1. Introduction

In China, infrastructure has been regarded as a key factor in national economic development, and this has led to a lot of ecological destruction, such as slope failures [

1,

2,

3,

4]. Therefore, many studies have been conducted on slope protection [

5,

6]. Concrete is one of the most widely used construction materials for slopes due to its high mechanical properties and nontoxicity [

7,

8]. However, traditional concrete used in the construction of slopes presents some problems, such as soil loss, because of its imperviousness [

9].

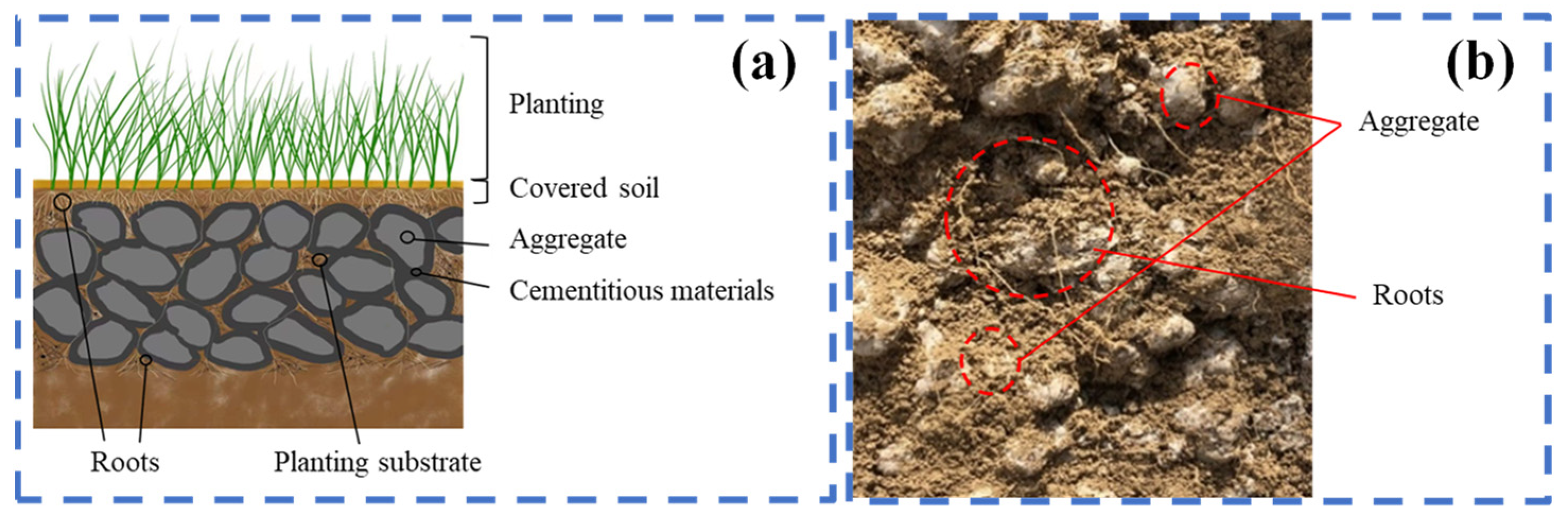

To solve these issues, PC was developed as a sustainable construction material [

10,

11] which provides excellent water permeability and relatively lower weight, as shown in

Figure 1. However, its high alkalinity, which is caused by the hydration contained in Portland cement [

12,

13,

14], has limited its extensive application. Calvo et al. [

15] used silica fumes and fly ash to reduce the pH values of cementitious material, finding that the pH values can be reduced to 12. Kong et al. [

16] used waste oyster shells as inert filler to fabricate porous concrete, discovering that the pH values could thereby be reduced to 8.52.

Recently, the methods of alkalinity reduction mainly include the modification of the planting substrate [

17], carbonization [

18], and chemical treatment [

19]. There are some further studies concerning the alkalinity reduction methods needed to obtain the required properties of PC. For instance, Li et al. [

20] generated low-alkali PC by adding fertilizer, and they found that the pore fluid alkalinity of the PC was about 8.2 and provided an excellent environment for plant growth. Li et al. [

21] used fly ash and slag to prepare PC through accelerating carbonization and natural carbonization, respectively, and they found that the lowest pH values reached 8.57, and that there was less compressive strength loss. Wang et al. [

22] used recycled aggregate and ultrafine slag to prepare PC through the solution spraying and soaking of ferrous sulfate, and they found that the pH values could be reduced significantly.

In this study, an orthogonal experimental design was used to optimize the mix design of the concrete, with the aim of reducing alkalinity and improving plant growth properties. The three factors included were PR, W/B, and FA addition level. Additionally, the compressive strength, interconnected porosity, and pH values were analyzed. Subsequently, a planting substrate method, a solution-soaking method, and a spraying method were used to reduce alkalinity. Finally, the plant growth properties were tested both indoors and outdoors. Stem length was used to evaluate the plant growth properties for different plants, which were grown in both NS and CW.

3. Results and Discussions

3.1. Range Analysis

The orthogonal experimental design was used to obtain the optimal mix design for PC. The compressive strength, interconnected porosity, and 28 d pH values were tested, as shown in

Table 6. Additionally, the results of the range analysis are shown in

Table 7,

Table 8 and

Table 9. The results of the single factor analysis are shown in

Figure 6.

3.1.1. Compressive Strength

The important order of factor for compressive strength is PR > FA > W/B, and the significance levels are 1/4, 0.26, and 0%, respectively. As the PR decreases from 1/4 to 1/7, both the 7 d and 28 d compressive strength decrease. The reason for this is that the lower PR exceeds the optimal thickness of the paste for the aggregate, which leads to less porosity [

27]. In addition, as the content of the FA increases from 0% to 30%, both the 7 d and 28 d compressive strength decrease. The reason for this is that the FA, as a pozzolanic material, shows slow rates of strength development [

28]. As the W/B increases from 0.26 to 0.35, both the 7 d and 28 d compressive strength increase.

3.1.2. Interconnected Porosity

The important order of factor for interconnected porosity is PR> W/B > FA, and the significance levels are 1/7, 0.26, and 30%, respectively. As the PR decreases from 1/4 to 1/7, the interconnected porosity increases. The reason for this is that clogging between adjacent aggregate is eliminated when the content of aggregate increases and the content of cement paste decreases [

29]. In addition, as the W/B increases from 0.26 to 0.35, the interconnected porosity decreases. The reason for this is that the lower water content results in a higher consistency of fresh cement paste, which easily wraps around the aggregate and strengthens the stress regions. As the content of FA increases from 0% to 30%, the interconnected porosity increases. The reason for this is that the FA addition level can increase the workability of fresh cement paste, which then easily wraps around aggregate [

30].

3.1.3. Alkalinity

The important order of factor for alkalinity is PR > FA > W/B, and the significance levels are 1/4, 0.35, and 0%, respectively. As the PR decreases from 1/4 to 1/7, the 28 d pH values decrease. The reason for this is that the content of cement is reduced. The pH values of concrete are mainly determined by the hydration of the cement. In addition, as FA addition level increases from 0% to 30%, the 28 d pH values decrease. The reason for this is that the use of FA reduces the content of cement. As W/B increases from 0.26 to 0.35, the 28 d pH values first increase and then decrease. The reason for this is that the low W/B lacks sufficient water to hydrate, but then hydration is promoted by soaking in the distilled water, which releases more OH−.

In summary, we consider the PR the most important factor to affecting the relevant properties, including the compressive strength, interconnected porosity, and alkalinity. According to the results of the range analysis and related requirements of the Chinese industrial standard JC/T 2557-2020 [

25], the optimal PR, W/B, and FA are 1/5, 0.29, and 10%, respectively.

3.2. Alkali Reduction Treatments

The three alkali reduction treatments, including the planting substrate method, the solution-soaking method, and the spraying method, were used to reduce the alkalinity of the PC. The effects of the alkali reduction treatments were evaluated using the changed pH values and compressive strength.

3.2.1. Planting Substrate Method

Unlike concrete, the planting substance directly touches the plant roots. Therefore, low pH values of planting substances are essential for plant growth. The changed pH values and the range analysis are shown in

Figure 7a. As the concentration of ferrous sulfate increased from 0.2% to 0.6%, the range decreased by 5–12%. Additionally, as the concentration of potassium dihydrogen phosphate increased from 0.2% to 0.6%, the range decreased by 3–9%. Therefore, based on the range analysis, both ferrous sulfate and potassium dihydrogen phosphate at concentrations of 0.4% are effective treatments. Subsequently, the compressive strength was tested, as shown in

Figure 7b. Compared with the control group, the compressive strength of the specimens which were treated using ferrous sulfate and potassium dihydrogen phosphate at concentration of 0.4% decreased by 5% and 6%, respectively. Therefore, ferrous sulfate at a concentration of 0.4% produces lower alkalinity and compressive strength loss.

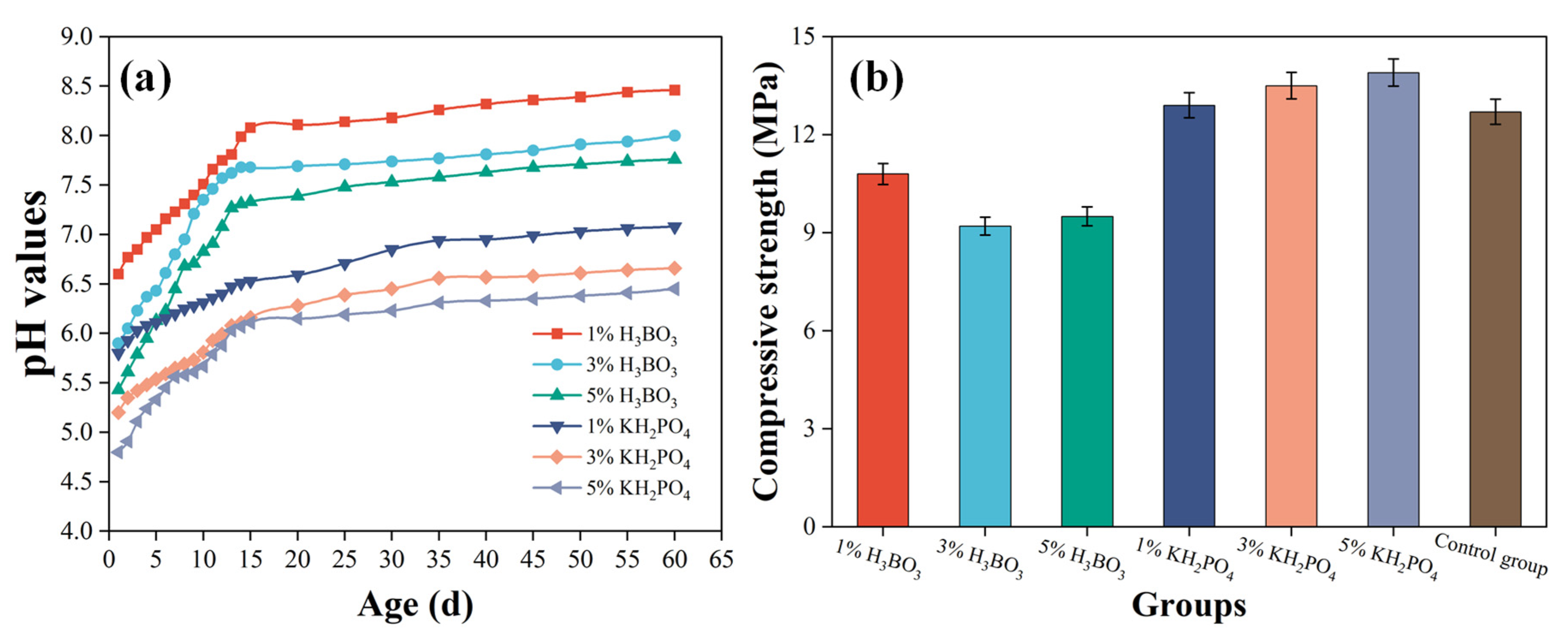

3.2.2. Solution-Soaking Method

The solution-soaking method aims to directly reduce the alkalinity of the PC. The changed pH values are shown in

Figure 8a. As the concentration of boric acid increased from 1% to 5%, the pH values changed by 0.28, 0.36, and 0.43. Additionally, as the concentration of potassium dihydrogen phosphate increased from 1% to 5%, the pH values changed by 0.22, 0.28, and 0.34. The reason for this is that boric acid reacts with calcium hydroxide, as shown in reactions (1) and (2). Therefore, the alkalinity of the hardened cement paste is reduced, and the morphology of the C-S-H gel changes, as shown in

Figure 9. Additionally, the compressive strength of each group is shown in

Figure 8b. The compressive strength loss produced by the use of boric acid is bigger than that produced using potassium dihydrogen phosphate. It is worth noting that as the concentration of potassium dihydrogen phosphate increased from 1% to 5%, the compressive strength increased from 2% to 9%. The reason for this is that the porous spaces of the hardened cement paste was filled with calcium phosphate, which is insoluble in water. In conclusion, we consider potassium dihydrogen phosphate at a concentration of 3% to be optimum.

3.2.3. Spraying Method

Spraying is the normal method due to the easiness of the operation. The changed pH values are shown in

Figure 10a. As the concentration of ferrous sulfate increased from 10% to 20%, the pH values changed by 0.62, 0.96, and 0.99. The reason for this is that ferrous sulfate reacts with calcium hydroxide, as shown in reactions (3)–(5). Ferric oxide deposits on the surface of the PC, which may prevent the OH

- from releasing. additionally, as the concentration of ferrous sulfate increased from 10% to 20%, the compressive strength decreased from 5% to 12%, as shown in

Figure 10b. The reason for this is that ferrous sulfate stays for a long time on the surface, resulting in an excess state. Therefore, the reaction always trends to consume calcium hydroxide, which leads to obvious compressive strength loss.

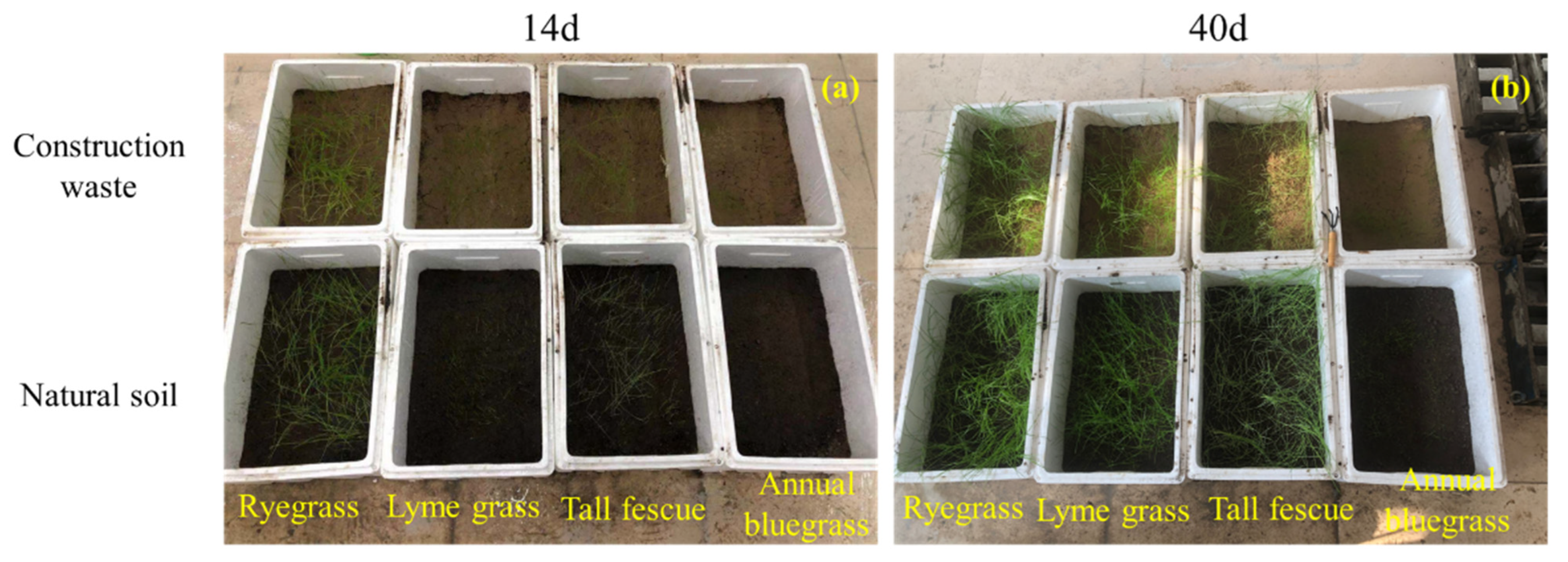

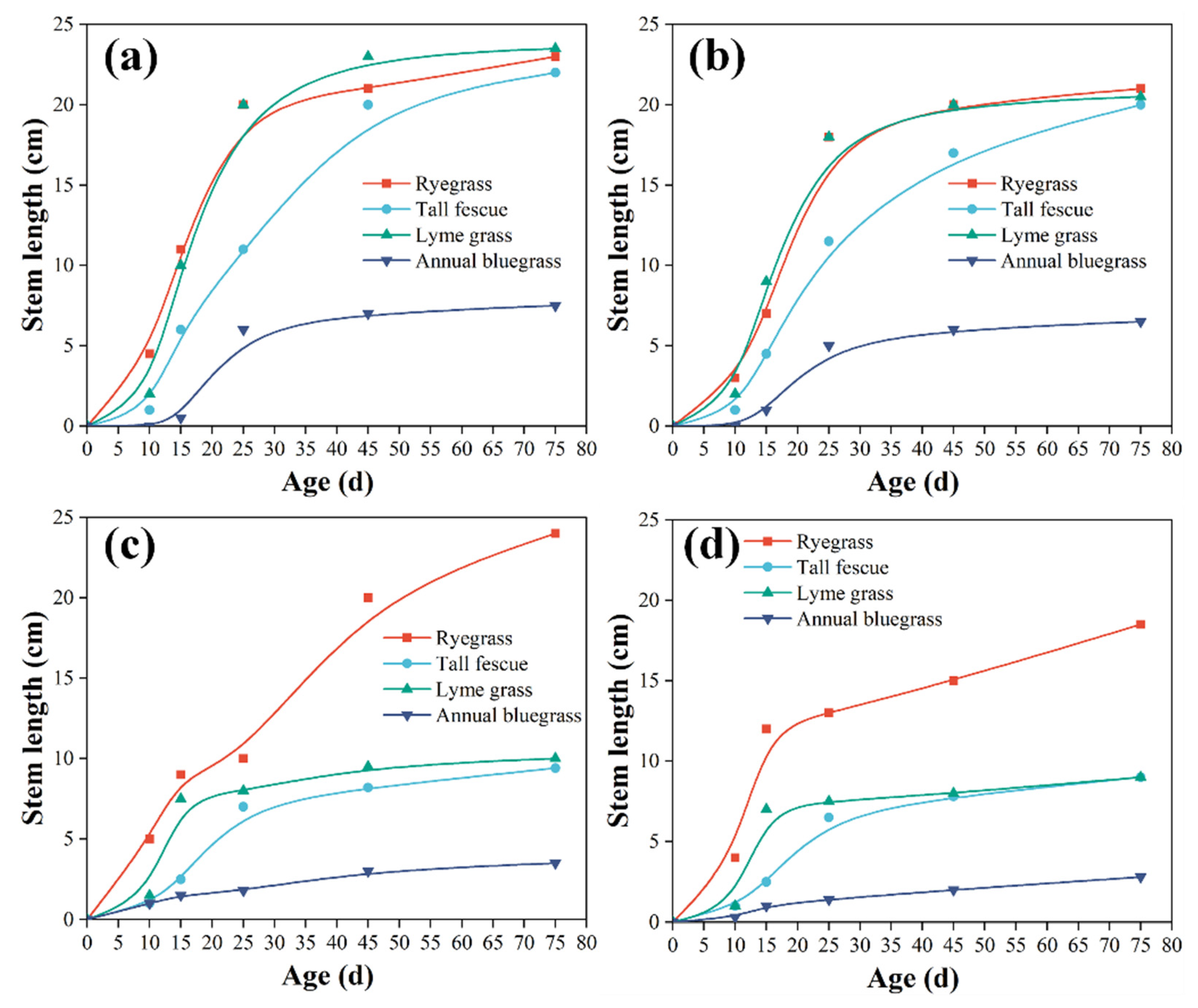

3.3. Plant Growth Properties

Based on the discussion above, both the planting substance method and solution-soaking method were used to reduce the alkalinity of the PC. Macrographs of the planting are shown in

Figure 11 and

Figure 12, and the changed stem length with age is shown in

Figure 13. The germination order is as follows: outdoors: ryegrass, lyme grass, tall fescue, annual bluegrass; indoors: ryegrass, tall fescue, lyme grass, annual bluegrass. Each of these were grown in both NS and CW. The stem lengths outdoors were shorter than those indoors. The reason for this is that the indoor temperature was higher than the outdoor temperature [

31]. The ryegrass, lyme grass, and tall fescue presented good germination rates and stem length, but the annual bluegrass showed poor plant growth properties no matter whether it was grown indoors or outdoors.

Compared with the annual bluegrass covered with NS, the stem length of the annual bluegrass covered with CW decreased by 13% (indoors) and 20% (outdoors). Both the ryegrass covered with NS and that covered with CW grew in a healthy state in the early stage. However, the leaning phenomenon occurred in the outdoor specimens covered with CW in the late stage. The reason for this is that the essential nutrients of the CW are lower than those of the NS. Compared with the ryegrass covered with NS, the stem length of the ryegrass covered with CW decreased by 9% (indoors) and 23% (outdoors). The leaves of the tall fescue were shiny, upright, and vigorous, providing excellent attractiveness. Compared with the tall fescue covered with NS, the stem length of the tall fescue covered with CW decreased by 9% (indoors) and 4% (outdoors). It is worth noting that the stem length of the tall fescue covered with CW grows close to that of the tall fescue covered with NS. Therefore, tall fescue may have potential applications in combination with CW. Compared with the lyme grass covered with NS, the stem length of the lyme grass covered with CW decreased by 13% (indoors) and 10% (outdoors). The low temperature resistance of lyme grass is poor, and its leaves are soft and weak, resulting in less attractiveness than ryegrass and tall fescue.