Abstract

Green manufacturing is becoming an important emerging field in the new round of global industrial revolution and scientific and technological competition. Scientific evaluation of China’s regional green manufacturing level has far-reaching significance for promoting the transformation and upgrading of the manufacturing industry and enhancing international competitiveness. This paper defines the connotation of green manufacturing in China in the new era, proposes four dimensions of green production, green emission, green technology, and green benefit as the framework of the evaluation system, and constructs the evaluation index system. By taking 30 provincial administrative regions as research samples, based on the data from 2017 to 2020, the combination weighting method and TOPSIS are used for evaluation from the perspective of “static” and “dynamic” to identify the current situation and development of green manufacturing level in each region. It was found that the important factors affecting the green manufacturing level in each region are green products, green invention patents, sulfur dioxide, green factories, and coal consumption. The “static” evaluation results show that the green manufacturing level varies significantly among regions. The eastern area is generally better than the central and western areas, and only six regions are at high-level and medium to high-level. In addition, the four dimensions in most regions are imbalanced, with an obvious Matthew effect. The “dynamic” evaluation results show that the green manufacturing level in 30 regions appears to have six different types of dynamic trends. There is a small change in the ranking of most regions, indicating that the dynamic development of green manufacturing level has clear regional dependence, which is difficult to change in the short term. The research results show that the index system and model can effectively evaluate the regional green manufacturing level. Finally, combined with the important influencing factors, some suggestions are proposed to enhance the regional green manufacturing level.

1. Introduction

Green manufacturing, as a new industrial pattern formed by the deep integration between green technology innovation and the transformation and development of the manufacturing industry, is becoming an important emerging field in the new round of global industrial revolution and technological competition.

Both developed countries and new economies regard green manufacturing as the key field to winning future industrial competitions and have introduced relevant policies to strengthen implementation measures. For example, the United States Congress passed environmental protection laws related to green manufacturing, such as the “Environmental Design of Electrical Equipment Act” and the “Electronic Waste Recycling Act” [1]. The President’s Council of Advisors on Science and Technology of the United States (PCAST) issued a strategy called “Accelerating U.S. Advanced Manufacturing”, known as AMP 2.0, which listed “sustainable manufacturing” as one of the 11 key technologies for revitalizing the manufacturing industry and made use of technological advantages to seek a new mode of green manufacturing development [2]. The European Union formulated a series of directives related to product environment, such as “Restriction of Hazardous Substances (RoHS)” and “Waste Electrical and Electronic Equipment (WEEE)”, which improved the environmental performance of electrical appliances, electronics, and automobiles in the European market and greatly promoted the green manufacturing of products [3]. Japan formulated a new version of the “Chemical Substance Control Law”, requiring enterprises in the chemical, household appliances, textile, toy production, and other industries to provide data on the safety of their products and to report and evaluate new chemical substances [4]. Germany formulated the “Circular Economy and Waste Management Law”, which takes “government promotion, market guidance, enterprise implementation, and public participation” as the guiding principle, and specifies the tasks of the government and enterprises to achieve the goal of “reduction, reuse, and recycling” [5].

China attaches great importance to the development of green manufacturing.

In 2006, the State Council of China issued “the Outline of Medium and Long Term Scientific and Technological Development Plan of China (2006–2020)”, which listed green manufacturing as one of the three major directions of the scientific and technological development of the manufacturing industry [6]. In 2011, the Ministry of Science and Technology of China launched “the 12th Five-Year Plan for Science and Technology Development”, which proposed to focus on the development of advanced green manufacturing technologies and products and make breakthroughs in key technologies such as green product design, environmental protection materials, energy conservation and environmental protection processes, and green recycling treatment in the manufacturing industry [7]. In 2015, the State Council of China launched “Made in China 2025”, proposing to comprehensively promote green manufacturing. In 2016, the Ministry of Industry and Information Technology of China (MIIT) issued “the Guidelines for the Implementation of Green Manufacturing Projects (2016–2020)”, which proposed the tasks of developing 10,000 green products, building 1000 green factories, building 100 green industrial parks, and creating the green supply chain [8]. In 2016, MIIT issued “the Notice on Developing Green Manufacturing System”, which formulated relevant standards and evaluation systems for a green product, green factory, green industrial park, and green supply chain [9]. After that, Beijing, Shanghai, Guangdong Province, and other regions formulated “the Implementation Plan of Green Manufacturing system construction (2018–2020)”, and green manufacturing has become the focus of government planning and academic research.

How is China’s regional green manufacturing level now? Which regions are at the forefront? Which regions need to be improved? How to measure and evaluate scientifically? The research on these issues will help clarify the context of regional green manufacturing. A scientific and reasonable construction of a regional green manufacturing level evaluation system and measurement of green manufacturing level will help to grasp the advantages and disadvantages of green manufacturing in each region and have important theoretical and practical value for wholly promoting China’s green manufacturing.

From the existing literature, some scholars noticed the importance of regional green manufacturing level evaluation and carried out empirical research on different regions. The research can be summarized into two aspects: the construction of an evaluation index system and the application of evaluation methods.

In terms of the construction of an evaluation index system, scholars conducted research from different perspectives. Lv [10] constructed an evaluation index system of regional green manufacturing development level, including five dimensions: the green level of product design, the clean level of the production process, the level of energy efficient utilization, the input level of environmental protection, and the level of industrial coupling integration. Wang [11] built a green manufacturing level evaluation index system from four aspects of green growth, green development, energy conservation and control, and technological innovation. From the perspective of the product life cycle, Wang et al. [12] constructed a green manufacturing level evaluation index system consisting of a development benefit index, production process index, environmental protection index, and industrial and technological innovation index. From the perspective of industry, Liu et al. [13] established an evaluation index system for industrial green manufacturing level from four dimensions of efficient development, low-carbon development, cleaner production, and circular development. You et al. [14] constructed an evaluation index system of green manufacturing performance, including five dimensions: development benefit, resource utilization, pollution emission, environmental protection, and technological innovation. Li et al. [15] explained the definition and development trend of green manufacturing and proposed an evaluation index system of green manufacturing level from five aspects of product ecological design, cleaner production, efficient utilization of energy, recycling of renewable resources, and product coupling integration. Based on the “PSR (pressure-state-response)” model and life cycle theory, Wang et al. [16] constructed a green manufacturing evaluation index system from four dimensions: environmental attribute, energy attribute, resource attribute, and economic attribute. Zhang et al. [17] built an evaluation index system of ecosystem green manufacturing from three aspects of the economy, ecology, and society.

In terms of application of evaluation methods, ANP, AHP, entropy weight method, TOPSIS, and standard deviation method are more commonly used. Lv [10] used the ANP-Fuzzy method to evaluate the green manufacturing development level of six provinces in Central China. Wang [11] used the grey relation analysis and TOPSIS model to evaluate the green manufacturing level of Feicheng City from 2010 to 2019. Wang et al. [12] measured the green manufacturing level of Jilin Province from 2007 to 2017 by using the standard deviation method and the synthetic weighted method. Liu et al. [13] evaluated the industrial green manufacturing level of 11 provinces, autonomous regions, and cities in Western China from 2011 to 2017 by using the entropy weight method, the analytical hierarchy process (AHP), and the synthetic weighted method. You et al. [14] used the standard deviation method to measure the green manufacturing performance of the China National Ecological Civilization Pilot Zone (Guizhou) from 2006 to 2016. Li et al. [15] used the synthetic weighted method to evaluate the green manufacturing level of nine industrial developed provinces and cities in eastern China in 2010. Karamaşa et al. [18] used multi-criteria decision making (MCDM) as the value-creating green approach to study the logistics companies operating in the TR A1 region. Alosta et al. [19] located EMS centers by using a multi-criteria decision-making approach, which consists of the AHP and RAFSI models.

The existing literature laid an important foundation for this study, but there are some deficiencies as follows: (1) The framework of the evaluation system is not systematic and scientific enough. Scholars have their own evaluation dimensions, but the inherent logical relationship between each dimension is loose and not rigorous enough. (2) The evaluation indicator does not keep pace with the times because scholars do not pay attention to the practical measures of promoting green manufacturing in China in recent years. The existing literature lack indicators that can better reflect the benefit of green manufacturing in provincial regions, such as a green industrial park, green factory, and green product, and lack indicators that can better reflect green technology, such as green patent, transaction value in technical markets, and green technology awarded. (3) There has been no research on the evaluation of green manufacturing level in China’s provincial administrative regions from the perspectives of “static” and “dynamic”.

Therefore, this paper focuses on improving the above three aspects, and the main work is as follows. (1) On the basis of defining the connotation of green manufacturing in China in the new era, this paper proposes four dimensions: green production, green emission, green technology, and green benefit, which constitute a systematic and scientific evaluation system framework. (2) According to the practice of promoting green manufacturing in China, this paper selected indicators with the times, especially the indicators of “green technology” and “green benefit”. Based on this, a characteristic evaluation index system was constructed. (3) By taking 30 provincial administrative regions in China (excluding Tibet, Hong Kong, Macao, and Taiwan) as research samples, this paper made a comprehensive evaluation of their green manufacturing level from the perspectives of “static” and “dynamic” using the data from 2017 to 2020. Then, some targeted suggestions were proposed based on the detailed analysis of the evaluation results.

The remainder of this paper is as follows: Section 2 defines the connotation of green manufacturing in China in the New Ara. Section 3 constructs the evaluation index system. Section 4 introduces research areas and data sources. Section 5 discusses the research methods. Section 6 calculates the indicator weight and analyzes the important affecting factors. Section 7 shows the static evaluation results and analysis. Section 8 shows the dynamic evaluation results and analysis. Section 9 summarizes this study and proposes some suggestions. Section 10 discusses the advantages and limitations of this study and then gives future research.

2. Connotation of Green Manufacturing in China in the New Ara

The Society of Manufacturing Engineers recognized green manufacturing from the perspective of environmental friendliness and first clearly gave its connotation; that is, the goal of green manufacturing was to minimize the harm to the environment in the entire product life cycle, including design, manufacturing, packing, transportation, usage, and waste disposal [20].

Chinese scholars expanded the perspective and integrated energy consumption and benefit into the connotation of green manufacturing. They believed that green manufacturing refers to the least consumption of energy and the least harm to the environment in the entire product life cycle so as to realize the coordinated development of economic benefit and social benefit [6,14,15,21,22,23,24,25].

With the promulgation of policies such as “Made in China 2025”, “Guidelines for the Implementation of Green Manufacturing Engineering”, and “Guidelines for the Construction of Green Manufacturing Standard System, China’s green manufacturing has entered a new era. Under the overall planning of MIIT, the application and research of the green manufacturing system integration project were carried out, emphasizing the important supporting role of technology in green manufacturing. All regions in China actively research and develop green products, construct green factories, and create green industrial parks, which add new content to the implementation of green manufacturing in China in the new era, that is, ecological benefit.

By drawing on the above, this paper integrated technology and ecological benefits into the connotation of green manufacturing in the new era. That is, green manufacturing refers to the use of advanced technology and equipment (green technology) in the entire product life cycle to improve energy utilization, achieve greater output value with less energy (green production), minimize pollutant emissions (green emission), and promote the research and development of a green product, the cultivation of green factory, and the establishment of a green industrial park, so as to finally realize the coordinated growth of economic benefit and ecological benefit (green benefit).

3. Construction of Evaluation Index System

According to the connotation of green manufacturing in China in the new era, four evaluation dimensions of “green production”, “green emission”, “green technology”, and “green benefit” are proposed to form the framework of the evaluation system. Based on the relevant literature, “China Statistical Yearbook”, “China Environmental Statistical Yearbook”, “China energy statistical yearbook”, and “Guidelines for the Implementation of Green Manufacturing Engineering”, this paper screened out the indicators with a higher frequency of use and then consulted experts in related fields. Based on expert evaluation and indicators modification, this paper constructed a scientific and applicable evaluation index system of China’s regional green manufacturing level, as shown in Table 1, and there are 18 second-level indicators.

Table 1.

The evaluation index system of China’s regional green manufacturing level.

The feature and novelty of the evaluation index system constructed in this paper are reflected in keeping pace with the times, integrating “green technology” and “green benefit” into the evaluation framework, integrating “green industrial park”, “green factory”, “green product”, “green patent”, and “green technology award” into the index system, and organically combining “average value indicators” and “absolute value indicators”. According to the connotation of green manufacturing in China in the new era, “average value indicators” are used for green production and green emission, and “absolute value indicators” are mainly used for green technology and green benefit.

3.1. Green Production

Manufacturing is the pillar industry of China’s economic development, so energy consumption is inevitable. China’s energy consumption structure is dominated by fossil energy. Green production refers to the consumption of less fossil energy to achieve greater output value via improving energy utilization and increasing the use of new clean energy. In this paper, four indicators were designed to measure the level of green production (A1~A4 in Table 1)

Among the four indicators, A1, A2, and A3 were used to measure the green production level achieved by saving energy and reducing consumption of fossil energy; A4 was used to measure the green production level achieved by strengthening the development of new clean energy (wind, solar, etc.)

3.2. Green Emission

Manufacturing consumes energy, so it is bound to emit pollutants. Green emission refers to the minimization of pollutant emissions by using pollution control and treatment technologies so as to promote the green development of the economy. Because there are many kinds of pollutants, it is necessary to screen out highly representative ones. Therefore, on the basis of the statistical indicators in “China Statistical Yearbook on Environment”, this study focused on the emission reduction indicators designated at the national level since China’s 11th Five-Year Plan and finally selected pollutants such as COD, ammonia nitrogen, sulfur dioxide, nitrogen oxide, and solid waste as the indicator design object, and designs five indicators to measure the green emission level (B1~B5 in Table 1).

Among the five indicators, B1 and B2 were used to measure the green emission level achieved by the treatment of pollutants in wastewater; B3 and B4 were used to measure the green emission level achieved by the treatment of pollutants in waste gas; B5 was used to measure the green emission level achieved by the treatment of solid wastes.

3.3. Green Technology

Green technology is a strong supporting factor for the in-depth implementation of green manufacturing. Advanced technology and equipment are needed for energy saving and consumption reduction, pollutant treatment, research and development of a green product, construction of a green factory, and establishment of a green industrial park. Therefore, green production, green emission, and green benefit all need the support of green technology. In this paper, the green technology level was measured from four indicators (C1~C4 in Table 1).

Among the four indicators, C1 and C2 were used to measure the green technology level from the perspective of green patent, C3 was used to measure the green technology level from the perspective of technological innovation activity and technology transfer scale, and C4 was used to measure the green technology level from the perspective of rewarded green technology.

3.4. Green Benefit

Green benefit refers to the economic benefit and social benefits of the implementation of green manufacturing. In this paper, the green benefit level was measured from five indicators (D1~D5 in Table 1).

Among the five indicators, D1, D2, and D3 were used to measure the ecological benefit achieved by the implementation of green manufacturing; D4 and D5 are used to measure the economic benefit achieved by the implementation of green manufacturing.

4. Research Areas and Data

4.1. Research Areas

There are 34 provincial administrative regions in China. Due to the limitation of data availability, Tibet, Hong Kong, Macao, and Taiwan were excluded. Therefore, the research areas for this paper were 30 provincial administrative regions in Mainland China.

4.2. Data Resource

The data used in this study are from relevant China’s government departments and China’s official statistical yearbook. Among them, A1~A4 data are from “China Energy Statistical Yearbook” and “China Statistical Yearbook”; B1~B5 data are from “China Statistical Yearbook on Environment” and “China Statistical Yearbook”; C1, C2 data are from China National Intellectual Property Administration; C4 data are from the organizers of technology awards; D1~D3 data are from MIIT; C3, D4, D5 data are from “China Statistical Yearbook”. The data span 4 years, from 2017 to 2020.

5. Research Methods

5.1. Combination Weighting Method

The methods to determine the weight included the subjective weighting method and objective weighting method. The advantage of the subjective weighting method is that it can gather the ideas of experts, while the disadvantage is that it relies too much on the subjective judgment of experts. The advantage of the objective weighting method is determining the weight according to the nature of the data, which is not disturbed by human factors, while the disadvantage is that it relies too much on quantitative calculation and cannot distinguish the importance of indicators from their own connotation. Therefore, the more scientific approach is to combine the subjective weighting method with the objective weighting method, that is, the combination weighting method. Some scholars used the combination weighting method in their academic research [37,38,39,40].

In this paper, AHP (Analytic Hierarchy Process) [41] was used to determine the subjective weight, the entropy weight method was used to determine the objective weight, and the two kinds of weights were optimally combined according to the principle of minimum discrimination information.

5.1.1. Determination of Subjective Weight by AHP

By consulting experts, the pairwise comparison matrices of each layer of indicators can be completed so that the AHP weight of each indicator can be calculated and expressed by as .

5.1.2. Calculation of Objective Weight by Entropy Weight Method

The entropy weight method uses information entropy to calculate the indicator weight [42]. For a certain indicator, the degree of its dispersion is judged by information entropy. The smaller the information entropy, the greater the dispersion of the indicator, indicating that the greater the role it plays in the evaluation, the larger its weight. On the contrary, the weight will be smaller.

The calculation steps are as follows:

Suppose is the original data of the j-th indicator in the i-th region, i = 1, 2, …, 30, j = 1, 2, …, 18.

(1) Calculate the proportion of the i-th region under the j-th indicator

This step is equivalent to the dimensionless processing of the original data. There is no need to use min–max method to standardize the data of positive indicator and negative indicator, respectively.

(2) Calculate the information entropy of each indicator

(3) Obtain the entropy weight of each indicator

5.1.3. Calculation of Combination Weight

Suppose the combined weight is . In order to make and as close as possible, the objective function was constructed according to the principle of minimum discrimination information [43], as shown in Equation (4).

The Lagrange multiplier method is used to solve Equation (4) and is obtained, as shown in Equation (5).

5.2. TOPSIS

TOPSIS (Technique for Order Preference by Similarity to an Ideal Solution) is a sort method for approaching the ideal solution. Its principle is to rank evaluation objects by detecting the Euclidean distance between the evaluation objects and the optimal and worst solutions. If an evaluation object is closest to the optimal solution and furthest away from the worst solution, it is the best [44].

The specific steps are as follows:

Suppose is the original data of the j-th indicator in the i-th region, i = 1, 2, …, 30, j = 1, 2, …, 18.

(1) Calculate normal matrix M by using the normalizing vector method

(2) Construct the weighted normal matrix Z

(3) Determine positive ideal solution and negative ideal solution

Suppose and are the maximum values and minimum values of the j-th indicator in matrix Z, respectively, then:

The positive ideal solution is:

The negative ideal solution is:

(4) Calculate the Euclidean distance of each evaluation object to the positive and negative ideal solution

(5) Calculate relative closeness of each evaluation object to the positive ideal solution

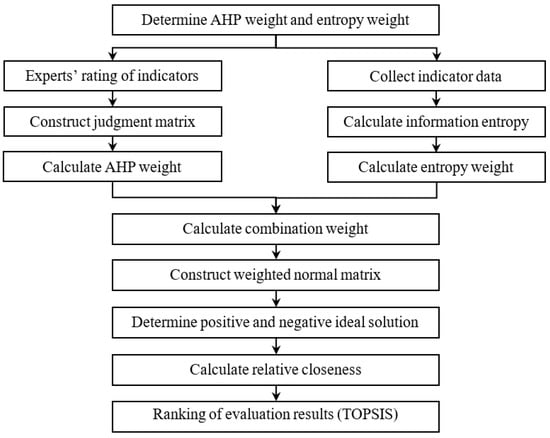

5.3. Flow Chart of Methodology

In order to clearly show the methodology, the flowchart is shown in Figure 1.

Figure 1.

The flowchart of methodology.

6. Calculation of Indicator Weights and Analysis of Important Factors

6.1. Calculation of Indicator Weights

The subjective weights were determined by using AHP. The consultation letters were sent to four experts, and the values of the judgment matrix were averaged. Finally, the subjective weights of 18 indicators were obtained, as shown in Table 2. The objective weights were determined by using the entropy weight method. According to Equations (1)–(3), the objective weights of 18 indicators from 2017 to 2020 were calculated, as shown in Table 2. Then, according to Equations (4) and (5), the combination weights from 2017 to 2020 were obtained, as shown in Table 3.

Table 2.

Subjective weights and objective weights of indicators.

Table 3.

The combination weights of indicators from 2017 to 2020.

6.2. Analysis of Important Factors

This section analyzes the top five indicators of weight ranking in 2020:

(1) Number of National Green Products (D3)

D3 dominated the ranking from 2017 to 2020, indicating that it is the first factor affecting the green manufacturing level in each region. Developing more national green products can enhance the green manufacturing level from the perspective of green benefits.

By 2020, MIIT had selected five batches of national green products, a total of 2187, covering dozens of products such as household detergent, degradable plastic, lithium-ion battery, printed circuit board, air conditioner, washing machines, household refrigerators, compound fertilizer, etc. Guangdong Province ranks first with 544 green products, Anhui Province ranks second with 306 green products, and Shandong Province ranks third with 274 green products;

(2) Number of Green Invention Patents (C1)

The weighted ranking of C1 changed from the third in 2017 to the second in 2020. In addition, the weight value increased year by year, from 0.0791 in 2017 to 0.0903 in 2020. The rise of the weight ranking and the increase in the weight value indicate that the influence of green invention patents on the green manufacturing level of each region is increasing year by year.

The implementation of green manufacturing is inseparable from the support of green technology, and green invention patent is the core of green technology. Increasing R&D efforts and creating more green invention patents are important technical driving forces to improve the green manufacturing level;

(3) SO2 emission (B3)

The weight ranking of B3 changed from fifth in 2017 to third in 2020. In addition, the weight value increased year by year, from 0.0641 in 2017 to 0.0744 in 2020. No matter the rise in ranking or the increase in value, it shows that the emission of sulfur dioxide is an important factor affecting the green manufacturing level of each region.

Sulfur dioxide is the main pollutant emitted from industrial waste gas. Excessive emissions lead to acid rain. Controlling the emission of sulfur dioxide is the biggest driving force in enhancing the level of green manufacturing in terms of green emission;

(4) Number of National Green Factories (D2)

The weight ranking of D2 was always in the top four from 2017 to 2020, and the fluctuation is small, indicating that green factory is an important and stable factor affecting the green manufacturing level of each region.

By 2020, MIIT had selected five batches of national green factories, a total of 2121, involving industries such as machinery, automobile, electronic information, light industry, textile, food, medicine, paper, etc. Guangdong Province ranks first with 195 green factories, Shandong Province ranks second with 192 green factories, and Jiangsu Province ranks third with 174 green factories;

(5) Coal consumption (A2)

The weight ranking of A2 changed from eighth in 2017 to fifth in 2020. In addition, the weight value increased year by year, from 0.0531 in 2017 to 0.0664 in 2020. The rise in the weight ranking and the increase in the weight value indicate that the influence of this indicator on the green manufacturing level of each region is increasing year by year.

Coal accounts for the largest proportion of energy consumption. This indicator can test the optimization and adjustment of industrial structure and energy structure and reflect the green transformation results of key industries and fields.

In summary, the effective way to improve the green manufacturing level of each region is to reduce sulfur dioxide emissions while reducing coal consumption with the help of green invention patents, develop more high-quality green products, and build more green factories.

7. Static Evaluation of Regional Green Manufacturing Level

This section evaluates the green manufacturing level of 30 regions in China in 2020.

7.1. Evaluation Ranking of Green Manufacturing Level of 30 Regions in 2020

Based on the data of 2020 and the TOPSIS method, this paper calculated the relative closeness of each evaluation object to the positive ideal solution according to Equations (6)–(12) and arranged 30 regions in descending order, as shown in Table 4.

Table 4.

Ranking of green manufacturing level of 30 regions in China in 2020.

The calculation of relative closeness of green production level, green emission level, green technology level, and green benefit level is similar to the green manufacturing level, but the indicator weight needs to be recalculated, that is, the weight of the second-level indicator to the corresponding first-level indicator needs to be determined.

7.2. Analysis of Evaluation results

7.2.1. Analysis of Regional Difference of Green Manufacturing Level

According to Table 4, the coefficients of variation in green manufacturing level and its four dimensions in 30 regions are counted, as shown in Table 5.

Table 5.

Coefficient of variation.

The coefficients of variation in the five statistical objects are greater than 0.2. By referring to the interpretation of the coefficient of variation in the literature [45,46], it shows that there are obvious gaps in the green manufacturing level and its four dimensions among regions, especially in the level of green technology and green emission. The spatial gap is that the eastern area is better than the central and western areas (Table 4). This is because the eastern area has gathered top-level innovation elements such as talents, science and technology, capital and other resources to jointly promote the implementation of green manufacturing.

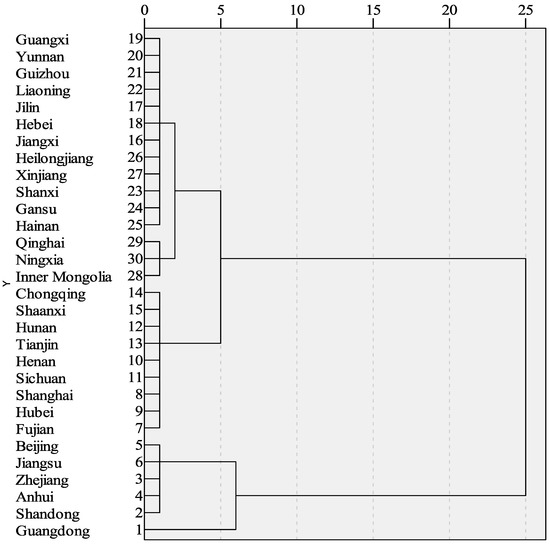

7.2.2. Analysis of the Classification of Regional Green Manufacturing Level

In order to scientifically classify the green manufacturing level of 30 regions, based on Table 4, this paper used the system clustering method with SPSS to obtain the clustering tree, as shown in Figure 2.

Figure 2.

Clustering tree of green manufacturing level of 30 regions in China in 2020.

Figure 2 shows that 30 regions are clustered into five categories so that they can be divided into five grades. The mean of the green manufacturing level () of 30 regions is 0.419 (Table 4). By comparing the distance between of each category and 0.419, it is suitable to use “high-level”, “medium to high-level”, “medium-level”, “low to medium-level”, and “low-level” to represent five grades. The classification result is shown in Table 6.

Table 6.

Classification of green manufacturing level of 30 regions in China in 2020.

Table 6 shows that Guangdong Province is “high-level“, 5 regions such as Shandong Province are “medium to high-level“, 9 regions such as Fujian Province are “medium-level“, 12 regions such as Jiangxi Province are “low to medium-level“, 3 regions such as Qinghai Province are “low-level“.

In 30 regions, 40% are “low to medium-level“, 30% are “medium-level”, and only 6 regions are above medium level, accounting for about 10%. This shows that China’s overall green manufacturing level is not strong, and most regions need to be improved.

7.2.3. Analysis of the Weak Factors of Regional Green Manufacturing Level

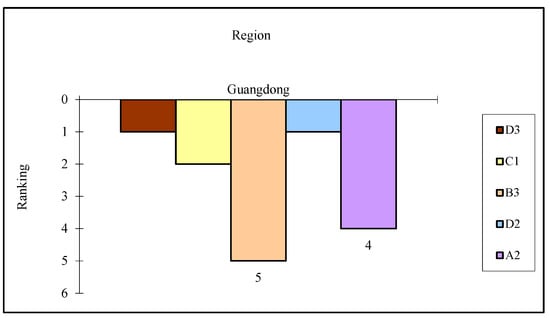

(1) Region with “High-Level”

The member of this kind of region is Guangdong Province.

At the macro level, the analysis was based on the ranking of four dimensions (Table 4). The strengths of Guangdong Province are green benefit (1st) and green technology (2nd), and there is more to be performed in green production (8th) and green emission (4th).

At the micro level, the analysis is based on the ranking of five important indicators (Figure 3). The relative weaknesses of Guangdong Province are B3 and A2. Improving these two factors can further enhance the green manufacturing level of Guangdong Province.

Figure 3.

Ranking of five important indicators in “high-level” region.

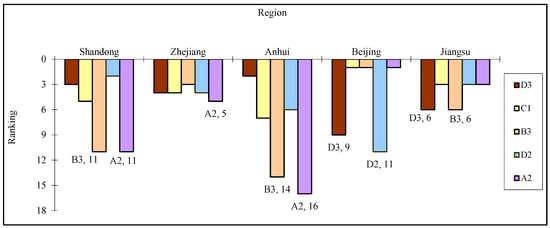

(2) Region with “Medium to High-Level”

Members of this kind of region include Shandong Province, Zhejiang Province, Anhui Province, Beijing, and Jiangsu Province.

At the macro level, the analysis was based on the ranking of four dimensions (Table 4). The weak spots of Shandong, Zhejiang, and Anhui Provinces mainly concentrate on green production (17th, 9th, and 12th, respectively) and green emission (14th, 9th, and 13th, respectively), indicating that three regions need to reduce pollutant emissions while reducing energy consumption. The weak spot of Beijing is the green benefit (13th), so the construction of green industrial parks and green factories needs to be strengthened, and more high-quality green products need to be developed. The weak spot of Jiangsu Province is green emission (8th), so it is necessary to reduce pollutant emissions while developing the economy.

At the micro level, the analysis was based on the ranking of five important indicators (Figure 4). The ranking gap among five important indicators in Shandong Province, Anhui Province, and Beijing is obvious, which is narrow in Zhejiang and Jiangsu Provinces. The weaknesses of Shandong and Anhui Provinces are B3 and A2, while Beijing is D2 and D3. The relative weakness of Zhejiang Province is A2, while D3 and B3 are the relative weaknesses of Jiangsu Province. The five regions need to take measures to reverse the weaknesses so as to further improve the level of green manufacturing.

Figure 4.

Ranking of five important indicators in “medium to high-level” region.

(3) Region with “Medium-Level”

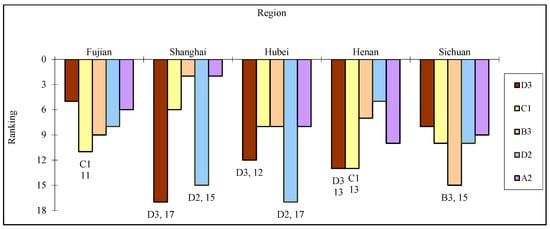

Members of this kind of region include Fujian Province, Shanghai, Hubei Province, Henan Province, Sichuan Province, Hunan Province, Tianjin, Chongqing, and Shaanxi Province.

At the macro level, the analysis was based on the ranking of four dimensions (Table 4). The biggest weak spot of the Fujian and Henan Provinces is green technology (13th and 11th, respectively), indicating that the two regions need to develop more green patents and promote the transformation of technological achievements. The biggest weak spot of Shanghai, Hubei, and Shaanxi Provinces is the green benefit (18th, 19th, and 22nd, respectively), so the three regions need to focus on developing improvement strategies in three aspects: green industrial parks, green factories, and green products. The weak spots of Sichuan Province are green production (13th) and green emission (15th), so it is necessary to reduce pollutant emissions while reducing energy consumption. The weak spots of Hunan Province, Tianjin, and Chongqing are green production, green technology, and green benefit, which need to be improved.

At the micro level, the analysis was based on the ranking of five important indicators (Figure 5 and Figure 6). The polarization of the five important indicators rankings in the Fujian and Hunan Provinces is not obvious, while the opposite is true in the other seven regions. The relative weakness of Fujian Province is C1, while that of Hunan Province is A2. The weaknesses of Shanghai and Hubei Province are very obvious, namely D3 and D2. The weaknesses of Henan Province are D3 and C1, while that of Sichuan Province and Chongqing are, respectively, B3 and D2. The biggest weakness of Tianjin is D3, followed by C1 and D2. The biggest weakness of Shaanxi Province is D3, followed by D2 and A2. The nine regions should take measures to reverse their respective weaknesses to improve the level of green manufacturing.

Figure 5.

Ranking of five important indicators in “medium-level” region (top 5 regions).

Figure 6.

Ranking of five important indicators in “medium-level” region (last 4 regions).

(4) Region with “Low to Medium-Level”

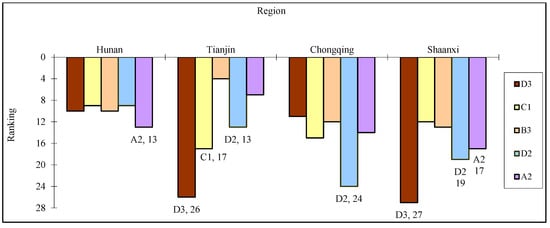

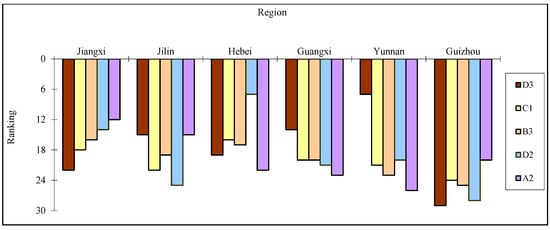

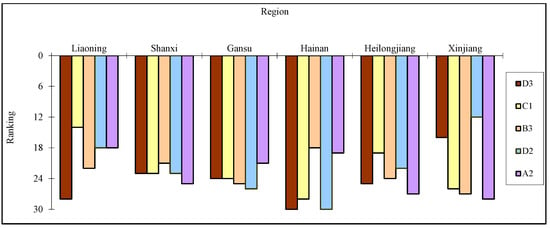

Members of this kind of region include Jiangxi Province, Jilin Province, Hebei Province, Guangxi Autonomous Region, Yunnan Province, Guizhou Province, Liaoning Province, Shanxi Province, Gansu Province, Hainan Province, Heilongjiang Province, and Xinjiang Autonomous Region.

At the macro level, the analysis was based on the ranking of four dimensions (Table 4). There are many weak lines in these regions. The weak spots of Jiangxi and Jilin Provinces are green emission (17th and 18th, respectively), green technology (20th and 23rd, respectively), and green benefit (12th and 27th, respectively). The weak spots of Hebei Province, Yunnan Province, and Xinjiang Autonomous Region are green production (23rd, 24th, and 28th, respectively), green emission (16th, 21st, and 25th, respectively), and green technology (16th, 19th, and 26th, respectively), while that of Liaoning Province are green production (19th), green emission (19th), and green technology (26th). The four dimensions of the other six regions are all backward.

At the micro level, the analysis was based on the ranking of five important indicators (Figure 7 and Figure 8). On the whole, the five indicators in these regions are all weak, except for D2 in Hebei (7th) and D3 in Yunnan (7th).

Figure 7.

Ranking of five important indicators in “low to medium-level” region (top 6 regions).

Figure 8.

Ranking of five important indicators in “low to medium-level” region (last 6 regions).

(5) Region with “low-level”

Members of this kind of region include Inner Mongolia Autonomous Region, Qinghai Province, and Ningxia Autonomous Region.

At the macro level, the analysis was based on the ranking of four dimensions (Table 4). The weak spots of Inner Mongolia and Ningxia Autonomous Regions are green production (29th and 30th, respectively), green emission (27th and 29th, respectively), and green technology (25th and 27th, respectively). The four dimensions of Qinghai Province are all backward.

At the micro level, the analysis of the ranking of five important indicators will not be carried out.

In summary, the green manufacturing level varies significantly among regions, and the eastern area is generally better than the central and western areas. In addition, the four dimensions in most regions are imbalanced, with an obvious Matthew effect. The regions with higher green manufacturing levels have fewer weak dimensions, and the regions with lower levels have more weak dimensions.

8. Dynamic Evaluation of Regional Green Manufacturing Level

This section analyzes the dynamic changes in the ranking of green manufacturing levels in 30 regions in China from 2017 to 2020.

8.1. Evaluation Ranking of Green Manufacturing Level of 30 Regions from 2017 to 2020

In order to grasp the dynamic change in the regional green manufacturing level, this paper further selects the data of 2017, 2018, and 2019 for evaluation and obtains the ranking of the green manufacturing level of 30 regions from 2017 to 2020, as shown in Table 7.

Table 7.

Ranking of green manufacturing level of 30 regions in China from 2017 to 2020.

8.2. Analysis of evaluation results

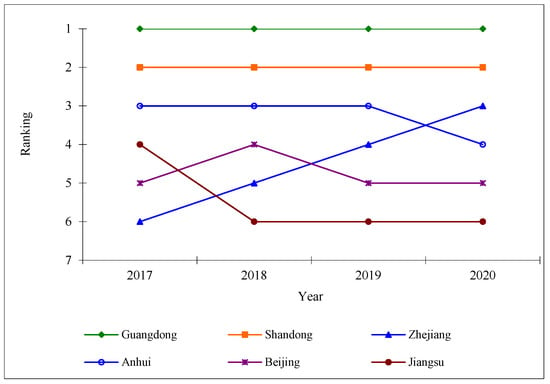

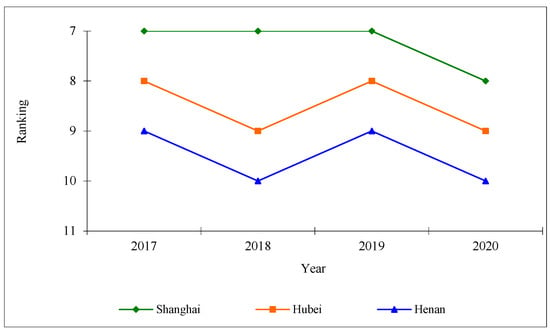

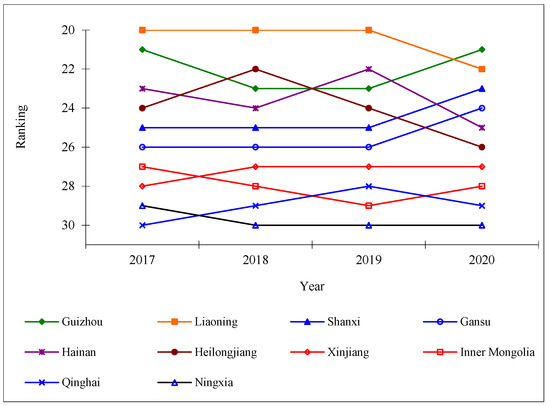

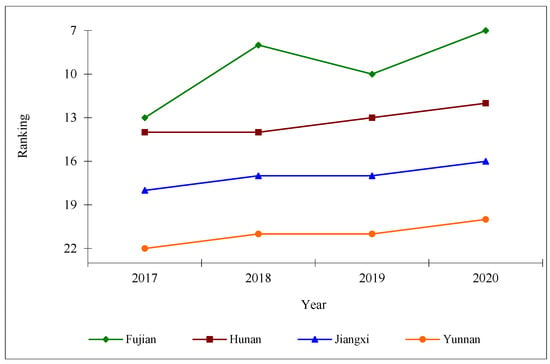

Based on Table 7, the dynamic changes in the ranking of green manufacturing level of 30 regions are divided into six categories, as shown in Table 8. In order to better present the dynamic changes, Figure 9, Figure 10, Figure 11, Figure 12, Figure 13 and Figure 14 are shown.

Table 8.

Dynamic changes in the ranking of green manufacturing level of 30 regions in China from 2017 to 2020.

Figure 9.

Regions that were consistently leading in the rank of green manufacturing level from 2017 to 2020.

Figure 10.

Regions that were consistently forward in the rank of green manufacturing level from 2017 to 2020.

Figure 11.

Regions that consistently lag behind in the rank of green manufacturing level from 2017 to 2020.

Figure 12.

Regions with moving up in the rank of green manufacturing level from 2017 to 2020.

Figure 13.

Regions with continuous decline in the rank of green manufacturing level from 2017 to 2020.

Figure 14.

Regions with small fluctuation in the rank of green manufacturing level from 2017 to 2020.

(1) Region with consistently leading ranking

There are six such regions (Table 8), and they consistently ranked in the top six from 2017 to 2020 (Figure 9). Among them, Guangdong and Shandong Provinces consistently ranked first and second, and Zhejiang Province noticeably moved up in the ranking year by year, from sixth in 2017 to third in 2020.

The reason why these six regions are “consistently leading” is mainly due to the strong driving force of five important indicators that were “consistently leading” in different degrees from 2017 to 2020.

For Guangdong Province, the five important indicators consistently ranked top 5. In particular, D3, with the largest weight, consistently ranked first from 2017 to 2020. For Shandong Province, the strong indicators are mainly D3 (2nd~3rd) and D2 (2nd~3rd). For Zhejiang Province, all five indicators consistently ranked around fourth. For Anhui Province, the superior indicators are mainly D3 (top 3) and D2 (4th~6th). For Beijing, the leading indicators are mainly C1, B3, and A2, all of which ranked first. For Jiangsu Province, the strong indicators are mainly D2 (top 3), C1 (2nd~3rd), and A2 (3rd~5th).

(2) Region with consistently forward ranking

There are three such regions (Table 8), and they consistently ranked 7th to 10th from 2017 to 2020 (Figure 10).

The reason why these three regions are “consistently forward” is mainly due to the support of five important indicators that were “consistently forward” in different degrees from 2017 to 2020.

Take Shanghai as an example; from 2017 to 2020, although D3 (12th~15th) and D2 (14th~15th) were not leading, B3 (constantly 2nd), A2 (constantly 2nd), and C1 (constantly 6th) were always ahead, so as to better drive Shanghai’s green manufacturing level.

(3) Region that consistently lags behind ranking

There are ten such regions (Table 8), and they consistently ranked 20th to 30th from 2017 to 2020 (Figure 11). Guizhou Province ranked 21st to 23rd, Liaoning Province ranked 20th to 22nd, Shanxi Province ranked 23rd to 25th, Gansu Province ranked 24th to 26th, Hainan Province ranked 22nd to 25th, and Heilongjiang Province ranked 22nd to 26th. In addition, Xinjiang Autonomous Region, Inner Mongolia Autonomous Region, Qinghai Province, and Ningxia Autonomous Region always ranked in the last four places.

The reason why these 10 regions “consistently lag behind” is mainly that the five important indicators were “consistently forward” in different degrees from 2017 to 2020.

By taking Ningxia Autonomous Region as an example, from 2017 to 2020, B3 and A2 constantly ranked last (30th), C1 consistently ranked 29th, and D2 always ranked around 25th. Although D3 ranked in the middle, other indicators were too poor, so Ningxia’s green manufacturing level remained anchored at the bottom of the list.

(4) Region with increasing ranking

There are four such regions (Table 8), and their ranking moved up by different ranges from 2017 to 2020 (Figure 12). Fujian Province rose to seventh in 2020, six places up from 2017. Hunan Province rose to 12th in 2020, two places up from 2017. Jiangxi and Yunnan Provinces also improved two places.

By comparing the ranking of indicator data in 2017–2020, it was found that the strong growth points of the four regions include parts of five important indicators, which confirms that the five indicators are important factors influencing the growth of green manufacturing level.

For Fujian Province, the indicator with the largest growth is D2, followed by D3. From 2017 to 2020, D2 ranked 22nd, 19th, 10th, and 8th, respectively, and D3 ranked 12th, 6th, 7th, and 5th, respectively. The former climbed 14 places, and the latter moved up seven places.

For Hunan Province, the indicator with the largest growth is A2, followed by D3. From 2017 to 2020, A2 rose by five places, and D3 rose by two places.

For Jiangxi Province, the indicator with the largest growth is C1, followed by B3. From 2017 to 2020, C1 jumped five places, and B3 moved up four places.

For Yunnan Province, the indicator with the largest growth is D3, followed by B3. From 2017 to 2020, D3 moved up five places, and B3 went up two places.

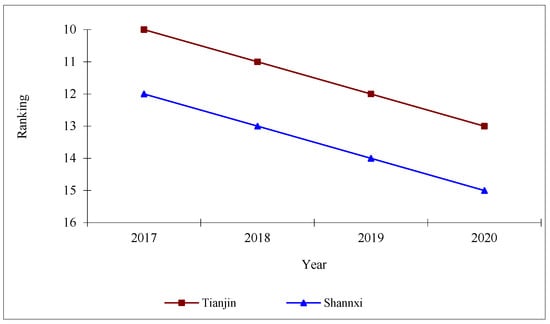

(5) Region with continuous declining ranking

There are two such regions (Table 8), and their ranking declined year by year (Figure 13). Tianjin dropped from 10th in 2017 to 13th in 2020. Shannxi Province dropped from 12th in 2017 to 15th in 2020.

By comparing the ranking of indicator data in 2017–2020, it was found that the large drop points of the two regions include parts of five important indicators, which confirms that the five indicators are important factors influencing the decline of green manufacturing level.

For Tianjin, the indicator with the largest decline is D3, followed by C1. From 2017 to 2020, D3 ranked 12th, 17th, 22nd, and 23rd, respectively, and C1 ranked 15h, 15th, 16th, and 17th, respectively. The former dropped 11 places, and the latter lost two places. Fortunately, B3 and A2 consistently ranked top 5 and top 7, respectively, and the ranking of D2 moved up year by year, which to some extent offset the great drop of D3 so that the ranking of Tianjin’s green manufacturing level did not decline seriously.

For Shannxi Province, the indicator with the largest decline is D3, followed by A2. From 2017 to 2020, D3 ranked 6th, 14th, 20th, and 22nd, respectively, and A2 ranked 14h, 13th, 16th, and 17th, respectively. The former dropped 16 places, and the latter lost three places. Fortunately, C1 consistently ranked 12th, and the ranking of B3 went up year by year, which to some extent offset the great drop of D3 so that the ranking of green manufacturing level in Shannxi Province did not decline seriously.

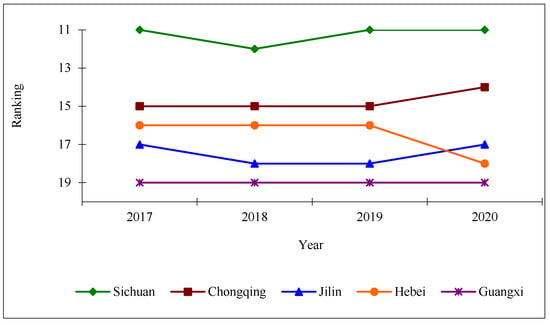

(6) Region with small fluctuation ranking

There are five such regions (Table 8), and the fluctuation range of their ranking was less than two places from 2017 to 2020 (Figure 14). Sichuan Province fluctuated one place between 11th and 12th, while Chongqing and Jilin Province fluctuated by the same range. Hebei Province fluctuated two places between the 16th and 18th, while Guangxi Autonomous Region is zero fluctuation.

The reason why the five regions are “small fluctuate” is related to the change in five important indicators. A detailed analysis was not carried out.

In summary, there was a small change in the ranking of most regions, indicating that the dynamic development of green manufacturing level has clear regional dependence, and the ranking landscape is relatively stable, which is difficult to be changed in the short term.

9. Conclusions and Suggestions

9.1. Conclusions

On the basis of defining the connotation of green manufacturing in China in the new era, this study constructed the evaluation index system of China’s regional green manufacturing level from 18 indicators in four aspects: green production, green emission, green technology, and green benefit. By taking 30 provincial administrative regions in China as the object, on the basis of the data from 2017 to 2020, the evaluation was carried out from the static and dynamic perspectives using the combined weight and TOPSIS. Based on the analysis of the results, the conclusions are as follows:

(1) The important factors affecting regional green manufacturing level are green products, green invention patents, sulfur dioxide, green factories, and coal consumption;

(2) The static evaluation results show that: First, the green manufacturing level of the 30 regions can be divided into five grades, including 1 high-level region, 5 medium to high-level regions, 9 medium-level regions, 12 low to medium-level regions, and 3 low-level regions. Second, there are obvious differences in the green manufacturing level among regions, and the eastern area is generally better than the central and western areas. Third, the four dimensions in most regions are imbalanced, with an obvious Matthew effect;

(3) The dynamic evaluation results show that: First, the green manufacturing level in 30 regions appears to have six different types of dynamic trends. Second, there is a small change in the ranking of most regions, indicating that the dynamic development of green manufacturing level has clear regional dependence;

(4) The index system and evaluation model constructed in this study can effectively evaluate the level of regional green manufacturing, which is reasonable and practical.

9.2. Suggestions

In combination with influencing factors, suggestions for enhancing green manufacturing levels are proposed as follows:

(1) To accelerate the green and low-carbon transformation of energy

First, appropriately control industrial coal consumption and actively promote economic and effective coal cleaning technology. Second, accelerate the large-scale and high-quality development of wind power and solar power. Third, actively promote the construction of hydropower bases according to local conditions. Fourth, promote the construction of coastal nuclear power projects in a safe and orderly manner;

(2) To actively adjust and optimize the industrial structure

First, strictly control the entry of high-energy consuming industries from the source, strictly control new projects in high-energy consuming industries, and curb the excessive growth of high-energy consuming industries. Second, strengthen efforts to eliminate unqualified and backward production capacity in heavily polluting manufacturing industries such as steel, nonferrous metals, chemical industry, papermaking, building materials, etc. Third, accelerate the cultivation and expansion of strategic emerging industries such as new generation information technology, biological industry, high-end equipment manufacturing industry, new material industry, new energy vehicles, etc.;

(3) To strengthen the application and innovation of green technology

First, actively research and develop cutting-edge technologies with low-carbon economic characteristics and overcome the technical difficulties of efficient and clean utilization of fossil fuels and pollution control. Second, promote the application of new green technologies in key fields such as steel, electric power, building material, and chemical industry to maximize energy conservation and emission reduction. Third, build the high-tech enterprise alliance and research and develop advanced and sophisticated technologies so as to lay a solid force for invention patent application, technology market trading, and green product development. Fourth, actively carry out international cooperation and exchange in green technology, and select energy utilization and environmental protection as the priority fields of cooperation.

10. Advantages, Limitations and Future Research

10.1. Advantages

The advantages of the proposed methodology and this study are as follows:

First, integrating ecological benefits enriches the connotation of green manufacturing in China in the new era, which serves as a scientific basis for building an evaluation index system.

Second, a systematic and distinctive evaluation index system is built for provincial administrative regions. The indicator system can also be used for the evaluation of prefecture-level cities after a slight adjustment.

Third, empirical analysis from both static and dynamic perspectives can not only understand the current situation but also grasp the dynamic development.

Fourth, the “principle of minimum discrimination information” is used to optimally combine subjective weight and objective weight, which is more scientific.

10.2. Limitations

The limitations of the proposed methodology and this study are as follows:

First, from the perspective of the selection of comprehensive evaluation methods, this study only used TOPSIS and did not use other methods, such as the gray correlation method or fuzzy comprehensive evaluation method, to demonstrate the accuracy of the evaluation results.

Second, from the perspective of comprehensive evaluation objects, this study only evaluated 30 provincial administrative regions in China, so the conclusions are only applicable to the comparison of provincial space.

Third, from the perspective of a comprehensive evaluation index system, due to the restriction of data availability, the index system proposed in this study was not perfect.

10.3. Future Research

The future research is as follows:

First, use the grey correlation method or fuzzy comprehensive evaluation method to conduct empirical analysis and compare it with the TOPSIS evaluation results of this study to demonstrate the accuracy of the evaluation conclusions.

Second, adjust the indicators to expand the application scope of the index system and evaluate and propose suggestions on the spatial scale of prefecture-level cities.

Third, collect further data and optimize the indicators so as to establish a more comprehensive green manufacturing level evaluation index system.

Author Contributions

Conceptualization, M.W. and C.Y.; methodology, M.W.; software, M.W. and D.Z.; validation D.Z.; formal analysis, M.W.; investigation, M.W.; resources, M.W.; data curation, M.W.; writing—original draft preparation, M.W.; writing—review and editing, C.Y.; visualization, M.W. and D.Z.; supervision, C.Y.; project administration, C.Y.; funding acquisition, C.Y. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Philosophy Social Science Planning Project of Shanghai (grant number 2022BGL010) and the National Natural Science Foundation of China (grant number 71840003).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Patil, R.A.; Ramakrishna, S.A. Comprehensive analysis of e-waste legislation worldwide. Environ. Sci. Pollut. Res. 2020, 27, 14412–14431. [Google Scholar] [CrossRef] [PubMed]

- Brewster, M.A. Perspective on advanced manufacturing and AMP2.0. MRS Bull. 2015, 40, 388. [Google Scholar] [CrossRef]

- Andersen, T.A. Comparative study of national variations of the European WEEE directive: Manufacturer’s view. Environ. Sci. Pollut. Res. 2022, 29, 19920–19939. [Google Scholar] [CrossRef] [PubMed]

- Yeo, M.K.; Han, T.H.; Kim, S.S.; Lee, J.A.; Park, H.G. Chemical management policies and a distribution model for chemical accidents. Mol. Cell. Toxicol. 2017, 13, 361–371. [Google Scholar] [CrossRef]

- Ilyassova, G.; Nukusheva, A.; Arenova, L.; Karzhassova, G.; Akimzhanova, M. Prospects of legal regulation in the field of electronic waste management in the context of a circular economy. Int. Environ. Agreem. 2021, 21, 367–388. [Google Scholar] [CrossRef]

- Sun, B.L. Simulation research on green manufacturing. Comput. Simul. 2015, 32, 1–4+50. [Google Scholar]

- Cao, H.J.; Li, H.C.; Zeng, D.; Ge, W.W. The State-of-art and future development strategies of green manufacturing. China Mech. Eng. 2020, 31, 135–144. [Google Scholar]

- Li, J.H. Green manufacturing and intelligent manufacturing in China: Development realities and future path. Res. Econ. Manag. 2022, 43, 3–12. [Google Scholar]

- Du, Z.; Chen, L.J.; Tian, J.P. Trajectory and policy evolution of Chinese industrial parks’ eco-transformation. Chin. J. Environ. Manag. 2019, 11, 107–112. [Google Scholar]

- Lv, Y.H. Research on Comprehensive Evaluation of Green Manufacturing Development level of Six Provinces in Central China. Master’s Thesis, Nanchang University, Nanchang, China, 2021. [Google Scholar]

- Wang, X.M. Dynamic Evaluation and Countermeasures of Green Manufacturing Development Level of Feicheng City. Master’s Thesis, Shandong Agricultural University, Tai’an, China, 2020. [Google Scholar]

- Wang, X.Q.; Zhao, Y.T. Evaluation of green manufacturing development level and empirical analysis of influencing factors in Jilin Province. Fortune Today 2020, 5, 13–14. [Google Scholar]

- Liu, X.H.; Jie, X.W. Study on the evaluation and Promotion Countermeasures of industrial green manufacturing system in Western China. North. Econ. 2020, 1, 37–40. [Google Scholar]

- You, J.M.; Zhang, W. Study on the performance evaluation and influencing factors of green manufacturing in national ecological civilization experimental zone: A case study of Guizhou. Guizhou Soc. Sci. 2018, 12, 120–128. [Google Scholar]

- Li, B.Y.; Gu, C.K. Evaluation system of green manufacturing for China region. Ind. Econ. Rev. 2015, 2, 23–30. [Google Scholar]

- Wang, Q.S.; Yuan, X.L.; Cao, D.Y.; Ma, C.Y.; Zhang, K. Research on evaluation index system for green manufacturing based on PSR model and life cycle. Appl. Mech. Mater. 2010, 34–35, 79–84. [Google Scholar]

- Zhang, X.M.; Zhang, H. Framework system of green manufacturing evaluation and optimization based on ecological civilization. Mod. Manuf. Eng. 2016, 10, 153–158. [Google Scholar]

- Karamaşa, Ç.; Ergün, M.; Gülcan, B.; Korucuk, S.; Memiş, S.; Vojinović, D. Ranking value-creating green approach practices in logistics companies operating in the TR A1 region and choosing ideal green marketing strategy. Oper. Res. Eng. Sci. Theory Appl. 2021, 4, 21–38. [Google Scholar] [CrossRef]

- Alossta, A.; Elmansouri, O.; Badi, I. Resolving a location selection problem by means of an integrated AHP-RAFSI approach. Rep. Mech. Eng. 2021, 2, 135–142. [Google Scholar] [CrossRef]

- Wu, Z.; Xi, J.J.; Xu, Y. Promoting green manufacturing and realizing sustainable development of manufacturing industry. Manuf. Auto. 2004, 26, 20–24+49. [Google Scholar]

- Lu, Y.X. Toward green manufacturing and intelligent manufacturing—Development road of China. China Mech. Eng. 2010, 21, 379–386+399. [Google Scholar]

- Chen, X.R.; Li, X.; Dong, H.B.; Bai, R.B. Green manufacturing of auto parts based on life cycle assessment. Environ. Eng. 2015, 33, 116–120+146. [Google Scholar]

- Tao, Y.; Li, Q.S.; Zhao, G. Research on the green manufacturing strategy based on product life. Forum Sci. Technol. China 2016, 9, 58–64. [Google Scholar]

- Ma, P.; Zhang, C. Pricing strategies for complementary products in green supply chain. Control Decis. 2018, 33, 1861–1870. [Google Scholar]

- Liu, P.J.; Liu, F.; Wang, X.; Yin, Z.B.; Cao, H.J.; Li, C.B. The theory and technology system of green manufacturing and their new frameworks. J. Mech. Eng. 2021, 57, 165–179. [Google Scholar]

- Chen, W.J.; Lu, R.Y.; Tuo, Y.Y. Comparison of two methods for the determination of COD. Qual. Saf. Insp. Test. 2020, 30, 92–93+100. [Google Scholar]

- Zhang, D.; Cao, H.B.; Zhao, Y.H. Economic analysis of industrial ammonia pollution abatement in different forms. China Envion. Sci. 2021, 41, 1474–1479. [Google Scholar]

- Wang, S.F. Analysis of industrial sulfur dioxide pollution emission and environmental protection mode. Cult. Geogr. 2017, 4, 126. [Google Scholar]

- Liang, J.; Zheng, J.; Han, M.M.; Ma, L.X.; Shi, Y. Harm of nitrogen oxide and its treatment technology. Technol. Innov. Appl. 2021, 11, 120–122. [Google Scholar]

- Liu, Z.S.; Zhang, X.L.; Yang, L.Q.; Shen, Y.J. Access to digital financial services and green technology advances: Regional evidence from China. Sustainability 2021, 13, 4927. [Google Scholar] [CrossRef]

- Yang, Y.R.; Liu, D.S.; Zhang, L.X.; Yin, Y.K. Social trust and green technology innovation: Evidence from listed firms in China. Sustainability 2021, 13, 4828. [Google Scholar] [CrossRef]

- CMES. Notice on Applying for the 8th Green Manufacturing Technology Progress Award. 2018. Available online: https://www.cmes.org/05f3d5c85f864a0daf7be27b00d1d086.html (accessed on 15 May 2022).

- CECA. Notice on Publicly Soliciting the Innovation Award of China Energy Conservation Association in 2022. Available online: http://kyy.hnu.edu.cn/info/1061/7525.htm (accessed on 10 June 2022).

- Hao, Z.C.; Duan, L.J.; Hao, D.W.; Wang, G.Q.; Song, Y.F. Establishment and application of green standard system in industrial park. Reg. Gov. 2020, 3, 74–77. [Google Scholar]

- Yang, M.; Li, H.S. Interpretation of the China national standard: General principles for assessment of green factory. Inf. Technol. Stand. 2019, 7, 32–35. [Google Scholar]

- Fu, Y.; Lin, L.; Gao, D.F. General principles for assessment of green product. Stand. Living 2018, 6, 34–37. [Google Scholar]

- Yi, L.Z.; Guo, Y.; Liu, N.A.; Liu, N.; Liu, J.Y.; Zhao, J.; Jiang, G.L. Health status sensing of catenary based on combination weighting and normal cloud model. Arabian J. Sci. Eng. 2022, 47, 2835–2849. [Google Scholar] [CrossRef]

- Zhang, F.; Wang, P.Y.; Mu, P.; Wang, M.L.; Han, L.F.; Sun, J.L. A comprehensive evaluation method for the service status of groins in waterways based on an AHP-improved CRITIC combination weighting optimization model. Sustainability 2022, 14, 10709. [Google Scholar] [CrossRef]

- Niu, D.P.; Guo, L.; Zhao, W.W.; Li, H.R. Operation performance evaluation of elevators based on condition monitoring and combination weighting method. Measurement 2022, 194, 111091. [Google Scholar] [CrossRef]

- Chen, S.F.; Liu, W.; Bai, Y.H.; Luo, X.Y.; Li, H.F.; Zha, X. Evaluation of watershed soil erosion hazard using combination weight and GIS: A case study from eroded soil in Southern China. Nat. Hazards 2021, 109, 1603–1628. [Google Scholar] [CrossRef]

- Kim, I.; Kim, S.; Choi, S.; Kim, D.; Choi, Y.; Kim, D.; Ni, Y.; Yin, J. Identifying key elements for establishing sustainable conventions and exhibitions: Use of the Delphi and AHP approaches. Sustainability 2022, 14, 1678. [Google Scholar] [CrossRef]

- Kaneesamkandi, Z.; Rehman, A.U.; Usmani, Y.S.; Umer, U. Methodology for assessment of alternative waste treatment strategies using entropy weights. Sustainability 2020, 12, 6689. [Google Scholar] [CrossRef]

- Xue, C.Y.; Shao, C.F.; Chen, S.H. SDGs-based river health assessment for small- and medium-sized watersheds. Sustainability 2020, 12, 1846. [Google Scholar] [CrossRef]

- Xu, B.S.; Qi, N.N.; Zhou, J.P.; Li, Q.F. Reliability assessment of highway bridges based on combined empowerment-TOPSIS method. Sustainability 2022, 14, 7793. [Google Scholar] [CrossRef]

- Jing, L.; Li, J.P.; Zhang, Y.; Ma, H.Y.; Li, J. Study on dry soil layers under different land-use systems in the Loess Plateau. Pratac Sci. 2018, 35, 1829–1835. [Google Scholar]

- Wu, X.J.; Du, D.B.; Xiao, G.; Guan, M.M. The temporal and spatial evolution of city innovation capability differences in the Yangtze River economic belt. Resour. Environ. Yangtze Basin 2017, 26, 490–499. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).