PV/Thermal as Promising Technologies in Buildings: A Comprehensive Review on Exergy Analysis

Abstract

:1. Introduction

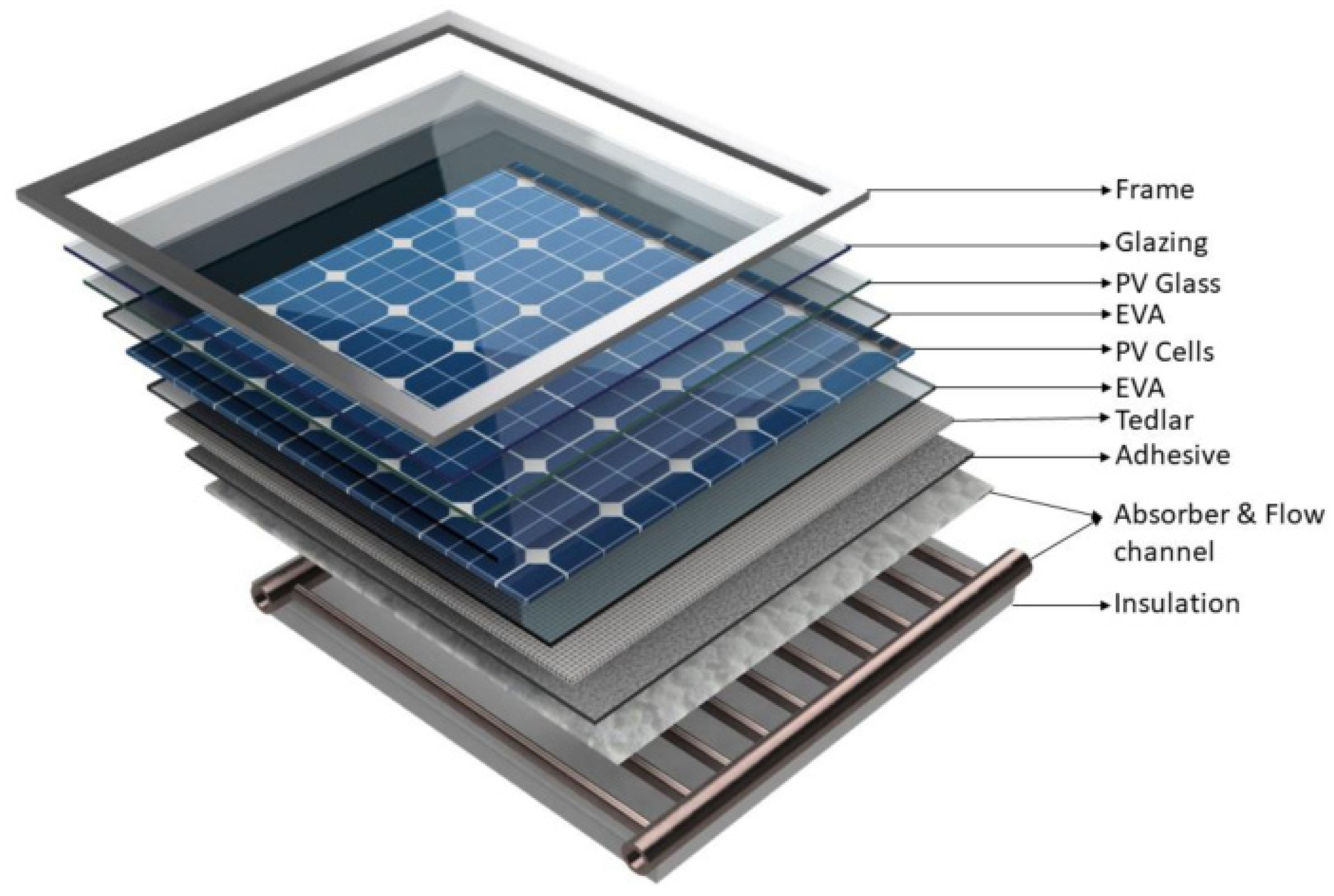

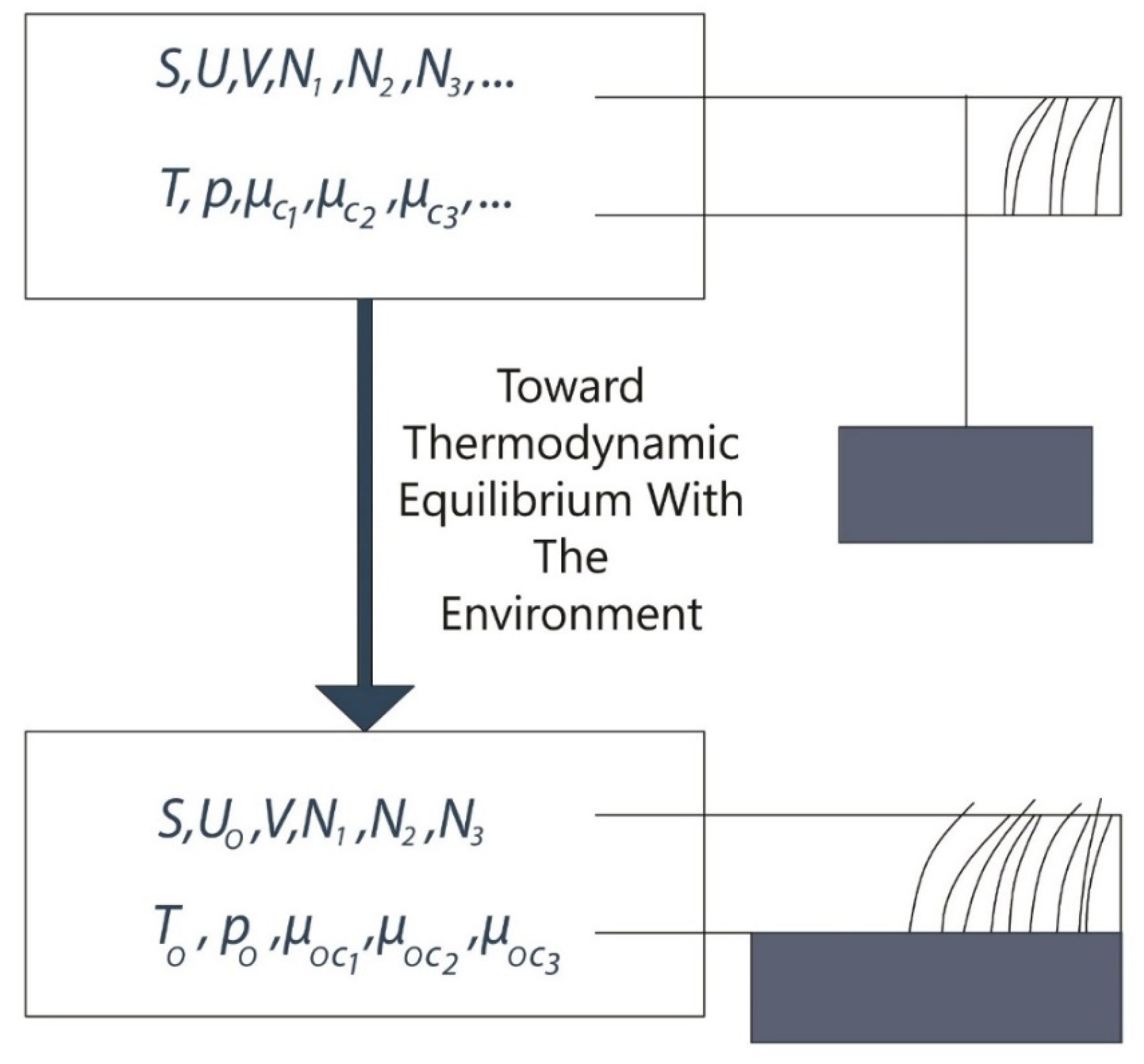

2. PV/T Systems in Buildings

3. Exergy Analysis of PV/T Systems

4. Suggestions for Future Research

5. Conclusions

- Various factors such as the weather condition, operating variables and system features can determine the exergy efficiency of PV/T systems.

- According to the system configuration, the overall exergy can be highly affected by the thermal or electrical exergy.

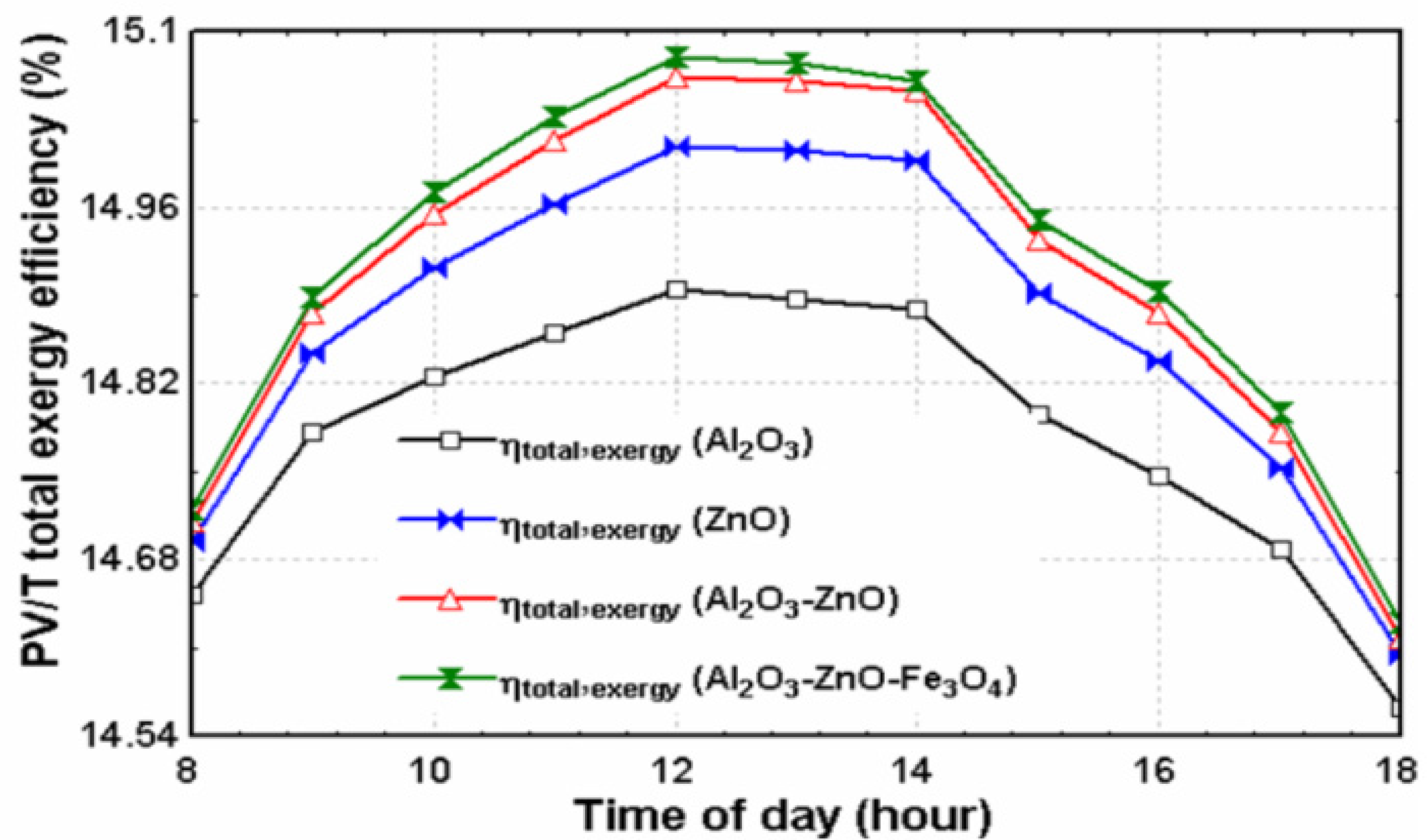

- Enhancement of energy and exergy efficiencies can be fulfilled by nanofluids.

- Although, nanofluids are able to improve the ratio of exergy efficiency, their performance relies on some factors such as the type of applied nanofluid, concentration and flow rate.

- Using nano-PCM and nanofluid simultaneously, can lead to an improvement in exergy efficiency of a PV/T system compared with using them individually.

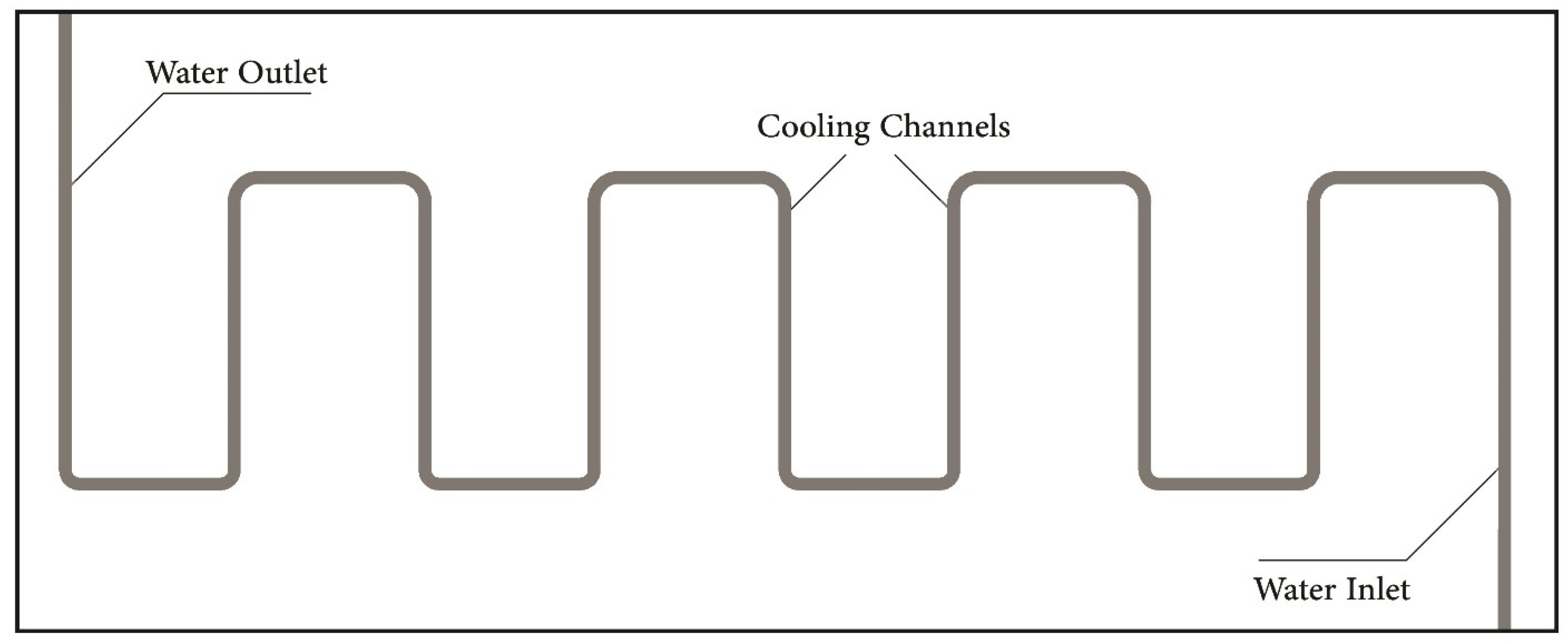

- Architectural alterations in a system such as applying wavy coolant channels, can improve the system exergy output.

- To boost the exergy of the system, it would be beneficial to use extra components such as a concentrator.

- Aiming to optimize the PV/T systems, the exergy concept can be beneficial.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

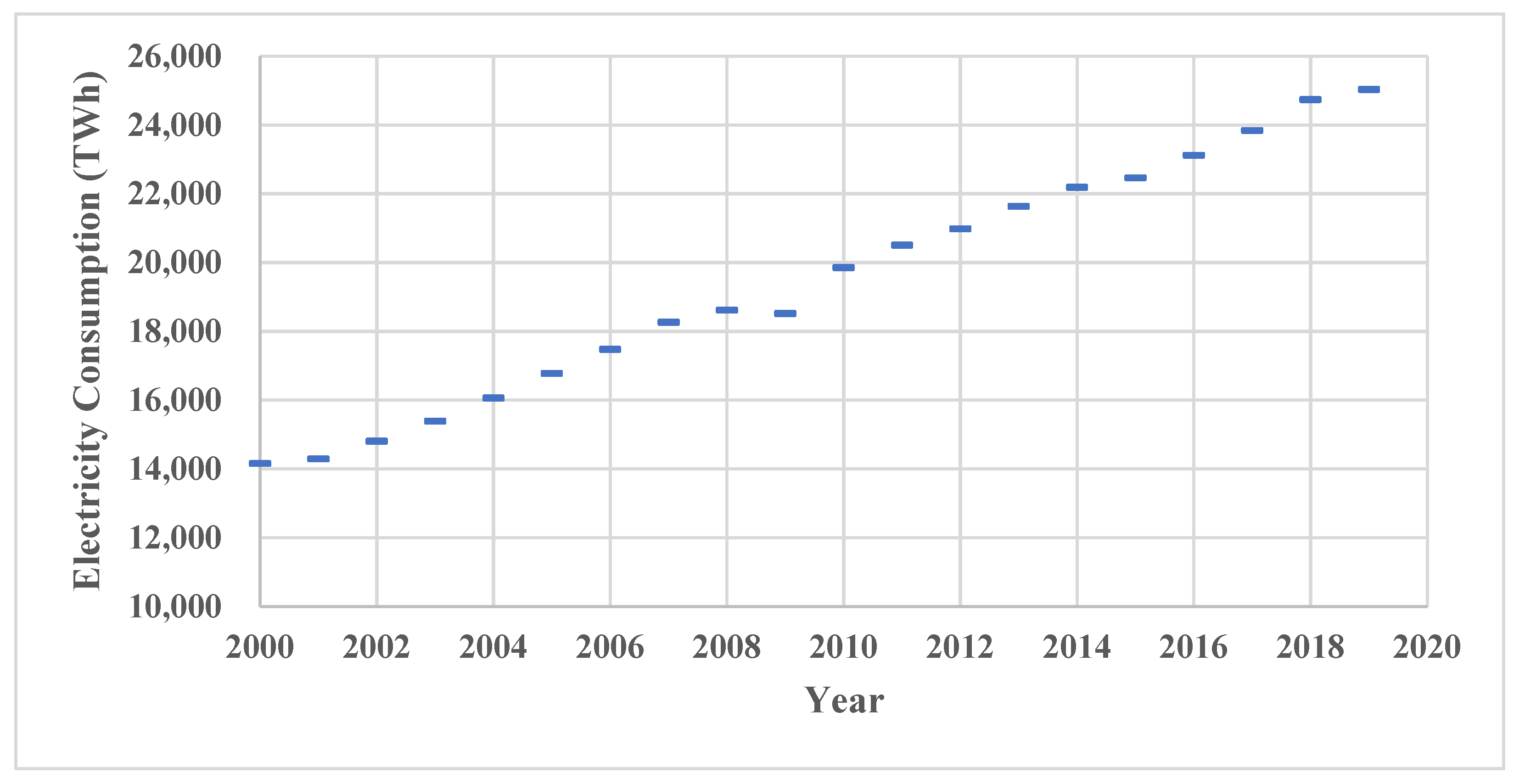

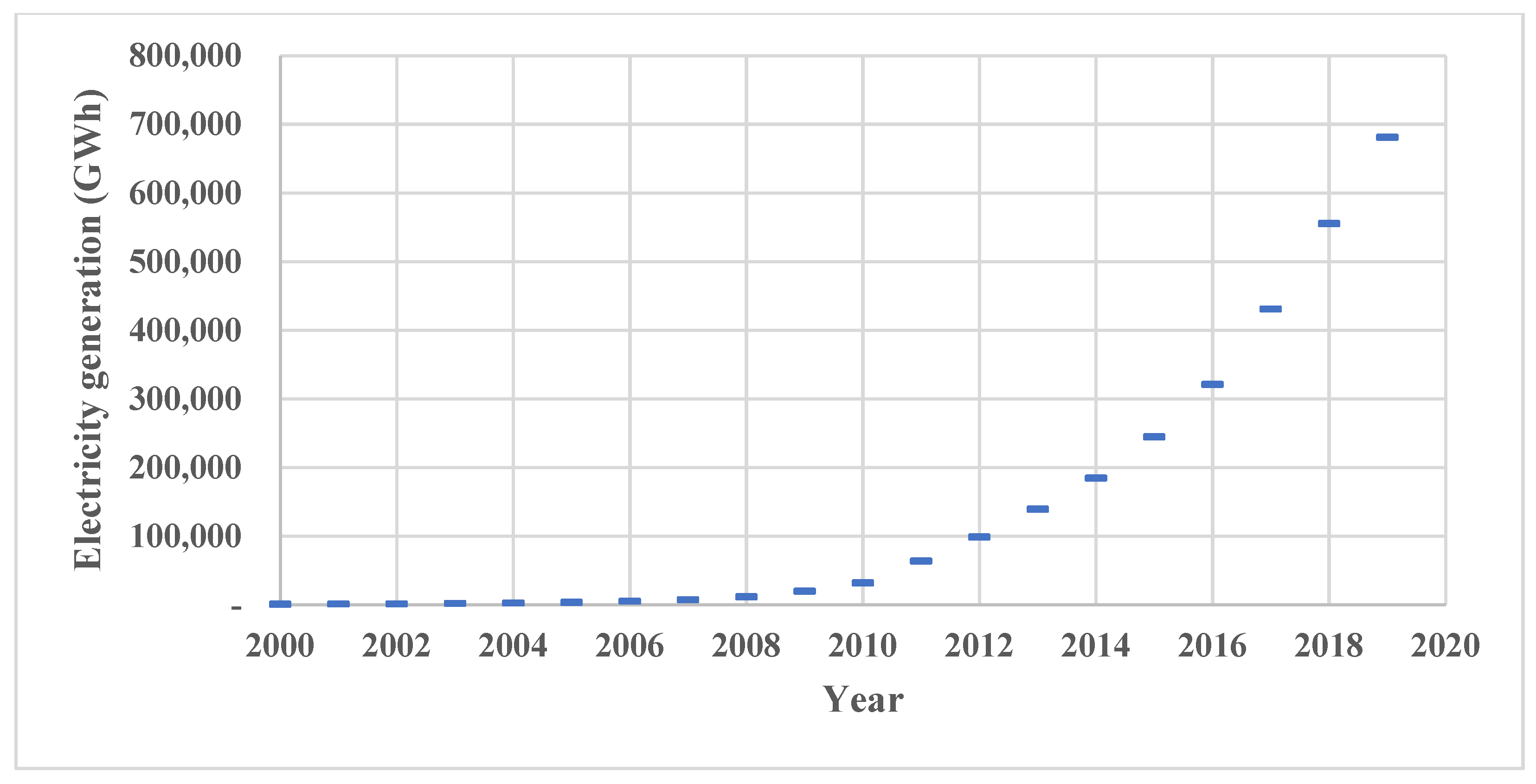

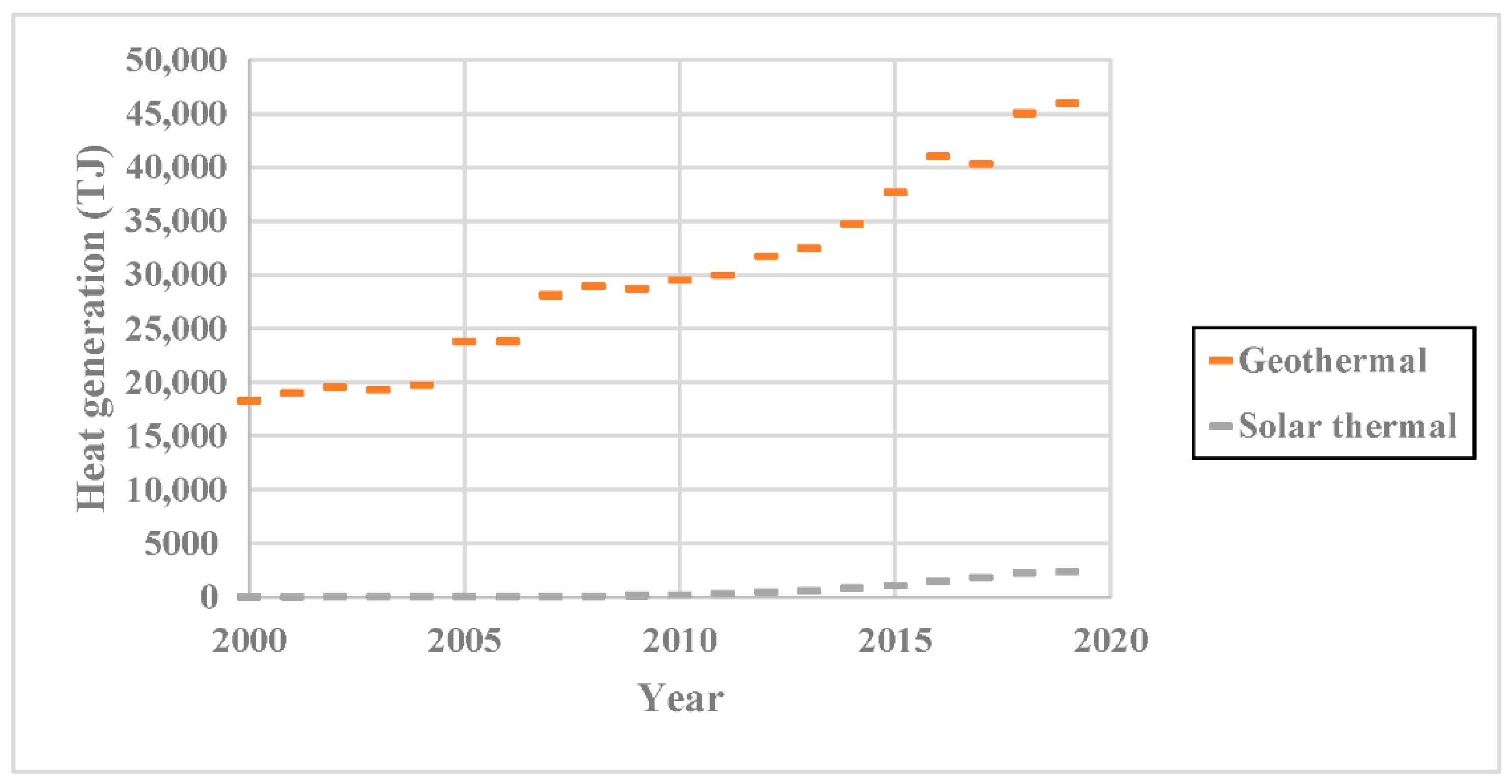

- Data and Statistics. International Energy Agency n.d. Available online: https://www.iea.org/data-and-statistics/ (accessed on 22 July 2022).

- Haghighi, A.; Pakatchian, M.R.; Assad, M.E.H.; Duy, V.N.; Nazari, M. A review on geothermal Organic Rankine cycles: Modeling and optimization. J. Therm. Anal. 2020, 144, 1799–1814. [Google Scholar] [CrossRef]

- El Haj Assad, M.; Alhuyi Nazari, M.; Rosen, M.A. Applications of renewable energy sources. In Design and Performance Optimization of Renewable Energy Systems; Elsevier: Amsterdam, The Netherlands, 2021; pp. 1–15. [Google Scholar] [CrossRef]

- Kharrich, M.; Mohammed, O.H.; Kamel, S.; Selim, A.; Sultan, H.M.; Akherraz, M.; Jurado, F. Development and Implementation of a Novel Optimization Algorithm for Reliable and Economic Grid-Independent Hybrid Power System. Appl. Sci. 2020, 10, 6604. [Google Scholar] [CrossRef]

- Joshi, S.S.; Dhoble, A.S. Photovoltaic—Thermal systems (PVT): Technology review and future trends. Renew. Sustain. Energy Rev. 2018, 92, 848–882. [Google Scholar] [CrossRef]

- Alizadeh, H.; Nazari, M.A.; Ghasempour, R.; Shafii, M.B.; Akbarzadeh, A. Numerical analysis of photovoltaic solar panel cooling by a flat plate closed-loop pulsating heat pipe. Sol. Energy 2020, 206, 455–463. [Google Scholar] [CrossRef]

- Rahim, W.; Ullah, I.; Ullah, N.; Alahmadi, A.A. Lightning Protection, Cost Analysis and Improved Efficiency of Solar Power Plant for Irrigation System. Sustainability 2022, 14, 6235. [Google Scholar] [CrossRef]

- Maleki, A.; Haghighi, A.; Assad, M.E.H.; Mahariq, I.; Nazari, M.A. A review on the approaches employed for cooling PV cells. Sol. Energy 2020, 209, 170–185. [Google Scholar] [CrossRef]

- Das, D.; Bordoloi, U.; Kamble, A.D.; Muigai, H.H.; Pai, R.K.; Kalita, P. Performance investigation of a rectangular spiral flow PV/T collector with a novel form-stable composite material. Appl. Therm. Eng. 2021, 182, 116035. [Google Scholar] [CrossRef]

- Asefi, G.; Habibollahzade, A.; Ma, T.; Houshfar, E.; Wang, R. Thermal management of building-integrated photovoltaic/thermal systems: A comprehensive review. Sol. Energy 2021, 216, 188–210. [Google Scholar] [CrossRef]

- Chauhan, A.; Tyagi, V.V.; Sawhney, A.; Anand, S. Comparative enviro-economic assessment and thermal optimization of two distinctly designed and experimentally validated PV/T collectors. J. Therm. Anal. 2021, 147, 1739–1755. [Google Scholar] [CrossRef]

- Cui, Y.; Zhu, J.; Zoras, S.; Zhang, J. Comprehensive review of the recent advances in PV/T system with loop-pipe configuration and nanofluid. Renew. Sustain. Energy Rev. 2021, 135, 110254. [Google Scholar] [CrossRef]

- Lamnatou, C.; Chemisana, D. Photovoltaic/thermal (PVT) systems: A review with emphasis on environmental issues. Renew. Energy 2017, 105, 270–287. [Google Scholar] [CrossRef]

- Roshanzadeh, B.; Premer, L.R.; Mohan, G. Developing an Advanced PVT System for Sustainable Domestic Hot Water Supply. Energies 2022, 15, 2346. [Google Scholar] [CrossRef]

- Vaishak, S.; Bhale, P.V. Investigation on the effect of different backsheet materials on performance characteristics of a photovoltaic/thermal (PV/T) system. Renew. Energy 2021, 168, 160–169. [Google Scholar] [CrossRef]

- Maadi, S.R.; Sabzali, H.; Kolahan, A.; Wood, D. Improving the performance of PV/T systems by using conical-leaf inserts in the coolant tubes. Sol. Energy 2020, 212, 84–100. [Google Scholar] [CrossRef]

- Yuan, W.; Ji, J.; Li, Z.; Zhou, F.; Ren, X.; Zhao, X.; Liu, S. Comparison study of the performance of two kinds of photovoltaic/thermal(PV/T) systems and a PV module at high ambient temperature. Energy 2018, 148, 1153–1161. [Google Scholar] [CrossRef]

- Abdallah, S.R.; Elsemary, I.M.M.; Altohamy, A.A.; Abdelrahman, M.A.; Attia, A.A.A.; Abdellatif, O.E. Experimental investigation on the effect of using nano fluid (Al2O3-Water) on the performance of PV/T system. Therm. Sci. Eng. Prog. 2018, 7, 1–7. [Google Scholar] [CrossRef]

- Kang, Z.; Lu, Z.; Song, G.; Yao, Q. A Numerical Study of Dual-Inlet Air-Cooled PV/T Solar Collectors with Various Airflow Channel Configurations. Sustainability 2022, 14, 9897. [Google Scholar] [CrossRef]

- Hussain, M.I.; Lee, G.-H.; Kim, J.-T. A Comprehensive Performance Characterization of a Nanofluid-Powered Dual-Fluid PV/T System under Outdoor Steady State Conditions. Sustainability 2021, 13, 13134. [Google Scholar] [CrossRef]

- Athukorala, A.U.C.D.; Jayasuriya, W.J.A.; Ragulageethan, S.; Sirimanna, M.P.G.; Attalage, R.A.; Perera, A.T.D. A techno-economic analysis for an integrated solar PV/T system with thermal and electrical storage—Case study. In Proceedings of the MERCon 2015—Moratuwa Engineering Research Conference, Moratuwa, Sri Lanka, 7–8 April 2015; pp. 182–187. [Google Scholar] [CrossRef]

- Parvez Mahmud, M.A.; Huda, N.; Farjana, S.H.; Lang, C. Environmental Life-Cycle Assessment and Techno-Economic Analysis of Photovoltaic (PV) and Photovoltaic/Thermal (PV/T) Systems. In Proceedings of the 2018 IEEE International Conference on Environment and Electrical Engineering and 2018 IEEE Industrial and Commercial Power Systems Europe, EEEIC/I and CPS Europe 2018, Palermo, Italy, 12–15 June 2018. [Google Scholar] [CrossRef]

- Zafar, S.; Dincer, I. Thermodynamic analysis of a combined PV/T–fuel cell system for power, heat, fresh water and hydrogen production. Int. J. Hydrogen Energy 2014, 39, 9962–9972. [Google Scholar] [CrossRef]

- Wu, S.-Y.; Guo, F.-H.; Xiao, L. A Review on the Methodology for Calculating Heat and Exergy Losses of a Conventional Solar PV/T System. Int. J. Green Energy 2014, 12, 379–397. [Google Scholar] [CrossRef]

- Yazdanifard, F.; Ameri, M. Exergetic advancement of photovoltaic/thermal systems (PV/T): A review. Renew. Sustain. Energy Rev. 2018, 97, 529–553. [Google Scholar] [CrossRef]

- Good, C.; Andresen, I.; Hestnes, A.G. Solar energy for net zero energy buildings—A comparison between solar thermal, PV and photovoltaic–thermal (PV/T) systems. Sol. Energy 2015, 122, 986–996. [Google Scholar] [CrossRef]

- Zogou, O.; Stapountzis, H. Flow and heat transfer inside a PV/T collector for building application. Appl. Energy 2012, 91, 103–115. [Google Scholar] [CrossRef]

- Herrando, M.; Ramos, A. Photovoltaic-Thermal (PV-T) Systems for Combined Cooling, Heating and Power in Buildings: A Review. Energies 2022, 15, 3021. [Google Scholar] [CrossRef]

- Żabnieńska-Góra, A.; Khordehgah, N.; Jouhara, H. Annual performance analysis of the PV/T system for the heat demand of a low-energy single-family building. Renew. Energy 2021, 163, 1923–1931. [Google Scholar] [CrossRef]

- Büker, M.S.; Mempouo, B.; Riffat, S.B. Performance evaluation and techno-economic analysis of a novel building integrated PV/T roof collector: An experimental validation. Energy Build. 2014, 76, 164–175. [Google Scholar] [CrossRef]

- Farshchimonfared, M.; Bilbao, J.I.; Sproul, A.B. Channel depth, air mass flow rate and air distribution duct diameter optimization of photovoltaic thermal (PV/T) air collectors linked to residential buildings. Renew. Energy 2015, 76, 27–35. [Google Scholar] [CrossRef]

- Farshchimonfared, M.; Bilbao, J.I.; Sproul, A.B. Full optimisation and sensitivity analysis of a photovoltaic–thermal (PV/T) air system linked to a typical residential building. Sol. Energy 2016, 136, 15–22. [Google Scholar] [CrossRef]

- Sotehi, O.; Chaker, A.; Maalouf, C. Hybrid PV/T water solar collector for net zero energy building and fresh water production: A theoretical approach. Desalination 2016, 385, 1–11. [Google Scholar] [CrossRef]

- Shao, N.; Ma, L.; Zhang, J. Experimental investigation on the performance of direct-expansion roof-PV/T heat pump system. Energy 2020, 195, 116959. [Google Scholar] [CrossRef]

- Bandaru, S.H.; Becerra, V.; Khanna, S.; Radulovic, J.; Hutchinson, D.; Khusainov, R. A Review of Photovoltaic Thermal (PVT) Technology for Residential Applications: Performance Indicators, Progress, and Opportunities. Energies 2021, 14, 3853. [Google Scholar] [CrossRef]

- Jørgensen, S.E. Exergy. In Encyclopedia of Ecology; Elsevier: Amsterdam, The Netherlands, 2008; pp. 1498–1509. [Google Scholar] [CrossRef]

- Saleh, B.; Sundar, L.S. Experimental study on heat transfer, friction factor, entropy and exergy efficiency analyses of a corrugated plate heat exchanger using Ni/water nanofluids. Int. J. Therm. Sci. 2021, 165, 106935. [Google Scholar] [CrossRef]

- Zhang, H.; Liu, X.; Liu, Y.; Duan, C.; Dou, Z.; Qin, J. Energy and exergy analyses of a novel cogeneration system coupled with absorption heat pump and organic Rankine cycle based on a direct air cooling coal-fired power plant. Energy 2021, 229, 120641. [Google Scholar] [CrossRef]

- Idir, A.; Perier-Muzet, M.; Aymé-Perrot, D.; Stitou, D. Thermodynamic Optimization of Electrical and Thermal Energy Production of PV Panels and Potential for Valorization of the PV Low-Grade Thermal Energy into Cold. Energies 2022, 15, 498. [Google Scholar] [CrossRef]

- Arslan, E.; Aktaş, M.; Can, F. Experimental and numerical investigation of a novel photovoltaic thermal (PV/T) collector with the energy and exergy analysis. J. Clean. Prod. 2020, 276, 123255. [Google Scholar] [CrossRef]

- Sarhaddi, F.; Farahat, S.; Ajam, H.; Behzadmehr, A. Exergetic performance assessment of a solar photovoltaic thermal (PV/T) air collector. Energy Build. 2010, 42, 2184–2199. [Google Scholar] [CrossRef]

- Joshi, A.S.; Dincer, I.; Reddy, B.V. Analysis of energy and exergy efficiencies for hybrid PV/T systems. Int. J. Low-Carbon Technol. 2011, 6, 64–69. [Google Scholar] [CrossRef]

- Maleki, A.; Ngo, P.T.T.; Shahrestani, M.I. Energy and exergy analysis of a PV module cooled by an active cooling approach. J. Therm. Anal. 2020, 141, 2475–2485. [Google Scholar] [CrossRef]

- Qingyang, J.; Jichun, Y.; Yanying, Z.; Huide, F. Energy and exergy analyses of PV, solar thermal and photovoltaic/thermal systems: A comparison study. Int. J. Low-Carbon Technol. 2021, 16, 604–611. [Google Scholar] [CrossRef]

- Saloux, E.; Teyssedou, A.; Sorin, M. Analysis of photovoltaic (PV) and photovoltaic/thermal (PV/T) systems using the exergy method. Energy Build. 2013, 67, 275–285. [Google Scholar] [CrossRef]

- Huang, M.; Wang, Y.; Li, M.; Keovisar, V.; Li, X.; Kong, D.; Yu, Q. Comparative study on energy and exergy properties of solar photovoltaic/thermal air collector based on amorphous silicon cells. Appl. Therm. Eng. 2020, 185, 116376. [Google Scholar] [CrossRef]

- Hazami, M.; Riahi, A.; Mehdaoui, F.; Nouicer, O.; Farhat, A. Energetic and exergetic performances analysis of a PV/T (photovoltaic thermal) solar system tested and simulated under to Tunisian (North Africa) climatic conditions. Energy 2016, 107, 78–94. [Google Scholar] [CrossRef]

- Wu, S.-Y.; Chen, C.; Xiao, L. Heat transfer characteristics and performance evaluation of water-cooled PV/T system with cooling channel above PV panel. Renew. Energy 2018, 125, 936–946. [Google Scholar] [CrossRef]

- Joshi, A.S.; Tiwari, G.N. Monthly energy and exergy analysis of hybrid photovoltaic thermal (PV/T) system for the Indian climate. Int. J. Ambient Energy 2011, 28, 99–112. [Google Scholar] [CrossRef]

- Jahromi, S.N.; Vadiee, A.; Yaghoubi, M. Exergy and Economic Evaluation of a Commercially Available PV/T Collector for Different Climates in Iran. Energy Procedia 2015, 75, 444–456. [Google Scholar] [CrossRef]

- Hossain, M.S.; Pandey, A.K.; Selvaraj, J.; Rahim, N.A.; Islam, M.M.; Tyagi, V.V. Two side serpentine flow based photovoltaic-thermal-phase change materials (PVT-PCM) system: Energy, exergy and economic analysis. Renew. Energy 2019, 136, 1320–1336. [Google Scholar] [CrossRef]

- Hassani, S.; Saidur, R.; Mekhilef, S.; Taylor, R.A. Environmental and exergy benefit of nanofluid-based hybrid PV/T systems. Energy Convers. Manag. 2016, 123, 431–444. [Google Scholar] [CrossRef]

- Adun, H.; Adedeji, M.; Dagbasi, M.; Bamisile, O.; Senol, M.; Kumar, R. A numerical and exergy analysis of the effect of ternary nanofluid on performance of Photovoltaic thermal collector. J. Therm. Anal. 2021, 145, 1413–1429. [Google Scholar] [CrossRef]

- Diniz, F.L.J.; Vital, C.V.P.; Gómez-Malagón, L.A. Parametric analysis of energy and exergy efficiencies of a hybrid PV/T system containing metallic nanofluids. Renew. Energy 2022, 186, 51–65. [Google Scholar] [CrossRef]

- Jing, D.; Hu, Y.; Liu, M.; Wei, J.; Guo, L. Preparation of highly dispersed nanofluid and CFD study of its utilization in a concentrating PV/T system. Sol. Energy 2015, 112, 30–40. [Google Scholar] [CrossRef]

- Rashidi, M.; Nazari, M.A.; Mahariq, I.; Ali, N. Modeling and Sensitivity Analysis of Thermal Conductivity of Ethylene Glycol-Water Based Nanofluids with Alumina Nanoparticles. Exp. Tech. 2022, 2022, 1–8. [Google Scholar] [CrossRef]

- Rashidi, M.M.; Nazari, M.A.; Mahariq, I.; Assad, M.E.H.; Ali, M.E.; Almuzaiqer, R.; Nuhait, A.; Murshid, N. Thermophysical Properties of Hybrid Nanofluids and the Proposed Models: An Updated Comprehensive Study. Nanomaterials 2021, 11, 3084. [Google Scholar] [CrossRef]

- Aberoumand, S.; Ghamari, S.; Shabani, B. Energy and exergy analysis of a photovoltaic thermal (PV/T) system using nanofluids: An experimental study. Sol. Energy 2018, 165, 167–177. [Google Scholar] [CrossRef]

- Adun, H.; Adedeji, M.; Ruwa, T.; Senol, M.; Kavaz, D.; Dagbasi, M. Energy, exergy, economic, environmental (4E) approach to assessing the performance of a photovoltaic-thermal system using a novel ternary nanofluid. Sustain. Energy Technol. Assess. 2022, 50, 101804. [Google Scholar] [CrossRef]

- Li, B.; Hong, W.; Li, H.; Lan, J.; Zi, J. Optimized energy distribution management in the nanofluid-assisted photovoltaic/thermal system via exergy efficiency analysis. Energy 2022, 242, 123018. [Google Scholar] [CrossRef]

- Masoud Parsa, S.; Yazdani, A.; Aberoumand, H.; Farhadi, Y.; Ansari, A.; Aberoumand, S.; Karimi, N.; Afrand, M.; Cheraghian, G.; Ali, H.M. A critical analysis on the energy and exergy performance of photovoltaic/thermal (PV/T) system: The role of nanofluids stability and synthesizing method. Sustain. Energy Technol. Assess. 2022, 51, 101887. [Google Scholar] [CrossRef]

- Sangeetha, M.; Manigandan, S.; Ashok, B.; Brindhadevi, K.; Pugazhendhi, A. Experimental investigation of nanofluid based photovoltaic thermal (PV/T) system for superior electrical efficiency and hydrogen production. Fuel 2021, 286, 119422. [Google Scholar] [CrossRef]

- Adun, H.; Mukhtar, M.; Adedeji, M.; Agwa, T.; Ibrahim, K.H.; Bamisile, O.; Dagbasi, M. Synthesis and Application of Ternary Nanofluid for Photovoltaic-Thermal System: Comparative Analysis of Energy and Exergy Performance with Single and Hybrid Nanofluids. Energies 2021, 14, 4434. [Google Scholar] [CrossRef]

- Sopian, K.; Al-Waeli, A.H.A.; Kazem, H.A. Energy, exergy and efficiency of four photovoltaic thermal collectors with different energy storage material. J. Energy Storage 2020, 29, 101245. [Google Scholar] [CrossRef]

- Wu, S.-Y.; Wang, T.; Xiao, L.; Shen, Z.-G. Effect of cooling channel position on heat transfer characteristics and thermoelectric performance of air-cooled PV/T system. Sol. Energy 2019, 180, 489–500. [Google Scholar] [CrossRef]

- Dubey, S.; Solanki, S.C.; Tiwari, A. Energy and exergy analysis of PV/T air collectors connected in series. Energy Build. 2009, 41, 863–870. [Google Scholar] [CrossRef]

- Ould-Lahoucine, C.; Ramdani, H.; Zied, D. Energy and exergy performances of a TiO2-water nanofluid-based hybrid photovoltaic/thermal collector and a proposed new method to determine the optimal height of the rectangular cooling channel. Sol. Energy 2021, 221, 292–306. [Google Scholar] [CrossRef]

- Eisapour, A.H.; Eisapour, M.; Hosseini, M.J.; Shafaghat, A.; Sardari, P.T.; Ranjbar, A.A. Toward a highly efficient photovoltaic thermal module: Energy and exergy analysis. Renew. Energy 2021, 169, 1351–1372. [Google Scholar] [CrossRef]

- Gao, Y.; Hu, G.; Zhang, Y.; Zhang, X. An experimental study of a hybrid photovoltaic thermal system based on ethanol phase change self-circulation technology: Energy and exergy analysis. Energy 2022, 238, 121663. [Google Scholar] [CrossRef]

- Chow, T.T.; Pei, G.; Fong, K.F.; Lin, Z.; Chan, A.L.S.; Ji, J. Energy and exergy analysis of photovoltaic–thermal collector with and without glass cover. Appl. Energy 2009, 86, 310–316. [Google Scholar] [CrossRef]

- Zuhur, S.; Ceylan, I.; Ergün, A. Energy, exergy and environmental impact analysis of concentrated PV/cooling system in Turkey. Sol. Energy 2019, 180, 567–574. [Google Scholar] [CrossRef]

- Du, M.; Tang, G.H.; Wang, T.M. Exergy analysis of a hybrid PV/T system based on plasmonic nanofluids and silica aerogel glazing. Sol. Energy 2019, 183, 501–511. [Google Scholar] [CrossRef]

- Sobhnamayan, F.; Sarhaddi, F.; Alavi, M.A.; Farahat, S.; Yazdanpanahi, J. Optimization of a solar photovoltaic thermal (PV/T) water collector based on exergy concept. Renew. Energy 2014, 68, 356–365. [Google Scholar] [CrossRef]

- Mahdavi, S.; Sarhaddi, F.; Hedayatizadeh, M. Energy/exergy based-evaluation of heating/cooling potential of PV/T and earth-air heat exchanger integration into a solar greenhouse. Appl. Therm. Eng. 2019, 149, 996–1007. [Google Scholar] [CrossRef]

- James, A.; Mohanraj, M.; Srinivas, M.; Jayaraj, S. Thermal analysis of heat pump systems using photovoltaic-thermal collectors: A review. J. Therm. Anal. 2020, 144, 2435–2448. [Google Scholar] [CrossRef]

- Ogbonnaya, C.; Turan, A.; Abeykoon, C. Energy and exergy efficiencies enhancement analysis of integrated photovoltaic-based energy systems. J. Energy Storage 2019, 26, 101029. [Google Scholar] [CrossRef]

- Caglar, B.; Araz, M.; Ozcan, H.G.; Calisan, A.; Hepbasli, A. Energy and exergy analysis of a PV-T integrated ethanol PEM electrolyzer. Int. J. Hydrogen Energy 2021, 46, 12615–12638. [Google Scholar] [CrossRef]

- Heydarian, R.; Shafii, M.B.; Shirin-Abadi, A.R.; Ghasempour, R.; Nazari, M.A. Experimental investigation of paraffin nano-encapsulated phase change material on heat transfer enhancement of pulsating heat pipe. J. Therm. Anal. 2019, 137, 1603–1613. [Google Scholar] [CrossRef]

- Nazari, M.A.; Maleki, A.; Assad, M.E.H.; Rosen, M.A.; Haghighi, A.; Sharabaty, H.; Chen, L. A review of nanomaterial incorporated phase change materials for solar thermal energy storage. Sol. Energy 2021, 228, 725–743. [Google Scholar] [CrossRef]

| Reference | System | Findings |

|---|---|---|

| Huang et al. [46] | PV/T with air | High mass flow rates of air caused higher efficiency (electrical) of PV/T compared with individual PV modules. |

| Wu et al. [48] | PV/T with water | For this configuration, cooling channel above the PV, effect of thermal exergy efficiency on the overall exergy efficiency was more remarkable compared with electrical exergy efficiency. |

| Aberoumand et al. [58] | PV/T with water and nanofluid | Improvement in the exergy efficiency was more notable in cases of higher concentrations and mass flow rates. |

| Adun et al. [59] | PV/T with ternary nanofluid | Solar irradiance pattern was seen in the total exergy. |

| Parsa et al. [61] | PV/T with nanofluid | Using the nanofluids obtained from one-step method caused higher exergy efficiency compared with the nanofluid prepared by two-step approach. |

| Hazami et al. [47] | PV/T with water | Electric exergy of the system in active mode was around 19.35% higher than in passive mode. |

| Joshi and Tiwari [49] | PV/T with air | Maximum monthly exergy of the system was dependent on the city. |

| Jahromi et al. [50] | PV/T with water/EG mixture | Exergy efficiency of the system was higher in winter (with lower ambient temperature) compared with summer (with higher ambient temperature). |

| Hossain et al. [51] | PV/T with PCM packets | Maximum exergy efficiencies of the PV/T system in optimal condition and PV were 12.19% and 7.09%, respectively. |

| Sangeetha et al. [62] | PV/T with nanofluids | Using MWCNT/water nanofluids provided higher exergy efficiency compared with TiO2/water and Al2O3/water. |

| Adun et al. [63] | PV/T system with different nanofluids | The highest exergy efficiency belonged to Al2O3-ZnO-Fe3O4/water that was followed by Al2O3-ZnO/water. |

| Sopian et al. [64] | PV/T with water, PV/T with water and PCM, PV/T with nanofluid and nano-PCM | The highest average electrical exergy efficiency belonged to the PV/T with nanofluid and nano-PCM. |

| Dubey et al. [66] | PV/T with air | Air flow below the absorber plate provided higher exergy gain compared with the case of flow above the plate. |

| Lahoucine et al. [67] | PV/T with water and nanofluid | Increment in cooling channel height causes reduction in exergy efficiency. |

| Eisapour et al. [68] | PV/T with different fluids | Using wavy channels with modified configuration (ascending) leads to the highest electrical exergy among the tested configurations. |

| Gao et al. [69] | PV/T with ethanol phase change self-circulation technology | Entropy generation in case of glazed system was lower than unglazed case. |

| Chow et al. [70] | PV/T with water | Under some working conditions, exergy efficiency of unglazed system can be better than glazed system. |

| Zuhur et al. [71] | PV/T with concentrator | Applying concentrator increased the exergy efficiency. |

| Du et al. [72] | PV/T with nanofluid and glazing | Enhancement of 13.3% in exergetic efficiency was observed compared with traditional system. |

| Sobhnamayan et al. [73] | PV/T with water | Optimization was performed on the system based on exergy concept. |

| Ogbonnaya et al. [76] | PV-battery, PV/T-battery, PV-battery-electrolyzer-fuel cell, PV-T- battery- electrolyzer-fuel cell | The highest exergy efficiency among these systems belonged to PV/T-battery. |

| Caglar et al. [77] | PV/T with electrolyzer | Increase in coolant flow rate can improve energy efficiency while there was no considerable impact on the exergy efficiency. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guedri, K.; Salem, M.; Assad, M.E.H.; Rungamornrat, J.; Malek Mohsen, F.; Buswig, Y.M. PV/Thermal as Promising Technologies in Buildings: A Comprehensive Review on Exergy Analysis. Sustainability 2022, 14, 12298. https://doi.org/10.3390/su141912298

Guedri K, Salem M, Assad MEH, Rungamornrat J, Malek Mohsen F, Buswig YM. PV/Thermal as Promising Technologies in Buildings: A Comprehensive Review on Exergy Analysis. Sustainability. 2022; 14(19):12298. https://doi.org/10.3390/su141912298

Chicago/Turabian StyleGuedri, Kamel, Mohamed Salem, Mamdouh El Haj Assad, Jaroon Rungamornrat, Fatimah Malek Mohsen, and Yonis M. Buswig. 2022. "PV/Thermal as Promising Technologies in Buildings: A Comprehensive Review on Exergy Analysis" Sustainability 14, no. 19: 12298. https://doi.org/10.3390/su141912298

APA StyleGuedri, K., Salem, M., Assad, M. E. H., Rungamornrat, J., Malek Mohsen, F., & Buswig, Y. M. (2022). PV/Thermal as Promising Technologies in Buildings: A Comprehensive Review on Exergy Analysis. Sustainability, 14(19), 12298. https://doi.org/10.3390/su141912298