Green Defense Industries in the European Union: The Case of the Battle Dress Uniform for Circular Economy

Abstract

1. Introduction

2. Materials and Methods

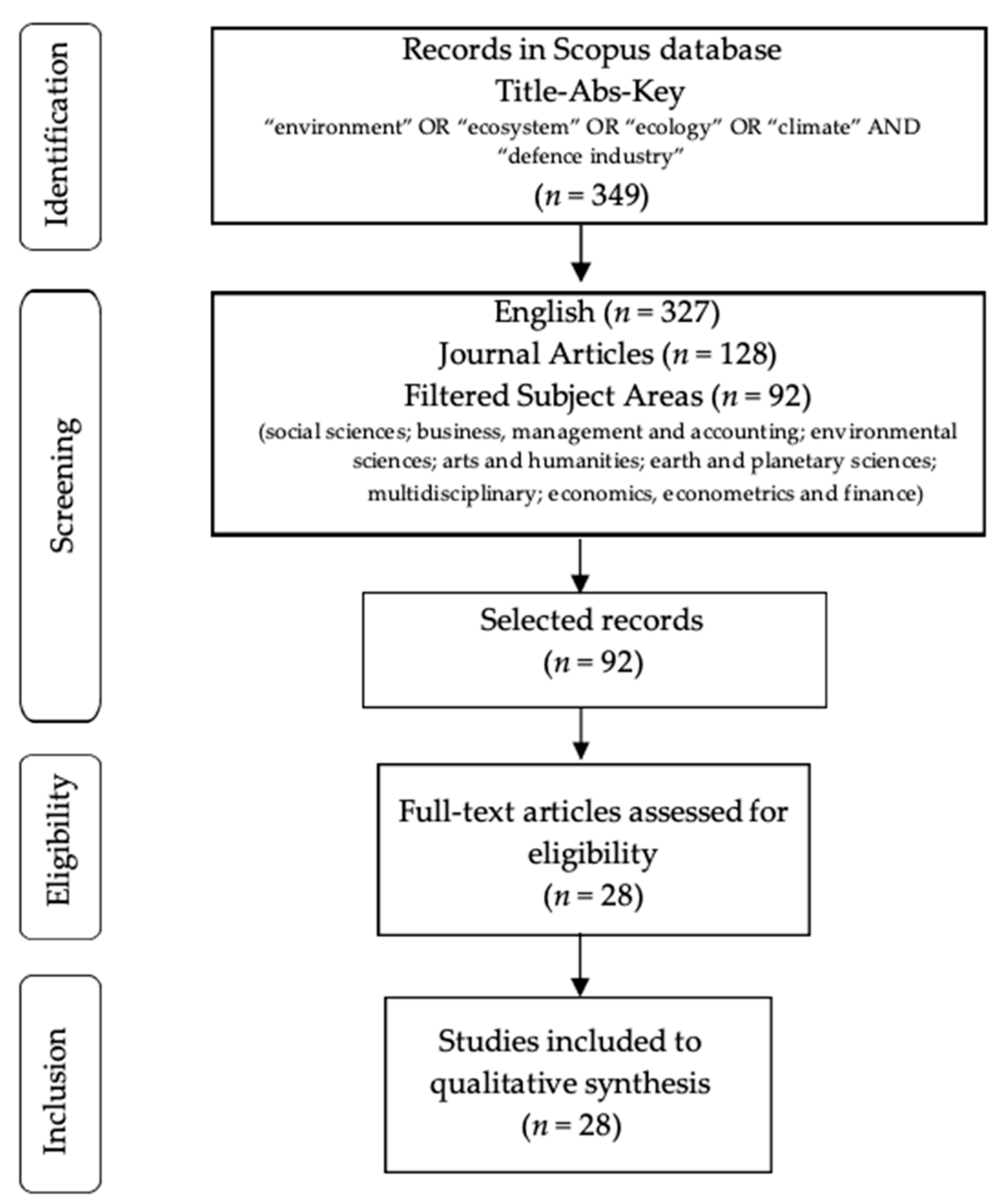

2.1. Systematic Literature Review

2.2. Case Study Research

2.3. Data Extraction, Synthesis and Analysis

3. Results and Discussion

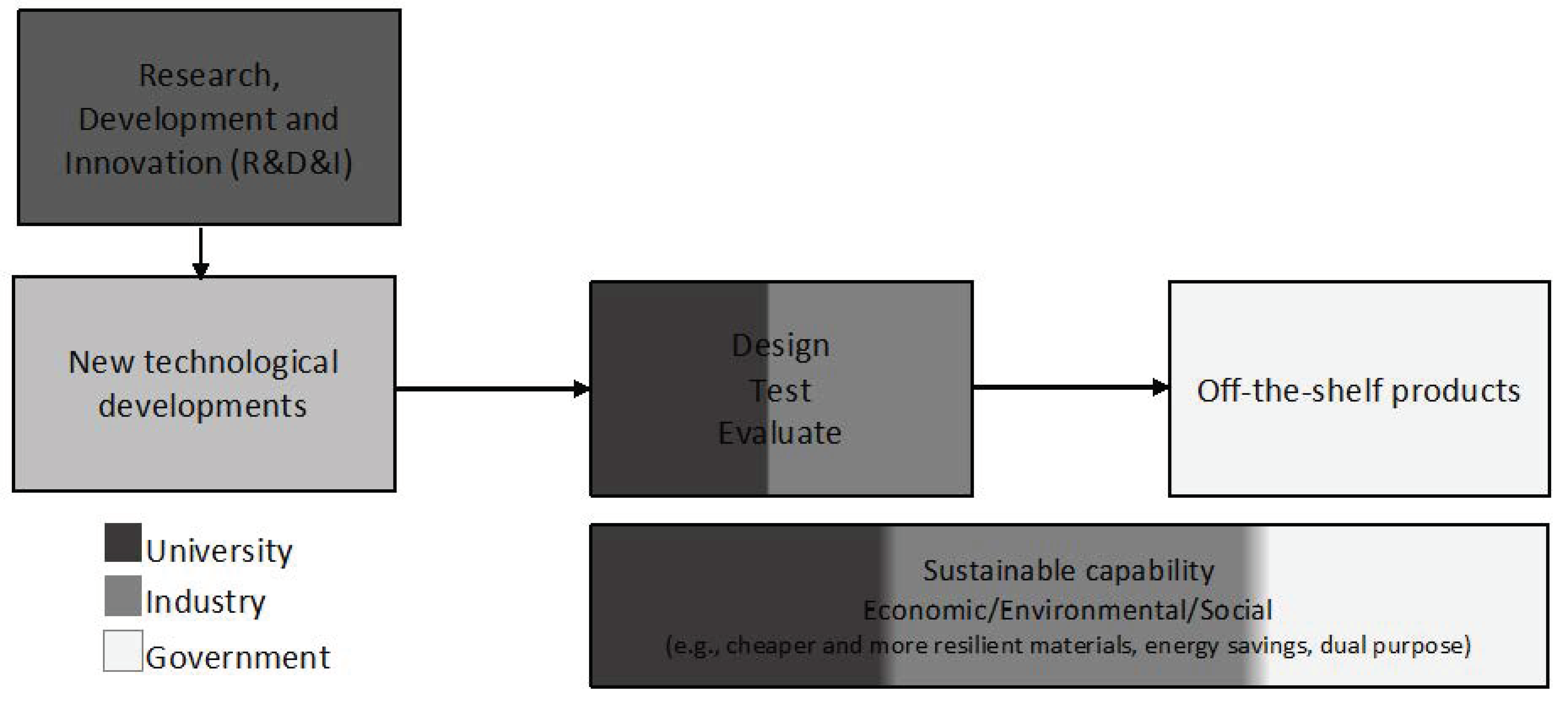

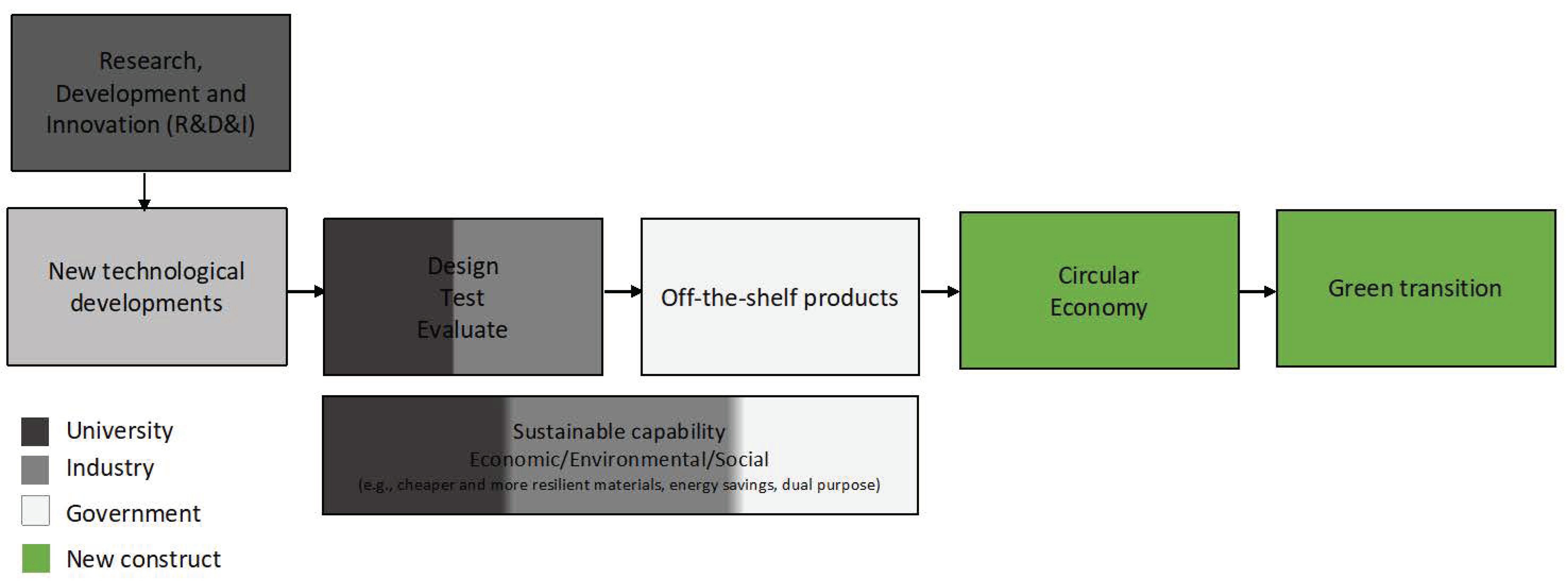

3.1. Conceptual Framework

3.2. Circular Economy: Going Back to the Literature

3.3. Green Defense Industry: An Empirical Framework

4. Conclusions

4.1. Theoretical and Managerial Contributions

4.2. Future Research Avenues

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- EDA. Consultation Forum for Sustainable Energy in the Defence and Security Sector (CF SEDSS). Available online: https://eda.europa.eu/docs/default-source/events/eden/phase-i/final-report/consultation-forum-for-sustainable-energy-in-the-defence-and-security-sector---final-report.pdf (accessed on 4 September 2022).

- Fiott, D. Reducing the Environmental Bootprint? Competition and Regulation in the Greening of Europe’s Defense Sector. Organ. Environ. 2014, 27, 263–278. [Google Scholar] [CrossRef]

- European Commission. Communication from the Commission to the European Parliament, the European Council, the Council, the European Economic and Social Committee and the Committee of the Regions—European Defence Action Plan. Available online: https://eur-lex.europa.eu/legal-content/en/txt/pdf/?uri=celex:52016dc0950&from=en (accessed on 7 September 2022).

- Lopes da Silva, D.; Tian, N.; Béraud-Sudreau, L.; Marksteiner, A.; Liang, X. Trends in World Military Expenditure, 2021; Stockholm International Peace Research Institute: Stockholm, Sweden, 2022. [Google Scholar]

- European Commission. Defence Industry: EU Takes Steps to Invest Almost €1.2 Billion to Support 61 Defence Industrial Cooperation Projects. Available online: https://ec.europa.eu/commission/presscorner/detail/en/ip_22_4595 (accessed on 2 September 2022).

- Stjepanović, S.; Tomić, D.; Škare, M. A new approach to measuring green GDP: A cross-country analysis. Entrep. Sustain. Issues 2017, 4, 574–590. [Google Scholar] [CrossRef]

- GGEI (Global Green Economy Index). Green Policy Platform. 2018. Available online: https://www.greengrowthknowledge.org/research/2018-global-green-economy-index-ggei (accessed on 24 September 2022).

- GGGI. Green Growth Index: Concepts, Methods and Applications. GGGI Technical Report, Nº 5, Global Green Growth Institute. Available online: https://greengrowthindex.gggi.org/wp-content/uploads/2019/12/Green-Growth-Index-Technical-Report_20191213.pdf (accessed on 24 September 2022).

- Carrone, N.; Lagunes, L.; Duijn, H.; Wilting, J.; Novak, M.; Metta, J.; Goesaert, T.; Bachus, K. Putting Circular Textiles to Work: The employment potential of circular clothing in the Netherlands. Goldschmeding Foundation. Available online: https://assets.website-files.com/5d26d80e8836af2d12ed1269/60d484479ef55512ac50d615_20210624%20-%20CJI%20Tex%20skills%20-%20paper%20-%20297x210mm.pdf (accessed on 23 September 2022).

- Kuhlman, T.; Farrington, J. What is sustainability? Sustainability 2010, 2, 3436–3448. [Google Scholar] [CrossRef]

- Vallance, S.; Perkins, H.; Dixon, J. What is social sustainability? A clarification of concepts. Geoforum 2011, 42, 342–348. [Google Scholar] [CrossRef]

- Wigell, M.; Hakala, E. Towards a Greener Defence: An Introduction. In Innovative Technologies and Renewed Policies for Achieving a Greener Defence; Iacovino, G., Wigell, M., Eds.; NATO Science for Peace and Security Series C: Environmental Security; Springer: Dordrecht, The Netherlands, 2022; pp. 1–6. ISBN 978-94-024-2185-9. [Google Scholar]

- Barberini, P. NATO Green Defence: From the 2014 Green Defence Framework to the 2021 Climate Change and Security Action Plan. In Innovative Technologies and Renewed Policies for Achieving a Greener Defence; Iacovino, G., Wigell, M., Eds.; NATO Science for Peace and Security Series C: Environmental Security; Springer: Dordrecht, The Netherlands, 2022; pp. 7–16. ISBN 978-94-024-2185-9. [Google Scholar]

- Nugee, R. The Operational Advantages of a Greener Defence: What Should Defence Be Prepared for in the Next 20–30 Years as a Result of Climate Change? In Innovative Technologies and Renewed Policies for Achieving a Greener Defence; Iacovino, G., Wigell, M., Eds.; NATO Science for Peace and Security Series C: Environmental Security; Springer: Dordrecht, The Netherlands, 2022; pp. 17–33. ISBN 978-94-024-2185-9. [Google Scholar]

- Massa, T. The Possible Contribution of the Defence Industry to the Green Transition. In Innovative Technologies and Renewed Policies for Achieving a Greener Defence; Iacovino, G., Wigell, M., Eds.; NATO Science for Peace and Security Series C: Environmental Security; Springer: Dordrecht, The Netherlands, 2022; pp. 85–94. ISBN 978-94-024-2185-9. [Google Scholar]

- Moher, D. Preferred Reporting Items for Systematic Reviews and Meta-Analyses: The PRISMA Statement. Ann. Intern. Med. 2009, 151, 264. [Google Scholar] [CrossRef] [PubMed]

- PRISMA-P Group; Moher, D.; Shamseer, L.; Clarke, M.; Ghersi, D.; Liberati, A.; Petticrew, M.; Shekelle, P.; Stewart, L.A. Preferred Reporting Items for Systematic Review and Meta-Analysis Protocols (PRISMA-P) 2015 Statement. Syst. Rev. 2015, 4, 1. [Google Scholar] [CrossRef]

- CASP (Critical Appraisal Skills Programme). Available online: https://casp-uk.net (accessed on 3 September 2022).

- Singh, J. Critical Appraisal Skills Programme. J. Pharmacol. Pharmacother. 2013, 4, 76–77. [Google Scholar] [CrossRef]

- Yin, R. Case Study Research and Applications: Design and Methods, 6th ed.; SAGE: Los Angeles, CA, USA, 2018; ISBN 978-1-5063-3616-9. [Google Scholar]

- Seawright, J. Multi-Method Social Science: Combining Qualitative and Quantitative Tools, 1st ed.; Cambridge University Press: Cambridge, UK, 2016; ISBN 978-1-107-09771-1. [Google Scholar]

- Reis, J.; Amorim, M.; Melão, N. Multichannel Service Failure and Recovery in a O2O Era: A Qualitative Multi-Method Research in the Banking Services Industry. Int. J. Prod. Econ. 2019, 215, 24–33. [Google Scholar] [CrossRef]

- Morgan, D.L. From Themes to Hypotheses: Following Up with Quantitative Methods. Qual. Health Res 2015, 25, 789–793. [Google Scholar] [CrossRef] [PubMed]

- Brannen, J. Mixing Methods: Qualitative and Quantitative Research; Routledge: Abingdon, UK, 2017; ISBN 978-1-351-91718-6. [Google Scholar]

- SJR (Scimago Journal Rank). Available online: https://www.scimagojr.com (accessed on 29 August 2022).

- Falagas, M.E.; Kouranos, V.D.; Arencibia-Jorge, R.; Karageorgopoulos, D.E. Comparison of SCImago Journal Rank Indicator with Journal Impact Factor. FASEB J. 2008, 22, 2623–2628. [Google Scholar] [CrossRef] [PubMed]

- Reis, J. Politics, Power, and Influence: Defense Industries in the Post-Cold War. Soc. Sci. 2021, 10, 10. [Google Scholar] [CrossRef]

- Thomé, A.M.T.; Scavarda, L.F.; Scavarda, A.J. Conducting Systematic Literature Review in Operations Management. Prod. Plan. Control 2016, 27, 408–420. [Google Scholar] [CrossRef]

- Scopus. About Scopus: Abstract and Citation Database—Elsevier. Available online: https://www.elsevier.com/solutions/scopus (accessed on 1 September 2022).

- Mongeon, P.; Paul-Hus, A. The Journal Coverage of Web of Science and Scopus: A Comparative Analysis. Scientometrics 2016, 106, 213–228. [Google Scholar] [CrossRef]

- Reis, J.; Marques, P.A.; Marques, P.C. Where Are Smart Cities Heading? A Meta-Review and Guidelines for Future Research. Appl. Sci. 2022, 12, 8328. [Google Scholar] [CrossRef]

- Bryman, A. Integrating Quantitative and Qualitative Research: How Is It Done? Qual. Res. 2006, 6, 97–113. [Google Scholar] [CrossRef]

- Etikan, I. Comparison of Convenience Sampling and Purposive Sampling. AJTAS 2016, 5, 1. [Google Scholar] [CrossRef]

- Berndt, A.E. Sampling Methods. J. Hum. Lact. 2020, 36, 224–226. [Google Scholar] [CrossRef] [PubMed]

- Turner, D. Qualitative Interview Design: A Practical Guide for Novice Investigators. TQR 2014, 15, 1178. [Google Scholar] [CrossRef]

- Scott, R.A.; Kosslyn, S.M.; Buchmann, M. Emerging Trends in the Social and Behavioral Sciences: An Interdisciplinary, Searchable, and Linkable Resource; Wiley: Hoboken, NJ, USA, 2015; ISBN 978-1-118-90077-2. [Google Scholar]

- Reis, J.; Amorim, M.; Melão, N.; Cohen, Y.; Rodrigues, M. Digitalization: A Literature Review and Research Agenda. In Proceedings on 25th International Joint Conference on Industrial Engineering and Operations Management—IJCIEOM, 15-17 July, Novi Sad, Serbia; Anisic, Z., Lalic, B., Gracanin, D., Eds.; Lecture Notes on Multidisciplinary Industrial Engineering; Springer International Publishing: Cham, Switzerland, 2020; pp. 443–456. ISBN 978-3-030-43615-5. [Google Scholar]

- Edhlund, B.M.; McDougall, A.G. NVivo 12 Essentials: Your Guide to the World’s Most Powerful Data Analysis Software; Lulu Press: Morrisville, NC, USA, 2019; ISBN 978-1-387-74949-2. [Google Scholar]

- NVIVO 12. QSR International – NVIVO software. Available online: https://www.qsrinternational.com (accessed on 2 September 2022).

- Reis, J.; Melão, N.; Costa, J.; Pernica, B. Defence Industries and Open Innovation: Ways to Increase Military Capabilities of the Portuguese Ground Forces. Def. Stud. 2022, 22, 354–377. [Google Scholar] [CrossRef]

- Garfin, G.; Falk, D.A.; O’Connor, C.D.; Jacobs, K.; Sagarin, R.D.; Haverland, A.C.; Haworth, A.; Baglee, A.; Weiss, J.; Overpeck, J.; et al. A New Mission: Mainstreaming Climate Adaptation in the US Department of Defense. Clim. Serv. 2021, 22, 100230. [Google Scholar] [CrossRef]

- Saulters, O.S. Enhancing Technology Development Through Integrated Environmental Analysis: Toward Sustainable Non-Lethal Military Systems. Integr. Environ. Assess. Manag. 2007, 6, 281–286. [Google Scholar] [CrossRef]

- Sandström, J. Greening the Swedish Defence Material Administration—A Case Study on the Force of Industry in Environmental Policy-Making: Greening The Swedish Defence Material Administration. Eur. Environ. 2004, 14, 356–367. [Google Scholar] [CrossRef]

- Sydorov, O.; Tarasov, S.; Tsybulnyk, N.; Tsybulnyk, T.; Rusetskyi, A. Financial Security Management of Enterprises Operating in the Defense Industry. J. Secur. Sustain. Issues 2020, 9, 1481–1495. [Google Scholar] [CrossRef]

- Ghorshi Nezhad, M.R.; Zolfani, S.H.; Moztarzadeh, F.; Zavadskas, E.K.; Bahrami, M. Planning the Priority of High Tech Industries Based on SWARA-WASPAS Methodology: The Case of the Nanotechnology Industry in Iran. Econ. Res. Ekon. Istraživanja 2015, 28, 1111–1137. [Google Scholar] [CrossRef]

- BAE Systems Takes Environmental Training to the Top: Senior Executives Learn How to Integrate Green Issues into Their Everyday Functions. Hum. Resour. Manag. Int. Dig. 2014, 22, 7–10. [CrossRef]

- Fernandes, L.L.; Rosa, G.F.; Araújo, L.O.D.; Júnior, J.L.A. The Triple Helix Approach in the Defence Industry: A Case Study at the Brazilian Army. World Rev. Sci. Technol. Sustain. Dev. 2020, 16, 22. [Google Scholar] [CrossRef]

- Da Silva, M.V.G.; Olavo-Quandt, C. Defense System, Industry and Academy: The Conceptual Model of Innovation of the Brazilian Army. J. Technol. Manag. Innov. 2019, 14, 53–62. [Google Scholar] [CrossRef][Green Version]

- Jan, T.-S.; Chen, H.-H. Systems Approaches for the Industrial Development of a Developing Country. Syst. Pract Act. Res. 2005, 18, 365–377. [Google Scholar] [CrossRef]

- Kirchherr, J.; Reike, D.; Hekkert, M. Conceptualizing the Circular Economy: An Analysis of 114 Definitions. Resour. Conserv. Recycl. 2017, 127, 221–232. [Google Scholar] [CrossRef]

- Morseletto, P. Targets for a Circular Economy. Resour. Conserv. Recycl. 2020, 153, 104553. [Google Scholar] [CrossRef]

- Potting, J.; Hekkert, M.; Worrell, E.; Hanemaaijer, A. Circular Economy: Measuring Innovation in the Product Chain; PBL Netherlands Assessment Agency: Amstedam, The Netherland, 2017; Volume 46.

- Lei, H.; Li, L.; Yang, W.; Bian, Y.; Li, C. An analytical review on application of life cycle assessment in circular economy for built environment. J. Build. Eng. 2021, 44, 103374. [Google Scholar] [CrossRef]

- Ghisellini, P.; Cialani, C.; Ulgiati, S. A Review on Circular Economy: The Expected Transition to a Balanced Interplay of Environmental and Economic Systems. J. Clean. Prod. 2016, 114, 11–32. [Google Scholar] [CrossRef]

- BSI. BS 8001:2017; Framework for Implementing the Principles of the Circular Economy in Organizations—Guide; The British Standards Institution: London, UK, 2017; Available online: https://www.bsigroup.com/en-GB/standards/benefits-of-using-standards/becoming-more-sustainable-with-standards/BS8001-Circular-Economy/ (accessed on 24 September 2022).

- Pauliuk, S. Critical appraisal of the circular economy standard BS 8001: 2017 and a dashboard of quantitative system indicators for its implementation in organizations. Resour. Conserv. Recycl. 2018, 129, 81–92. [Google Scholar] [CrossRef]

- National Defense. IdD–Platform of National Defense Industries, S.A. Available online: https://www.defesa.gov.pt/pt/defesa/organizacao/see/paginas/default_idd.aspx (accessed on 2 September 2022).

- idD—Portugal. IdD Portugal Defence. Available online: https://www.iddportugal.pt/en/ (accessed on 2 September 2022).

- EDA (European Defense Agency). Circular Economy in Defense: Advancing Circular Economy in Defense. Available online: https://eda.europa.eu/webzine/issue20/in-the-field/advancing-circular-economy-in-defence (accessed on 23 September 2022).

- EDA (European Defense Agency). EDA´s New Forum for Circular Economy in European Defense Underway. Available online: https://eda.europa.eu/news-and-events/news/2022/01/27/eda-s-new-forum-for-circular-economy (accessed on 23 September 2022).

- VESTLIFE. Vestlife—Ultralight Modular Bullet Proof Integral Solution. Available online: http://vestlife-project.eu (accessed on 4 September 2022).

- CITEVE. Vestlife—Ultralight Modular Bullet Proof Integral Solution. Available online: https://www.citeve.pt/artigo/vestlife (accessed on 4 September 2022).

- Holweg, M. The Genealogy of Lean Production. J. Oper. Manag. 2007, 25, 420–437. [Google Scholar] [CrossRef]

- Soufani, K.; Tse, T.; Esposito, M.; Dimitrou, G.; Kikiras, P. A Roadmap to Circular Economy in EU Defence Inspired by the Case of the Dutch Ministry of Defence; The European Financial Review: London, UK, 2018; pp. 55–60. [Google Scholar]

| Method | Sub-Method(s) | Source(s) of Data Collection | Method Description | Relationship Between Methods |

|---|---|---|---|---|

| Systematic Literature Review (qualitative) | PRISMA Synth Rep CASP & SJR | Elsevier´ Scopus | Identify, evaluate and synthesize the existing literature | Provides the opportunity to learn about the main theories, concepts, ideas and debates about green defense industries. This method generated theoretical insights for the next phase. |

| Case study research (qualitative) | Case study research (incl. Protocols) | Interviews, official documents and direct observations | Investigate the phenomenon in its real-world setting with rich contextual data (e.g., interviews) to generate new insights. | This method empirically validates the theoretical insights and build upon these new contributions to theory and practice. |

| Target | ID | R Strategy | Definition |

|---|---|---|---|

| Target 3: Smarter product use and manufacture | R0 | Refuse | The product abandons its function or offers the same function with a radically different product. |

| R1 | Rethink | Make the use of the product more intensive. It may involve reworking ideas and concepts, uses and post-uses of a product. | |

| R2 | Reduce | Increase efficiency in manufacturing (e.g., energy) or use of products consuming fewer natural resources. | |

| Target 2: Extend lifespan of product and its parts | R3 | Reuse | Defined as second use (by another owner) of a product that is still in good condition and can fulfill its original function. |

| R4 | Repair | Repair and maintenance of a defective or used product so that it can be used for its original function. | |

| R5 | Refurbish | Restore an old product and update it. | |

| R6 | Remanufacture | Use of parts of the discarded product in a new product with the same function. | |

| R7 | Repurpose | Repurpose or decontextualizing is the use of discarded products or their part in a new product with different function. | |

| Target 1: Useful application of materials | R8 | Recycle | Extraction of materials from discarded products to obtain the same (high grade) or inferior (low grade) quality. |

| R9 | Recover | Recovery as material incineration with energy recovery. Refers to waste that is not recycled but is used as an energy source. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Reis, J.; Rosado, D.P.; Cohen, Y.; Pousa, C.; Cavalieri, A. Green Defense Industries in the European Union: The Case of the Battle Dress Uniform for Circular Economy. Sustainability 2022, 14, 13018. https://doi.org/10.3390/su142013018

Reis J, Rosado DP, Cohen Y, Pousa C, Cavalieri A. Green Defense Industries in the European Union: The Case of the Battle Dress Uniform for Circular Economy. Sustainability. 2022; 14(20):13018. https://doi.org/10.3390/su142013018

Chicago/Turabian StyleReis, João, David Pascoal Rosado, Yuval Cohen, César Pousa, and Adriane Cavalieri. 2022. "Green Defense Industries in the European Union: The Case of the Battle Dress Uniform for Circular Economy" Sustainability 14, no. 20: 13018. https://doi.org/10.3390/su142013018

APA StyleReis, J., Rosado, D. P., Cohen, Y., Pousa, C., & Cavalieri, A. (2022). Green Defense Industries in the European Union: The Case of the Battle Dress Uniform for Circular Economy. Sustainability, 14(20), 13018. https://doi.org/10.3390/su142013018