An Assessment Approach to Circular Business Models within an Industrial Ecosystem for Sustainable Territorial Development

Abstract

:1. Introduction

- -

- increasing the negative impact on the environment caused by higher emissions of pollutants into the atmosphere;

- -

- a significant number of industrial enterprises exceed the maximum permissible impact limits (emissions, discharges);

- -

- low level of use and recycling of production and consumption waste, etc.

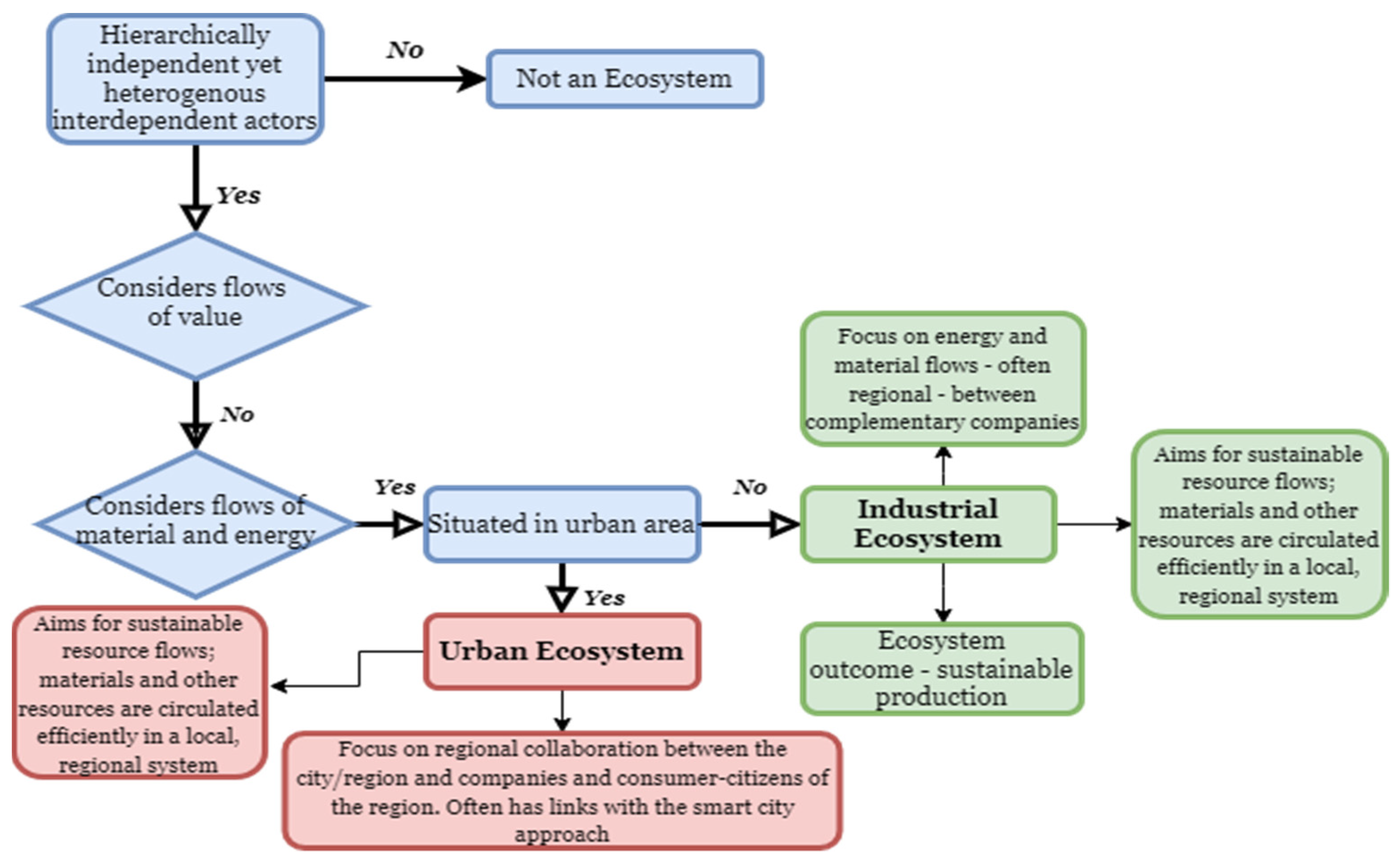

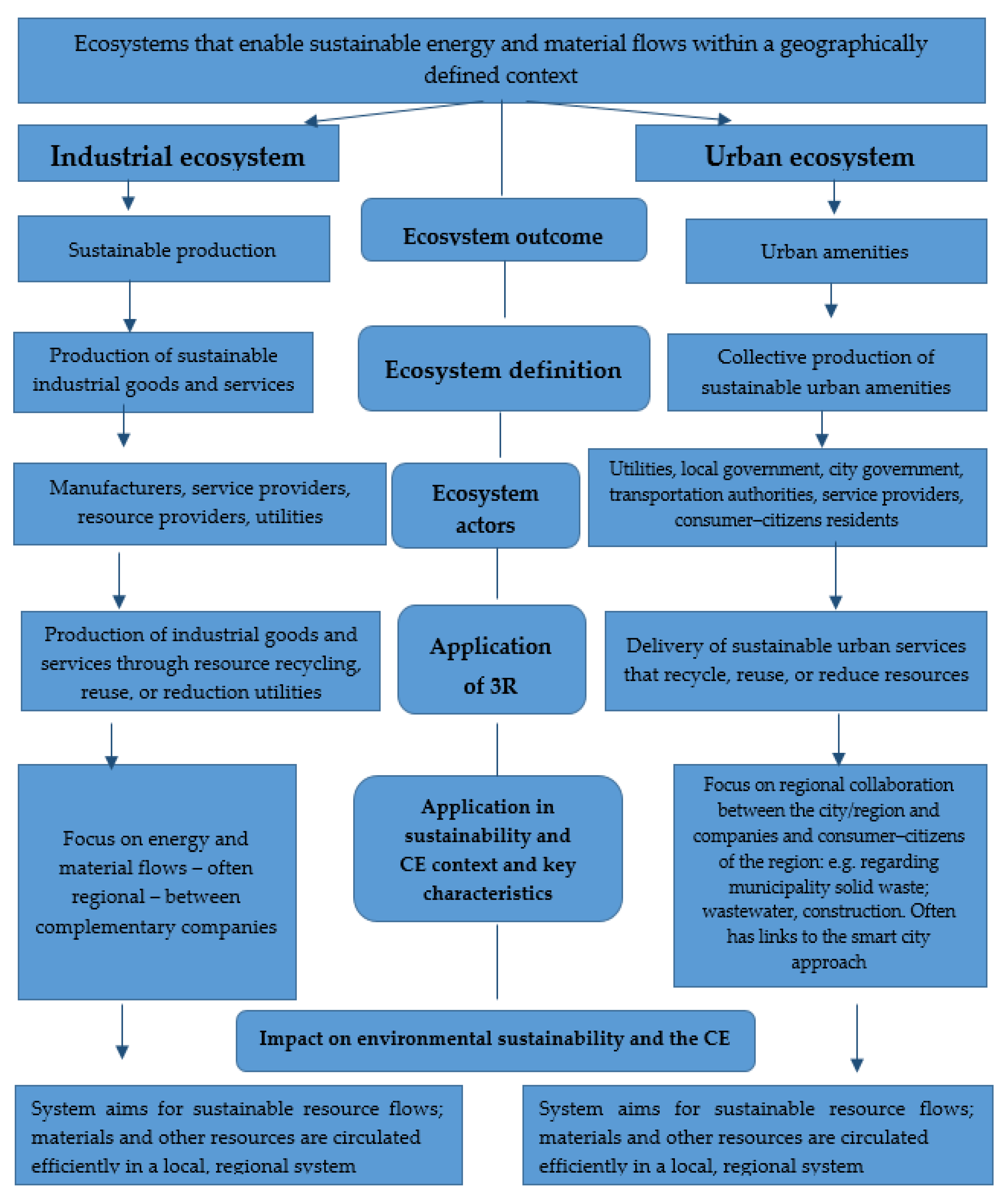

2. Literature Review

- ➢

- technological innovation;

- ➢

- social innovation;

- ➢

- organizational innovation.

- ✓

- to form the apparent necessity for strategic changes and environmental priorities on micro-, meso-, and macro-levels (see Table 1);

- ✓

- to ensure the interaction of interest groups applicable to ecology;

- ✓

- to exchange experience and knowledge, to educate and teach;

- ✓

- to form monitoring data and indicators for evaluating recycling maturity of an individual actor and the whole ecosystem.

- ✓

- the use of renewable or secondary materials instead of traditional raw materials. Resource efficiency increases due to the closed-loop material flows. Currently, such business models are used mainly in the production of various consumer goods [41];

- ✓

- resource recovery models characterized by converting waste into secondary raw materials. Meanwhile, the material flows are closed through processing, upcycling or cascading, and thereby resource efficiency increases. This business model is especially widespread in the industrial sector [41];

- ✓

- business models for product life extension that contribute to the slowdown of material flows in various industries. For example, the service life of cars can be extended by maintenance and repair, and by avoiding planned obsolescence [41];

- ✓

- platforms for joint consumption (sharing) aimed at increasing the intensity of using available products through their lease, rental or sharing. Since marketing is aimed at offering usage, rather than possessing specific goods, they contribute to the reduction in resource flows. The sharing economy is presented in many industries, in particular, in the short-term rental housing and transport rental [41];

- ✓

- models of product-service systems (PSS), e.g., provision of services instead of products, help reduce resource consumption as well. The customers are given the right to use products being the property of the manufacturer or supplier. This business model is applied, for example, when leasing vehicles [41].

3. Methodological Framework

- ✓

- production and consumption;

- ✓

- waste management;

- ✓

- secondary raw materials;

- ✓

- competitiveness and innovation.

- ✓

- generation and treatment of production and consumption waste;

- ✓

- MSW generation per capita as an indicator for consumption efficiency;

- ✓

- resource efficiency of the economy as a whole, including material consumption in absolute values and per unit of GDP;

- ✓

- resource efficiency of industrial sectors, including material consumption by types of economic activity, indicators for the use of secondary resources and loss of resources in the production process [9].

- ✓

- an exchange of material and energy resources within the ecosystem;

- ✓

- creation of closed-loop water supply systems for the key processes of the ecosystem actors;

- ✓

- creation of a common management system for material and energy resources of the ecosystem;

- ✓

- using an overall ecosystem infrastructure, including administrative, transport, energy and water supply, and waste management systems.

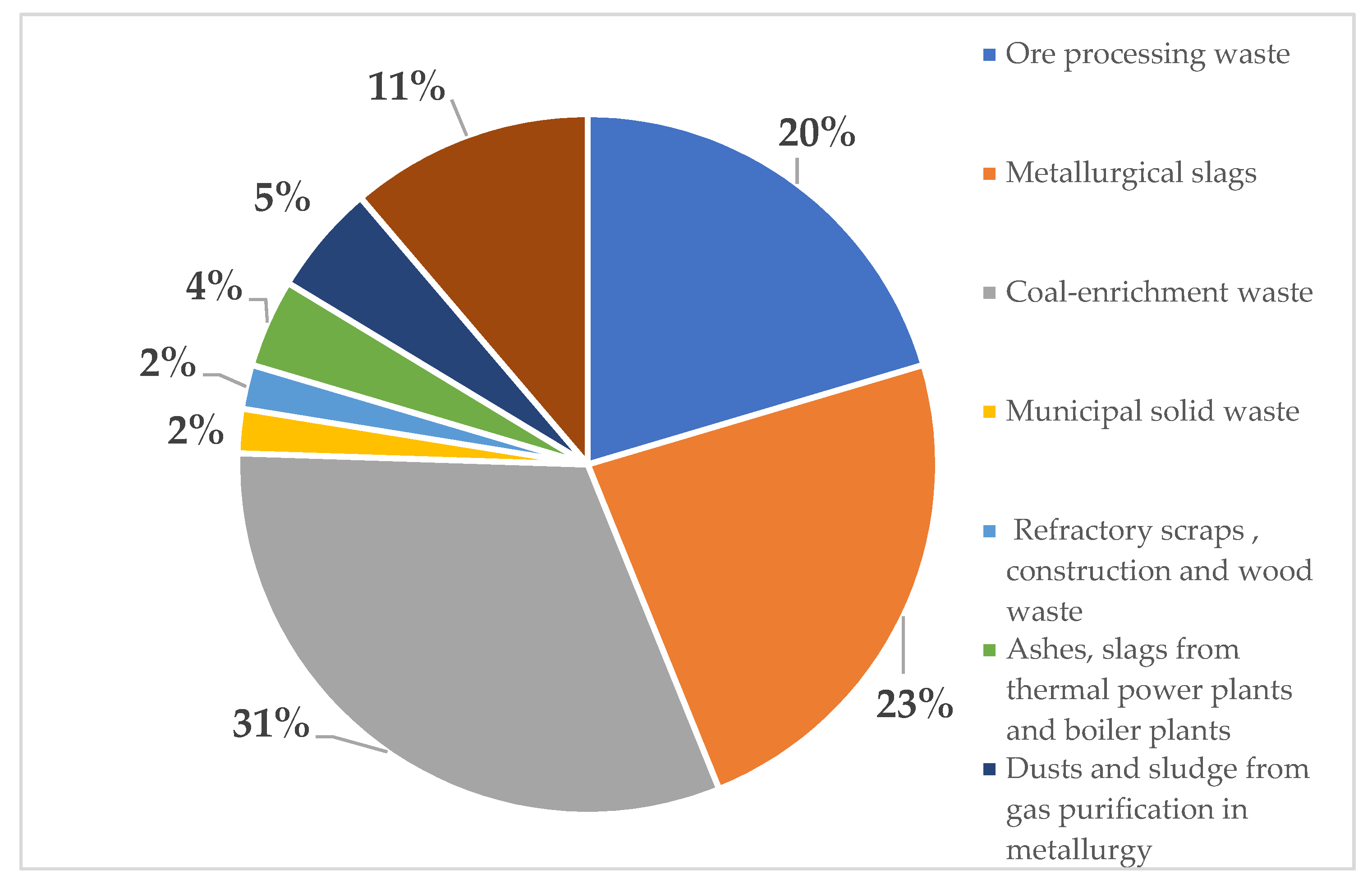

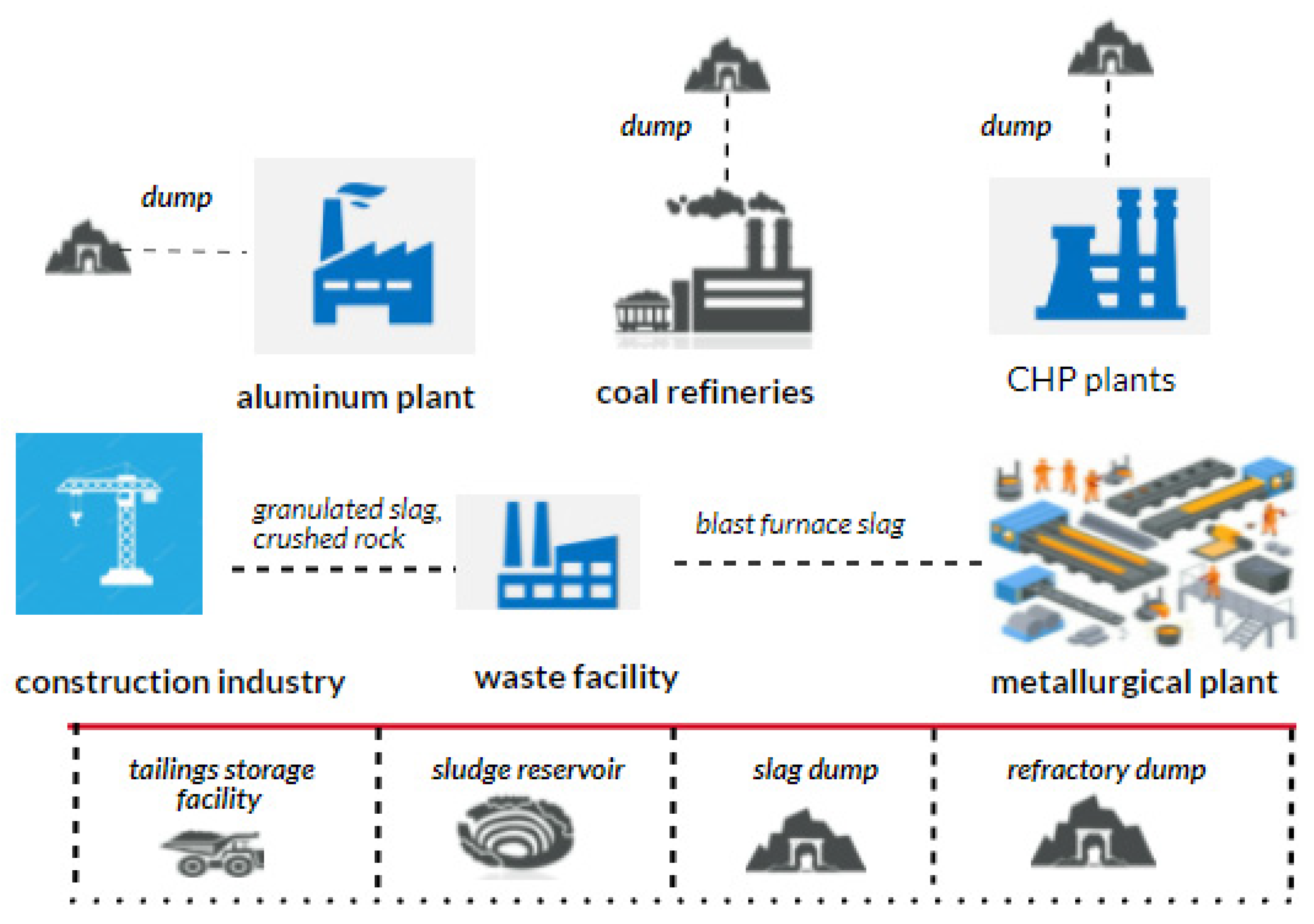

4. A Case Study: Analysis and Assessment of Industrial Ecosystem (Novokuznetsk)

An Analysis of Environmental Problems in Novokuznetsk

5. Results

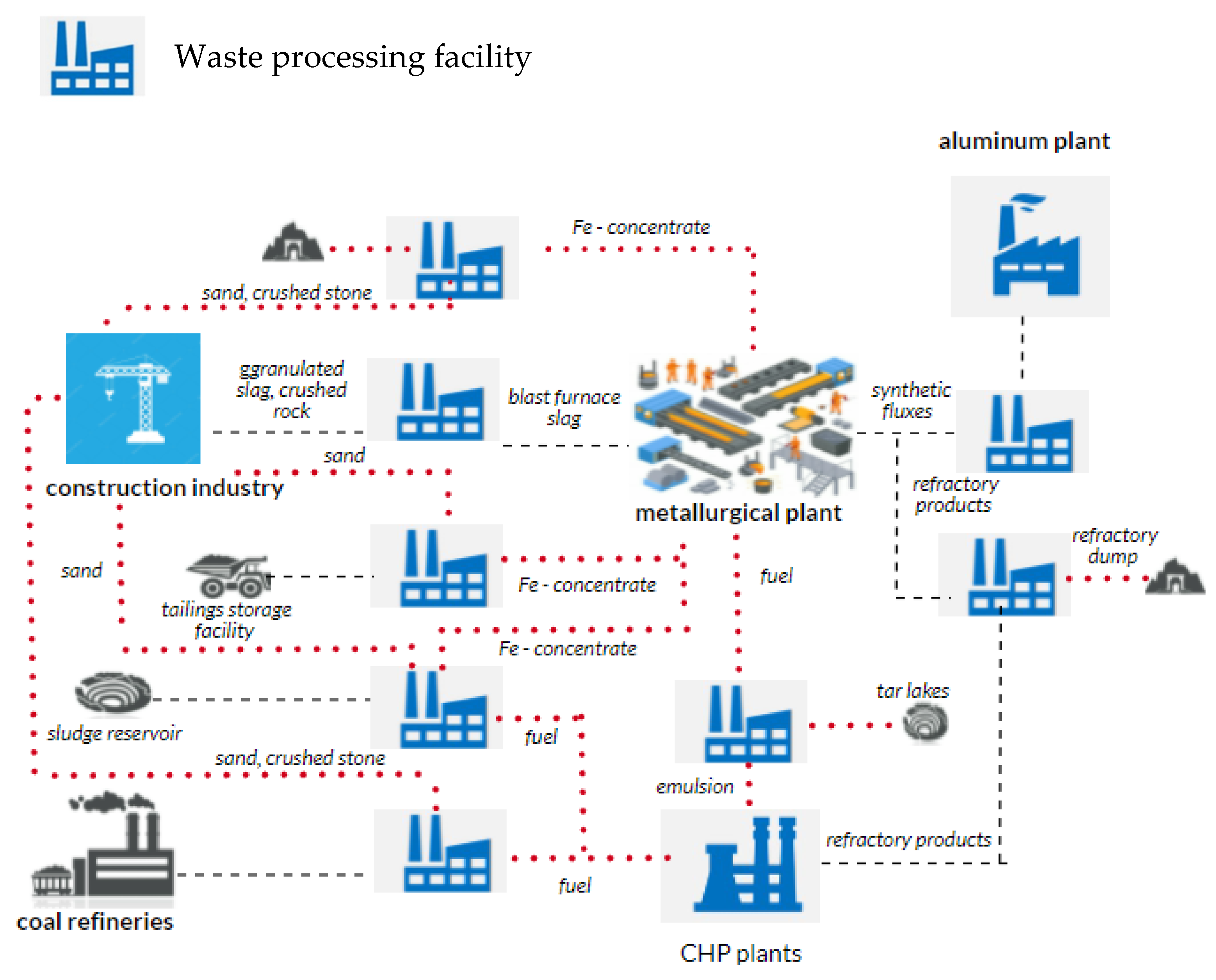

An Assessment of Material Flows within the Circular Industrial Ecosystem of Novokuznetsk

6. Discussion and Conclusions

- ✓

- ecodesign (design of products for a long service life and their feasible modernization, reuse, repair, and refurbishment; product design based on environmentally sustainable and limited use of resources that ensures recycling to obtain high-quality secondary raw materials at the end of the product service life; elimination of hazardous materials from products and processes to ensure the purity of material flows);

- ✓

- repair and refurbishment;

- ✓

- recycling (processing of the maximum waste volume and nomenclature into high-quality secondary raw materials; avoiding cascading; existence of well-functioning secondary raw materials markets; and avoiding mixing and contamination of materials; cascading in case of impossibility of recycling to obtain high-quality secondary raw materials).

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Order of the Government of the Russian Federation of October 29, 2021 No. 3052-r “On Approval of the Strategy for the Socio-Economic Development of the Russian Federation with a Low Level of Greenhouse Gas Emissions until 2050”. Available online: https://www.garant.ru/products/ipo/prime/doc/402894476/#1000 (accessed on 16 October 2021).

- European Commission. Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions, ‘Closing the Loop — An EU Action Plan for the Circular Economy’. 2015. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:52015DC0614 (accessed on 15 October 2021).

- European Commission. Communication from the Commission to the European Parliament, the Council, the Economic and Social Committee and the Committee of the Regions “A new circular economy action plan for a cleaner and more competitive Europe”. 2020. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=COM:2020:98:FIN&WT.mc_id=Twitter (accessed on 15 October 2021).

- European Environment Agency (EEA). Circular by Design — Products in the Circular Economy, EEA Report No 6/2017. Available online: https://www.eea.europa.eu/publications/circular-by-design (accessed on 16 October 2021).

- Sverko Grdic, Z.; Krstinic Nizic, M.; Rudan, E. Circular Economy Concept in the Context of Economic Development in EU Countries. Sustainability 2020, 12, 3060. [Google Scholar] [CrossRef] [Green Version]

- European Environment Agency (EEA). Paving the Way for a Circular Economy: Insights on Status and Potentials, EEA Report No 11/2019. Available online: https://www.eea.europa.eu/publications/circular-economy-in-europe-insights (accessed on 16 October 2021).

- International Resource Panel. 2019. Available online: https://www.resourcepanel.org/news-events/international-resource-panel-2019-highlights (accessed on 16 October 2021).

- OECD. Global Material Resources Outlook to 2060 Economic Drivers and Environmental Consequences. 2018. Available online: https://www.oecd.org/environment/waste/highlights-global-material-resources-outlook-to-2060.pdf (accessed on 23 September 2021).

- Bobylev, S.N.; Solovyeva, S.V. Circular economy and its indicators for Russia. World New Econ. 2020, 14, 63–72. [Google Scholar] [CrossRef]

- Federal Service for Supervision of Natural Resources. Actual Indicator Values for Integrated MSW Management System Federal Project for 2020. Available online: https://rpn.gov.ru/activity/regulation/help/ (accessed on 13 November 2021).

- Order of the Government of the Russian Federation of January 25, 2018 N 84-r On Approval of the Strategy for the Development of Industry for Processing, Utilization and Neutralization of Production and Consumption Waste for the Period until 2030. Available online: http://static.government.ru/media/files/y8PMkQGZLfbY7jhn6QMruaKoferAowzJ.pdf (accessed on 23 September 2021).

- Guman, O.; Wegner-Kozlova, E. Impact of the regional development specifics on the system of circular economy assessment. E3S Web Conf. 2020, 208, 01004. [Google Scholar] [CrossRef]

- Steffen, W.; Richardson, K.; Rockström, J.; Cornell, S.E.; Fetzer, I.; Bennett, E.M.; Biggs, R.; Carpenter, S.R.; de Vries, W.; de Wit, C.A.; et al. Faculty Opinions recommendation of Sustainability. Planetary boundaries: Guiding human development on a changing planet. Science 2015, 347, 1259855. [Google Scholar] [CrossRef] [Green Version]

- Ellen McArthur Foundation. A New Textiles Economy: Redesigning Fashion’s Future. 2017. Available online: https://ellenmacarthurfoundation.org/a-new-textiles-economy (accessed on 23 November 2021).

- Bocken, N.M.P.; de Pauw, I.; Bakker, C.; van der Grinten, B. Product design and business model strategies for a circular economy. J. Indust. Prod. Eng. 2016, 33, 308–320. [Google Scholar] [CrossRef] [Green Version]

- Bocken, N.M.P.; Ritala, P. Six ways to build circular business models. J. Bus. Strat. 2021. Available online: https://doi.org/10.1108/JBS-11-2020-0258 (accessed on 5 April 2021). [CrossRef]

- Kirchherr, J.; Reike, D.; Hekkert, M. Conceptualizing the circular economy: An analysis of 114 definitions. Resour. Conserv. Recycl. 2017, 127, 211–232. [Google Scholar] [CrossRef]

- Korhonen, J.; Nuur, C.; Feldmann, A.; Birkie, S.E. Circular economy as an essentially contested concept. J. Clean. Prod. 2018, 175, 544–552. [Google Scholar] [CrossRef]

- Woolven, J. A New Measure of Business Success. Medium. 2021. Available online: https://medium.com/circulatenews/a-new-measure-of-business-success-9e53b7aafafa (accessed on 5 November 2021).

- Jacobides, M.G.; Cennamo, C.; Gawer, A. Towards a theory of ecosystems. Strat. Manag. J. 2018, 39, 2255–2276. [Google Scholar] [CrossRef] [Green Version]

- Thomas, L.D.W.; Autio, E. Innovation Ecosystems. 2019. Available online: https://papers.ssrn.com/sol3/papers.cfm?abstract_id=3476925 (accessed on 15 October 2021).

- Tolstykh, T.; Shmeleva, N.; Gamidullaeva, L. Evaluation of circular and integration potentials of innovation ecosystems for industrial sustainability. Sustainability 2020, 12, 4574. [Google Scholar] [CrossRef]

- Aarikka-Stenroos, L.; Ritala, P.; Thomas, L.D.W. Circular economy ecosystems: A typology, definitions, and implications. In Research Handbook of Sustainability Agency; Edward Elgar Publishing: Cheltenham, UK, 2021. [Google Scholar]

- Aarikka-Stenroos, L.; Ritala, P. Network management in the era of ecosystems: Systematic review and management framework. Ind. Mark. Manag. 2017, 67, 23–36. [Google Scholar] [CrossRef]

- Tansley, A.G. The use and abuse of vegetational concepts and terms. Ecology 1935, 16, 284–307. [Google Scholar] [CrossRef]

- Frosch, R.A.; Gallopoulos, N.E. Strategies for manufacturing. Sci. America. 1989, 261, 144–152. [Google Scholar] [CrossRef]

- Korhonen, J. Four ecosystem principles for an industrial ecosystem. J. Clean. Prod. 2001, 9, 253–259. [Google Scholar] [CrossRef]

- Lowe, E.A.; Evans, L.K. Industrial ecology and industrial ecosystems. J. Clean. Prod. 1995, 3, 47–53. [Google Scholar] [CrossRef]

- Chertow, M.R. Industrial symbiosis: Literature and taxonomy. Ann. Rev. Energy Environ. 2000, 25, 313–337. [Google Scholar] [CrossRef] [Green Version]

- Gómez, A.M.M.; González, F.A.; Bárcena, M.M. Smart eco-industrial parks: A circular economy implementation based on industrial metabolism. Resour. Conserv. Recycl. 2018, 135, 58–69. [Google Scholar] [CrossRef]

- Uusikartano, J.; Väyrynen, H.; Aarikka-Stenroos, L. Public actors and their diverse roles in eco-industrial parks: A multiple-case study. J. Clean. Prod. 2021, 296, 126463. [Google Scholar] [CrossRef]

- Allenby, B.R. Implementing industrial ecology: The AT&T matrix system. Interfaces 2000, 30, 42–54. [Google Scholar]

- Tolstykh, T.; Gamidullaeva, L.; Shmeleva, N.; Lapygin, Y. Regional development in Russia: An ecosystem approach to territorial sustainability assessment. Sustainability 2020, 12, 6424. [Google Scholar] [CrossRef]

- Tolstykh, T.; Gamidullaeva, L.; Shmeleva, N.; Woźniak, M.; Vasin, S. An assessment of regional sustainability via the maturity level of entrepreneurial ecosystems. J. Open Innov. Technol. Mark. Complex. 2020, 7, 5. [Google Scholar] [CrossRef]

- Tolstykh, T.; Gamidullaeva, L.; & Shmeleva, N. Approach to the formation of an innovation portfolio in industrial ecosystems based on the life cycle concept. J. Open Innov. Technol. Mark. Complex. 2020, 6, 151. [Google Scholar] [CrossRef]

- Schroeder, P.; Anggraeni, K.; Weber, U. The relevance of circular economy practices to the sustainable development goals. J. Ind. Ecol. 2019, 23, 77–95. [Google Scholar] [CrossRef] [Green Version]

- Moreno-Juez, J.; Vegas, I.J.; Gebremariam, A.T.; García-Cortés, V.; Di Maio, F. Treatment of end-of-life concrete in an innovative heating-air classification system for circular cement-based products. J. Clean. Prod. 2020, 263, 121515. [Google Scholar] [CrossRef]

- Shojaei, B.; Abtahi, M.; Najafi, M. Chemical recycling of PET: A stepping-stone toward sustainability. Polym. Adv. Technol. 2020, 31, 2912–2938. [Google Scholar] [CrossRef]

- Turken, N.; Cannataro, V.; Geda, A.; Dixit, A. Nature inspired supply chain solutions: Definitions, analogies, and future research directions. Int. J. Prod. Res. 2020, 58, 4689–4715. [Google Scholar] [CrossRef]

- Corona, B.; Shen, L.; Reike, D.; Rosales Carreón, J.; Worrell, E. Towards sustainable development through the circular economy—A review and critical assessment on current circularity metrics. Resour. Conserv. Recycl. 2019, 151, 104498. [Google Scholar] [CrossRef]

- OECD Environmental Performance Reviews: Denmark 2019. Available online: https://doi.org/10.1787/1eeec492-en (accessed on 5 November 2021).

- Environmental Performance Index. 2018 EPI Results. Available online: https://epi.yale.edu/epi-countries (accessed on 5 November 2021).

- Material Productivity and Waste. 2017, pp. 44–49. Available online: https://doi.org/10.1787/9789264268586-7-en (accessed on 5 November 2021).

- Green Growth Indicators 2017. 2017. Available online: https://doi.org/10.1787/9789264268586-en (accessed on 5 November 2021).

- Monitoring Framework - Circular Economy – Eurostat. Available online: https://ec.europa.eu/eurostat/web/circular-economy/indicators (accessed on 15 October 2021).

- Eurostat. Resource Efficiency Scoreboard. 2014. Available online: https://ec.europa.eu/environment/resource_efficiency/documents/re_scoreboard_2014.pdf (accessed on 15 October 2021).

- EU. Decision No 1386/2013/EU of the European Parliament and of the Council of 20 November 2013 on a General Union Environment Action Programme to 2020 Living Well, within the Limits of Our Planet, OJ L 354. 2013, pp. 171–200. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=celex%3A32013D1386 (accessed on 15 October 2021).

- EC. Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions — Roadmap to a Resource Efficient Europe, COM(2011) 571 Final, Brussels. 2011. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:52011DC0571 (accessed on 15 October 2021).

- Gilbert, T.F. Human Competence: Engineering Worthy Performance; Tribute Edition; Pfeiffer: Nashua, NH, USA, 2007. [Google Scholar]

- Doranova, A.; Roman, L. Cooperation Fostering Industrial Symbiosis Market Potential, Good Practice and Policy Actions. Final Report. Teresa Domenech. University College London. Technopolis Group Matthew Smith, Irati Artola — Trinomics. Publications Office of the European Union. 2018. Available online: https://www.technopolis-group.com/wp-content/uploads/2020/02/Cooperation-fostering-industrial-symbiosis-market-potential-good-practice-and-policy-actions.pdf (accessed on 15 October 2021).

- Savina, I.N.; Vodoleev, A.S.; Zakharova, M.; Domnin, K.I. Environmental policy of Novokuznetsk in the context of modern requirements for metallurgical industry development. Izv. Ferr. Met. 2020, 63, 512–520. [Google Scholar] [CrossRef]

- Kuzbass Association of waste recyclers, Novokuznetsk, Russia. Available online: http://wasteinfo.ru/ (accessed on 15 October 2021).

- EVRAZ. Sustainability Report 2020. Available online: https://ar2020.evraz.com/en/meet-evraz (accessed on 15 October 2021).

- RUSAL. Sustainability Report 2020. Available online: https://rusal.ru/upload/iblock/afa/afa0a5c7124865007de322e052db776c.pdf (accessed on 15 October 2021).

- ESG Ranking of Russian Companies RAEX-Europe. Available online: https://raex-a.ru/rankingtable/ESG_ranking_companies/16/09/2021 (accessed on 15 October 2021).

- Batova, N.; Wilts, H.; Dorozhko, S.; Lobanov, E.; Sysoev, S.; Tochickaja, I.; Shershunovich, I.; Shushkevich, A. Circular Economy: Conceptual Approaches and Tools for Their Implementation: A Monograph for Specialists of Government Bodies, Business and the Interested Public; Medisont: Minsk, Belarus, 2020. [Google Scholar]

| Levels | Targets |

|---|---|

| Macro- | Formation of “green” infrastructure; development and implementation of institutional mechanisms for ensuring a circular economy; collection and assessment of data on the circularity level of economy |

| Meso- | Ensuring the interactions of interest groups in the field of ecology; formation of a system of sectoral and territorial tools for supporting the circular economy; formation of data that assess the recycling maturity of territories and industries |

| Micro- | Introduction of innovative resource-saving and environmental technologies; implementation of organizational recycling models and approaches; formation of a motivation system and “green” competencies of employees; formation of monitoring systems for indicators to evaluate recycling maturity. |

| Waste Processing Technology | Types of Generated and Accumulated Production Waste | Types of Secondary Raw Materials and Products |

|---|---|---|

| Waste processing technology for iron ore dressing | Iron ore dressing waste | Iron ore concentrate, etalized iron product, pyrite concentrate, garnet concentrate, sulphide concentrate, construction sands |

| Coal-enrichment waste processing technology | Coal-enrichment waste | Coal concentrate, biomass briquettes, ceramic bricks, construction sands |

| Metallurgical slag processing technology | Metallurgical (steelmaking) slags | Iron ore concentrate, crushed rock, construction sands |

| Metallurgical sludge processing technology | Metallurgical (steelmaking) sludges | Iron ore concentrate, zinc concentrate, construction sands |

| Liquid waste processing technology of the coke and by-product process | Liquid wastes of the coke and by-product process | Sintering plasticizer for the coke and by-product process, sleeper impregnation oil, binders for briquettes |

| Processing of ash and slag waste of CHP plants and boiler houses | Ash and slag waste of CHP plants and boiler houses | Ferrous and non-ferrous metal concentrates, construction materials |

| Indicators | 2019 | 2020 |

|---|---|---|

| Operating activities | ||

| Steel production, thousand tonnes | 13,814 | 13,630 |

| Coal production, thousand tonnes | 26,140 | 20,653 |

| Steel sales revenue, million U.S. dollars | 8143 | 6969 |

| Coal sales revenue, million U.S. dollars | 2021 | 1490 |

| Material costs for steel production, million U.S. dollars | 2587 | 2025 |

| Material costs for coal production, million U.S. dollars | 159 | 110 |

| Energy costs in steel production, million U.S. dollars | 439 | 398 |

| Energy costs in coal mining, million U.S. dollars | 51 | 43 |

| Environmental activities | ||

| Metallurgical waste, million tonnes | 8.9 | 9 |

| Cost of metallurgical waste (iron-and-steel scrap), million U.S. dollars | 3316 | 3316 |

| Mining waste (recycled waste), million tonnes | 35.5 | 38.6 |

| Mining waste recycling rate, % | 38 | 28.5 |

| Water consumption in steel production, million m3 | 164.7 | 162.2 |

| Water consumption in coal mining, million m3 | 32.13 | 36.12 |

| Water costs in steel production, million U.S. dollars (in line with industrial water tariffs) | 50.3 | 51.1 |

| Water costs in coal mining, million U.S. dollars | 9.8 | 12 |

| Total water recycling for own use, % | 93.3 | 93.3 |

| Total air emissions (steel), kt | 396 | 382 |

| Total air emissions (coal), kt | 403.2 | 429.7 |

| Greenhouse gases, million tons of CO2 equivalent for steel sector | 27.34 | 26.58 |

| Greenhouse gases, million tons of CO2 equivalent for coal sector | 11.72 | 12.98 |

| Resource efficiency | ||

| Material intensity of steel production | 0.378 | 0.290 |

| Material intensity of coal mining | 0.078 | 0.073 |

| Energy intensity of steel production | 0.054 | 0.057 |

| Energy intensity of coal mining | 0.025 | 0.029 |

| Indicators | 2019 | 2020 |

|---|---|---|

| Operating activities | ||

| Aluminum production, thousand tonnes | 215 | 215 |

| Aluminum sales revenue, million U.S. dollars | 457.1 | 404 |

| Material costs for aluminum production, million U.S. dollars | 240.3 | 217.6 |

| Power consumption, million GJ | 27.2 | 26.0 |

| Energy costs in aluminum production, million U.S. dollars | 176.8 | 169 |

| Environmental activities | ||

| Aluminum production waste, million tonnes | 0.78 | 0.82 |

| Metal waste recycling rate, % | 57 | 59 |

| Cost of aluminum production waste, million U.S. dollars | 1.17 | 1.23 |

| Water consumption in aluminum production, million m3 | 10.9 | 11.1 |

| Industrial water costs, million U.S. dollars | 1.4 | 1.4 |

| Total water recycling for own use, % | 93.2 | 92.6 |

| Total air emissions (metal), kt | 0.56 | 0.62 |

| Greenhouse gases, million tons of CO2 equivalent/a ton of aluminum | 2.03 | 2.04 |

| Resource efficiency | ||

| Material intensity of aluminum production | 0.526 | 0.537 |

| Energy intensity of aluminum production | 0.387 | 0.418 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gamidullaeva, L.; Shmeleva, N.; Tolstykh, T.; Shmatko, A. An Assessment Approach to Circular Business Models within an Industrial Ecosystem for Sustainable Territorial Development. Sustainability 2022, 14, 704. https://doi.org/10.3390/su14020704

Gamidullaeva L, Shmeleva N, Tolstykh T, Shmatko A. An Assessment Approach to Circular Business Models within an Industrial Ecosystem for Sustainable Territorial Development. Sustainability. 2022; 14(2):704. https://doi.org/10.3390/su14020704

Chicago/Turabian StyleGamidullaeva, Leyla, Nadezhda Shmeleva, Tatyana Tolstykh, and Alexey Shmatko. 2022. "An Assessment Approach to Circular Business Models within an Industrial Ecosystem for Sustainable Territorial Development" Sustainability 14, no. 2: 704. https://doi.org/10.3390/su14020704

APA StyleGamidullaeva, L., Shmeleva, N., Tolstykh, T., & Shmatko, A. (2022). An Assessment Approach to Circular Business Models within an Industrial Ecosystem for Sustainable Territorial Development. Sustainability, 14(2), 704. https://doi.org/10.3390/su14020704