Fiber Reinforced Concrete with Natural Plant Fibers—Investigations on the Application of Bamboo Fibers in Ultra-High Performance Concrete

Abstract

1. Introduction

2. State of Research

2.1. Plant Fibers

2.2. Plant Fiber Reinforced Cement Based Composites

2.3. Ultra-High Performance Fiber-Reinforced Concrete

2.4. Summary and Conclusions of the State of Research

3. Experimental Investigations

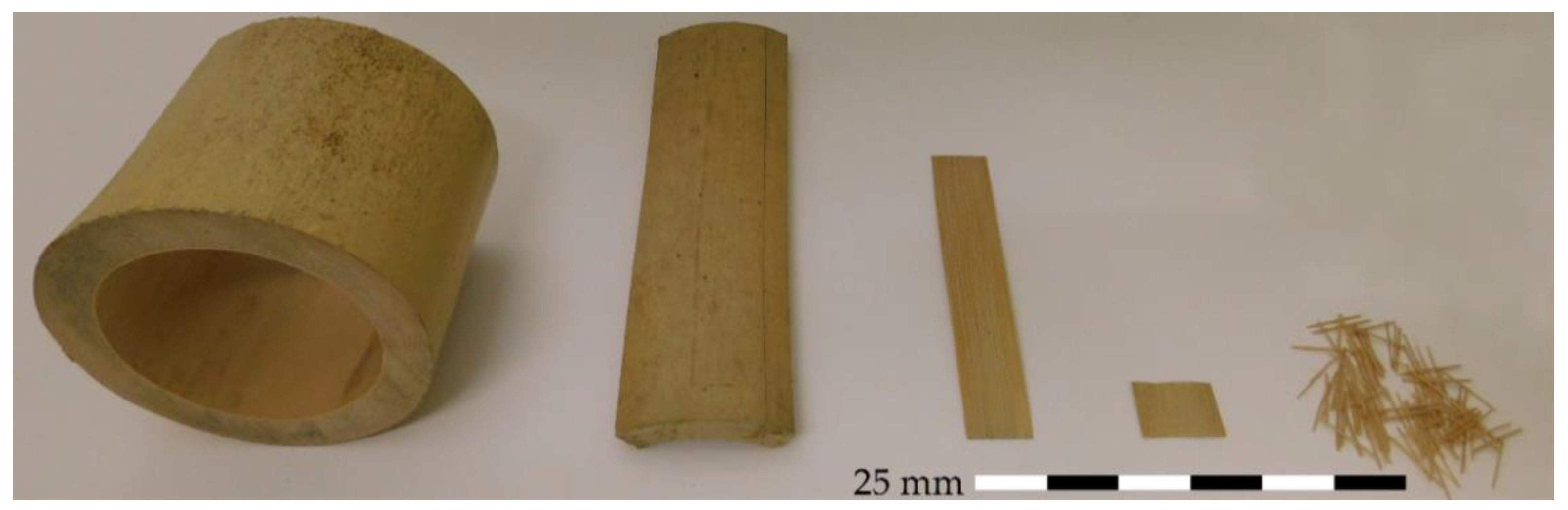

3.1. Test Specimen

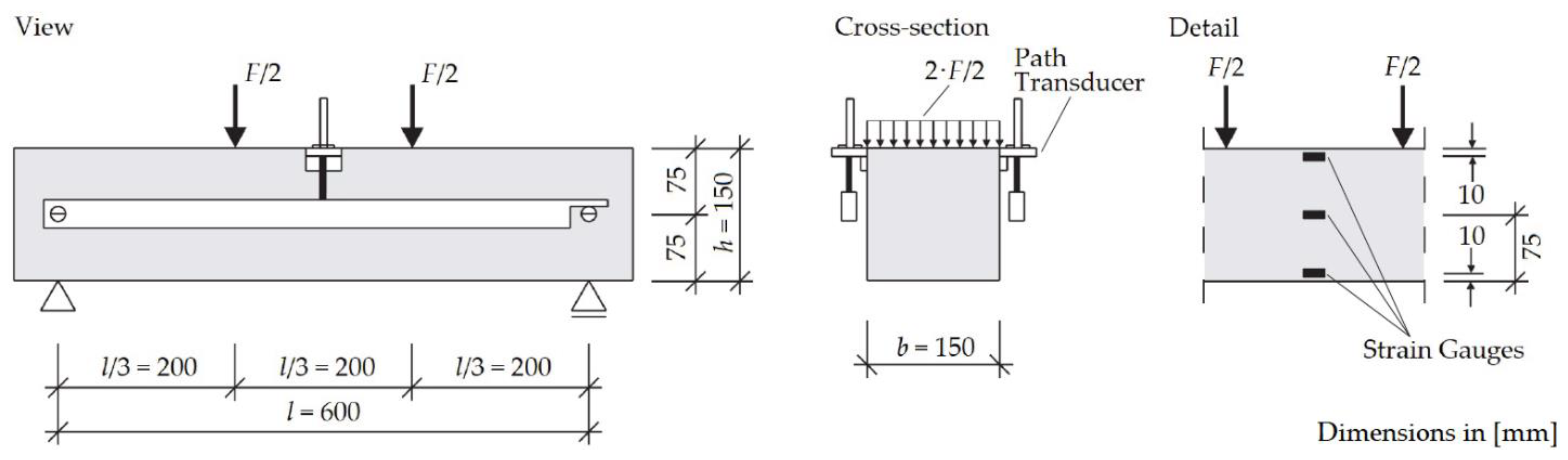

3.2. Test Setup and Execution

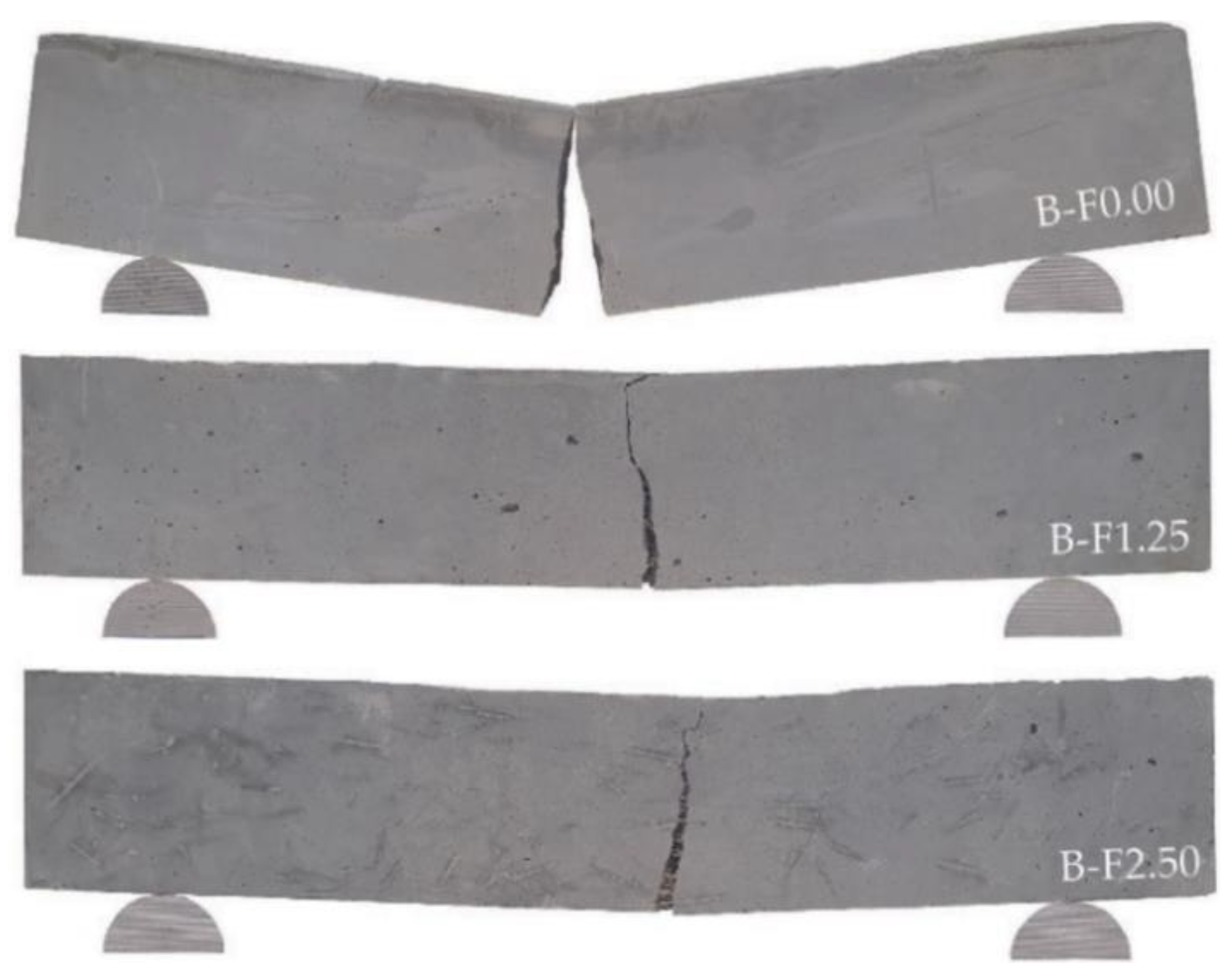

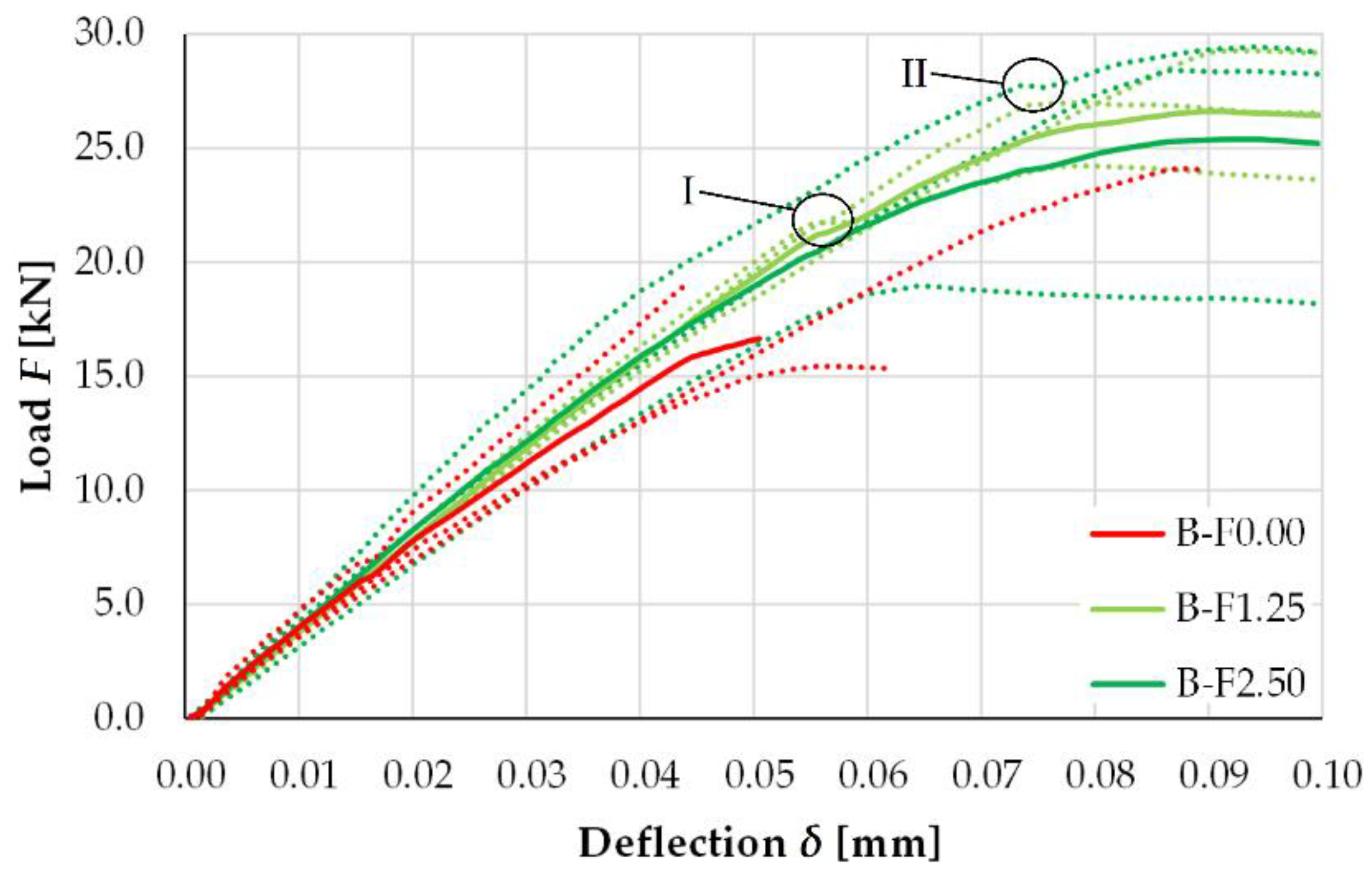

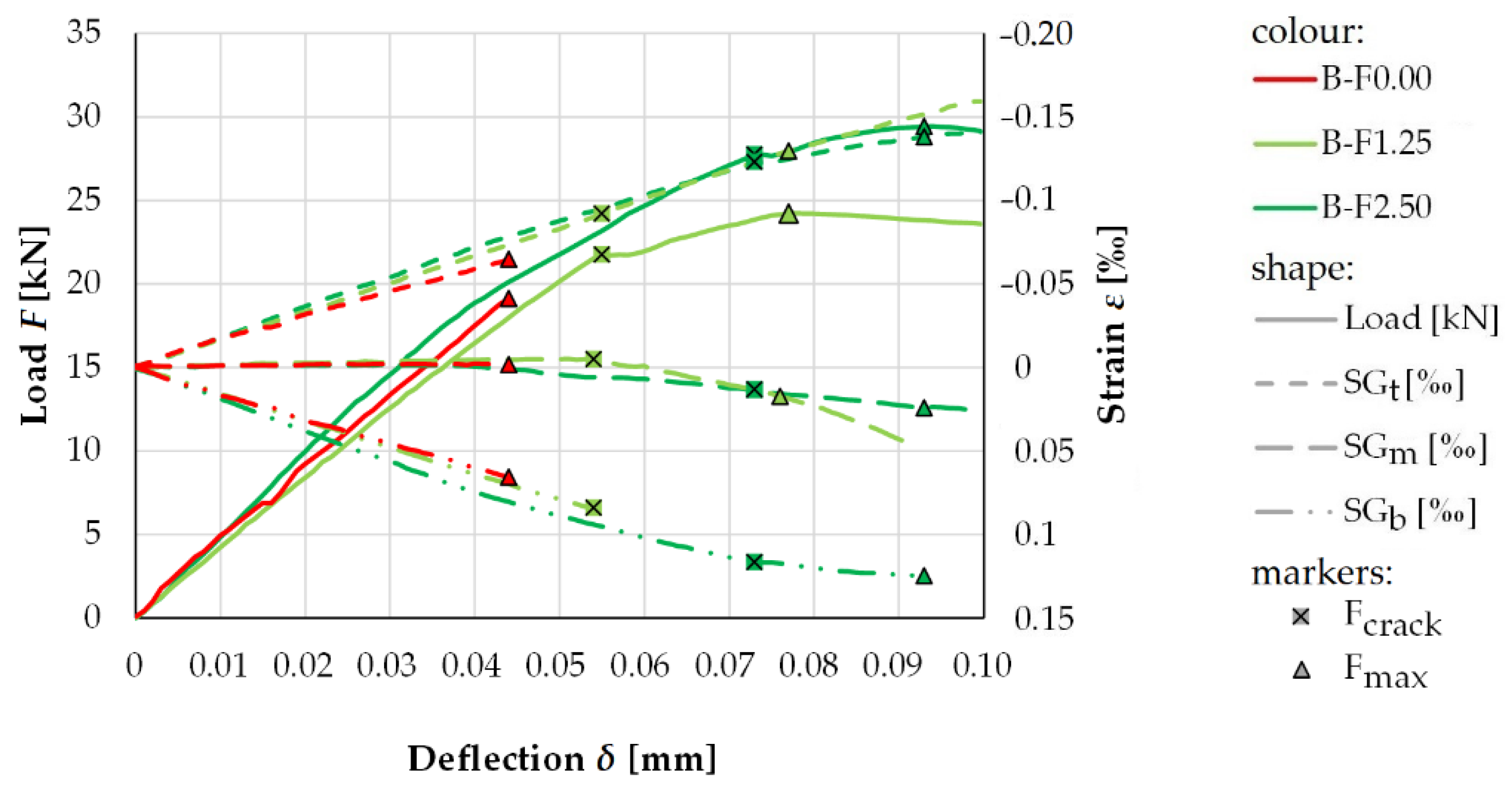

3.3. Experimental Results

4. Discussion and Comparison of the Results

5. Conclusions and Suggestions for Future Research

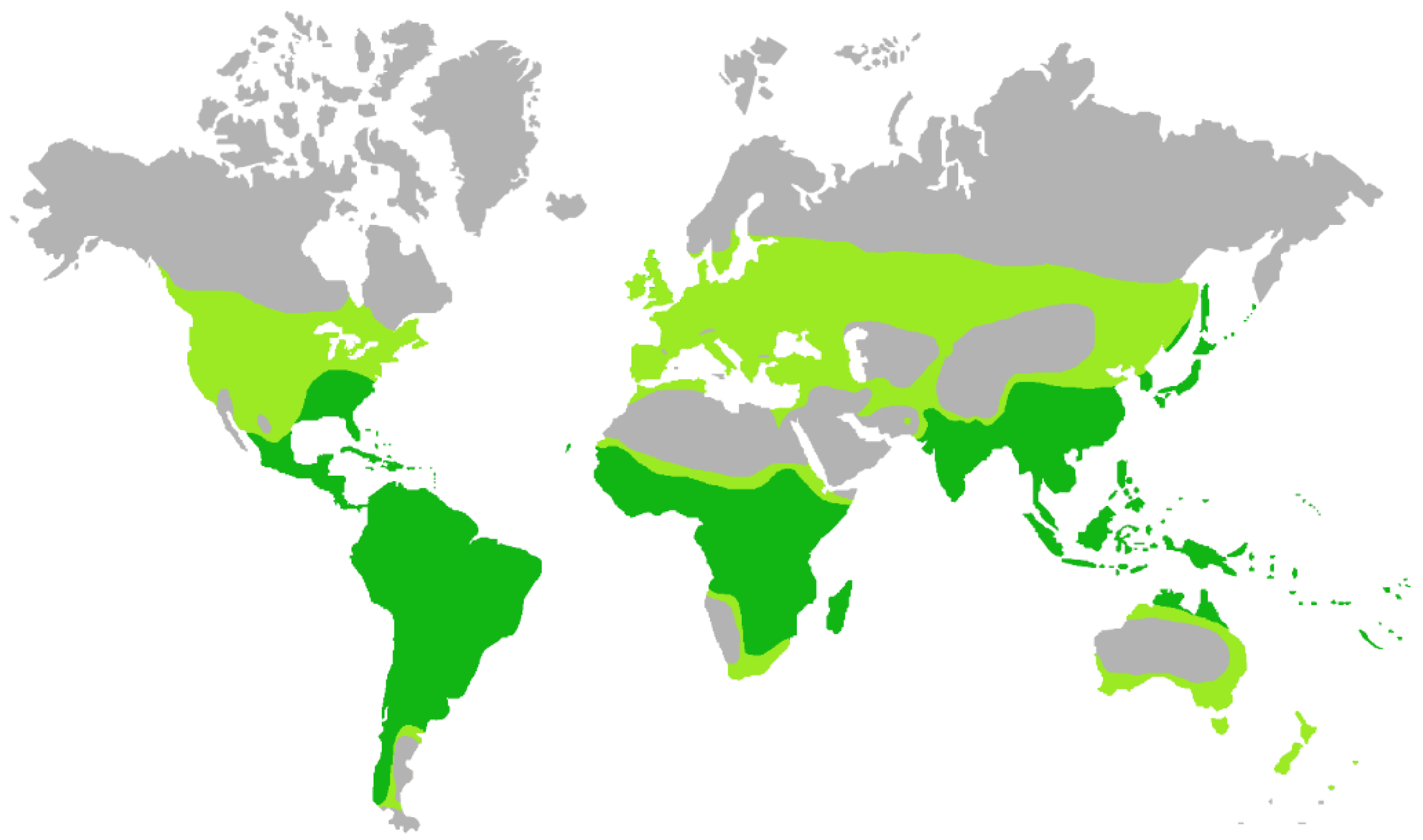

- Bamboo fibers have the potential to become a sustainable alternative to conventional steel fibers, especially in view of the worldwide distribution and cultivation possibilities, the rapid growth, the simple harvesting and processing, as well as the very good mechanical properties of bamboo (Table 1 and Figure 1).

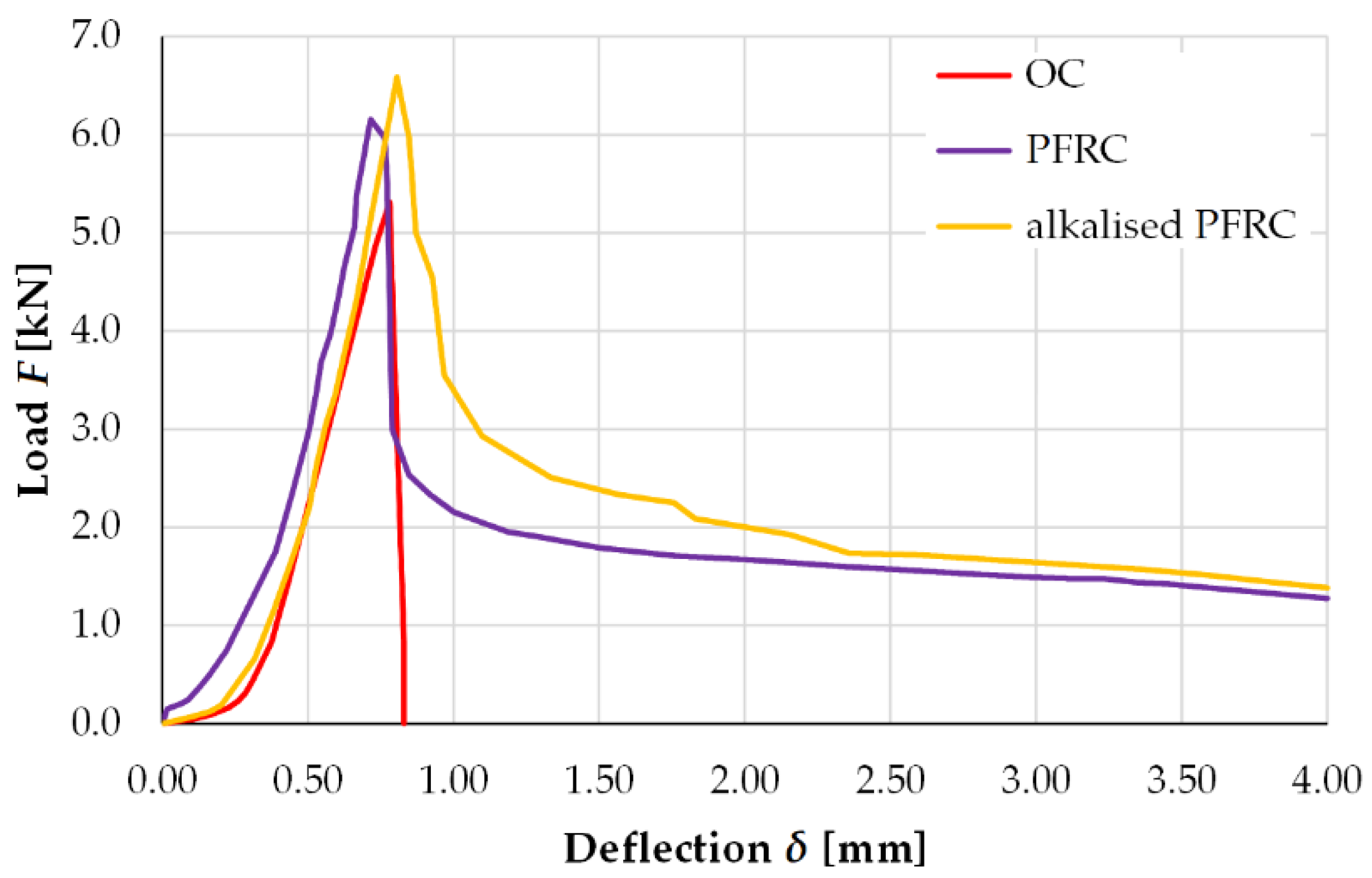

- In experimental investigations already carried out, the use of plant fibers prevented the brittle failure of concrete subjected to bending stress and achieved ductile behavior. However, the load-bearing capacity of the plant fiber-reinforced concrete was limited, in particular, by the poor bond between the fibers. In addition, corrosion in the alkaline environment of the concrete and the swelling behavior of the fibers pose a fundamental problem.

- Ultra-high performance concretes (UHPC) are characterized by, among other things, low alkalinity, high impermeability, low water/cement ratio, and very good bonding, and thus could overcome the problems mentioned in point 2 that exist with the use of plant fibers in cementitious materials. Furthermore, UHPC can be used to produce very thin-walled and thus resource-optimized and sustainable components and structures.

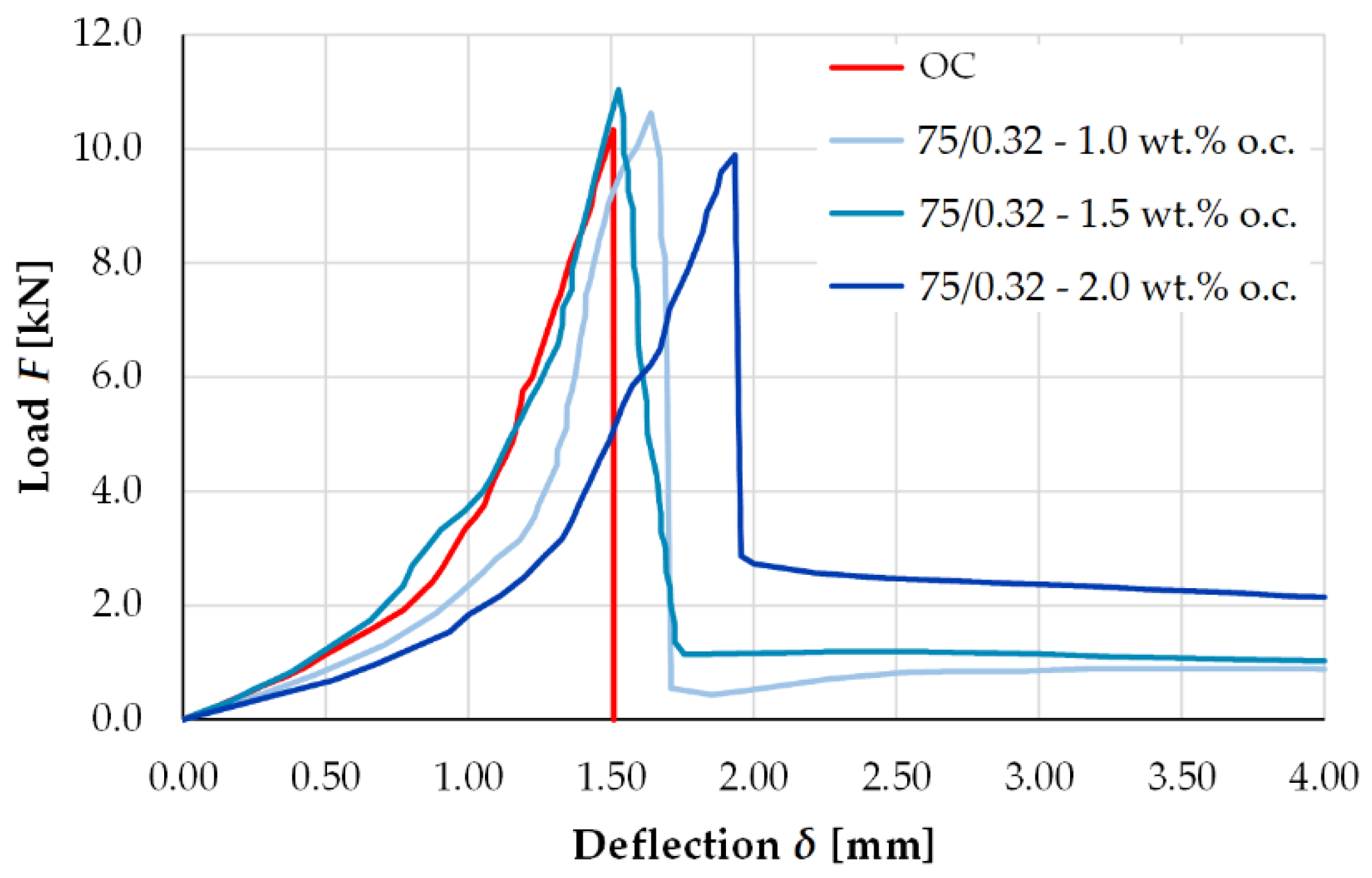

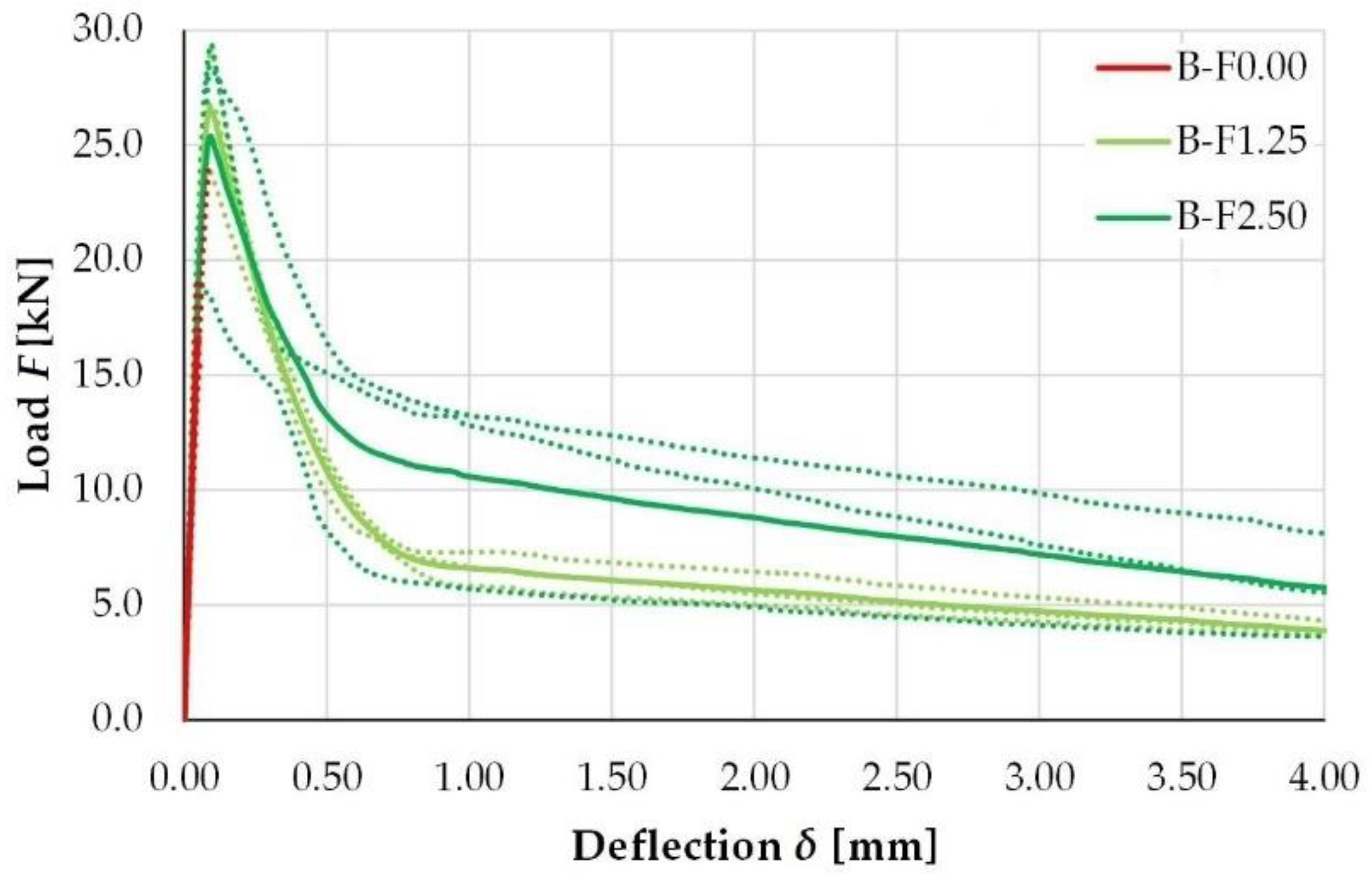

- The use of 1.25 wt.% o.c. (9.6 kg/m3) and 2.50 wt.% o.c. (19.2 kg/m3) bamboo fibers bridged existing microcracks and delayed macrocrack formation in the experimental tests conducted on UHPC bending beams. As a result, the maximum load could be increased by 37.1% and 30.9% (48.2%) from 19.5 kN to 26.8 kN and 25.6 kN (28.9 kN), respectively (Figure 8).

- The bamboo fibers were able to prevent the brittle failure of the UHPC and ensure ductile behavior by the crack-bridging effect. With deflection-softening behavior, the beams with a dosage of fibers of 1.25 wt.% o.c. (9.6 kg/m3) were capable of 11.3 kN (42.5% of the maximum load ) at a post-crack deflection of 0.4 mm, and at a post-crack deflection of 3.4 mm, 4.4 kN (16.4% of ), whereas the bending beams with a dosage of fibers of 2.50 wt.% o.c. (19.2 kg/m3) could support 13.6 kN (53.3% of ) and 7.0 kN (27.3% of ), respectively (Figure 10).

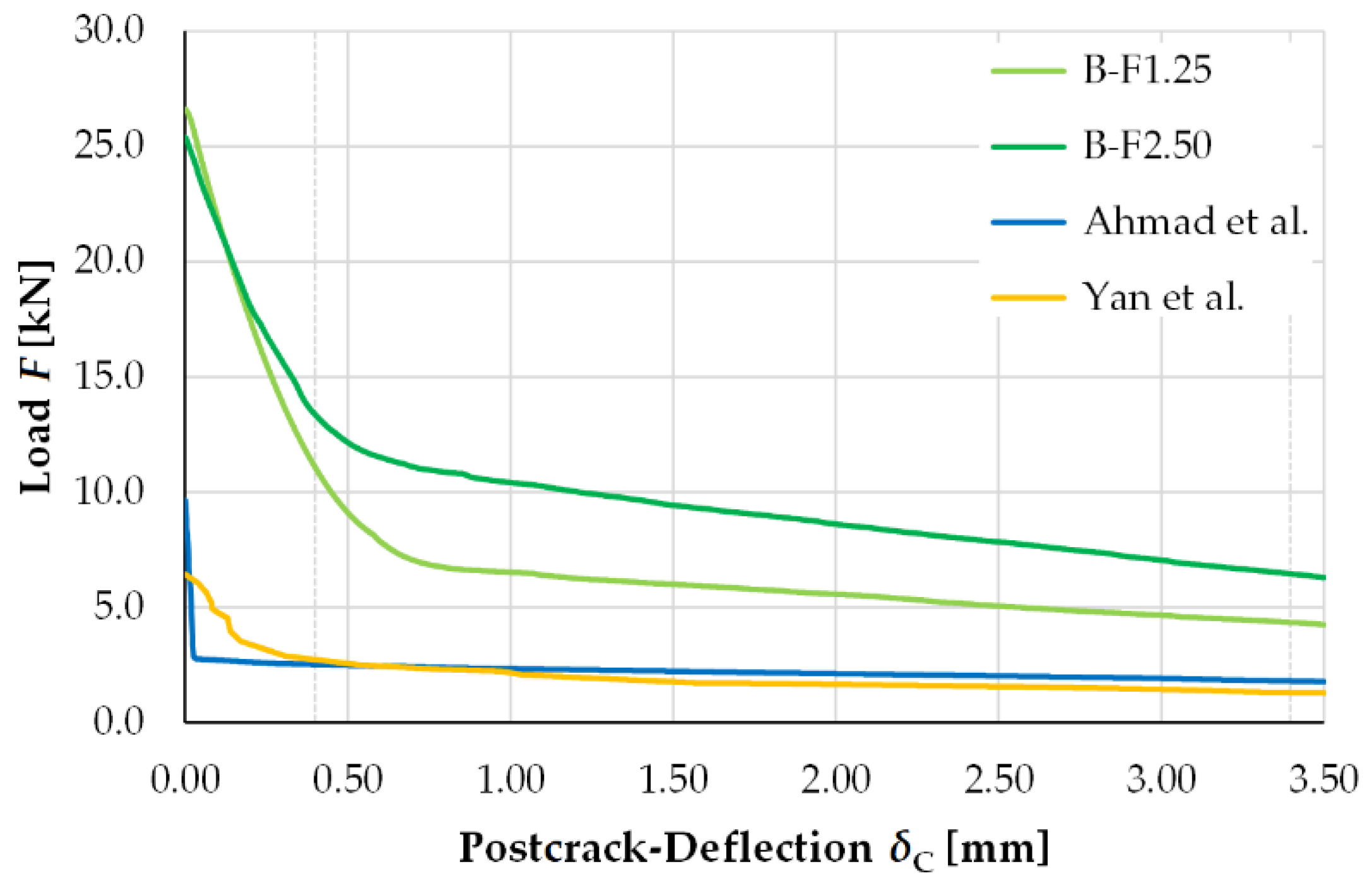

- A comparison of the post-cracking behavior of the own bending tests with those of the literature, which were carried out on normal-strength concretes reinforced with (alkalised) coir, clearly shows that a significant improvement of the load-bearing and deflection behavior in the cracked state can be achieved by a combination of bamboo fibers and UHPC (Figure 11).

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- German Committee for Structural Concrete. Sachstandsbericht Ultrahochfester Beton—Betontechnik und Bemessung (DAfStb-Issue 561); Beuth Publishing: Berlin, Germany, 2008; ISBN 978-3-410-65045-4. [Google Scholar]

- Tiberti, G.; Germano, F.; Mudadu, A.; Plizzari, G. An overview of the flexural post-cracking behavior of steel fiber reinforced concrete. Struct. Concr. 2017, 19, 695–718. [Google Scholar] [CrossRef]

- Conforti, A.; Zerbino, R.; Plizzari, G. Influence of steel, glass and polymer fibers on the cracking behavior of reinforced concrete beams under flexure. Struct. Concr. 2018, 20, 133–143. [Google Scholar] [CrossRef]

- Oettel, V.; Schulz, M.; Haist, M. Empirical approach for the residual flexural tensile strength of steel fiber-reinforced concrete based on notched three-point bending tests. Struct. Concr. 2022, 23, 993–1004. [Google Scholar] [CrossRef]

- Empelmann, M.; Oettel, V.; Cramer, J. Berechnung der Rissbreite von mit Stahlfasern und Betonstahl bewehrten Betonbauteilen. Beton-Und Stahlbetonbau 2020, 115, 136–145. [Google Scholar] [CrossRef]

- Oettel, V. Steel Fiber Reinforced RC Beams in Pure Torsion—Load-Bearing Behaviour and Modified Space Truss Model. Struct. Concr. 2022. [Google Scholar] [CrossRef]

- Holschemacher, K.; Dehn, F.; Müller, T.; Lobisch, F. Grundlagen des Faserbetons. In Beton-Kalender 2017: Spannbeton, Spezialbetone; Ernst & Sohn: Hoboken, NJ, USA, 2017; pp. 382–472. [Google Scholar] [CrossRef]

- Destrée, X. Steel-Fibre-Reinforced Concrete elevated suspended Slabs: Design cases in Europe and the USA. In Joint ACI-FIB International Workshop Fibre-Reinforced-Concrete: From Design to Structural Applications; FRC: Lausanne, Switzerland, 2016. [Google Scholar] [CrossRef]

- Hammond, G.; Jones, C. Embobdied Carbon—The Inventory of Carbon and Energy (BSRIA); University of Bath: Bath, UK, 2010; ISBN 978-0-86022-703-8. [Google Scholar]

- Kotaro, K.; Kaito, S. Environmental impact of carbon fibers fabricated by an innovative manufacturing process on life cycle greenhouse gas emissions. Sustain. Mater. Technol. 2022, 31, e00365. [Google Scholar] [CrossRef]

- Hebel, D.E.; Heisel, F.; Javadian, A. Bambus statt Stahl. Betonexperimente—TEC21 2013, 35, 36–40. [Google Scholar] [CrossRef]

- Hebel, D.E. Bamboo could turn the world. ECOS 2014, 199, 1–3. [Google Scholar] [CrossRef]

- Hebel, D.E.; Heisel, F. Fiber Composite Reinforced Concrete—A Material Research, Tropical Zone Worldwide; Future Cities Laboratory (FCL): Singapore, 2013. [Google Scholar]

- Das, S.; Warren, J.; West, D.; Schexnayder, S.M. Global Carbon Fiber Composites Supply Chain Competitiveness Analysis; Clean Energy Manufacturing Analysis Center: Denver, CO, USA, 2016. [Google Scholar]

- Grand View Research. Glass Fiber Reinforced Concrete Market Size, Share & Trends Analysis Report By Process; Grand View Research: San Francisco, CA, USA, 2020. [Google Scholar]

- Wagenführ, A. Naturfaserverbunde im Leichtbau. Lightweight Des. 2017, 10, 3. [Google Scholar] [CrossRef]

- Yan, L.; Chouw, N.; Huang, L.; Kasel, B. Effect of alkali treatment on microstructure and mechanical properties of coir fibres, coir fibre reinforced-polymer composites and reinforced-cementitious composites. Constr. Build. Mater. 2016, 112, 168–182. [Google Scholar] [CrossRef]

- Archila, H.; Kaminski, S.; Trujillo, D.; Escamilla, E.Z.; Harries, K.A. Bamboo reinforced concrete: A critical review. Mater. Struct. 2018, 51, 102. [Google Scholar] [CrossRef]

- Kesikidou, F.; Stefanidou, M. Natural fiber-reinforced mortars. J. Build. Eng. 2019, 25, 100786. [Google Scholar] [CrossRef]

- Franck, R.R. Bast and Other Plant Fibres; Elsevier, B.V.: Amsterdam, The Netherlands, 2005; ISBN 978-1-85573-684-9. [Google Scholar]

- Mwaikambo, L.Y.; Ansell, M.P. Mechanical properties of alkali treated plant fibres and their potential as reinforcement materials. I. hemp fibres. J. Mater. Sci. 2006, 41, 2483–2496. [Google Scholar] [CrossRef]

- Azwa, Z.N.; Yousif, B.F.; Manalo, A.C.; Karunasena, W. A review on the degradability of polymeric composites based on natural fibres. Mater. Des. 2013, 47, 424–442. [Google Scholar] [CrossRef]

- Mwaikambo, L.Y.; Ansell, M.P. Mechanical properties of alkali treated plant fibres and their potential as reinforcement materials II. Sisal fibres. J. Mater. Sci. 2006, 41, 2497–2508. [Google Scholar] [CrossRef]

- Chokshi, S.; Parmar, V.; Gohil, P.; Chaudhary, V. Chemical Composition and Mechanical Properties of Natural Fibers. J. Nat. Fibers 2020, 19, 3942–3953. [Google Scholar] [CrossRef]

- Hebel, D.E.; Heisel, F.; Javadian, A. Engineering Bamboo: Composite Fiber Materials as an Alternative Reinforcement in Structural Concrete Applications; Future Cities Laboratory (FCL): Singapore, 2013; pp. 46–59. [Google Scholar] [CrossRef]

- Canavan, S.; Richardson, D.M.; Visser, V.; le Roux, J.J.; Vorontsova, M.S.; Wilson, J.R. The global distribution of bamboos: Assessing correlates of introduction and invasion. AoB PLANTS 2017, 9, plw078. [Google Scholar] [CrossRef]

- Javadian, A.; Smith, I.F.C.; Hebel, D.E. Application of Sustainable Bamboo-Based Composite Reinforcement in Structural-Concrete Beams: Design and Evaluation. Materials 2020, 13, 696. [Google Scholar] [CrossRef]

- Lomelí-Ramírez, M.G.; Anda, R.R.; Satyanarayana, K.G.; de Muniz, G.I.; Iwakiri, S. Comparative Study of the Characteristics of Green and Brown Coconut Fibers for Development of Green Composites. Bio Resour. 2018, 13, 1637–1660. [Google Scholar] [CrossRef]

- Lu, X.-S.; Wang, K.-Q.; Yi, X.-C.; Liou, J.; He, J.-X. A study on the physico-mechanical properties of culmwood of Phyll. glauca of Shandong. J. Bamboo Res. 1985, 4, 98–106. [Google Scholar]

- Huang, Y.-H.; Fei, B.-H.; Yu, Y.; Zhao, R.-J. Plant age effect on mechanical properties of Moso bamboo (Phyllostachys heterocycla var. Pubescens) single fibers. Wood Fiber Sci. 2012, 44, 196–201. [Google Scholar]

- Hidalgo-Lopez, O. Bamboo—The Gift of the Gods; O. Hidalgo-Lopez: Bogota, Columbia, 2003; ISBN 9789583342981. [Google Scholar]

- Ferreira, G. Vigas de Concreto Armadas com Taliscas de Bamboo Dendrocalamus Giganteus. Ph.D. Thesis, UNICAMP State University of Campinas, Campinas, Brazil, 2007. [Google Scholar] [CrossRef]

- Lewin, M.; Pearce, E.M. Fiber chemistry. In Handbook of Fiber Science and Technology; Marcel Dekker Inc.: New York, NY, USA, 1985. [Google Scholar]

- Sahu, P.; Gupta, M.K. Sisal (Agave sisalana) fibre and its polymer-based composites: A review on current developments. J. Reinf. Plast. Compos. 2017, 36, 1759–1780. [Google Scholar] [CrossRef]

- John, M.J.; Anandjiwala, R.D. Recent developments in chemical modification and characterization of natural fibre-reinforced composites. Polym. Compos. 2008, 29, 187–207. [Google Scholar] [CrossRef]

- Sahu, P.; Gupta, M.K. A review on the properties of natural fibres and its bio-composites: Effect of alkali treatment. J. Mater. Des. Appl. 2020, 234, 198–217. [Google Scholar] [CrossRef]

- Futami, E.; Shafigh, P.; Katman, H.Y.B.; Ibrahim, Z. Recent Progress in the Application of Coconut and Palm Oil Fibres in Cement-Based Materials. Sustainability 2021, 13, 2865. [Google Scholar] [CrossRef]

- Janssen, J.J.A. Mechanical Properties of Bamboo; Springer: Berlin, Germany, 1991. [Google Scholar] [CrossRef]

- Yeasmin, L.; Ali, M.N.; Gantailt, S.; Chakraborty, S. Bamboo: An overview on its genetic diversity and characterization. 3 Biotech 2015, 5, 1–11. [Google Scholar] [CrossRef]

- Breckle, S.-W. Walter’s Vegetation of the Earth—The Ecological Systems of the Geo-Biosphere; Springer Publishing: Berlin, Germany, 2002; ISBN 978-3-540-43315-6. [Google Scholar]

- Ali, M.; Liu, A.; Sou, H.; Chouw, N. Mechanical and dynamic properties of coconut fibre reinforced concrete. Constr. Build. Mater. 2012, 30, 814–825. [Google Scholar] [CrossRef]

- German Committee for Structural Concrete. Commentary on the DAfStb Guideline “Steel Fiber Reinforced Concrete” (DAfStb-Issue 614); Beuth Publishing: Berlin, Germany, 2015; ISBN 978-3-410-65279-3. [Google Scholar]

- Pereira, M.V.; Fujiyama, R.; Darwish, F.; Alves, G.T. On the Strengthening of Cement Mortar by Natural Fibers. Mater. Res. 2015, 18, 177–183. [Google Scholar] [CrossRef]

- Ramli, M.; Dawood, E.T. Effects of palm fiber on the mechanical properties of lightweight concrete crushed brick. Am. J. Eng. Appl. Sci. 2010, 3, 489–493. [Google Scholar] [CrossRef]

- Hwang, C.-L.; Tran, V.-A.; Hong, J.-W.; Hsieh, Y.-C. Effects of short coconut fiber on the mechanical properties, plastic cracking behavior, and impact resistance of cementitious composites. Constr. Build. Mater. 2016, 127, 984–992. [Google Scholar] [CrossRef]

- Baruah, P.; Talukdar, S. A comparative study of compressive, flexural, tensile and shear strength of concrete with fibres of different origins. Indian Concr. J. 2007, 81, 17–24. [Google Scholar]

- Filho, R.D.T.; Ghavami, K.; Sanjuán, M.A.; England, G. Free, restrained and drying shrinkage of cement mortar composites reinforced with vegetable fibres. Cem. Concr. Compos. 2005, 27, 537–546. [Google Scholar] [CrossRef]

- Silva, D.A.; Mobasher, B.; Soranakom, C.; Filho, R.D.T. Effect of fiber shape and morphology on interfacial bond and cracking behaviors of sisal fiber cement based composites. Cem. Concr. Compos. 2011, 33, 814–823. [Google Scholar] [CrossRef]

- Ray, D.; Sarkar, B.K.; Rana, A.K. Fracture behavior of vinylester resin matrix composites reinforced with alkali-treated jute fibers. J. Appl. Polym. Sci. 2002, 85, 2588–2593. [Google Scholar] [CrossRef]

- Widnyana, A.; Rian, I.G.; Surata, I.W.; Nindhia, T.G.T. Tensile Properties of coconut Coir single fiber with alkali treatment and reinforcement effect on unsaturated polyester polymer. Mater. Today Proc. 2020, 22, 300–305. [Google Scholar] [CrossRef]

- Momoh, E.O.; Osofero, A.I.; Menshykov, O. Bond Behaviour of Treated Natural Fibre in Concrete. Nano Hybrids Compos. 2022, 34, 37–44. [Google Scholar] [CrossRef]

- EN 14651 Test Method for Metallic Fibre Concrete—Measuringthe Flexural Tensile Strength (Limit or Proportionality (LOP), Residual); European Committee for Standardization (CEN): Brussels, Belgium, 2005; ISBN 978-0-580-61052-3.

- Ozerkan, N.G.; Ahsan, B.; Mansour, S.; Iyengar, S.R. Mechanical performance and durability of treated palm fiber reinforced mortars. Int. J. Sustain. Built Environ. 2013, 2, 131–142. [Google Scholar] [CrossRef]

- Zhou, X.; Saini, H.; Kastiukas, G. Engineering Properties of Treated Natural Hemp Fiber-Reinforced Concrete. Front. Built Environ. 2017, 3, 33–42. [Google Scholar] [CrossRef]

- Thomas, B.C.; Jose, Y.S. Impact of sisal fiber reinforced concrete and its performance analysis: A review. Evol. Intell. 2019, 15, 865–875. [Google Scholar] [CrossRef]

- John, V.M.; Cincotto, M.A.; Sjostrom, C.; Agopyan, V.; Oliveir, C.T.A. Durability of slag mortar reinforced with coconut fibre. Cem. Concr. Compos. 2005, 27, 565–574. [Google Scholar] [CrossRef]

- Khan, M.; Rehman, A.; Ali, M. Efficiency of silica-fume content in plain and natural fiber reinforced concrete for concrete road. Constr. Build. Mater. 2020, 224, 118382. [Google Scholar] [CrossRef]

- Ahmad, W.; Farooq, S.H.; Usman, M.; Khan, M.; Ahmad, M.; Aslam, F.; Yousef, R.A.; Abduljabbar, H.A.; Sufian, M. Effect of Coconut Fiber Length and Content on Properties of High Strength Concrete. Materials 2020, 13, 1075. [Google Scholar] [CrossRef] [PubMed]

- Fehling, E.; Schmidt, M.; Walraven, J.; Leutbecher, T.; Fröhlich, S. Ultra-High Performance Concrete UHPC; Ernst & Sohn: Berlin, Germany, 2014; ISBN 978-3-433-03087-5. [Google Scholar]

- Femandez, J.E. Flax fiber reinforced concrete—A natural fiber biocomposite for sustainable building materials. High Perform. Struct. Compos. 2002, 59, 15. [Google Scholar]

- Athijayamani, A.; Thiruchitrambalam, M.; Natarajana, U.; Pazhanivelc, B. Effect of moisture absorption on the mechanical properties of randomly oriented natural fibers/polyester hybrid composite. Mater. Sci. Eng. A 2009, 517, 344–353. [Google Scholar] [CrossRef]

- Naamandadin, N.A.; Rosdi, M.S.; Mustafa, W.A.; Aman, M.N.S.S. Mechanical behaviour on concrete of coconut coir fiber as additive. IOP Conf. Ser. Mater. Sci. Eng. 2020, 932, 012098. [Google Scholar] [CrossRef]

- Pacheco-Torgal, F.; Jalali, S. Cementitious building materials reinforced with vegetable fibres: A review. Constr. Build. Mater. 2011, 25, 575–581. [Google Scholar] [CrossRef]

- Schmidt, M.; Fehling, E. Ultra-High-Performance Concrete: Research, Development and Application in Europe. ACI Symp. Publ. 2005, 228, 51–78. [Google Scholar] [CrossRef]

- Wiens, U. Erweiterte Untersuchungen zur Alkalität von Betonen mit hohen Puzzolangehalten; Fraunhofer IRB Publishing: Stuttgart, Germany, 1999; ISBN 9783816754787. [Google Scholar]

- Rao, R.; Stroeven, P.; Hendriks, C.F. Mechanical Properties of Reactive Powder Concrete Beams. ACI Symp. Publ. 2005, 228, 1237–1252. [Google Scholar]

- Ludwig, H.-M.; Thiel, R. Dauerhaftigkeit von UHFB. In Innovationen im Bauwesen—Ultrahochfester Beton (UHFB); Bauwerk-Publishing: Berlin, Germany, 2003. [Google Scholar]

- Reinhardt, H.-W.; Jooß, M. Wasserspeicher aus UHFB—Technologie. In Innovationen im Bauwesen—Ultrahochfester Beton; Bauwerk-Publishing: Berlin, Germany, 2003. [Google Scholar]

- Oettel, V. Torsionstragverhalten von stahlfaserbewehrten Beton-, Stahlbeton- und Spannbetonbalken. Ph.D. Thesis, Technical University of Braunschweig, Braunschweig, Germany, 2016. [Google Scholar] [CrossRef]

- Oettel, V.; Rieke, A.; Empelmann, M. Production and testing of thin-walled UHPFRC precast elements. BFT Int. 2014, 80, 64–74. [Google Scholar]

- Bertola, N.; Küpfer, C.; Kälin, E.; Brühwiler, E. Assessment of the Environmental Impacts of Bridge Designs Involving UHPFRC. Sustainability 2021, 13, 12399. [Google Scholar] [CrossRef]

- Habert, G.; Denarié, E.; Šajna, A.; Rossi, P. Lowering the global warming impact of bridge rehabilitations by using Ultra High Performance Fibre Reinforced Concretes. Cem. Concr. Compos. 2013, 38, 1–11. [Google Scholar] [CrossRef]

- Racky, P. Cost-effectiveness and sustainability of UHPC. In Proceedings of the International Symposium on Ultra High Performance Concrete, Kassel, Germany, 13–15 September 2004; pp. 797–805, ISBN 3-89958-086-9. [Google Scholar]

- Aitcin, P. Cements of yesterday and today—Concrete of tomorrow, Cem. Concr. Res. 2000, 30, 1349–1359. [Google Scholar] [CrossRef]

- Oettel, V.; Matz, H.; Empelmann, M. Bestimmung der zentrischen Nachrisszugfestigkeit von UHPFRC mithilfe gekerbter 3-Punkt-Biegezugversuche. Beton-Und Stahlbetonbau 2019, 114, 255–264. [Google Scholar] [CrossRef]

- Chan, Y.-W.; Chu, S.-H. Effect of silica fume on steel fiber bond characteristics in reactive powder concrete. Cem. Concr. Res. 2004, 34, 1167–1172. [Google Scholar] [CrossRef]

- Rocky, B.P.; Thompson, A.J. Production of natural bamboo fibers-1: Experimental approaches to different processes and analyses. J. Text. Inst. 2018, 109, 1381–1391. [Google Scholar] [CrossRef]

- Mark, P.; Oettel, V.; Look, K.; Empelmann, M. Neuauflage DAfStb-Richtlinie Stahlfaserbeton. Beton-Und Stahlbetonbau 2021, 116, 19–25. [Google Scholar] [CrossRef]

- Oettel, V.; Lanwer, J.-P.; Empelmann, M. Auszugverhalten von Mikrostahlfasern aus UHPC unter monoton steigender und zyklischer Belastung. Bauingenieur 2021, 96, 1–10. [Google Scholar] [CrossRef]

- Basaldella, M.; Jentsch, M.; Oneschkow, N.; Markert, M.; Lohaus, L. Compressive Fatigue Investigation on High-Strength and Ultra-High-Strength Concrete within the SPP 2020. Materials 2022, 15, 3793. [Google Scholar] [CrossRef]

- Basaldella, M.; Oneschkow, N.; Lohaus, L. Influence of the specimen production and preparation on the compressive strength and the fatigue resistance of HPC and UHPC. Mater. Struct. 2021, 54, 99. [Google Scholar] [CrossRef]

- Liese, W. The Anatomy of Bambus Colums; International Network for Bamboo and Rattan: Beijing, China, 1998. [Google Scholar]

- Deutsche Ausschuss für Stahlbeton DAfStb-Richtlinie Stahlfaserbeton: 2021-06; Beuth-Publishing: Berlin, Germany, 2021.

- Yoo, D.-Y.; Yoon, Y.-S.; Banthia, N. Flexural response of steel-fiber-reinforced concrete beams: Effects of strength, fiber content, and strain-rate. Cem. Concr. Compos. 2015, 64, 84–92. [Google Scholar] [CrossRef]

- Qian, D.; Yu, R.; Shui, Z.; Sun, Y.; Jiang, C.; Zhou, F.; Ding, M.; Tong, X.; He, Y. A novel development of green ultra-high performance concrete (UHPC) based on appropriate application of recycled cementitious material. J. Clean. Prod. 2020, 261, 121231. [Google Scholar] [CrossRef]

- Shi, Y.; Long, G.; Zeng, X.; Sie, Y.; Wang, H. Green ultra-high performance concrete with very low cement content low cement content. Constr. Build. Mater. 2021, 303, 124482. [Google Scholar] [CrossRef]

| Fiber | Cellulose [%] | Relevant MFA [°] | Tensile Strength [N/mm2] | Module of Elasticity [N/mm2] |

|---|---|---|---|---|

| Flax | 70 | 7 | 1000 | 60,000 |

| Hemp | 65 | 4 | 700 | 50,000 |

| Sisal | 65 | 17 | 450 | 40,000 |

| Coir | 35 | 45 | 150 | 5000 |

| Bamboo | 60 | 8 | 400 | 35,000 |

| Components | UHPC | UHPPFRC-F1.25 | UHPPFRC-F2.50 |

|---|---|---|---|

| CEM I 52.5 R-SR3/NA (Holcim Sulfo 5R) | 786.2 | 771.8 | 766.8 |

| Silica fume (Sika® Silicoll P (uncompacted)) | 166.7 | 163.6 | 162.6 |

| Quartz powder (Quarzwerke MILLSIL® W12) | 196.1 | 192.5 | 191.3 |

| Quartz sand (0/0.5 mm) (Quarzwerke H33) | 959.8 | 942.2 | 936.1 |

| Superplasticiser (BASF MasterGlenium® ACE 394) | 24.1 | 35.1 | 34.9 |

| Water | 185.7 | 182.3 | 181.2 |

| 0.0 | 9.6 | 19.2 |

| Characteristic | UHPC | UHPPFRC-F1.25 | UHPPFRC-F1.25 |

|---|---|---|---|

| Temperature of fresh concrete [°C] | 24.0 ± 1.0 | ||

| Slump-flow measure (without locking ring) [mm] | 735 | 820 | 715 |

| Air content [%] | 4.1 | 4.2 | 4.3 |

| Density [kg/m3] | 2270 | 2257 | 2240 |

| No. | Name | Description |

|---|---|---|

| 1 | Divide I | Divide the bamboo culm into nodes and internodes |

| 2 | Split | Split internodes into 50 mm wide splits |

| 3 | Soaking I | Soak splits for 3 days |

| 4 | Planing | Divide the splits into slices with a hand plane |

| 5 | Soaking II | Soak slices for 1 day |

| 6 | Divide II | Cut the slices into segments with tin snips |

| 7 | Separation | Separate the fibres from the segments with a carpet knife |

| 8 | Drying | Air-dry the obtained fibres for one week |

| Series | UHPC Mixture | Dosage of the Fibers [wt% o.c.] | Number of Specimens |

|---|---|---|---|

| B-F0.00 | UHPC | 0.00 | 3 |

| B-F1.25 | UHPPFRC-F1.25 | 1.25 | 3 |

| B-F2.50 | UHPPFRC-F2.50 | 2.50 | 3 |

| Series | Maximum Load Fmax [kN] | Strain When Reaching the Maximum Load | Load | Load |

|---|---|---|---|---|

| B-F0.00 | 19.5 (±4.5) | 0.065 | - | - |

| B-F1.25 | 26.8 (±2.6) | 0.084 | 11.3 (±1.2) | 4.4 (±0.6) |

| B-F2.50 | 25.6 (±6.6) | 0.125 | 13.6 (±4.6) | 7.0 (±3.6) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bittner, C.M.; Oettel, V. Fiber Reinforced Concrete with Natural Plant Fibers—Investigations on the Application of Bamboo Fibers in Ultra-High Performance Concrete. Sustainability 2022, 14, 12011. https://doi.org/10.3390/su141912011

Bittner CM, Oettel V. Fiber Reinforced Concrete with Natural Plant Fibers—Investigations on the Application of Bamboo Fibers in Ultra-High Performance Concrete. Sustainability. 2022; 14(19):12011. https://doi.org/10.3390/su141912011

Chicago/Turabian StyleBittner, Can Mark, and Vincent Oettel. 2022. "Fiber Reinforced Concrete with Natural Plant Fibers—Investigations on the Application of Bamboo Fibers in Ultra-High Performance Concrete" Sustainability 14, no. 19: 12011. https://doi.org/10.3390/su141912011

APA StyleBittner, C. M., & Oettel, V. (2022). Fiber Reinforced Concrete with Natural Plant Fibers—Investigations on the Application of Bamboo Fibers in Ultra-High Performance Concrete. Sustainability, 14(19), 12011. https://doi.org/10.3390/su141912011