Performance Assessment of Sewer Networks under Different Blockage Situations Using Internet-of-Things-Based Technologies

Abstract

1. Introduction

1.1. Background

1.2. The Internet of Things Applications in Drainage Systems

1.3. Point of Departure and Objectives of the Study

- -

- What is the impact of the blockage on the sewer network, and how could it be detected?

- -

- How will the sewage network performance vary and be affected in case of blockage occurrence?

- -

- What is the impact on the network performance occurring in the case of periodic cleaning?

- To investigate the impact of blockage on the sewer network in terms of the residual time to overflow.

- To compare the performance of the sewage network before and after the occurrence of the blockage.

- To investigate the efficiency of cleaning works on solving different blockage situations by comparing the performance before and after cleaning.

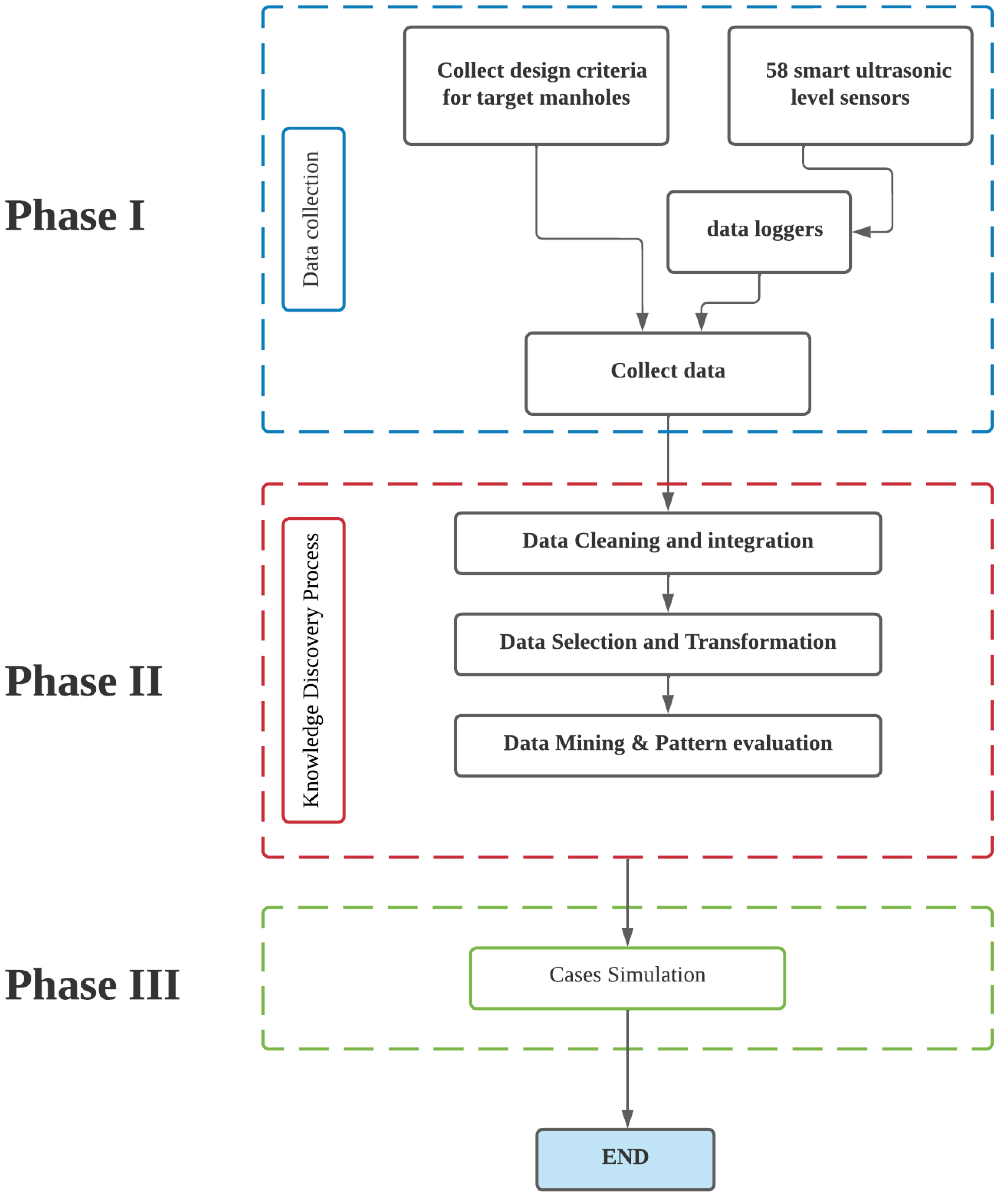

2. Methodology

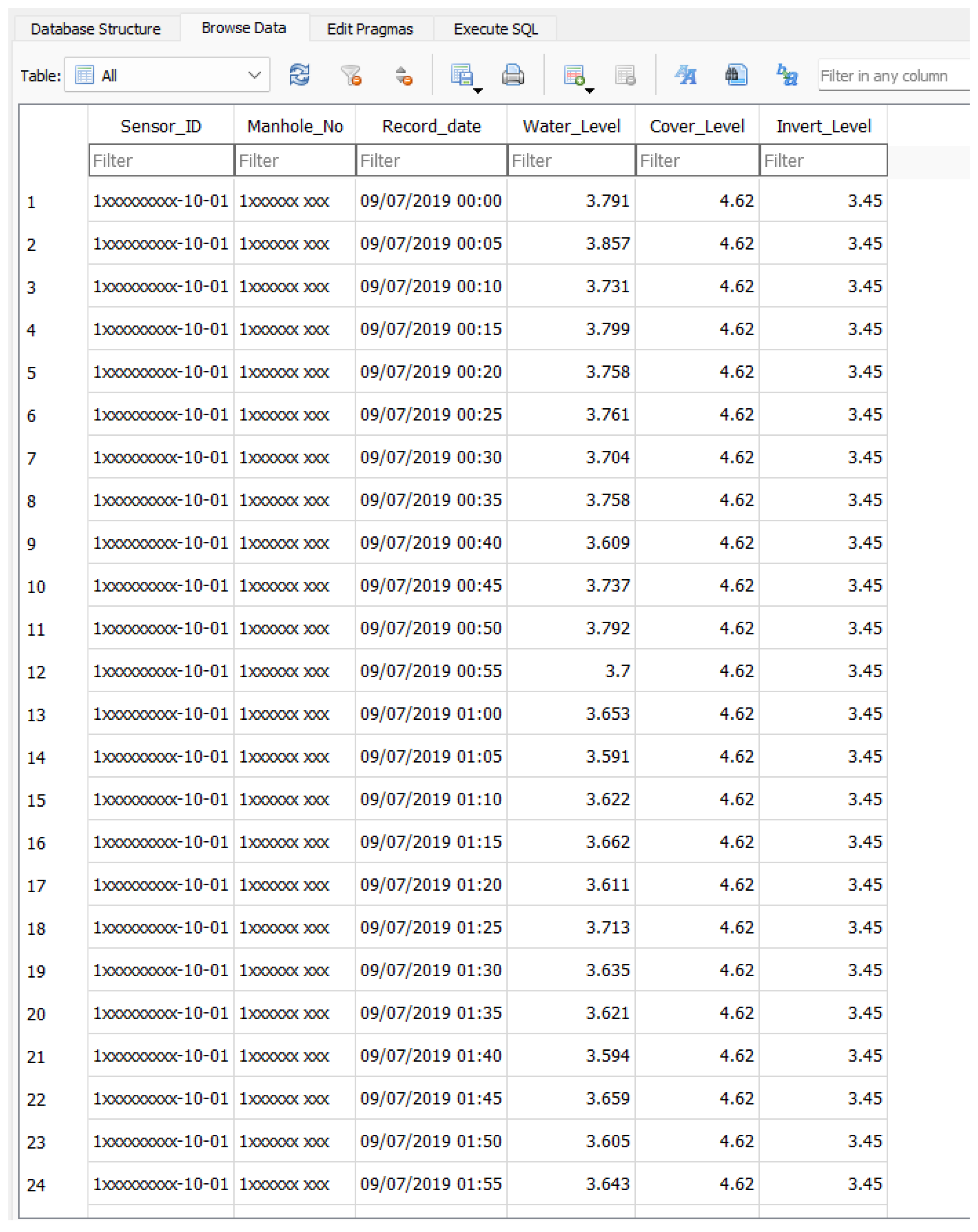

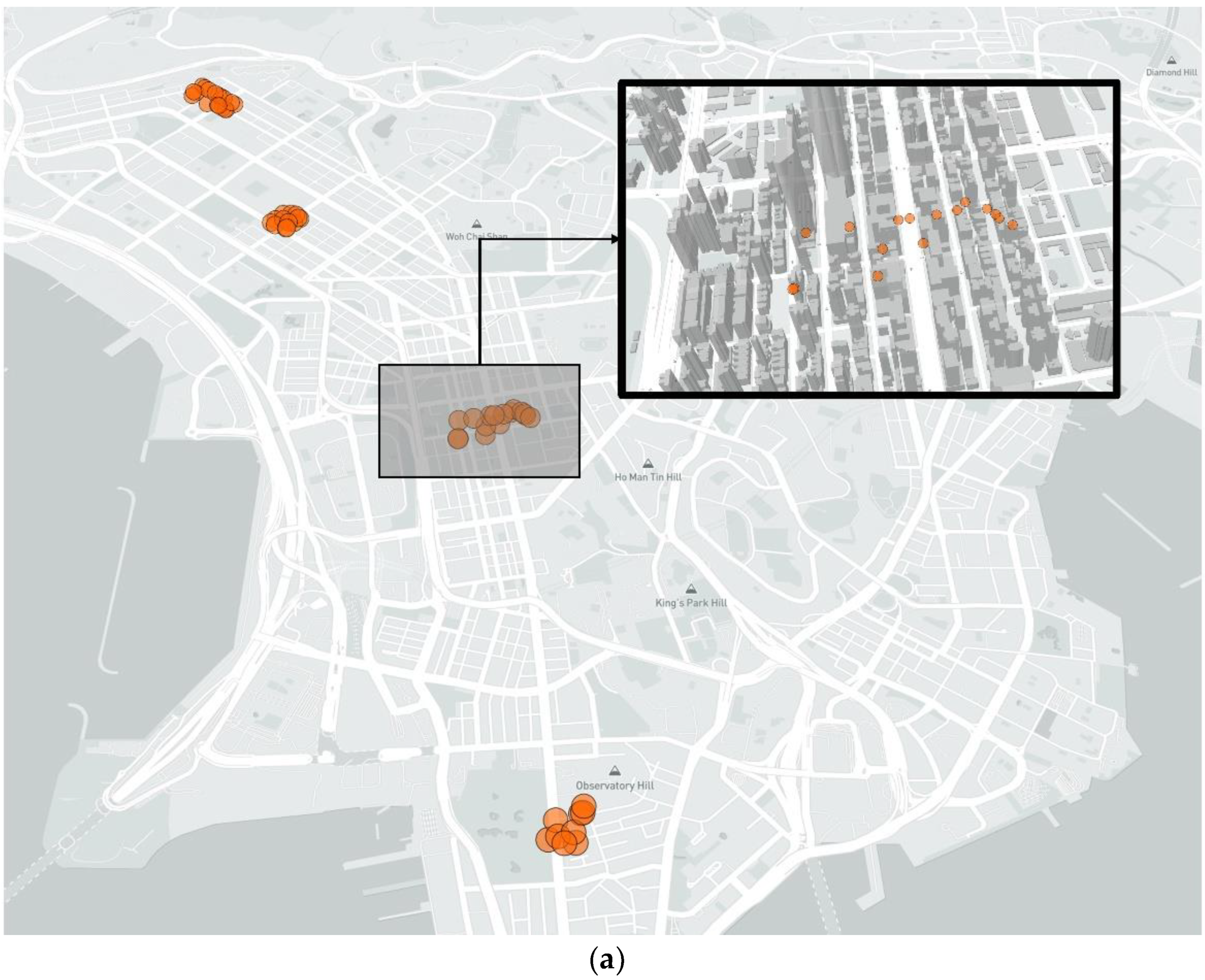

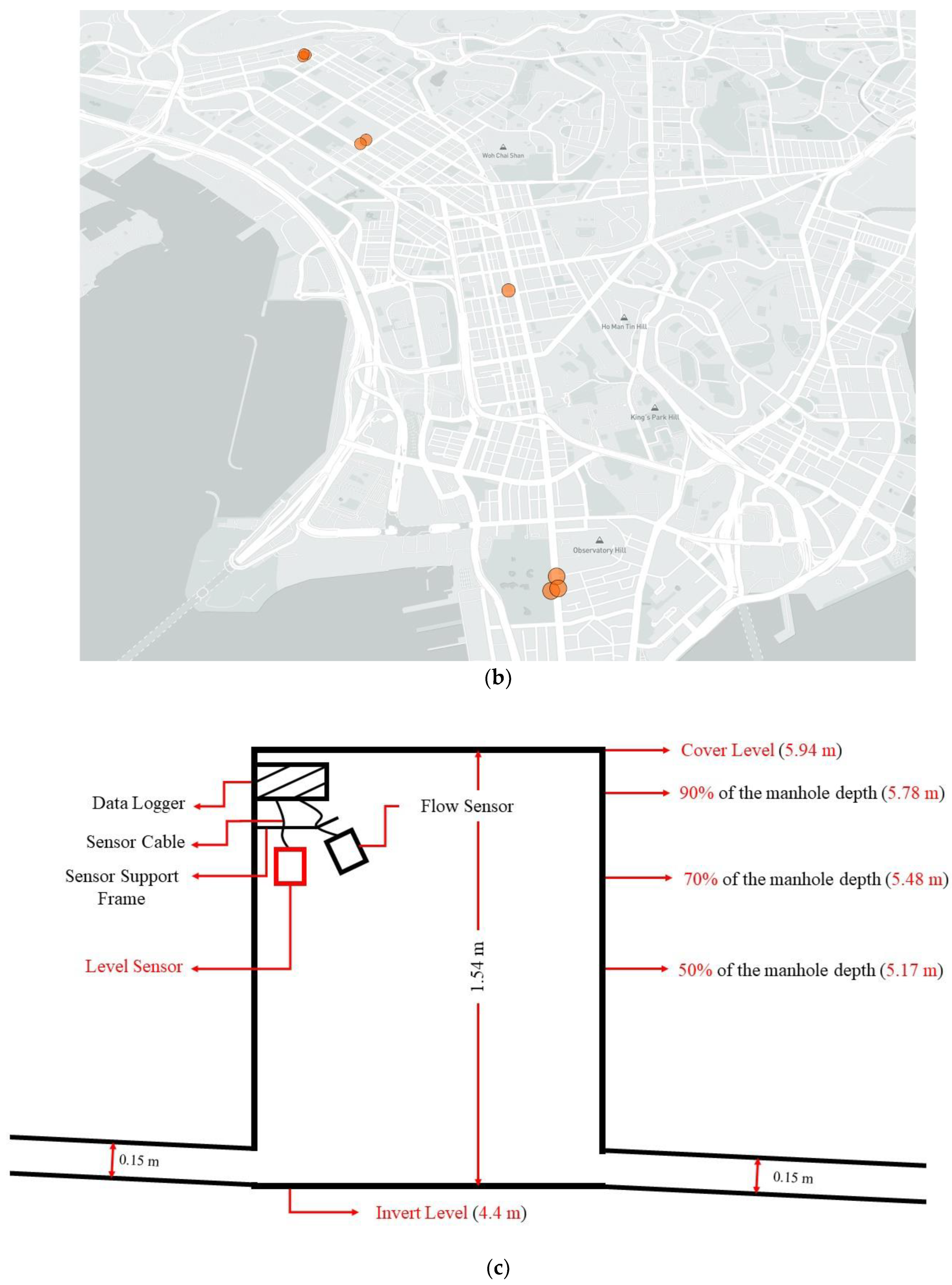

2.1. Phase I: Data Collection

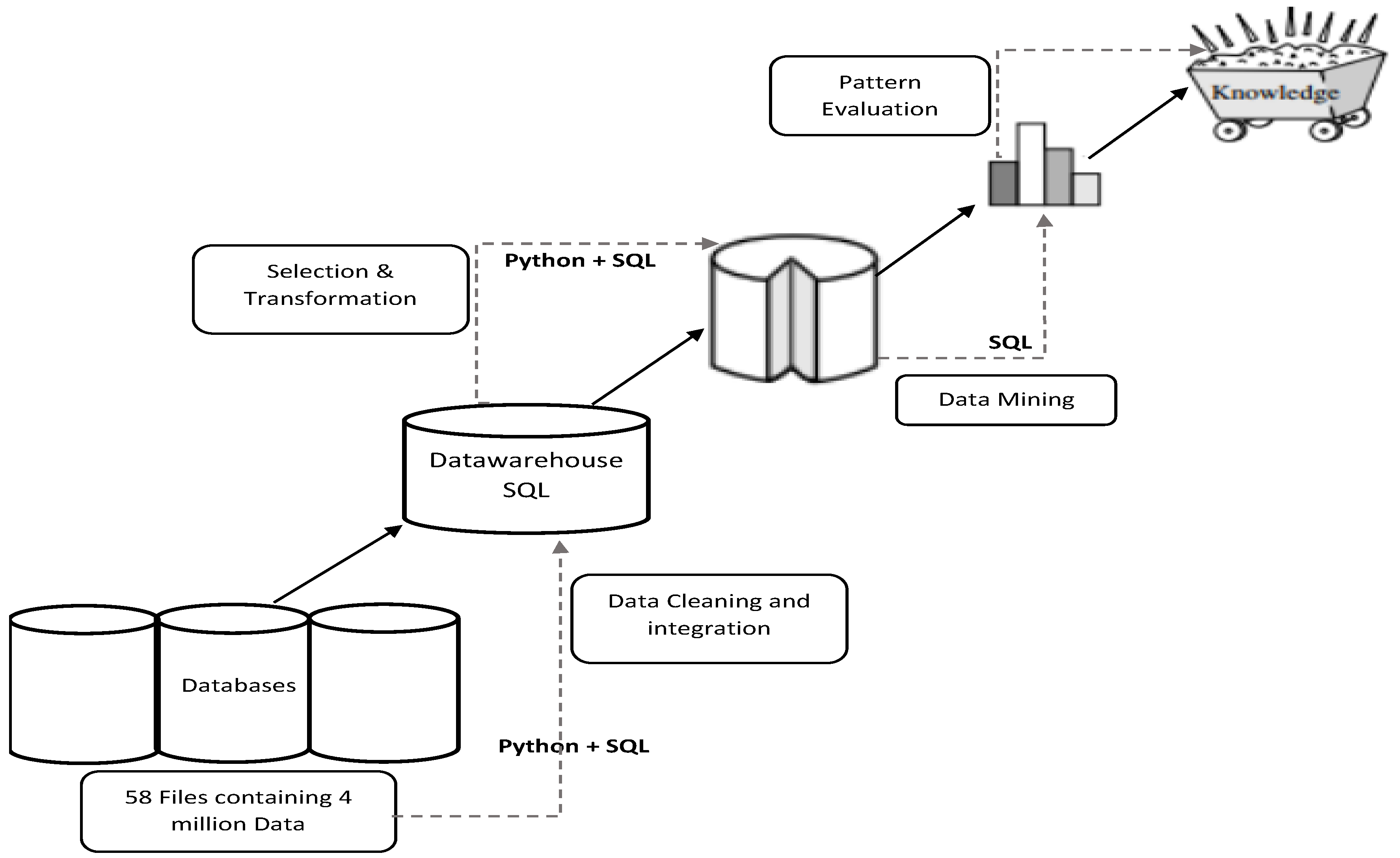

2.2. Phase II: Knowledge Discovery Process

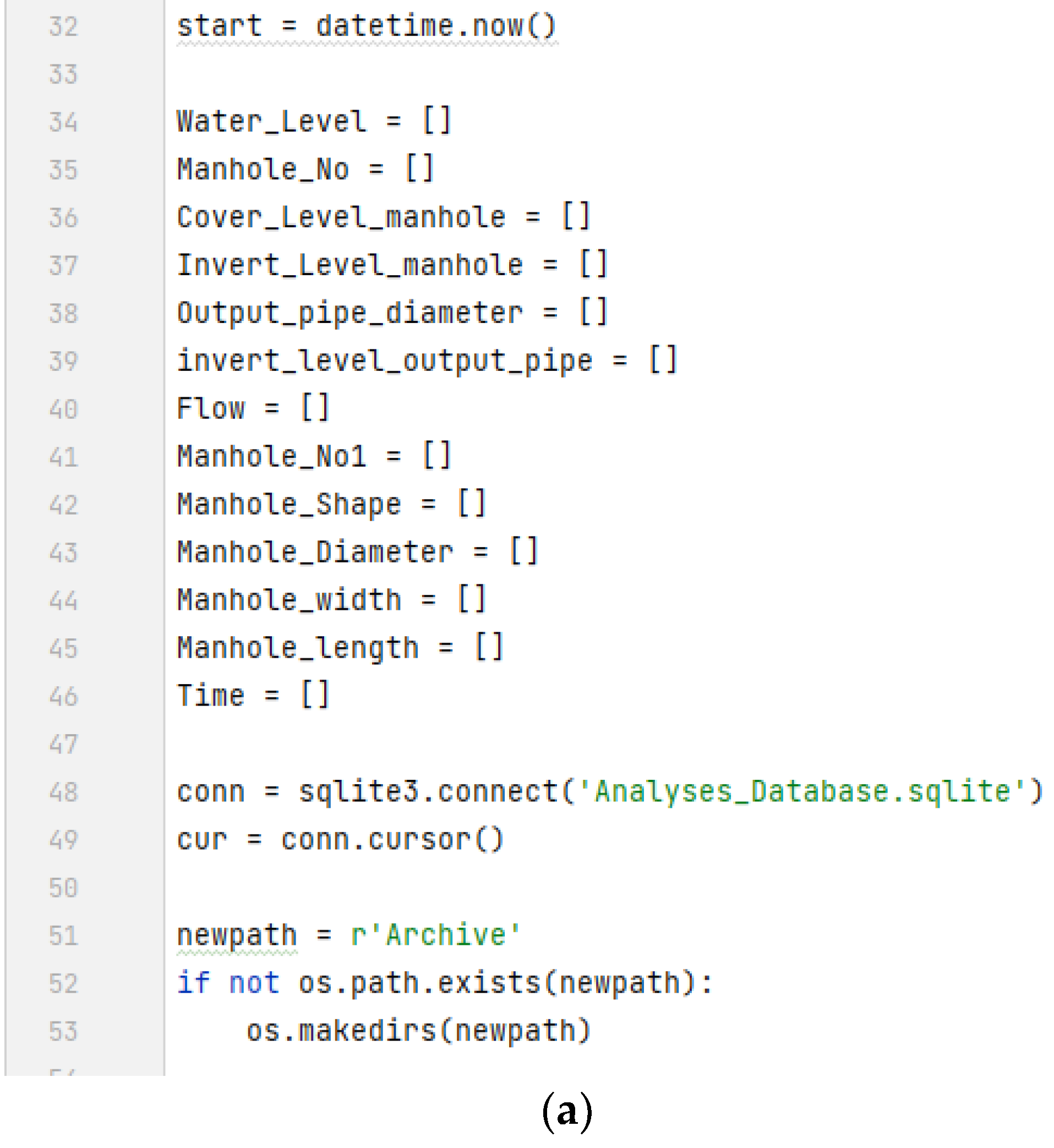

2.2.1. Data Cleaning and Integration

2.2.2. Data Selection and Transformation

2.2.3. Data Mining and Pattern Evaluation

2.3. Phase III: Cases Simulation

3. Results and Discussion

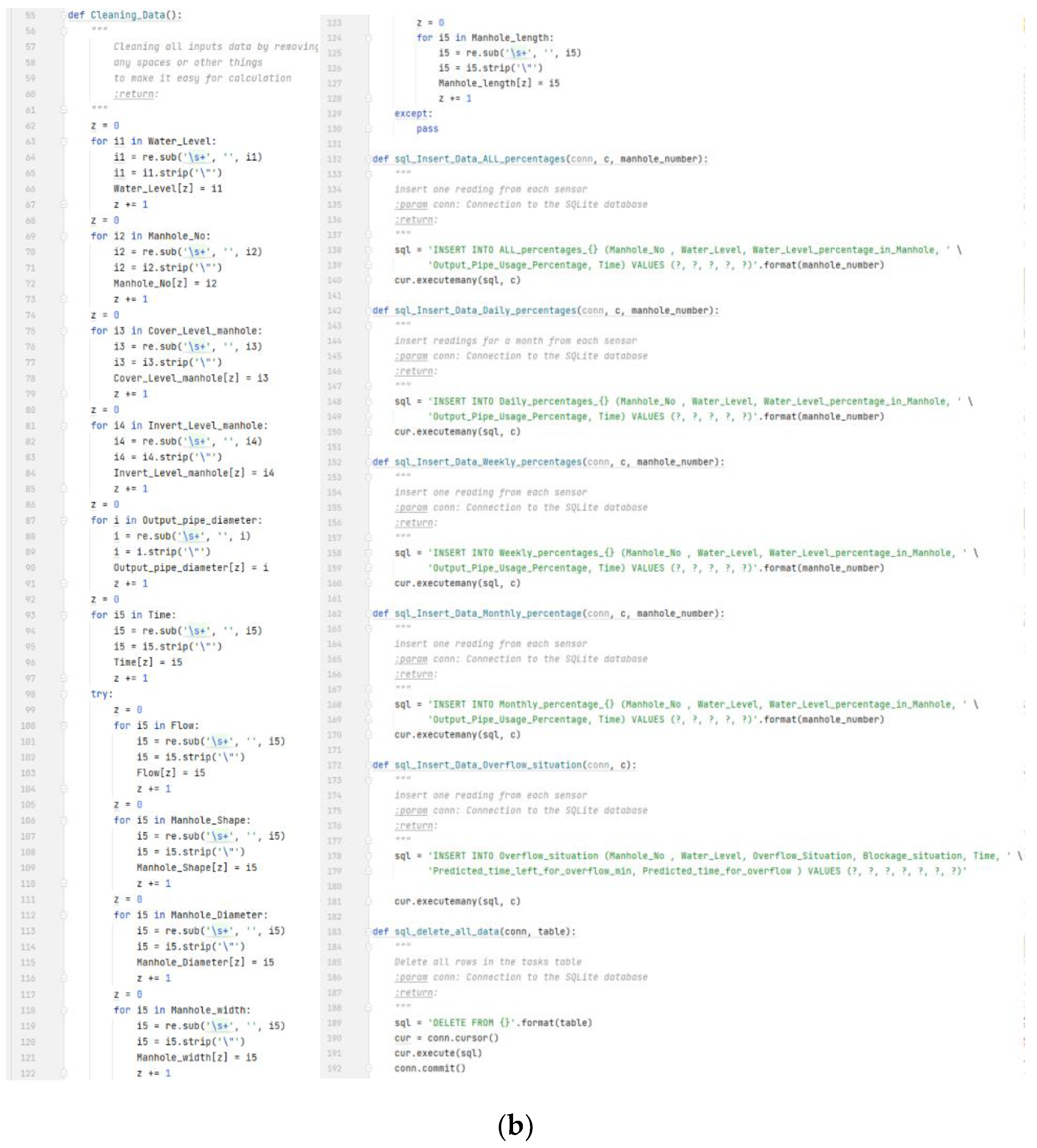

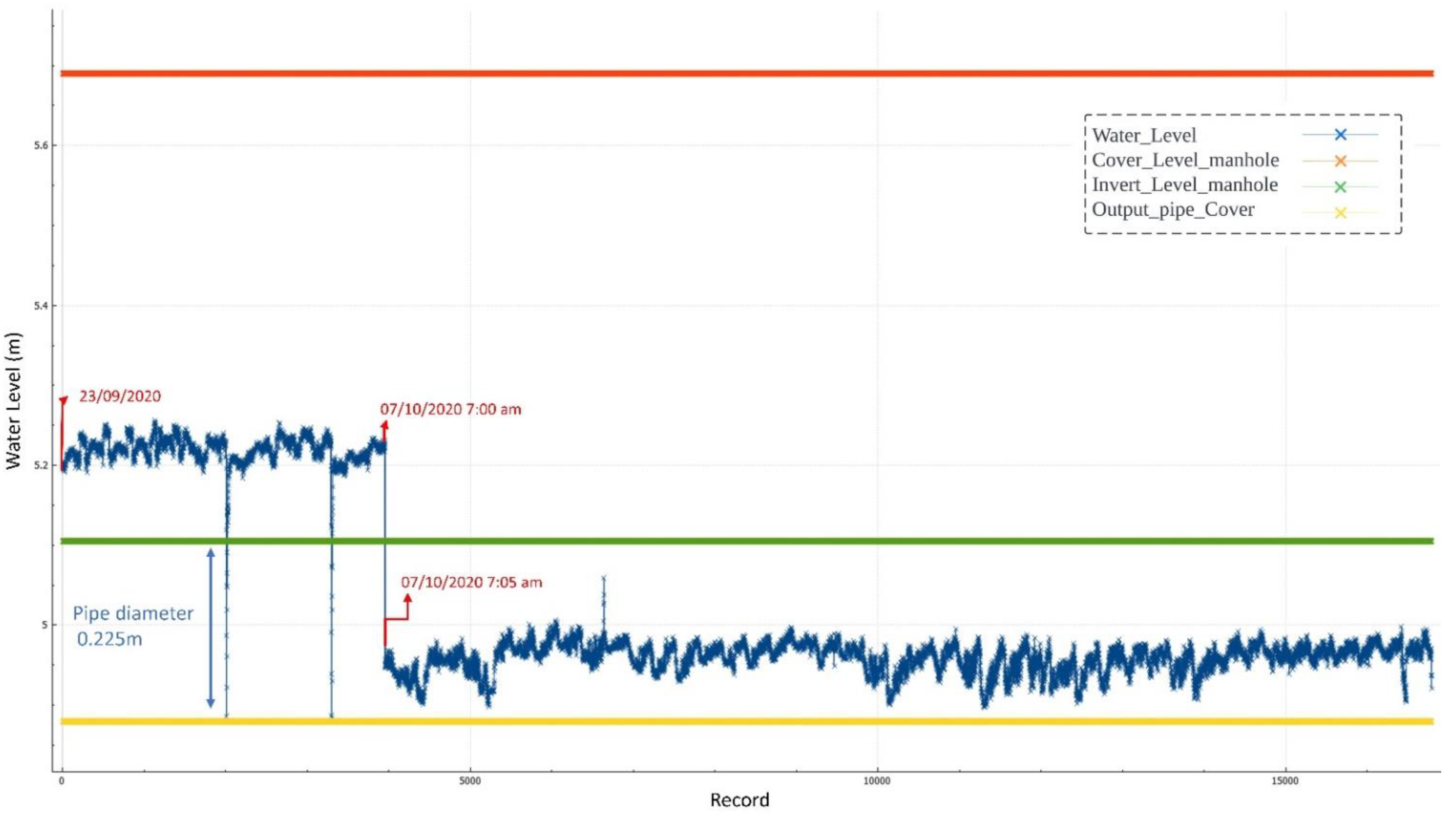

3.1. General Performance Assessment

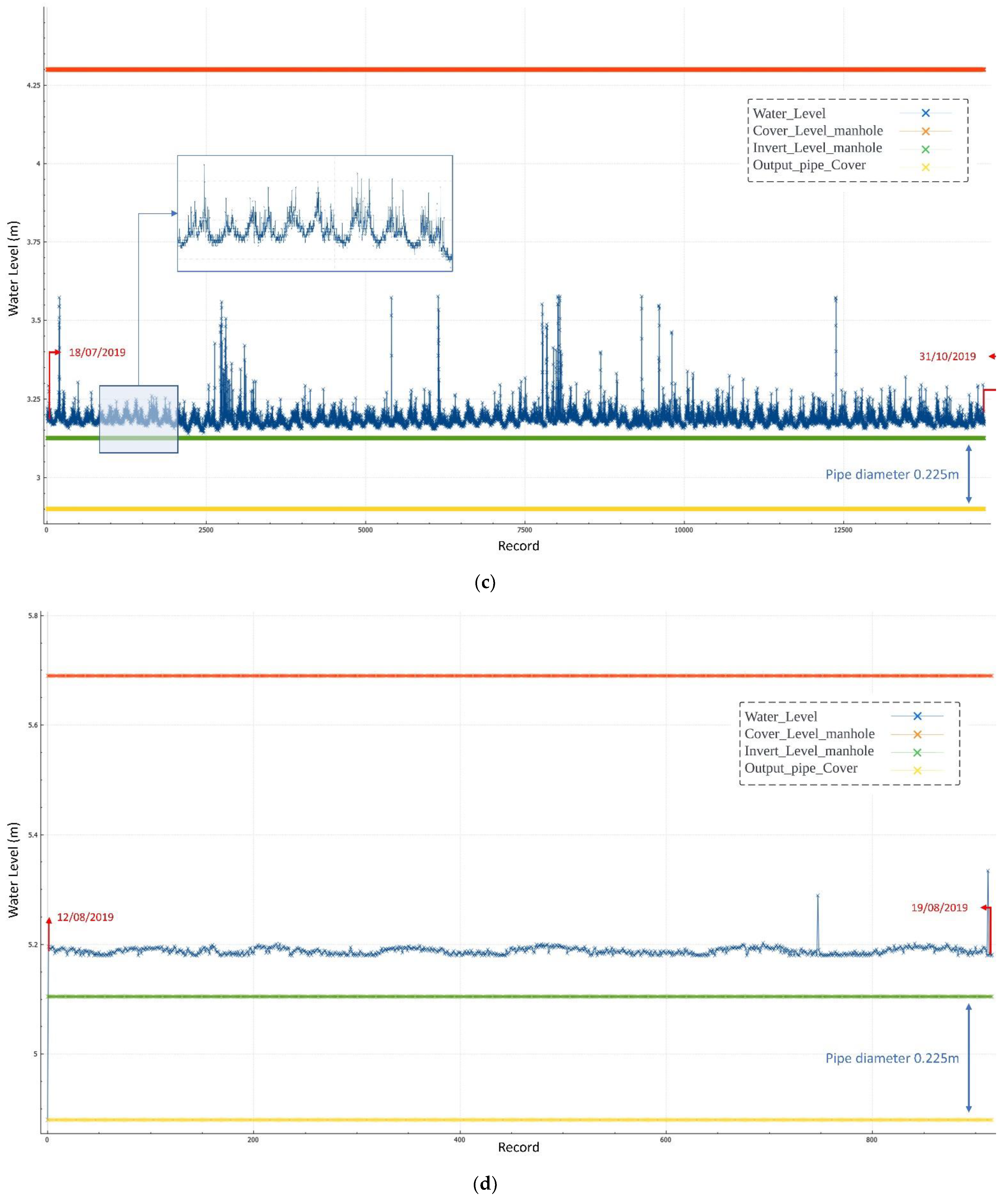

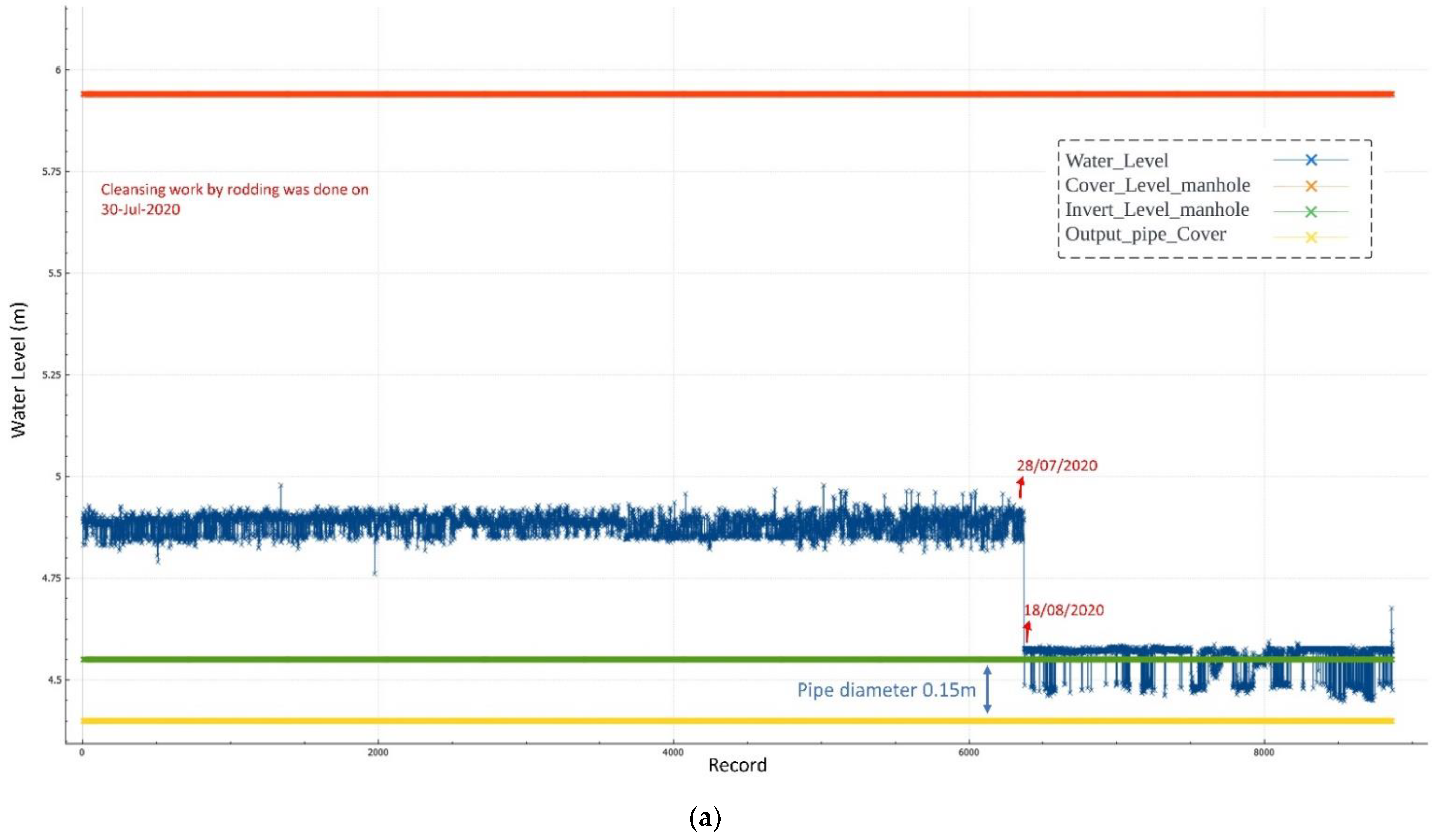

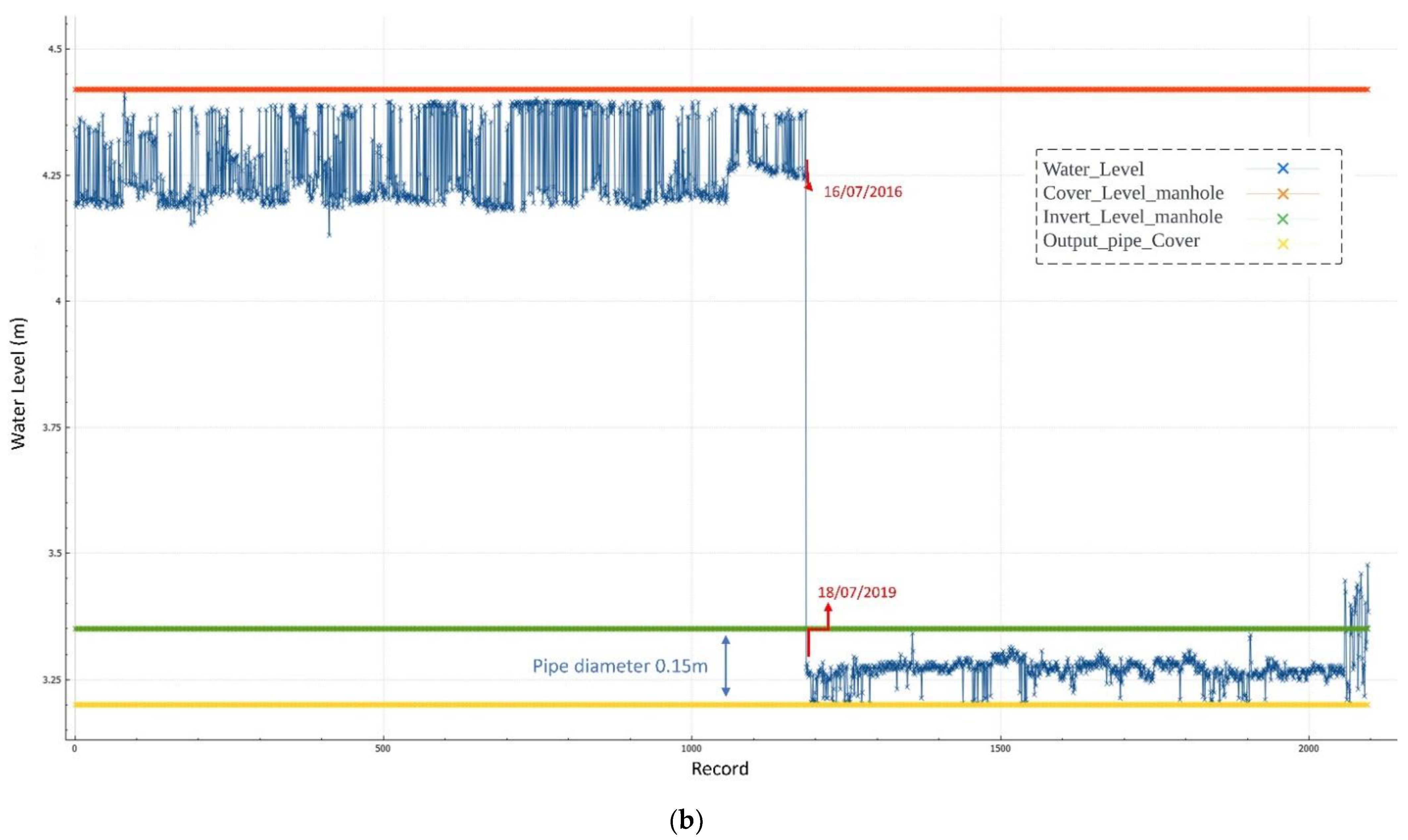

3.2. Performance Assessment before and after Blockages Occurrence

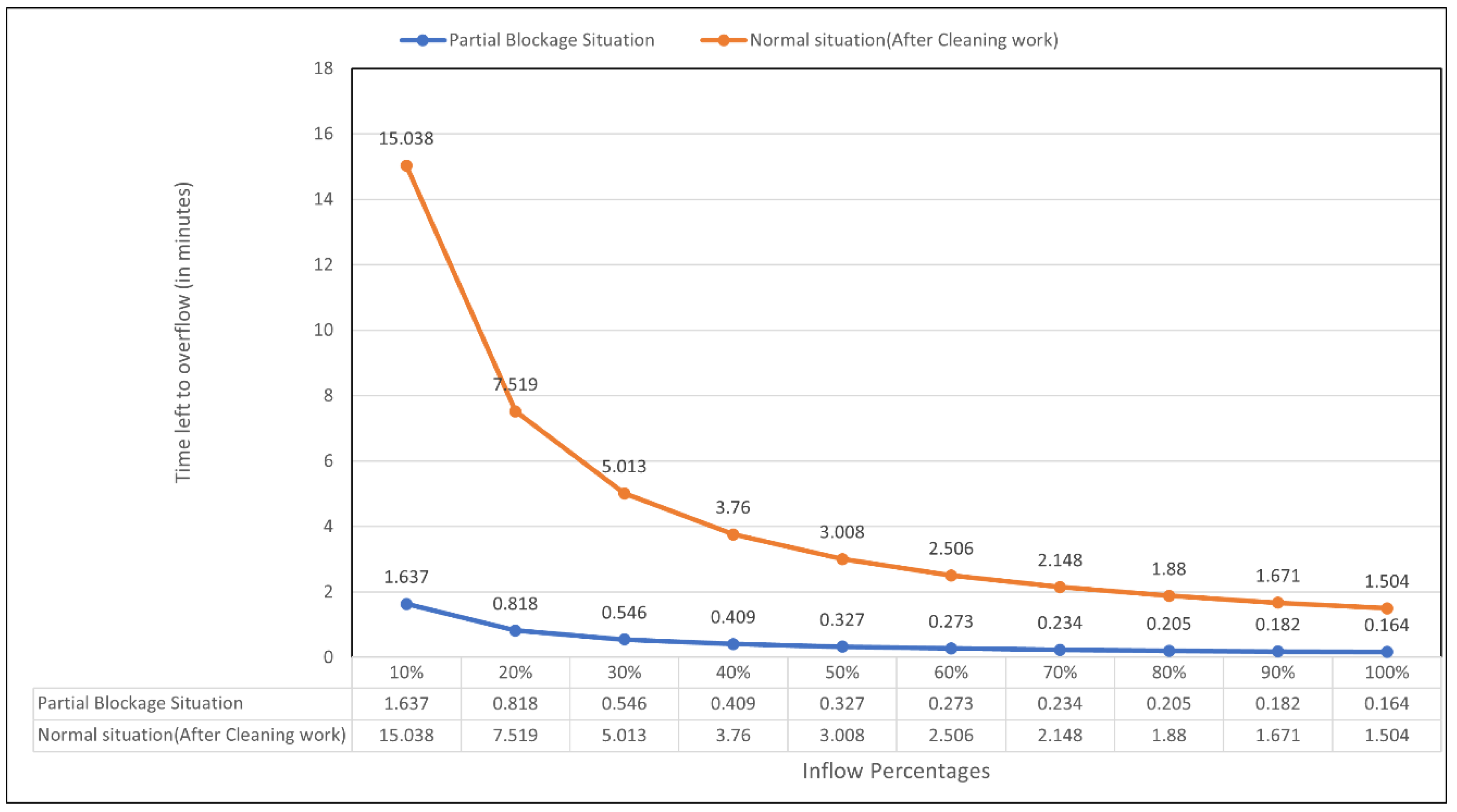

3.3. Performance Assessment before and after Cleaning Works

4. Implications

4.1. Research Implications

4.2. Managerial Implications

5. Limitations and Future Works

- There was a lack of the number of sensors coverage and distribution around HK, so one of our recommendations for concerned authorities was the need for sensors network expansion to reflect a more accurate situation for the drainage network there.

- Although the finding of the impact of blockages on the sewer overflow occurrence was an identical point for this research, we emphasize the need to build a monitor system connected between the pipelines blockage situations and sewer overflow occurrence for our future work. Such a developed system should predict blockage occurrence by real-time analysis of streamed data provided by the sensor so that sewer overflow would be predicted and proactive decisions could be made.

- Another limitation was the paucity of data on blockage locations inside the pipe, sewage level from different manholes around the blockage problem (i.e., readings from manholes in the same line), and physical properties such as age and materials that may provide more critical insights into blockage risks and occurrence percentage. Thus, it is recommended to collect the needed data from the different resources in future research to improve the proposed equation for estimating the remaining time to flood using other critical factors such as pipe inclination, roughness coefficient, and self-cleaning velocity.

- While the sensors provide the decision-makers with raw data that can give an initial indication of the situation of the drainage network, the lack of connection between the sensors and an effective system depends on IoT and AI techniques to ensure accurate, smooth, and fast streaming of the network make the process less advanced, which will be the start point for our next system we intend to build. Hence, finding a stable and strong technic connection between the system and the sensors through clouding would be a foundation for that system.

6. Conclusions

- Through comparisons between sewer performance and blockage situations in different cases, it was found that the general performance of the sewer was reduced by 35% due to the partial blockage situation.

- According to the simulated cases, the risks of complete blockage are seen to be much higher, because the inside of the outlet pipe is completely blocked, causing the inlet flow to reach 100% of the pipe’s cross-sectional area. Accordingly, if the flow velocity is 0.5 m/s and 5 m/s, the sewer only takes 1.82 and 0.19 min to reach the manhole cover level.

- It was found that the overall performance of the sewers that went through cleaning procedures was improved by 85%. In addition, different situations were simulated to study the impact of cleaning work, and it was found that if a complete blockage occurs before cleaning work, an overflow occurs within 2 min, even if the inflow is less than 10% of the inlet pipe. In the opposite direction, the sewage reaches the manhole cover level within 15 min, which means three readings to detect this increase.

- Sewer blockages significantly reduce the performance of the sewer pipelines, and accordingly, this will lead to the occurrence of overflow.

- There is a strong relationship and correlation between the increased velocity and the occurrence of overflow.

- The appropriate and prudent strategies for the cleaning of sewer pipelines lead to significant improvements in the sewer pipeline’s performance.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Blockage Percentage In Output Pipe (SLPBC = 4.982m, SD = 0.582 m) | Blockage Percentage In Output Pipe (SLPBC = 4.476 m, SD = 0.08 m) | |||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| I: Flow Velocity = 0.5 m/s | ||||||||||||||||||||

| Input Flow Percentage | 0.1 | 0.2 | 0.3 | 0.4 | 0.5 | 0.6 | 0.7 | 0.8 | 0.9 | 1 | 0.1 | 0.2 | 0.3 | 0.4 | 0.5 | 0.6 | 0.7 | 0.8 | 0.9 | 1 |

| 0.1 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | 12.20 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | 18.65 |

| 0.2 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | 12.20 | 6.10 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | 18.65 | 9.32 |

| 0.3 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | 12.20 | 6.10 | 4.07 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | 18.65 | 9.32 | 6.22 |

| 0.4 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | 12.20 | 6.10 | 4.07 | 3.05 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | 18.65 | 9.32 | 6.22 | 4.66 |

| 0.5 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | 12.20 | 6.10 | 4.07 | 3.05 | 2.44 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | 18.65 | 9.32 | 6.22 | 4.66 | 3.73 |

| 0.6 | −1.00 | −1.00 | −1.00 | −1.00 | 12.20 | 6.10 | 4.07 | 3.05 | 2.44 | 2.03 | −1.00 | −1.00 | −1.00 | −1.00 | 18.65 | 9.32 | 6.22 | 4.66 | 3.73 | 3.11 |

| 0.7 | −1.00 | −1.00 | −1.00 | 12.20 | 6.10 | 4.07 | 3.05 | 2.44 | 2.03 | 1.74 | −1.00 | −1.00 | −1.00 | 18.65 | 9.32 | 6.22 | 4.66 | 3.73 | 3.11 | 2.66 |

| 0.8 | −1.00 | −1.00 | 12.20 | 6.10 | 4.07 | 3.05 | 2.44 | 2.03 | 1.74 | 1.53 | −1.00 | −1.00 | 18.65 | 9.32 | 6.22 | 4.66 | 3.73 | 3.11 | 2.66 | 2.33 |

| 0.9 | −1.00 | 12.20 | 6.10 | 4.07 | 3.05 | 2.44 | 2.03 | 1.74 | 1.53 | 1.36 | −1.00 | 18.65 | 9.32 | 6.22 | 4.66 | 3.73 | 3.11 | 2.66 | 2.33 | 2.07 |

| 1 | 12.20 | 6.10 | 4.07 | 3.05 | 2.44 | 2.03 | 1.74 | 1.53 | 1.36 | 1.22 | 18.65 | 9.32 | 6.22 | 4.66 | 3.73 | 3.11 | 2.66 | 2.33 | 2.07 | 1.86 |

| II: Flow Velocity = 1.0 m/s | ||||||||||||||||||||

| Input Flow Percentage | 0.1 | 0.2 | 0.3 | 0.4 | 0.5 | 0.6 | 0.7 | 0.8 | 0.9 | 1 | 0.1 | 0.2 | 0.3 | 0.4 | 0.5 | 0.6 | 0.7 | 0.8 | 0.9 | 1 |

| 0.1 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | 6.10 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | 9.32 |

| 0.2 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | 6.10 | 3.05 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | 9.32 | 4.66 |

| 0.3 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | 6.10 | 3.05 | 2.03 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | 9.32 | 4.66 | 3.11 |

| 0.4 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | 6.10 | 3.05 | 2.03 | 1.53 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | 9.32 | 4.66 | 3.11 | 2.33 |

| 0.5 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | 6.10 | 3.05 | 2.03 | 1.53 | 1.22 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | 9.32 | 4.66 | 3.11 | 2.33 | 1.86 |

| 0.6 | −1.00 | −1.00 | −1.00 | −1.00 | 6.10 | 3.05 | 2.03 | 1.53 | 1.22 | 1.02 | −1.00 | −1.00 | −1.00 | −1.00 | 9.32 | 4.66 | 3.11 | 2.33 | 1.86 | 1.55 |

| 0.7 | −1.00 | −1.00 | −1.00 | 6.10 | 3.05 | 2.03 | 1.53 | 1.22 | 1.02 | 0.87 | −1.00 | −1.00 | −1.00 | 9.32 | 4.66 | 3.11 | 2.33 | 1.86 | 1.55 | 1.33 |

| 0.8 | −1.00 | −1.00 | 6.10 | 3.05 | 2.03 | 1.53 | 1.22 | 1.02 | 0.87 | 0.76 | −1.00 | −1.00 | 9.32 | 4.66 | 3.11 | 2.33 | 1.86 | 1.55 | 1.33 | 1.17 |

| 0.9 | −1.00 | 6.10 | 3.05 | 2.03 | 1.53 | 1.22 | 1.02 | 0.87 | 0.76 | 0.68 | −1.00 | 9.32 | 4.66 | 3.11 | 2.33 | 1.86 | 1.55 | 1.33 | 1.17 | 1.04 |

| 1 | 6.10 | 3.05 | 2.03 | 1.53 | 1.22 | 1.02 | 0.87 | 0.76 | 0.68 | 0.61 | 9.32 | 4.66 | 3.11 | 2.33 | 1.86 | 1.55 | 1.33 | 1.17 | 1.04 | 0.93 |

| III: Flow Velocity = 2.0 m/s | ||||||||||||||||||||

| Input Flow Percentage | 0.1 | 0.2 | 0.3 | 0.4 | 0.5 | 0.6 | 0.7 | 0.8 | 0.9 | 1 | 0.1 | 0.2 | 0.3 | 0.4 | 0.5 | 0.6 | 0.7 | 0.8 | 0.9 | 1 |

| 0.1 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | 3.05 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | 4.66 |

| 0.2 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | 3.05 | 1.53 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | 4.66 | 2.33 |

| 0.3 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | 3.05 | 1.53 | 1.02 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | 4.66 | 2.33 | 1.55 |

| 0.4 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | 3.05 | 1.53 | 1.02 | 0.76 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | 4.66 | 2.33 | 1.55 | 1.17 |

| 0.5 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | 3.05 | 1.53 | 1.02 | 0.76 | 0.61 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | 4.66 | 2.33 | 1.55 | 1.17 | 0.93 |

| 0.6 | −1.00 | −1.00 | −1.00 | −1.00 | 3.05 | 1.53 | 1.02 | 0.76 | 0.61 | 0.51 | −1.00 | −1.00 | −1.00 | −1.00 | 4.66 | 2.33 | 1.55 | 1.17 | 0.93 | 0.78 |

| 0.7 | −1.00 | −1.00 | −1.00 | 3.05 | 1.53 | 1.02 | 0.76 | 0.61 | 0.51 | 0.44 | −1.00 | −1.00 | −1.00 | 4.66 | 2.33 | 1.55 | 1.17 | 0.93 | 0.78 | 0.67 |

| 0.8 | −1.00 | −1.00 | 3.05 | 1.53 | 1.02 | 0.76 | 0.61 | 0.51 | 0.44 | 0.38 | −1.00 | −1.00 | 4.66 | 2.33 | 1.55 | 1.17 | 0.93 | 0.78 | 0.67 | 0.58 |

| 0.9 | −1.00 | 3.05 | 1.53 | 1.02 | 0.76 | 0.61 | 0.51 | 0.44 | 0.38 | 0.34 | −1.00 | 4.66 | 2.33 | 1.55 | 1.17 | 0.93 | 0.78 | 0.67 | 0.58 | 0.52 |

| 1 | 3.05 | 1.53 | 1.02 | 0.76 | 0.61 | 0.51 | 0.44 | 0.38 | 0.34 | 0.31 | 4.66 | 2.33 | 1.55 | 1.17 | 0.93 | 0.78 | 0.67 | 0.58 | 0.52 | 0.47 |

| IV: Flow Velocity = 3.0 m/s | ||||||||||||||||||||

| Input Flow Percentage | 0.1 | 0.2 | 0.3 | 0.4 | 0.5 | 0.6 | 0.7 | 0.8 | 0.9 | 1 | 0.1 | 0.2 | 0.3 | 0.4 | 0.5 | 0.6 | 0.7 | 0.8 | 0.9 | 1 |

| 0.1 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | 2.03 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | 3.11 |

| 0.2 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | 2.03 | 1.02 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | 3.11 | 1.55 |

| 0.3 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | 2.03 | 1.02 | 0.68 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | 2.03 | 1.02 | 1.04 |

| 0.4 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | 2.03 | 1.02 | 0.68 | 0.51 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | 3.11 | 1.55 | 1.04 | 0.78 |

| 0.5 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | 2.03 | 1.02 | 0.68 | 0.51 | 0.41 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | 3.11 | 1.55 | 1.04 | 0.78 | 0.62 |

| 0.6 | −1.00 | −1.00 | −1.00 | −1.00 | 2.03 | 1.02 | 0.68 | 0.51 | 0.41 | 0.34 | −1.00 | −1.00 | −1.00 | −1.00 | 3.11 | 1.55 | 1.04 | 0.78 | 0.62 | 0.52 |

| 0.7 | −1.00 | −1.00 | −1.00 | 2.03 | 1.02 | 0.68 | 0.51 | 0.41 | 0.34 | 0.29 | −1.00 | −1.00 | −1.00 | 3.11 | 1.55 | 1.04 | 0.78 | 0.62 | 0.52 | 0.44 |

| 0.8 | −1.00 | −1.00 | 2.03 | 1.02 | 0.68 | 0.51 | 0.41 | 0.34 | 0.29 | 0.25 | −1.00 | −1.00 | 3.11 | 1.55 | 1.04 | 0.78 | 0.62 | 0.52 | 0.44 | 0.39 |

| 0.9 | −1.00 | 2.03 | 1.02 | 0.68 | 0.51 | 0.41 | 0.34 | 0.29 | 0.25 | 0.23 | −1.00 | 3.11 | 1.55 | 1.04 | 0.78 | 0.62 | 0.52 | 0.44 | 0.39 | 0.35 |

| 1 | 2.03 | 1.02 | 0.68 | 0.51 | 0.41 | 0.34 | 0.29 | 0.25 | 0.23 | 0.20 | 3.11 | 1.55 | 1.04 | 0.78 | 0.62 | 0.52 | 0.44 | 0.39 | 0.35 | 0.20 |

| V: Flow Velocity = 5.0 m/s | ||||||||||||||||||||

| Input Flow Percentage | 0.1 | 0.2 | 0.3 | 0.4 | 0.5 | 0.6 | 0.7 | 0.8 | 0.9 | 1 | 0.1 | 0.2 | 0.3 | 0.4 | 0.5 | 0.6 | 0.7 | 0.8 | 0.9 | 1 |

| 0.1 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | 1.22 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | 1.86 |

| 0.2 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | 1.22 | 0.61 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | 1.86 | 0.93 |

| 0.3 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | 2.03 | 1.02 | 0.68 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | 3.11 | 1.55 | 1.04 |

| 0.4 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | 1.22 | 0.61 | 0.41 | 0.31 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | 1.86 | 0.93 | 0.62 | 0.47 |

| 0.5 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | 1.22 | 0.61 | 0.41 | 0.31 | 0.24 | −1.00 | −1.00 | −1.00 | −1.00 | −1.00 | 1.86 | 0.93 | 0.62 | 0.47 | 0.37 |

| 0.6 | −1.00 | −1.00 | −1.00 | −1.00 | 1.22 | 0.61 | 0.41 | 0.31 | 0.24 | 0.20 | −1.00 | −1.00 | −1.00 | −1.00 | 1.86 | 0.93 | 0.62 | 0.47 | 0.37 | 0.31 |

| 0.7 | −1.00 | −1.00 | −1.00 | 1.22 | 0.61 | 0.41 | 0.31 | 0.24 | 0.20 | 0.17 | −1.00 | −1.00 | −1.00 | 1.86 | 0.93 | 0.62 | 0.47 | 0.37 | 0.31 | 0.27 |

| 0.8 | −1.00 | −1.00 | 1.22 | 0.61 | 0.41 | 0.31 | 0.24 | 0.20 | 0.17 | 0.15 | −1.00 | −1.00 | 1.86 | 0.93 | 0.62 | 0.47 | 0.37 | 0.31 | 0.27 | 0.23 |

| 0.9 | −1.00 | 1.22 | 0.61 | 0.41 | 0.31 | 0.24 | 0.20 | 0.17 | 0.15 | 0.14 | −1.00 | 1.86 | 0.93 | 0.62 | 0.47 | 0.37 | 0.31 | 0.27 | 0.23 | 0.21 |

| 1 | 1.22 | 0.61 | 0.41 | 0.31 | 0.24 | 0.20 | 0.17 | 0.15 | 0.14 | 0.12 | 1.86 | 0.93 | 0.62 | 0.47 | 0.37 | 0.31 | 0.27 | 0.23 | 0.21 | 0.19 |

Appendix B

References

- Hamed, M.M.; Elsayad, M.A.; Mahfouz, S.Y.; Khadr, W.M.H. Graphical user interface for water distribution network pressure—driven analysis using artificial elements. Sustain. Water Resour. Manag. 2022, 8, 89. [Google Scholar] [CrossRef]

- Abbas, M.Z.; Abu Baker, K.; Ayaz, M.; Mohamed, H.; Tariq, M.; Ahmed, A.; Faheem, M. Key factors involved in pipeline monitoring techniques using robots and WSNs: Comprehensive survey. J. Pipeline Syst. Eng. Pract. 2018, 9, 4018001. [Google Scholar] [CrossRef]

- Hawari, A.; Alkadour, F.; Elmasry, M.; Zayed, T. A state of the art review on condition assessment models developed for sewer pipelines. Eng. Appl. Artif. Intell. 2020, 93, 103721. [Google Scholar] [CrossRef]

- Rocher, J.; García-Navas, J.L.; Romero, O.; Lloret, J. A WSN-based monitoring system to control Sewerage. In Proceedings of the 2019 Sixth International Conference on Internet of Things: Systems, Management and Security (IOTSMS), Granada, Spain, 22–25 October 2019; IEEE: Piscataway, NJ, USA, 2019; pp. 277–282. [Google Scholar]

- Altarabsheh, A.; Ventresca, M.; Kandil, A.; Abraham, D. Markov chain modulated Poisson process to stimulate the number of blockages in sewer networks. Can. J. Civ. Eng. 2019, 46, 1174–1186. [Google Scholar] [CrossRef]

- Arthur, S.; Crow, H.; Pedezert, L. Understanding Blockage Formation in Combined Sewer Networks. In Proceedings of the Institution of Civil Engineers-Water Management; Thomas Telford Ltd.: London, UK, 2008; Volume 161, pp. 215–221. [Google Scholar]

- Okwori, E.; Viklander, M.; Hedström, A. Performance assessment of Swedish sewer pipe networks using pipe blockage and other associated performance indicators. H2Open J. 2020, 3, 46–57. [Google Scholar] [CrossRef]

- Okwori, E.; Viklander, M.; Hedström, A. Spatial heterogeneity assessment of factors affecting sewer pipe blockages and predictions. Water Res. 2021, 194, 116934. [Google Scholar] [CrossRef] [PubMed]

- Ugarelli, R.; Kristensen, S.M.; Røstum, J.; Sægrov, S.; Di Federico, V. Statistical analysis and definition of blockages-prediction formulae for the wastewater network of Oslo by evolutionary computing. Water Sci. Technol. 2009, 59, 1457–1470. [Google Scholar] [CrossRef] [PubMed]

- Butler, D.; Digman, C.; Makropoulos, C.; Davies, J.W. Urban Drainage, 4th ed.; Crc Press: Boca Raton, FL, USA, 2018; ISBN 9781498752930. [Google Scholar]

- Rodríguez, J.P.; McIntyre, N.; Díaz-Granados, M.; Maksimović, Č. A database and model to support proactive management of sediment-related sewer blockages. Water Res. 2012, 46, 4571–4586. [Google Scholar] [CrossRef] [PubMed]

- Arthur, S.; Crow, H.; Pedezert, L.; Karikas, N. The holistic prioritisation of proactive sewer maintenance. Water Sci. Technol. 2009, 59, 1385–1396. [Google Scholar] [CrossRef] [PubMed]

- Hillas, T.T. Reducing the Occurrence of Flooding Through the Effective Management of Sewer Blockages. Master’s Thesis, University of Exeter, Exeter, UK, June 2014. [Google Scholar]

- Hafskjold, L.S.; Kønig, A.; Sægrov, S.; Schilling, W.; Saegrov, S.; Schilling, W. Improved assessment of sewer pipe condition. In Proceedings of the CityNet 19th European Junior Scientist Workshop on Process Data and Integrated Urban Water Modelling, Meaux-la-Montagne, France, 15 March 2004. [Google Scholar]

- Ikeshoji, T.; Hafskjold, B.; Furuholt, H. Molecular-level calculation scheme for pressure in inhomogeneous systems of flat and spherical layers. Mol. Simul. 2003, 29, 101–109. [Google Scholar] [CrossRef]

- Ugarelli, R.; Venkatesh, G.; Brattebø, H.; Di Federico, V.; Sægrov, S. Historical analysis of blockages in wastewater pipelines in Oslo and diagnosis of causative pipeline characteristics. Urban Water J. 2010, 7, 335–343. [Google Scholar] [CrossRef]

- Pingel, J.; Bartels, E.M.; Nielsen, J.B. New perspectives on the development of muscle contractures following central motor lesions. J. Physiol. 2017, 595, 1027–1038. [Google Scholar] [CrossRef] [PubMed]

- Priyanka, E.B.; Maheswari, C.; Thangavel, S.; Bala, M.P. Integrating IoT with LQR-PID controller for online surveillance and control of flow and pressure in fluid transportation system. J. Ind. Inf. Integr. 2020, 17, 100127. [Google Scholar] [CrossRef]

- Bhaskaran, P.E.; Maheswari, C.; Thangavel, S.; Ponnibala, M.; Kalavathidevi, T.; Sivakumar, N.S. IoT Based monitoring and control of fluid transportation using machine learning. Comput. Electr. Eng. 2021, 89, 106899. [Google Scholar] [CrossRef]

- Ramadhin, S.P.K.; Anand, S.; Aishwarya, R.; Yogitha, R. Smart Drainage and Health Monitoring System of Manual Scavenger using IoT. In Proceedings of the 2021 5th International Conference on Intelligent Computing and Control Systems (ICICCS), Madurai, India, 6–8 May 2021; IEEE: Piscataway, NJ, USA, 2021; pp. 412–416. [Google Scholar]

- Chen, A.; Dong, H. A Pipeline On-line Detection and Control System Based on the IoT. In Proceedings of the 2021 IEEE 4th International Conference on Electronics Technology (ICET), Chengdu, China, 7–10 May 2021; IEEE: Piscataway, NJ, USA, 2021; pp. 1095–1098. [Google Scholar]

- Villars, R.L.; Olofson, C.W.; Eastwood, M. Big Data: What It Is and Why You Should Care. White Paper; IDC: Framingham, MA, USA, 2011. [Google Scholar]

- Wu, S.-H.; Mou, C.-Y.; Lin, H.-P. Synthesis of mesoporous silica nanoparticles. Chem. Soc. Rev. 2013, 42, 3862–3875. [Google Scholar] [CrossRef] [PubMed]

- Chen, M.-S.; Han, J.; Yu, P.S. Data mining: An overview from a database perspective. IEEE Trans. Knowl. Data Eng. 1996, 8, 866–883. [Google Scholar] [CrossRef]

- Cios, K.J.; Pedrycz, W.; Swiniarski, R.W. Data Mining Methods for Knowledge Discovery; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2012; Volume 458, ISBN 978-1-4615-5589-6. [Google Scholar]

- Hand, D.J. Data mining: Statistics and more? Am. Stat. 1998, 52, 112–118. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alshami, A.; Elsayed, M.; Mohandes, S.R.; Kineber, A.F.; Zayed, T.; Alyanbaawi, A.; Hamed, M.M. Performance Assessment of Sewer Networks under Different Blockage Situations Using Internet-of-Things-Based Technologies. Sustainability 2022, 14, 14036. https://doi.org/10.3390/su142114036

Alshami A, Elsayed M, Mohandes SR, Kineber AF, Zayed T, Alyanbaawi A, Hamed MM. Performance Assessment of Sewer Networks under Different Blockage Situations Using Internet-of-Things-Based Technologies. Sustainability. 2022; 14(21):14036. https://doi.org/10.3390/su142114036

Chicago/Turabian StyleAlshami, Ahmad, Moustafa Elsayed, Saeed Reza Mohandes, Ahmed Farouk Kineber, Tarek Zayed, Ashraf Alyanbaawi, and Mohammed Magdy Hamed. 2022. "Performance Assessment of Sewer Networks under Different Blockage Situations Using Internet-of-Things-Based Technologies" Sustainability 14, no. 21: 14036. https://doi.org/10.3390/su142114036

APA StyleAlshami, A., Elsayed, M., Mohandes, S. R., Kineber, A. F., Zayed, T., Alyanbaawi, A., & Hamed, M. M. (2022). Performance Assessment of Sewer Networks under Different Blockage Situations Using Internet-of-Things-Based Technologies. Sustainability, 14(21), 14036. https://doi.org/10.3390/su142114036