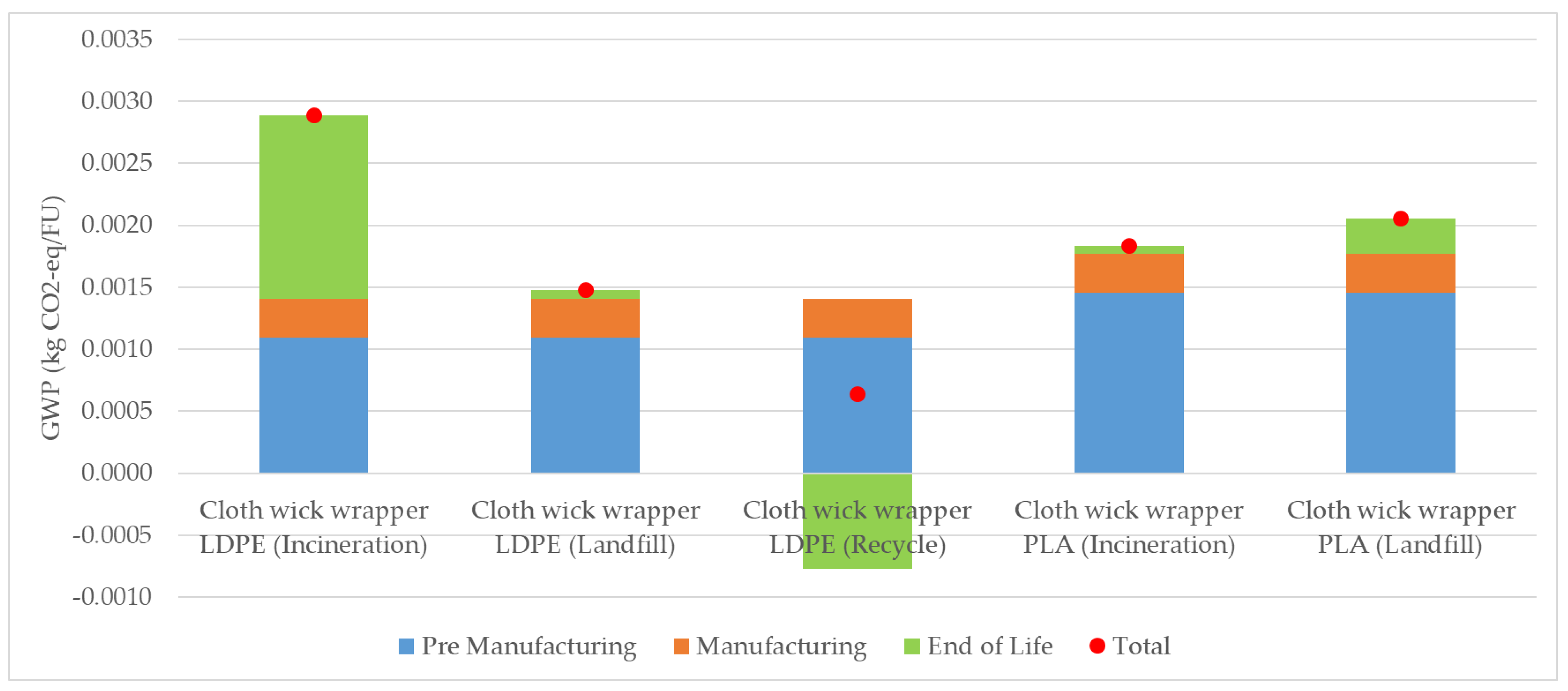

3.2.4. Cloth Wick Wrappers

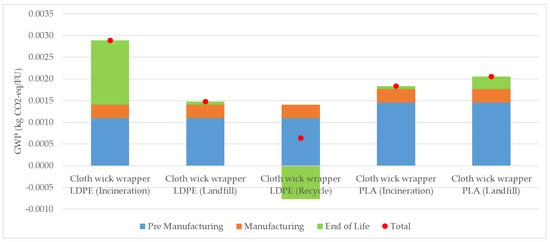

Figure 7 displays the comparison of the GWP impact of the different life cycle stages of LDPE and PLA cloth wick wrappers. It shows that the total GWP impact of LDPE cloth wick wrappers are 0.0029 kg CO2 (eq) for 100% incineration, 0.0015 kg CO2 (eq) for 100% landfill and 0.0006 kg CO2 (eq) for 100% recycling. The GWP impact of PLA cloth wick wrappers is shown to be 0.0018 kg CO2 (eq) for 100% incineration, and 0.0012 kg CO2 (eq) for 100% landfill. The results indicate that the LDPE and PLA based cloth wick wrappers had almost equal environmental impact in terms of GWP, while for the LDPE cloth wick wrappers with recycling method, the impact was comparatively better than the other scenarios and PLA cloth wick wrappers. Remarkably, the GWP of LDPE cloth wick wrappers with incineration plays a major role in the environment compared to other alternatives. Therefore, promoting LDPE cloth wick wrappers with a recycling approach at the end of life will be an advantage for the reduction of significant GWP. Figures S5 and S6 in the supplementary document provide the ReCiPe midpoint impacts assessment information for cloth wick wrappers. With the exception of fossil fuel (which is a raw material for LDPE), the other impacts are comparatively higher for the PLA due to the pre-manufacturing stage associated with environmental burdens.

Figure 7.

Comparison of global warming potential for cloth wick wrappers.

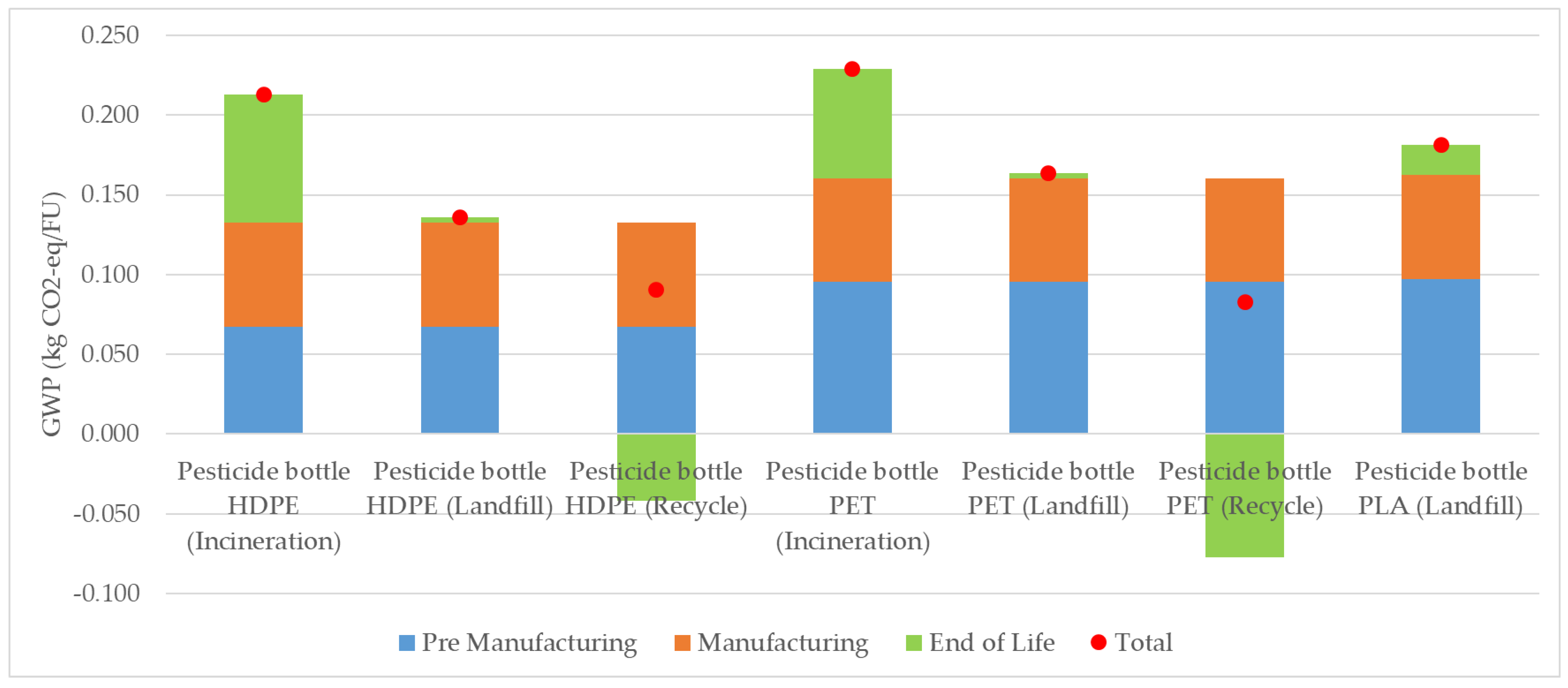

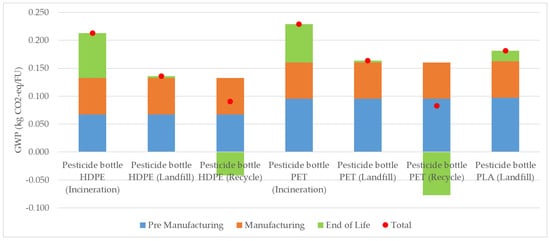

3.2.5. Pesticide Bottle

Figure 8 presents the GWP comparison of the different life cycle stages of pesticide bottles for the material of HDPE, PET and PLA. Results reveal that total GWP impact of HDPE pesticide bottles is 0.228 kg CO2 (eq) for 100% incineration, 0.137 kg CO2 (eq) for 100% landfill and 0.080 kg CO2 (eq) for 100% recycling. The GWP impact of PET pesticide bottles is 0.229 kg CO2 (eq) for 100% incineration, 0.163 kg CO2 (eq) for 100% landfill and 0.083 kg CO2 (eq) for 100% recycling. In addition, it depicts that the GWP of PLA pesticide bottles is shown to be 0.166 kg CO2 (eq) for 100% incineration, and 0.181 kg CO2 (eq) for 100% landfill.

Figure 8.

Comparison of global warming potential for Pesticide bottle.

The results emphasized that the HDPE and PET-based pesticide bottles with incineration practice at the end of life were the most GWP impact scenario, while for the HDPE and PET-based pesticide bottles with a recycling approach, the environmental performances were better, indicating a 50% lower impact than all other alternatives. The PLA-based pesticide bottle has an almost equal significant impact in both end-of-life situations. According to the results, therefore, encouraging HDPE and PET-based pesticide bottles with a recycling practice for its end-of-life will be advantageous for the significant GWP reduction compared to other all scenarios. Figures S7 and S8 in the supplementary document provide the ReCiPe midpoint impacts assessment information for pesticide bottles. With the exception of fossil fuel (which is a raw material for HDPE and PET), the other impacts are comparatively higher for the PLA due to the pre-manufacturing stage-associated environmental burdens.

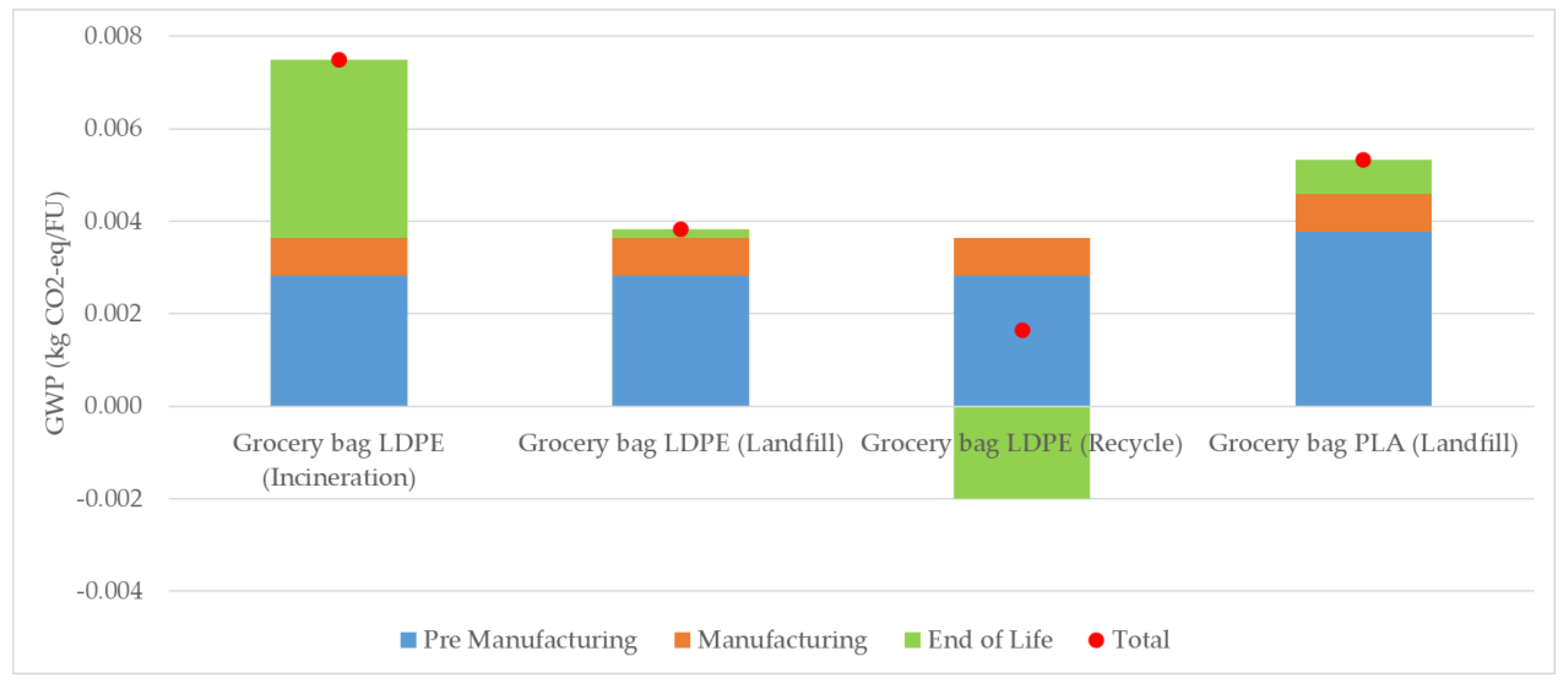

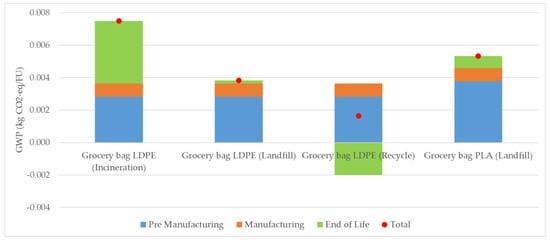

3.2.6. Grocery Bag

Figure 9 shows the comparison of the GWP impact of the different life cycle stages of LDPE and PLA grocery bags. It describes that the total GWP impact of LDPE grocery bags is 0.0075 kg CO2 (eq) for 100% incineration, 0.0038 kg CO2 (eq) for 100% landfill and 0.0016 kg CO2 (eq) for 100% recycling. The GWP impact of PLA grocery bags is shown to be 0.0047 kg CO2 (eq) for 100% incineration, and 0.0053 kg CO2 (eq) for 100% landfill. The results highlighted that the LDPE and PLA-based grocery bags were approximately equal environmentally impact products in terms of GWP, while for the LDPE grocery bag with the recycling method, the impact was comparatively better than other scenarios and PLA grocery bags. However, the GWP of LDPE grocery bags with incineration approaches plays a significant role in the environmental damage compared to other alternative scenarios. Therefore, promoting LDPE grocery bags with a recycling approach at the end of life will be an advantage for the substantial reduction of GWP. Figures S9 and S10 in the supplementary document provide the ReCiPe midpoint impacts assessment information for grocery bags. With the exception of fossil fuel (which is a raw material for LDPE), the other impacts are comparatively higher for the PLA due to the pre-manufacturing stage associated with environmental burdens.

Figure 9.

Comparison of global warming potential for the Grocery bag.

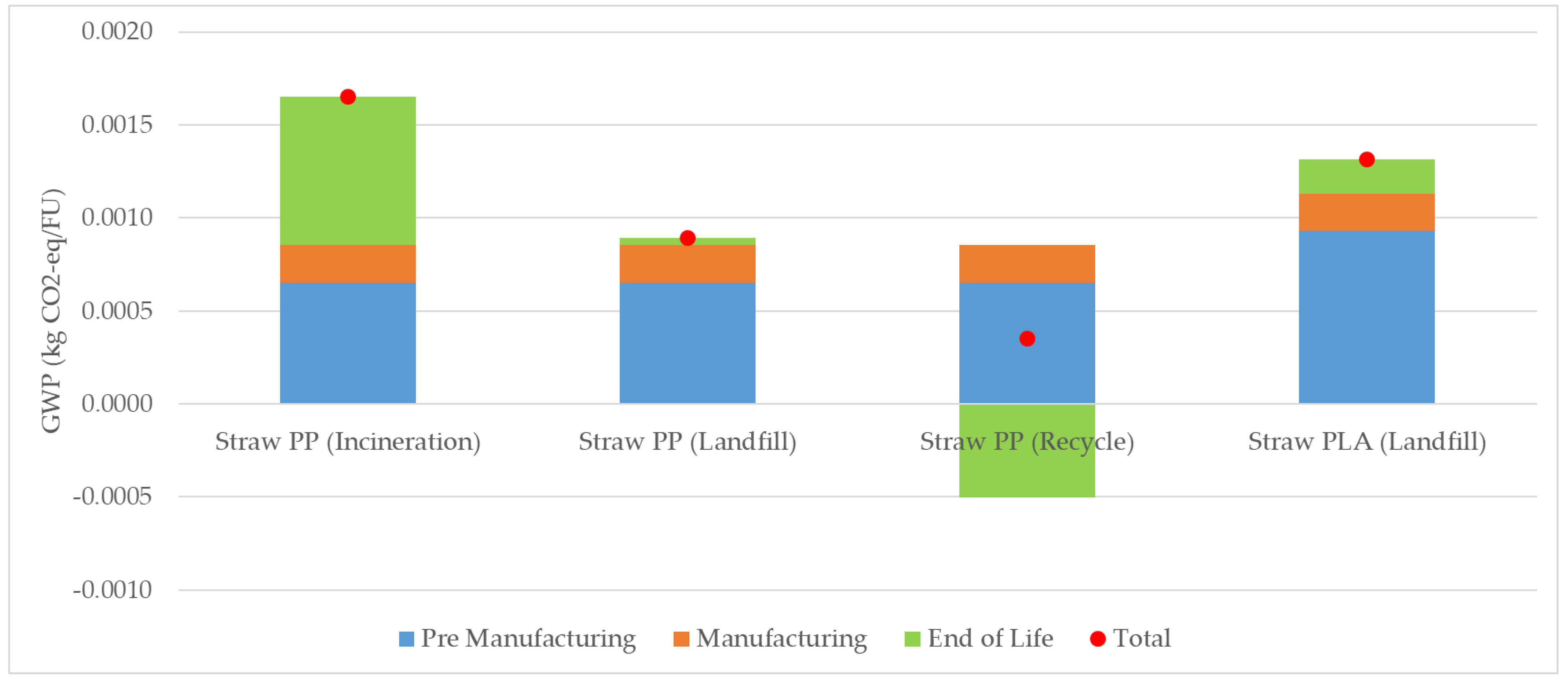

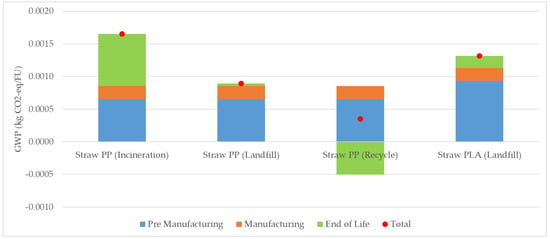

3.2.7. Straws

Figure 10 presents the contribution of GWP impact of the different life cycle stages of PP and PLA straws. It describes that the total GWP impact of the PP straw is 0.0017 kg CO2 (eq) for 100% incineration, 0.0009 kg CO2 (eq) for 100% landfill and 0.0004 kg CO2 (eq) for 100% recycling. The GWP impact of the PLA straw is presented to be 0.0012 kg CO2 (eq) for 100% incineration, and 0.0013 kg CO2 (eq) for 100% landfill. The results emphasized that the PP and PLA-based straws were nearly equal environmental impact creating products in terms of GWP, while for the PP straw with recycling method, the impact was comparatively better than other scenarios and the PLA straw. However, the GWP of PP straw with incineration shows a significant contribution to the environment compared to other alternative scenarios. Therefore, promoting PP straws with recycling methods at the end of life will be an advantage for the potential GWP reduction. Figures S11 and S12 in the supplementary document provide the ReCiPe midpoint impacts assessment information for straws. With the exception fossil fuel (which is a raw material for LDPE), the other impacts are comparatively higher for PLA due to the pre-manufacturing stage associated with environmental burdens.

Figure 10.

Comparison of global warming potential for straws.

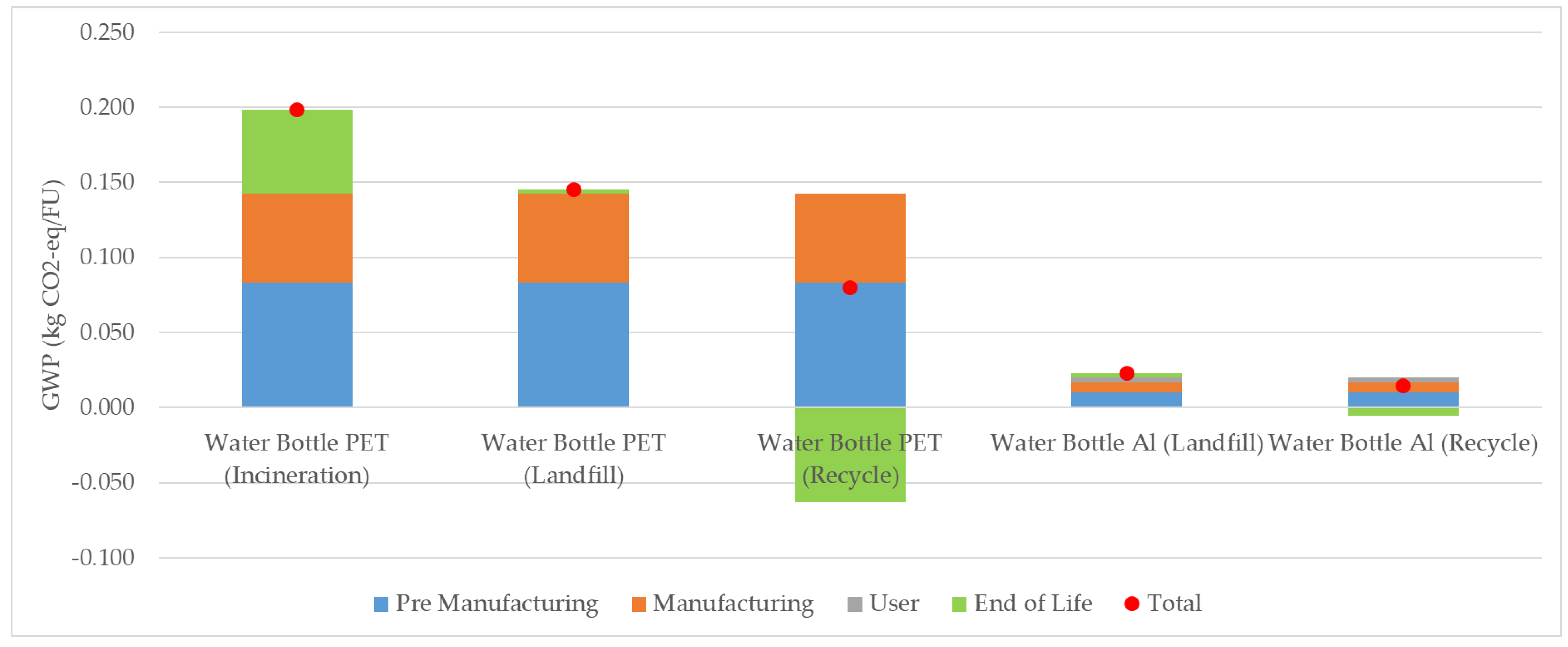

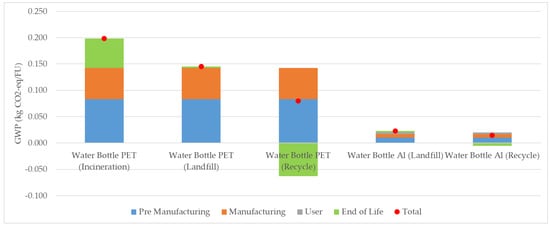

3.2.8. Water Bottle

Figure 11 illustrates the GWP comparison of the different life cycle stages of a water bottle for the materials PET, PLA and aluminum. Results show that the total GWP impact of PET water bottles is 0.206 kg CO2 (eq) for 100% incineration, 0.146 kg CO2 (eq) for 100% landfill and 0.075 kg CO2 (eq) for 100% recycling. The GWP impact of PLA water bottles is shown to be 0.150 kg CO2 (eq) for 100% incineration, and 0.163 kg CO2 (eq) for 100% landfill. In addition, it depicts that the GWP of aluminum water bottles is 0.022 kg CO2 (eq) for 100% incineration, 0.023 kg CO2 (eq) for 100% landfill and 0.0152 kg CO2 (eq) for 100% recycling. In particular, the incineration of aluminum water bottles describes the combustion of the acrylonitrile butadiene styrene (ABS) material-based cap in a water bottle.

Figure 11.

Comparison of global warming potential for Water bottle.

The results highlighted that the PET and PLA-based water bottles were the most environmentally sound products in terms of GWP, while for the one-time use aluminum water bottle, the environmental performance was six times lower than the alternatives. Therefore, promoting aluminum water bottles will be beneficial for the significant reduction of GWP. Considering the PET and PLA water bottles, the results reveal that the pre-manufacturing phase was a significant contribution to GWP and its contribution to the total impacts of the system was over 50%. Notably, the net GWP impact of PET water bottles with recycling practice at the end of life shows a better performance, and can be also considered as a potential alternative among PET and PLA water bottles.

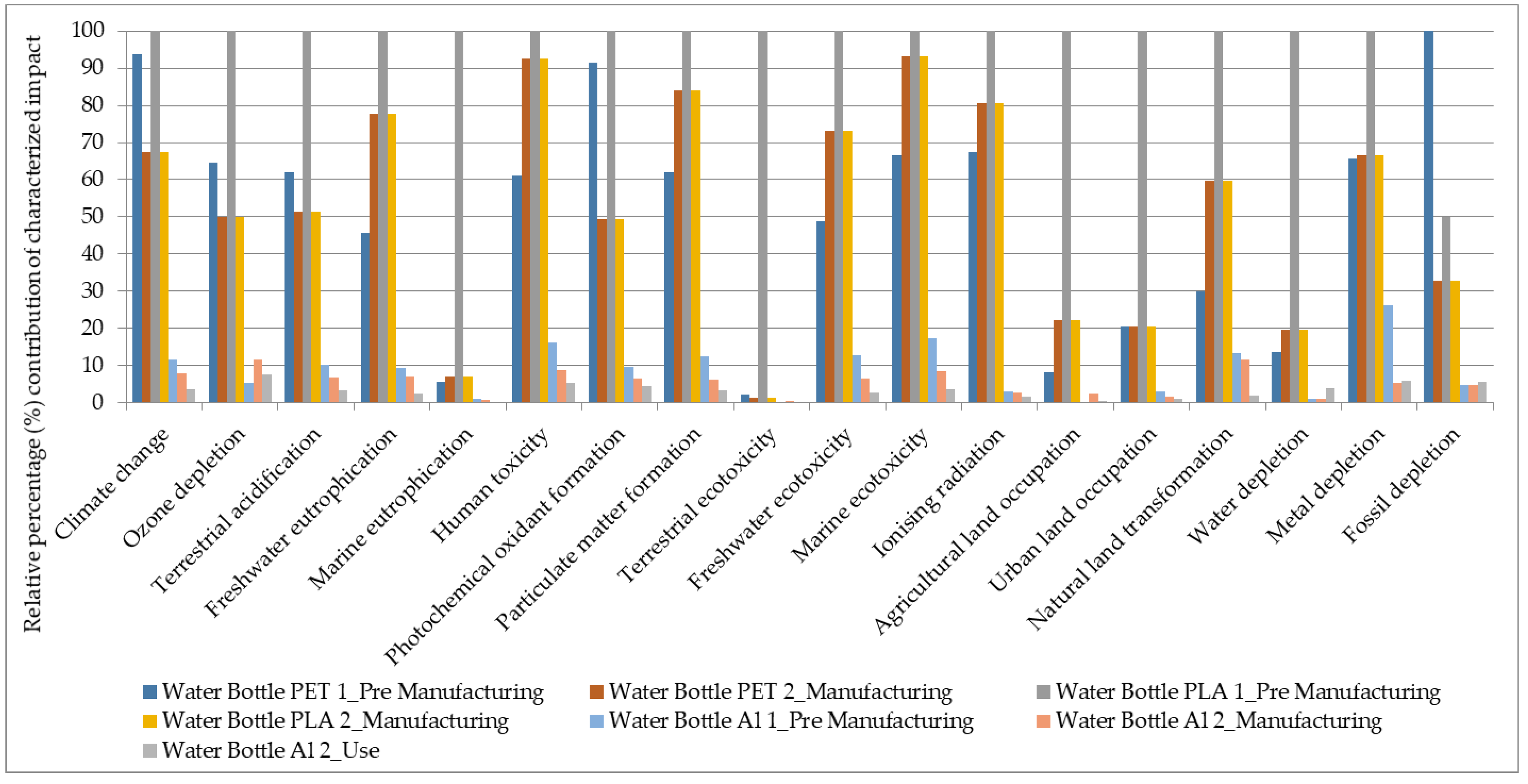

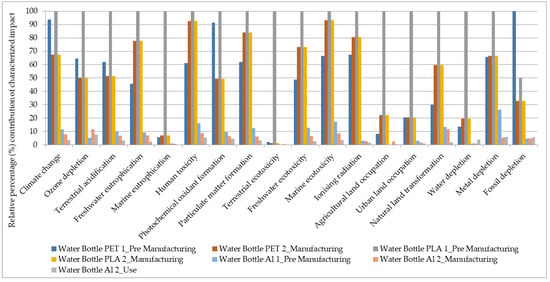

Figure 12 describes the ReCiPe midpoint analysis of all three water bottle alternatives: PET, PLA and aluminum. Only pre-manufacturing and manufacturing phases prior to midpoint comparison are considered. The midpoint analysis of the water bottle emphasized that PLA production was the most impactful for all midpoint impact categories, except fossil depletion. It is PLA resin production that contributes significantly to all impact categories. Notably, PLA water bottles offer savings for fossil fuel resource use but lead to higher impacts for other impact categories, while PET production plays a significant role in fossil depletion. Moreover, the literature highlighted that PLA bottle production generally has higher impacts than PET bottle production, globally or regionally depending on the categories [30].

Figure 12.

Comparison of ReCiPe Midpoint Characterization of Water Bottle.

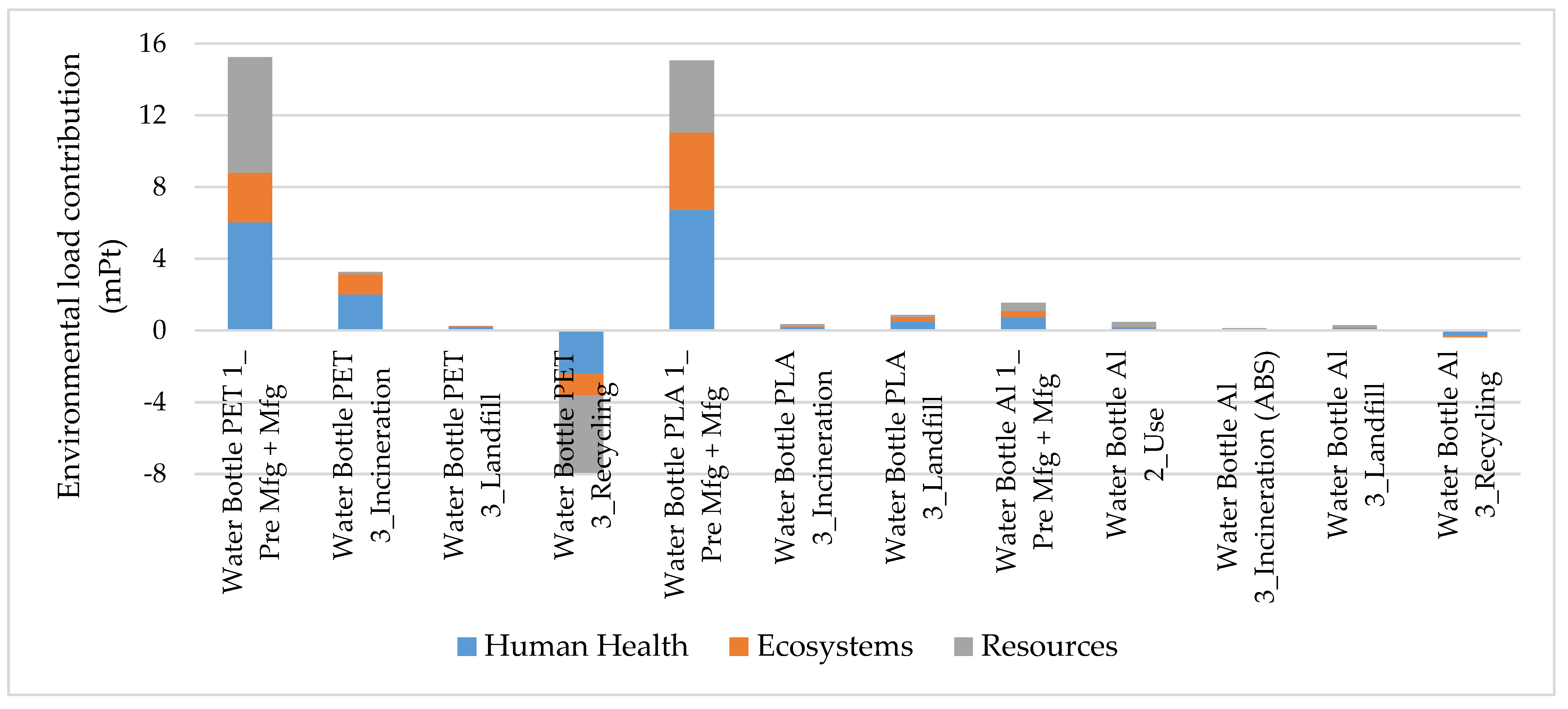

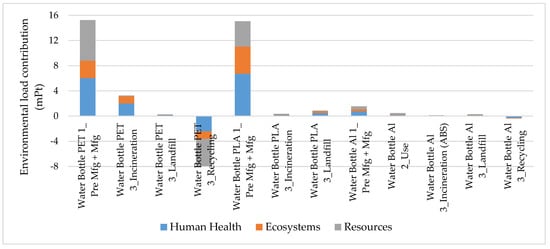

Figure 13 depicts the ReCiPe endpoint assessment of single score comparison for the PET, PLA and aluminum water bottles. According to the endpoint single score results, all three impact categories (human health, ecosystem, and resources) were almost equally significantly affected by the pre-manufacturing and manufacturing phases of PET and PLA water bottles. It is essential to consider that the recycling of PET water bottles shows a positive impact on the environment and that they need to be promoted in end-of-life practices. The aluminum water bottle shows the best environmental performance in all situations, throughout the life cycle. Therefore, it will be recommended to promote aluminum water bottles instead of its alternatives. According to the overall environmental performance and disposal scenario, the aluminum water bottle is the best candidate and should be promoted, instead of other alternatives.

Figure 13.

Comparison of ReCiPe Endpoint Single Score of Water Bottle.

3.3. Sri Lankan Situation of SUPPs Regulating Process

An overview of the national-level legal instruments in place in Sri Lanka that are relevant for waste management and specifically for SUPPs at the national level is given in Table 3.

Table 3.

Overview of national legal and policy instruments applicable for the protection of the environment from plastic pollution in Sri Lanka.

4. Discussion

4.1. Life Cycle Inventory (LCI) Data in Sri Lanka

LCI includes “the quantification and compilation of inputs and outputs associated with SUPPs throughout their life cycle.” The life cycle inventory and the process was identified and compiled for each SUPP in Sri Lanka. Sources of LCI data include commercial LCI databases, public LCI databases, measured data, data from peer-reviewed literature, reports from public organizations, and data from manufacturers. When considering the manufacturing process, PP-, PE-, PS-, and PLA-based products undergo the same process as SimaPro. The use of grid-related information, such as the consumption of water and soap for washing metal cutlery (fork/spoon) and aluminum water bottles, was taken from the literature. The end-of-life phase of each product category was based on the potential and likely scenario of waste management practices in Sri Lanka. End-of-life process data were primarily taken from SimaPro software. All transportation distances are based on assumptions and not measured.

At present, the capability of conducting comprehensive LCA studies in Sri Lanka is limited due to the lack of country-specific LCI data, and the global background data available in the LCA software (e.g., SimaPro, GaBi) does not include specific LCI data for the Sri Lankan context in most of the categories including plastics. It creates LCA practitioners to collect raw data through data survey methods or adopt other countries’ specific data and regulate them for country-specific conditions. However, this approach and method of LCA practice may lead to many variations, uncertainty, and biases in the results and decision-making [43].

Although there is a wide availability of data related to the major products and processes in Sri Lanka, these available data are in different formats and used for objectives other than LCA. The Sri Lankan government and other related constitutional bodies have acknowledged the importance of the consideration of full life cycle impacts of plastics in order to minimize the environmental impacts of plastics and plastic waste [44]. However, to assess the full life cycle impacts, an effective strategy needs to be established in order to mainstream the LCI data for Sri Lanka. Accumulation of the available data, in a usable form, in national data, will be essential for promoting the LCA approach in Sri Lanka, as well as for the decision-making process in implementing sustainable development practices.

4.2. Interpretation of Life Cycle Impact Assessment (LCIA)

The life cycle impact assessment of SUPPs and possible alternatives were carried out and compared considering their life cycle stages including end-of-life practices.

4.2.1. Global Warming Potential (GWP)

The analysis reveals that SUPPs made from PS, PP, LDPE, HDPE, and PET have a significant contribution in all life cycle stages in terms of GWP. However, the net GWP impact of these SUPPs with recycling practice at the end of life shows better performance compared to incineration and landfill scenarios. Recycling plastics diminishes the waste to be landfilled, reducing the piling up of plastic virgin material on the earth [6]. In addition, it is essential to highlight that incineration of all SUPPs (PS-, PP-, LDPE-, HDPE-, and PET-based products) have the highest impact in terms of GWP. The observations comparing the bioplastics (PLA) and the SUPPs indicate no advantage of using PLA over SUPPs. Moreover, the present waste management system in Sri Lanka is not designed for PLA collection or compositing [26].

The comparison of PET and HDPE recycling’ (Figure 8) indicates more environmental gain in PET recycling over HDPE recycling. This is due to the avoided virgin PET pre-manufacturing, providing a 41.5% larger GWP reduction over the HDPE. In other words, the PET premanufacturing stage has a 41.5% higher GWP than the HDPE premanufacturing stage [45]. Considering the product end-of-life management in Sri Lanka (the MOE, Sri Lanka [26]), the preferred choice for pesticide bottle end-of-life management is co-incineration in cement kilns, considering the hazardous nature which limits the recycling under present waste management systems in developing countries [46]. Considering the incineration end-of-life scenario for the pesticide bottles, the HDPE indicates a 7.6% lower GWP compared to PET.

For steel cutlery (reusable), the largest GWP-associated life cycle stage is the user phase, which includes cleaning (97.5%). However, the overall reduction of GWP by the steel considering the best (PS with recycling) and worst (PS with incineration) case scenarios with single-use items are 0.01 and 0.05 kg CO2 (eq), respectively (Figure 2). The study by Wei et al. (2022) indicates 0.01–0.02 kg CO2 (eq) per one-time use [47], which is in the same range as the observations made by the present study. The preferred options for cutlery are reusable cutlery, followed by the recycling of the PS-based SUPPs. However, the present waste management system in Sri Lanka does not accommodate PS recycling [26]. Thermal recycling (incineration with energy recovery) is one potential option. Other than that, nature-based products such as wooden cutlery can also be considered. However, the present LCA study did not consider such alternatives due to the unavailability of data. A similar range of GWP is reported between bamboo-based (natural) cutlery and PS-based cutlery [46]. Nevertheless, future studies should consider nature-based alternatives with the primary data (LCI) collection in Sri Lanka.

Joss-stick wrappers (Figure 6) and cloth wick wrappers (Figure 7) indicate similar trends when comparing the different raw materials (LDPE and PLA) and end-of-life scenarios (incinerations, landfill and recycling). The recycling of LDPE appears to be the best scenario, considering the avoidance of virgin plastic production. Recycling LDPE joss-stick wrappers and cloth wick wrappers provides a comparative reduction of 81.9% and 69.1% GWP reduction compared to PLA, respectively. However, the incineration scenario increases the GWP potential by 25.7% and 36.6%, respectively. At present, LDPE recycling is practiced in Sri Lanka on a small scale [48]. In terms of the joss-stick wrappers and cloth wick wrappers, the contamination of other impurities can be minimized if properly collected; extended producer responsibility (EPR) applications could be effectively used for the collection of these LDPEs for recycling. Even though the grocery bags (LDPE and PLA) indicated a similar pattern of GWP (Figure 9) to the joss-stick wrappers and cloth wick wrappers, recycling could be challenging due to the presence of food and other contaminations [49]. The present study does not consider reusable grocery bags due to the limitations of LCI. However, it is recommended to consider reusable bags for future studies. In general, reusable bags can be environmentally friendly, if they are reused 50–150 times, while paper bags create more GWP compared to plastic bags [50].

Cotton buds (Figure 5) and straws (10) indicated a similar variation pattern of GWP in terms of raw material (PP and PLA) and end-of-life scenarios. With complete recycling of PP SUPPs, the avoided virgin polymer production provides a reduction in GWP. The PP-based cotton buds and straws indicated a 73.3% GWP reduction for the recycling scenario compared to the landfilling of PLA. Similar to grocery bags, source separation and collection are challenging under the present waste management system [26]. Here, the nature-based solutions could also be considered as replacements for the SUPPs.

Reusable al-water bottles indicated the lowest GWP compared to all the end-of-life scenarios of the PET bottles. The GWP reductions by reusable bottles compared to the best (PET bottle recycle) and worst (PET bottle incineration) case scenarios of the PET bottles are 81.6% and 92.6%, respectively. The reusable bottles indicate a higher advantage over the SUPPs in drinking water packaging. A study by Pathwater (2018) concluded that three- or more time-reused aluminum bottles provide less GWP than the SUPPs [51].

4.2.2. Mid and Endpoint Impact Categories

The PLA-based products also show a significant impact on GWP in both their mid- and end-point impact categories. Remarkably, the midpoint analysis of PLA-based products and alternatives emphasized that PLA production was the most impactful for most of the midpoint impact categories due to PLA resin production, which contributes significantly to all impact categories. PLA has good physical and mechanical properties, which makes it a good candidate for replacing petrochemical thermoplastics [52]. Although PLA is both bio-based and biodegradable, and has therefore attracted increased attention for SUPPs applications, the process of energy use in the conversion from biomass to PLA polymer was identified as the main environmental hotspot [2]. However, the potential impacts of SUPPs leaked into the environment cannot be ignored, even though those are yet to be integrated into LCIAs [19,53]. However, recent findings indicate that the fate and the impacts of microplastics depend on polymer types. The potential physical impact of microplastics on biota is greater for HDPE compared to PLA [54]. Due to the environmental leakage, which depends on the waste management system of a country, the PLA products’ marine litter impacts can be lower than the SUPP’s marine litter impacts. Nevertheless, the study which compared the marine litter impacts and GWP impact indicated that the impact due to GWP is comparatively higher for plastic products compared to the microplastic-related impacts on biota [54].

4.3. Policy Recommendations

Sri Lanka has taken many policy measures to protect the environment from plastic pollution (Table 3). The plastic ban in 2017 restricted certain SUPPs. However, the consideration of substitute products and comparison of the environmental impacts of potential substitutes have not been conducted for the full life cycle. Therefore, based on the findings of this LCA and the present waste management situation in Sri Lanka [26], some specific recommendations have been identified and summarized in Table 4. In addition, the government of Sri Lanka needs to improve the country’s waste management practices by introducing strong economic and environmental policies that push for a more circular model of design and production of plastics at upstream and sustainable lifestyles and consumption patterns to change the habits of consumers, retailers and manufacturers. While the information on alternative materials and products is limited in the country, the government should partner with academic and business sectors to conduct joint research for the development of alternative materials and sustainable products. In addition, the government of Sri Lanka needs to strengthen its law enforcement and monitoring. As described in the NAPPWM, certain actions are in progress [42]. These actions include plastic inventory system establishment, EPR, and national plastic waste management center establishment to coordinate all the stakeholders [26,55].

Table 4.

Summary of recommendations for the Sri Lankan Context.

4.4. Challenges of LCA as a Tool for Policy Recommendation in Sri Lanka

LCA is a scientific and quantitative methodology used to assess the environmental impact along an entire life cycle by considering the life cycle characteristics of the products according to the ISO 14040, 44 guidelines [20]. The manufacturing domain is integrated with a vast amount of heterogeneous information including operational, supply chain, materials, energy, resource, waste, and preliminary data from the whole life cycle of the products or services. Therefore, the acquisition of product- or process-related life cycle data is of vital importance to managing the life cycle of the product, process, and systems through the LCA approach. However, LCA is not a one-way process because, in the life cycle, certain changes can take place during the product’s lifespan. Therefore, continuous re-evaluation of the product throughout its life cycle needs to be considered when the product is available in the market for various reasons, such as changes in raw material and supply, alteration of technology, the variation of energy source, etc.

The data are generally collected manually from field visits. The collection of LCI data has required the support of process engineers, supervisors, technicians, operators, production record books, forms, bills, open literature, LCA libraries, and others from the manufacturing domain. Hence, manual data collection is the most difficult, complex, and resource and time-consuming process. In addition, there are some other practical difficulties during manual data collection, such as resource and energy allocation, data accuracy, data reliability and uncertainty, data availability, acquisition hardness and technical support, etc. Life cycle assessment is broadly applied in decision-making as an assessment tool for environmental performance. However, the final decision cannot rely solely on environmental assessment results.

The implementation of LCT and LCA among the organizations in Sri Lanka is an important step to transform them from merely complying with environmental regulations to more proactive environmentally responsible entities. Currently, the ability to conduct LCA studies is limited in Sri Lanka due to the lack of available LCI data at the national level, and the lack of foreign background databases available for LCA software, which do not include data specific to the Sri Lankan context. The accuracy of the decisions made by LCA depends on the appropriateness and low uncertainty of the data used in the analysis [15]. The LCI of products, processes and systems is crucial to support Sri Lanka’s environmental and commercial work, such as the life cycle impact assessment, the development of environmentally friendly products, the planning of resource utilization and the making of governmental policy. The strategic plans for the sustainable development of Sri Lanka are focused on eco-friendly products, processes, and systems in terms of improved energy efficiencies with reduced environmental impacts. Notably, LCA-based effective decision-making for more sustainable products and processes requires an extensive range of reliable and updated data concerning their environmental consequences. Therefore, reliable and country-specific LCI data related to product and process is necessary to carry out a comprehensive LCA study, to promote LCT and LCA approach in Sri Lanka as well as for the decision-making process in implementing sustainable development practices.

5. Conclusions

This study provides important insights into the interests of policy making and recommendations in Sri Lanka using LCA techniques, while considering the limitations of LCA. Accordingly, the cradle-to-grave environmental performance of eight selected SUPPs and their possible alternatives were evaluated and compared using LCA techniques. In addition, this study investigated whether banning these SUPPs is an appropriate strategy to protect the environment. The LCA analysis was performed for the determined system boundary, and GWP, ReCiPe Midpoint, and Endpoint were examined. LCA analysis is performed using SimaPro 8.3.0.0 software.

In particular, for steel cutlery (reusable), the largest GWP-associated life cycle stage is the user phase (97.5%), which includes cleaning the cutlery. However, the overall reduction of GWP by steel, considering the best (PS with recycling) and worst (PS with incineration) case scenarios with single-use items, are 0.01 and 0.05 kg CO2 (eq), respectively. For joss-stick wrappers and cloth wick wrappers, recycling of LDPE appears to be the best scenario considering the avoided virgin plastic production. Recycling LDPE joss-stick wrappers and cloth wick wrappers provides a comparative GWP reduction of 81.9% and 69.1% compared to PLA, respectively. However, the incineration scenario increases the GWP potential by 25.7% and 36.6%, respectively. In the case of pesticide bottles, with the preferred end-of-life option being incineration, the HDPE indicates a 7.6% lower GWP compared to PET.

The overall results of the analysis highlighted that SUPPs produced using PS, PP, LDPE, HDPE, and PET have a significant contribution in all life cycle stages in terms of GWP and endpoint impact categories. However, the net GWP impact of these SUPPs with recycling practice at the end of life shows a better performance compared to incineration and landfill. In addition, the PLA-based products also show a significant impact on GWP in the mid- and end-point impact categories. Remarkably, the midpoint analysis of PLA-based products and alternatives emphasized that PLA production was the most impactful for most of the midpoint impact categories due to PLA resin production, which contributes significantly to all impact categories. Although PLA is both bio-based and biodegradable, and has attracted increased attention for SUPPs applications, energy use in the conversion from biomass to PLA polymer was identified as the main environmental hotspot. On the other hand, the study highlights that the capacity to conduct a comprehensive LCA in Sri Lanka is limited due to the lack of country-specific LCI data and relevant waste management practices in Sri Lanka. Overall, the results show that conducting LCA will facilitate scientific decision-making for policy interventions related to SUP products and processes. Moreover, the study explores suitable alternatives for SUPPs which supports the circular economy approach as this study tries to find suitable alternatives for SUPPs that could be either reused multiple times or can be recycled brought back to the energy and material stage, remanufactured or refurbished, and brought back to the production stage.

Based on the results and discussion of this study, the following key recommendations are proposed.

- Promoting al and steel (multiple cycles) products will be beneficial for the significant GWP reduction.

- Even though fossil fuel-based SUPPs with the ability for multiple uses and proper recycling practices can be recommendable.

- PLA-based single-use products are not recommended by the CEA, Sri Lanka due to the limited capacity in the country for monitoring and quality control of PLA-based SUPPs.

- Accumulation of the available data in a usable form in a national database will be essential for promoting LCT and LCA approaches in Sri Lanka.

- National-level LCI data is crucial for the decision-making process in implementing sustainable development practices.

- Incorporating Sri Lankan LCI databases with commercial LCA software is an essential initiative.

- LCA results provide policymakers the science-based evidence that embraces the full life cycle of plastic products and alternatives to support decision making however it is equally important to consider the social and economic aspects while making decisions.

- Hence, future studies should explore more alternatives for selected SUPPs for analyzing not only the environment but also the social and economic impact of the SUPPs in Sri Lanka.

- The study also identified the importance of addressing single-use plastic in a more holistic manner rather than just taking policy decisions to ban and leave selected SUPPs. These policy decisions may cause increasing environmental pollution. The planning of addressing single-use plastic start with assessing the existing single-use plastic materials and products and their alternatives using the LCA. This helps to target the most problematic single-use plastics, assess their impacts and consider the best actions. These actions need to cover a more circular model of design and production of plastic materials to improve waste management practices to handle those which cannot further reuse or recycle.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/su142114170/s1, Table S1: List of items announced by MOE, Sri Lanka in 2021–2022 for regulating process; Table S2: Life cycle inventory summary of SUPPs; Figure S1: Comparison of ReCiPe Midpoint Characterization of Cotton bud; Figure S2: Comparison of ReCiPe Endpoint Single Score of Cotton bud; Figure S3: Comparison of ReCiPe Midpoint Characterization of Joss-Stick wrappers; Figure S4: Comparison of ReCiPe Endpoint Single Score of Joss-Stick wrappers; Figure S5: Comparison of ReCiPe Midpoint Characterization of cloth wick wrappers; Figure S6: Comparison of ReCiPe Endpoint Single Score of cloth wick wrappers; Figure S7: Comparison of ReCiPe Midpoint Characterization of Pesticide bottle; Figure S8: Comparison of ReCiPe Endpoint Single Score of Pesticide bottle; Figure S9: Comparison of ReCiPe Midpoint Characterization of Grocery bag; Figure S10: Comparison of ReCiPe Endpoint Single Score of Grocery bag; Figure S11: Comparison of ReCiPe Midpoint Characterization of Straw; Figure S12: Comparison of ReCiPe Endpoint Single Score of Straw.

Author Contributions

Conceptualization, S.K., A.A, A.K.K., R.K.S., M.T. and P.J.D.G.; methodology, S.K., A.A, A.K.K., and P.J.D.G.; software, K.S and A.K.K.; validation, S.K.; A.A. and A.K.K.; investigation, S.K. and A.K.K.; resources, A.K.K. and R.K.S.; data curation, A.K.K.; writing—original draft preparation, S.K. and A.A.; writing—review and editing, S.K., A.A, A.K.K., R.K.S., M.T. and P.J.D.G.; visualization, S.K. and A.A.; supervision, A.A. and A.K.K.; project administration, A.A., R.K.S., M.T., P.J.D.G. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Institute for Global Environmental Strategies (IGES)—Strategic research fund FY2021, grant number IGES-SRF-FY2021 and by Life Cycle Analysis and Management Research Cluster (LCAMRC), Department of Manufacturing & Industrial Engineering, Faculty of Engineering, University of Peradeniya, Sri Lanka: Grants-2021/2022.

Data Availability Statement

Data used in this manuscript can be requested for research purposes by the corresponding authors.

Acknowledgments

The authors would like to acknowledge funding support from the Institute for Global Environmental Strategies (IGES) and Life Cycle Analysis and Management Research Cluster of the Department of Manufacturing & Industrial Engineering, University of Peradeniya. The authors would like to acknowledge Sujeewa Fernando, assistant director, environmental pollution control & chemical management (EPC&CM), Ministry of Environment (MOE), Sri Lanka and Sarojinie Jayasekara, Director, Waste Management, Central Environment Authority (CEA), Sri Lanka for the information provided. The authors are also grateful for the assistance provided by industry collaborators when collecting SUPPs-related LCI data. The opinions expressed in this work are the responsibility of the authors and do not necessarily reflect the openions of individuals or institution acknowledged here.

Conflicts of Interest

The authors declare no conflict of interest.

References

- UNEP. United Nations Environment Assembly of the United Nations Environment Programme. 2022. Available online: https://wedocs.unep.org/bitstream/handle/20.500.11822/38525/k2200647_-_unep-ea-5-l-23-rev-1_-_advance.pdf?sequence=1&isAllowed=y (accessed on 18 July 2022).

- Moretti, C.; Hamelin, L.; Jakobsen, L.G.; Junginger, M.H.; Steingrimsdottir, M.M.; Høibye, L.; Shen, L. Cradle-to-grave life cycle assessment of single-use cups made from PLA, PP and PET. Resour. Conserv. Recycl. 2021, 169, 105508. [Google Scholar] [CrossRef]

- Gursel, I.V.; Moretti, C.; Hamelin, L.; Jakobsen, L.G.; Steingrimsdottir, M.M.; Junginger, M.; Høibye, L.; Shen, L. Comparative cradle-to-grave life cycle assessment of bio-based and petrochemical PET bottles. Sci. Total Environ. 2021, 793, 148642. [Google Scholar] [CrossRef] [PubMed]

- Herberz, T.; Barlow, C.Y.; Finkbeiner, M. Sustainability assessment of a single-use plastics ban. Sustainability 2020, 12, 3746. [Google Scholar] [CrossRef]

- Majeed, K.; Jawaid, M.; Hassan, A.A.; Bakar, A.A.; Khalil, H.A.; Salema, A.A.; Inuwa, I. Potential materials for food packaging from nanoclay/natural fibres filled hybrid composites. Mater. Des. 2013, 46, 391–410. [Google Scholar] [CrossRef]

- Jayalath, G.N.; Thilakarathne, E.P.; Abeygunawardana, A.P.; Silva, A.P.; Egodauyana, K.P.; Nawarathna, A.M.; Gunasekara, A.J. Status of Plastic Waste Generation and Propose a Circular Economy-Based Policy Framework to Manage Plastic Waste in Sri Lanka. IOSR J. Environ. Sci. Toxicol. Food Technol. 2021, 15, 24–38. [Google Scholar]

- Plastic Waste Management, Country Situation Report—Sri Lanka. 2021. Available online: https://ipen.org/sites/default/files/documents/plastic_waste_management_in_sri_lanka.pdf (accessed on 18 July 2022).

- United Nations Environment Programme; World Travel & Tourism Council. Rethinking Single-Use Plastic Products in Travel & Tourism—Impacts, Management Practices and Recommendations; UNEP: Nairobi, Kenya; World Travel & Tourism Council: London, UK, 2021. [Google Scholar]

- Kaluarachchi, K.A.U.A.; Thathsarani, M.; Nilmini, W.; Namal Arachchi, N.A.K.A.; Silva, J.L.K.C. Current plastic wastage and introducing new innovations to minimize plastic wastage in Sri Lanka. J. Res. Technol. Eng. 2017, 1, 4–10. [Google Scholar]

- Shantha, A.A.; Samarakoon, A. Cost Benefit Analysis for the National Post Consumer Plastic Waste Management Project; Central Environmental Authority: Colombo, Sri Lanka, 2018. [Google Scholar]

- Ministry of Environment, Sri Lanka. National Action Plan on Plastic Waste Management. 2021. Available online: https://www.ccet.jp/sites/default/files/2021-08/srilanka_report_web_fin_pw.pdf (accessed on 18 July 2022).

- Japan International Cooperation Agency, Kokusai Kogyo Co, Ltd. Data Collection Survey on Solid Waste Management in Democratic Socialist Republic of Sri Lanka Final Report Democratic Socialist Republic of Sri Lanka Japan International Cooperation Agency (JICA) Ten (10) Priority Local Authorities; Japan International Cooperation Agency; Kokusai Kogyo Co., Ltd.: Tokoyo, Japan, 2016; p. 22. Available online: http://open_jicareport.jica.go.jp/pdf/12250213.pdf (accessed on 16 July 2022).

- UNEP. Legal Limits on Single-Use Plastics and Microplastics: A Global Review of National Laws and Regulations. 2018. Available online: https://www.unep.org/resources/publication/legal-limits-single-use-plastics-and-microplastics-global-review-national (accessed on 21 October 2022).

- Life Cycle Initiative. What is Life Cycle Thinking. 2022. Available online: https://www.lifecycleinitiative.org/starting-life-cycle-thinking/what-is-life-cycle-thinking/ (accessed on 18 July 2022).

- Kumarasena, S.; Weerathunga, U.A.; Rathnayake, M. Development of National LCA Database Roadmaps, Including Further Development of the Technical Helpdesk for National LCA Databases; Life Cycle Initiative: Paris, France; UNEP: Nairobi, Kenya, 2022; Available online: https://helpdesk.lifecycleinitiative.org/wp-content/uploads/2020/11/d_4.4_final_roadmap_report_lk.pdf (accessed on 18 July 2022).

- UNEP. Addressing Single-Use Plastic Products Pollution. 2019. Available online: https://wedocs.unep.org/bitstream/handle/20.500.11822/28473/English.pdf?sequence=3&isAllowed=y (accessed on 18 July 2022).

- UNEP. End Plastic Pollution: Towards an International Legally Binding Instrument, 2022. UNEP Document Repository. Available online: https://wedocs.unep.org/handle/20.500.11822/38525 (accessed on 18 July 2022).

- Life Cycle Initiative. Single-Use Plastic Products (SUPP) and Their Alternatives: Recommendations from Life Cycle Assessments. 2022. Available online: https://www.lifecycleinitiative.org/activities/key-programme-areas/technical-policy-advice/single-use-plastic-products-studies/ (accessed on 18 July 2022).

- Woods, J.S.; Verones, F.; Jolliet, O.; Vázquez-Rowe, I.; Boulay, A.M. A framework for the assessment of marine litter impacts in life cycle impact assessment. Ecol. Indic. 2021, 129, 107918. [Google Scholar] [CrossRef]

- Ng, C.Y. Green product design and development using life cycle assessment and ant colony optimization. Int. J. Adv. Manuf. Technol. 2018, 95, 3101–3109. [Google Scholar] [CrossRef]

- ISO 14040:2006; Environmental Management—Life Cycle Assessment—Principles and Framework. International Organization for Standardization: Geneve, Switzerland, 2006.

- ISO 14044:2006; Environmental Management—Life Cycle Assessment—Requirements and Guidelines. International Organization for Standardization: Geneve, Switzerland, 2006.

- Bouyarmane, H.; Sallaou, M. Environmental assessment in the early stages of product design. In Proceedings of the 5th International Conference on Optimization and Applications (ICOA), Kenitra, Morocco, 25–26 April 2019; pp. 1–5. [Google Scholar]

- Luthe, T.; Kägi, T.; Reger, J. A systems approach to sustainable technical product design: Combining life cycle assessment and virtual development in the case of skis. J. Ind. Ecol. 2013, 17, 605–617. [Google Scholar] [CrossRef]

- CEA. Regulations on Polythene & Plastic Management 2017. Available online: http://www.cea.lk/web/?option=com_content&view=article&layout=edit&id=1080 (accessed on 18 July 2022).

- Fernando, S. (Ministry of Environment, Colombo, Sri Lanka). Personal communication, 2021. [Google Scholar]

- Jem, K.J.; Tan, B. The development and challenges of poly (lactic acid) and poly (glycolic acid). Adv. Ind. Eng. Polym. Res. 2020, 3, 60–70. [Google Scholar] [CrossRef]

- Sombatsompop, N.; Srimalanon, P.; Markpin, T.; Prapagdee, B. Polylactic Acid (PLA): Improve It, Use It, and Dump It Faster. BioResources 2021, 16, 2196–2199. [Google Scholar] [CrossRef]

- Zanghelini, G.M.; Cherubini, E.; Dias, R.; Kabe, Y.H.; Delgado, J.J. Comparative life cycle assessment of drinking straws in Brazil. J. Clean. Prod. 2020, 276, 123070. [Google Scholar] [CrossRef]

- Tamburini, E.; Costa, S.; Summa, D.; Battistella, L.; Fano, E.A.; Castaldelli, G. Plastic (PET) vs. bioplastic (PLA) or refillable aluminium bottles–What is the most sustainable choice for drinking water? A life-cycle (LCA) analysis. Environ. Res. 2021, 196, 110974. [Google Scholar] [CrossRef] [PubMed]

- Ferrara, C.; De Feo, G.; Picone, V. LCA of Glass Versus PET Mineral Water Bottles: An Italian Case Study. Recycling 2021, 6, 50. [Google Scholar] [CrossRef]

- Democratic Socialist Republic of Sri Lankan Parliament Secretariat. The Constitution of the Democratic Socialist Republic of Sri Lanka, Revised ed.—2021. Available online: https://www.parliament.lk/files/pdf/constitution.pdf (accessed on 18 July 2022).

- Code of Criminal Procedure. 1979. Available online: https://www.lawnet.gov.lk/code-of-criminal-procedure-2/ (accessed on 18 July 2022).

- National Environmental (Amendment) Act, No. 53 of 2000. Available online: http://www.cea.lk/web/images/pdf/acts/act53-2000.pdf (accessed on 18 July 2022).

- National Environment Policy and Strategies. 2003. Available online: http://extwprlegs1.fao.org/docs/pdf/srl174812.pdf (accessed on 18 July 2022).

- National Policy and Strategy for Cleaner Production. 2005. Available online: https://policy.asiapacificenergy.org/sites/default/files/National%20Policy%20and%20Strategy%20for%20Cleaner%20Production.pdf (accessed on 18 July 2022).

- Bandara, S. National Policy on Solid Waste Management and Implementation Mechanisms in Sri Lanka. Available online: https://www.unescap.org/sites/default/files/2_MoE_S%20Bandara.pdf (accessed on 18 July 2022).

- Parliament of the Democratic Socialist Republic of Sri Lanka. Marine Pollution Prevention ACT, No. 35 OF 2008. Available online: https://www.lawnet.gov.lk/wp-content/uploads/2016/12/MARINE-POLLUTION-PREVENTION-ACT-NO-35-OF-2008.pdf (accessed on 18 July 2022).

- Chaturika. A Critical Analysis of Environmental taxation for Sri Lanaka in a Sustainomic Framework. 2014. Available online: http://dl.lib.uom.lk/bitstream/handle/123/11371/105333.pdf?sequence=1&isAllowed=y (accessed on 18 July 2022).

- National Environment Policy. 2021. Available online: https://www.env.gov.lk/web/images/pdf/notices/2021/NationalEnvPolicy2021_final_draft_public_comments_English.pdf (accessed on 18 July 2022).

- Ban on sachets, PET, PVC from March 31. 2021. Available online: http://dailynews.lk/2021/02/22/local/242205/ban-sachets-pet-pvc-march-31 (accessed on 18 July 2022).

- Democratic Socialist Republic of Sri Lankan Ministry of Environment. National Action Plan on Plastic Waste Management 2021–2030. 2021. Available online: http://env.gov.lk/web/images/pdf/policies/National_Action_Plan_on_Waste_Management.pdf (accessed on 18 July 2022).

- UNEP. Addressing Single-Use Plastic Products Pollution Using a Life Cycle Approach. 2021. Available online: https://www.lifecycleinitiative.org/wp-content/uploads/2021/02/Addressing-SUP-Products-using-LCA_UNEP-2021_FINAL-Report-sml.pdf (accessed on 18 July 2022).

- NEP. 2019. Available online: http://env.gov.lk/web/images/pdf/policies/National_Action_Plan_on_Waste_Management.pdf (accessed on 18 July 2022).

- Vora, N.; Christensen, P.R.; Demarteau, J.; Baral, N.R.; Keasling, J.D.; Helms, B.A.; Scown, C.D. Leveling the cost and carbon footprint of circular polymers that are chemically recycled to monomer. Sci. Adv. 2021, 7, eabf0187. [Google Scholar] [CrossRef] [PubMed]

- Ishikawa, Y.; Herat, S. Use of Cement Kilns for Managing Hazardous Waste in Developing Countries. In Waste To Energy; Springer: London, UK, 2012; pp. 137–155. [Google Scholar]

- Wei, F.; Tan, Q.; Dong, K.; Li, J. Revealing the feasibility and environmental benefits of replacing disposable plastic tableware in aviation catering: An AHP-LCA integrated study. Resour. Conserv. Recycl. 2022, 187, 106615. [Google Scholar] [CrossRef]

- JAK. Recycling of waste plastics, HDPE, LDPE, and PP. 2022. Available online: https://jakplastics.lk/jakrecyclecenter.php (accessed on 20 October 2022).

- Liu, C.; Nguyen, T.T.; Ishimura, Y. Current situation and key challenges on the use of single-use plastic in Hanoi. Waste Manag. 2021, 121, 422–431. [Google Scholar] [CrossRef] [PubMed]

- Life Cycle Initiative. Single-Use Plastic Bags and Their Alternatives: Recommendations from Life Cycle Assessments. 2020. Available online: https://www.lifecycleinitiative.org/single-use-plastic-bags-and-their-alternatives-recommendations-from-life-cycle-assessments/ (accessed on 20 October 2022).

- Pathwater. Sustainable Bottled Water, the PATHWATER Life Cycle Assessment. 2019. Available online: https://drinkpathwater.com/blogs/news/sustainable-bottled-water-the-pathwater-life-cycle-assessment (accessed on 20 October 2022).

- Bałdowska-Witos, P.; Piasecka, I.; Flizikowski, J.; Tomporowski, A.; Idzikowski, A.; Zawada, M. Life Cycle Assessment of Two Alternative Plastics for Bottle Production. Materials 2021, 14, 4552. [Google Scholar] [CrossRef] [PubMed]

- Abeynayaka, A.; Norihiro, I. A Framework to Incorporate Aquatic Plastic into Life Cycle Assessment of Plastic Products. In Proceedings of the 11th International Symposium on Environmentally Conscious Design and Inverse Manufacturing (EcoDesign 2019), Yokohama, Japan, 25–27 November 2019; pp. 261–265. [Google Scholar]

- Corella-Puertas, E.; Guieu, P.; Aufoujal, A.; Bulle, C.; Boulay, A.-M. Development of simplified characterization factors for the assessment of expanded polystyrene and tire wear microplastic emissions applied in a food container life cycle assessment. J. Ind. Ecol. 2022, 1–13. [Google Scholar] [CrossRef]

- Biodiversity Sir Lanka. Moves to Establish and Operationalize Private Sector Consortia to Facilitate Extended Producer Responsibility (EPR) Implementation. 2022. Available online: https://biodiversitysrilanka.org/moves-to-establish-and-operationalize-private-sector-consortia-to-facilitate-epr-implementation/ (accessed on 20 October 2022).

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).