Abstract

With the evolution of Industry 4.0, some problems related to inefficient digitalization become clearer in organizations. To minimize these problems, implementation of the lean philosophy is needed in the digital environment. However, before Lean can start to solve the digitalization problems, there is a need to digitalize its tools so that they can comprehend the Industry 4.0 dynamics and become more effective. The aim of this study is to contribute to the theoretical development of Lean tools in the context of Industry 4.0, promoting directions for the industrial sector from the evolution, difficulties, benefits, implementation and trends of Lean 4.0 tools. To achieve this objective, this study performs a systematic literature review and content analysis of 53 papers from 35 journals. The main results of the research show: (i) the characterization of the Lean 4.0 tools; (ii) the evolution of the Lean tools after the integration with digital technologies; (iii) the main trends of Lean 4.0; (iv) the proposal of a Lean 4.0 theoretical framework. From these results, this paper seeks to promote insights for studies in the area of Lean 4.0, as well as for companies to implement and use the Lean 4.0 tools for better improvement in their digital processes and avoid the digital waste.

1. Introduction

In 2011, the fourth industrial revolution, also called Industry 4.0, had its concept introduced during the technology fair in Hannover, Germany in Academia and Business Practices. Integrated manufacturing in the digital perspective generated the premise of creating an intelligent and independent factory allowing machines to communicate with each other [1], using technologies such as: internet of things, Big Data, digital twins and simulation, additive manufacturing, self-guided robots, cyber-physical systems, augmented reality, cloud computing [2] and artificial intelligence with neural networks [3]. Thus, it has enabled mass customization of products and relocation of layouts, speed of production and communication of machines for process control. The report carried out by [4] in 2019, in partnership with the World Economic Forum, it has highlighted the potential for manufacturers and suppliers that implement Industry 4.0 to generate an added value of 3.7 trillion dollars in revenue for the year 2025. Even with all this potential, according to [4], despite the digital transformation, they end up facing five main barriers that block their innovation projects: (i) insufficient resources or lack of knowledge; (ii) high implementation costs; (iii) difficulty in justifying the investment in the business without a short-term return; (iv) prototype projects do not justify the investment; (v) too many cases to justify implementation. In this sense, digital implementation needs to be linked to the planning, organization and concern of the culture to receive digital transformation. When done successfully, it implies reducing waste in several areas of the organization in addition to financial investment [5] and providing employees with autonomy and empowerment [6,7]. Historically, the most used philosophy to reduce waste is Lean. One of the ways to give autonomy to the human being in the industrial environment is by inserting the Lean philosophy through Lean thinking [8]. Ref. [9] also points out that organizations need to focus on human elements, in addition to tool implementations for a successful Lean transformation. Ref. [10] reinforces that organizations aimed at digitization need to focus on the development of people because they are responsible for decision-making.

The Lean philosophy was developed in Toyota factories after the end of the Second World War in order to eliminate any activity that did not add value [11]. Its creator [12] pointed out that Lean aimed to combat seven types of waste: Inventory, Transport, Waiting, Defects, Excessive Production, Movements and Unnecessary Processes on the line. In addition to these seven, ref. [12] also identified the eighth category of waste that came from the misuse of skills and practical training of people [13]. In the Lean philosophy, some of the main tools used to combat waste stand out: 5 s, Jidoka, just in time, Kanban, Kaizen, PDCA Cycle (Plan, Do, Check Act), VSM (Value Steam Mapping), TPM (Total Productive Maintenance) and Poka yoke.

Both Lean and its tools underwent transformations and concept updates when they were immersed in the fourth industrial revolution; thus, emerging a new way of thinking about Lean, now with a digital perspective [14].

In the report elaborated by [15], it is highlighted that digital technologies improve acceptance of the Lean tools and allow for better improvements in future strategy plans of the industries. However, there is the issue of cyber security that digital technologies bring to organizations, as pointed out in the report by [16]. Ref. [17] suggested that predictive maintenance is becoming one of the most improved Lean procedures by the Industry 4.0 technologies, and thus becoming an example of how to create an improved digital procedure. However, ref. [15] points out that until 2025, the added value of digital procedures is estimated to be above 640 billion of dollars; also, there was a prediction that almost 70% of industries, by the year 2020, were going to use cloud computing to some extent. However, if not implemented right, digital transformation can become a source of waste and result in failure, ref. [15] reports show that almost 70% of the digital transformation processes fail because of the lack of strategy and long-term thinking.

To potentialize this opportunity, Lean 4.0 is taking the lead by helping to add value to the new digital transformation. Authors in [18] identify that Lean is seen as an important agent in the implementation of Industry 4.0 and highlights Lean concepts such as standardization of work, organization and transparency as bridges to allow a more effective digital consolidation. In fact, there is a contribution from Industry 4.0 in improving Lean, mainly through integrated information and communication systems, supplying conventional practices and reducing production waste [13]. The authors in [19] address the co-existence of Lean and Industry 4.0; in their literature review, the author points out that there is a possibility of linking the approaches by exemplifying cases of intelligent products, machines and improved operators, with a focus on lean production; thus, identifying that they can support each other.

However, updated Industry 4.0 technologies also provide benefits for Lean, generating a new level of visibility and access to real-time performance data at various levels of operations. This generates increased productivity and reduced costs and waiting time [20]. Even though the concepts of Lean and Industry 4.0 are fundamentally different, as one focuses on reducing excesses and the other on digitizing and innovating with new technologies, the ultimate goal of valuing production systems are the same. That is why, when properly combined, they give rise to Lean 4.0 and become capable of complementing each other in the industries [21]. Even with the literature suggesting that there is a positive interaction between Lean and Industry 4.0, this topic still needs more research in the literature to understand how this synthesis is carried out [20] and how the digital aspect of Lean impacts the reduction in performance waste produced by Industry 4.0 implementations, also called digital waste [22]. An example of digital waste is the excess of data processed by cloud computing operations based on Big Data or high investments in training for workers to deal with digital technology [1].

As such, Lean 4.0 can be defined as a perspective of Lean that can implement the new digital technologies in its main tools to improve waste detection and reduction in both digital and real processes. However, there is still a lack of literature about how Lean 4.0 works, what its main tools are that are influenced by digital technologies and how Lean 4.0 can be implemented in the industry. To answer that, this article proposes a new framework called D-LEAMIN to facilitate the Lean 4.0 implementation by pointing out which tools are implemented first, why they go first and the overall benefits and trends for Lean 4.0.

It is worth noting that the implementation of Lean 4.0 has the potential to improve the quality of life of workers in organizations, giving rise to a new way of thinking and training employees in favor of the Lean digital culture. This, in the long term, generates an economic benefit for operations by reducing digital waste from excessive or poorly implemented scans without Lean bias. The search for minimizing the social impact caused by digitalization allowed this article to study the Lean tools that went through a digitalization process seeking to reduce all forms of waste and rethink the Industry 4.0 implementation. Inspired by the necessity to map out how the process of evolution and creation of the Lean 4.0 concept emerged, and also the aim of identifying its current state from the perspective of the digitalized Lean tools. Thus, a literature review and content analysis were carried out in order to answer the following research questions:

- How to characterize the benefits and difficulties of implementing Lean tools to promote implementation trends in the context of Industry 4.0.

- How to identify the evolution of Lean tools in the face of digitalization.

- What are the main trends for Lean 4.0?

- How to implement Lean 4.0.

As such, the aim of this study is to contribute to the theoretical development of Lean tools in the context of Industry 4.0, promoting directions for the industrial sector from the evolution, difficulties, benefits, implementation and trends of Lean 4.0 tools. To achieve this objective, a literature review will be carried out using the PRISMA methodology. Furthermore, content analysis will be performed with the assistance of the QSR-NVIVO version 10 software. The expected results from this literature review are: (i) the characterization of the Lean 4.0 tools; (ii) the evolution of the Lean tools after the integration with digital technologies; (iii) the main trends of the Lean 4.0; (iv) the proposal of a Lean 4.0 theoretical framework. The main points of originality presented in this paper are: the development of the Lean 4.0 framework; characterization of the main trends about the Lean 4.0 implementation and its difficulties and benefits; and characterization of the digital waste concepts in the eight wastes as defined by [12].

This paper is organized in the following format: Section 2 presents the methodology used, reporting the steps for searching and analyzing the article portfolio by means of a Systematic Literature Review, Bibliometric Analysis and Content Analysis. Section 3 presents the results and discussions, subdivided into sections presenting the bibliometric analysis and content analysis for the characterization of the Lean 4.0 tools. Section 4 presents the discussion about the Lean 4.0 trends and its implication, along with the Lean 4.0 implementation framework. Finally, Section 5 presents the final considerations of this paper.

2. Materials and Methods

The main purpose of this article is to contribute to the theoretical development of Lean tools in the context of Industry 4.0, promoting directions for the evolution, difficulties and benefits, and the main trends after the Lean 4.0 implementation. For this, the research methodology was structured in 4 main steps: (i) Definition of the Research Problem; (ii) Systematic Literature Review; (iii) Bibliometric Analysis; and (iv) Content Analysis. Table 1 presents an overview of each of these steps, the main activities carried out and the results achieved.

Table 1.

Methodology Steps.

Application of the PRISMA Method according to its main steps: (i) Identification, (ii) Screening and (iii) Inclusion:

2.1. Step 1 Research Problem Definition

With the need to identify the evolution of the Lean tools in the digital context, we are thus seeking to analyze how this synergy allows the reduction in digital waste arising from the non-Lean implementation of Industry 4.0 and the implication on the main trends. For this, the research questions on the topic are presented:

RQ1: How to characterize the benefits and difficulties of implementing Lean tools to promote implementation trends in the context of Industry 4.0. Reason: it shows how Lean 4.0 synergy operates in relation to each Lean tool and what the main improvements and main difficulties are in the digital environment for its implementation.

RQ2: How to identify the evolution of Lean tools in the face of digitalization. Reason: it shows how Lean 4.0 tools have transformed and how they differ from their classic Lean version.

RQ3: What are the trends for Lean 4.0? Reason: it shows the future trends of Lean 4.0 and the possible impacts on organizations.

RQ4: How to implement Lean 4.0. Reason: it shows a theoretical framework for the implementation of the Lean 4.0 model based on the Lean 4.0 tools.

2.2. Step 2 Systematic Literature Review

We decided to carry out a systematic literature review linked to software-aided content analysis. A systematic literature review can be defined as an analysis of evidence, based on a question formulated, to investigate a topic aided by systemic methods that evaluate and select relevant research in order to extract and analyze data critically [23].

There are many methods available in the literature to conduct this type of research, refs. [24,25,26,27,28], it is up to researchers to choose the appropriate method according to the nature of each research topic.

To carry out the Systematic Literature Review of this research, the PRISMA Method (Preferred Reporting Items for Systematic Reviews and Meta-Analyses) was used, according to its 3 main steps: Identification, Screening and Inclusion [27]. This method was chosen over the others because of its protocol creation procedures, wide acceptance in academic articles from different subject areas and adequate treatment for analyzing conference articles.

In order to carry out the Identification stage, the keywords were initially defined that relate the main thematic axes of this research: Industry 4.0 and Lean. Based on this definition, it was then possible to establish the research protocol Table 2 to search for articles in the databases.

Table 2.

Research Protocol.

The search for articles according to the Research Protocol was carried out on 8 March 2022 and three main databases were used: Scopus, Web of Science and IEEE explore. At the end of this step, a total of 1084 articles were collected.

The second stage of PRISMA is Screening which consists of reading the title, abstract and keywords of all the articles to identify potential articles for the review. Thus, identifying whether the terms Lean and Industry 4.0 were aligned with the main theme of the article and its contributions. To carry out this step, a protocol was prepared containing some exclusion criteria for the evaluation of articles. The first exclusion criterion was to exclude articles in partial format or without access because without the complete location of the official document it is not possible to carry out content and bibliometric analysis. The second criterion is the exclusion of documents that are not part of the type proposed in the research protocol; thus, excluding book chapters, reports and other works that are not the 3 types of articles stipulated in the research protocol. The third exclusion criterion will be implemented during the initial readings of the title, abstract and keywords to evaluate the content of the articles, if they do not fit the quest to characterize Lean 4.0 from the digitization of the tools. Finally, the fourth criterion is the exclusion of partially correlated articles, from the full reading and evaluation of the ability to encode excerpts of the article in the nodes; if this is not possible, it will be excluded from the portfolio. After the exclusion of the title, keywords and abstract, the remaining articles were downloaded to the databases for complete reading.

The last step of PRISMA Is the in”lusi’n method, where research can be added to the portfolio by reference analysis methods of articles. For this article, however, no other external articles were added to what was collected and filtered in the previous steps.

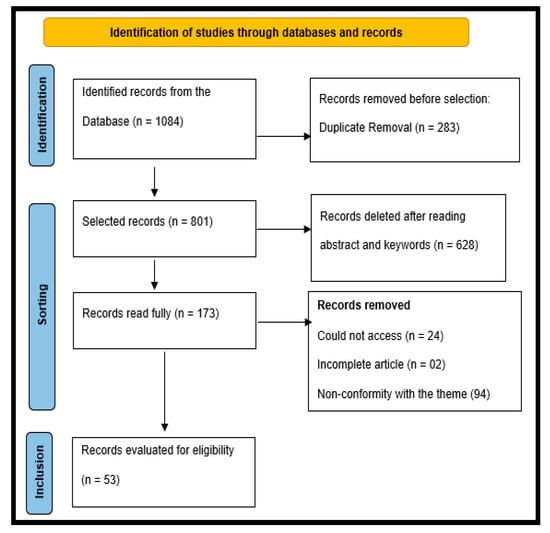

From the application of the PRISMA Method, it was then possible to define a final portfolio of 53 articles that relate Industry 4.0 technologies and Lean tools that will be used in the next steps of this research: bibliometric and network analysis and content analysis. Figure 1 presents a detailed view of each of the application stages of the PRISMA Method and the number of articles corresponding to each one.

Figure 1.

The PRISMA diagram.

2.3. Step 3: Bibliometric Analysis

The bibliometric review helps to assess the main topics and trends in publications on the topic, as well as the main journals that are publishing it [29]. From the portfolio of articles defined at the end of the Inclusion stage, the metadata was carried out in Mendeley™ [30] for the correct count of journals and year of publication. With the correct metadata, it was possible to count the number of publications per year and plot a graph in Microsoft Excel. This graph is responsible for characterizing the portfolio and generating the analysis of publications per year.

2.4. Step 4: Content Analysis

Content analysis is defined as a procedure that aims to obtain a knowledge of works from a systematic reading of their sentences and messages [31]. This type of analysis allows the researcher to critically analyze the content of articles in a literature review in this way, classifying them and grouping them into similar themes to quantify this content.

Ref. [32] points out the main characteristics of a content analysis study, it allows the researcher to: study data; interpret theories; establish and consolidate concepts; develop relationships between concepts; and synthesize the research results in frameworks or other examples.

We chose to use the NvivoR software [33] to assist in content analysis; thus, allowing transparency and replicability [34]. The first stage of content analysis is the pre-analysis, they were imported into the program via importing PDF files. The second stage was the reading of the articles in the program and the elaboration of nodes to encode the text; in this stage, the researcher grouped the main themes of the research and, thus, created the initial nodes to address the main topics covered in this article.

The third stage was the coding of excerpts from the articles in the nodes previously prepared in order to identify the occurrence of the theme and interpret this content from the point of view of the different authors, this coding in nodes allows clarity and reduction in excess data for reading during the content analysis [35]. This step of consolidation in nodes has a dynamic and volatile characteristic, in which readings were made on nodes of small occurrences and then they were migrated to larger clusters. To allow more robustness to the analysis nodes, several discussions were held between the authors; finally, a final grouping of nodes related to the most found Lean tools in the portfolio was reached in which the answer to the research questions proposed by this article was translated into the content analysis.

3. Results

This section of the article addresses the results obtained by the bibliometrics of the 53 articles obtained after the selection and filtering process using the PRISMA methodology. These works were analyzed and defined as capable of aggregating to answer the research questions of this article. For this, a bibliometric analysis was carried out with the aim of identifying the number of publications in the intervals of a year and which journals they are being published in.

3.1. Bibliometric Analysis

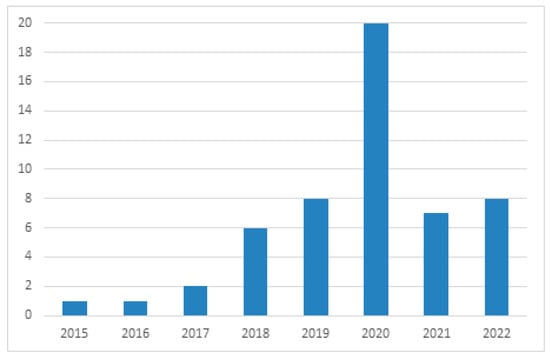

The first bibliometric analysis to be carried out in the portfolio of 53 articles is the mapping of publications in a time interval. The article portfolio is presented in the Appendix A section of Table A1. In this way, how many articles were published each year were counted, and this is shown in Figure 2 with the Number of articles presented on the Y axis and the temporal clipping presented on the X axis.

Figure 2.

Publications per Year.

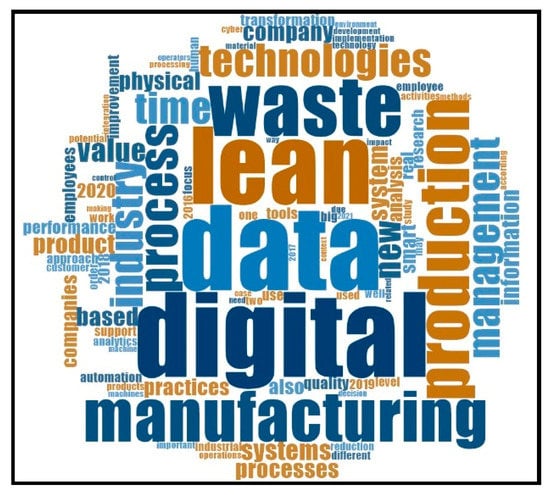

Figure 3 presents a keyword cloud generated from the 53 articles in the portfolio with the research concept and the identification of the research streams.

Figure 3.

Research concept flows.

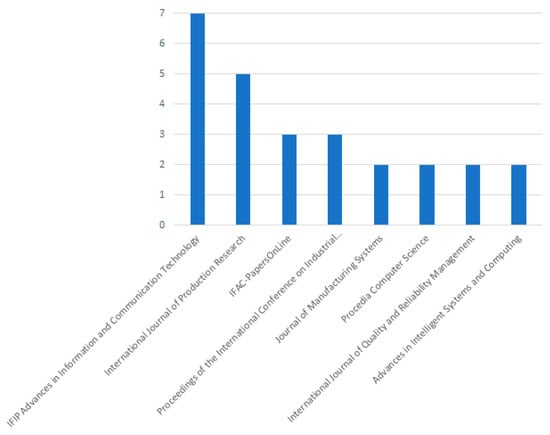

Of the 53 articles included in the portfolio, a total of 28 articles were published at conferences, and the other 25 are journal articles. The main conferences in which the topic is being published are the “IFIP Advances in Information and Communication Technology” with a total of seven publications and the “Proceedings of the International Conference on Industrial Engineering and Operations Management” with three publications. As for journals, the International Journal of Production Research stands out as the main journal with five total articles in the portfolio and an impact factor of 8568. Figure A1 in Appendix B presents the occurrence of the two or more articles in the journals identified in the portfolio.

3.2. Content Analysis and Discussion about the Sinergy between Lean Tools

In this section of the content analysis, it will be described how each Lean 4.0 tool researched and identified in the bibliographic portfolio undergoes digital transformation. Therefore, the aim of the content analysis is to detail how each Lean tool had its concept updated by digitalization, its main technologies researched, and the benefits and difficulties of implementing Lean 4.0 in organizations. The works of authors such as [36,37,38] point to several Industry 4.0 technologies such as IoT, Big Data, Cloud computing and how they interact with Lean tools. However, according to [39], not all authors agree on which are the main Industry 4.0 technologies that impact Lean. Ref. [40] reinforces that those digital technologies, when properly integrated into a Lean 4.0 environment, can improve processes of a pulled nature aiming at greater just-in-time efficiency. In order to identify the current state of Lean 4.0, it is necessary to identify, in current research, which of its principles and tools are being researched and with what intensity. Thus, from the content analysis, the occurrences of which articles cited, researched and evaluated how to carry out the interaction of Industry 4.0 technologies with Lean tools in the search for their updating to the digital environment were identified. The analysis of the most mentioned Lean 4.0 tools in the portfolio will be presented below: Lean thinking 4.0, VSM 4.0, Kanban 4.0, Visual management 4.0, ERP 4.0, Andon 4.0, Jidoka 4.0, Lean Six Sigma 4.0, Poka yoke 4.0, TPM 4.0, Kaizen 4.0 and just-in-time 4.0.

3.2.1. Lean Thinking 4.0

Lean thinking emerged as a Lean response to combating the waste of training people and employees, focusing on solving problems, implementing technologies and facilitating the flow of information in organizations [8]. As in the past, it will also be necessary to introduce Lean thinking from a digital perspective to start the transformation to Lean 4.0. If Lean thinking is not implemented in advance to support Lean 4.0 thinking, organizations will be digitizing waste in the future [41]. This philosophy serves as the basis for Industry 4.0 implementations [42] because it is from there that Lean thinking and the fight against traditional and digital waste are introduced, simultaneously. In this article, we are treating Lean thinking 4.0 as part of the research into the Lean 4.0 tools because of the identification of its capacity to upgrade and innovate the industries while avoiding digital waste and regular waste and improving workers’ empowerment.

It is pointed out that Lean thinking from a digital perspective is also important for organizations to more successfully implement their own digitalization process [9]. As more than technology, Digital Lean Thinking (DIT) provides the emergence of thinking and critical workers to the organization’s processes, developing digital skills aimed at the culture of digital innovation and digital literacy [18] and reducing waste [9]. Refs. [43,44] also reinforces that, instead of starting a process of digitization in the organization by acquiring and implementing technologies, it is more efficient to first raise awareness and train employees from the DLT in order to promote innovation initiatives, accelerate the Industry 4.0 implementation and reduce waste of time and resources digitally or otherwise. Starting from operation support and permeating the Industry 4.0 culture from the DLT that empowers workers and increases performance. Table 3 shows the characterization of DLT based on content analysis.

Table 3.

Lean thinking 4.0.

3.2.2. VSM 4.0

The VSM was introduced by Lean Manufacturing, aiming to map the points of value in the production processes in order to identify failures, bottlenecks, points of improvement and the flow of additives. Complementing the basis of Lean 4.0 implementation, VSM 4.0 is introduced as a pillar of support for Lean operations due to its ability to monitor, in real-time, the flows of values inside and outside organizations. Aligning with Kanban 4.0 (Section 3.2.3) and visual management technologies (Section 3.2.4), VSM 4.0 enables greater transparency of operations [48], correctly reporting process variables such as conditions of materials, machinery and employees [49]. It can also be accessed by employees using digital devices, such as phones and tablets, to align maintenance information and process downtimes, seeking to optimize each micro-step of the process [48]. This dynamic of VSM 4.0, enabling digital control and tracking in real-time, brings organizations closer to just in time 4.0 (Section 3.2.7) in addition to allowing them to identify points of improvement and reduce waste of information, transparency of processes and unnecessary activities [50].

VSM 4.0 is directly related to Big Data technology and cloud computing [36], as they are responsible for collecting, storing and processing the data to be processed in order to evaluate all variables and fluctuations in the process to improve performance [51]. Ref. [38] states that in addition to the digital capability of the tool, it is also possible to solve problems of worker allocation when VSM is linked to these technologies. These VSM 4.0 capabilities allow the identification of different types of information in real-time with the help of sensors and autonomous robots [36] that were not previously possible to map [49]. This real-time mapping enables integration with Stakeholders from inside and outside the organization [36], allowing remote access at any time. This tool can also be implemented for the control and monitoring of ERP 4.0 and the mapping of manufacturing flowcharts [52,53]. However, ref. [54] points out that it is necessary for the VSM 4.0 to be able to handle large amounts of data to provide accurate information at the appropriate time; however, if this tool is poorly implemented, it can cause waste in the process and lack of information. Finally, Table 4 presents the synthesis of VSM 4.0 from the nodes of the content analysis.

Table 4.

VSM 4.0.

3.2.3. Kanban 4.0

Kanban emerged from the need to have some kind of dashboard that was simple to operate in order to show all the locomotion stages that products go through. As with VSM 4.0, Kanban 4.0 can be considered the second pillar of Lean 4.0 implementation. Ref. [45] points out that the digitization of Kanban was a matter of time and that this process was already happening with the advancement of Industry 4.0 technologies. It is also used as inventory control and replenishment alert tool [13] and supports other Lean practices in the digital world [61]. The replacement of the whiteboards and cards in the traditional model by digital technology intrinsically makes the tool itself even more Lean [62]. Sharing the same characteristics of real-time process control [55], transparency [48] and stakeholder integration [36], this Lean tool when digitized helps the organization to accurately map their processes, integrating them into the digital environment. Its digitization eliminates the use of old physical cards, reducing human error and eliminating erroneous procedures and calculations about process management [63]. Not only that, but when this tool is inserted into the digital world, it also reduces the overall effort of operationalizing and interpreting the data contained in it [45].

In addition to the similarity with the properties of VSM 4.0, digital Kanban has the ability to integrate other principles of Lean 4.0 aimed at visual management such as digital Andon and Jidoka 4.0 aimed at monitoring compliance in the process [64]. Enabling the replication of activities in just in time, digital Kanban can be aligned, for example, with 3D printers to produce parts on demand [21]. Still, from the perspective of just-in-time approximation, it is possible to reduce the information transfer time from ordering, delivery and storage, aligning automatic orders between customers and suppliers [3]. While VSM 4.0 organizes the flow of the value chain in general, Kanban 4.0 assists in the search for just-in-time aimed at controlling the collaboration in more punctual parts of the processes such as inventory management and production schedule modifications [36]. Table 5 presents a summary of the digital Kanban information from the content analysis.

Table 5.

Kanban 4.0.

3.2.4. Visual Management (as a Complement to Lean 4.0 Support Tools)

It is necessary to manage processes by going beyond the use of Kanban 4.0 and VSM 4.0 tools to identify data in real-time. For this, tools such as ERP 4.0, digital Andon, Visual management 4.0 and the principle of Jidoka 4.0 are used to complement the implementation of Lean 4.0, aiming to improve the total performance of operations in real-time and machine communication [41]. These tools enable the acquisition of information in real-time and can use machine-learning technologies to process past data and operate with the prediction of future problems in the process [64].

ERP 4.0 systems were allocated along the Visual Management because of their capabilities to allow information flows in real-time [65,74]. This tool can support Kanban 4.0 to manage inventories and materials management throughout the process, allowing for quality and efficiency in deliveries [63]. Updating stocks automatically by ERP 4.0 reduces stock counting errors and informs employees in real-time of the minimum need for each station [52]. Meanwhile, the Visual Management 4.0 support model allows more flexibility to make process adjustments in real-time [48], collecting information from Industry 4.0 technologies and informing all collaborators in real-time [50]. With the help of digital twin technology, it is possible to simulate bottlenecks and operational problems and confirm the process status in advance for decision-making and evaluation of the quality of the real-time monitoring provided by Kanban 4.0 and VSM 4.0 [51]. This group is shown in Table 6.

Table 6.

Visual management and ERP 4.0.

Jidoka 4.0 assists in production flexibility [61] providing cost reduction by recognizing possible failures through CPS before they happen [64]. Ref. [21] also points out the integration with IoT in the pursuit of continuous improvement via Jidoka 4.0. Finally, digital Andon provides digital solutions to reduce the impact of process downtime on the verge of a failure, using data on machinery condition, capacity and production progress. All of this with remote access anywhere [48]. In the digital environment, Industry 4.0 technologies can help implement a more assertive control of each step of these processes [45,75]. This is shown in Table 7.

Table 7.

Digital Andon and Jidoka 4.0.

3.2.5. Lean Six Sigma 4.0

Lean six sigma (LSS) emerged as a combination of Lean thinking and the 6 sigma defect methodology to maintain process quality while operating in a Lean way. As such, the Lean Six Sigma is a Lean tool with high potential for integration with Industry 4.0 [46], given its characteristic of standardizing, adding value and providing quality products and operations. Above all, using statistical analysis to reduce the recurrence of problems and, at the same time, optimize the entire process either by data mining or machine learning [79].

This tool, when integrated with digital technologies, has the ability to integrate both with Kanban 4.0 [80] and with VSM 4.0 [81]; thus, having a prominent position in helping to control the real-time processes. While visual management focuses on helping with more information for decision-making, LSS 4.0 helps to maintain the quality of the mapping in real-time through its statistical analysis. It is also seen as the bridge that connects the quality perceived by the customer at the end of the digital process, LSS 4.0 guarantees in principle that all changes that may be requested in the middle of the production process are delivered without delays and without interfering with the process [47].

Authors, such as [52,82], point out that LSS 4.0 needs to be disseminated in Lean organizations that want to be digital, as it is responsible for maintaining quality and standardization in pulled processes, developing flexibility, enhancing workers’ training and integrating throughout the organization. Ref. [83] points out that the faster the multi-information flow is carried out, the easier it is to identify points of improvement and points of waste and, thus, intensify continuous improvement in processes that add value to the customer. Table 8 summarizes the LSS 4.0 information based on the node analysis.

Table 8.

Lean six sigma 4.0.

3.2.6. Lean 4.0 Implementation Support Tools

Poka yoke is a Lean tool that seeks to standardize and organize processes so that they are error-proof and reduce non-compliance. Poka yoke 4.0 has the ability to allow machines to continuously evaluate products during the process to track and identify any problems during the process [5]. Linked with IoT and RFID technologies, with a focus on traceability and digital systems of Cloud Computing and Augmented Reality, this Lean tool has the ability to inspect and solve problems of inconsistency in the production line, as well as allow for quick repairs and adjustments without a loss of time on the part of the employees [84]. It is also possible to control processes with simulation to analyze possible risks of non-compliance in logistics [54].

Ref. [36] also points to the use of self-guided vehicles (AGV) as an adjustment and adaptation technology for Poka yoke 4.0, since AGVs can adapt almost immediately to new changes in paths and routes in terms of internal logistics of organizations. A summary of the content analysis for Poka yoke 4.0 is presented in Table 9.

Table 9.

Poka yoke 4.0.

TPM is a Lean tool that aims to integrate the entire organization to produce maintenance plans and scheduled shutdowns, avoiding waste and unexpected failures in operations because of poor maintenance practice. The focus of TPM 4.0 is on predictive maintenance philosophies such that when linked with digital technologies, such as IoT, Big Data, Cloud, AGVs and augmented reality [36,41,80], it is possible to monitor machines and equipment more accurately than designing an entire maintenance engineering, reducing the waste of time and resources. At the beginning of Lean 4.0 research, it was already pointed out that machines would need to understand their operations and learn from failures to design digital maintenance plans with a Lean bias [13]. TPM 4.0 is one of the tools of Lean 4.0 that has the potential to be integrated with almost all digital technologies of Industry 4.0, given its nature and its innate digitalization potential [13]. In an environment of total synergy, the machines become independent and intelligent to be able to identify in the system when it will be necessary to carry out their maintenance, and in Lean 4.0 systems, it can already allocate the resources of parts and employees to carry out intelligent predictive maintenance [5,54]. To help organizations design these systems and also train employees to follow up, ref. [48] points out that virtual and augmented reality platforms can be used for training and integration or simulation of how the system will operate and what its difficulties are. However, this demands a huge amount of data that is also complex to analyze. Ref. [85] point out that through artificial intelligence it is possible for machines to learn from failures or situations that were not mapped in the cloud or in the data they had and, thus, can improve their maintenance plans. The results of the analysis of nodes for TPM 4.0 are presented in Table 10.

Table 10.

TPM 4.0.

After the basic implementation of Lean 4.0, organizations can develop Kaizen 4.0, organizing their information flows [36] and generating continuous improvement activities in pursuit of the Lean 4.0 culture. For this, a highly digitized environment is needed to provide data without waste and autonomy in the organization [76]. This reflects organizations with a higher level of maturity and, with Lean 4.0 processes, employees are consolidated in the philosophy. When this happens, employees are able to identify in the process, through simulation and augmented reality technologies, possible points of improvement and value generation for the production chain [36]. In addition, the use of Kaizen 4.0 also impacts the development of workers’ digital skills and improves the human–robot relationship [86]. Table 11 shows the coded information from the content analysis for Kaizen 4.0.

Table 11.

Kaizen 4.0.

3.2.7. Just in Time 4.0

Just in time was the principle that motivated the generation of Lean and its entire philosophy of waste reduction; just in time also undergoes digital transformation. However, it is relatively difficult to fully integrate this concept into the real world. In this article, we treat just in time 4.0 as a Lean tool because of how it can synergize with the Industry 4.0 technologies and how it can benefit this improvement, just like the other Lean 4.0 tools discussed before. Authors, such as [41,48,51,53], report its compatibility with various technologies of Industry 4.0 such as: IoT, sensors, Additive manufacturing, Real-time data control, Big Data and Cloud. Just in time 4.0 is the union of all Lean tools updated in Industry 4.0 converging to the complete reduction in physical and digital waste and linking all possible 4.0 technologies [14,20,21]. Ref. [66] points out that organizations always need to be linked to just in time 4.0 to keep their production flows always pulled and tracked in real-time without generating excessive production. Another thing that the authors point out is that digital technologies can bring theoretical just in time closer to practice by solving their real-time process control failures and, also, continuous flow interruptions [88]. Ref. [51] points out a new approach to just in time 4.0 which is to link the philosophy to machine learning technology, similar to Poka yoke 4.0, allowing more autonomy for machines to interfere and readjust the process with the supervision of man in the industry. Ref. [3] also projects just in time into the future being encompassed by Big Data solutions and machine-to-machine integration to assist in real-time control stability. Table 12 shows the encodings for just in time 4.0.

Table 12.

Just in time 4.0.

3.2.8. Digital Transformation of Lean Tools

In addition to the Lean 4.0 synergy, the content analysis pointed out some points for improvement and extensions in the use of Lean 4.0 tools. In this way, in Table 13 the synthesis of the evolution of Lean 4.0 tools was generated, showing the main points before digitization that were updated.

Table 13.

Lean tools characteristics before and after Industry 4.0.

4. Discussion

Authors in [37] point out that the evolution of Lean will closely follow Industry 4.0 being improved and the improving Industry 4.0 operations. Lean 4.0 has the ability to develop new information distribution channels and, thus, reducing the digital waste that is generated by the excess information can also be classified as the nature of the stock mapped by [12]. This is punctuated by [89] who states that a well-established Industry 4.0 guided by Lean tools and philosophies has the ability to develop quick responses to problems in post-production lines, develop innovative products and map the entire chain. In real-time, the use of sensors and real-time monitoring allows Lean 4.0 to determine the metrics for evaluating sectors in real-time operations; thus, aligning strategies and improving process decision-making [52]. For this, it is necessary for Lean 4.0 to be able to identify which digital waste each organization has and identify the main solutions. Ref. [90] mapped eight possible types of waste from the digital industry: digital visualization; precision; speed; time flexibility; space flexibility; feedback; commitment; and prevention. Thus, Lean 4.0 has as one of the solutions, to reduce and control the flow of information from the industry, destining it to be the correct receiver at the correct intensity and at the appropriate time. It is worth noting that there is also a waste arising from the storage of digital information. As Industry 4.0 is producing data all the time and it is stored in the cloud and processed by Big Data, there is a load of waste in storage that Lean 4.0 has the ability to reduce [91]. It is possible with the implementation of tools to provide Lean collection, processing and distribution by learning them. It is worth mentioning that the new technologies of Lean 4.0 also generate data and, therefore, caution and it is necessary to carry out the digital implementation of the technology without it contributing to the waste of data but instead reducing it [47].

However, Industry 4.0 has different technological levels, and it may be the case that it has more technologies than it needs or its technological capability is outdated [61]. Thus, Lean 4.0 emerges as a solution with the purpose of identifying the digital technological state of the organization and balancing it according to its needs and operations [20], reducing waste from excess technology or supplementing the lack of it.

Finally, it has identified another waste in Industry 4.0 related to worker talent; this waste is aligned with excessive training and human-machine integration disparities. Industries tend to invest less in personal training and skills development than in the implementation of digital technologies. Ref. [92] points out that for the Industry 4.0 transformation to happen properly, the engagement and contribution of the organization’s employees are necessary to visualize the process that will be digitized and implement improvements. Ref. [39] reinforces that without the development of professional skills and competencies for Industry 4.0, the organization may have problems when implementing new technologies. This transformation, when carried out and guided by Lean and Lean thinking, will result in professional engagement, development of digital skills and process improvement [9,91,93].

4.1. Intelligent Processes Aimed at Improving the Human Being

The authors in [92] pointed out that the mass involvement of people in the digitization process increases its efficiency. According to the authors, one of the ways to increase this involvement is through Lean 4.0. In this way, Lean 4.0 in the future will also have the role of empowering and enabling people to improve organizations. Ref. [13] highlights those motivated workers that naturally develop the Industry 4.0 culture rather than being forced to do so by their management. As pointed out by [67], the priority of resource allocations in Industry 4.0 has to be on workers so that they can, through new methods and deployment of innovative technologies, reduce people’s work effort while adding value and not increasing it, causing stress and reducing value in the process. Processes only focused on digital technologies tend to be less efficient than processes based on Lean and that are rethought by people [77]. In this way, workers are the center of innovation in a sustainable way [68], it is from them that comes the ability to improve processes and develop specific improvements for organizations, and it is up to them to focus on improving their skills and training them to deal with digital technologies [39,68]. To do this, it is necessary to implement the Lean thinking 4.0 tool where employees integrate and improve digital processes [68]. It is also possible to carry out training and capacity building on digital platforms to accelerate the process of integration to Industry 4.0, ref. [67] points out that this accelerates rapid learning for qualification and the requalification of employees’ skills. Another form of rapid learning is by issuing constant feedback from both the machine and people, with the purpose of seeking continuous improvement without offending or criticizing [76]. It is also up to digital leaders to know how to separate and allocate their teams for each appropriate training in order to deal with digital technologies, it is important that the leader also plans training and training in a Lean way for their workers [94]. These, if well trained and integrated into the process, have the ability to solve production line problems and improve the process in a Lean way [36]. Another positive aspect of employee empowerment by Lean 4.0 is that it facilitates the relationship of members outside the industry, such as customers and suppliers, as there is an improvement in communication channels [56]. Ref. [95] highlights how skills related to problem-solving and critical thinking can enhance the development of Lean automation. Finally, ref. [91] points out how empowerment and engagement through Lean 4.0 not only improve the production process but also reduce talent waste and reinforce the emergence of the Lean 4.0 culture in organizations.

The implementation of Lean thinking 4.0 results in the emergence of the Lean 4.0 culture through the empowerment of workers. This can be a key factor for the industry to keep improving its processes and re-structuring the aims for long-term strategies while avoiding skills waste and maintaining a sustainable workforce aiming at the Sustainable Development Goals (SDGs) [18].

4.2. Real-Time Process Monitoring

One of the trends in the evolution toward Lean 4.0 is the improvement of real-time process control. The digital technologies already help Lean tools and principles to integrate into the digital world and fast response and flexibility [61,89], but further advances in the literature are still needed. In this article, seven works were identified that addressed this theme, for example, ref. [80] points to a possibility of leveraging Lean 4.0 with a meta-heuristic algorithm and real-time control. The authors also highlight the lack of studies on the inclusion of the customer in the control of information in real-time. Ref. [37] highlights that the main nature of Lean in the digital environment has to be the flexibility to relate to different technologies. However, this can lead to overinvestments and leveraged operations costs, it is necessary to control the evolution of Lean so that it does not become a waste by itself. Ref. [96] reinforces that this flexibility of Lean systems and Industry 4.0 work as a standardized digital structure oversees both digital and real processes, receiving and processing CPS information for more assertive decision-making. Ref. [21] identifies that the structures like this have the ability to operate in a decentralized way and allow for independence of adjustment of each sector of the factory in search of the most effective capacity. Sensors, video cameras and IoT can also be used to assist in collecting information [52]. Process mapping and real-time monitoring are one of the key pieces for the implementation of Lean 4.0 because, without it, it is not possible to identify whether operations are behaving in a Lean way. Bottlenecks and production inefficiencies can be discovered and solved in a faster way to mitigate all kind ofwastes while providing compliance among stakeholders like suppliers and clients.

4.3. Lean 4.0 Information

The authors in [8] already pointed out that one of the difficulties of the digital industry is to manage the use of digital technologies in order to provide adequate information at the right time, without excess. Ref. [13] points out that organizations need to put all the data in real-time and in a simple way for their employees to visualize at hand and pass on the feedback of the operations. Ref. [97] points out that a Lean 4.0 framework that can integrate this information to connect people in real-time has the ability to make businesses more competitive. It is also necessary for the data to be intelligent and easily filtered from Big Data to a real and tangible information platform, improving decision-making processes [66]. In addition, it is also possible to improve the sustainable factors of information integration in the Lean way, generating cleaner product life cycles that have less digital data linked to them [47]. It is important to control the data in real-time since its acquisition because this way, it enhances the organization’s connectivity and integration for a Lean 4.0 development [21,66]. Controlled data in real-time can speed up the decision process while maintaining the information from Lean and providing more assertive decisions pursuing long-term strategies.

4.4. Minimal Investment in the Essential Technologies

The authors in [21] highlight that with the new digital industries and waste of information, energy and data arising from digitization. These new ways of interpreting Lean waste in the digital character can impact production and increase costs precisely because of the excessive investment in technology to perform certain functions. In the case of a lack of harmony between both, there is waste arising from digitization [65]. However, ref. [66] already points out that digital technologies reduce the waste of the physical world of the organization, but it is necessary for industries to get closer to academies and research institutions to be able to facilitate the correct implementation of Industry 4.0 technologies to avoid the waste of digital excess [81]. It is also worth noting that the implementation of Lean thinking in organizations keeps thinking aligned with Lean, avoiding digital waste [41]. With the investments guided by Lean 4.0, industries can improve their digitalization-process success ratio. Therefore, providing an overall cost reduction in the acquisition and implementation of the Industry 4.0 technologies and maintaining the continuously evolving process.

4.5. Avoiding Digital Waste

It is pointed out in [21] that the new Lean 4.0 will have to deal with new types of waste, also called the MUDA of the digital environment. The authors highlight data overload as one of the main problems for digital industries, both product data and process data. There are three types of data waste, the first is incompletely or partially distributed information, leading to interpretation problems; the second is data that is collected but does not add value to the process; and, finally, the third type highlights the data that collect information about equipment but do not contribute to improvements. Ref. [8] also identified possible points for improvement in waste arising from digital data, excess data can disrupt machine learning processes and vitiate collection mechanisms. It is necessary to align accurate information to the right person at the right time and in the right amount; otherwise, this can lead to reworking and misinformation. Ref. [88] also points out that excess data collected by traceability technologies can impact their storage and processing.

Ref. [42] highlights that it is also wasteful to allocate workers to roles that can be performed by robots. In the author’s view, these workers should be in higher positions and responsible for the strategy and decisions of the processes. Non-utilizing talents in Industry 4.0 is also a form of digital waste [71]. Ref. [67] reinforces the need to implement Lean 4.0 to also avoid waste in programs that operate digital machines, as these programs have complex structures and need to be transformed into something simpler and more accurate. Ref. [53] also points out the digital waste in the skills and competence of workers immersed in the processes. Thus, it is necessary to improve training and simplify tasks to reduce the intensity of work with digital machines. Ref. [76] points out that this instability of the information provided by Industry 4.0 devices without Lean bias causes insecurity in procedures and consequently worsens waste. This culminates in worse data generated, data reception problems, lack of sensor calibration and incomplete decisions based on lack of data. In this way, these digital wastes can culminate in worse problems for the organization and can overcome the negative impacts caused by other types of physical waste [76]. Table 14 shows the correlation between the characteristics identified by the content analysis of the digital waste with the original eight types of waste in Lean.

Table 14.

Characterization of the Digital waste in the eight original Lean wastes.

4.6. Lean 4.0 Main Trends

Finally, with the help of the content analysis, the interpretation of the results about each digitalized Lean tool and its benefits empowers workers, avoid digital waste and provide the right amount of information. This paper provides the main trends of Lean 4.0 and its main implications for both the industry and society as a whole are presented, seeking future integration of industry and digital society in Table 15.

Table 15.

Lean 4.0 main trends.

The three trends mapped are not isolated from Lean, they are necessary for integration between them, mainly as digital waste implies worse conditions for industries aiming to be digital and this generates a reduction in the accuracy and performance of the processes in real-time. In this way, these and their modifications are able to implement new research changes that can still be studied more comprehensively. One concern is how the Lean 4.0 culture is generated and established and which organizational forums this can cause. From new training methodologies, short courses and even changes in teaching courses and faculties to qualify new thinking workers in digital literature with their own solver in these areas. If this allows security in new production processes and in the organization itself, which strengthens itself in the market and seeks innovations as digital technology does not enter the market. However, it is necessary to be aware of the waste of digital technology so as not to activate how new technologies and how exchanges of outdated equipment do not cause environmental and greater energy impacts; therefore, it is also necessary to develop models of recycling or reuse in a circular economy of electronics. that may end up being generated.

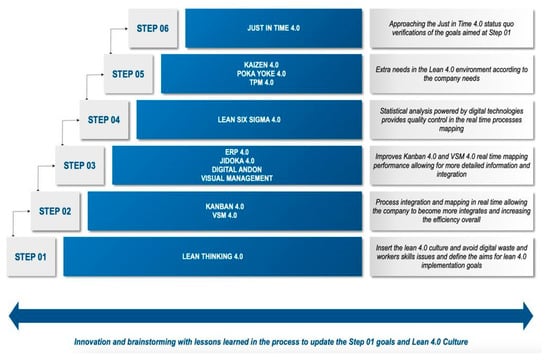

4.7. The Framework D-LEaMIN (Digital Lean Manufacturing Implementation) for Lean 4.0 Synthesis and Implementation

With the mapping of each advantage and disadvantage of the Lean 4.0 tools and after analyzing all the main trends of Lean 4.0, one can see the link between how to integrate processes that strengthen the human being with the introduction of Lean thinking 4.0 and real-time process mapping with Kanban 4.0 and VSM 4.0 tools, complemented by other visual management tools. All of this converges with the other Lean tools analyzed in this article to avoid waste. The waste in the digital environment, so-called digital waste, arises as a consequence of problems in the implementation and use of industry 4.0 technologies. Therefore, with the categorization of all Lean 4.0 tools identified in this research in Section 4 and the main trends of Lean 4.0 in the industries within the section. This framework aims to provide 6 steps of implementation of the Lean 4.0 tools in industries providing a description of each step and its main featured tools and the justification of why each tool is presented in the proper step.

Step 1: Identification of the main objective of the Lean 4.0 implementation is to achieve the just-in-time 4.0 model, reducing overall waste and adding value to the maximum efficiency in all the organization’s processes.

To achieve this goal, it will be important to start implementing Lean 4.0, it is necessary to introduce Lean thinking 4.0 into organizations so that there is preparation for digital transformation from Lean thinking. If they already have some level of digitization, Digital Lean Thinking is used to assess their readiness to do so according to the level of their Lean 4.0 culture and introduction of Lean 4.0 tools. Lean thinking serves as the basis for the next Lean 4.0 tools to act without generating waste and start the process of mapping digital processes; thus, being identified as the first step of implementation.

Step 2: Implementation and consolidation of the two main pillars that support Lean 4.0 operations Kanban 4.0 and VSM 4.0. Both share the same nature of mapping processes in real-time and allow organizations to digitally integrate into the pursuit of just in time. They are distinguished by the synergy with the other Lean 4.0 tools, proving to be fundamental for implementation before the others.

Step 3: Complement and reinforce Kanban 4.0 and VSM 4.0 operations. To complement the main tools of digital mapping, its necessary to implement support tools aimed at Visual Management in Lean 4.0. For that, this step features Andon 4.0, Jidoka 4.0, ERP 4.0 and Visual Management 4.0 that have the ability to deepen the details of Kanban 4.0 and VSM 4.0 mappings, allowing fault control, better information flows and real-time complementary information for the entire organization.

Step 4: Implementation of Lean six sigma 4.0. This step is responsible for supporting real-time mapping, which aims to be the bridge between Kanban 4.0 and VSM 4.0 operations while maintaining statistic and quality control and information standardization. Thus, it is possible to complement the core of digital mapping with details in visual management and quality.

Step 5: Complementing industrial activities that take place after a real-time Lean 4.0 quality mapping. This step introduces the importance of implementing the Lean 4.0 tools: Poka yoke 4.0, Kaizen 4.0 and TPM 4.0 as complementary tools that function at best in an advanced stage in Lean 4.0 to avoid problems of use and operationalization. These tools stand out for being the driving force for the continuous improvement of Lean 4.0 processes, but they need a previous consolidation of the other tools so that they can extract their full capacity and not generate waste.

Step 6: Reaching the last level of Lean 4.0 implementation. To achieve the maximum possible efficiency that the organization needs from just in time 4.0, keeping processes operating with minimal waste and investment and in a Lean way. This allows for the empowered workers to use the lessons learned in a brainstorming meeting during the end of the implementation process to improve the Step 1 goals. With this, it is possible to carry out innovation and improvement procedures in the organization to update the goals and improve its Lean 4.0 culture little by little so that Lean 4.0 integration becomes a continuous improvement allowing to provide new goals to upgrade the operations.

Figure 4 presents a scheme of the proposed theoretical framework for Lean 4.0 implementation.

Figure 4.

The framework D-LEaMIN.

With this framework, it is possible to understand how Lean 4.0 can act in organizations to carry out an Industry 4.0 digitization process linked to Lean, avoiding waste and increasing their chances of success. The great basis is Lean thinking aimed at strengthening employees. This already provides another line of thinking against the paradigm that Industry 4.0 will end people’s jobs. Just as it was in the third industrial revolution, with automation, jobs were modified and changed, and some even went extinct; these job changes via technology followed the evolution of the human being until today and will continue with the Industry 4.0 evolution [7]. The job can change, but the world will always need people to work in it, which is where Lean 4.0 comes in as an alternative to align technology and people because without them there are no creativity and innovation environments. Impacts of Lean 4.0 implementation through digital Lean thinking and its competencies reflect that it will be necessary to train and update the mental model of entrepreneurs and employees so that in addition to digital workers, conscious and sustainable digital citizens are also formed for a new model of an intelligent society.

5. Conclusions

Even with the advent of the fourth industrial revolution, the philosophy of Lean manufacturing is still present as a solution to solve the problems of organizations related to generating all kinds of waste. However, now with the introduction of digital technologies such as Big Data, IoT and Cloud computing, in the Lean tools, the new Lean 4.0 also manages to intervene in digitization processes, showing a new perspective and increasing success ratios on Industry 4.0 implementation.

Thus, this article carried out a literature review aided by bibliometrics and content analysis to answer research questions about the characterization of Lean 4.0 tools, their benefits and their main barriers; the classification of changes in the digitization of Lean 4.0 tools shows the before and after of Industry 4.0 technologies; and pointing out the main Lean 4.0 implementation trends, their challenges and impacts for the future. With these questions, this article aimed to answer how the new digital Lean tools work with each other, their benefits in relation to the older version of each tool, how to implement Lean 4.0 supported by the creation of the D-LEaMIN framework and how the main trends will impact industries in the future.

The new proposed D-LEaMIN framework provides a want for Lean 4.0 implementation following a logical 6 defined steps highlighting which tools need to be integrated into the organization with higher priorities. Following the gap provided by the Lean 4.0 implementation framework, this article also provides the identification of Lean 4.0 trends for the future and their possible impacts such as new training models to proposals for restructuring curricula aiming to prepare the Lean 4.0 workers and making more sustainable professionals that can impact new perspectives of society is highlighted.

Academic contributions of this article: This article points out a theoretical framework for Lean 4.0 implementation to prepare for the digitization process, highlighting the role of each Lean 4.0 tool, which is impacted and the order for it to be integrated. The framework also has the potential to serve as a guide for integration between Lean 4.0 tools, showing a new perspective of integration, and allowing for new research and practical studies of how this works in real cases. One of the contributions of this article is the classification of types of digital waste found in the content analysis in each of the eight Lean wastes created by [12]. Finally, the last academic contribution of this article is the research proposals based in Table 15 on the future of Lean 4.0. This will impact new research involving Lean 4.0 integration in the social aspect of sustainability, research into digital waste that still needs contributions to its state of the art and practical research to deliver information in real-time.

From an economic point of view, this article contributes by showing that the existence of digital waste can impact organizations that are digitizing themselves without any support from Lean 4.0 and that this can cause excessive spending on training, maintenance and equipment. It also points out that Lean 4.0 helps small and medium-sized companies to dose their digitization intensity and outline digitization projects aimed at the long term, as Lean 4.0 has the ability to allow a controlled Lean 4.0 digitization to deliver the expected results.

Finally, from a social and environmental point of view, this article points out the problem of digital waste and that it needs to be controlled because of energy expenditures and uncontrolled investments in Industry 4.0 technologies. It is also worth noting that the identification of the strength of the employee for Lean 4.0 transformations is through Digital Lean Thinking. Workers with no waste of talent integrated into their work with Industry 4.0 machines was one of the identifications for the first step towards Lean 4.0 implementation. As in the past, without thinking people there is no Lean, and without Lean, there is no waste control, whether digital or not. This has the potential to impact the transition from the fourth industrial revolution to a new bias of Industry 5.0 or Society 5.0, in which, in addition to machines, employees are also a fundamental part of the industrial process, and Lean 4.0 converges along this same line of thought. Thus, there is a need for further research to understand what impacts Lean 4.0 has on the new way of thinking about Society 5.0 and if they can go together and what their intersection points are.

The limitation of this article is also highlighted; first, the content analysis was focused on how to carry out the Lean 4.0 synthesis from research that already addressed Lean tools and their integration with digital technologies, whether theoretical or practical. Thus, some articles on other parts of the Lean 4.0 theme such as automation, and theoretical studies that did not involve the tools ended up outside the portfolio. Thus, this article is limited to contributing to the Lean 4.0 state of the art only from the perspective of the tools and not from the perspective of who comes before or after and what are the impacts of Lean on 4.0 and vice versa. The second limitation is that this article starts with the concept that Lean 4.0 is already a topic in evolution in the literature and its main results aim to contribute to filling the gap of how Lean works in synthesis with Industry 4.0 highlighting 10 Lean 4.0 tools with the purpose of solving the problems of digital waste. The third limitation of this article is that the conception of the theoretical D-LEAMIN framework in which it starts from the assumption that organizations need to digitize themselves and for that, they will seek Lean 4.0 as a means to do so. This theoretical framework has not been tested in a case study and it cannot be said that without its organizations will not be digitized. It does, however, show another path based on Lean 4.0 and, depending on the organization’s needs, this can be more attractive. This article is also limited to the study of the synergy of the 10 Lean tools found in the portfolio in the content analysis and its impacts on pointing out the new trends for Lean 4.0 and trying to solve the digital waste problem.

Finally, this article emphasizes that research contributions are still needed to address the relationship between digital waste and understand more about how it can be researched and whether there are still more categories to classify and identify on this topic. The suggestion that digital waste could be the eleventh waste of Lean created by Industry 4.0 after the Politics and Energy wastes [78] or just a repetition of the same 8 initial wastes of Lean is theorized by [12]. Another suggestion for future work is to identify the impacts of Lean 4.0 on workers’ skills and how this implies a digital way of life outside the industry. Aiming to answer if it is possible to provide a fast and efficient Lean 4.0 literacy and training for quick gains in waste reduction. Another research topic that can be provided by this article is to ask what are the impacts of Lean 4.0 in the future Society 5.0 theme that is growing up in recent years and how can Lean 4.0 impact factors outside the industries and help society become Leaner overall. If it will be possible that this new way of life outside of work has the ability to impact citizens of the future to keep up with the digital evolution of cities while maintaining a Lean and sustainable lifestyle.

Author Contributions

Conceptualization: A.H.G.R., G.B.M., J.P., P.L., E.M., L.M.M.D.R. and R.T.Y.; Methodology: A.H.G.R., J.P., P.L. and F.T.T.; Formal Analysis: A.H.G.R., G.B.M., J.P., P.L. and F.T.T.; Funding acquisition: P.L.; Validation: A.H.G.R., J.P., P.L. and F.T.T.; Visualization: A.H.G.R., G.B.M., J.P., P.L. and F.T.T.; Supervision: J.P. and P.L.; Writing—original draft: A.H.G.R. and J.P.; Writing—review: A.H.G.R., J.P., P.L., E.M., L.M.M.D.R. and R.T.Y.; Editing: A.H.G.R. All authors have read and agreed to the published version of the manuscript.

Funding

This research has been supported by FCT—Fundação para a Ciência e Tecnologia within the Project Scope UIDB/05757/2020. The realization of this work was possible due to the scientific initiation grant provided by UTFPR, to which we are immensely grateful.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

Appendix A

Table A1.

Articles in the Portfolio.

Table A1.

Articles in the Portfolio.

| Article Number | Article Citation | Title | Type |

|---|---|---|---|

| 01 | [3] | The synergic relationship between industry 4.0 and lean management: Best practices from the literature | Review Article |

| 02 | [5] | Leveraging industrie 4.0 to extend Lean Manufacturing gains | Conference Article |

| 03 | [8] | Lean thinking in the digital Era | Conference Article |

| 04 | [9] | Industry 4.0 triggered by Lean Thinking: insights from a systematic literature review | Review Article |

| 05 | [14] | Lean Automation enabled by Industry 4.0 Technologies | Conference Article |

| 06 | [18] | Contributions of Lean Thinking Principles to Foster Industry 4.0 and Sustainable Development Goals | Conference Article |

| 07 | [20] | One-to-one relationships between Industry 4.0 technologies and Lean Production techniques: a multiple case study. | Research Article |

| 08 | [22] | Digital Muda—The new form of waste by Industry 4.0. | Research Article |

| 09 | [36] | Lean 4.0: A New Holistic Approach for the Integration of Lean Manufacturing Tools and Digital Technologies | Review Article |

| 10 | [37] | Assessing the synergies between lean manufacturing and Industry 4.0 | Review Article |

| 11 | [38] | Towards ‘Lean Industry 4.0’—Current trends and future perspectives. | Review Article |

| 12 | [41] | Lean and Digitalization— Contradictions or Complements? | Conference Article |

| 13 | [42] | Lean Thinking contributions for Industry 4.0: a Systematic Literature Review | Conference Article |

| 14 | [43] | Five Management Pillars for Digital Transformation Integrating the Lean Thinking Philosophy | Conference Article |

| 15 | [48] | Lean 4.0—A conceptual conjunction of lean management and Industry 4.0 | Conference Article |

| 16 | [49] | Industry 4.0: Development of a multi-agent system for dynamic value stream mapping in SMEs | Research Article |

| 17 | [50] | Impacts of Industry 4.0 technologies on Lean principles | Research Article |

| 18 | [51] | Industry 4.0 Application in Lean Manufacturing—A Systematic Review | Conference Article |

| 19 | [52] | Towards Digital Lean Manufacturing: A Brazilian Case | Research Article |

| 20 | [53] | Lean Industry 4.0—Wastes Versus Technology Framework | Research Article |

| 21 | [45] | Investigating the Challenges and Opportunities for Production Planning and Control in Digital Lean Manufacturing | Research Article |

| 22 | [61] | The link between Industry 4.0 and lean manufacturing: mapping current research and establishing a research agenda | Review Article |

| 23 | [62] | Lean and Industry 4.0 Strive to Create Smart Factory Through Integration of Systems: An Exploratory Review | Conference Article |

| 24 | [55] | Industry 4.0 impact on Lean Manufacturing: Literature. Review | Conference Article |

| 25 | [63] | Corporate survival in Industry 4.0 era: the enabling role of lean-digitized manufacturing | Research Article |

| 26 | [64] | A Literature Review on the Evolution of Lean Manufacturing | Review Article |

| 27 | [74] | Impacts of Industry 4.0 technologies on Lean management tools: A bibliometric analysis | Review Article |

| 28 | [75] | Convergence and contradiction between lean and industry 4.0 for inventive design of smart production systems | Conference Article |

| 29 | [46] | Simulation-based lean six sigma for Industry 4.0: an action research in the process industry | Research Article |

| 30 | [79] | Data perspective of lean six sigma in industry 4.0 era: A guide to improve quality | Conference Article |

| 31 | [81] | Lean Six Sigma and Industry 4.0 integration for Operational Excellence: evidence from Italian manufacturing companies | Research Article |

| 32 | [47] | Integrated Sustainable Production Value Measurement Model Based on Lean and Six Sigma in Industry 4.0 Context | Research Article |

| 33 | [82] | Design of cyber physical system architecture for industry 4.0 through lean six sigma: conceptual foundations and research issues | Research Article |

| 34 | [83] | New Paradigm of Lean Six Sigma in the 4th Industrial Revolution Era | Research Article |

| 35 | [84] | Improving data consistency in industry 4.0: an application of digital lean to the maintenance record process | Conference Article |

| 36 | [85] | Empowering Process and Control in Lean 4.0 with Artificial Intelligence | Conference Article |

| 37 | [76] | Digital lean cyber-physical production systems: The emergence of digital lean manufacturing and the significance of digital waste. Advances in Production Management Systems | Conference Article |

| 38 | [86] | Cyber-Physical Waste Identification and Elimination Strategies in the Digital Lean Manufacturing World | Conference Article |

| 39 | [66] | Towards digital lean cyber-physical production systems: Industry 4.0 technologies as enablers of leaner production | Conference Article |

| 40 | [93] | The significance of employee behaviors and soft management practices to avoid digital waste during a digital transformation | Research Article |

| 41 | [68] | Advancing zero defect manufacturing: A state-of-the-art perspective and future research directions | Research Article |

| 42 | [56] | Stories Told by Publications about the Relationship between Industry 4.0 and Lean: Systematic Literature Review and Future Research Agenda | Review Article |

| 43 | [96] | Kaizen 4.0 Towards an Integrated Framework for the Lean-Industry 4.0 Transformation | Conference Article |

| 44 | [57] | Extending the lean value stream mapping to the context of Industry 4.0: An agent-based technology approach | Research Article |

| 45 | [58] | Integration of Lean practices and Industry 4.0 technologies: smart manufacturing for next-generation enterprises | Research Article |

| 46 | [59] | Contact points between Lean Six Sigma and Industry 4.0: a systematic review and conceptual framework | Review Article |

| 47 | [60] | Supporting the lean journey with simulation and optimization in the context of Industry 4.0 | Conference Article |

| 48 | [69] | Lean and industry 4.0: A leading harmony | Conference Article |

| 49 | [70] | Competence Requirements in Manufacturing Companies in the Context of Lean 4.0 | Conference Article |

| 50 | [71] | Industry 4.0 concepts and lean manufacturing implementation for optimizing a company logistics flows | Conference Article |

| 51 | [72] | Integration of Visual Management in the Industry 4.0: Case Study | Conference Article |

| 52 | [73] | Towards a lean automation interface for workstations | Research Article |

| 53 | [87] | Rethinking jidoka systems under automation & learning perspectives in the digital lean manufacturing world | Conference Article |

Appendix B

Figure A1.

Journals occurrences.

References

- Liao, Y.; Deschamps, F.; Loures, E.F.R.; Ramos, L.F.P. Past, present and future of Industry 4.0—A systematic review of the literature and proposed research agenda. Int. J. Prod. Res. 2017, 55, 3609–3629. [Google Scholar] [CrossRef]

- Hofmann, E.; Rüsch, M. Industry 4.0 and the current status as well as future prospects on logistics. Comput. Ind. 2017, 89, 23–34. [Google Scholar] [CrossRef]

- Santos, B.P.; Enrique, D.V.; Maciel, V.B.P.; Lima, T.M.; Charrua-Santos, F.; Walczak, R. The synergic relationship between industry 4.0 and lean management: Best practices from the literature. Manag. Prod. Eng. Rev. 2021, 12, 94–107. [Google Scholar] [CrossRef]

- Schmitz, C.; Tschiesner, A.; Jansen, C.; Hallerstede, S.; Garms, F. Industry 4.0: Capturing Value at Scale in Discrete Manufacturing. In Technical Report. McKinsey & Company. 2019. Available online: https://www.mckinsey.com/industries/advanced-electronics/our-insights/capturing-value-at-scale-in-discrete-manufacturing-with-industry-4-0 (accessed on 2 August 2022).

- Garner, W.; Bateman, R.J.; Steve, M. Leveraging industrie 4.0 to extend Lean Manufacturing gains. In Proceedings of the In-ternational Conference on Industrial Engineering and Operations Management, Rabat, Morocco, 11–13 April 2017. [Google Scholar]

- McKinsey & Company. In Disruptive Times, the Power Comes from People: An Interview with Eric Schmidt. McKinsey Quarterly March. 2020. Available online: https://www.mckinsey.com/capabilities/mckinsey-digital/our-insights/in-disruptive-times-the-power-comes-from-people-an-interview-with-eric-schmidt (accessed on 2 August 2022).