1. Introduction

This study investigated and developed a generic full bottom-up model framework that looks at the single vessel voyage through its port call stages. Two main data sources were used in this study. The first data source is the Israel Navy’s movements log, and the second data source is the Israel Administration of Shipping and Ports (ASP)’s operational vessel movements and cargo log. The years of observation are 2010–2018, with a focus on the Ocean-Going Vessels (OGV) type only. This model was used to estimate the daily port emission inventory for Haifa and Ashdod (with Ashkelon) and for vessel movement across the Israel shoreline. “Big data” analytics with Structured Query Language (SQL) query techniques were used to deal with the analysis process, where advanced data mining methods with Python queries were used to complete missing technical information from known maritime professional sites.

1.1. Aims and Objectives

This study aims to provide decision makers valuable information concerning emissions arising from OGV movements in the port area.

Such information includes:

Identifying the constraints to be overcome in order to prevent “pollution haven” or “pollution leakage” to mainland.

Providing estimates and identifying the port’s share of contribution compared to other main pollutant emitters in the area.

The emission results reported can then be used for air quality analysis and the development of recommended marine emission reduction policy as well as recommended emission reduction targets for each vessel category type and category class.

The generic port emission inventory model targets only Ocean-Going Vessels (OGVs), thus excluding all marine traffic of private yachts, domestic vessels movements (tugs, navy, fishing, service vessels, etc.), trucks (heavy or light), trains or any machinery/equipment emissions that were operated in the port jurisdiction area in the calendar years noted.

The scope of this research for the study case will look at Haifa Port, one of Israel’s main ports. The Haifa emission inventory analysis includes all the vessel traffic in Haifa Port and in the Israel Shipyards’ port (currently the only private port in Israel). This decision to aggregate was made due to the proximity of the two ports and which cannot be overlooked.

The exhaust emissions of the following pollutants were estimated in this study:

Common Air Contaminants (CACs)—SOx, NOx, CO, HC and total Particulate matter (PM) (10-micron and 2.5-micron); Greenhouse Gases (GHGs)—CO2.

Key Assumptions

The Auxiliary Engine (AE) and boilers were considered to be sharing the same fuel type, as no legislative actions were required otherwise and operation using the same fuel type is economically justified.

Sulfur levels were based on an Israel ASP Fuel Consumption (FC) survey and are assumed to be consistent for the study calendar years 2010–2018 in order to provide a conservative estimate, although a rate of 4.5% of sulfur content was a possibility for the years 2010 and 2011.

The FC factor figure for vessel port time is based on ASP FC survey records, thus providing a concrete low-bound estimation for emissions arising from vessel activity at port and port-related area. This estimation is lacking FC figures concerning the “full away” stage and sailing in and out of the port area. Nevertheless, these stages are considered insignificant in terms of FC compared to vessel port time FC performance.

1.2. Port Emission Inventory Analysis in Literature

There are limited studies that target emission inventories arising from vessel activity at global and regional levels. These studies examine the emission contribution of international vessel movements. Limited studies were also done on emissions arising from vessels while present in ports, based on their activity profile. These studies are mostly carried out by private consulting companies and therefore most of the data regarding the FC, vessel visits history, vessel technical data, time in port, etc., are not available for public analysis.

In addition, acquisition and analysis of the vessel movement history data requires specialized big data techniques requiring a huge purchasing cost of supplemental datasets. Therefore, it is generally considered highly expensive for research institutes. The majority of studies based their analyses on Engine Power (EP), load factor assumptions for Main Engines (MEs) and AEs in relation to a vessel’s activity-based profile, where a small pro-portion of these studies based their analyses on FC assumptions. This resulted in a limited availability of vessel FC data in the literature or in any official publication of the IMO. In addition, the majority of these studies used an approach for vessel type categories, but not for vessel type with a category class for vessel type (sub-categories of vessel type) [

1].

In the last years, two different studies have tried to evaluate the reliability of FC and EP approach methods. Although each approach has different advantages and disadvantages, both of the studies recommend the use of a real FC data approach when available, for emission inventory calculation either for the high seas or for port, since the FC data approach was found to be more reliable compared to the EP approach. The FC data approach is based on real-time FC data taken from the vessel and is therefore considered to be more reliable than the EP approach [

2,

3].

Emission inventories can also be developed using regression models [

4]. The use of this approach in studies focusing on vessel-related activity emission inventories has been found to be uncommon.

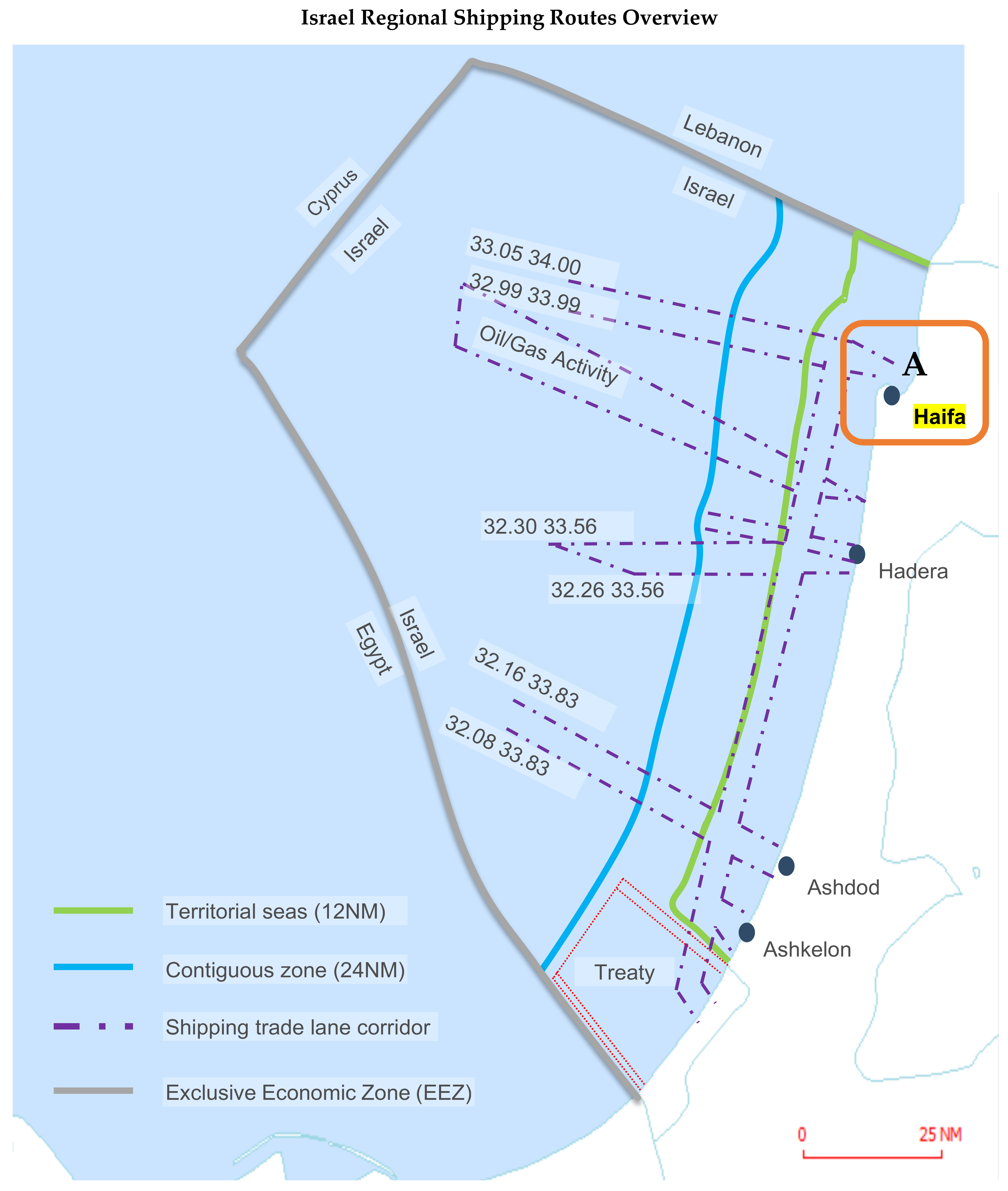

1.3. Israel Ports

Israel seaports are responsible for more than 99% of Israel international trade in terms of export and import and around 80% in terms of value [

5]. Israel’s main international trade ports are Haifa and Ashdod, as illustrated in

Figure 1. All Israel ports are all currently (2021) publicly owned port companies except for the Haifa–Israel Shipyard company port and Eilat Port that are privately owned. In this research, the Haifa Port case study is present in details to demonstrate the model capabilities.

Haifa Port

The Port of Haifa was constructed in 1933 by the British Empire. Since 1948, it has been rebuilt and developed by the Israeli government. Haifa Port serves as one of the two main significant ports and economic bridges connecting Israel with the outside world. During 2010, under the port expansion program, it was resolved to open a new container terminal. The new Carmel Port dock provides an additional 700 m of quayage with a depth of 15.8 m which is capable of handling up to 14 K TEU size container vessels [

6].

Located in the Middle East, Haifa Port serves both local and international trade interests (from Asia, Europe, America, Africa, etc.). The port was included in the Belt and Road initiative. As a result, an expansion program of Haifa Port is now underway and is expected to complete the construction of a newer container terminal. The HaMifratz Port dock, which is scheduled to open in late 2021. The new dock will feature an additional 800 m of quay-age with a depth of 17.3 m and will be capable of handling up to 15 K TEU size container vessels. Haifa’s new port is expected to enhance traffic at the port and to contribute to local economic growth.

Haifa Port includes container, bulk and general cargo (i.e., break-bulk), cruise and oil/liquid (included chemical) terminals. Haifa Port is located in a high-altitude terrain topography that surrounds the Haifa Bay area. The dominant wind direction is northwest to southeast, while in the summer the dominant wind direction shifts to southwest to northwest [

7], as illustrated in

Figure 2.

Figure 1.

Israel maritime boundary map relative to regional shipping routes. Source: Own composition, based on CSA Ocean Sciences Inc. 2016 [

8], Flanders Marine Institute. 2016 [

9] and Israel Navy data.

Figure 1.

Israel maritime boundary map relative to regional shipping routes. Source: Own composition, based on CSA Ocean Sciences Inc. 2016 [

8], Flanders Marine Institute. 2016 [

9] and Israel Navy data.

1.4. Claims and Contributions

This study claims that vessels’ contribution to local emission inventory cannot be overlooked since this study makes the analogy that each vessel should be treated as a “Floating Industrial Plant” and should be treated in terms of emissions as a land-based plant. This study claims that emissions arising from both a land-based plant with a small and/or mid and/or high dynamic emission level contribution and emissions arising from vessels in port and port-related areas should be managed at a high-level overview, since they both can be considered heavy industrial pollution zones in terms of daily, monthly and yearly emission level.

This study claims that on certain days, emissions arising from the port area exceed even the daily industrial zone limits. This study makes an analogous claim that each area should be examined and managed as a collection of “flue gas stacks”, as shown in

Figure 3. In addition, this study claims that, due to the height of the flue gas stacks on board vessels, which are significantly lower compared to flue gas stacks installed in land-based plants, they may affect area air quality significantly more than the industrial zone. The latter are usually subject to extensive environmental emission regulations compared to vessels in port.

This study developed a generic full bottom-up model framework that looks at the single vessel voyage through its port call stages. The results gained from this study can serve as a decision support tool, for decision makers’ assessment of the single vessel’s contribution to the emission level in ports and port-related areas worldwide, thus allowing ports across the globe to identify the main pollution contributors, based on a daily FC and emission calculation performance. This study model framework has the potential to promote green sea freight transportation while trying to prevent the “pollution leakage” phenomena (i.e., transshipment of sea freight cargo to land transportation means). Moreover, it could even be used as a source of information when setting emission reduction targets for the international shipping sector in the short to medium term, as the shipping industry is expected to incorporate major technological improvements in its fleet in the next decades (i.e. helping ports develop and check their environmental management policies).

1.5. The Study Structure

The following sections present the Model Input Data section, which explains and specifies key variables and assumptions used for the Haifa Port emission inventory model. The daily emission inventory estimations are presented in the Results section. The last section concludes with a summary review, discussion and policy recommendation.

2. Methodology

This study will present the methodology procedure and the material analysis in logical order, as described in

Figure 4. The following case study presents an in-depth analysis of Haifa Port Emission Inventory based on daily port and shoreline Emission Inventory Model [

11]. For a full bottom-up approach in emission inventory estimation examining the single vessel voyage’s emission performance, “Big data” analytics with SQL queries techniques were used to deal with the analysis process examine the port daily emission levels, segmentized by OGVs category type and class for pollutant contributors’ analysis.

All vessels in this study were categorized by type of cargo based on IMO 4th GHG study logic. The international merchant vessel fleet varies in cargo designation, capacity classification and physical size. In order to maintain consistency, this study follows the IMO Fourth GHG report, which is consistent and follows with IMO’s Third GHG report guideline (i.e., segmentation of vessel category type, classes, etc.) [

12,

13].

2.1. Model Emission Factors and Engine Assumptions

The emissions calculation methodology is based on the multiplication of an Emission Factor (EF) for each GHG and CAC emission with FC (with specific consumption factor). The results are then totaled for each category type of vessel, class, fuel and engine type in use for a daily analysis.

The emissions reported in this study are based on ASP FC figures taken from an official FC survey for each type and class of vessel. The survey was conducted officially by the Israel Inspection Division from the Israel Shipping Authority (each form submitted was signed by the vessel master)

The following section presents the latest known EF existing today and is acknowledged by IMO, EPA and the EU.

2.1.1. Emission Factors

The main emission factors used in this study are based on EFs reported in the Fourth IMO GHG Study, ENTEC 2002/2005/2007/2019 Studies, IVL Swedish Environmental Research Institute 2004 Study [

14] and HOK Marine consult ApS 2015 Study [

15]. Most of the EFs reported in these studies are based on the [

16]. analysis study commonly known in the literature as Lloyd’s Register 1995 Study.

SFOC

In general, the EFs reported and cited in these studies are presented in g pollutant/kWh units and were therefore converted to a fuel-based EF by dividing by Specific Fuel Oil Consumption (SFOC), which is presented in g pollutant/g fuel or kg units. Each related SFOC was corresponded to each related fuel and engine type associated with its related EFs.

Equation (1) was used to convert energy-baseline EFs in g pollutant/kWh to fuel-based emission factors in g pollutant/g fuel consumed emission factors for the port inventory study.

The SFOCs were derived from the IVL study as reported in IMO’s last GHG report. The IVL study on SFOCs based its analysis on EFs reported in the ENTEC 2002 study that were also used in this study [

12,

14,

15,

16,

17,

18,

19,

20,

21].

Baseline Emissions Factors

The baseline EFs used in this study are used for both for AE and boiler FC (with further justification for fuel type and engine rate in use per each vessel), whether the vessel engines were found to be pre-IMO Tier I (i.e., Tier 0) or Tier I standard or if they meet IMO Tier II or Tier III standard requirements. The vessel engine configuration, fuel type and SC assumptions used in the study are presented in

Table 1 and

Table 2 [

12,

14,

15,

16,

17,

18,

19,

20,

21].

Particulate Matter (PM) EFs, reported and cited in literature, vary significantly between studies depending on each practice used. Nevertheless, for SOx EFs, there is a consensus for EFs reported based on the analysis of the Lloyd’s Register 1995 study, as shown in the following equations, which were used to develop the baseline and actual emission factors for the port inventory study, as presented below in Equations (2)–(7) and as presented in

Table 1 [

17].

Both PM and SOx EFs are affected by the level of percentage of sulfur content existing in fuel. In order to provide a conservative figure, the reported PM EFs (with % SC adjusted), as reported in the Fourth IMO GHG study, were not chosen as they present high EF numbers or were considered not current compared to new studies in the field. Therefore, PM EFs for auxiliary engines were derived from the EMEP/CORINAIR 2007 and 2009 as reported in the HOK Marine consult ApS 2015 study, as shown in Equations (6) and (7) and as presented in

Table 1 [

12,

13,

15,

22].

Table 1.

Baseline emission factors (fuel based)—CO2, CO, HC, NOx, SOx, PM.

Table 1.

Baseline emission factors (fuel based)—CO2, CO, HC, NOx, SOx, PM.

| | Engine Type | Speed Rate | Fuel Type | Unit | Engine | Study EF | Study EF Source | IMO

EF | IMO EF Source | # | Eq. | n for NOx |

|---|

| CO2 emission | 2-stroke/

4-stroke | SSD/MSD/HSD | HFO | g/kg fuel | AE/ME | 3114 | MEPC 62/23, Annex 8 | 3114 | MEPC 62/23, Annex 8 | | #2 | |

| | 2-stroke/

4-stroke | SSD/MSD/HSD | MGO | g/kg fuel | AE/ME | 3206 | MEPC 62/23, Annex 8 | 3206 | MEPC 62/23, Annex 8 | | #2 | |

| CO emission | 2-stroke | SSD/MSD/HSD | HFO/MGO | g/kWh | AE/ME | 0.35 | [16] | 0.54 | [23] | | #3 | |

| HC emission | 2-stroke/

4-stroke | SSD/MSD/HSD | HFO/MGO | g/kWh | AE/ME | 0.5 | [16] | 0.5 | [14] | | #4 | |

| NOx emission | Tier 0 | 2-stroke | SSD | HFO/MGO | g/kWh | ME | 19.8 | [14] | 18.1 | [17] | | #5 | n = ~130 |

| Tier I | 2-stroke | SSD | HFO/MGO | g/kWh | ME | 17 | IMO Standard | n/a | [13] | * | #5 | n = ~130 |

| Tier II | 2-stroke | SSD | HFO/MGO | g/kWh | ME | 14.4 | IMO Standard | n/a | [13] | * | #5 | n = ~130 |

| Tier III | 2-stroke | SSD | HFO/MGO | g/kWh | ME | 3.4 | IMO Standard | n/a | [13] | | #5 | n = ~130 |

| Tier 0 | 4-stroke | MSD/HSD | HFO/MGO | g/kWh | AE | 14.2 | [14] | 13.2 | [13] | ** | #5 | n = ~745 |

| Tier I | 4-stroke | MSD/HSD | HFO/MGO | g/kWh | AE | 11.7 | IMO Standard | 11.7 | [13] | ** | #5 | n = ~745 |

| Tier II | 4-stroke | MSD/HSD | HFO/MGO | g/kWh | AE | 9.6 | IMO Standard | 9.7 | [13] | ** | #5 | n = ~745 |

| Tier III | 4-stroke | MSD/HSD | HFO/MGO | g/kWh | AE | 2.4 | IMO Standard | n/a | | * | #5 | n = ~745 |

| SO2 emission | 2-stroke/

4-stroke | SSD/MSD/HSD | HFO/MGO | g/kWh | AE/ME | 20×SC | [16] | 20×SC | [16] | | #6 | |

| PM emission | 2-stroke/

4-stroke | SSD/MSD/HSD | HFO/MGO | g/kWh | AE/ME | Eq 6 | [24] | 0.854×EXP (SC%×0.745) | [25] | | #7 | |

Table 2.

Vessel engine, fuel type and SC per vessel category type assumption.

Table 2.

Vessel engine, fuel type and SC per vessel category type assumption.

| Vessel Category Type | High Sea (ME) | Port (AE) | S.C |

|---|

Engine

Speed Design | Engine Type | Fuel Type | Engine

Speed Design | Engine Type | Fuel Type |

|---|

| Container | SSD | 2-stroke | HFO | MSD/HSD | 4-stroke | HFO | 2.48% |

| General Cargo | SSD | 2-stroke | HFO | MSD/HSD | 4-stroke | HFO | 2.48% |

| Chemical Tanker | SSD | 2-stroke | HFO | MSD/HSD | 4-stroke | HFO | 2.48% |

| Oil Tanker | SSD | 2-stroke | HFO | MSD/HSD | 4-stroke | HFO | 2.48% |

| Bulk Carrier | SSD | 2-stroke | HFO | MSD/HSD | 4-stroke | HFO | 2.48% |

| Ro-Ro | SSD | 2-stroke | HFO | MSD/HSD | 4-stroke | HFO | 2.48% |

| Cruise/Passenger | MSD/HSD | DE | MGO | MSD/HSD | DE | MGO | 1% |

| TSHD Dreger | MSD/HSD | 4-stroke | HFO | MSD/HSD | 4-stroke | HFO | 3% |

| Dreger (small) | MSD/HSD | 4-stroke | MGO | MSD/HSD | 4-stroke | MGO | 0.1% |

The following equations were used to develop the baseline and actual emissions factors for the port inventory study, as presented below:

2.1.2. Vessel Engine, Fuel Type and SC Assumptions per Vessel Category

Vessel engines are designed around the fuels they plan to burn. The OGV engines are usually considered high consumers of energy; therefore, vessel owners usually face two main alternatives while selecting the main propulsion machinery during shipyard construction: 2-stroke or 4-stroke engines. In the maritime industry, for OGV the 2-stroke engine is more commonly used as a ME, while the 4-stroke engine is more commonly used as an auxiliary engine. Boilers are mainly considered an onboard heat production unit and so consume energy but do not produce energy [

14,

17]. An OGV can be installed with two or more auxiliary engines to support its energy needs while at port/hoteling (i.e., 4-stroke), where OGV can be installed with up to two MEs depending on vessel size [

17,

26].

Both the 2-stroke and 4-stroke engines allow the use of Residual Marine (RM) and Distillate Marine (DM) from low-grade fuel oil. A 2-stroke combustion engine that is fueled with RM fuel will present a higher efficiency performance compared to a 4-stroke engine combustion engine [

17,

26]. The 2-stroke engine’s massive size allows it to operate as an “Omnivore” engine, as it can accept any existing material in nature with some energy factor and transpose it to raw energy.

The cruise ships require high maneuvering performance since they operate close to residential areas and frequently change passengers. This sensitive issue led vessel owners in this sector to operate on two main configurations of engine. The first one is the full Diesel-Electric (DE) engine, typically in used in cruise, passenger and ferry vessels. These vessels can be fueled with DM or RM fuel, although they are typically fueled with DM fuel with an SC of less than 1.5% depending on the regulations under which they operate. The second configuration is a geared shaft configuration where the ME and the auxiliary diesel-electric engines are used for different energy efforts [

27].

To summarize, the vessel engine configuration, fuel type and SC assumptions used in the study are presented in

Table 2.

2.2. Model Implications—Israel Ports—Case Studies

The following sections will present the implications of the Port Emission Inventory Model Framework for Israel’s main ports. Each section presents a description and background data inputs and explains key variables and assumptions used for each relevant case study that lay the foundations for the model’s implications for Israel’s ports.

2.2.1. Israel Maritime Transportation—In Numbers

The primary source of data for the Israel ports study is based on Israel Navy and Israel ASP records. The Israel Navy and ASP databases provide crucial information for the bottom-up approach. Cross-matching queries were carried to validate and ensure and the credibility of these datasets and this study.

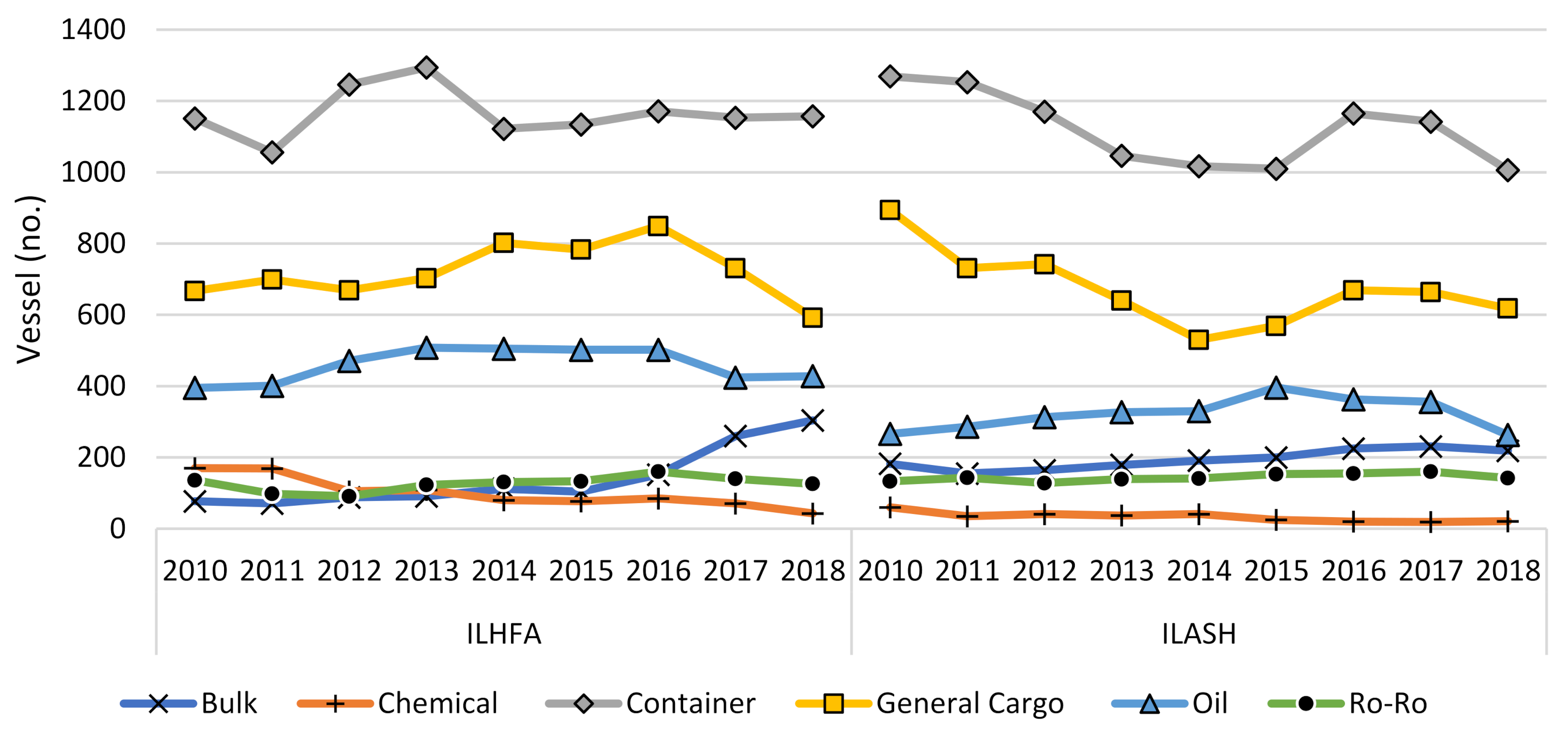

Container vessels are the dominant vessel in the ports in terms of visit call, followed by general cargo and oil tankers, as shown in

Figure 5. From the analysis, a decreasing in visit trend can be seen for containers and general cargo for both ports, and an increasing visit trend can be seen for bulk carriers for both ports.

2.2.2. Israel Port—Fuel Type in Use

HFO is the most commonly used fuel in Israel ports. This assumption is logical and economically wise for all vessels within ports as Israel does not have a local set of limitations for SC in bunker fuels, since Israel’s current policy is to be in line with IMO global regulation. Yet, to strengthen this assumption, the data samples of the FC survey were analyzed by fuel type for ME, AE and boilers, thereby removing any uncertainty in the model for this issue. As expected, findings show that HFO was the most common fuel in use for OGV vessels within Israeli ports for ME, AE and boilers alike.

2.2.3. Accuracy and Reliability

Vessel movement data and FC data are the pillars of the port and shoreline emission inventory model frameworks. The strength of the first pillar, vessel movement data, relies on the fact that it comes from official sources. The Israeli Navy and the Israeli ASP are two different entities with separate and different methods for collecting and documenting vessel movements within Israel. Nevertheless, the accuracy of the datasets received from the Israel Navy and Israel ASP is considered extremely high, as both serve as “watch dogs” for maritime movements.

The strength of the second pillar, FC data, relies on the fact that the data comes from an official survey conducted by the ASP Department of Supervision and Control. All FC figures in this study were validated by recognized professional sources.

3. Model Results

3.1. Port Emission Inventory and Maritime Transportation (Freight and Fleet) Trend Effect

While examining the emission inventory in ports and its magnitude in relation to the maritime transportation in Israeli ports, this study assumed that segmentation of each category of vessel to class could play a significant role in the calculation of port emission inventory. This factor could reflect changes in both freight, fleet size and emission trends. Therefore, this study addressed the selected period of 2010–2018, an indication of port emission trends, and vessel category/class with tier analysis for each type of GHG and CAC emissions as described above.

Fleet Call Israel Ports

Findings from the Port Emission Inventory Model framework shows that between 2010 and 2018, the 5360 unique vessels of the merchandise fleet called at Israel’s main ports. This fleet is dominated by Tier 0 and Tier 1 engine grade, 36% and 48%, respectively, where Tier 2 and 3 totals 16%, as can be seen in

Figure 6. These findings are based on the analysis of vessels’ technical characteristics and year of manufacture.

Analysis of the Israel Navy and ASP datasets’ classification processes for the actual and predictive vessel size for this model framework made it possible to segment the current fleet into different category types and into different of classes of engine tier grade as shown in

Figure 7.

In terms of tier analysis per category, there is a similar ratio for the Tier 0 and Tier 1 engine grades for almost all vessels in different category types, except for the Bulk and RO-RO category, which shows a greater ratio for engine grade Tier 2 and 3.

3.2. Israel Main Ports Overviews

The following sections present the analysis results of the Port Emission Inventory Model. To present the total emission contribution of the single vessel voyage while in port and port-related area, it is necessary to include the ME, AE and boiler FC contribution to the analysis. Findings from the analysis indicate that the ME FC contribution to the total port FC is estimated at ~2.6–4.8% of the total annual port FC (depending on port and year), i.e., the ME FC contribution to the Port Emission Inventory Model is not significant to the model results. Therefore, to present conservative figures, the following analysis sections were based only on AE and Boiler FC performance, as the ME FC figures were not included in the original ASP FC survey.

3.3. Haifa Port Emission Inventory

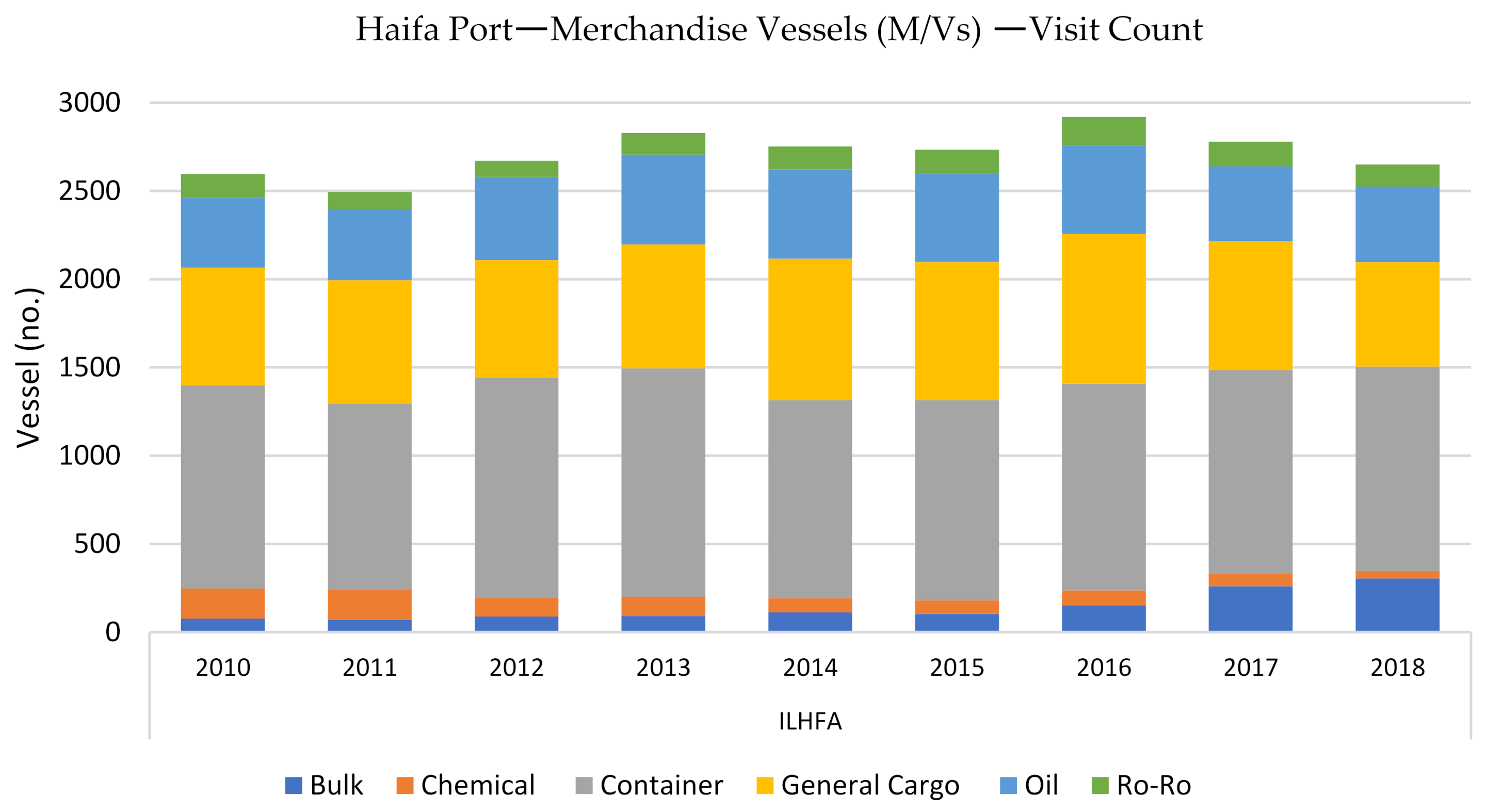

Findings from the Port Emission Inventory Model framework show that container, general cargo, and oil tankers dominate Haifa vessel statistics port calls, as shown in

Figure 8. The average annual statistic for port calls for the investigated periods is ~2600 unique visits. Furthermore, the results indicate an increase in the dry bulk, general cargo and container vessels’ port call statistics, in contrast to a decrease in the chemical tanker sector. The reduction in the chemical tanker sector can be explained due to the closing of the Haifa chemicals plant and its ammonia tank, which were the main players in this vessel sector.

Findings from the Port Emission Inventory Model framework show that the estimated total emission inventory in Haifa Bay due to vessel activity stands at an annual average of between ~1400 and ~2100 tons of NOx and an annual average of between ~1300 and ~2000 tons of SOx. This can be translated to a weekly average of 27–40 tons of NOx and 25–38 tons of SOx, as shown in

Figure 9. These finding are heavily dependent on vessel category type and class composition and the volume of vessels in port.

From an analysis of nine years of historical OGV maritime traffic in port and emission inventory performance, findings from the model indicate a gradual increase in daily and yearly inventory for the period 2016–2018, compared to previous period performance, as shown in

Figure 10. This phenomenon of an increase in daily and yearly inventory can be explained by an increase in waiting time and the increase vessel presence volume in the port area. These events are a byproduct of recurrent employee sanctions. The strike actions started to take place in increasing frequency from the time of the announcement of the port structure reform in 2013 and gradually increased to a peak in 2018 as the decision date approached.

In addition, the increase in container vessels and dry bulk calls (shown in

Figure 8) can be explained by the increase in transshipment activity for container vessels and an increase in small/handysize bulk vessel calls, due to a market share growth of the Israel Shipyard port (i.e., the privately owned port) in the dry bulk and general cargo sectors. This is also reflected in an increase in FC ratio for these sectors for 2015–2018 (

Figure 11). These sectors show a long dwell time, due to their position in the Haifa Port pilot service operational line (i.e., last in line).

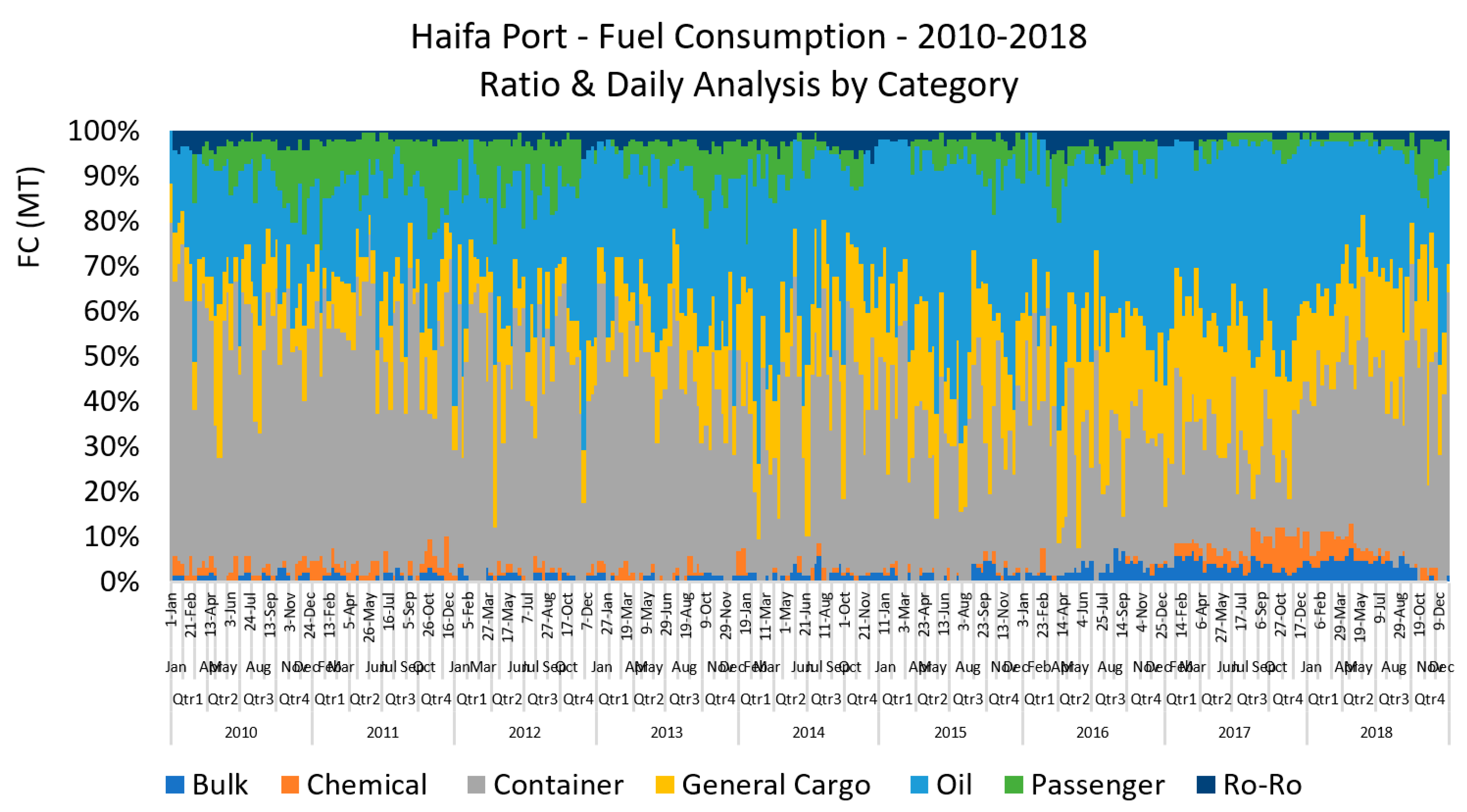

Changing the perspective of the model results to the FC ratio per vessel category type, as shown in

Figure 11, reveals the domination of Container and Oil vessel contributions to the daily and annual level of the port emission inventory.

In estimating GHG or CAC emissions from vessel traffic in the port area, this study assumed that vessel FC factors for ME, AE and boiler (for maneuvering and dwell operations) for each vessel category type and class would be an important element for port emission inventory estimation. However, a high level of analysis (i.e., class) at this stage could lead to an overload of information for the common reader. Therefore, this study ad-dressed selected sectors in maritime transportation, which serve as indicators for category-type emission contribution. The following stack column charts will present the annual and daily contribution for the two selected types of emission investigated, NOx and Sox. This will demonstrate the complexity level of the analysis and will serve as an example of the daily port emission method’s analysis capabilities.

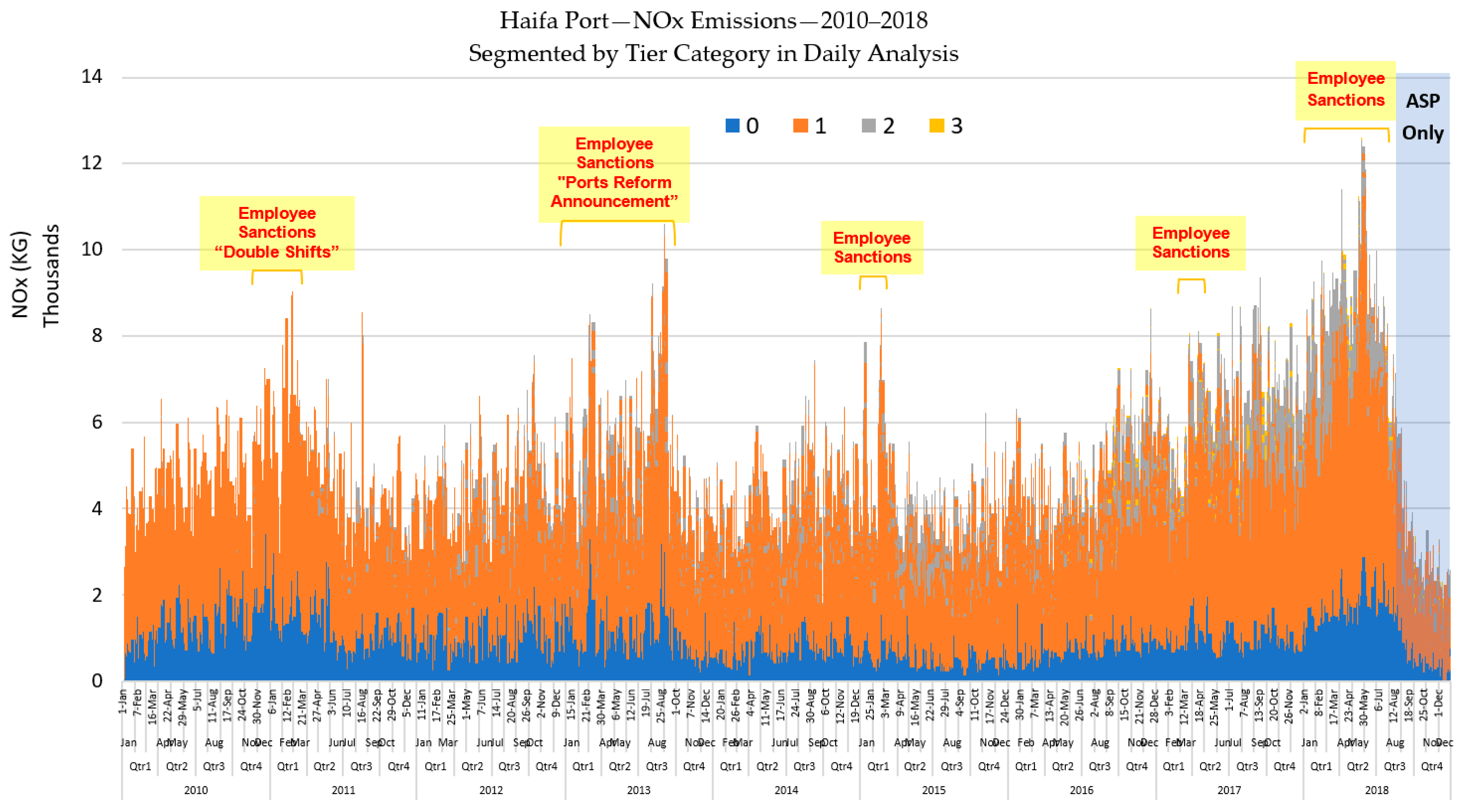

3.3.1. NOx

In terms of annual NOx emission, this study addressed tiers 0, 1, 2, and 3, which serve as indicators for NOx emission standards. Findings from the Port Emission Inventory Model, as illustrated in

Figure 12, show a shift in Tier 0 engine grade, which translates to a decrease in contribution for the years 2014–2015. This is due mainly to a change in container vessels. However, this change was found to be temporary as from 2016 and on, there was an increase for Tier 0 engine grade compared to previous levels. This increase was due to an increase in appearance and waiting time for general cargo vessels.

In terms of daily contribution based on tier-grade-level analysis, as expected, the main contributors to daily levels are vessels with Tier 1 and Tier 0 engine grades, as illustrated in

Figure 13. Additional findings show that the daily average contribution of Haifa Port is estimated in the range ~4 to 6 tons for 2010–2016, while the daily average contribution for 2017–2018 ranges between ~6 and 10 tons, an increase of 50% to 67%, respectively. This temporary increase was the effect of recurrent employee sanctions that increased the waiting time and vessel presence volume of the port area during strike days. Quarters Three and Four in 2018 show a drastic reduction in emission levels. These reductions were achieved only because the Port Emission Inventory Model input for maritime movements in this period was based on the ASP dataset source. Nevertheless, this period was added (marked in gray) to show the partial cover of ASP data on the maritime movements in ports, thus demonstrating that its perspective for vessel time at port is narrowed down to operational aspects only.

3.3.2. SOx

When examining the SO

X emissions, findings from the model, as illustrated in

Figure 14, show that the average annual SOx emissions in Haifa Port range between ~1.3 K and ~2 K MT for years 2010–2018. An average increase in the trend for the upper boundary to ~2.2 can be seen starting from 2016. The main contributors were found to be container and oil vessels. This can be explained by several factors: increase in frequency of vessels call from size 5K TEU and above, an increase in waiting time, and an increase in the frequency of employee sanctions.

In terms of daily SOx emission contribution, as expected, the main daily contributors were the container and oil tankers sectors, as illustrated in

Figure 15. Findings show that the daily average contribution of Haifa Port is estimated in the range of ~4 to 5.6 tons for 2010–2016, while the daily average contribution for 2017–2018 ranged between ~6 and 8.2 tons, an average increase of ~50%. This increase can be explained by an increase in waiting time (especially for oil/chemical tankers and bulk) and an increase in frequency calls of the Very Large Container Ships (VLCS), which carry 8 K TEU and above. Some of these vessels (i.e., container) are known for their high FC performance while at port and are discussed in depth in the sector classes analysis.

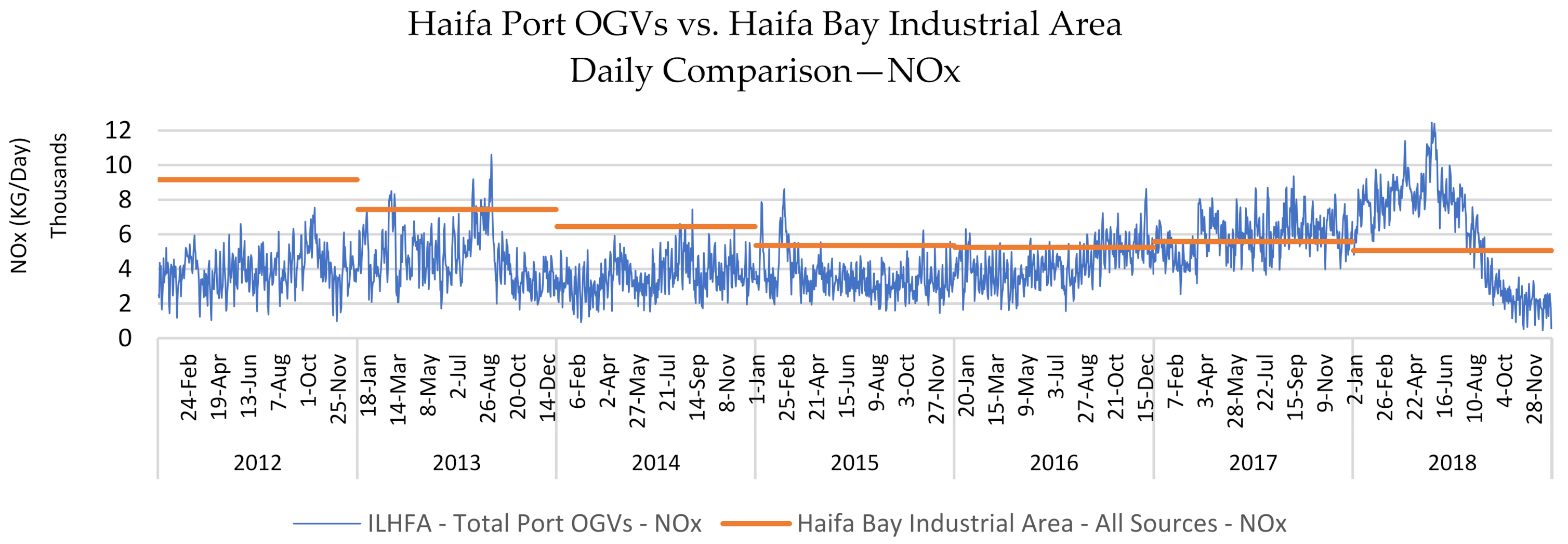

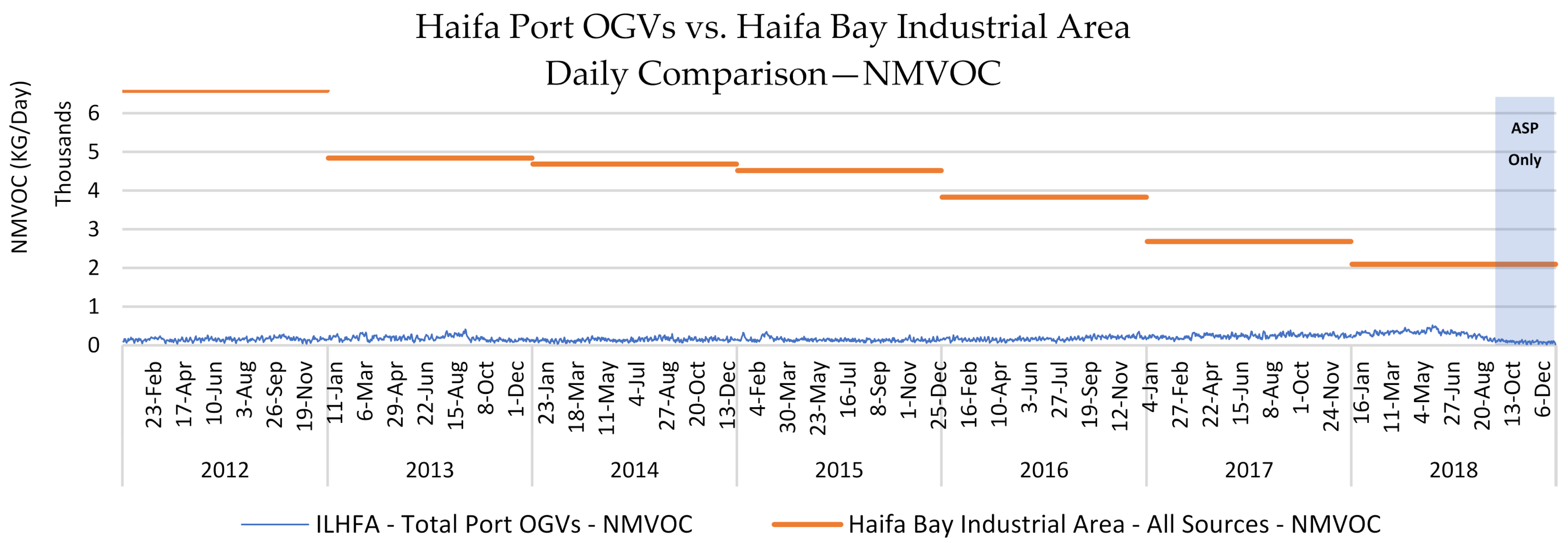

3.4. Haifa Port Emission Inventory

To better understand the magnitude of the vessel’s emissions during their port stay, a wide comparison analysis between all Haifa Bay emission sources is required. To com-pare emission concentrations, this study needed to use an atmospheric dispersion model to simulate vessel’s air pollutants dispersal in the area, thus assessing its contribution to the wind patterns each day. However, an additional technique could be considered, i.e., comparative assessments of annual emission inventories of all known sources of pollution in the Haifa Bay area. Therefore, a comparative assessment was made, comparing all known sources of cumulative emission inventory with Haifa Port vessels traffic.

Emission data regarding industrial sources are based on the Israel Ministry of Environmental Pollution (MoEP) Pollutant Release and Transfer Register (PRTR) inventory database for all emission sources. The database includes information for the years 2012–2018. Therefore, model findings were compared to the total emission pollution in the Haifa Bay area for each year in the Israel MoEP PRTR analysis period [

28].

From an analysis of seven years of historical OGV maritime traffic in port and emission inventory performance, findings from the model indicate a gradual increase in the yearly inventory for the period 2012–2018, compared to Haifa industrial area’s similar period performance. The reduction trend described in

Figure 16 is a result of the switching effort in Haifa Bay industrial plants to use clean, gas-based energy as their main energy source along with additional efforts to reduce CAC emission levels [

29].

For more details regarding plants included in the Haifa Bay industrial area annual emission inventories comparison analysis, see

Appendix A—Israel Haifa Industrial Area Annual Emission Inventories (

Table A1 and

Table A2).

Using inventory analysis comparison, this study’s reviewed findings (

Figure 16), show that Haifa Port was found to be constant to within ~40–44% of all the known sources for the total NOx emission inventory (i.e., all industrial emission inventory sources in the PRTR with port findings combined) in 2012–2015 and with a gradual increase to ~49%, ~56% and ~62% for 2016, 2017 and 2018, respectively.

In terms of SOx emissions, Haifa Port was found to be the main contributor, with ~30% for 2012 and ~50–65% for 2013–2014 and constant to within ~72–77% of all the known sources total for the SOx emission for 2016–2018. This mean port share increased by a factor of ~2.1 in about 6 years.

In terms of TPM emissions (which also includes Black Carbon—BC emissions as a component of final PM), findings showed that the annual TPM emissions in Haifa Port ranged between ~67% and 85% of all the known sources for the years 2013–2018 (as illustrated in

Figure 16).

HC emissions are considered a good hallmark of general air quality as they include ~98% NMVOC emissions as a component of final HC [

30]. According to this study’s reviewed findings, Haifa Port was found to be constant to within ~3–4% of all known sources total for the NMVOC emission in 2012–2016 and an average of ~9% for 2017–2018.

CO emissions were found to be insignificant, as Haifa Port was found to be constant to within ~2% of all the known sources total for the CO emission for 2012–2016 and with a gradual increase to ~5% and ~7% for 2017 and 2018, respectively.

With the very rough assumption that industrial area production is stable on a daily basis, and therefore emits the same level of inventory emission in the daily total. When examining this study’s reviewed findings from a wider perspective, using daily inventory analysis comparison, Haifa Port was found to be constant in exceeding Haifa Bay industrial area also in daily levels. These daily emission comparisons are significantly important, as they enable this study to focus on other implications and impacts of this study’s reviewed findings, and as such, to fully understand their impact. Therefore, according to this study’s figures showing high fluctuation in port-related daily emission, the main findings indicate that the current methods used by the Israel MoEP for the calculation of the emission concentrations of the industrial plants and for the transportation sector are likely to hold selection biases, since they unknowingly included the contribution of the daily emission emitted by the shipping sector (which is a significant factor in the mix emissions compound in the region), as illustrated in

Figure 17,

Figure 18,

Figure 19 and

Figure 20.

In terms of the magnitude of Haifa Port’s contribution, it is also important to indicate and emphasize that OGVs are usually equipped with a low-altitude exhaust funnel and operate in port in local dense concentrations and at low speeds; therefore, while at port, they can be considered static, as compared to the industrial area plants that are scattered over a wide area and are equipped with high-altitude exhaust funnels.

4. Discussion

The results of this study show that a full bottom-up approach in emission inventory estimation that examines the single vessel’s duration of stay is reliable and durable, therefore opening a new era for a new tariff structure for port dues based on incorporating the single vessel emission contribution.

The results of this study show that the merchandise fleet at Israel’s main ports (Haifa, Ashdod and Ashkelon) is dominated by Tier 0 (pre 2000 and unregulated) and Tier 1 (2000–2011) engine grade. Therefore, this study claims that the lack of effort for legal action or economic incentives to attract vessels with advanced tier grade or emission reduction equipment may have created “pollution leakage”, as vessels that do not comply with emission regulations in Europe or the US, etc., may have found their place in Israel, the Middle East or other third world countries. The results of this study show that the boiler FC share in the daily port FC (i.e., full day excluding maneuvering FC contribution) is significant and cannot be overlooked in the way that it currently is by the IMO in all of its GHG reports. Therefore, these findings are sufficiently significant to affect the daily and yearly port emission inventory levels and consequently affect all previous IMO GHG report findings regarding GHG and CAC emission in hoteling and berth times.

The results of this study indicate a gradual increase in daily and yearly inventory for the period 2016–2018 for Haifa Port compared to the previous period’s performance. This phenomenon of an increase in daily and yearly inventory can be explained by several fac-tors, such as an increase in waiting time (due recurrent employee sanctions), increase in vessel presence volume in the port area, and increase in VLCS calls. Additional results indicate that upon arrival to the port jurisdiction areas, the VLCS were very frequently found to be responsible for half of the daily total port emissions in comparison to the total existing OGV fleet in Haifa Port on that day. This analysis would be subject to change if each vessel’s operational reefers (i.e., refrigerated containers) onboards were to be incorporated in this analysis (as they are expected to increase vessel FC).

These findings assure the study’s analogous claim that each port and industrial area should be examined and managed as a collection of “flue gas stacks” as illustrated in

Figure 21. As this study claims that due to the significantly lower height of the flue gas stacks onboard vessels compared to flue gas stacks installed in land-based plants. Considering wind and topographic conditions, the flue gas stacks onboard vessels may affect city area air quality significantly more than those in the industrial zone. The latter are usually subject to extensive environmental emission regulations compared to vessels in port.

In addition, it is also important to indicate and emphasize that OGVs usually operate in port at low speed and are densely concentrated, since they are limited to anchorage circles and port berth stay. Therefore, while at port they can be considered static, in contrast to industrial areas, which may include power stations and plants that are scattered and less densely concentrated and equipped with high-altitude exhaust funnels and other equipment for emission reduction.

This study serves as a low-bound estimation, as it may not fully reflect the full impact of other emission sources in port and port-related areas, such as domestic marine traffic (i.e., navy, harbor craft, dredging and assist tugs), cargo handling (load/unload) equipment (i.e., bridge crane, forklift, yard tractor, etc.), heavy/light duty trucks and train (rail)-related sources.

Vessel movement data and FC data are the pillars of the port and shoreline emission inventory model frameworks. The strength of the first pillar, vessel movement data, relies on the fact that it comes from official sources. The Israeli Navy and the Israeli ASP are two different entities with separate and different methods for collecting and documenting vessel movements within Israel. Nevertheless, the accuracy of the datasets received from the Israel Navy and Israel ASP, is considered extremely high, as both of them serve as “watch dogs” for maritime movements. Contrastingly, the strength of the second pillar, FC data, relies on the fact that the daily FC figures used in this study were based on an analysis of an official survey conducted by the ASP Department of Supervision and Control and by operational data (provided by a major shipping company in the liner sector). All FC figures in this study were validated by recognized professional sources. Additionally, machinery such as reefer containers, vessel pumps (in/out), onboard crane activity, etc., may con-tribute significantly to vessel FC performance in the port. Due to the lack of accurate data, these processes’ contribution to pollution levels were ignored and were considered incorporated within the FC figures as part of the FC figures that were collected for the overall time at port according to the ASP logic. Moreover, this study cannot rule out biases due to unmeasured confounders/factors, such as engine type/performance and/or auxiliary engine or ME demand for lubricant oil contribution. However, these variables mostly contribute to an increase in the level of emissions since all engines were considered efficient with no accompanying loss of energy. To summarize the above, future analysis of this study, with more accurate data regarding vessel FC, may provide additional and more accurate information, but the emission findings will not be reduced since the limitations mentioned above are those that most contribute to an increased level of emissions emitted from vessel activity in port and port-related area. Therefore, this study can represent a low-estimation boundary for the emissions related to maritime activity in the port area.

This study calls for future research to investigate the spatial-temporal dynamics of emissions from shipping activity in ports [

31].

This study recommends the split of the anchorage area into two categories:

a. Anchorage area for vessels with valid schedule work plans (i.e., ships with a valid scheduled work plan, assigned with date, pilots shift, designated terminal and pier working labor shift, cranes, etc.). b. Anchorage area for vessels with temporary work plans (in-valid schedules) and anchorage visit calls. Therefore, the anchorage area from category A should be positioned a short distance away from port (to maintain port pilot and tug-boat efficiency). Additionally, anchorage area from category B should be positioned at a relevant distance that considers environmental factors as well as the mental and physical needs of the merchant mariner’s crew (e.g., a usable mobile phone signal, etc.) and other logistic factors.

This study recommends imposing an Emission Control Area (ECA) in Israel contiguous and territorial water. This study recommends an additional cost charged (selective tariff in port) to reflect the external social cost linked to the single vessel air pollution combined with supportive technological infrastructure (i.e., ship-to-shore connector) and economic incentive tools (e.g., electric subsidy and/or grant for installation of Alternative Marine Power—AMP) to attract or influence vessel owners to assign vessels equipped with new engine tier grades for calls at Israeli ports.