Experimental Research of Gaseous Emissions Impact on the Performance of New-Design Cylindrical Multi-Channel Cyclone with Adjustable Half-Rings

Abstract

:1. Introduction

2. Materials and Methods

2.1. Devices and Equipment

- Aspirator M-822. Air traction velocity—0–10 L/min; air traction velocity margin of error—±6%;

- Testo 400. Temperature measurement range—2 to 70 °C; margin of error—±0.2 °C; velocity measurement range—1–30 m/s; margin of error—±0.05 m/s;

- Testo 350 XL. Concentration measurement range: O2—0 to 25%; CO—0 to 10,000 ppm; NO—0 to 3000 ppm; NO2—0 to 500 ppm;

- Differential pressure gauge DSM-1. Pressure measurement range—0 to 20,000 kPa; margin of error—±5 Pa;

- Retsch RM200 mill;

- Elution shaker Rotoshake RS 12;

- Analytical scales KERN 770. Weight measurement range—0–210 g; measurement accuracy—±0.00005 g;

- Drying cabinet. Maximum temperature—200 °C;

- Air compressor Cosmos. Working pressure—10 bar;

- Ventilator ALTEKO. Engine power—2.2 kW;

- A particle sprayer;

- Chronometer Sekonda. Margin of error—±0.2 s;

- A sampling tube with a head;

- An exicator;

- AFA-VP-20 filters;

- Tweezers;

- A filtering cartridge for external filtering.

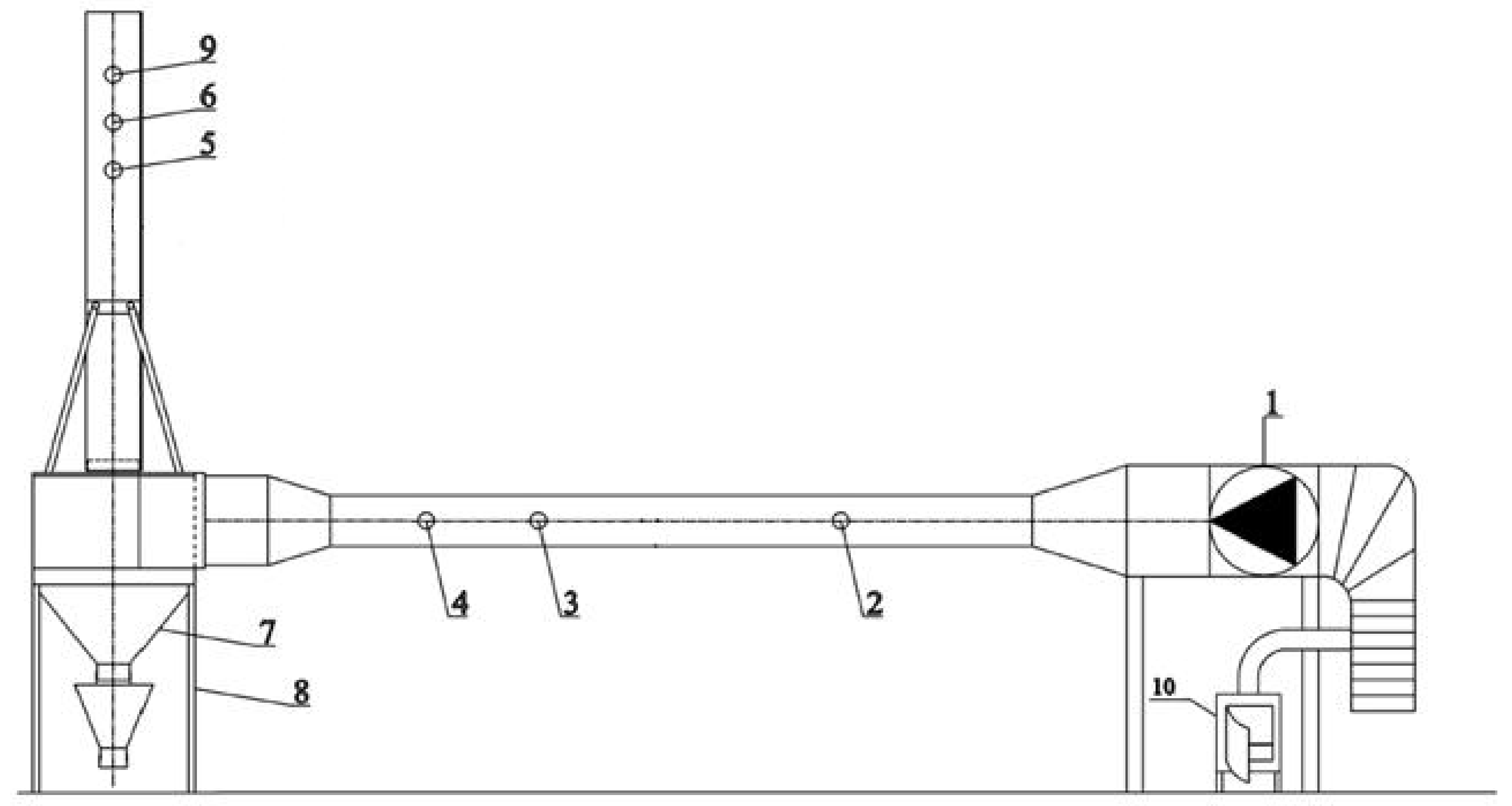

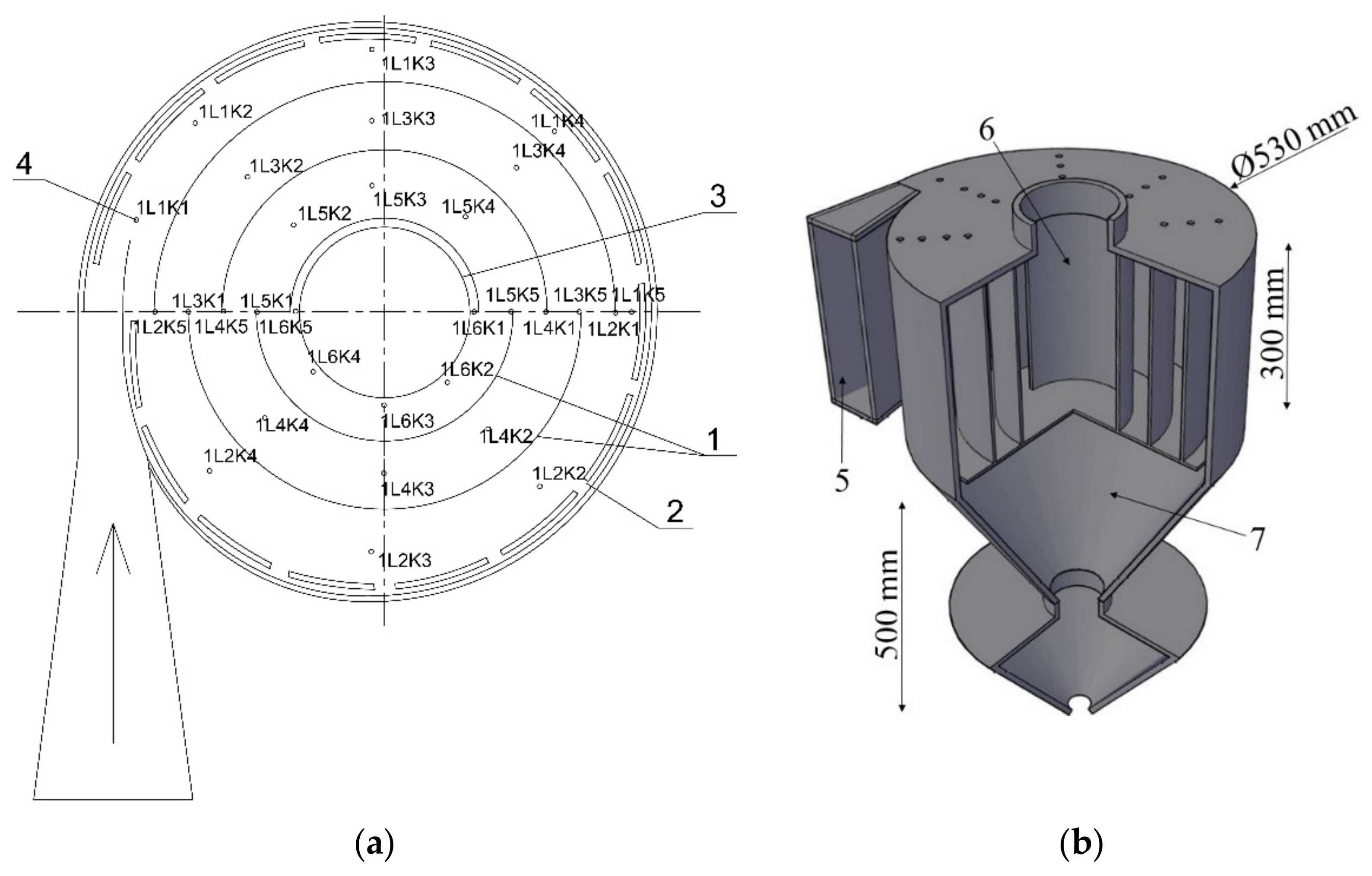

2.2. Experimental Setup

2.2.1. Creation of a Smoke (Gas) and Particulate Matter Source

2.2.2. Aerodynamic Parameters

2.2.3. Pollutant Concentration and Treatment Efficiency

2.3. Theoretical Research

2.3.1. Methodology of Theoretical Evaluation of Aerodynamic Parameters in the Multi-Channel Cyclone-Separator

2.3.2. Methodology of Theoretical Evaluation of Impact of the Gas (Air) Temperature’s and Smoke (Gas) on the Purification Efficiency of the Multi-Channel Cyclone

2.3.3. Methodology of Theoretical Evaluation of the Impact of Smoke (Gas) on the Purification Efficiency of the Multi-Channel Cyclone

3. Results and Discussion

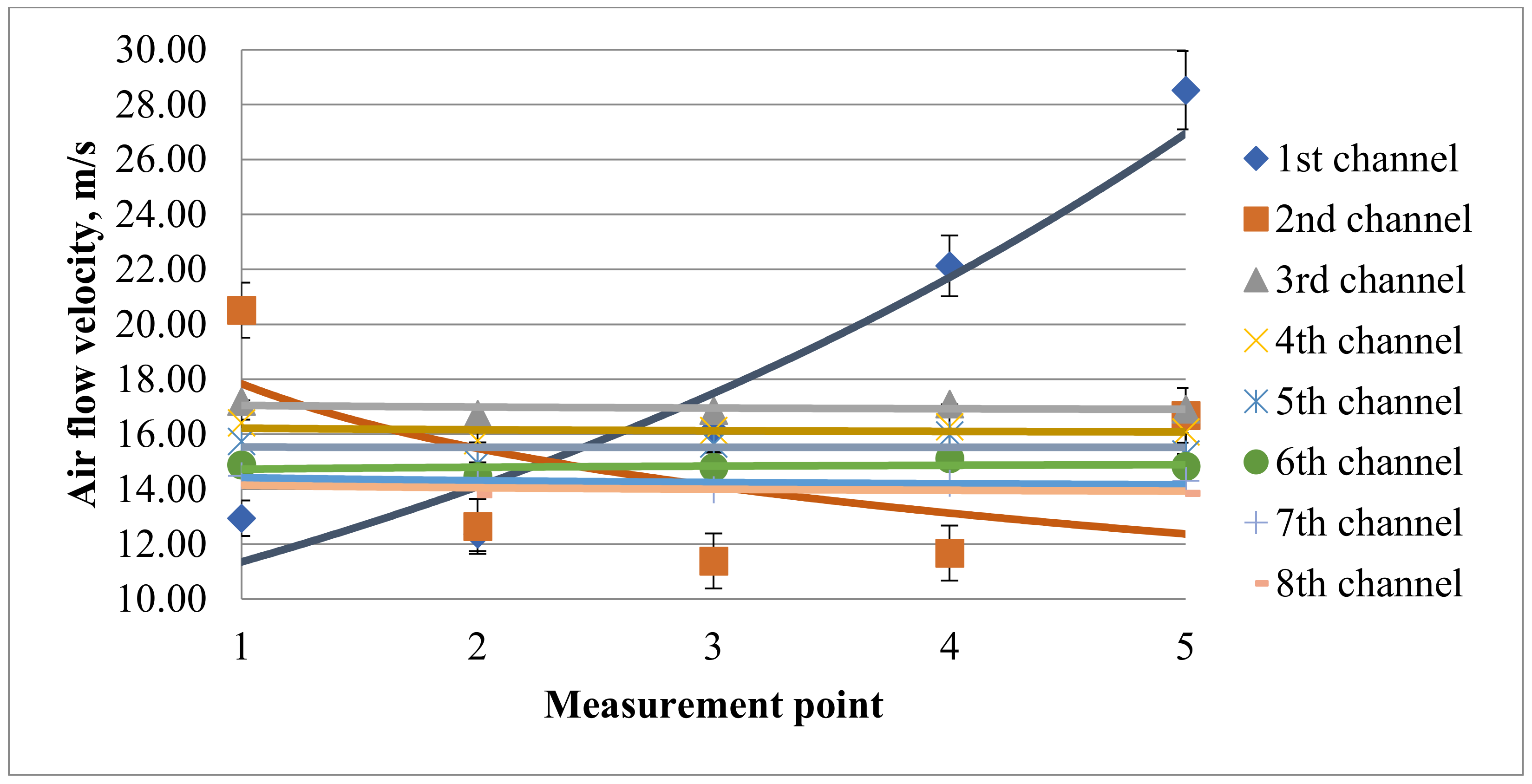

3.1. Analysis of Gas Flow Velocity Distribution in Channels of the Three-Level Cyclone-Separator

3.2. Theoretical Evaluation of Aerodynamic Parameters

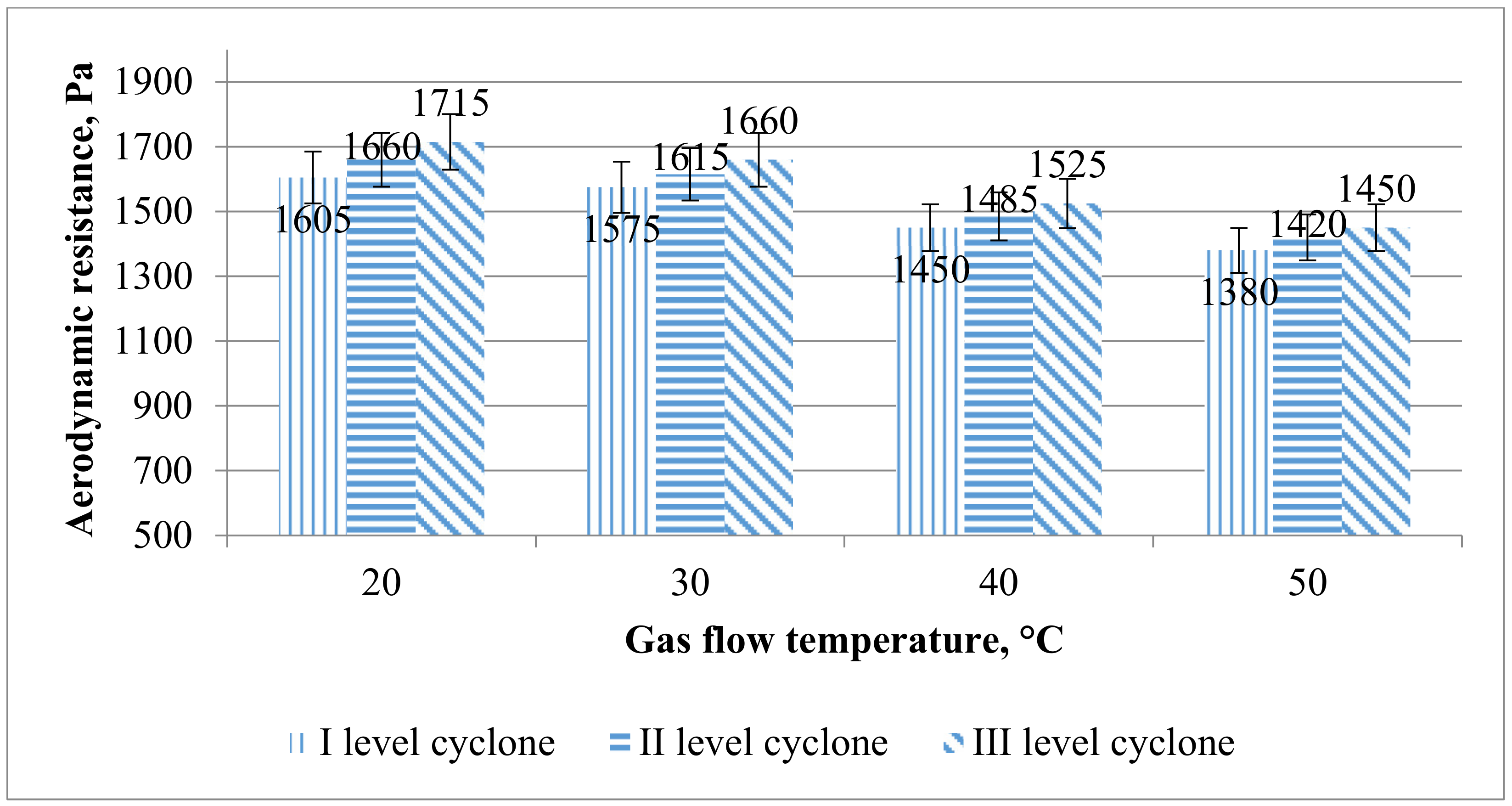

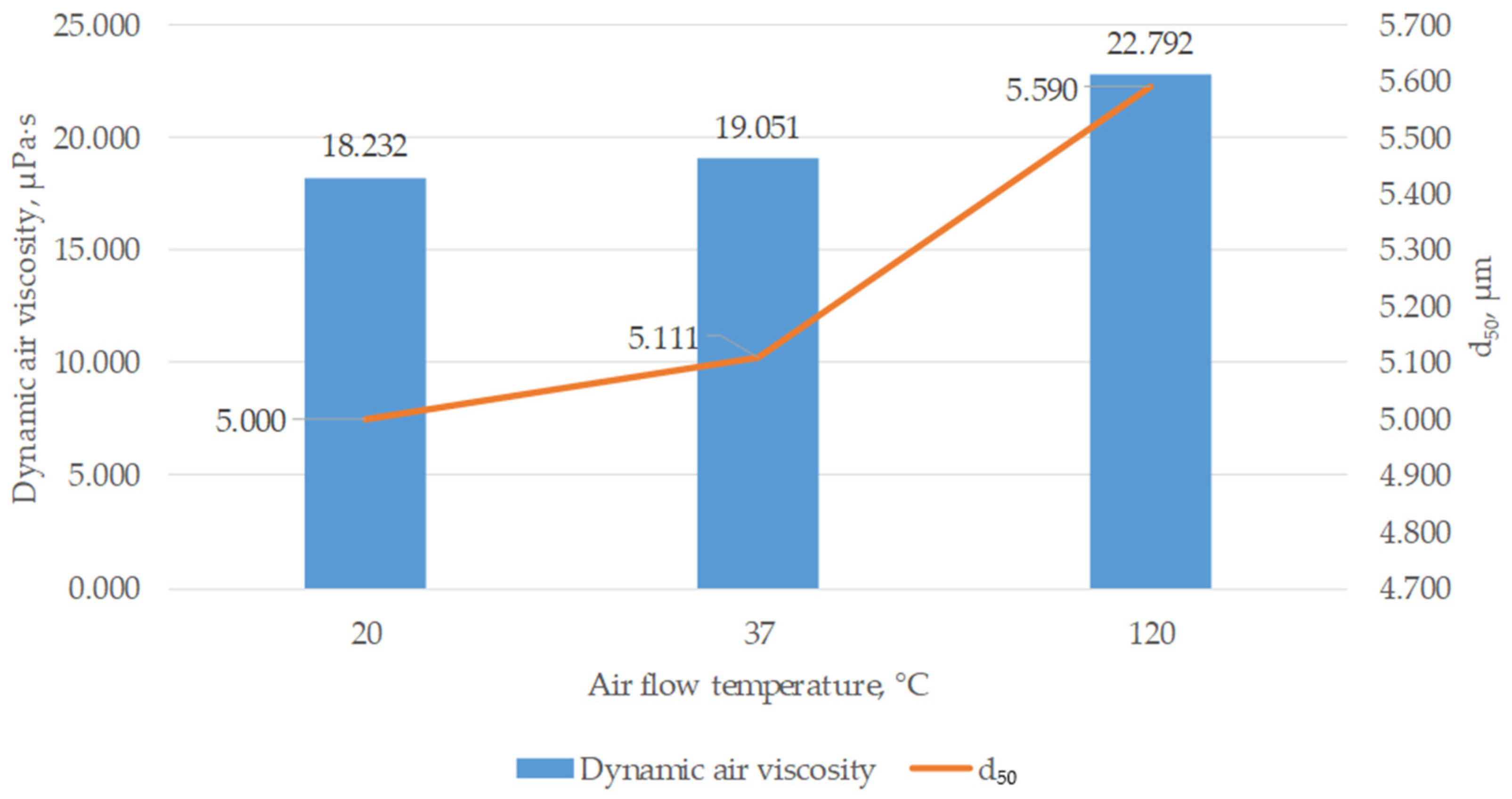

3.3. Theoretical Evaluation of Impact of the Gas (Air) Temperatures and Smoke (Gas) on the Purification Efficiency of the Multi-Channel Cyclone

4. Conclusions

5. Patents

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Rajabi, H.; Hadi Mosleh, M.; Mandal, P.; Lea-Langton, A.; Sedighi, M. Emissions of Volatile Organic Compounds from Crude Oil Processing—Global Emission Inventory and Environmental Release. Sci. Total Environ. 2020, 727, 138654. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Talbi, K.; Nemouchi, Z.; Donnot, A.; Belghar, N. An Experimental Study and a Numerical Simulation of the Turbulent Flow under the Vortex Finder of a Cyclone Separator. J. Appl. Fluid Mech. 2011, 4, 69–75. [Google Scholar]

- Baltrėnas, P.; Chlebnikovas, A. Removal of Fine Solid Particles in Aggressive Gas Flows in a Newly Designed Multi-Channel Cyclone. Powder Technol. 2019, 356, 480–492. [Google Scholar] [CrossRef]

- Baltrėnas, P.; Chlebnikovas, A. Cylindrical Multi-Level Multi-Channel Cyclone-Filter; European Patent Office: Munich, Germany, 2013; pp. 1–16. [Google Scholar]

- Vekteris, V.; Strishka, V.; Ozarovskis, D.; Mokshin, V. Experimental Investigation of Processes in Acoustic Cyclone Separator. Adv. Powder Technol. 2014, 25, 1118–1123. [Google Scholar] [CrossRef]

- Vekteris, V.; Tetsman, I.; Mokshin, V. Investigation of the Efficiency of the Lateral Exhaust Hood Enhanced by Aeroacoustic Air Flow. Process Saf. Environ. Prot. 2017, 109, 224–232. [Google Scholar] [CrossRef]

- Baltrėnas, P.; Chlebnikovas, A. Investigation into the Aerodynamic Parameters of the Recently Designed Two-Level Cylindrical Multi-Channel Cyclone-Separator. Sep. Sci. Technol. 2015, 50, 1257–1269. [Google Scholar] [CrossRef]

- Serebryanskyy, D.; Semeniuk, M.; Plashykhin, S. Research of Distribution of Concentration and Disperse Structure of Firm Particles in Gas Streams in System of Channels with the Closed Contours. Ind. Heat. Eng. 2013, 35, 83–92. [Google Scholar]

- Vaitiekunas, P.; Petraitis, E.; Venslovas, A.; Chlebnikovas, A. Air Stream Velocity Modelling in Multichannel Spiral Cyclone Separator. J. Environ. Eng. Landsc. Manag. 2014, 22, 183–193. [Google Scholar] [CrossRef]

- Tananaev, A.V. Inertial Filter-Separator; Russian Patent Office: Moscow, Russia, 1997; pp. 1–5. [Google Scholar]

- Jakstoniene, I.; Serebryanskyy, D.; Vaitiekûnas, P. Experimental Research on the Work of Centrifugal Filter When Eliminating Solid Particles from Clinker Cooling System. In Proceedings of the 8th International Conference on Environmental Engineering, ICEE, Kitakyushu, Japan, 30 November–2 December 2011; Volume 1. [Google Scholar]

- Li, Y.; Qin, G.; Xiong, Z.; Ji, Y.F.; Fan, L. The Effect of Particle Humidity on Separation Efficiency for an Axial Cyclone Separator. Adv. Powder Technol. 2019, 30, 724–731. [Google Scholar] [CrossRef]

- Kang, Z.; Yuan, Q.; Zhao, L.; Dai, Y.; Sun, B.; Wang, T. Study of the Performance, Simplification and Characteristics of SNCR de-NOx in Large-Scale Cyclone Separator. Appl. Therm. Eng. 2017, 123, 635–645. [Google Scholar] [CrossRef]

- Haake, J.; Oggian, T.; Utzig, J.; Rosa, L.M.; Meier, H.F. Investigation of the Pressure Drop Increase in a Square Free-Vortex Cyclonic Separator Operating at Low Particle Concentration. Powder Technol. 2020, 374, 95–105. [Google Scholar] [CrossRef]

- Edelmann, D.; Móri, T.F.; Székely, G.J. On Relationships between the Pearson and the Distance Correlation Coefficients. Stat. Probab. Lett. 2021, 169, 108960. [Google Scholar] [CrossRef]

- Djordjević, B.; Mane, A.S.; Krmac, E. Analysis of Dependency and Importance of Key Indicators for Railway Sustainability Monitoring: A New Integrated Approach with DEA and Pearson Correlation. Res. Transp. Bus. Manag. 2021, 41, 100650. [Google Scholar] [CrossRef]

- Liu, C.; Zhang, Y.; Sun, L.; Gao, W.; Jing, X.; Ye, W. Influence of Indoor Air Temperature and Relative Humidity on Learning Performance of Undergraduates. Case Stud. Therm. Eng. 2021, 28, 101458. [Google Scholar] [CrossRef]

- Martínez-Mariño, S.; Eguía-Oller, P.; Granada-Álvarez, E.; Erkoreka-González, A. Simulation and Validation of Indoor Temperatures and Relative Humidity in Multi-Zone Buildings under Occupancy Conditions Using Multi-Objective Calibration. Build. Environ. 2021, 200, 107973. [Google Scholar] [CrossRef]

- Poole, C.F.; Atapattu, S.N. Determination of Physicochemical Properties of Ionic Liquids by Gas Chromatography. J. Chromatogr. A 2021, 1644, 461964. [Google Scholar] [CrossRef] [PubMed]

- Kartikawati, N.A.; Safdar, R.; Lal, B.; Mutalib, M.I.B.A.; Shariff, A.M. Measurement and Correlation of the Physical Properties of Aqueous Solutions of Ammonium Based Ionic Liquids. J. Mol. Liq. 2018, 253, 250–258. [Google Scholar] [CrossRef]

- Patil, K.R.; Patil, S.K.; Shaikh, V.R.; Dagade, D.H.; Patil, K.J. Studies of Osmotic and Activity Coefficient Properties of Aqueous Solutions of Triethylammonium Formate and Triethylammonium Glycolate Protic Ionic Liquids at 298.15 K. J. Mol. Liq. 2021, 324, 115143. [Google Scholar] [CrossRef]

- Guo, D.-S.; Li, X.-B.; Zhang, H.-N.; Li, F.-C.; Ming, P.-J.; Oishi, M.; Oshima, M. Experimental Study on the Characteristics of Temperature Dependent Surface/Interfacial Properties of a Non-Ionic Surfactant Aqueous Solution at Quasi-Thermal Equilibrium Condition. Int. J. Heat Mass Transf. 2022, 182, 122003. [Google Scholar] [CrossRef]

- Yan, J.; Wang, H.; Zheng, Y.; Huang, X.; Meng, H.; Tan, C. A Novel Dew Point Measurement System Based on the Thermal Effect of Humidity Sensitive Thin Film. Measurement 2022, 187, 110248. [Google Scholar] [CrossRef]

- Lv, J.; Xu, H.; Xu, T.; Liu, H.; Qin, J. Study on the Performance of a Unit Dew-Point Evaporative Cooler with Fibrous Membrane and Its Application in Typical Regions. Case Stud. Therm. Eng. 2021, 24, 100881. [Google Scholar] [CrossRef]

- Lv, J.; Zhu, M.; Xu, H.; Wang, L.; Zhou, B. The Entransy Analysis in the Wet Channel of Dew Point Evaporative Cooler. J. Build. Eng. 2021, 44, 103371. [Google Scholar] [CrossRef]

- Pumo, D.; Noto, L. V Exploring the Linkage between Dew Point Temperature and Precipitation Extremes: A Multi-Time-Scale Analysis on a Semi-Arid Mediterranean Region. Atmos. Res. 2021, 254, 105508. [Google Scholar] [CrossRef]

- Troxel, T.R.; Gadberry, M.S.; Beck, P.A. Temperature, Relative Humidity, and Dew Point of 6 Commercial Trailer Compartments during Summer Transportations of Beef Calves in the Mid-South. Prof. Anim. Sci. 2016, 32, 461–469. [Google Scholar] [CrossRef]

- Ismail, I.M.I.; Rashid, M.I.; Ali, N.; Altaf, B.A.S.; Munir, M. Temperature, Humidity and Outdoor Air Quality Indicators Influence COVID-19 Spread Rate and Mortality in Major Cities of Saudi Arabia. Environ. Res. 2022, 204, 112071. [Google Scholar] [CrossRef] [PubMed]

- Chlebnikovas, A. Experimental Investigation of a One-Level Eight-Channel Cyclone-Separator Incorporating Quarter-Rings. Hem. Ind. 2021, 75, 241–251. [Google Scholar] [CrossRef]

| No. | Gas Temperature, °C | CO Concentration, g/m3 | d50, µm |

|---|---|---|---|

| 1 | 37 | 4 | 5.097 |

| 2 | 37 | 17 | 5.110 |

| 3 | 37 | 31 | 5.125 |

| 4 | 120 | 0.532 | 5.449 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chlebnikovas, A.; Paliulis, D.; Kilikevičienė, K.; Kilikevičius, A. Experimental Research of Gaseous Emissions Impact on the Performance of New-Design Cylindrical Multi-Channel Cyclone with Adjustable Half-Rings. Sustainability 2022, 14, 902. https://doi.org/10.3390/su14020902

Chlebnikovas A, Paliulis D, Kilikevičienė K, Kilikevičius A. Experimental Research of Gaseous Emissions Impact on the Performance of New-Design Cylindrical Multi-Channel Cyclone with Adjustable Half-Rings. Sustainability. 2022; 14(2):902. https://doi.org/10.3390/su14020902

Chicago/Turabian StyleChlebnikovas, Aleksandras, Dainius Paliulis, Kristina Kilikevičienė, and Artūras Kilikevičius. 2022. "Experimental Research of Gaseous Emissions Impact on the Performance of New-Design Cylindrical Multi-Channel Cyclone with Adjustable Half-Rings" Sustainability 14, no. 2: 902. https://doi.org/10.3390/su14020902

APA StyleChlebnikovas, A., Paliulis, D., Kilikevičienė, K., & Kilikevičius, A. (2022). Experimental Research of Gaseous Emissions Impact on the Performance of New-Design Cylindrical Multi-Channel Cyclone with Adjustable Half-Rings. Sustainability, 14(2), 902. https://doi.org/10.3390/su14020902