A Study on the Reliability of Mass, Density, and Fire Performance of Recycled Wastepaper Building Finishing Material Made with Large Wet Cellulose 3D Printers

Abstract

1. Introduction

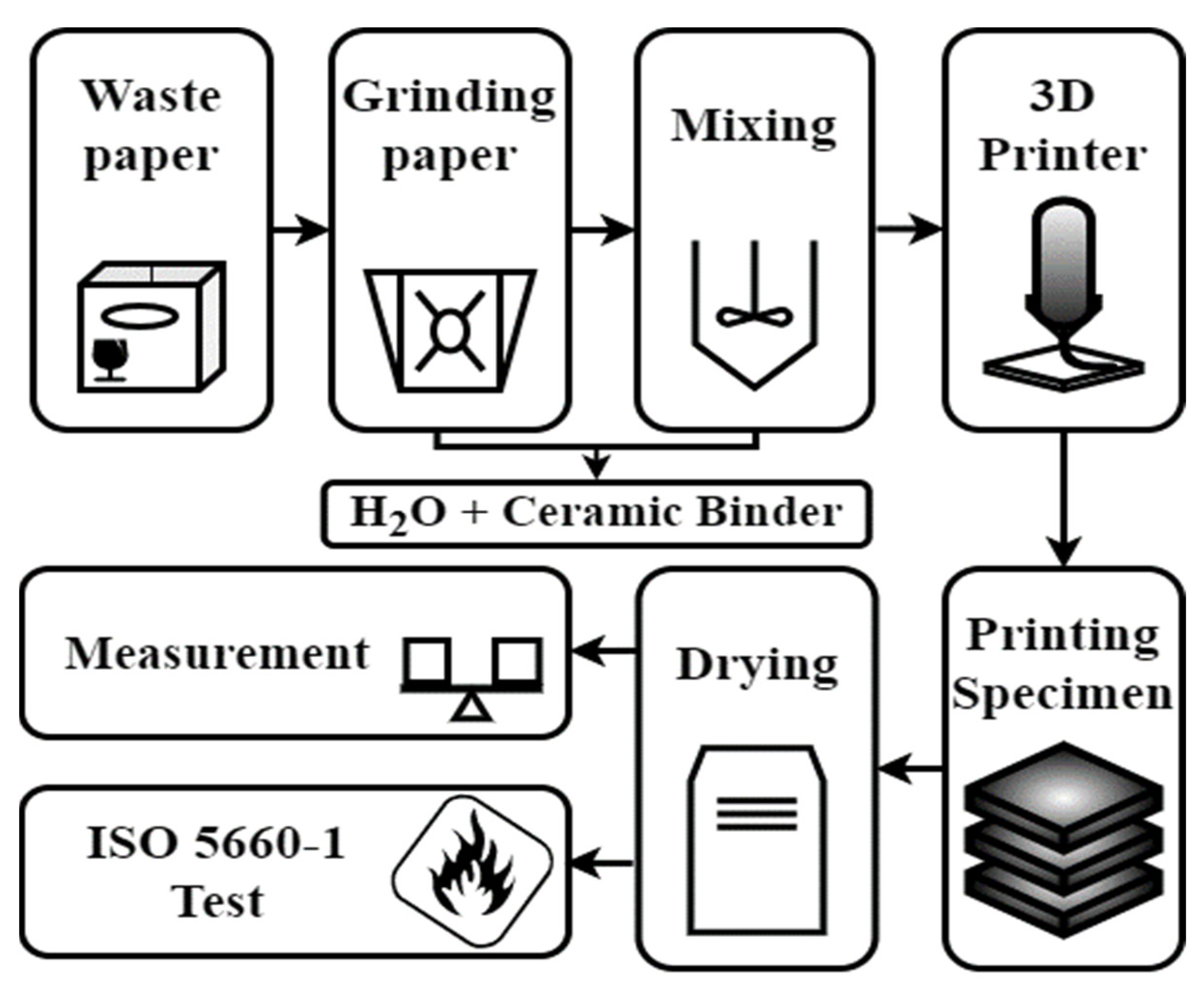

- The grinding of wastepaper;

- The mixing of ceramic binder with water;

- Printing with a 3D printer;

- Drying.

2. Making a Specimen and Physical Characteristics

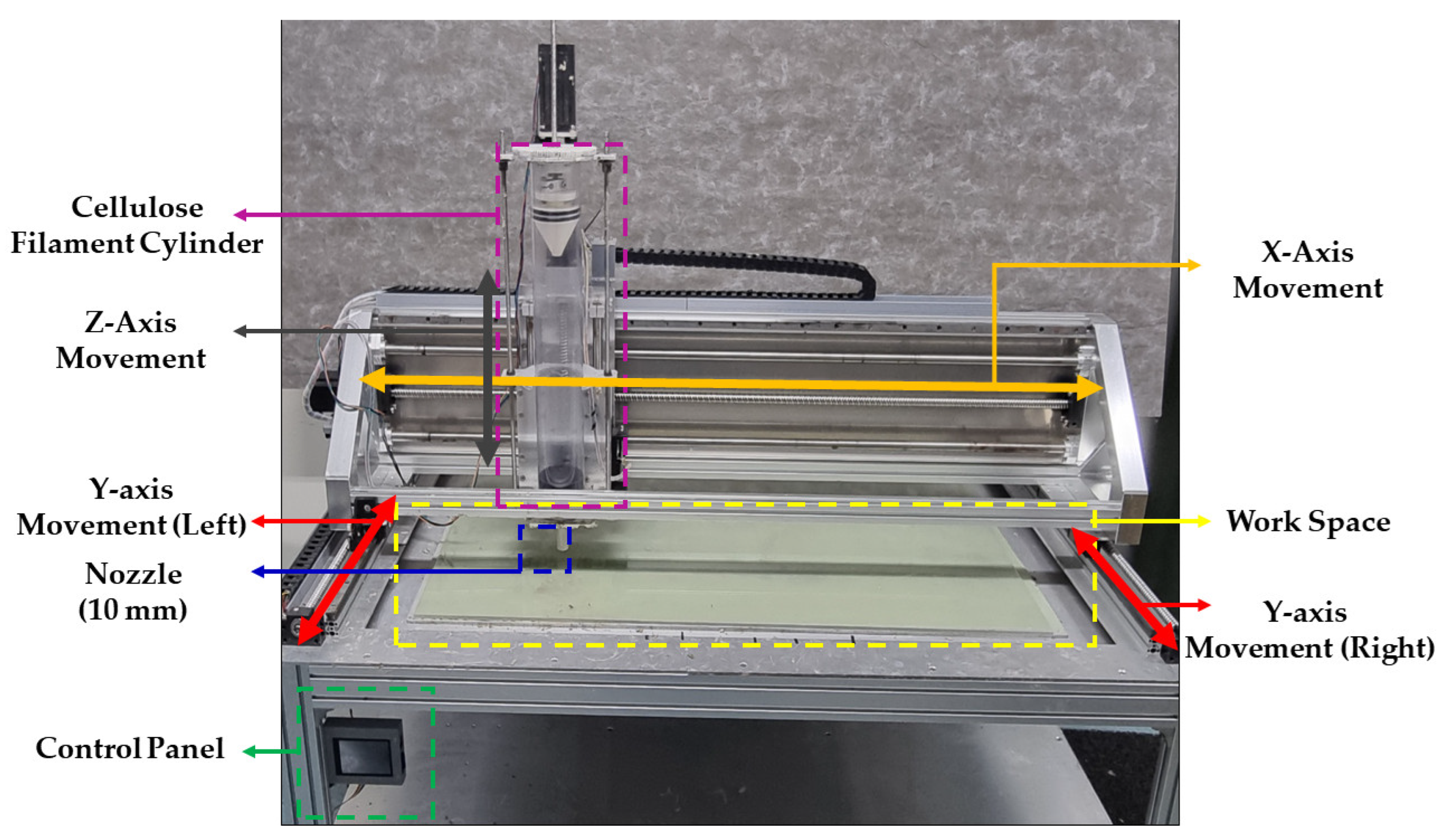

2.1. Wet Cellulose 3D Printer

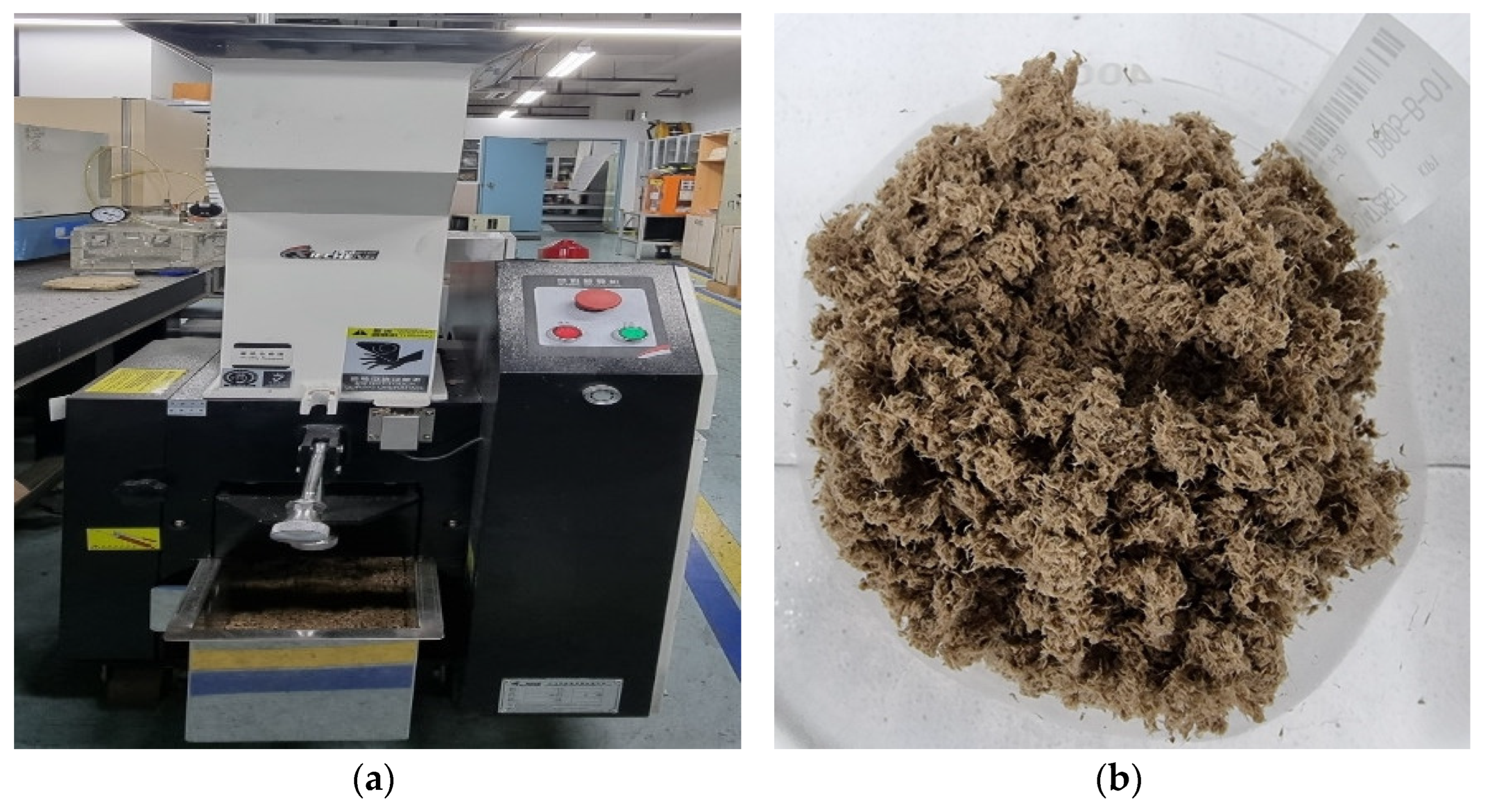

2.2. Cellulose Filament Production

2.3. Wet Cellulose (WC) 3D Printing

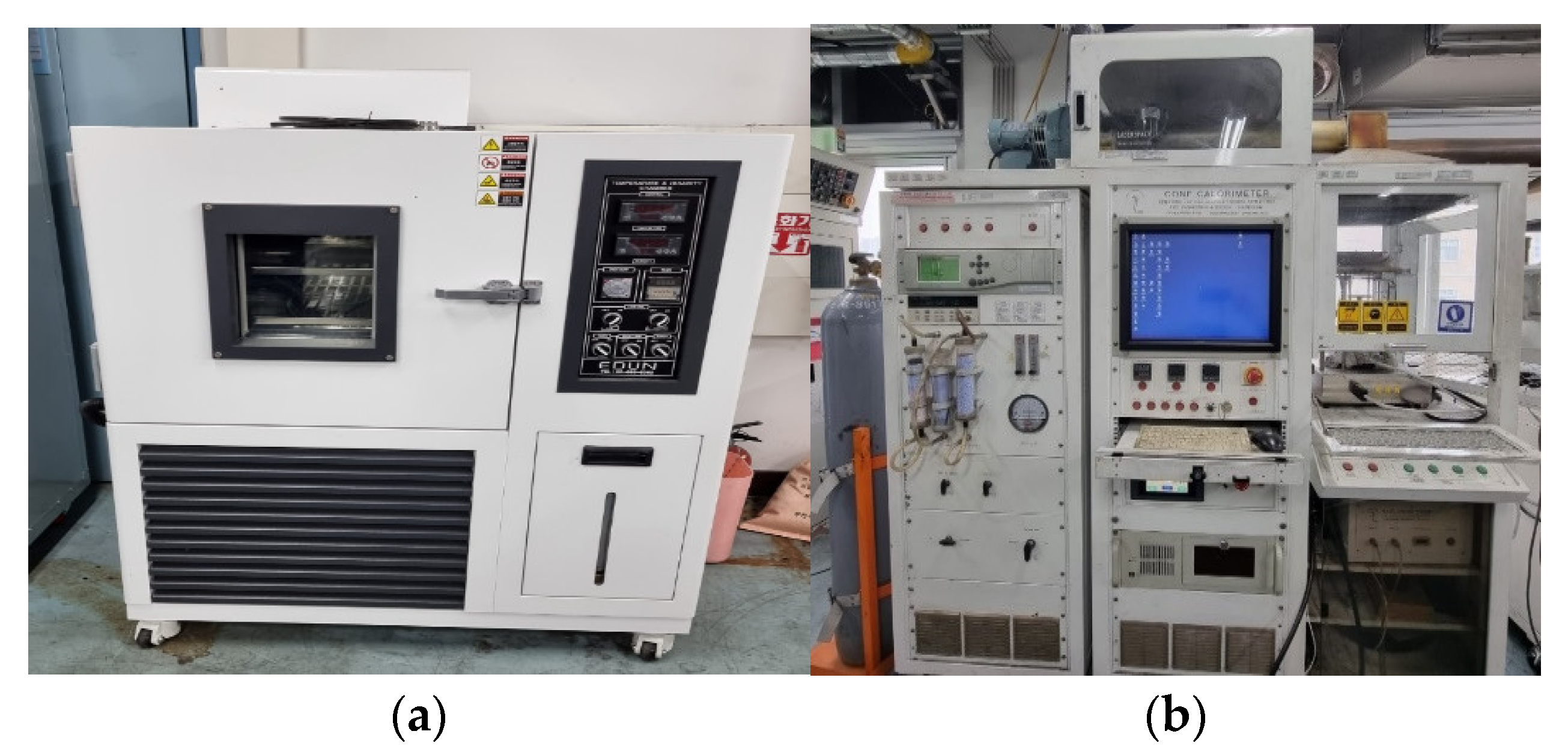

2.4. Description of the Heat Release Rate Test

3. Result of the ISO 5660-1 Test

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Unnikrishnan, A.; Figliozzi, M.A. A Study of the Impact of COVID-19 on Home Delivery Purchases and Expenditure. Publisher Working Paper: 2020. Available online: https://pdxscholar.library.pdx.edu/cengin_fac/557/ (accessed on 6 November 2020).

- “Corona Raid” Had More Than 3.3 Billion Packages Last Year. A 21% Surge. Chosun Biz. Available online: https://biz.chosun.com/site/data/html_dir/2021/02/19/2021021902282.html (accessed on 19 February 2021).

- Ministry of Environment, Korea Environment Corporation. National Waste Generation and Disposal Status. Available online: http://www.kwaste.or.kr/bbs/content.php?co_id=sub0401 (accessed on 16 June 2020).

- The Parcel Shipping Boom Continues. Statista. Available online: https://www.statista.com/chart/10922/parcel-shipping-volume-and-parcel-spend-in-selected-countries/ (accessed on 28 September 2021).

- Yamato Transport Parcel Delivery Figures Hit Record High in October. The Japan Times. Available online: https://www.japantimes.co.jp/news/2020/11/06/business/yamato-transport-parcel-delivery-figures-hit-record-high-october/ (accessed on 6 November 2020).

- IMPACT: Industrial Technologies Program, Summary of Program Results for CY 2009, U.S. Department of Energy, p. 8. Available online: https://www.energy.gov/eere/downloads/impacts-industrial-technologies-program-summary-program-results-cy2009 (accessed on 6 November 2013).

- Resilient U.S. Paper Industry Maintains High Recycling Rate in 2020. American Forest & Paper Association. Available online: https://www.afandpa.org/news/2021/resilient-us-paper-industry-maintains-high-recycling-rate-2020 (accessed on 13 May 2021).

- Stawicki, B.; Read, B. The Future of Paper Recycling in Europe: Opportunities and Limitations, 2010 The Final Report of COST Action E48. Bury, UK: The Paper Industry Technical Association (PITA), p.202. Available online: https://www.cost.eu/publication/the-future-of-paper-recycling-in-europe-opportunities-and-limitations/ (accessed on 16 June 2022).

- Suseno, N. Utilization of Rice Straw and Used Paper for the Recycle Papermaking. IOP Conf. Ser. Mater. Sci. Eng. 2019, 703, 012044. [Google Scholar] [CrossRef]

- Raut, S.; Sedmake, R.; Dhunde, S.; Ralegaonkar, R.; Mandavgane, S.A. Reuse of recycle paper mill waste in energy absorbing light weight bricks. Constr. Build. Mater. 2012, 27, 247–251. [Google Scholar] [CrossRef]

- Pathak, C.S. Application of recycle paper mill waste (rpmw) as a thermal insulation material. Waste Biomass Valoriz. 2019, 10, 2343–2352. [Google Scholar] [CrossRef]

- Astrauskas, T. Method to recycle paper sludge waste: Production of panels for sound absorption applications. Environ. Clim. Technol. 2020, 24, 364–372. [Google Scholar] [CrossRef]

- Barakat, N. Fire at Address Hotel on New Year’s Eve Caused by Electrical Fault: Dubai Police. Available online: https://gulfnews.com/news/uae/emergencies/fire-at-address-hotel-on-new-year-seve-caused-by-electrical-fault-dubai-police-1.1656786 (accessed on 8 July 2018).

- WootLiff, R. Hundreds of Israeli Buildings ‘as Vulnerable’ as London’s Grenfell Tower. Available online: https://www.timesofisrael.com/hundreds-israeli-buildings-as-vulnerable-as-londons-grenfell-tower/ (accessed on 26 June 2017).

- Chen, T.B.Y.; Yuen, A.C.Y.; Yeoh, G.H.; Yang, W.; Chan, Q.N. Fire Risk Assessment of Combustible Exterior Cladding Using a Collective Numerical Database. Fire 2019, 2, 11. [Google Scholar] [CrossRef]

- Kwon, S.A.; Lee, J.; Yong, U.B.; Lee, H.-J.; You, S.; Yoo, H.J. Safety Measure for Overcoming Fire Vulnerability of Multiuse Facilities—A Comparative Analysis of Disastrous Conflagrations between Miryang and Jecheon. Crisisonomy 2018, 14, 149–167. [Google Scholar] [CrossRef]

- Lee, E.-P. Analysis of the Causes of Casualties of Jecheon Sports Center Fire—Focus on an Initial Response and Management. Fire Sci. Eng. 2018, 32, 57–66. [Google Scholar] [CrossRef]

- Cladding Risks Raised by Melbourne Fire Brigade before Neo200 Blaze, but Council Deemed Risk ‘Low’. ABC News. Available online: https://www.abc.net.au/news/2019-06-23/melbourne-city-councilneo200-advice-before-fire-at-tower/11225992 (accessed on 23 June 2019).

- Yeom, G.-W. A Study on the Policy Measures for the Prevention of Large Fire Accidents—Focused on fire accidents at Icheon Logistics Warehouse. Law Rev. 2020, 20, 399–419. Available online: https://kiss.kstudy.com/thesis/thesis-view.asp?key=3810023 (accessed on 28 December 2020).

- Cho, H.J. Analysis of fires case through on-field survey of residential and commercial building in Ulsan. In Proceedings of the Korean Institute of Building Construction Conference; The Korean Institute of Building Construction: Seoul, Korea, 2021; pp. 84–85. Available online: https://www.koreascience.or.kr/article/CFKO202132648239396.page (accessed on 28 December 2020).

- Dowling, V.P.; Ramsay, G.C. Recent Approaches to Regulating the Fire Performance of Materials in Buildings; Fire Code Reform Centre: Sydney, Australia, 1995; pp. 29–30. [Google Scholar]

- Hakkarainen, T.; Hayashi, Y. Comparison of Japanese and European Fire Classification Systems for Surface Linings. Fire Sci. Technol. 2001, 21, 19–42. [Google Scholar] [CrossRef]

- Ministry of Land. Infrastructure and Transport. Code for the Flame—Retardant Performance of Building Finishing Materials and the Fire Preventing Structure. No. 2022-1106. 2022. Available online: https://www.law.go.kr/admRulLsInfoP.do?chrClsCd=&admRulSeq=2100000195901 (accessed on 28 December 2020).

- Naser, M.Z.; Thavarajah, P. Ceramic Tiles as Sustainable, Functional and Insulating Materials to Mitigate Fire Damage. Adv. Appl. Ceram. 2021, 120, 227–239. [Google Scholar] [CrossRef]

- Xu, F.; Zhang, H.; Wu, J. Synergistic Catalytic Flame Retardant Effect of Zirconium Phosphate on the Poplar Plywood. Constr. Build. Mater. 2021, 290, 123208. [Google Scholar] [CrossRef]

- Chun, K.; Kim, J.; Rie, D. Thermal Characteristics of Expandable Graphite–Wood Particle Composites. Materials 2020, 13, 2732. [Google Scholar] [CrossRef] [PubMed]

- Beh, J.H.; Yew, M.C.; Saw, L.H. Fire Protection Performance and Thermal Behavior of Thin Film Intumescent Coating. Coatings 2019, 9, 483. [Google Scholar] [CrossRef]

- Li, P.; Zhang, Y.; Zuo, Y.; Lu, J.; Yuan, G.; Wu, Y. Preparation and Characterization of Sodium Silicate Impregnated Chinese Fir Wood with High Strength, Water Resistance, Flame Retardant and Smoke Suppression. J. Mater. Res. Technol. 2020, 9, 1043–1053. [Google Scholar] [CrossRef]

- Lim, Y.S. A Study on the Influence and Potential of a 3D Printerin the Design and Construction Processesof the Architectural Industry; Yonsei University Department Architectureal Engineering, 2015; Available online: http://www.riss.kr/link?id=T13872996 (accessed on 28 December 2020).

- Seung, I.-B.; Baek, H.-S.; Park, J.-H. Overseas Case Study of 3D Printing Technology for Construction and Commercialization Plan in Korea. J. Korean Soc. Ind. Converg. 2018, 21, 273–284. [Google Scholar] [CrossRef]

- Hwang, J.; Park, D.; Kim, S.; Rie, D. A Study on the Flame-Retardant Performance of Recycled Paper Building Materials Manufactured by 3D Printer. Sustainability 2022, 14, 4798. [Google Scholar] [CrossRef]

- ISO 5660-1; Reaction-to-Fire Tests. Heat Release, Smoke Production and Mass Loss Rate. Part 1, Heat Release Rate (Cone Calorimeter Method) and Smoke Production Rate (Dynamic Measurement). International Organization for Standardization: Geneva, Switzerland, 2015.

| Country | Korea | UK | Germany | United States | Japan |

|---|---|---|---|---|---|

| Increase rate | 20.93% | 32% | 11% | 37% | 20.7% |

| Date | Casualties | Fire Location | Country | Reference No. | |

|---|---|---|---|---|---|

| Death | Injury | ||||

| 2015. 12 | - | 15 | The address downtown | Dubai (UAE) | [13] |

| 2016. 06 | 79 | - | Ramat Gan (a residential high-rise building) | Israel | [14] |

| 2017. 06 | 80 | 70 | Granfell Tower | UK | [15] |

| 2017. 12 | 29 | 37 | Jecheon Sports Center | Korea | [16,17] |

| 2019. 02 | - | 1 | Neo 200 building | Australia | [18] |

| 2020. 04 | 38 | 10 | Icheon warehouse | Korea | [19] |

| 2020. 10 | - | 91 | Ulsan mixed-use apartment | Korea | [20] |

| Mechanical | ||

| Main body size | 1.4 m × 1.4 m × 0.7 m | |

| Motor frame Size | Axis motor | 57 mm |

| Extrusion motor | 57 mm | |

| Motor step angle | Axis motor | 1.8° (±5%, full step) |

| Extrusion motor | 1.8° (±5%, 2-Phase) | |

| Power specification | 10 A, 250 V | |

| Printing | ||

| Zero adjustment | X, Y axes | Limit Sensor |

| Z axis | BL Touch sensor | |

| Nozzle diameter | 10 mm | |

| Extrusion method | Use of cylinder upper lead screw rotational force | |

| Software | ||

| Program | Design 123D, Cura 15.04.6 | |

| File format | G-code, STL | |

| Specimen Name | Basic Material | Flame Retardant | Wetting Agent | Flocculent |

|---|---|---|---|---|

| Wastepaper | Ceramic Binder | Water | PAM | |

| A | 100 (100) | 0 (0) | 500 | 5 |

| B | 100 (83.34) | 20 (16.67) | 750 | |

| C | 100 (76.92) | 30 (23.07) | 800 | |

| D | 100 (71.42) | 40 (28.57) | 850 | |

| E | 100 (66.67) | 50 (33.33) | 900 |

| Category | Before Drying | Drying | After Drying |

|---|---|---|---|

| Specimen (ISO 5660-1) |  |  |  |

| Specimen Name | Specimen No. | Weight (g) | Density (g/cm3) | ||

|---|---|---|---|---|---|

| Before Drying | After Drying | Before Drying | After Drying | ||

| A | 1 | 317 | 60 | 0.87 | 0.25 |

| 2 | 321 | 60 | 0.88 | 0.26 | |

| 3 | 319 | 59 | 0.88 | 0.24 | |

| B | 1 | 317 | 60 | 0.77 | 0.21 |

| 2 | 323 | 60 | 0.72 | 0.22 | |

| 3 | 326 | 60 | 0.82 | 0.23 | |

| C | 1 | 380 | 74 | 0.88 | 0.27 |

| 2 | 370 | 73 | 0.86 | 0.27 | |

| 3 | 382 | 76 | 0.88 | 0.26 | |

| D | 1 | 385 | 87 | 0.89 | 0.34 |

| 2 | 381 | 86 | 0.88 | 0.33 | |

| 3 | 378 | 86 | 0.81 | 0.34 | |

| E | 1 | 389 | 88 | 0.86 | 0.32 |

| 2 | 384 | 87 | 0.85 | 0.31 | |

| 3 | 384 | 89 | 0.87 | 0.33 | |

| Specimen Name | Standard Deviation | |||

|---|---|---|---|---|

| Weight (g) | Density (g/cm3) | |||

| Before Drying | After Drying | Before Drying | After Drying | |

| A | 2 | 0.57 | 0.005 | 0.01 |

| B | 4.58 | 0 | 0.05 | 0.01 |

| C | 6.42 | 1.52 | 0.01 | 0.005 |

| D | 3.51 | 0.57 | 0.04 | 0.005 |

| E | 2.88 | 1 | 0.01 | 0.01 |

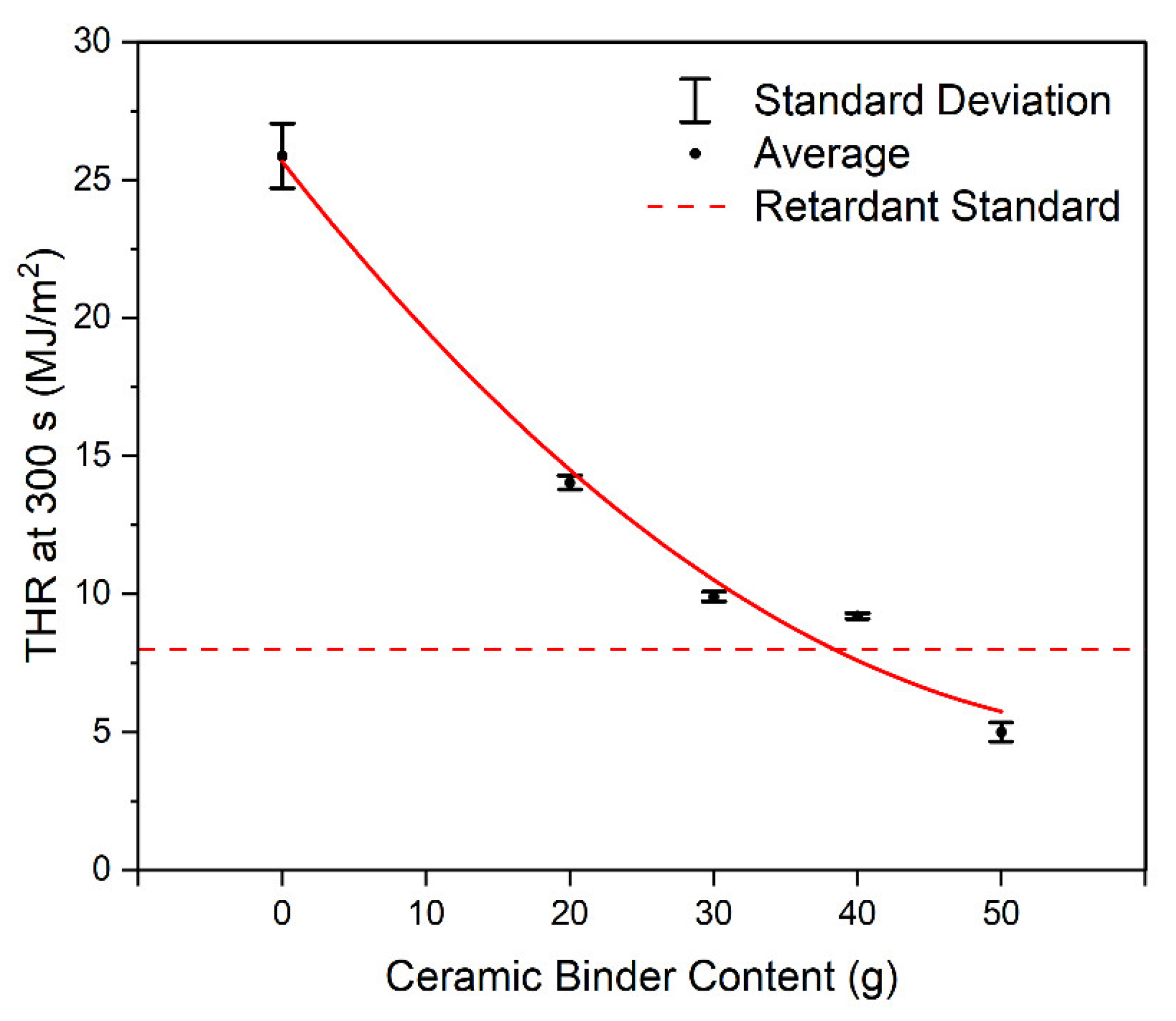

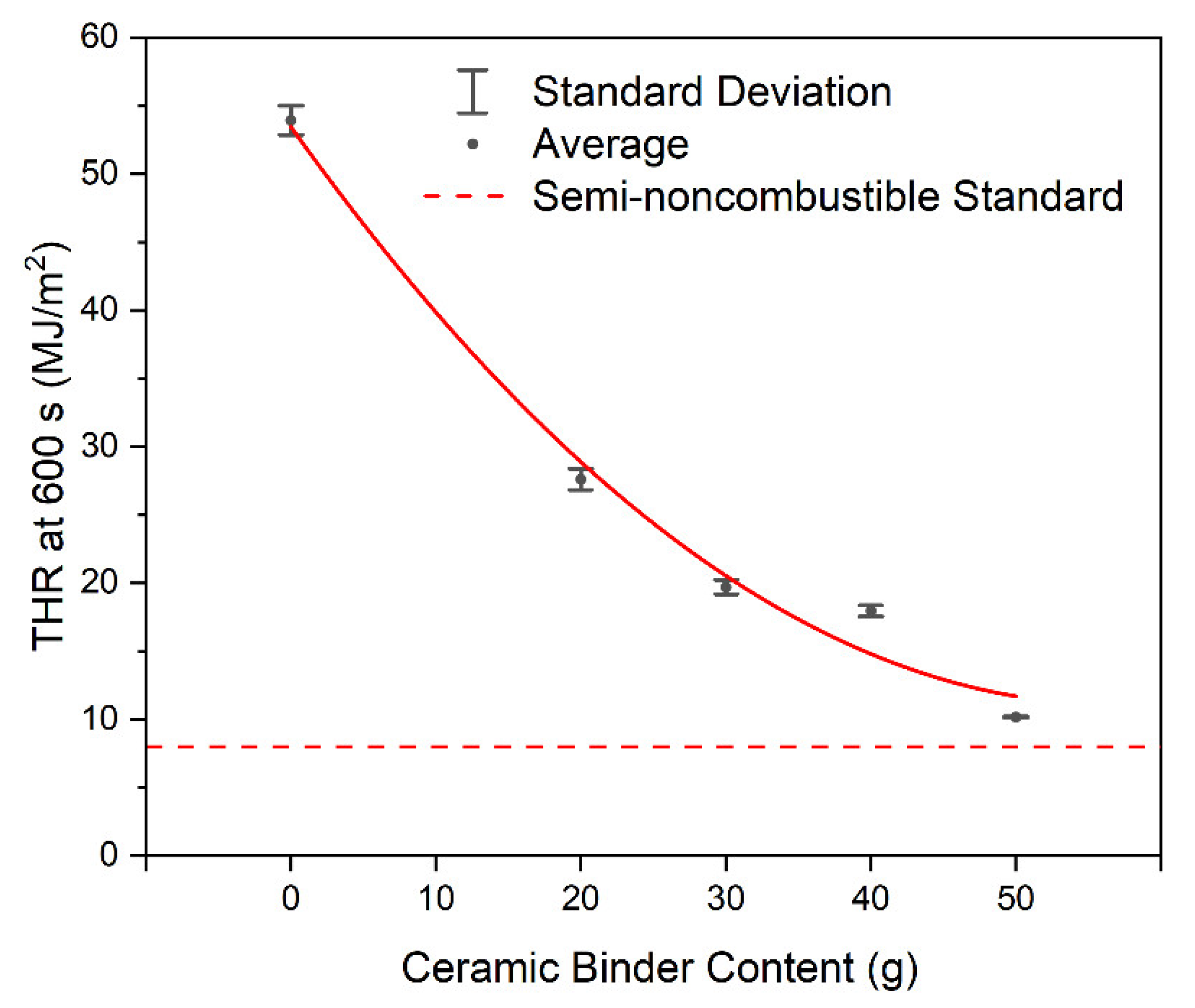

| Standard | Class | Evaluation Criteria |

|---|---|---|

| ISO 5660-1 (cone calorimeter method) | Semi- non-combustible material | The total radiant heat 10 min after heating is 8 MJ/m². Within 10 min, the max. heat radiant rate does not exceed 200 kW/m² for longer than 10 consecutive seconds. There shall not be crack that penetrates sample, hole, or melting (for mixed content materials, which includes the melting and dissipation of all core materials) after heating for 10 min. |

| ISO 5660-1 (cone calorimeter method) | Fire-retardant material | Total radiant heat 5 min after heating is 8 MJ/m². Within 5 min, the max. heat radiant rate does not exceed 200 kW/m² for longer than 10 consecutive seconds. There shall not be crack that penetrates sample, hole, or melting (for mixed content materials, which includes the melting and dissipating of all core materials) after heating for 10 min. |

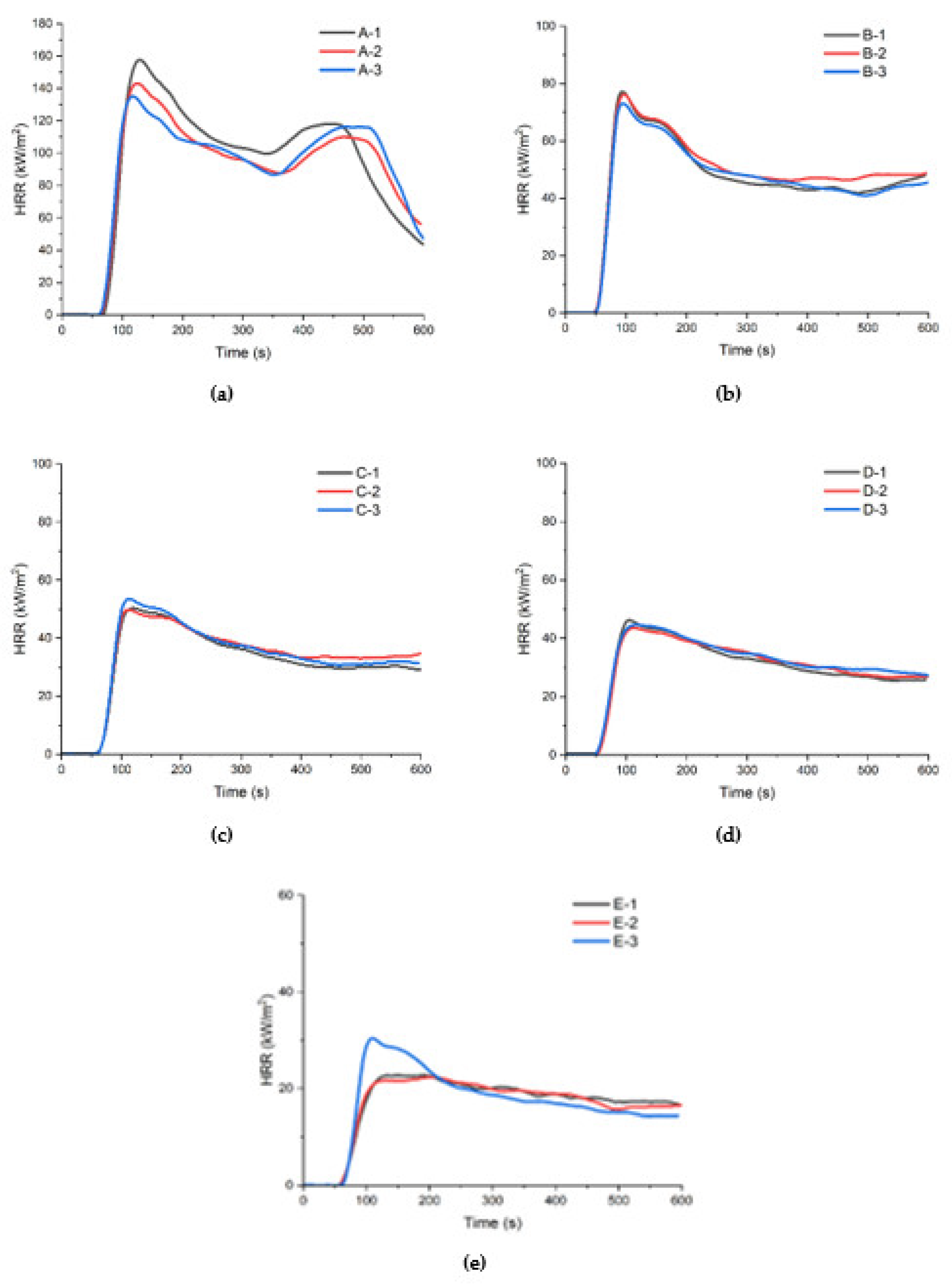

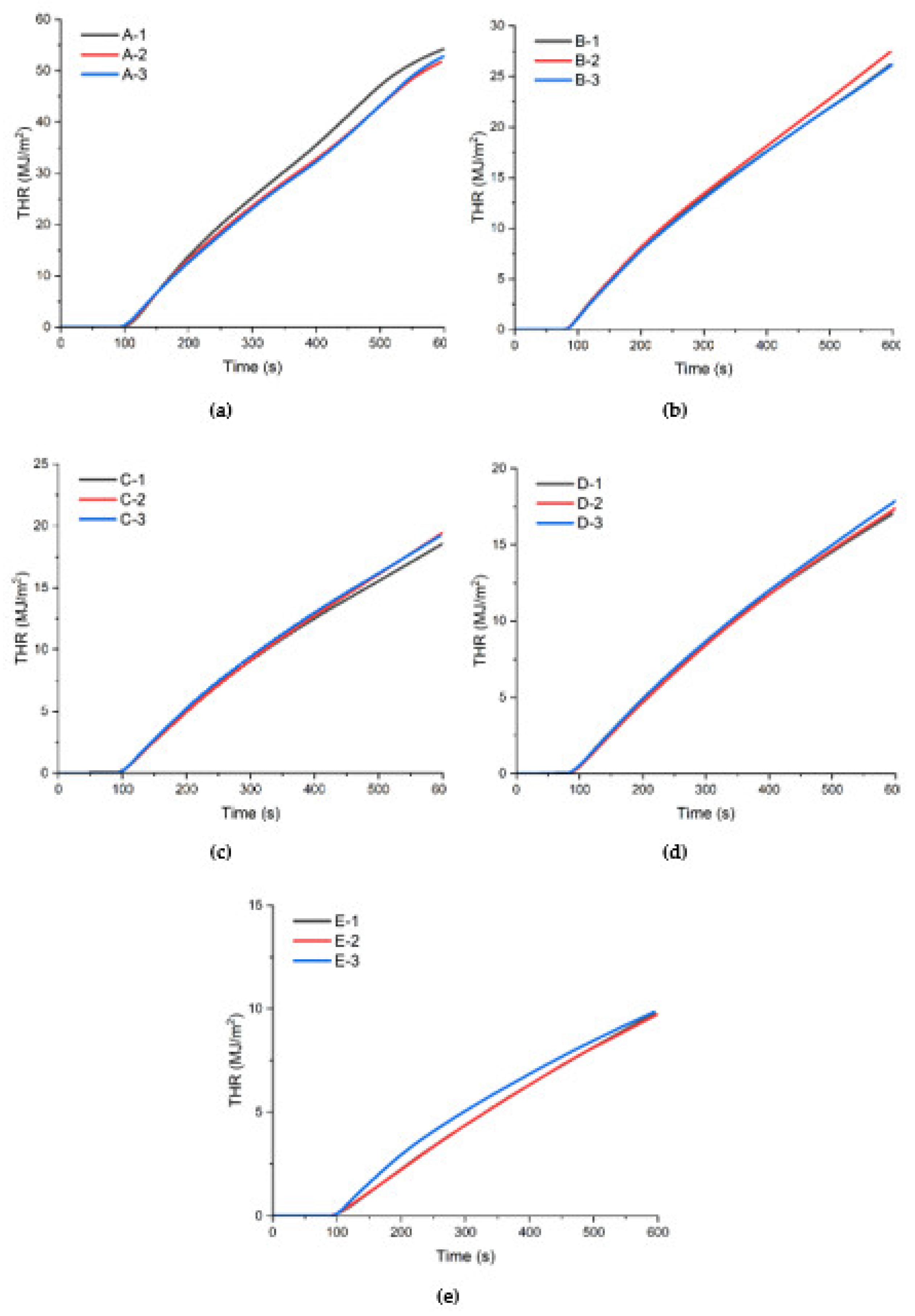

| Name. | No. | PHRR (kW/m2) | Standard Deviation (PHRR) | THR (MJ/m2) | Standard Deviation (THR) | ||

|---|---|---|---|---|---|---|---|

| at 300 s | at 600 s | at 300 s | at 600 s | ||||

| A | 1 | 160.42 | 11.44 | 27.2 | 55.1 | 1.17 | 1.06 |

| 2 | 145.65 | 25.4 | 53.0 | ||||

| 3 | 137.9 | 25.0 | 53.7 | ||||

| B | 1 | 79.89 | 2.64 | 14.0 | 27.3 | 0.25 | 0.79 |

| 2 | 79.08 | 14.3 | 28.5 | ||||

| 3 | 74.96 | 13.8 | 27.0 | ||||

| C | 1 | 51.05 | 2.10 | 9.8 | 19.1 | 0.17 | 0.52 |

| 2 | 50.79 | 9.8 | 20.1 | ||||

| 3 | 54.56 | 10.1 | 19.9 | ||||

| D | 1 | 47.11 | 1.58 | 9.2 | 17.6 | 0.1 | 0.40 |

| 2 | 43.96 | 9.1 | 17.9 | ||||

| 3 | 45.19 | 9.3 | 18.4 | ||||

| E | 1 | 23.18 | 5.09 | 4.8 | 10.2 | 0.34 | 0.05 |

| 2 | 22.57 | 4.8 | 10.1 | ||||

| 3 | 31.68 | 5.4 | 10.2 | ||||

| Specimen Type | Average (kW/m2) | SD (kW/m2) | RSD (%) |

|---|---|---|---|

| A | 147.99 | 11.44 | 7.73 |

| B | 77.97 | 2.64 | 3.39 |

| C | 52.13 | 2.10 | 4.03 |

| D | 45.42 | 1.58 | 3.49 |

| E | 25.81 | 5.09 | 19.72 |

| Name. | Average (MJ/m2) | SD (MJ/m2) | RSD (%) |

|---|---|---|---|

| A | 25.86 | 1.17 | 4.53 |

| B | 14.03 | 0.25 | 1.79 |

| C | 9.9 | 0.17 | 1.74 |

| D | 9.2 | 0.1 | 1.08 |

| E | 5 | 0.34 | 6.8 |

| Name. | Average (MJ/m2) | SD (MJ/m2) | RSD (%) |

|---|---|---|---|

| A | 53.93 | 1.06 | 1.98 |

| B | 27.6 | 0.79 | 2.87 |

| C | 19.7 | 0.52 | 2.68 |

| D | 17.96 | 0.40 | 2.24 |

| E | 10.16 | 0.05 | 0.56 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ahn, C.; Park, D.; Hwang, J.; Rie, D. A Study on the Reliability of Mass, Density, and Fire Performance of Recycled Wastepaper Building Finishing Material Made with Large Wet Cellulose 3D Printers. Sustainability 2022, 14, 13090. https://doi.org/10.3390/su142013090

Ahn C, Park D, Hwang J, Rie D. A Study on the Reliability of Mass, Density, and Fire Performance of Recycled Wastepaper Building Finishing Material Made with Large Wet Cellulose 3D Printers. Sustainability. 2022; 14(20):13090. https://doi.org/10.3390/su142013090

Chicago/Turabian StyleAhn, Chansol, Dongin Park, Jeo Hwang, and Dongho Rie. 2022. "A Study on the Reliability of Mass, Density, and Fire Performance of Recycled Wastepaper Building Finishing Material Made with Large Wet Cellulose 3D Printers" Sustainability 14, no. 20: 13090. https://doi.org/10.3390/su142013090

APA StyleAhn, C., Park, D., Hwang, J., & Rie, D. (2022). A Study on the Reliability of Mass, Density, and Fire Performance of Recycled Wastepaper Building Finishing Material Made with Large Wet Cellulose 3D Printers. Sustainability, 14(20), 13090. https://doi.org/10.3390/su142013090