Digitalization as an Enabler to SMEs Implementing Lean-Green? A Systematic Review through the Topic Modelling Approach

Abstract

1. Introduction

2. Background

2.1. Digital Transformation (DT)

2.2. Lean Manufacturing and Lean-Green

2.3. Small and Medium Enterprises (SMEs)

2.4. Latent Dirichlet Allocation (LDA) Applied to Topic Modelling in SLRs

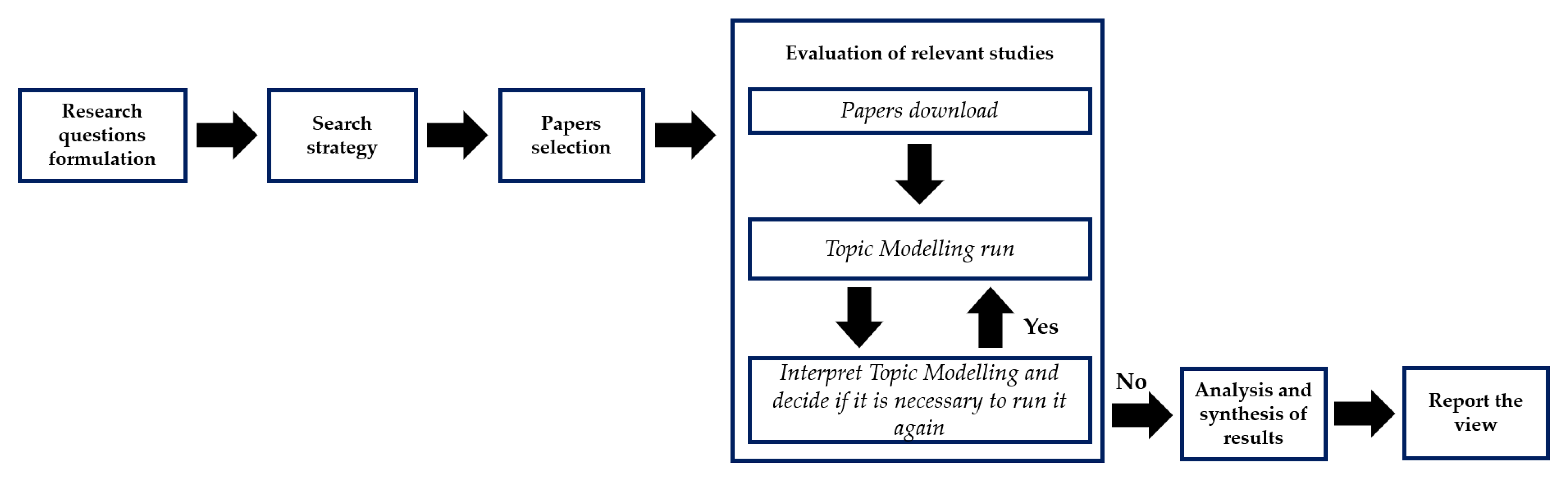

3. Materials and Methods

4. Results

5. Discussion

5.1. How Can Digitalization Support Lean Implementation in SMEs?

5.2. How Can Digitalization Support Lean-Green Implementation in SMEs?

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A. SLR Protocol

| Literature Review Protocol | ||

| Objective | To understand how digitalization enables Lean in SMEs. | |

| Research Question | RQ1. How can digitalization support Lean implementation in SMEs? RQ2. How can digitalization be an enabler in implementing Lean-Green in SMEs? | |

| Keywords and Synonyms | digital transformation; digital transition; digital innovation; digitalization; industry 4.0; SME; small- and medium-sized enterprises; digital media; social media; social network; internet; technology; ICT; small and middle compan*; small and middle firm; lean; Toyota production system; just in time. | |

| Source Selection Criteria Definition | Criteria: The sources should be available and globally recognized as high-quality sources. Studies Language: English. Source Search Methods: The sources should be available and globally recognized as high-quality sources. Source List: Web of Sciences and Scopus. | |

| Studies Type Definition | Research published in journals, books, and conferences. | |

| Studies Initial Selection: | 3 August 2022. | |

| Studies Quality Evaluation: | The quality is defined by the databases selected. | |

| Search string | Web of Science (38 papers returned): TS = ((((((“digital transformation” or “digital transition” or “digitalization” or “industry 4.0” or “digital media” or “social media” or “social network” or “internet” or “digital” or “technology” or “ICT”) and (“lean” OR “toyota production system” OR “Just in time “) and (“sme” or “small and medium firm” or “small and medium compan*” or “small and medium-sized enterprise”)))))) Scoupus (182 papers returned): TITLE-ABS-KEY (((“digital transformation” OR “digital transition” OR “digitalization” OR “industry 4.0” OR “digital media” OR “social media” OR “social network” OR “internet” OR “digital” OR “technology” OR “ICT” ) AND (“lean” OR “toyota production system” OR “Just in time”) AND ( “sme” OR “small and medium firm” OR “small and medium compan*” OR “small and medium-sized enterprise”))) | |

| Data Extraction Form Fields | Filter 1—Exclusion of duplicate studies. Filter 2—Download of papers. Filter 3—Topic modelling application for papers extraction. | |

| Inclusion Criteria | Exclusion Criteria | |

| Study Selection Criteria (Filter 4), executed through human reading |

|

|

| Studies analysis | Forty studies were analyzed, focusing on answering the RQs. | |

References

- Rauch, E.; Dallasega, P.; Matt, D.T. Critical Factors for Introducing Lean Product Development to Small and Medium Sized Enterprises in Italy. Procedia CIRP 2017, 60, 362–367. [Google Scholar] [CrossRef]

- Dombrowski, U.; Crespo, I.; Zahn, T. Adaptive Configuration of a Lean Production System in Small and Medium-Sized Enterprises. Prod. Eng. 2010, 4, 341–348. [Google Scholar] [CrossRef]

- Siegel, R.; Antony, J.; Garza-Reyes, J.A.; Cherrafi, A.; Lameijer, B. Integrated Green Lean Approach and Sustainability for SMEs: From Literature Review to a Conceptual Framework. J. Clean. Prod. 2019, 240, 118205. [Google Scholar] [CrossRef]

- Womack, J.P.; Jones, D.T. Lean Thinking: Banish Waste and Create Wealth in Your Corporation; Free Press: New York, NY, USA, 2003. [Google Scholar]

- Da Silva, F.W.S.; Alves, A.C.; Figueiredo, M.C.B. Lean Production in Small and Medium Sized Companies from the Free Economic Zone of Manaus: A Reality or Just Fiction? Gestao e Producao 2019, 26, 1–14. [Google Scholar] [CrossRef]

- AlMulhim, A.F. Smart Supply Chain and Firm Performance: The Role of Digital Technologies. Bus. Process Manag. J. 2021, 27, 1353–1372. [Google Scholar] [CrossRef]

- Khalid, B.; Naumova, E. Digital transformation SCM in view of COVID-19 from Thailand SMEs perspective. Glob. Chall. Digit. Transform. Mark. 2021, 49–66. [Google Scholar]

- AlMujaini, H.; Hilmi, M.F.; Abudaqa, A.; Alzahmi, R. Corporate Foresight Organizational Learning and Performance: The Moderating Role of Digital Transformation and Mediating Role of Innovativeness in SMEs. Int. J. Data Netw. Sci. 2021, 5, 703–712. [Google Scholar] [CrossRef]

- Jaiswal, P.; Singh, A.; Misra, S.C.; Kumar, A. Barriers in Implementing Lean Manufacturing in Indian SMEs: A Multi-Criteria Decision-Making Approach. J. Model. Manag. 2021, 16, 339–356. [Google Scholar] [CrossRef]

- Marinho, B.F.D.; Costa Melo, I. Fostering Innovative SMEs in a Developing Country: The ALI Program Experience. Sustainability 2022, 14, 13344. [Google Scholar] [CrossRef]

- Lu, Y.; Liu, Z.; Min, Q. A Digital Twin-Enabled Value Stream Mapping Approach for Production Process Reengineering in SMEs. Int. J. Comput. Integr. Manuf. 2021, 34, 764–782. [Google Scholar] [CrossRef]

- Mohammed, I.K.; Trzcielinski, S. The Interconnections Between ICT, Industry 4.0 and Agile Manufacturing. Manag. Prod. Eng. Rev. 2021, 12, 99–110. [Google Scholar] [CrossRef]

- Rozak, H.; Adhiatma, A.; Fachrunnisa, O.; Rahayu, T. Social Media Engagement, Organizational Agility and Digitalization Strategic Plan to Improve SMEs’ Performance. IEEE Trans. Eng. Manag. 2021, 1–10. [Google Scholar] [CrossRef]

- Klimecka-Tatar, D.; Ingaldi, M. Digitization of Processes in Manufacturing SMEs-Value Stream Mapping and OEE Analysis. Procedia Comput. Sci. 2022, 200, 660–668. [Google Scholar] [CrossRef]

- Minh, N.D.; Kien, D.T. A Four-Phase Framework for Lean Implementation in Small and Medium Enterprises. Management 2021, 25, 259–277. [Google Scholar] [CrossRef]

- Gandhi, N.S.; Thanki, S.J.; Thakkar, J.J. Ranking of Drivers for Integrated Lean-Green Manufacturing for Indian Manufacturing SMEs. J. Clean. Prod. 2018, 171, 675–689. [Google Scholar] [CrossRef]

- Thanki, S.; Thakkar, J.J. An Investigation on Lean–Green Performance of Indian Manufacturing SMEs. Int. J. Product. Perform. Manag. 2020, 69, 489–517. [Google Scholar] [CrossRef]

- Sá, J.C.; Reis, M.; Dinis-Carvalho, J.; Silva, F.J.G.; Santos, G.; Ferreira, L.P.; Lima, V. The Development of an Excellence Model Integrating the Shingo Model and Sustainability. Sustainability 2022, 14, 9472. [Google Scholar] [CrossRef]

- Hoellthaler, G.; Braunreuther, S.; Reinhart, G. Digital Lean Production-An Approach to Identify Potentials for the Migration to a Digitalized Production System in SMEs from a Lean Perspective. Procedia CIRP 2018, 67, 522–527. [Google Scholar] [CrossRef]

- Ferreira, W.D.P.; Armellini, F.; de Santa-Eulalia, L.A.; Thomasset-Laperrière, V. Extending the lean value stream mapping to the context of Industry 4.0: An agent-based technology approach. J. Manuf. Syst. 2022, 63, 1–14. [Google Scholar] [CrossRef]

- Saha, B. Application of Topic Modelling for Literature Review in Management Research. In Interdisciplinary Research in Technology and Management; CRC Press: Boca Raton, FL, USA, 2021; pp. 249–256. ISBN 9781003202240. [Google Scholar]

- Asmussen, C.B.; Møller, C. Smart Literature Review: A Practical Topic Modelling Approach to Exploratory Literature Review. J. Big Data 2019, 6, 93. [Google Scholar] [CrossRef]

- Riedl, R.; Benlian, A.; Hess, T.; Stelzer, D.; Sikora, H. On the Relationship between Information Management and Digitalization. Bus. Inf. Syst. Eng. 2017, 59, 475–482. [Google Scholar] [CrossRef]

- Mertens, P.; Wiener, M. Riding the Digitalization Wave: Toward a Sustainable Nomenclature in Wirtschaftsinformatik. Bus. Inf. Syst. Eng. 2018, 60, 367–372. [Google Scholar] [CrossRef]

- Legner, C.; Eymann, T.; Hess, T.; Matt, C.; Böhmann, T.; Drews, P.; Mädche, A.; Urbach, N.; Ahlemann, F. Digitalization: Opportunity and Challenge for the Business and Information Systems Engineering Community. Bus. Inf. Syst. Eng. 2017, 59, 301–308. [Google Scholar] [CrossRef]

- Gong, C.; Ribiere, V. Developing a Unified Definition of Digital Transformation. Technovation 2021, 102, 102217. [Google Scholar] [CrossRef]

- Culot, G.; Nassimbeni, G.; Orzes, G.; Sartor, M. Behind the Definition of Industry 4.0: Analysis and Open Questions. Int. J. Prod. Econ. 2020, 226, 107617. [Google Scholar] [CrossRef]

- Bouwman, H.; Nikou, S.; de Reuver, M. Digitalization, Business Models and SMEs: How Do Business Model Innovation Practices Improve Performance of Digitalizing SMEs? Telecommun. Policy 2019, 43, 101828. [Google Scholar] [CrossRef]

- Liker, J.K.; Morgan, J.M. The Toyota Way in Services: The Case of Lean Product Development. Acad. Manag. Perspect. 2006, 20, 5–20. [Google Scholar] [CrossRef]

- Jastia, N.V.K.; Kodali, R. Lean Production: Literature Review and Trends. Int. J. Prod. Res. 2015, 53, 867–885. [Google Scholar] [CrossRef]

- Mostafa, S.; Dumrak, J.; Soltan, H. A Framework for Lean Manufacturing Implementation. Prod. Manuf. Res. 2013, 1, 44–64. [Google Scholar] [CrossRef]

- Shah, R.; Ward, P.T. Defining and Developing Measures of Lean Production. J. Oper. Manag. 2007, 25, 785–805. [Google Scholar] [CrossRef]

- Liker, J.K. Toyota Way: 14 Management Principles from the World’s Greatest Manufacturer; McGraw-Hill Education: New York, NY, USA, 2004. [Google Scholar]

- Arlbjørn, J.S.; Freytag, P.V.; de Haas, H. Service Supply Chain Management: A Survey of Lean Application in the Municipal Sector. Int. J. Phys. Distrib. Logist. Manag. 2011, 41, 277–295. [Google Scholar] [CrossRef]

- Jaiswal, P.; Kumar, A.; Prasad, K. Assessment of Drivers to Implement Lean Manufacturing in Indian SMEs Using Intuitionistic Fuzzy Based TOPSIS Approach. Int. J. Mod. Manuf. Technol. 2017, 9, 30–38. [Google Scholar]

- Losonci, D.; Demeter, K. Lean Production and Business Performance: International Empirical Results. Compet. Rev. 2013, 23, 218–233. [Google Scholar] [CrossRef]

- Teixeira, P.; Sá, J.C.; Silva, F.J.G.; Ferreira, L.P.; Santos, G.; Fontoura, P. Connecting Lean and Green with Sustainability towards a Conceptual Model. J. Clean. Prod. 2021, 322, 129047. [Google Scholar] [CrossRef]

- Bhattacharya, A.; Nand, A.; Castka, P. Lean-Green Integration and Its Impact on Sustainability Performance: A Critical Review. J. Clean. Prod. 2019, 236, 117697. [Google Scholar] [CrossRef]

- Garza-Reyes, J.A. Lean and Green-a Systematic Review of the State of the Art Literature. J. Clean. Prod. 2015, 102, 18–29. [Google Scholar] [CrossRef]

- Cobra, R.L.R.B.; Guardia, M.; Queiroz, G.A.; Oliveira, J.A.; Ometto, A.R.; Esposto, K.F. “Waste” as the Common “Gene” Connecting Cleaner Production and Lean Manufacturing: A Proposition of a Hybrid Definition. Environ. Qual. Manag. 2015, 25, 25–40. [Google Scholar] [CrossRef]

- Cherrafi, A.; Elfezazi, S.; Chiarini, A.; Mokhlis, A.; Benhida, K. The Integration of Lean Manufacturing, Six Sigma and Sustainability: A Literature Review and Future Research Directions for Developing a Specific Model. J. Clean. Prod. 2016, 139, 828–846. [Google Scholar] [CrossRef]

- Dieste, M.; Panizzolo, R.; Garza-Reyes, J.A. Evaluating the Impact of Lean Practices on Environmental Performance: Evidences from Five Manufacturing Companies. Prod. Plan. Control 2020, 31, 739–756. [Google Scholar] [CrossRef]

- Iranmanesh, M.; Zailani, S.; Hyun, S.; Ali, M.; Kim, K. Impact of Lean Manufacturing Practices on Firms’ Sustainable Performance: Lean Culture as a Moderator. Sustainability 2019, 11, 1112. [Google Scholar] [CrossRef]

- Caldera, H.T.S.; Desha, C.; Dawes, L. Evaluating the Enablers and Barriers for Successful Implementation of Sustainable Business Practice in ‘Lean’ SMEs. J. Clean. Prod. 2019, 218, 575–590. [Google Scholar] [CrossRef]

- Charrua-Santos, F.; Santos, B.P.; Enrique, D.V.; Alberto, A.; Bibete, H.; Osório, G.J.; Lima, T.M. An Overview of Lean Production and Industry 4.0 in Different Context. In Proceedings of the ICITM 2020—2020 9th International Conference on Industrial Technology and Management, Oxford, UK, 11–13 February 2020; pp. 69–72. [Google Scholar] [CrossRef]

- Chen, J.C.; Chen, K.M. Application of ORFPM System for Lean Implementation: An Industrial Case Study. Int. J. Adv. Manuf. Technol. 2014, 72, 839–852. [Google Scholar] [CrossRef]

- Kolberg, D.; Zühlke, D. Lean Automation Enabled by Industry 4.0 Technologies. IFAC-PapersOnLine 2015, 48, 1870–1875. [Google Scholar] [CrossRef]

- Sanders, A.; Elangeswaran, C.; Wulfsberg, J. Industry 4.0 Implies Lean Manufacturing: Research Activities in Industry 4.0 Function as Enablers for Lean Manufacturing. J. Ind. Eng. Manag. 2016, 9, 811. [Google Scholar] [CrossRef]

- Kolla, S.; Minufekr, M.; Plapper, P. Deriving Essential Components of Lean and Industry 4.0 Assessment Model for Manufacturing SMEs. Procedia CIRP 2019, 81, 753–758. [Google Scholar] [CrossRef]

- Garcia-Garcia, G.; Singh, Y.; Jagtap, S. Optimising Changeover through Lean-Manufacturing Principles: A Case Study in a Food Factory. Sustainability 2022, 14, 8279. [Google Scholar] [CrossRef]

- Garcia-Garcia, G.; Coulthard, G.; Jagtap, S.; Afy-Shararah, M.; Patsavellas, J.; Salonitis, K. Business Process Re-Engineering to Digitalise Quality Control Checks for Reducing Physical Waste and Resource Use in a Food Company. Sustainability 2021, 13, 12341. [Google Scholar] [CrossRef]

- Souza, J.P.E.; Alves, J.M. Lean-Integrated Management System: A Model for Sustainability Improvement. J. Clean. Prod. 2018, 172, 2667–2682. [Google Scholar] [CrossRef]

- Vinodh, S.; Ben Ruben, R.; Asokan, P. Life Cycle Assessment Integrated Value Stream Mapping Framework to Ensure Sustainable Manufacturing: A Case Study. Clean Technol. Environ. Policy 2016, 18, 279–295. [Google Scholar] [CrossRef]

- Faulkner, W.; Badurdeen, F. Sustainable Value Stream Mapping (Sus-VSM): Methodology to Visualize and Assess Manufacturing Sustainability Performance. J. Clean. Prod. 2014, 85, 8–18. [Google Scholar] [CrossRef]

- Kaswan, M.S.; Rathi, R. Green Lean Six Sigma for Sustainable Development: Integration and Framework. Env. Impact Assess. Rev. 2020, 83, 106396. [Google Scholar] [CrossRef]

- Lucato, W.C.; Vieira, M.; Da Silva Santos, J.C. Eco-Six Sigma: Integration of Environmental Variables into the Six Sigma Technique. Prod. Plan. Control. 2015, 26, 605–616. [Google Scholar] [CrossRef]

- Helleno, A.L.; de Moraes, A.J.I.; Simon, A.T.; Helleno, A.L. Integrating Sustainability Indicators and Lean Manufacturing to Assess Manufacturing Processes: Application Case Studies in Brazilian Industry. J. Clean. Prod. 2017, 153, 405–416. [Google Scholar] [CrossRef]

- European Commission SME Definition. Available online: https://ec.europa.eu/eurostat/web/structural-business-statistics/small-and-medium-sized-enterprises (accessed on 11 October 2022).

- OECD Brazil|Financing SMEs and Entrepreneurs 2020: An OECD Scoreboard|OECD ILibrary. Available online: https://www.oecd-ilibrary.org/sites/8153da8d-en/index.html?itemId=/content/component/8153da8d-en (accessed on 5 April 2022).

- Library of Chilean Congress [Biblioteca del Congreso Chileno] Estatuto de Las PYMES—Ley Fácil—Biblioteca Del Congreso Nacional de Chile. Available online: https://www.bcn.cl/leyfacil/recurso/estatuto-de-las-pymes (accessed on 7 January 2022).

- Government of Japan Small and Medium Enterprise Agency. Available online: https://www.chusho.meti.go.jp/sme_english/outline/07/01.html (accessed on 5 April 2022).

- U.S. Small Business Administration (SBA). Table of Size Standards; U.S. Small Business Administration (SBA): Washington, DC, USA, 2022.

- World Trade Organization. Levelling the Trading Field for SMEs; World Trade Organization: Geneva, Switzerland, 2017. [Google Scholar]

- Kim, S.-S. Sustainable Growth Variables by Industry Sectors and Their Influence on Changes in Business Models of SMEs in the Era of Digital Transformation. Sustainability 2021, 13, 7114. [Google Scholar] [CrossRef]

- Troise, C.; Corvello, V.; Ghobadian, A.; O’Regan, N. How Can SMEs Successfully Navigate VUCA Environment: The Role of Agility in the Digital Transformation Era. Technol. Forecast. Soc. Chang. 2022, 174, 121227. [Google Scholar] [CrossRef]

- Kankaanhuhta, V.; Packalen, T.; Väätäinen, K. Digital Transformation of Forest Services in Finland—A Case Study for Improving Business Processes. Forests 2021, 12, 781. [Google Scholar] [CrossRef]

- Dutta, G.; Kumar, R.; Sindhwani, R.; Singh, R.K. Digital Transformation Priorities of India’s Discrete Manufacturing SMEs—A Conceptual Study in Perspective of Industry 4.0. Compet. Rev. 2020, 30, 289–314. [Google Scholar] [CrossRef]

- Quinn, K.M.; Monroe, B.L.; Colaresi, M.; Crespin, M.H.; Radev, D.R. How to Analyze Political Attention with Minimal Assumptions and Costs. Am. J. Pol. Sci. 2010, 54, 209–228. [Google Scholar] [CrossRef]

- Lancichinetti, A.; Sirer, M.I.; Wang, J.X.; Acuna, D.; Körding, K.; Amaral, L.A.N. High-Reproducibility and High-Accuracy Method for Automated Topic Classification. Phys. Rev. X 2015, 5, 011007. [Google Scholar] [CrossRef]

- Blei, D.M. Probabilistic Topic Models. Commun. ACM 2012, 55, 77–84. [Google Scholar] [CrossRef]

- Denyer, D.; Tranfield, D. Producing a Systematic Review. In the Sage Handbook of Organizational Research Methods; Buchanan, D.A., Bryman, A., Eds.; American Psychological Association: Washington, DC, USA, 2009; pp. 671–689. [Google Scholar]

- Moher, D.; Liberati, A.; Tetzlaff, J.; Altman, D.G. Preferred Reporting Items for Systematic Reviews and Meta-Analyses: The PRISMA Statement. PLoS Med. 2009, 6, e1000097. [Google Scholar] [CrossRef] [PubMed]

- Aghaei Chadegani, A.; Salehi, H.; Md Yunus, M.M.; Farhadi, H.; Fooladi, M.; Farhadi, M.; Ale Ebrahim, N. A Comparison between Two Main Academic Literature Collections: Web of Science and Scopus Databases. Asian Soc. Sci. 2013, 9, 18–26. [Google Scholar] [CrossRef]

- Levy, Y.; Ellis, T.J. A Systems Approach to Conduct an Effective Literature Review in Support of Information Systems Research. Inf. Sci. Int. J. Emerg. Transdiscipl. 2006, 9, 181–212. [Google Scholar] [CrossRef]

- Kiatcharoenpol, T.; Laosirihongthong, T.; Chaiyawong, P.; Hierarchy, A.A.; Ahp, P. A Study of Critical Success Factors and Prioritization by Using Analysis Hierarchy Process in Lean Manufacturing Implementation for Thai SMEs. In Proceedings of the 5th International Asia Conference on Industrial Engineering and Management Innovation; Atlantis Press: Paris, France, 2015; pp. 10–13. [Google Scholar] [CrossRef]

- Bakri, A.; Alkbir, M.F.M.; Awang, N.; Januddi, F.; Ismail, M.A.; Aizat Ahmad, A.N.; Zakaria, I.H. Addressing the Issues of Maintenance Management in Smes: Towards Sustainable and Lean Maintenance Approach. Emerg. Sci. J. 2021, 5, 367–379. [Google Scholar] [CrossRef]

- Salma, A.; Anas, C.; Mohammed, E.H. Bibliographic Study on the Difficulties Encountered by SMEs during the Implementation of Lean Manufacturing. J. Adv. Manuf. Syst. 2021, 20, 163–190. [Google Scholar] [CrossRef]

- MLADINEO, M.; Cubic, M.; Nikola, G.; Marina, C.Z. Human-Centric Approach of the Lean Management as an Enabler of Industry 5.0 in SMEs. In Proceedings of the International Conference “Mechanical Technologies and Sctrucutural Materials”, Split, Croatia, 23–24 September 2021. [Google Scholar]

- Tiwari, R.K.; Tiwari, J.K. Identification of Key Lean Practices within Indian Automotive SMEs Environment. Int. J. Ind. Syst. Eng. 2019, 33, 17–37. [Google Scholar] [CrossRef]

- Wadhwa, R.S. Implementing Continuous Improvement in Metal Casting: Case Study of an Aluminum Foundry. Adv. Mat. Res. 2013, 622, 433–436. [Google Scholar] [CrossRef]

- Anuar, A.; Sadek, D.M.; Abdull Rahman, N.L.; Othman, N. Lean Principles Improving Entrepreneurial Ecosystem in Malaysian SMEs. Int. J. Supply Chain. Manag. 2020, 9, 73–77. [Google Scholar]

- Ruiz, S.; Simón, A.; Sotelo, F.; Raymundo, C. Optimized Plant Distribution and 5S Model That Allows SMEs to Increase Productivity in Textiles. In Proceedings of the 17th LACCEI international Multi-Conference for Engineering, Education and Technology: “Industry, Innovation, And Infrastructure for Sustainable Cities and Communities”, Montego Bay, Jamaica, 24–26 July 2019. [Google Scholar] [CrossRef]

- Dowlatshahi, S.; Taham, F. The Development of a Conceptual Framework for Just-In-Time Implementation in SMEs. Prod. Plan. Control. 2009, 20, 611–621. [Google Scholar] [CrossRef]

- Jaiswal, P.; Kumar, A. Analyzing Barriers of Lean Manufacturing Adoption in Indian SMEs Using an Integrated Approach of Grey Decision Making Trial and Evaluation Laboratory (DEMATEL). Lect. Notes Eng. Comput. Sci. 2016, 2224, 688–691. [Google Scholar]

- Prasad, S.; Baltov, M.; Neelakanteswara Rao, A.; Lanka, K. Interdependency Analysis of Lean Manufacturing Practices in Case of Bulgarian SMEs: Interpretive Structural Modelling and Interpretive Ranking Modelling Approach. Int. J. Lean Six Sigma 2020, 12, 503–535. [Google Scholar] [CrossRef]

- Iris, C.; Cebeci, U. Analyzing Relationship between ERP Utilization and Lean Manufacturing Maturity of Turkish SMEs. J. Enterp. Inf. Manag. 2014, 27, 261–277. [Google Scholar] [CrossRef]

- Maryam, M.; Rezaei, S.; Shahijan, M.K. Agile Supply Chain Management (ASCM): A Management Decision Making Approach. Asia Pac. J. Mark. Logist. 2017, 29, 1–17. [Google Scholar] [CrossRef]

- Ho, D.C.K.; Mo, D.Y.W.; Wong, E.Y.C.; Leung, S.M.K. Business Intelligence for Order Fulfilment Management in Small and Medium Enterprises. Int. J. Internet Manuf. Serv. 2019, 6, 169–184. [Google Scholar] [CrossRef]

- Goti, A.; de la Calle, A.; Gil, M.J.; Errasti, A.; Bom, P.R.D.; García-Bringas, P. Development and Application of an Assessment Complement for Production System Audits Based on Data Quality, IT Infrastructure and Sustainability. Sustainability 2018, 10, 4679. [Google Scholar] [CrossRef]

- Neubert, M. Digitalization’s impact on lean global, start-up firms’ internationalization speed. Innov. Manag. Entrep. Sustain. 2018, volume, 765–775. [Google Scholar]

- Dallasega, P.; Woschank, M.; Ramingwong, S.; Tippayawong, K.Y.; Chonsawat, N. Field Study to Identify Requirements for Smart Logistics of European, US and Asian SMEs. In Proceedings of the International Conference on Industrial Engineering and Operations Management, Bangkok, Thailand, 5–7 March 2019; Volume 2019, pp. 844–855. [Google Scholar]

- Mofolasayo, A.; Young, S.; Martinez, P.; Ahmad, R. How to Adapt Lean Practices in SMEs to Support Industry 4.0 in Manufacturing. Procedia Comput. Sci. 2022, 200, 934–943. [Google Scholar] [CrossRef]

- Dossou, P.E.; Rafael, P.; Cristiane, S.; Joao, C.J. How to Use Lean Manufacturing for Improving a Healthcare Logistics Performance. Procedia Manuf. 2020, 51, 1657–1664. [Google Scholar] [CrossRef]

- Bin Zhou, S.; Ji, F.X. Impact of Lean Supply Chain Management on Operational Performance. Int. J. Bus. Anal. 2015, 2, 1–19. [Google Scholar] [CrossRef]

- Peng, C.; Zhong, L. Intelligent Transformation of Small and Medium-Sized Manufacturing Enterprise in China-Case Study of Dongguan Taiwei Electronics. In Proceedings of the 2021 International Conference on Computer Engineering and Artificial Intelligence, Tianjin, China, 23–26 April 2021; pp. 511–518. [Google Scholar] [CrossRef]

- Woschank, M.; Dallasega, P. The Impact of Logistics 4.0 on Performance in Manufacturing Companies: A Pilot Study. Procedia Manuf. 2021, 55, 487–491. [Google Scholar] [CrossRef]

- Adeyeri, M.K.; Ayodeji, S.P.; Akinnuli, B.O.; Farayibi, P.K.; Ojo, O.O.; Adeleke, K. Development of SMEs Coping Model for Operations Advancement in Manufacturing Technology; Elsevier Inc.: Amsterdam, The Netherlands, 2018; ISBN 9780081024140. [Google Scholar]

- Grube, D.; Malik, A.A.; Bilberg, A. Generic Challenges and Automation Solutions in Manufacturing SMEs. In Proceedings of the Annals of DAAAM and Proceedings of the International DAAAM Symposium, Zadar, Croatia, 8–11 November 2017; Volume 28, pp. 1161–1169. [CrossRef]

- Jesemann, I.; Beichter, T.; Constantinescu, C.; Herburger, K.; Rüger, M. Investigation of the “Lean Startup” Approach in Large Manufacturing Companies towards Customer Driven Product Innovation in SMEs. Procedia CIRP 2021, 99, 711–716. [Google Scholar] [CrossRef]

- Papetti, A.; Marilungo, E.; Gregori, F.; Germani, M. Driving Process Innovation: A Structured Method for Improving Efficiency in SMEs. Procedia CIRP 2016, 50, 448–453. [Google Scholar] [CrossRef][Green Version]

- Rother, M.; Shook, J. Learning to See: Value Stream Mapping to Add Value and Eliminate MUDA.; Lean Enterprise Institute, Ed.; Lean Enterprise Institute: Boston, MA, USA, 1999; Volume 1, ISBN 9780966784305. [Google Scholar]

- Frontoni, E.; Rosetti, R.; Paolanti, M.; Alves, A.C. HATS Project for Lean and Smart Global Logistic: A Shipping Company Case Study. Manuf. Lett. 2020, 23, 71–74. [Google Scholar] [CrossRef]

- Alshamaila, Y.; Papagiannidis, S.; Li, F. Cloud computing adoption by SMEs in the north east of England. J. Enterp. Inf. Manag. 2013, 26, 250–275. [Google Scholar] [CrossRef]

| T1 | T2 | T3 | T4 | T5 | T6 | T7 | T8 | T9 | T10 | T11 |

|---|---|---|---|---|---|---|---|---|---|---|

| lean | industri | servic | firm | data | var | vsm | suppli | learn | product | lean |

| implement | manufactur | construct | jit | erp | mainten | board | chain | construct | process | manufactur |

| startup | digit | agil | carbon | inform | cell | simul | manag | project | manag | smes |

| principl | factori | forest | adopt | bim | manufactur | director | strategi | train | system | manag |

| success | product | data | technolog | document | machin | audit | organis | plan | compani | implement |

| agre | procedia | softwar | malaysia | system | implement | govern | firm | cours | develop | perform |

| custom | autom | iot | cost | project | layout | twin | jit | technic | lean | factor |

| statement | smes | cloud | suppli | supplier | reduc | agent | technolog | elearn | research | green |

| disagre | logist | asset | relat | user | part | firm | supplier | educ | model | environment |

| compani | smart | transform | energi | order | engin | high | signific | engin | technolog | enabl |

| T1 | T2 | T3 | T4 | T5 |

|---|---|---|---|---|

| industri | design | lean | product | compani |

| product | system | manag | process | manag |

| manufactur | learn | implement | manufactur | technolog |

| digit | develop | smes | data | develop |

| smes | cost | product | time | inform |

| technolog | process | suppli | system | research |

| system | technic | manufactur | model | process |

| process | cell | chain | improv | model |

| lean | time | factor | vsm | project |

| custom | team | practic | sustain | andn |

| Paper | Focus | Main Results |

|---|---|---|

| [15] | To provide and verify a step-by-step strategy from the low-to-high level of Lean application with appropriate tools and techniques to achieve the goals in each specific phase. | A roadmap for SMEs to successfully apply Lean in the context of limited resources. |

| [75] | This study identifies and prioritises critical success factors (CSF) based on implementing Lean Manufacturing for Thai SMEs. | “Technology resource” is the most important to enhance the implementation of Lean in SME organizations. |

| [76] | To identify the CSFs in managing maintenance (MM) activity in SMEs. | By identifying the CSF constructs, SMEs can utilize the information to improve their approach to a systematic MM program. |

| [77] | To provide an in-depth analysis of the implementation of Lean manufacturing in SMEs worldwide, to identify and present the critical difficulties that impact the undertaking, and to highlight the success factors of manufacturing firms. | The main barriers to Lean implementation are lack of leadership, commitment of top management, financial resources, resistance to change, training and knowledge about Lean tools, and know-how, skills, and expertise. |

| [1] | To provide a survey-based evaluation of applicability, benefits, and critical factors of Lean in SME product development and to identify how the Lean start-up approach operates in product development. | Lean methods can be introduced very quickly, promising high potential for improvements, and Lean methods combined with industry 4.0 technologies act as a booster for efficiency optimization in product development. |

| [78] | Based on the literature review, select the key success factors for Lean implementation in SMEs. These factors are then put in the context of industry 5.0 to explore the possibilities of Lean management as an enabler of industry 5.0. | Most of the success factors and tools are people-oriented, thus giving the human-centric approach to organizational and process improvement, as required by industry 5.0. |

| [79] | To identify key Lean practices for Indian automotive SMEs to reap the maximum benefits. | The findings show that customer involvement is the most important Lean practice, followed by problem identification and prevention, total productive maintenance, and others. |

| [80] | To identify and suggest improvements in two areas crucial for implementing Lean principles in an aluminium semi-permanent casting small to medium enterprise (SME). | This paper builds an analytical model to measure production performance and presents a case study of an aluminium foundry. The case study reveals that using two Lean principles of bottleneck identification and Lean buffering could allow for a timely response to customer requirements. |

| [81] | To explore how Lean principles can improve the entrepreneurial ecosystem in Malaysian SMEs. | Using Lean principles could be more cost-effective because they avoid lengthy implementations of unproven strategies and investments in the entrepreneurial ecosystem. |

| [82] | To identify the steps SMEs can follow in searching for a plant distribution model and applying layout improvement to increase productivity. | Implementing the tools for plant distribution and 5S was proposed to reduce waste in the production process since this generated a high total cycle time. |

| [83] | To analyse which aspects of the JIT philosophy also apply to small- and medium-sized enterprises (SMEs). | Barriers include a lack of supplier cooperation and partnerships, an inability to develop the necessary technologies and methodologies to reduce or eliminate waste, difficulties in managing demand fluctuations, a lack of capital to acquire advanced technologies, quality control problems, and inadequate employee training and development. Enablers include the ability to empower employees, reduce JIT implementation time, overcome employee resistance to change, and receive various forms of governmental support. |

| [84] | To investigate the opposing factors in adopting Lean manufacturing in Indian SMEs and systematically evaluate causal/effect barriers by the Grey-DEMATEL technique. | Nine out of fourteen barriers belong to the casual group, and five barriers belong to the effect group. This study revealed that fear of adopting new technology is a high influencing barrier among all barriers. |

| [9] | To investigate the interrelationships among LM adoption barriers in Indian SMEs. | The findings show that limited financial resources, fear of adopting new technology, lack of top management commitment, and poor leadership quality are the most critical barriers to LM diffusion in Indian SMEs. |

| [85] | To analyse the contextual relationship and dependency amongst enablers for LM implementation in Bulgarian SMEs. | The findings demonstrated that “leadership and commitment by management,” “human resource management,” “customer relation management,” “supplier relation management,” and “information technology system” are the most significant enablers for Lean implementation in Bulgarian SMEs. |

| Paper | Focus | Main Results |

|---|---|---|

| [20] | To explore the integration of the VSM with simulation to help industry 4.0 initiatives. | VSM combined with simulation can help enterprises understand changes in materials, equipment, processes, and information flows associated with industry 4.0 application scenarios. |

| [86] | To understand how effective Turkish SMEs use enterprise resource planning (ERP) systems to assess their adherence to Lean. | The effective usage of specific ERP modules can contribute toward applying Lean principles and vice versa. |

| [11] | To propose a digital twin-enabled VSM approach for SMEs. | A theoretical framework which combines IoT data-driven production process planning and simulation methods. |

| [87] | To propose that entrepreneurial orientation (EO), participative management style, supplier relations, resource management, JIT, and technology utilization are several drivers of an effective management decision-making approach. | EO, supplier relations, resource management, JIT methodology, and TU positively impact agile supply chain management. |

| [45] | To understand how Lean and industry 4.0 integration can contribute to increased flexibility and productivity. | Implementation of LP and industry 4.0 concepts in Angola are not being uniformed in terms of company size and geography. Five S is the leanest tool implemented. |

| [88] | To investigate business intelligence (BI) tools that help an SME to improve its supplier order fulfilment management. | SMEs can benefit from BI tools at an affordable cost, joining the emergent trend of deploying business analytics to make systematic innovations and collaborating with supplier relationships to implement a just-in-time strategy. |

| [7] | To discuss the problem of digital transformation of supply chain management (SCM) due to the changing business environment and the desire to meet customer demand in Thailand. | SCM processes are altered, such as reduction in product design and a manufacturing period, faster delivery of products to customers, easily meeting of the preferences and demands of customers, and faster and effective decision-making supported by big data and analytical decision techniques. |

| [49] | To provide state-of-the-art literature on existing assessment models and consequently map Lean and industry 4.0 components to the specific characteristics of manufacturing SMEs. | Development of a hybrid model including Lean and industry 4.0 features suitable for manufacturing SMEs. |

| [89] | To document the positive experience of one enterprise in jointly auditing and improving data quality and IT infrastructure, which better aligned its XPS with sustainability objectives. | The paper provides a management supporting tool to promote change in the natural evolution of businesses, for example, the BI panels. Regarding the link between sustainability and business objectives via big data and BI tools, the company detected one weakness concerning data analysis. |

| [19] | To demonstrate the state-of-art regarding Lean production and digitization and to present an approach based on the consistent opinion of the reviewed literature, which formulates digitization as the next step of Lean management in production systems. | This study reveals the demand for a methodological approach in an SME environment that quantifies the profitability of implementing digital technologies in Lean. It formulates digitization as the next step of Lean in production systems. |

| [90] | This paper aims to understand the impact of digitalization on international, Lean, and global start-up speeds (LGS). | Digitalization allows LGS to increase decision-making efficiency and optimize international market evaluation strategies and processes. |

| [14] | This paper presents the value stream mapping analysis results supported by the overall equipment effectiveness (OEE) coefficient analysis. | It was found that the partial digitization of the one production operations in SMEs has a positive effect on the course of the process. Creating a running chart for the variability of Total Productive Maintenance (TPM) indicators helps to improve the organization and efficiency of work. |

| [91] | To present the outcomes of expert workshops to identify requirements of SMEs in the field of smart logistics management. | SMEs will only benefit from industry 4.0 by following customized implementation strategies, approaches, concepts, and technological solutions. |

| [92] | To evaluate how Lean can support industry 4.0 in pursuit of greater customer value and manufacturing excellence. | This paper finds that the pursuit of SMEs toward process efficiency and waste reduction can be best achieved through a focus on foundational digitalization and data management, then taking a stepwise approach towards the cyber-physical systems of industry 4.0. |

| [93] | To investigate Lean manufacturing and healthcare logistics 4.0 concepts, methods, and tools. | The framework elaborated for implementing industry 4.0 and logistics 4.0 concepts in SMEs, in opposition to many architectures of the literature, considers sustainability as the kernel of industry 4.0 concept implementation in SMEs. |

| [94] | To examine driving factors of Lean supply chain management and major supply chain and information technology solutions applied in SMEs. | There is a positive relationship between the successfulness of Lean supply chain practices and IT solutions adopted, and the Lean supply chain would increase. It is also shown that these supply chain and information technologies play crucial roles in helping small companies transform into leaner organizations. |

| [95] | To present a case study about a Chinese company that constructed an intelligent Lean system. | China’s small- and medium-sized manufacturing enterprises can promote intelligent Lean through the path of “standardization, lean, digital, intelligent” concepts. |

| [96] | To investigate the relationship between Logistics 4.0 concepts and technologies and logistics performance indicators in manufacturing enterprises. | The implementation of smart and Lean concepts has a major impact on logistics performance, whereas information and communication technologies, as well as autonomous logistics systems and vehicles, are not completely implemented and exploited yet. |

| [12] | To analyze the relationship between information and communication technologies (ICT), industry 4.0, and agile manufacturing. | ICT plays a key role, but it is not a goal itself. They are a prerequisite for the implementation of industry 4.0. Still, they serve to achieve agility in the manufacturing system and, as a result, achieve a competitive advantage for enterprises operating in turbulent and unpredictable environments. |

| Paper | Focus | Main Results |

|---|---|---|

| [97] | A theoretical association of advances in manufacturing technology and tools. | Framework with the technologies and process improvement methodologies to point out the difficulties of SMEs to obtain technological advancements because of limited resources and lack of finances available to them. |

| [66] | To study the functional areas which can potentially leverage industry 4.0 technologies and help India’s SMEs to adopt digital technologies for the identified functional areas. | Manufacturers want to change their design and manufacturing strategies based on performance metrics. Therefore, they need first to capture real-time machine data, analyze it, and then incorporate the resulting improvements in manufacturing and design decisions in that order. |

| [98] | In this paper, the analysis of the SMEs, and automation integrators of the project, identify a correlation between the challenges, age, and size of the SMEs. | It is presented that a strategic focus on production with “simple” smart technology concepts can enable SMEs to become more adaptable to the changing and dynamic environment. For example, collaborative robots and AGVs (automatic guided vehicles) in a reconfigurable environment can adapt to changing environments. |

| [99] | To show global challenges, such as digital transformation, are urging companies to become more dynamic and flexible. | The Lean start-up approach in large manufacturing companies examined the feasibility of accelerating product development while it makes innovation processes cheaper, more flexible, and more reliable. |

| Paper | Focus | Main Results |

|---|---|---|

| [100] | This paper proposes a method to drive process innovation toward the increase in efficiency of a production plant. | Correct data management permits to plan the best practices to improve processes and systems involved, in terms of environmental and economic impacts, meaning a process of sustainable innovation. |

| [17] | To analyse the Lean-Green performance of Indian manufacturing SMEs by investigating the influential relationships of various factors and the firm’s set of Lean and Green practices. | Enterprises need to decrease their operational sizes to improve operational and environmental performance. The possible alternative and more practical strategy could be introducing new technology innovation and holistic adoption of manufacturing excellence initiatives, such as Lean-Green. |

| [16] | To identify the drivers for integrated Lean and Green manufacturing from the combined support of existing literature and expert opinions. | The results reveal that top management commitment, technology up-gradation, current legislation, green brand image, and future legislation are the five most important drivers for implementing integrated Lean-Green in Indian manufacturing SMEs. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Queiroz, G.A.; Alves Junior, P.N.; Costa Melo, I. Digitalization as an Enabler to SMEs Implementing Lean-Green? A Systematic Review through the Topic Modelling Approach. Sustainability 2022, 14, 14089. https://doi.org/10.3390/su142114089

Queiroz GA, Alves Junior PN, Costa Melo I. Digitalization as an Enabler to SMEs Implementing Lean-Green? A Systematic Review through the Topic Modelling Approach. Sustainability. 2022; 14(21):14089. https://doi.org/10.3390/su142114089

Chicago/Turabian StyleQueiroz, Geandra Alves, Paulo Nocera Alves Junior, and Isotilia Costa Melo. 2022. "Digitalization as an Enabler to SMEs Implementing Lean-Green? A Systematic Review through the Topic Modelling Approach" Sustainability 14, no. 21: 14089. https://doi.org/10.3390/su142114089

APA StyleQueiroz, G. A., Alves Junior, P. N., & Costa Melo, I. (2022). Digitalization as an Enabler to SMEs Implementing Lean-Green? A Systematic Review through the Topic Modelling Approach. Sustainability, 14(21), 14089. https://doi.org/10.3390/su142114089