1. Introduction

The energy management system is one of the control systems that aims to dispatch energy with efficiency, according to demand. Nowadays, in large buildings, such as shopping malls, offices, commercial buildings, or hotels, the energy management system has been applied. There are many types of energy needs in buildings, such as electric, cooling, or heat energy. For supply, the generation system can produce the energy, or the operator can purchase energy from the power grid. In specific important operations, energy sources in the building consist of combined heat and power (CHP) as the main power source [

1]. In [

2], the BEMS has

CHP as the main power source and works in conjunction with TES, which stores the waste heat generated by

CHP in the electric power production process and aims to reduce total operating cost and CO

2 emission. Likewise, Ref. [

3] proposed the optimal operation for reducing carbon emissions by using a two-layer model for AC-DC hybrid microgrids. Carbon trading mechanisms and uncertainty are considered.

To plan for energy dispatch, load demand prediction plays an important role in demand management and making distribution planning as efficient as possible. For predicting load demand, there are a variety of methods, such as neural networks, unit consumption methods, and trend forecasting methods, which can be applied according to the amount of data and desired period of time for prediction. There are research reports on load demand prediction, which takes the load demand forecast error into consideration when planning the power distribution. The prediction error is classified in the form of uncertainty. Various prediction methods are widely used. In [

4], the load is predicted, and the uncertainty is estimated using long short-term memory for a day-ahead load of EV charging stations. There are research works taking predictions into consideration when planning energy distribution. In [

5], predicting the load demand with an artificial neural network model is used to plan energy distribution and reduce the operating costs of a smart house. Modelling load demand forecast errors can adjust dispatch strategies whenever the hourly power load demand changes. Likewise, Ref. [

6] proposed the energy dispatch strategy to schedule the charging and discharging of the battery-integrated power system. The fluctuating behavior of electrical loads was analyzed to find a suitable strategy by taking the battery characteristics and system parameters into consideration. A robust energy management system is an efficient energy management system to handle load uncertainty in the system. For a small system, such as a microgrid with renewable energy, the uncertainty of the power source is important to consider. In [

7], the authors proposed the robust energy management system to deal with the uncertainty using the dual decomposition and find the optimal solution that reduces the operating cost. Similarly, in the stand-alone microgrid, the errors from predicting the power generation, including solar power, wind power, and the electricity load demand of local electricity users, are taken into account for planning the schedule of the microgrid supply [

8]. For cluster microgrids, the prediction of the load demand in the short-term using ANN was used to manage the operations [

9].

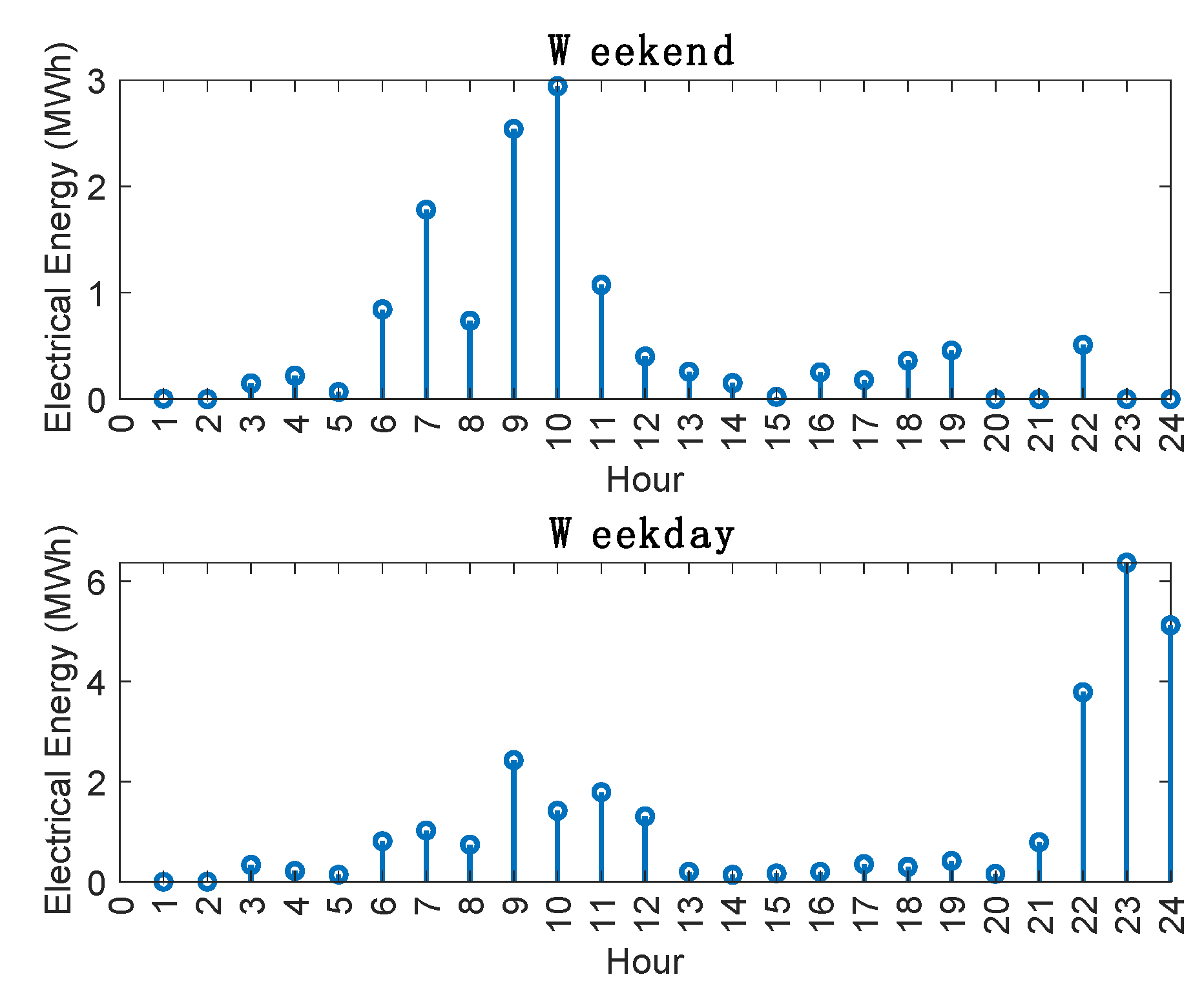

There are various sources of uncertainty occurring within the system, such as renewable energy and electrical load demand. This uncertainty is difficult to control, but it is important to deal with the uncertainty that arises in load demand predictions. In this paper, we propose the multi-objective optimal operation of a building energy management system (BEMS) with thermal energy storage (TES) and battery energy storage (BES), with consideration of the load demand uncertainty. Moreover, we will find the trade-off performance between the operating cost and carbon dioxide emission and analyze the power flow. The proposed BEMS is applicable to large commercial buildings with electrical, cooling, or thermal load demands. Large commercial buildings include shopping malls, office buildings, hotels, or factories. We consider the electrical and thermal energy supply and consumption for efficiency and comfort. The ratio between electrical and thermal energy is concerned with electrical energy from

CHP and BES and thermal energy from

CHP. The ratio plays a vital role in the power-to-heat (

P2H) coefficient. In this work, load characteristics consist of time variation and uncertainty. The proposed BEMS can accommodate large buildings subject to the load variation. For planning the dispatch strategies, the load uncertainty is taken into account. The proposed BEMS has

CHP as the main generating component.

CHP typically achieves a total efficiency of 65 to 80%.

CHP requires less fuel to produce energy output and depends on a natural gas source. Typically,

CHP range in size from 50 kW to over 1 MW electrical capacity [

10]. Therefore, the size of

CHP can be chosen to suit the power and heat consumption of the building. The proposed BEMS incorporates TES and BES, which manage the excess heat energy and electricity to be used during the on-peak period. Moreover, the uncertainty of the load demand is taken into account in the energy dispatch of the proposed BEMS. The optimal strategy is designed to accommodate the load uncertainty and provide economic and environmental benefits to users. We demonstrate that the improvement of

TOC using the proposed BEMS occurring in the case of economic optimal operation and multi-objective operation in the presence of load uncertainty. This approach is universal for the types of loads with uncertainty.

The paper is organized as follows. In

Section 2, we describe the BEMS.

Section 3 presents load demand forecasting and load uncertainty.

Section 4 provides the formulation of the optimal dispatch of the proposed BEMS.

Section 5 shows the comparison results, in terms of

TOC and

TCOE and energy flow. The conclusion is provided in

Section 6.

2. BEMS Description

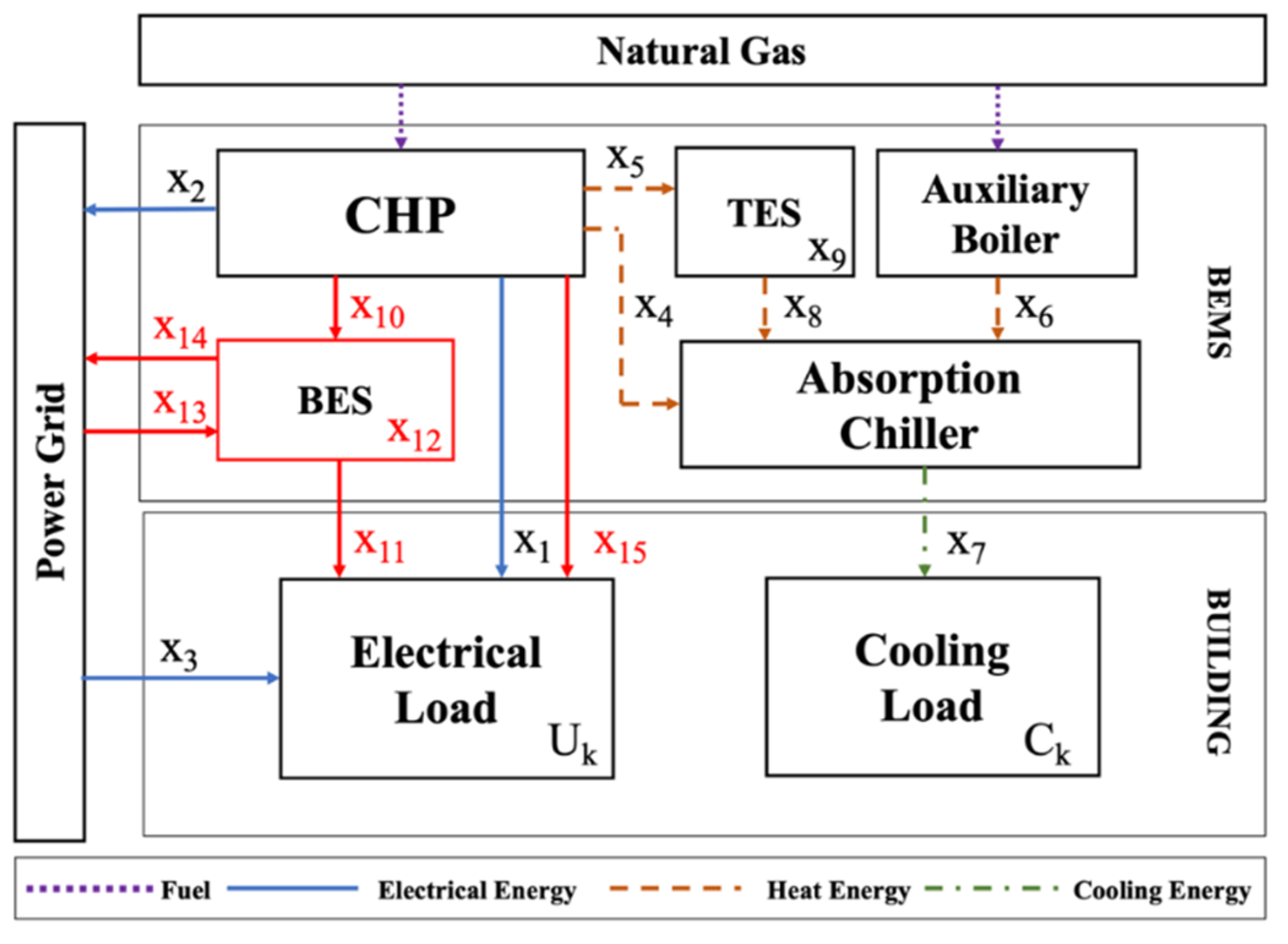

The proposed system consists of

CHP, absorption chiller, auxiliary boiler, TES, BES, and power grid.

CHP is the main component of power generation for distribution by producing electrical energy and heat energy simultaneously, together with the electric power from the BES and SR. BES and SR are available to operate when load demand uncertainty arises, and there is a power grid that will help protect them in the event of a power shortage. The proposed BEMS diagram is shown in

Figure 1. In addition,

CHP makes profits from exchanging electrical energy to the grid. Moreover, an absorption chiller is an element that converts heat energy into cooling energy to supply cooling load demands within a building. The chiller has a heat source from the

CHP, TES, and auxiliary boiler. From the electrical power generation process of

CHP, the waste heat is stored in TES for further use. The description of the variables is shown in

Table A1 in the

Appendix A.

4. Optimal Dispatch Strategies

To determine the appropriate dispatch strategy, the specific objectives were considered, in order to make the strategy effective and meet the demands. We formulate the problem of finding an optimal strategy for energy management in a building.

4.1. Dispatch Strategies

For the dispatch strategy of the proposed BEMS, two objectives will be considered. They are economics optimal operation and environmental optimal operation. After that, both objectives are simultaneously considered, namely multi-objective optimal operation. There are two types of energy needed in buildings, namely electrical and cooling loads. Energy dispatch strategies are divided into two categories, based on the type of load demand. In the BEMS, thermal energy storage (TES) and battery energy storage (BES) are installed. Moreover, an additional amount of energy from

CHP is called the spinning reserve (SR) to tackle the load uncertainty. Next, we present the characteristics of the elements and dispatch strategies. Note that the description of system parameters and acronyms are given in

Appendix A,

Table A2 and

Table A3, respectively.

4.1.1. Thermal Energy Storage

TES is a device for temporarily retaining thermal energy for later use. The waste heat from the electrical production process of

CHP will be stored in TES. The constraints of the TES consist of the rate of charge and discharge, state-of-charge, and operating boundary between the minimum and maximum capacity. The dispatch of TES is as follows.

4.1.2. Battery Energy Storage

BES is the storage of electrical energy to be used during the on peak period and support the BEMS during the load uncertainty. BES will charge the energy during the first four hours of the day and discharge energy to support the uncertainty which arises. The constraints for BES include the charge and discharge rates, state-of-charge, and operating boundary between minimum and maximum capacity. The dispatch of BES is as follows.

4.1.3. Spinning Reserve

SR is the energy from

CHP to support the uncertainty of the electrical load, together with BES. SR can be an additional energy resource when the generation does not exceed the maximum capacity of

CHP [

14]. SR works in conjunction with the BES to support the load demand uncertainty. The dispatch of SR is as follows.

4.1.4. Electrical Energy

For the strategy to dispatch the electricity, a set of predicted load demands are planned in the energy dispatch. It was divided into four cases, based on predicted load, under load demand uncertainty. CHP is the main components to supply electrical power to the electric load. The first case is when there is no demand for electrical loads, and all components in the system will shut down. Regarding the second case, when the actual load demand is less than the predicted load demand, CHP cooperates with BES to supply the energy to meet demands. In the third case, the actual load demand is less than the predicted load demand and maximum capacity of CHP. CHP supplies electrical energy equal to the predicted load demand. BES cooperate with SR to support part of the uncertainty. The last case is when the actual load demand is less than the predicted load demand and more than the maximum capacity of CHP. CHP supplies electrical energy equal to the predicted load demand. BES cooperate with SR and purchase electrical energy from power grid to support the uncertainty. The electrical energy dispatch strategy is shown below.

end.

end.

end.

Note that CHP does not operate beyond the boundary of the power output and ramp rate. Similarly, BES does not operate beyond the boundary of capacity, and the state-of-charge is updated every time instant k.

4.1.5. Cooling Energy

The cooling energy dispatch strategy is divided into four cases, as well as the electric energy dispatch strategy. The main components of cooling energy dispatch include CHP, auxiliary boiler absorption chiller, and TES. In the first case, there is no load demand of cooling energy. The second case is that the cooling load demand is less than the minimum operating value of the absorption chiller. CHP and TES work together to supply heat to the absorption chiller, and the absorption chiller operates at the minimum value of the machine rating. In the third case, the cooling load demand is greater than the minimum operating value of the absorption chiller, and CHP can provide sufficient heat energy. CHP cooperates with TES to supply heat to the absorption chiller. In the last case, CHP cannot provide enough heat energy. TES cooperate with auxiliary boiler to supply heat energy to the absorption chiller. The cooling energy dispatch strategy is shown below.

Else if

, then

Else if

, then

end.

Note that and are the minimum and maximum of the cooling production of the absorption chiller. is the coefficient of the performance of a single-type absorption chiller. and are the minimum and maximum of heat energy production of auxiliary boiler.

4.2. Economics and Environmental Optimal Operations

In the proposed BEMS, the objective functions are divided into economics optimal operation and environmental optimal operation. Both objectives are subjected to energy dispatch conditions, i.e., electrical and cooling loads.

4.2.1. Economics Optimal Operation

Economics optimal operation defines the objective function to be the

TOC. The

TOC is the summation of the energy and demand charge costs [

15]. The demand charge cost depends on the maximum imported electricity from the power grid. The objective is to minimize

TOC.

Note that xi,k is the energy flow. qk and pk represent the price of electrical energy exporting and importing to grids. CCHP and CAB are operating costs of the CHP and auxiliary boiler, respectively, and depend on fuel price. Moreover, dPG is the demand charge from power grids. Δt is the time duration of each time interval, n is the number of time interval in one day, and d is the number of days.

4.2.2. Environmental Optimal Operation

Environmental optimal operation defines the objective function to be the total CO

2 emissions. It is calculated from the CO

2 emissions in the energy production of the components in the system, with the aim of minimizing the total CO

2 emissions.

Note that represents the CO2 emission of CHP in ton per megawatt-hour, represents the CO2 emission of auxiliary boiler in ton per megawatt-hour, is the CO2 emission of power grid in ton per megawatt-hour, and is the efficiency of the auxiliary boiler.

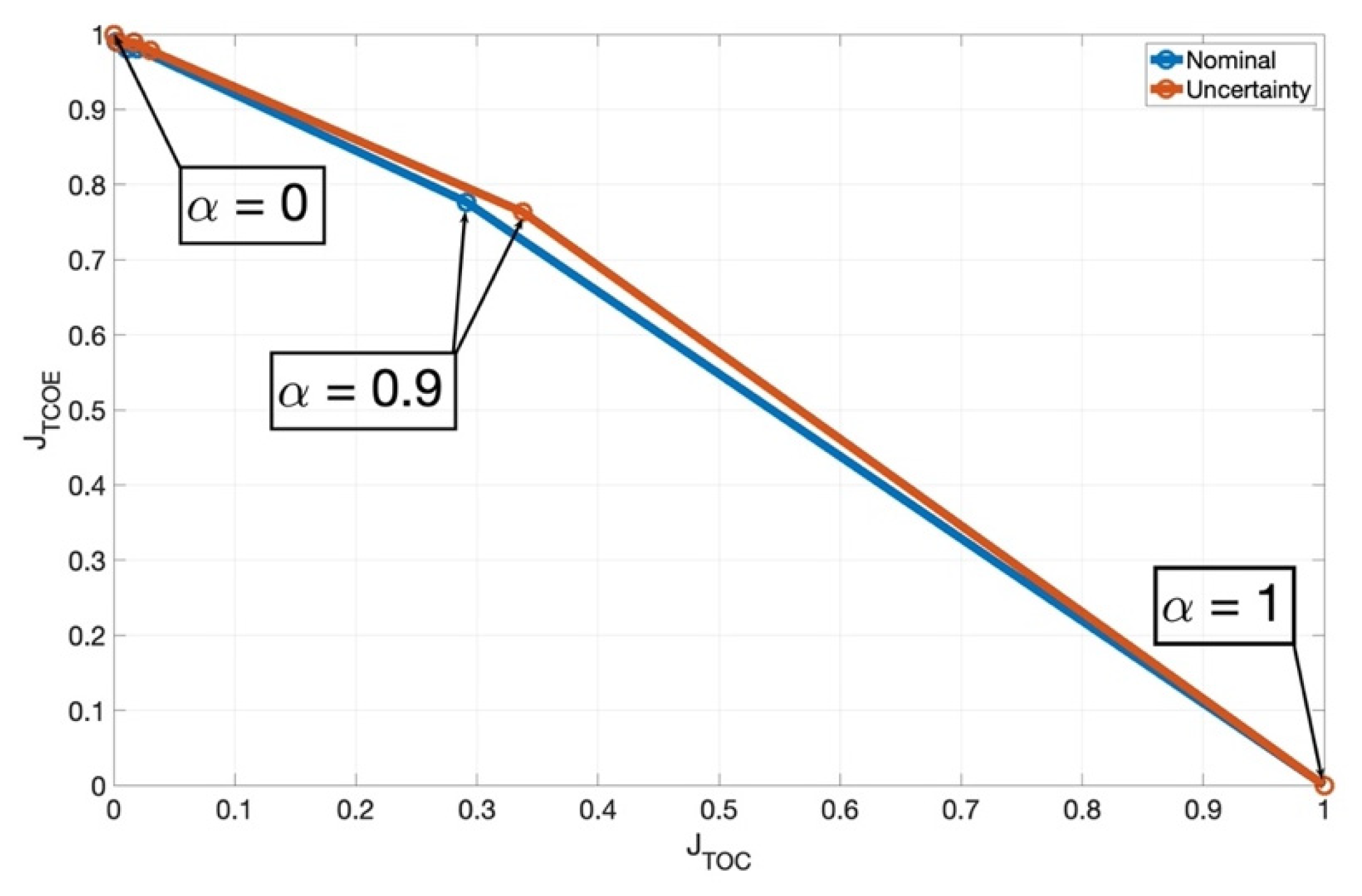

4.3. Multi-Objective Optimal Operation

From

Section 4.2, there are two different objective functions, which are economics optimal operation and environmental optimal operation. To find the relationship between the two objectives, the multi-objective optimal operation is introduced. The relationship between the two objectives is represented by the weighting factor

and provided in the form of trade-off performance. The dispatch strategy of multi-objective optimal operation using the same energy dispatch strategy as described in

Section 4.1.

In order to keep the cost function at the same unit of measure, we apply the normalization to the objective functions. The method is referred to the min–max normalization. This method is commonly used to normalize the cost function, where the lowest value is converted to 0 and highest value is converted to 1; all other values are converted to values between 0 and 1. Both objective functions will be normalized. The normalized total operating cost is represented by

JTOC, and the normalized total CO

2 emission is

JTCOE. The normalization of

TOC and

TCOE are expressed as follows:

where

TOCmin is the minimum

TOC,

TOCmax is the maximum

TOC,

TCOEmin is the minimum total CO

2 emission, and

TCOEmax is the maximum

TCOE. From the normalized

TOC and

TCOE, we can combine them into a multi-objective function

J, defined as follows.

where

is the weighting factor between 0 and 1 to represent the weight between

TOC and

TCOE and have a step size of 0.1. The weights are 0 is the case, which considers only the economics optimal operation, and the weight is equal to 1, when considering only the environmental optimal operation.

For the uncertainty case, the minimum TOC is the TOC from economics optimal operation, and the minimum TCOE is the result of environmental optimal operation. On the other hand, the maximum of TOC is the operating cost of the environmental optimal operation, and the maximum value of TCOE is the CO2 emission of economics optimal operation. For the nominal case, the energy dispatch is based on the predicted load, without considering the load uncertainty. The minimum TOC comes from the economics optimal operation of the nominal load. The minimum TCOE is obtained from the environmental optimal operation of the nominal load. The maximum TOC is from the environmental optimal operation result. The maximum TCOE is the result of the economic optimal operation.

4.4. Linear Programming and Algorithm

Linear programming is an optimization problem with a linear cost function subjected to the linear constraints. The operations of the proposed BEMS in the presence of the uncertainty in the electrical load demand can be formulated as linear programs. The linear program is described as follows.

where

c is the constant vector related to the cost function. The cost function is either

TOC or

TCOE.

x is the decision variable, expressed as the energy flow, as shown in BEMS diagram. The constraints consist of the dispatch conditions of each component in BEMS, as described in

Section 4.1. The optimization problem is defined as the minimization problem under the constraints of the dispatching condition of BEMS. The constraints are in the form of equations and inequalities to define operating conditions and boundaries. The optimal solution is the most suitable answer out of the feasible answers.

6. Conclusions

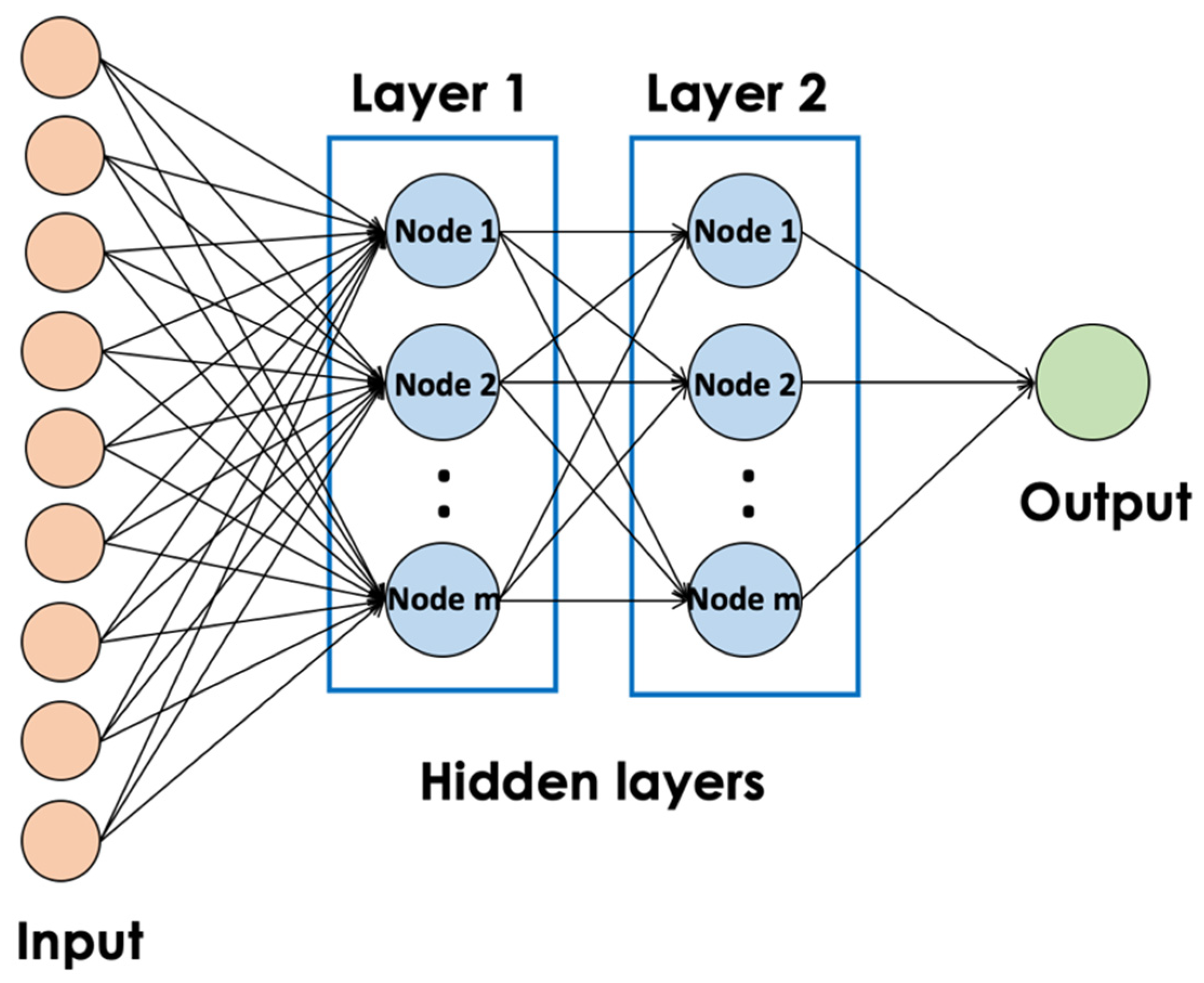

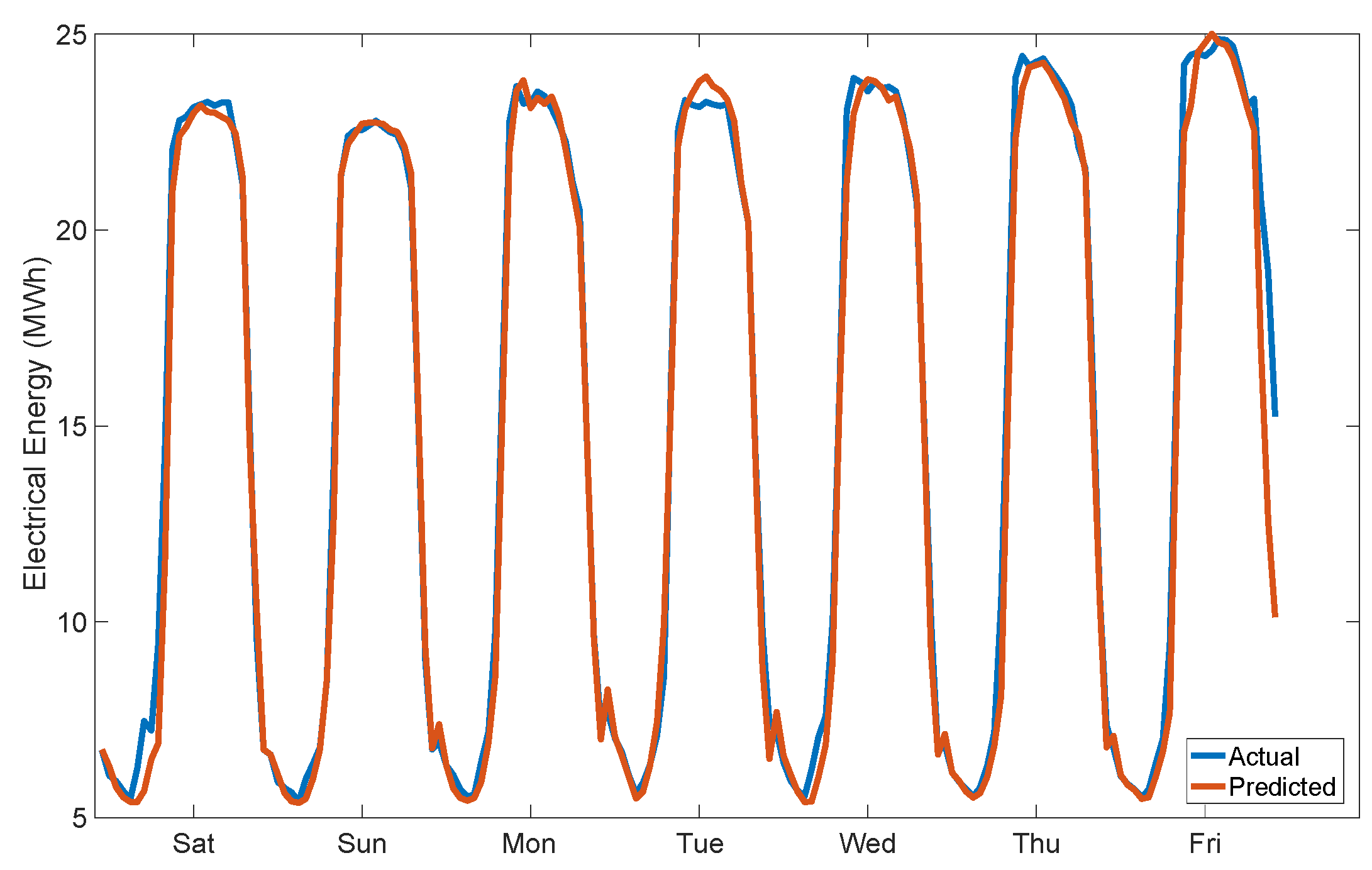

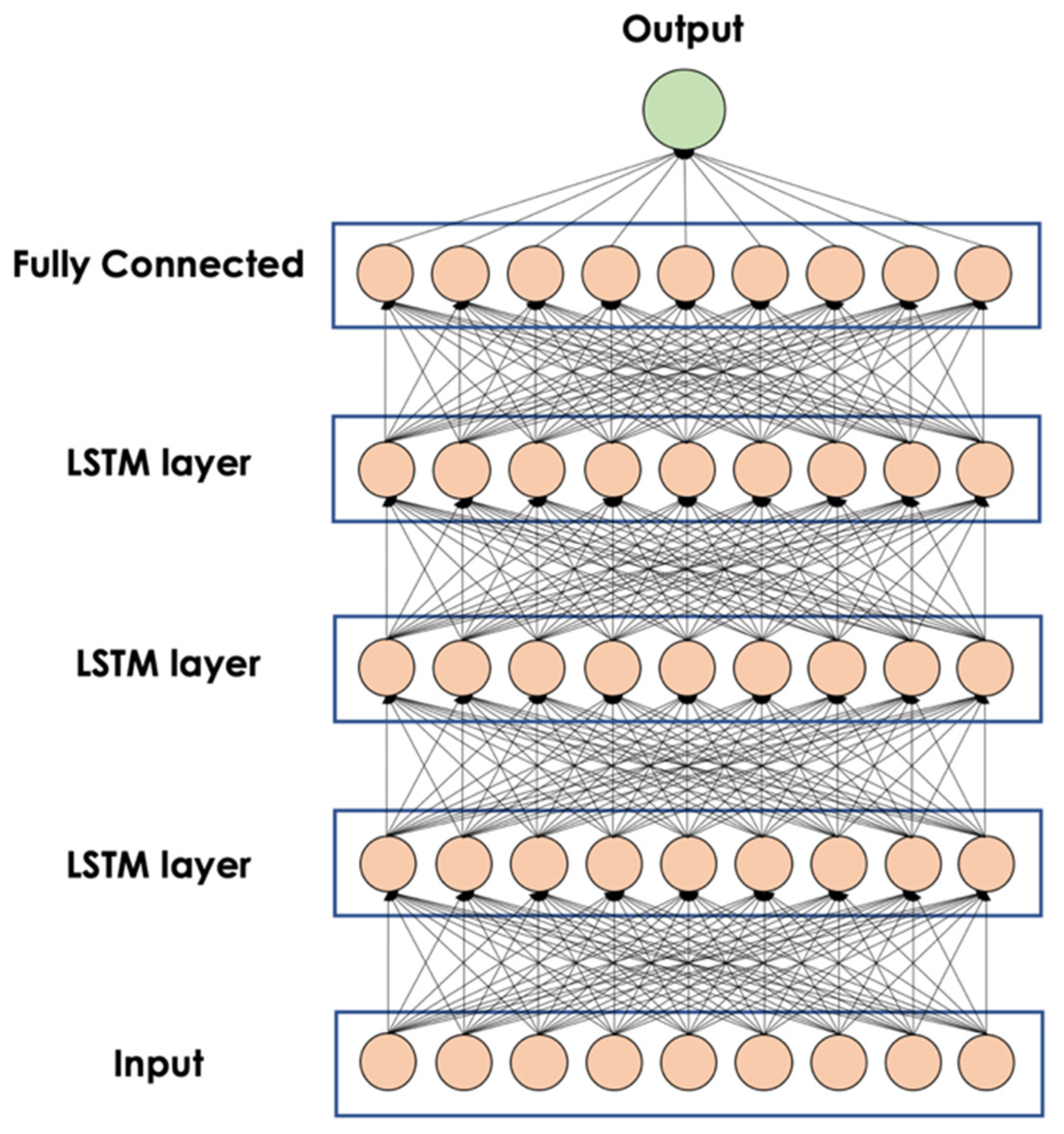

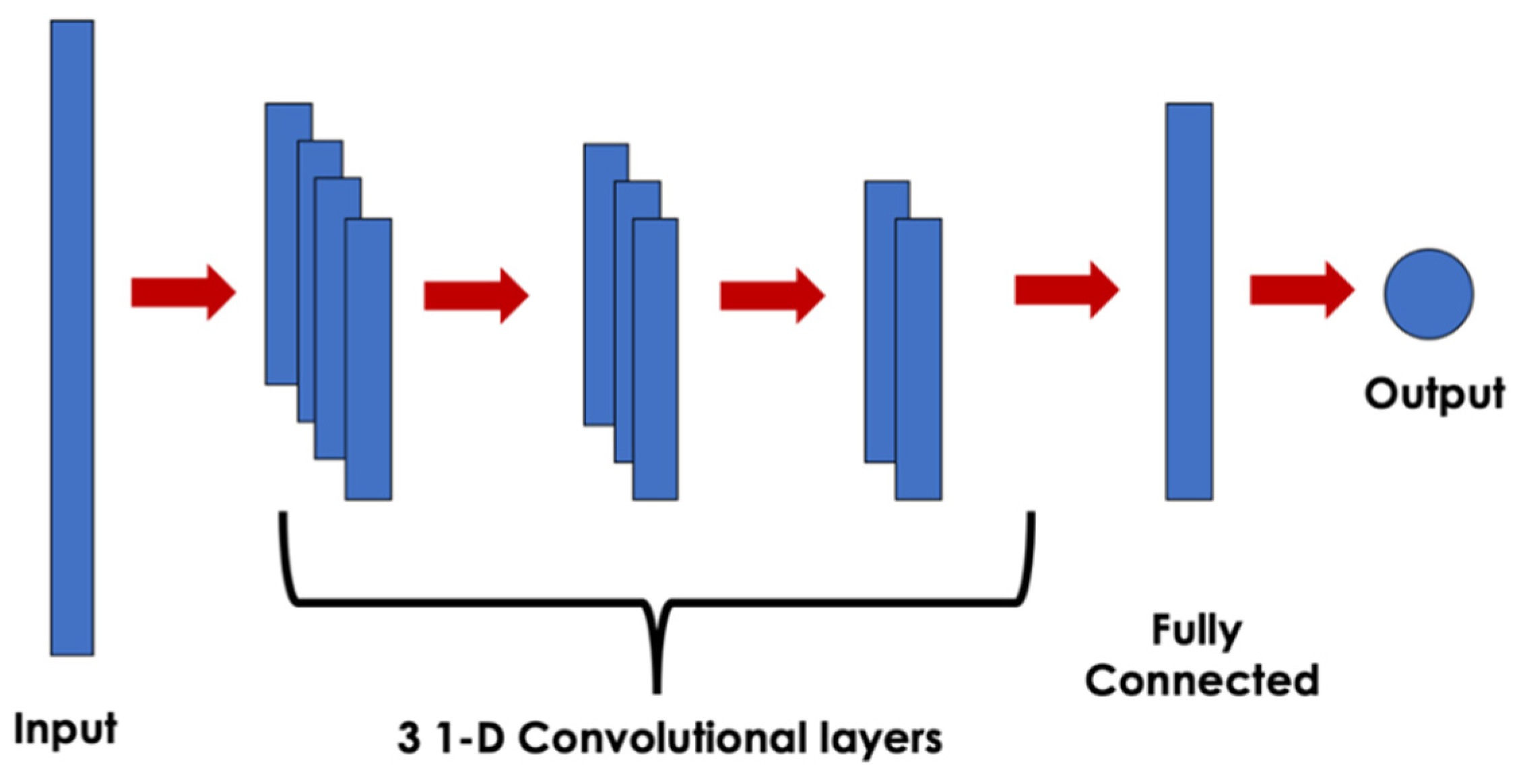

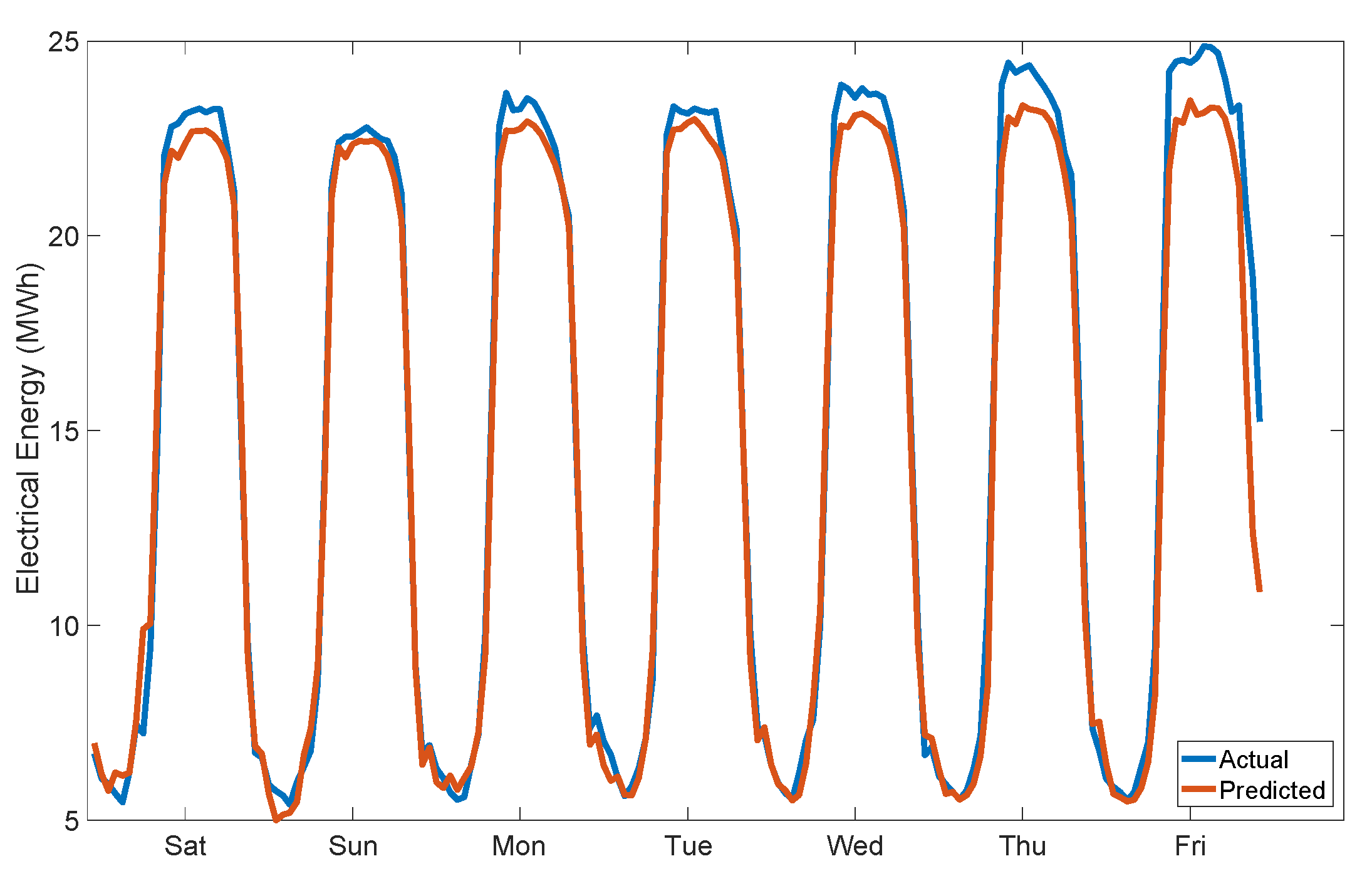

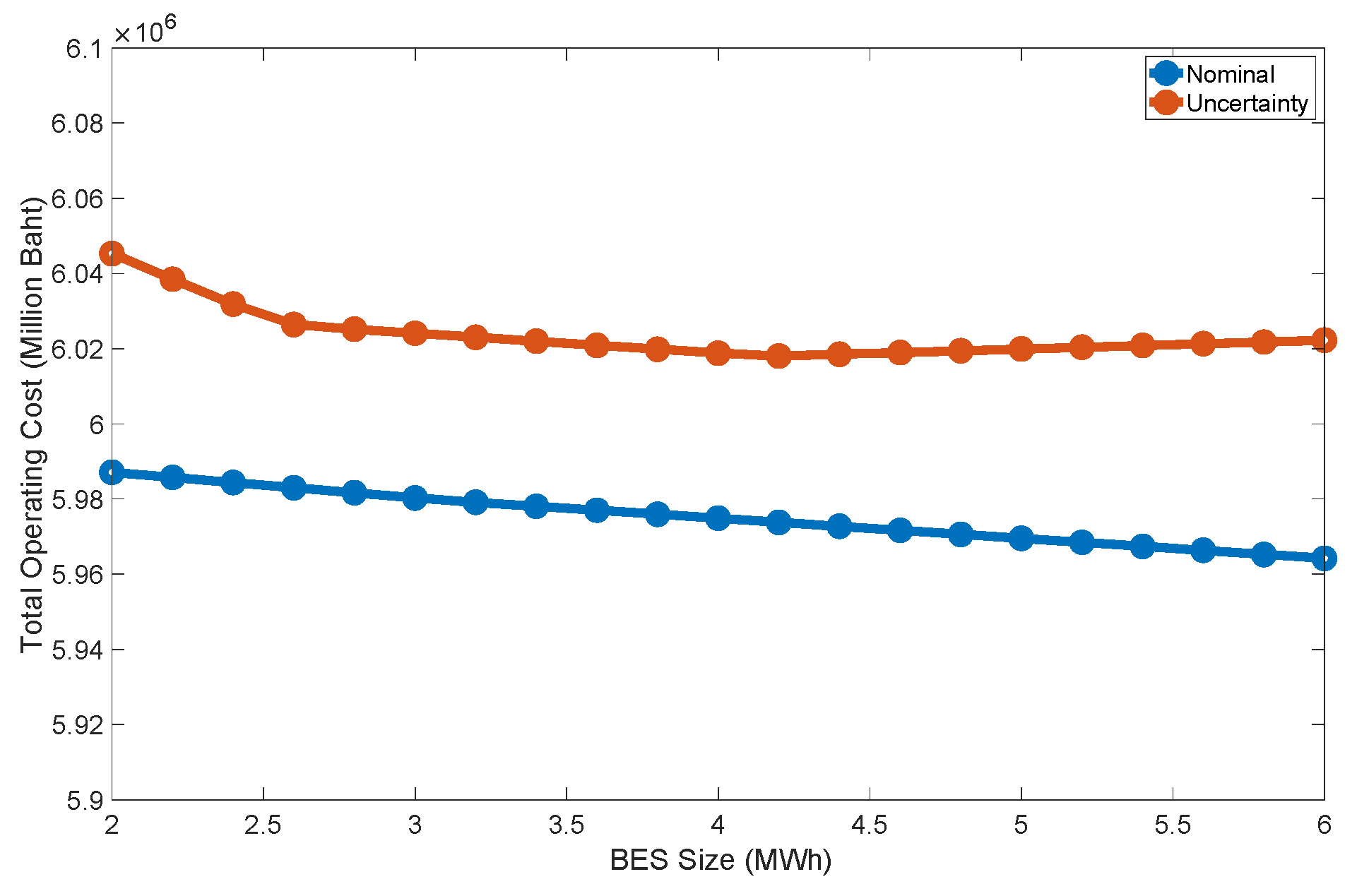

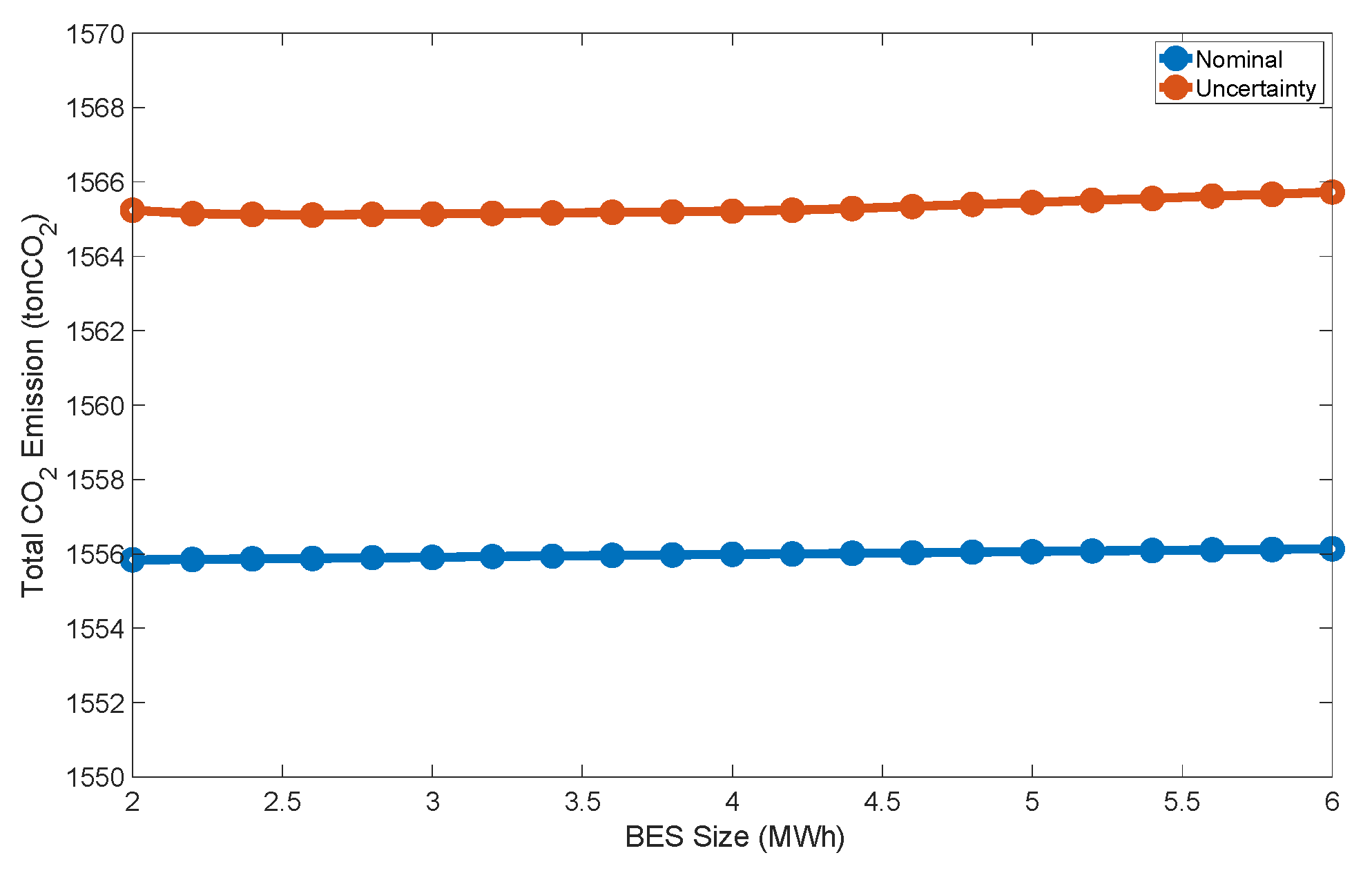

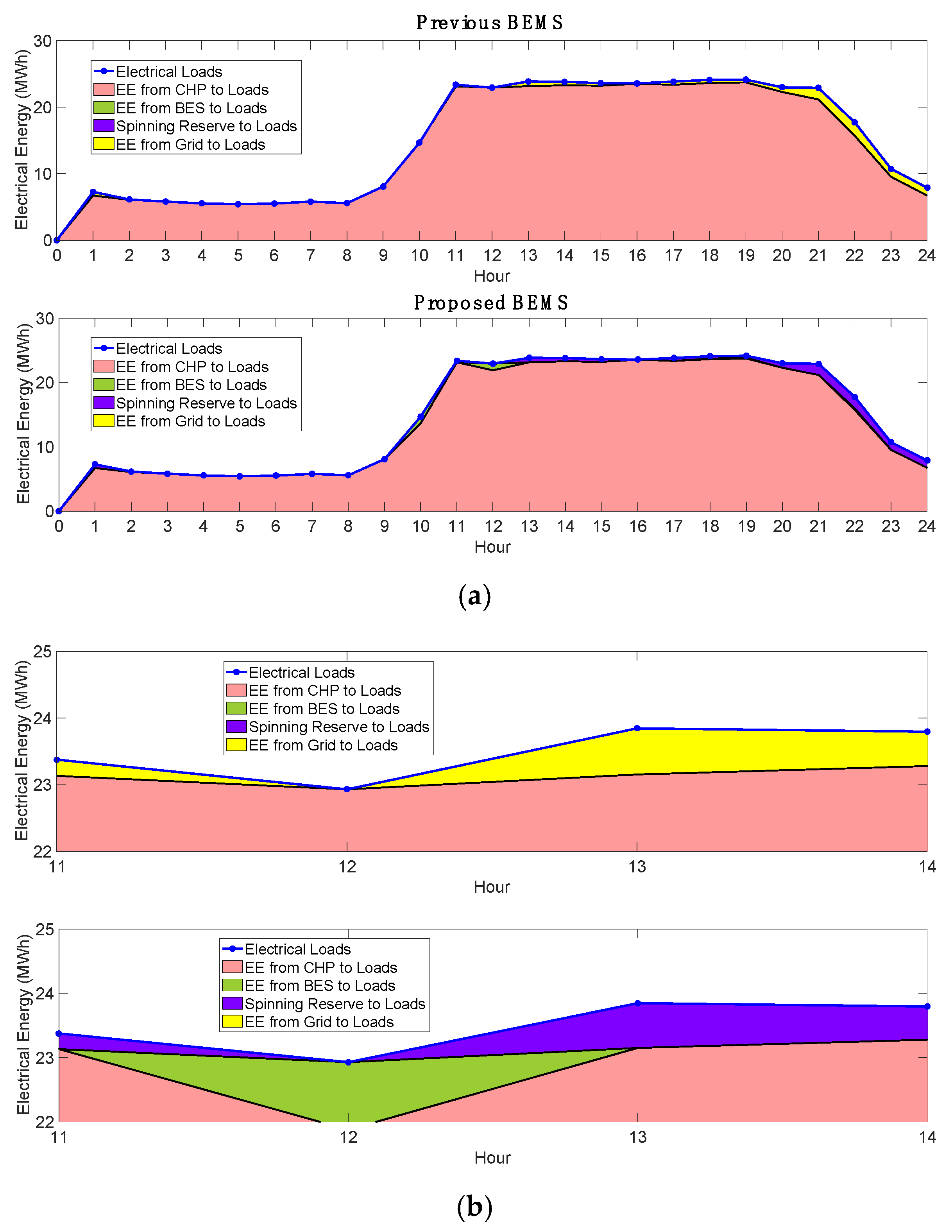

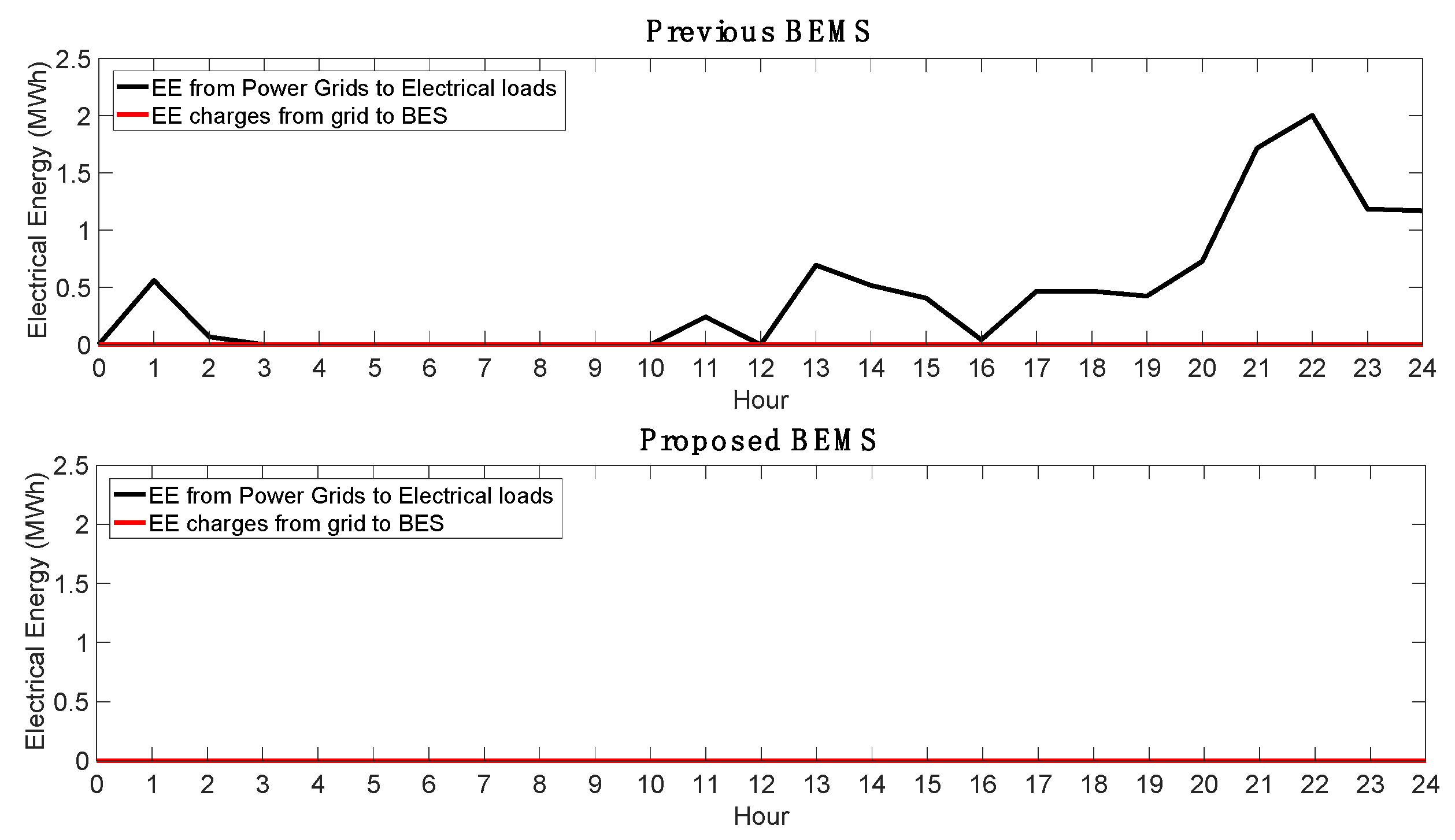

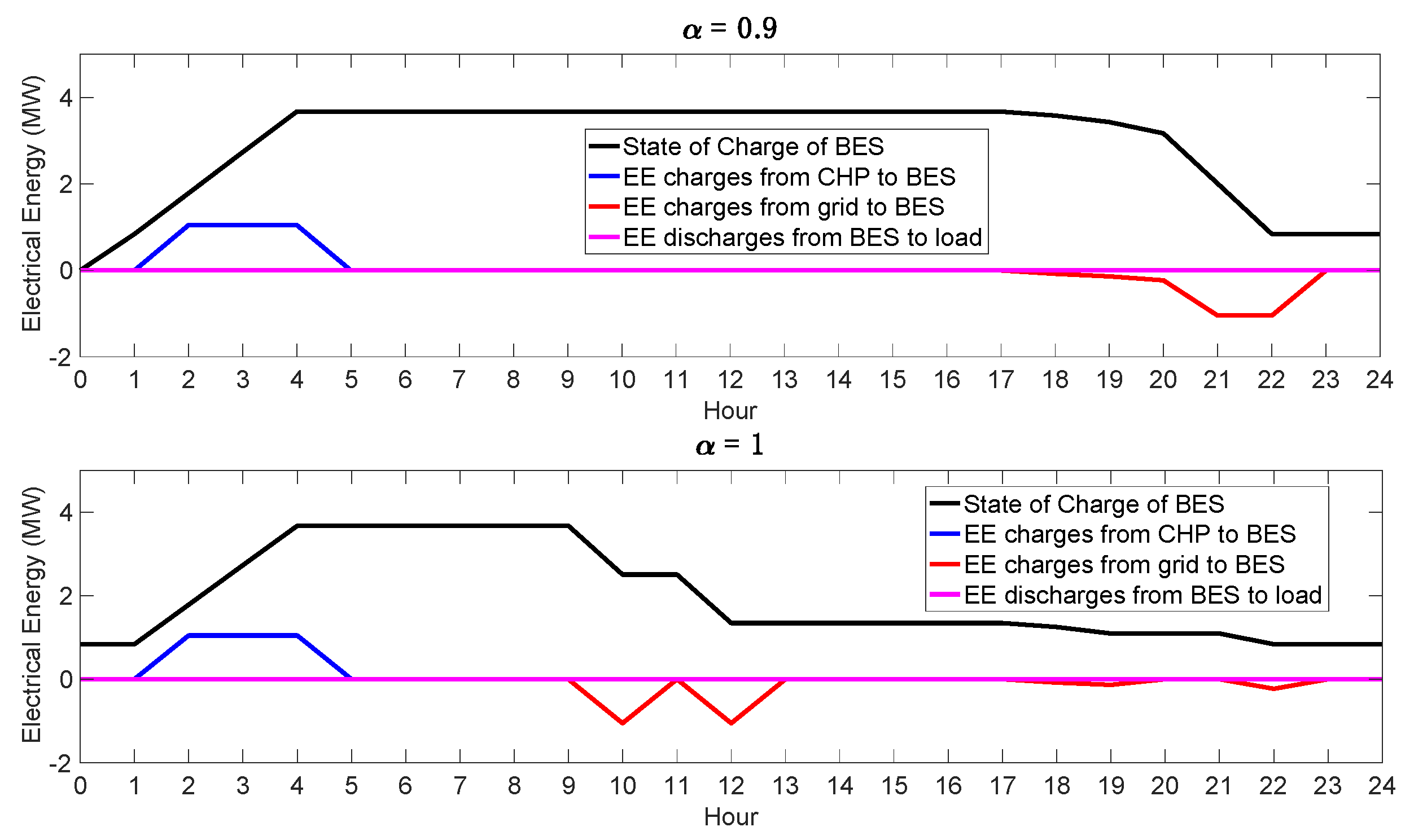

This paper proposes the optimal dispatch strategies of BEMS with cogeneration, TES, and BES, considering load demand uncertainty. The objectives are two-fold. The first objective is the economics optimal operation, which aims to minimize the TOC. The second objective is the environmental optimal operation, which aims to minimize the TCOE. Afterward, the two objectives are combined into the multi-objective optimal operation. We present a prediction of the electrical load demand using the ANN, LSTM, and CNN models, followed by analysis of the load demand uncertainty. As a result, we obtain the predicted load and load demand uncertainty, which are used for planning the energy dispatch. We apply the proposed dispatch strategies of electrical and cooling energy to a large shopping mall. For the load uncertainty case, the proposed BEMS reduces TOC by 9.68% under economic optimal operation and reduces TCOE by 0.25% under environmental optimal operation. For the nominal case, the proposed BEMS reduces TOC by 1.26% under economic optimal operation. However, the TCOE under environmental optimal operation is slightly increased by 0.71%. Moreover, the results show that BES provides a significant contribution to cutting the imported electricity from the power grid.

For the multi-objective optimal operation, we propose the normalized TOC and TCOE and consider the cost function as a linear combination of the normalized TOC and TCOE. The results show the relationship of TOC and TCOE as a trade-off performance. It can help users decide the operating point of BEMS. For energy flow analysis, the multi-objective optimal operation can completely meet the energy demand, as well as cut the import of electricity from the power grid. For the weight of 0.9, the proposed BEMS reduced TOC by 7.33%, whereas TCOE is increased by 4.2%.

Considering the rated power of CHP, it can be seen that the increase of efficiency of CHP clearly decreased TOC and TCOE. Likewise, the increase of efficiency of auxiliary boiler decreased TOC and TCOE from the boiler. Moreover, the other important factor is the P2H that represents the ratio between electricity from cogeneration and useful heat, when operating in full cogeneration mode. The cogeneration system works most efficiently when the P2H of the cogeneration system is close to the P2H of the building. Therefore, system parameters affect the results of TOC and TCOE.