A Comparative Life Cycle Assessment: Polystyrene or Polypropylene Packaging Crates to Reduce Citrus Loss and Waste in Transportation?

Abstract

1. Introduction

2. Materials and Methods

2.1. Farm

2.2. Transportation

2.3. CMFV and Retailers

3. LCA and Results

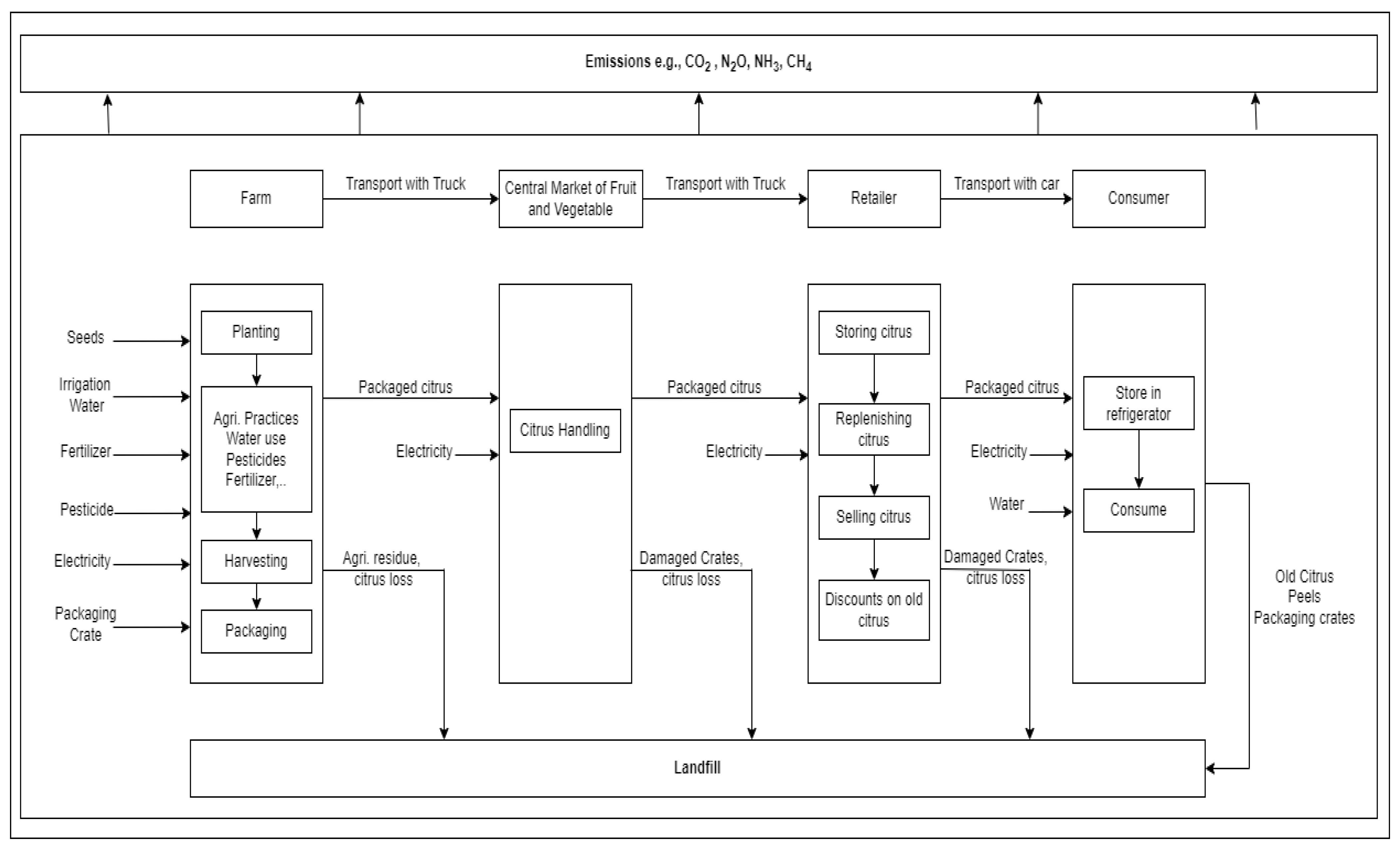

3.1. Goal and Scope Definition Phase

3.2. System Boundaries

3.3. Effect of Vibration and Stress While Transporting Citrus

3.4. Inventory Analysis

3.5. Assumptions

3.6. Inventory Analysis

3.7. Relationship to CLW

3.8. Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Alzubi, E.; Noche, B. Improving Sustainability of Orange Supply Chain: A System Dynamics Model to Eliminating Pre-Harvesting Loss, Increase Workers, to Improve farmer’ s Profit. In Proceedings of the International Conference on Industrial Engineering and Operations Management Istanbul 2022, Istanbul, Turkey, 7–10 March 2022. [Google Scholar]

- FAO. Global Food Losses and Food Waste—Extent, Causes and Prevention; FAO: Düsseldorf, Germany; Available online: http://www.fao.org/3/mb060e/mb060e.pdf (accessed on 1 November 2021).

- Hamdi-Asl, A.; Amoozad-Khalili, H.; Tavakkoli-Moghaddam, R.; Hajiaghaei-Keshteli, M. Toward sustainability in designing agricultural supply chain network: A case study on palm date. Sci. Iran. 2021. [CrossRef]

- Porat, R.; Lichter, A.; Terry, L.A.; Harker, R.; Buzby, J. Postharvest losses of fruit and vegetables during retail and in consumers’ homes: Quantifications, causes, and means of prevention. Postharvest Biol. Technol. 2018, 139, 135–149. [Google Scholar] [CrossRef]

- Alzubi, E.; Atieh, A.M.; Abu Shgair, K.; Damiani, J.; Sunna, S.; Madi, A. Hybrid integrations of value stream mapping, theory of constraints and simulation: Application to wooden furniture industry. Processes 2019, 7, 816. [Google Scholar] [CrossRef]

- Viswanadham, N.; Kameshwaran, S. The Supply Chain Ecosystem Framework. In Ecosystem-Aware Global Supply Chain Management; World Scientific Publishing Co. Pte. Ltd.: Singapore, 2013; Chapter 2; pp. 17–44. [Google Scholar] [CrossRef]

- Hasan, S.; Haque, M.E.; Afrad, M.S.I.; Alam, M.Z.; Hoque, M.Z.; Islam, M.R. Pest Risk Analysis and Management Practices for Increasing Profitability of Lemon Production. J. Agric. Ecol. Res. Int. 2021, 22, 26–35. [Google Scholar] [CrossRef]

- Ademosun, A.O. Citrus peels odyssey: From the waste bin to the lab bench to the dining table. Appl. Food Res. 2022, 2, 100083. [Google Scholar] [CrossRef]

- FAO. Food Balances. 2010. Available online: https://www.fao.org/faostat/en/#data/FBS (accessed on 31 August 2022).

- Sasaki, Y.; Orikasa, T.; Nakamura, N.; Hayashi, K.; Yasaka, Y.; Makino, N.; Shobatake, K.; Koide, S.; Shiina, T. Life cycle assessment of peach transportation considering tradeoff between food loss and environmental impact. Int. J. Life Cycle Assess. 2021, 26, 822–837. [Google Scholar] [CrossRef]

- Al-Dairi, M.; Pathare, P.B.; Al-Mahdouri, A. Impact of vibration on the quality of tomato produced by stimulated transport. IOP Conf. Ser. Earth Environ. Sci. 2021, 653, 012101. [Google Scholar] [CrossRef]

- Fadiji, T.; Coetzee, C.; Chen, L.; Chukwu, O.; Opara, U.L. Susceptibility of apples to bruising inside ventilated corrugated paperboard packages during simulated transport damage. Postharvest Biol. Technol. 2016, 118, 111–119. [Google Scholar] [CrossRef]

- Vursavuş, K.; Özgüven, F. Determining the effects of vibration parameters and packaging method on mechanical damage in golden delicious apples. Turkish J. Agric. For 2004, 28, 311–320. [Google Scholar] [CrossRef]

- Tabatabaekoloor, R.; Hashemi, S.J.; Taghizade, G. Vibration Damage to Kiwifruits during. Int. J. Agric. Food Sci. Technol. 2013, 4, 467–474. [Google Scholar]

- Wasala, W.M.C.B.; Dharmasena, D.A.N.; Dissanayake, T.M.R.; Thilakarathne, B.M.K.S. Vibration simulation testing of banana bulk transport packaging systems. Trop. Agric. Res. 2015, 26, 355. [Google Scholar] [CrossRef]

- Chonhenchob, V.; Singh, S.P. Packaging performance comparison for distribution and export of papaya fruit. Packag. Technol. Sci. 2005, 18, 125–131. [Google Scholar] [CrossRef]

- Shahbazi, F.; Rajabipour, A.; Mohtasebi, S.; Rafie, S. Simulated in-transit vibration damage to watermelons. J. Agric. Sci. Technol. 2010, 12, 23–34. [Google Scholar]

- Zheng, D.; Chen, J.; Lin, M.; Wang, D.; Lin, Q.; Cao, J.; Yang, X.; Duan, Y.; Ye, X.; Sun, C.; et al. Packaging Design to Protect Hongmeiren Orange Fruit from Mechanical Damage during Simulated and Road Transportation. Horticulturae 2022, 8, 258. [Google Scholar] [CrossRef]

- La Scalia, G.; Aiello, G.; Miceli, A.; Nasca, A.; Alfonzo, A.; Settanni, L. Effect of Vibration on the Quality of Strawberry Fruits Caused by Simulated Transport. J. Food Process Eng. 2016, 39, 140–156. [Google Scholar] [CrossRef]

- Chen, X.; Chen, M.; Xu, C.; Yam, K.L. Critical review of controlled release packaging to improve food safety and quality. Crit. Rev. Food Sci. Nutr. 2019, 59, 2386–2399. [Google Scholar] [CrossRef]

- Finkbeiner, M.; Inaba, A.; Tan, R.; Christiansen, K.; Klüppel, H.-J. The New International Standards for Life Cycle Assessment: ISO 14040 and ISO 14044. Int. J. Life Cycle Assess. 2006, 11, 80–85. [Google Scholar] [CrossRef]

- Muralikrishna, I.V.; Manickam, V. Life Cycle Assessment. In Environmental Management; Elsevier: Amsterdam, The Netherlands, 2017; pp. 57–75. [Google Scholar] [CrossRef]

- Ge, C. Theory and practice of cushion curve: A supplementary discussion. Packag. Technol. Sci. 2019, 32, 185–197. [Google Scholar] [CrossRef]

- Eriksson, M.; Strid, I.; Hansson, P.A. Waste of organic and conventional meat and dairy products—A case study from Swedish retail. Resour. Conserv. Recycl. 2014, 83, 44–52. [Google Scholar] [CrossRef]

- Alzubi, E.; Akkerman, R. Sustainable supply chain management practices in developing countries: An empirical study of Jordanian manufacturing companies. Clean. Prod. Lett. 2022, 2, 100005. [Google Scholar] [CrossRef]

- Lacirignola, C.; D’onghia, A.M. The Mediterranean citriculture: Productions and perspectives. Citrus tristeza virus Toxoptera citricidus a serious Threat to Mediterr. Citrus Ind. 2009, 17, 13–17. [Google Scholar]

- KNOEMA. World – Citrus fruit production quantity. 2022. Available online: https://knoema.com/atlas/World/topics/Agriculture/Crops-Production-Quantity-tonnes/Citrus-fruit-production (accessed on 15 September 2022).

- Statista. World production of citrus fruits in 2020, by region (in thousand metric tons). 2022. Available online: https://www.statista.com/statistics/264002/production-of-citrus-fruits-worldwide-by-region/ (accessed on 15 September 2022).

- Zacarias, L.; Cronje, P.J.R.; Palou, L. Postharvest technology of citrus fruits. Genus Citrus 2020, 421–446. [Google Scholar] [CrossRef]

- Department of Statistics in Jordan. Dep. Stat. Jordan. 2021. Available online: http://dosweb.dos.gov.jo/product-category/jordan-in-figures (accessed on 11 June 2022).

- Defraeye, T.; Lambrecht, R.; Tsige, A.A.; Delele, M.A.; Opara, U.L.; Cronjé, P.; Verboven, P.; Nicolai, B. Forced-convective cooling of citrus fruit: Package design. J. Food Eng. 2013, 118, 8–18. [Google Scholar] [CrossRef]

- Berry, T.M.; Defraeye, T.; Wu, W.; Sibiya, M.G.; North, J.; Cronje, P.J.R. Cooling of ambient-loaded citrus in refrigerated containers: What impacts do packaging and loading temperature have? Biosyst. Eng. 2021, 201, 11–22. [Google Scholar] [CrossRef]

- Toniolo, S.; Tosato, R.C.; Gambaro, F.; Ren, J. Life cycle thinking tools: Life cycle assessment, life cycle costing and social life cycle assessment. In Life Cycle Sustainability Assessment for Decision-Making: Methodologies and Case Studies; Elsevier: Amsterdam, The Netherlands, 2019; pp. 39–56. [Google Scholar] [CrossRef]

- Yang, S.; Ma, K.; Liu, Z.; Ren, J.; Man, Y. Development and applicability of life cycle impact assessment methodologies"," in Life Cycle Sustainability Assessment for Decision-Making: Methodologies and Case Studies; Elsevier: Amsterdam, The Netherlands, 2019; pp. 95–124. [Google Scholar] [CrossRef]

- Martin-Gorriz, B.; Maestre-Valero, J.F. Life Cycle Assessment of farming practices that improve citrus orchards sustainability in semiarid areas. In Proceedings of theEuropean Conference on Crop Diversification, Budapest, Hungary, 18–21 August 2019; Volume 24, pp. 1515–1532. [Google Scholar] [CrossRef]

- Chen, L. Benefits of Anaerobic Digestion. University of Idaho. 2014. Available online: http://171.67.100.116/courses/2017/ph240/huang1/docs/cis-1215.pdf (accessed on 31 August 2022).

- Wikström, F.; Williams, H.; Verghese, K.; Clune, S. The influence of packaging attributes on consumer behaviour in food-packaging life cycle assessment studies—A neglected topic. J. Clean. Prod. 2014, 73, 100–108. [Google Scholar] [CrossRef]

- European Commission. PEFCR Guidance Document—Guidance for Product Environmental Footprint Category Rules (PEFCRs). In PEFCR Guide; 2018. Available online: https://ec.europa.eu/environment/eussd/smgp/pdf/PEFCR_guidance_v6.3.pdf (accessed on 29 August 2022).

| Scenario | Loaded Crates | Total Crate Weigh | Layers of Crates Loaded in the Truck | Loss% with Reference to Distance Traveled (km) | ||||

|---|---|---|---|---|---|---|---|---|

| 0 | 40 | 70 | 100 | 140 | ||||

| S1: PS | 400 | 5 kg | 8 | 2.13% | 11.71% | 12.33% | 13.62% | 15.92% |

| S2: PP | 250 | 20 kg | 5 | 0.00% | 3.90% | 4.54% | 4.75% | 5.11% |

| 0 km | 40 km | 70 km | 100 km | 14 km | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| S1 | S2 | S1 | S2 | S1 | S2 | S1 | S2 | S1 | S2 | |

| Farm | ||||||||||

| Citrus (kg) | 1.24 | 1.20 | 1.43 | 1.28 | 1.45 | 1.29 | 1.47 | 1.30 | 1.52 | 1.30 |

| Crate Production (kg) | 0.05 | 0.21 | 0.05 | 0.21 | 0.05 | 0.21 | 0.05 | 0.21 | 0.05 | 0.21 |

| Transportation from the farm to the CMFV | ||||||||||

| ≤7.5 tons truck (kg) | 1.29 | 1.41 | 1.48 | 1.49 | 1.50 | 1.50 | 1.52 | 1.51 | 1.57 | 1.51 |

| 0 km | 40 km | 70 km | 100 km | 140 km | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| S1 | S2 | S1 | S2 | S1 | S2 | S1 | S2 | S1 | S2 | |

| Waste due to loss (kg) (Landfill) in CM | 0.02 | 0.00 | 0.12 | 0.04 | 0.12 | 0.05 | 0.14 | 0.05 | 0.16 | 0.05 |

| Transportation from CM to retailers | ||||||||||

| Citrus (kg) | 1.27 | 1.41 | 1.37 | 1.45 | 1.37 | 1.46 | 1.39 | 1.46 | 1.41 | 1.46 |

| Waste due to loss (kg) (Landfill) | 0.02 | 0.00 | 0.12 | 0.04 | 0.12 | 0.05 | 0.13 | 0.05 | 0.16 | 0.05 |

| Waste inedible (kg) (landfill) | 0.30 | 0.30 | 0.30 | 0.30 | 0.30 | 0.30 | 0.30 | 0.30 | 0.30 | 0.30 |

| Crate material | ||||||||||

| Waste (kg) (Landfill) | 0.05 | 0.00 | 0.05 | 0.00 | 0.05 | 0.00 | 0.05 | 0.00 | 0.05 | 0.00 |

| Reusable crates to farm (kg) | - | 0.21 | - | 0.21 | - | 0.21 | - | 0.21 | - | 0.21 |

| 0 km | 40 km | 70 km | 100 km | 140 km | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| S1 | S2 | S1 | S2 | S1 | S2 | S1 | S2 | S1 | S2 | |||

| Acidification | molc H+ eq | ×10−4 | 4.3 | 2.6 | 5.4 | 1.5 | 8.3 | 1.5 | 8.5 | 1.5 | 8.5 | 1.5 |

| Climate change | kg CO2 eq | ×10−1 | 1.7 | 1.4 | 2.0 | 1.0 | 3.3 | 1.0 | 3.8 | 6.3 | 4.5 | 6.3 |

| Freshwater ecotoxicity | CTUe | ×10−2 | 2.0 | 5.6 | 2.0 | 2.1 | 2.3 | 2.1 | 2.3 | 1.2 | 2.3 | 1.2 |

| Freshwater eutrophication | kg P eq | ×10−4 | 5.8 | 5.4 | 5.8 | 7.9 | 6.6 | 8.7 | 5.9 | 8.8 | 6.8 | 8.9 |

| Land use | kg C deficit | ×10−4 | 5.2 | 5.2 | 5.8 | 2.4 | 6.1 | 1.3 | 6.2 | 1.4 | 6.2 | 1.2 |

| Ozone depletion | kg CFC-11 eq | ×10−9 | 1.6 | 1.5 | 1.6 | 2.2 | 1.6 | 2.2 | 1.6 | 2.2 | 1.6 | 2.2 |

| Particulate matter | kg PM2.5 eq | ×10−5 | 3.3 | 5.8 | 3.3 | 3.3 | 5.8 | 3.3 | 3.3 | 5.8 | 3.3 | 5.8 |

| Water resource depletion | m3 water eq | ×10−3 | 1.0 | 1.7 | 1.0 | 3.7 | 1.0 | 3.7 | 1.0 | 3.7 | 1.0 | 3.7 |

| Resource depletion | kg Sb eq | ×10−7 | 5.4 | 2.1 | 4.4 | −2.7 | 4.2 | −2.7 | 3.2 | −2.7 | 2.3 | −2.7 |

| 0 km | 40 km | 70 km | 100 km | 140 km | |

|---|---|---|---|---|---|

| Acidification | −38.6% | 71.7% | 81.6% | 81.9% | 82.5% |

| Climate change | −16.5% | 47.7% | 68.2% | 83.3% | 85.9% |

| Freshwater ecotoxicity | −7.6% | 6.1% | 7.6% | 6.2% | 6.2% |

| Freshwater eutrophication | −7.2% | 35.8% | 31.9% | 48.1% | 29.9% |

| Land use | 0.0% | 59.3% | 78.4% | 77.6% | 81.0% |

| Ozone depletion | −5.1% | 43.2 % | 85.6% | 85.6% | 85.6% |

| Particulate matter | 76.9% | 76.8% | 82.3% | 82.3% | 82.3% |

| Water resource depletion | 70.6% | 63.4% | 63.2% | 63.2% | 63.2% |

| Resource depletion | −60.2% | 160.7% | 163.4% | 183.7% | 216.8% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alzubi, E.; Kassem, A.; Noche, B. A Comparative Life Cycle Assessment: Polystyrene or Polypropylene Packaging Crates to Reduce Citrus Loss and Waste in Transportation? Sustainability 2022, 14, 12644. https://doi.org/10.3390/su141912644

Alzubi E, Kassem A, Noche B. A Comparative Life Cycle Assessment: Polystyrene or Polypropylene Packaging Crates to Reduce Citrus Loss and Waste in Transportation? Sustainability. 2022; 14(19):12644. https://doi.org/10.3390/su141912644

Chicago/Turabian StyleAlzubi, Emad, Ahmed Kassem, and Bernd Noche. 2022. "A Comparative Life Cycle Assessment: Polystyrene or Polypropylene Packaging Crates to Reduce Citrus Loss and Waste in Transportation?" Sustainability 14, no. 19: 12644. https://doi.org/10.3390/su141912644

APA StyleAlzubi, E., Kassem, A., & Noche, B. (2022). A Comparative Life Cycle Assessment: Polystyrene or Polypropylene Packaging Crates to Reduce Citrus Loss and Waste in Transportation? Sustainability, 14(19), 12644. https://doi.org/10.3390/su141912644