1. Introduction

In 2022, renewable energy growth is accelerating as interest in climate change increases, in line with augmented technical, environmental, and social considerations and governance support. In this context, the demand for cleaner energy sources from most market sectors is accelerating. Fortunately, the penetration of renewable energy resources in radial distribution systems (RDSs) helps improve the performance of these systems [

1,

2]. Optimal allocation (i.e., location and size) of multiple centralized/decentralized renewable energy resources at different buses of the system can give numerous benefits [

3], such as reducing the system power losses and peak power requirements, boosting the voltage profile, ancillary services provisioning, deferring the upgrading process of distribution system lines/cables, and enhancing the system reliability [

4,

5]. Moreover, reactive power compensators such as capacitor banks (CBs), series compensators, shunt reactors, static VAR compensators (SVCs) [

6], static synchronous compensators, and synchronous condensers can be added to these systems to enhance the voltage profile of nodes and improve the power factor of loads [

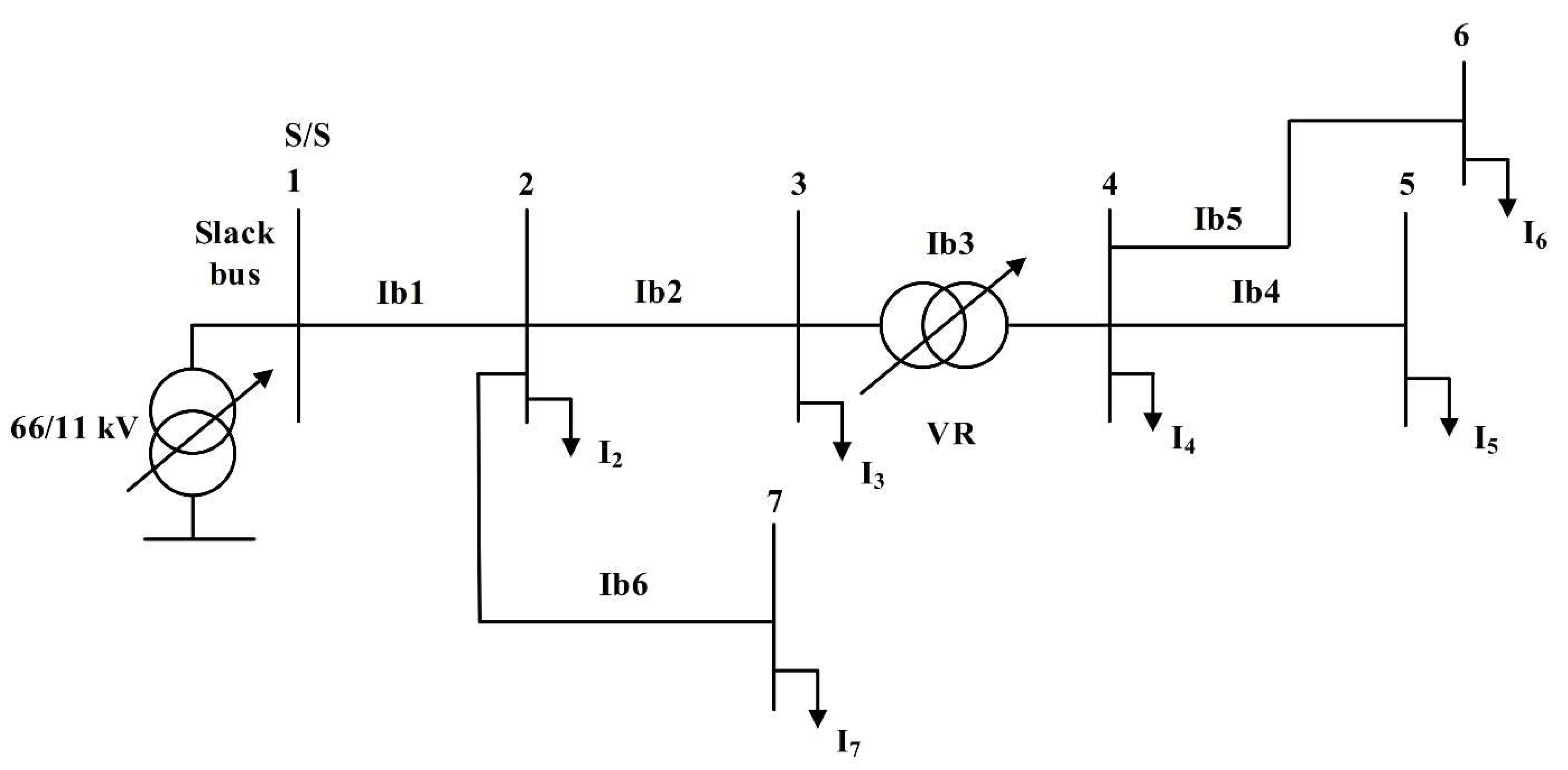

7]. Voltage regulators (VRs) can also be an efficient solution to minimize voltage deviations in RDSs. The recent VR technologies provide significant advantages over traditional VR designs—electronic control with more advanced features to support innovative grid technologies and quick-drive tap changers that operate within only 10 s through 32 steps; this allows fast recovery from large voltage swings and power quality improvement.

Unfortunately, non-optimal integration of renewables and reactive power compensators may increase power system losses and cause thermal overloading and overvoltage problems, weaken systems’ power quality (PQ) and reliability [

8], and trigger harmonic distortion problems by inverter-based distributed generation units, especially if feeding nonlinear loads.

Several studies have been conducted to solve these problems by quantifying the proper penetration of renewables in hosting capacity (HC) analysis frameworks. HC is an indicator for network operators of the available renewable capabilities, so that the power system can effectively make the best use of them. The HC border in the distribution network is an easy-to-calculate indicator, on scientific but reliable grounds, to decide where and when more renewables can be added to the system without surpassing the operational constraints [

9,

10]. In this context, several actions can enhance the HC of a system, such as (i) voltage control using on-load tap changers (OLTCs), which is considered an efficient way to control voltage profiles; (ii) reactive power control, which is regarded as one of the most efficient solutions to solve reactive power and voltage problems by adding external compensators such as CBs, static VAR compensators (SVCs), and others; (iii) active power control, in which active power curtailment techniques can be applied in centralized renewables-based power stations to control their output power by balancing the mismatch between power generation and consumption; and (iv) using energy storage systems to overcome the overvoltage problems from the high penetration of renewables. The proper planning of energy storage units can postpone the upgrading process of modern distribution systems: (v) reinforcing and/or reconfiguring power system networks in planning stages can also accommodate high HC levels, and (vi) harmonic management can be used to minimize harmonic distortion, as the nonlinearity degree of loads can impact the targeted HC level. It should be mentioned that more than one solution can be applied to make the best use of renewables and to get the highest possible HC.

Distribution networks connect high-voltage transmission systems to low-voltage customers. RDSs have a simple design and construction and cheap cost advantages. Load growth in RDSs has a detrimental influence on power system quality, resulting in increased voltage variations, feeder overloading (increased values of branch currents), and increased power loss in systems not ready for it. Simultaneous allocation of distributed generation (DG) units, VRs, and reactive compensators can be an efficient solution to enhance the PQ of these deteriorated RDSs. In this regard, few studies have examined the optimal allocation of DGs, CBs, and VRs for maximizing the HC of deteriorated RDSs.

Many research studies have been conducted to allocate DGs and CBs simultaneously in RDSs in the literature [

11,

12,

13,

14]. In [

11], the authors identified appropriate DG and CB locations, sizes, and types for small, isolated networks with nonlinear loads at the planning phase. In [

12], the Manta ray foraging optimization technique manages the DGs and CBs allocation in RDSs for reducing energy loss using appropriate data to meet customer expectations. The firefly and backtracking optimization techniques were used in [

14] to solve the optimal coordination issue for DGs and CBs in RDSs for reducing power loss and enhancing the voltage magnitude of all buses. In [

13], the authors suggested a multiobjective model with a two-stage fuzzy approach based on the grasshopper optimization algorithm for optimum allocation of DGs, CBs, and EV charging stations, while considering various technical PQ performance indicators.

Additionally, the problem of optimal coordination between DGs and VRs was addressed in [

15,

16,

17] to decrease system losses, control and improve the voltage profile, and enhance voltage stability. In addition, the authors of [

18] discussed using multi-agents (DGs, CBS/SVC, or VRs) to improve the performance of RDSs, while considering various PQ indices. However, HC analysis was not conducted in detail.

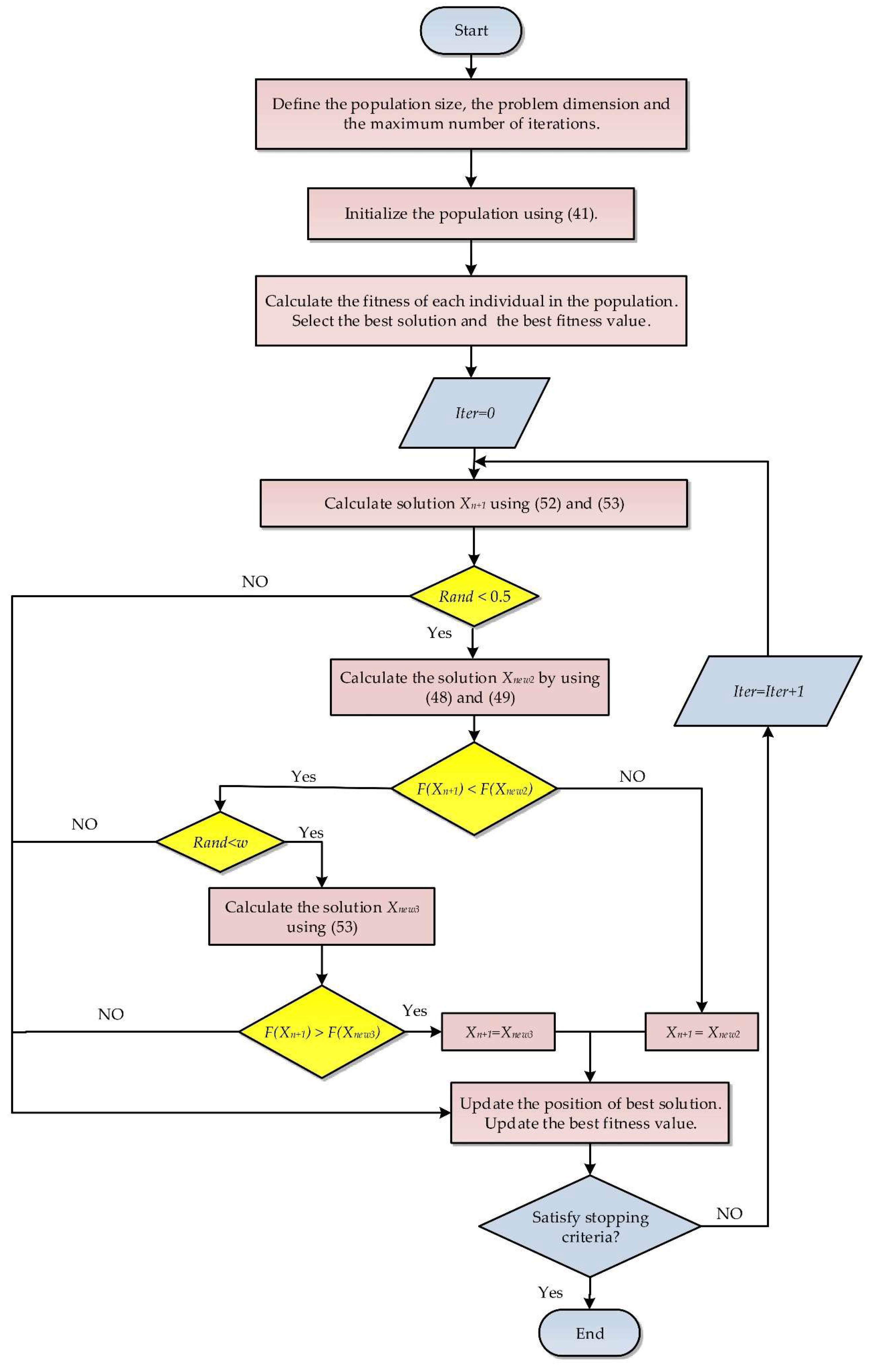

This article applies a new optimization technique to obtain optimal locations and sizes of DGs, CBs, and VRs to increase HC for a rural Egyptian radial feeder system called the Egyptian Talla system (ETS). A recently introduced RUN optimization technique is used to solve the desired allocation problem in two cases. The first case considers reverse power flow to the utility, while the second prevents reverse power flow in the feeder. RUN relies on mathematical concepts and principles of the widely known Runge–Kutta (RK) method. Furthermore, this paper presents a cost-benefit analysis (CBA) that includes fixed and operating costs of the compensators (DGs, CBs, and VRs) and the benefits obtained by enhancing the voltage stability of the system and reducing the active power loss, voltage deviation, loading capacity, and power purchased from the utility. The CBA can measure the benefits of a particular action for system operators and customers minus the costs of taking that action.

In addition, the current requirements of Egyptian electricity distribution companies were met in the formulated optimization problem to improve the HC of this rural system. Uncertain loading conditions were taken into account in this study. The main load demand clusters were obtained using the soft fuzzy C-means clustering approach according to load consumption patterns in this system.

The core contributions of this article are summarized in the following points:

A new optimization methodology is applied to obtain the optimal allocation of various units (DGs, CBs, and VRs) to maximize the HC in a real deteriorated Egyptian system, while taking into consideration load demand uncertainty.

A probabilistic HC planning model is proposed, increasing renewables penetration and meeting load demands in the studied system.

A CBA is introduced, considering the costs of all compensators (DGs, CBs, and VRs) and the benefits of decreasing the power losses and the total power purchased from the utility.

The simulation results validate the efficiency of solving the simultaneous allocation problem of DGs, CBs, and VRs, while complying with the considered linear and nonlinear constraints in an efficient techno-economical manner.

The simulation results show the proposed strategy’s efficiency in solving the optimal sizing and siting problem cost-effectively. The probabilistic HC of the system reaches 100% when allowing a reverse power flow to the utility. In comparison, this becomes 49% when not allowing the reverse power to flow back to the utility.

The rest of the paper is arranged as follows:

Section 2 presents an overview of recent related HC studies.

Section 3 illustrates the VR model and optimal load flow.

Section 4 explains the system under study, the problem formulation, and the RUN optimization algorithm employed.

Section 5 presents the obtained simulation results and their discussion. The conclusions derived from this study are provided in

Section 6.

2. Related Works

The terminology “hosting capacity” (HC) is a relatively new concept that refers to the maximum penetration of DGs that a system can host without operational problems [

19,

20,

21].

Figure 1 illustrates HC calculation using a generic performance index versus penetration level. The performance index is determined based on the issue in the power network.

Figure 2 shows the typical operational problems and HC enhancement solutions in modern RDSs. In the near past, conventional rules of thumb were used to decide on adding renewables. However, they were not widely used as the HC definition. Nowadays, HC determination can assess the addition of renewables reasonably. HC has been embedded in several well-known simulation software applications due to its importance, such as DIGSilent, CYME, EPRI (DRIVE), ETAP, and Siemens, as shown in

Table 1. The reader can refer to [

19,

20,

21] for more details about HC calculation.

SVCs were optimally designed using multi-stage stochastic optimization to allocate photovoltaic (PV) units [

22]. An appropriately sized C-type harmonic filter enhanced the HC of a system operating under non-sinusoidal conditions in [

23]. In [

24], HC was analyzed for an 18-node practical distribution feeder using a decoupled harmonic power flow model, and it was found that by decentralizing the DG capacity, higher penetration levels could be obtained. In [

25], the authors examined the influence of autonomous voltage control techniques on the PV-HC in LV distribution feeders. The operating strategies explored were based on the PV systems’ active and reactive power control capabilities and the capability of OLTCs. The authors of [

26] examined the effect of reactive power management of the PV inverter on the PV-based HC of a distribution network. When a DG unit’s output power exceeds the load requirement, the excess electricity is returned to the grid. As a result, a voltage rise at the load bus may occur, potentially resulting in an overload at the adjacent feeder. In addition, the effects of tap locations of OLTCs and SVCs configurations were investigated.

Uncertainties of generation, load demand, and renewables are challenging to model and risky to manage in a deterministic way. The main difficulty is determining the appropriate solutions for calculating deviations of these parameters from their nominal values. The authors of [

10] proposed an HC maximization approach considering different technical constraints, such as power flow equations and feeders’ maximum allowable voltages and currents, and economic conditions, such as the cost of energy procurement from the upstream network and power generation by renewable energy sources. The authors presented a stochastic multi-objective optimization model to maximize the HC and minimize the energy procurement costs in a power system integrated with wind systems. Shayani et al. [

27] evaluated the influence of high PV penetration on electrical networks. The authors discovered that when DG penetration is substantial, the voltage rise and the continuous conductor maximum current are the primary indices that exceed the permitted limits. The authors concluded from their calculations that installing DG level between 1 and 2 p.u of the load power could be possible.

The authors of [

28] provided an approach in which a multi-objective and multi-period optimization model was formulated, where the demand response is utilized as an effective tool to increase HC and decrease energy losses simultaneously. The authors of [

29] developed a multi-objective bilevel optimization problem to optimize the HC that meets distribution system reconfiguration (DSR) and placement of soft opening points (SOP) for two real distribution systems, one with 59 nodes in Egypt and another with 83 nodes in Taiwan. The outcomes demonstrated the efficacy of DSR and SOP allocation to optimize the HC of the distribution systems. The authors of [

30] proposed a maximum HC evaluation method, while considering the robust optimal operation of OLTCs and SVCs, as well as the uncertainty of DG power outputs and load demands. An actual 55-bus rural feeder in China was modeled to demonstrate the advantages of the proposed technique over the standard method and validate the value in PV-planning decision making for utilities. The sensitivity of interval-valued PV-HC to the number of Monte Carlo simulations was investigated. In this regard, uncertainty analysis has gained much attention in these works [

31,

32]. In [

33], a stochastic optimization was devised for the best position of SVCs to enhance the penetration of solar PV energy, while accounting for renewables and load uncertainty.

The authors of [

34] introduced an enhanced grey wolf algorithm (EGWA) for allocating DG units in coordination with capacitor banks and VRs. Load alteration was introduced via three-stepped load levels—light, shoulder, and peak demand—to minimize investment costs for the coordinated equipment while maximizing advantages gained from enhancing the voltage profile and loading capacity, reducing power loss and the amount of power imported from the utility. In addition, the authors of [

35] proposed an optimal two-stage strategy for allocating SVC equipment in conjunction with fixed capacitors and distributed energy resources using EGWA. Several objectives were handled, including reducing the investment costs associated with installing new devices, the expenses related to grid power production, active power losses, and system voltage deviations, and enhancing power transfer capabilities by minimizing the load balancing index. However, HC analysis was not conducted.

This overview shows that the four main problematic issues are overvoltage, overloading and power loss complications, PQ issues, and protection problems [

36,

37], as shown in

Figure 2. The HC approach gathers the technical restrictions implemented by operators and customers to guarantee that the power system runs satisfactorily. This means that the HC calculation is not static, with a single answer that relies on one performance metric. However, HC would be calculated for several performance indices, such as voltage and frequency variations, PQ, thermal overload capacity, system reliability and stability, and others. A detailed overview of HC—progresses, assessment practices, and enhanced technologies—is presented by Ismael et al. in [

38]. The hands-on experience (rule-of-thumb) of distribution system operatives, PQ markets, and decisions from actual case studies are presented and discussed [

38]. The authors in [

39] also demonstrated a detailed analysis of HC theory and its influences on power networks, challenges, and solutions.

To conclude, the main focus of researchers is moving towards empowering distribution systems with highly penetrated renewables by unlocking the uncontrolled or the uncoordinated HC, while offering multi-functionality facilities to enhance it whenever possible. Finally, HC can be boosted by several methods: (a) using OLTCs to control the voltage profile (not included in this paper); (b) adding external compensators such as CBs, which provide reactive power control, which is regarded as one of the most effective solutions to solve reactive power and voltage problems (this method is included in the paper); (c) using VRs, which provide a better voltage profile and better branch current values so that both branch current values and bus voltage magnitudes are in the certain allowable limits (this method is provided in the paper, and it can be considered a novel way to improve the HC); and (d) using renewable-based DGs, which can improve the active power flow in the system (this method is included in the paper). Moreover, there are mainly two methods to improve the HC: the first is reconfiguring the distribution system, which is not applicable in our case, and the second is adding external compensators to the system (DGs, CBs, and VRs). We studied the effect of each compensator alone on the distribution system, but the best results were obtained by simultaneously using all these compensators.

5. Numerical Results and Discussion

5.1. Uncompensated System

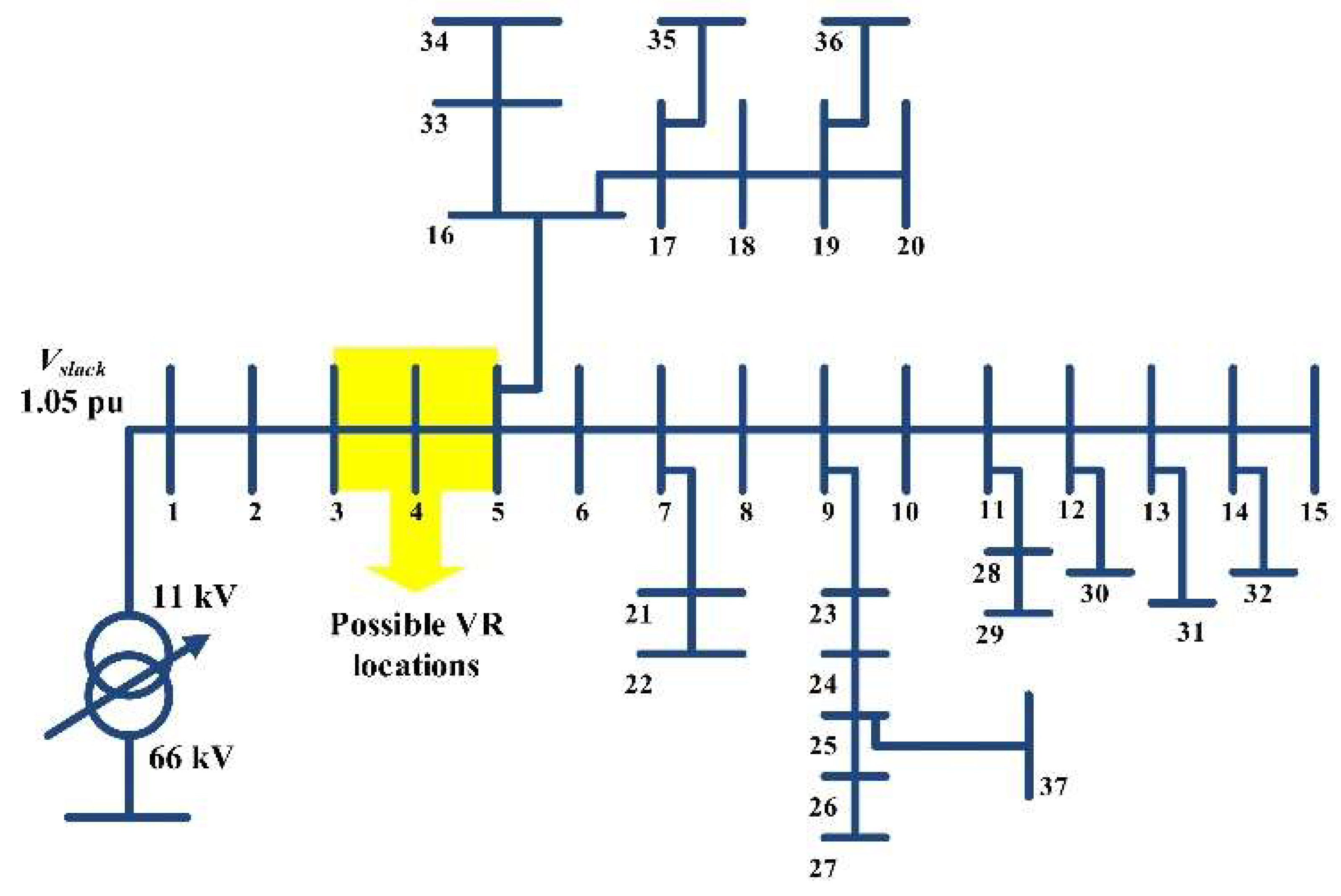

The decision variables of the investigated problem under study are the location and sizes of DGs and CBs and the tapping positions of the VRs. The locations are considered integer variables and are set to be from 2 to

Nbuses (system number of buses). The discrete CB sizes are assumed to be from 0 to 1200 kVAr in a 150 kVAr step. It should be noted that more than one capacitor can be connected to the same bus. The DG sizes are assumed to be continuous in the 0–2 MW range. The numbers of CBs and DGs are considered to be seven and three, respectively, plus one VR location. These mixed variables—locations and sizes—are produced randomly within their allowable ranges. Then, the RUN optimization algorithm is used for solving this issue and calculating the optimal values for these parameters when HC maximization is considered. The backward/forward sweep algorithm performs the load flow.

Table 3 explores the values of the load demand in percentages and the probability of occurrence of the corresponding demand scenarios for the system under investigation given in

Figure 5.

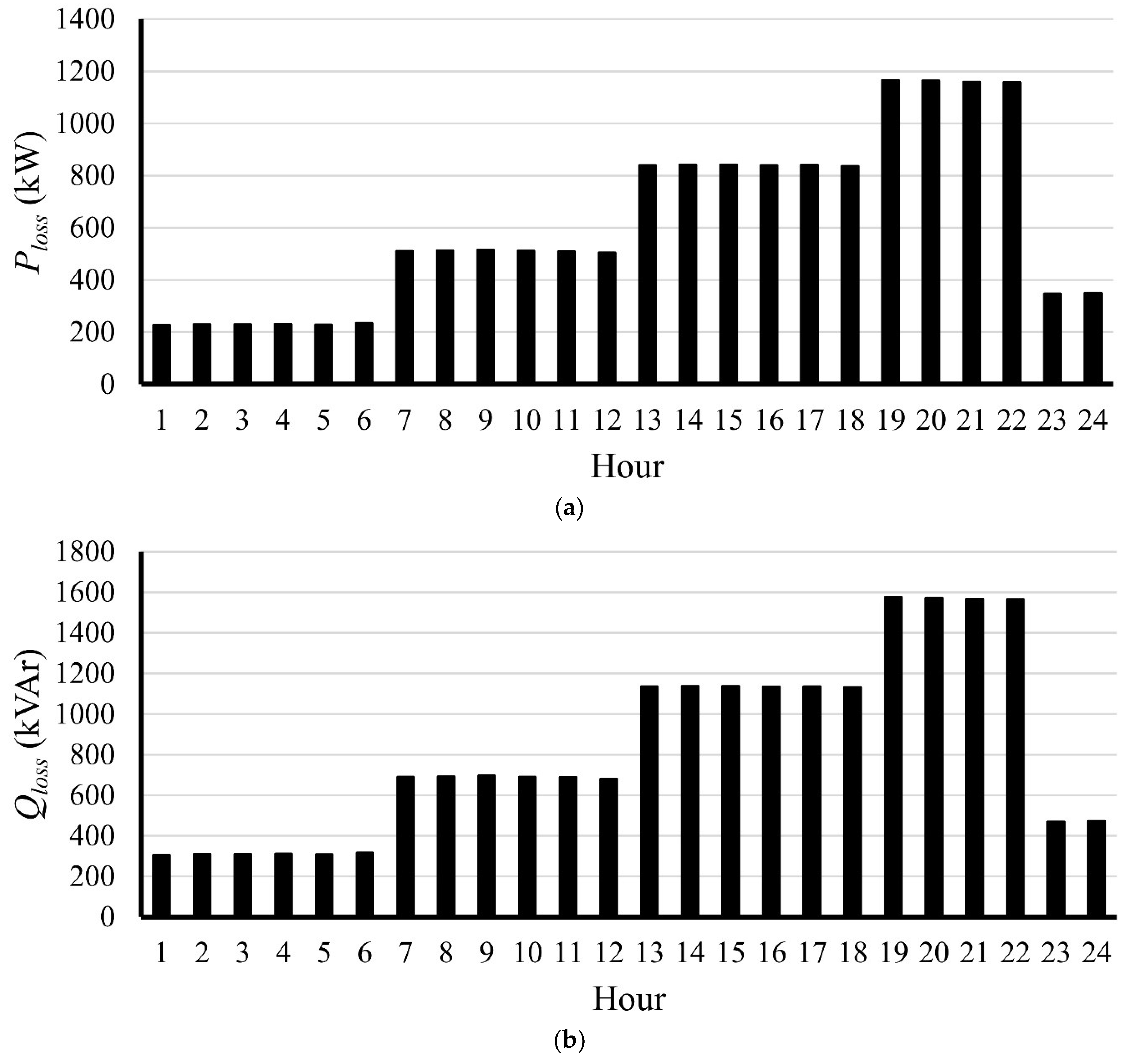

Table 4 presents the results of ETS’s initial load flow without applying any enhancement technique (base case). It can be noted that the system’s losses (active and reactive) are very high, especially in high loading conditions (i.e.,

LL3 and

LL4).

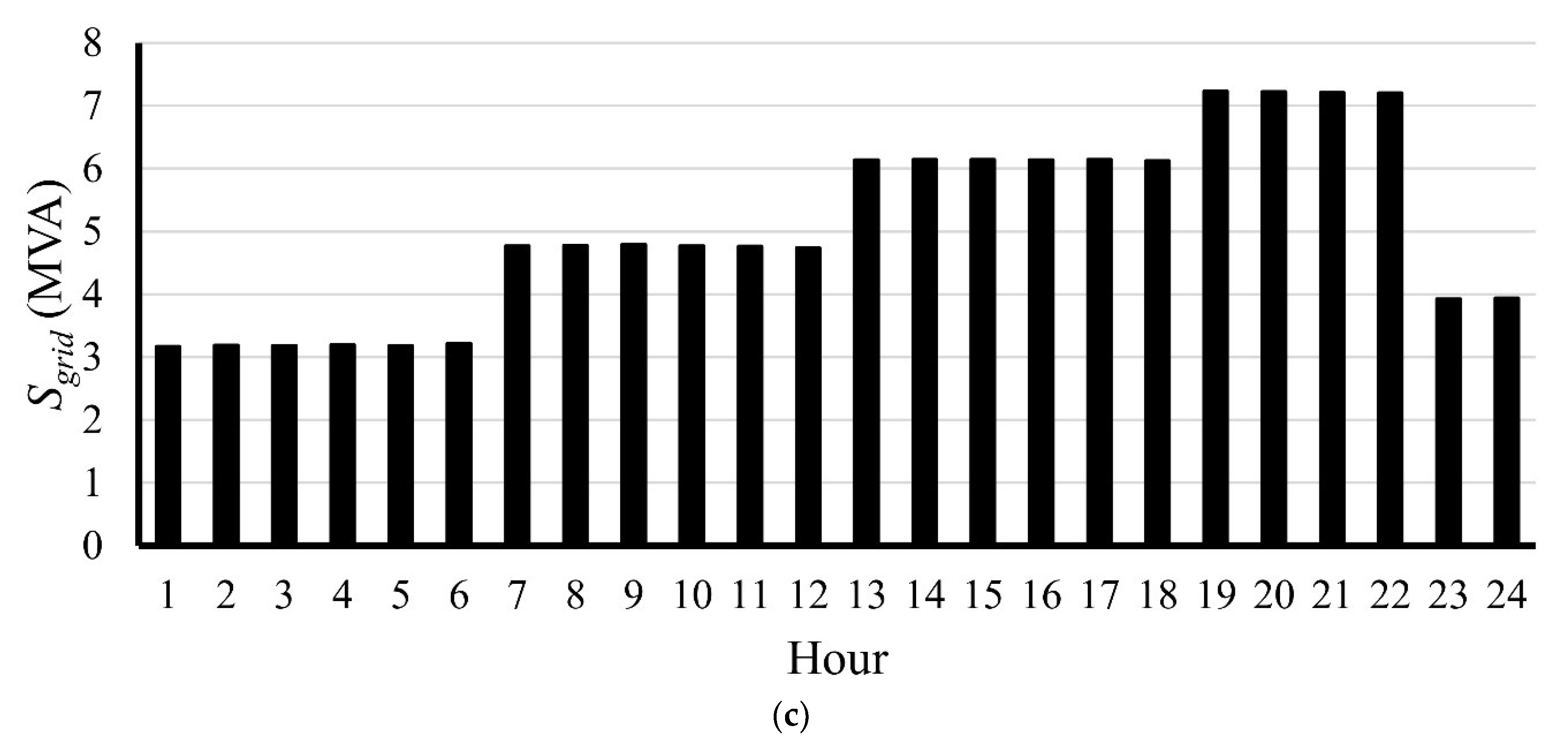

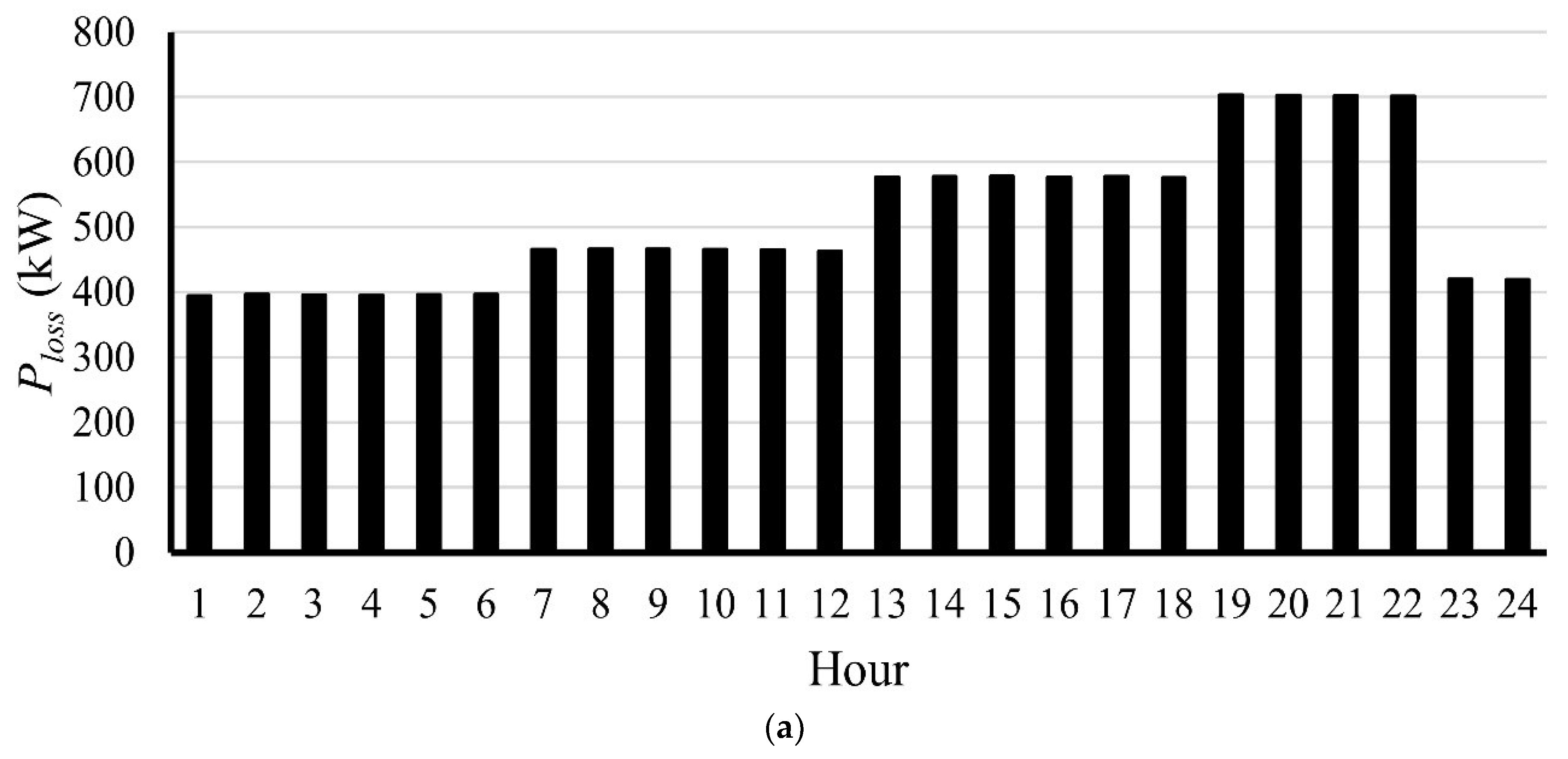

Figure 8 shows the active power loss, reactive power loss, and complex power purchased from the grid throughout the day. It can be seen that the active power loss, reactive power loss, and complex purchased power from the utility are significantly high, especially at hours 19–22, due to the high loading conditions.

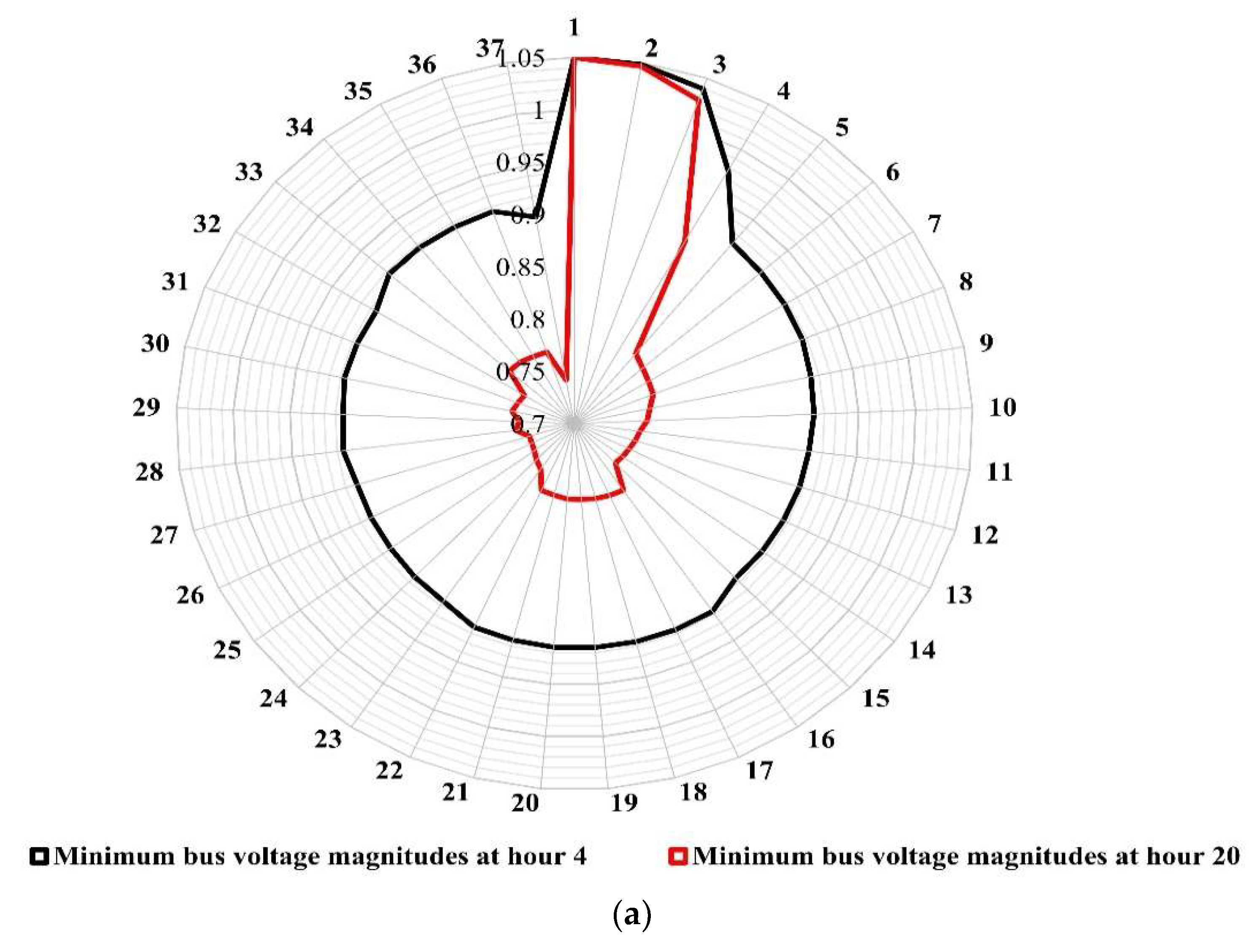

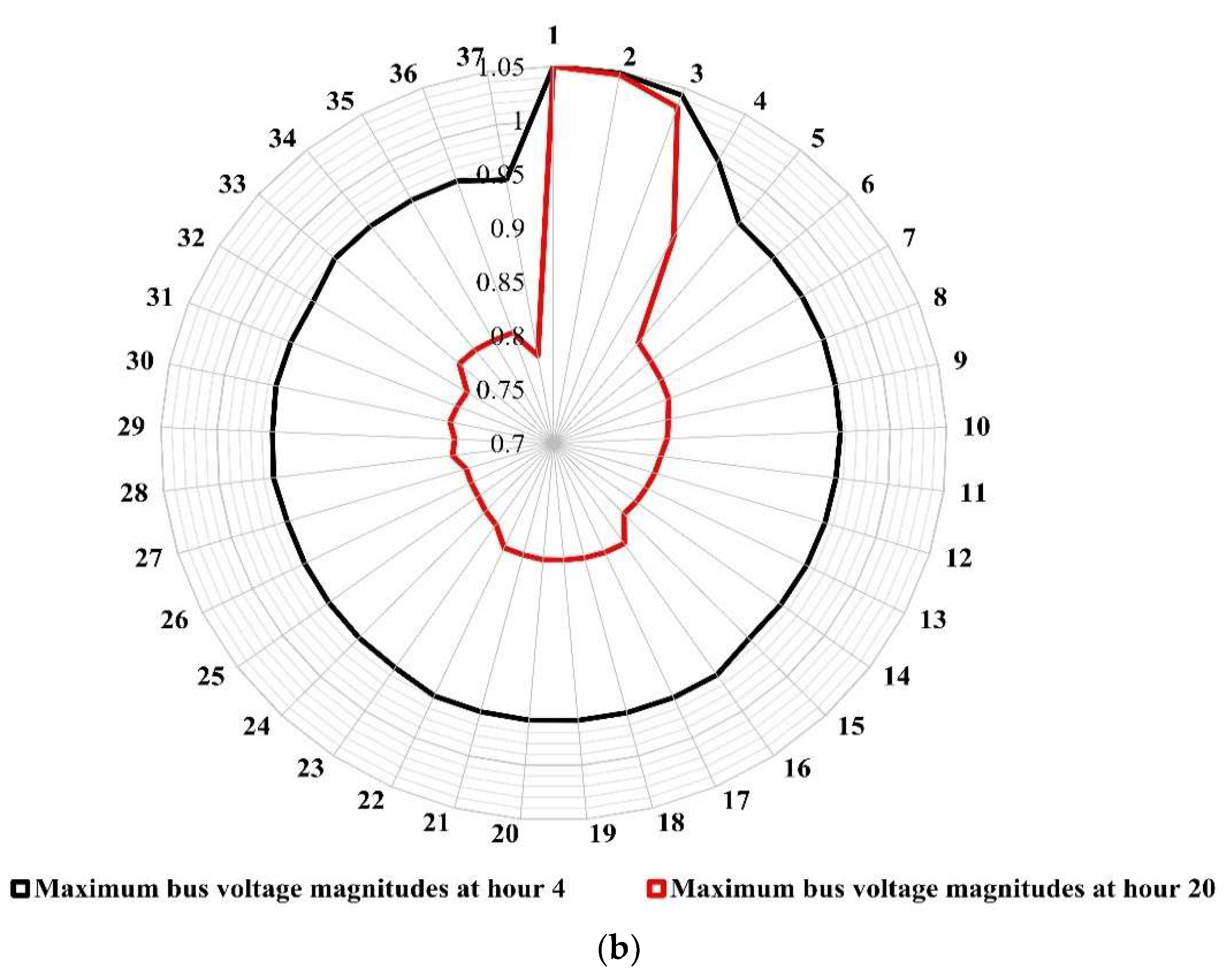

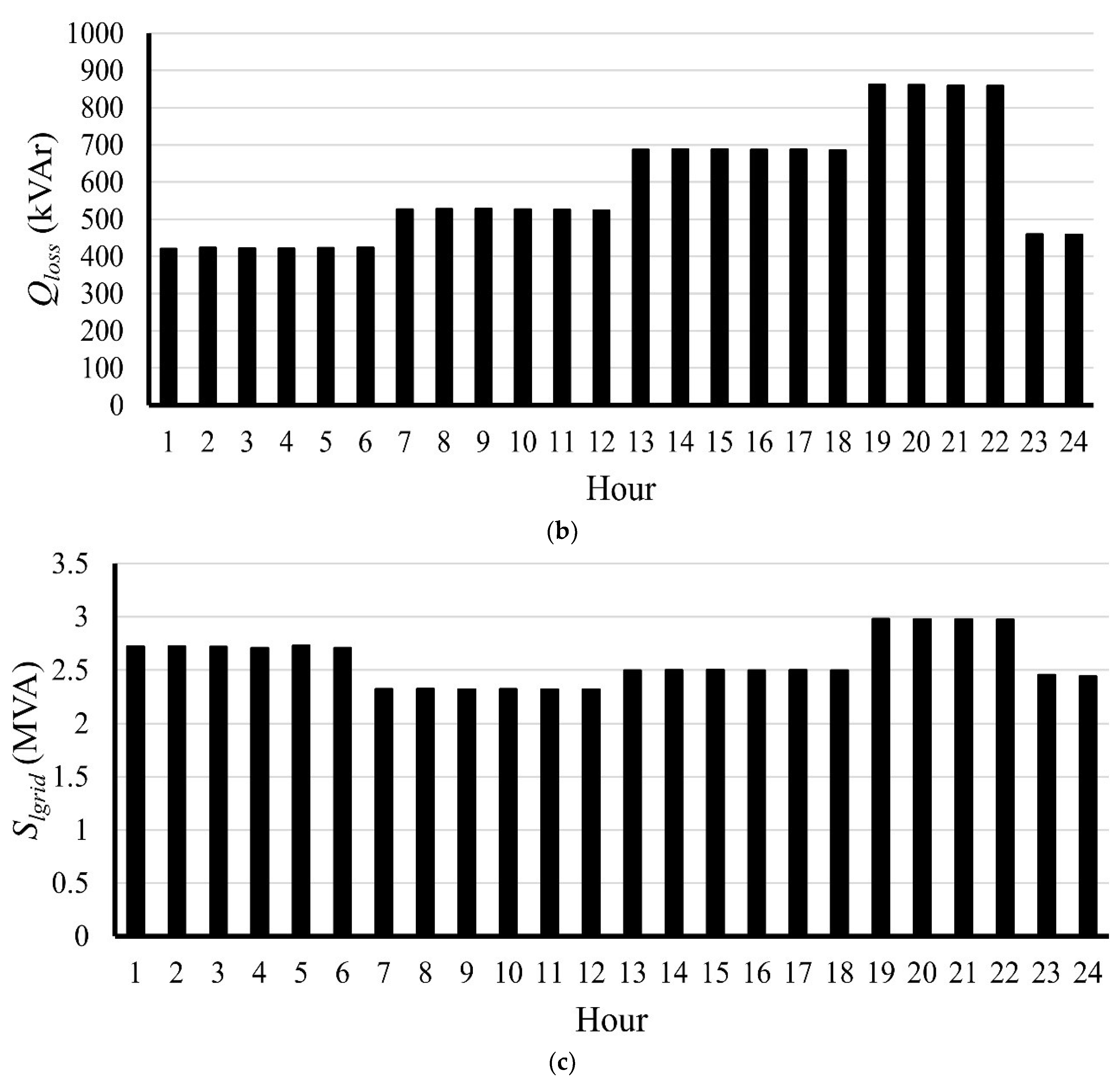

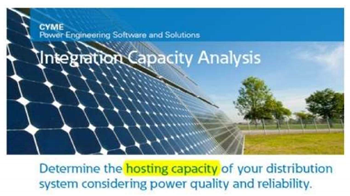

Figure 9a illustrates the minimum values of the bus voltage magnitudes of the uncompensated ETS at hours 4 and 20, respectively, in which hour 4 represents the light loading condition, and hour 20 represents the peak loading condition. In addition,

Figure 9b shows the maximum bus voltage magnitudes at the same chosen hours. Minimum and maximum bus voltage magnitudes were obtained by obtaining minimum and maximum values for the five scenarios per hour. The bus voltage magnitudes can be considered slightly low due to the geographical nature of the system, where the system contains some long branches (about 13 km for branches 3–4 and 4–5). These are the possible locations for the VR, as marked in

Figure 5. Moreover, the branch currents at hour 20 are slightly high due to the peak loading conditions.

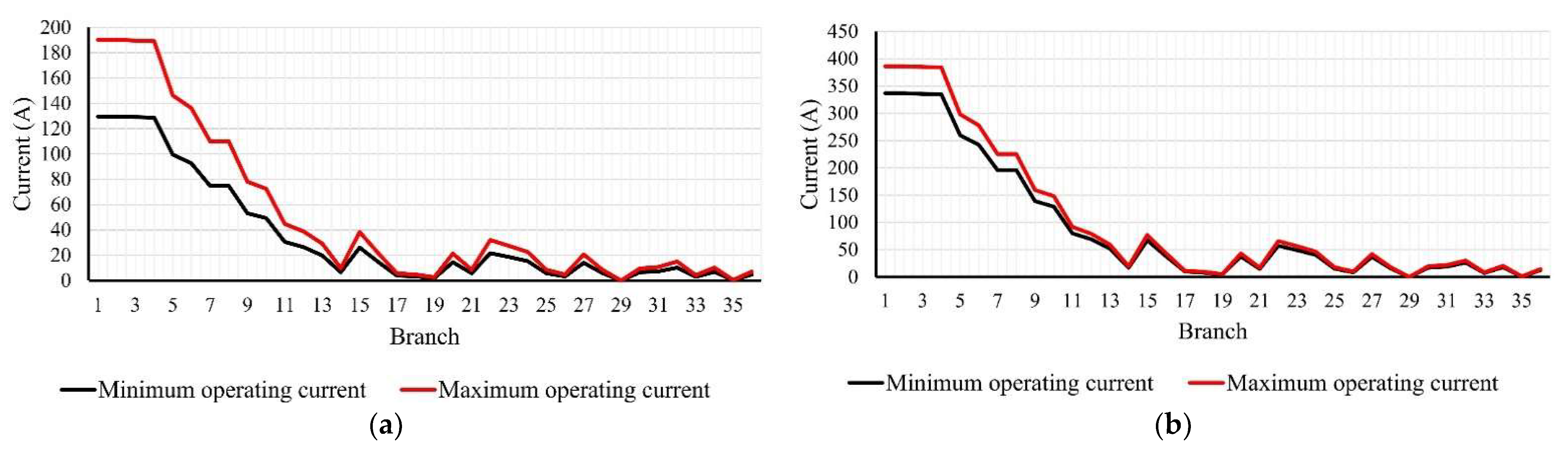

Figure 10 shows the base case system’s current values (minimum and maximum values of each branch current) at the same chosen hours.

5.2. Compensated System

The RUN optimization algorithm has been used to obtain the optimal allocation of the compensators used for the performance enhancement of ETS. In the two cases considered, we assumed that the candidate locations for one VR are (i) between buses 4–5 or (ii) between buses 3–4.

In this case, it was assumed that the DNO has upgraded facilities to deal with the system’s bi-directional power flow, which may occur due to the DGs, and thus reverse power flow might be allowed in the system’s branches. The output results are shown in

Table 5, considering that the candidate location of the VR is before bus 5, while

Table 6 shows the detailed results if the candidate location for the VR is before bus 4.

Although the system operating HC reaches 100% in the two candidate locations for the VR, the real power loss, reactive power loss, and complex power purchased from the grid throughout the day in the first location are less than their corresponding values in the second location, so we decided to visualize the results obtained when using the first VR location.

Figure 11 illustrates the real power loss, reactive power loss, and complex power purchased from the grid throughout the day. It is apparent that the system losses (i.e., active and reactive) and the purchasing power from this grid in the candidate’s two locations are significantly decreased compared with the base case due to the optimal coordination allocation of DG units, CBs, and VRs.

Figure 12a presents the minimum values of the bus voltage magnitudes of the compensated ETS at hours 4 and 20, respectively. Moreover,

Figure 12b shows the maximum bus voltage magnitudes at the same chosen hours.

Figure 13 illustrates the compensated system’s minimum and maximum branch current values at the same investigated hours.

Figure 12 and

Figure 13 present the bus voltage magnitudes and system branch currents after compensation, in which the current of each branch is decreased, and the bus voltage magnitudes are enhanced within the allowable limits. The minimum voltage at hour 4 is improved to 0.9792 p.u, compared to 0.8996 p.u at the base case; and the maximum voltage at hour 4 is increased to 1.0839 p.u (preserved within the acceptable limits), compared to 1.05 p.u at the base case. Moreover, the minimum voltage at hour 20 is improved to 0.9365 p.u, compared to 0.7411 p.u at the base case. The benefits achieved in this case can be summarized as follows: the active power loss is reduced from 14.81 MW in the base case to 1.60 while VR is in its first location and reaches 2.35 MW in the second location, and the reactive power loss is reduced from 20.02 MVAr in the base case to 1.71 MVAr in the first location and becomes 2.76 MVAr in the second location. Besides, the complex power purchased from the utility is significantly decreased in the first location to 70.72 MVA, and 98.83 MVA in the second location, compared with the 121.28 MVA base case.

In addition, at h = 19, the LC of the system is improved to 0.2963 in the first location and 0.4140 in the second location, compared to 0.7320 in the base case. Moreover, the VSImin at the same hour is improved to be 0.9206 in the first location and 0.7155 in the second location, compared to 0.3545 in the base case.

In the first possible VR location, the revenue obtained from power loss and total power reduction is USD 1.3967 million annually. The total saving, defined as compensators’ benefits minus their costs, is annually about USD 0.0127 million.

In this case, it was assumed that the DNO restricts the reverse power flow in the system’s branches. The output results are explored in

Table 7, considering that the suggested location of the VR is between buses 4 and 5, while

Table 8 illustrates the detailed results if the proposed location for the VR is between buses 3 and 4.

Figure 14 shows the real power loss, reactive power loss, and complex power purchased from the grid throughout the day. It can be noted that the system power losses and the power supplied by the utility are higher than their values in the case of allowing reverse power flow, which is accompanied by changing the protection system settings.

Figure 15a shows the minimum values of the bus voltage magnitudes of the compensated ETS while not permitting reverse power flow at hours 4 and 20, respectively. Moreover,

Figure 15b presents the maximum bus voltage magnitudes at the same chosen hours. It can be noted that the minimum voltage magnitude at hour 4 is 0.9823 p.u, compared to 0.8996 p.u at the base case. Moreover, the minimum voltage magnitude at hour 20 is 0.9028 p.u, compared with 0.7411 p.u at the base case.

Figure 16 shows the compensated system’s minimum and maximum branch current values while not allowing reverse power flow at the same hours. At hour 4, the current value of the first branch drops from 190.26 A in the base case to 158.12 A. In addition, at hour 20, the current value for the same branch drops from 386.04 A in the base case to 159.10 A.

The benefits achieved in this case can be summarized as follows: the active power loss is reduced from 14.81 MW in the base case to 12.28 MW while VR is in its first location and reaches 11.41 MW in the second location, and the reactive power loss is reduced from 20.02 MVAr in the base case to 14.17 MVAr in the first location and becomes 12.86 MVAr in the second location. The complex power purchased from the utility is significantly decreased in the first location to 61.97 MVA, and 94.07 MVA in the second location, compared with the 121.28 MVA base case.

In addition, the LC of the system at h = 19 is improved to 0.6920 in the first location and 0.6175 in the second location compared to 0.7320 in the base case. Moreover, the VSImin at the same hour is improved to 0.8651 in the first location, and 0.7390 in the second location, compared to 0.3545 in the base case.

The benefits of power loss and apparent power reduction in the first possible VR location are USD 1.3543 million annually. Moreover, the annual total saving is USD 0.4423 million.

Finally, it should be noted that allowing reverse power flow necessities updating the network protection setting and configurations in the presence of renewables and reverse fault currents. Multiple working groups and researchers worldwide are currently working on analyzing and resolving these issues. Conversely, it would be an oversimplification to say that reverse power flow should be avoided. It was apparent in this work that one of the advantages of allowing this reverse power is increasing the HC to reach 100%, while it only reaches 49% when not permitting it.

6. Conclusions and Future Works

This paper proposes the RUN optimization algorithm to solve the optimal coordination problem between DGs, CBs, and VRs in the studied ETS. The results validate that RUN is an efficient optimization tool due to its high convergence speed and balance between exploration and exploitation in solving engineering optimization problems. The soft fuzzy C-means clustering approach considered daily load variations through different loading conditions (i.e., five loading levels). The objective is to maximize the HC under linear and nonlinear constraints in two cases: the first one allows reverse power flow in the system’s branches, and the second one restricts reverse power flow in the system’s branches. The optimal active and reactive power compensators and voltage regulators have been able to maximize the hosting capacity, reduce the system’s total real and reactive power losses, reduce the bought power from the grid, and improve the loading capability and stability of the system.

The optimal allocation of the different units in the distribution system provides a practical technical and economic benefit to the distribution system. The suggested model successfully allocated the different equipment (DGs, CBs, and VRs) for the two studied scenarios. In the case of allowing reverse power flow to the grid while the VR is before bus five, the costs of the compensators are USD 1.384 million per year, and the benefits gained by power loss and total power reduction are USD 1.3967 million per year; therefore, the total saving, defined as the benefits minus the costs, is USD 0.0127 million per year. In the case of restricting the reverse power flow to the grid while VR is in the same location, the equipment costs are USD 0.912 million per year, and the benefits obtained by power loss and complex power reduction are USD 1.3543 million per year; therefore, the total saving is USD 0.4423 million per year. Significant savings occur due to the optimal coordination allocation of DGs, CBs, and VRs at an acceptable voltage profile. This voltage profile improvement is due to the distribution of the capacitors bank at different laterals. We presented HC solutions with and without permission of reverse power flow, allowing or restricting reverse power flow, and the related protection issues are still under investigation in the Egyptian distribution codes. Finally, the integration of energy storage systems will be considered in future works.