Abstract

Self-compacting concrete (SCC) uses a lot of natural resources, much like regular concrete, which results in unsustainable construction. Even though silica fume (SF) and other secondary cementitious materials are the subjects of a lot of studies, to determine the past, present, and future direction of research, information must first be reviewed. This paper compiles data on SSC with SF substations. Slump flow, slump T50, L-box, and V-funnel tests were used to investigate fresh SCC properties, such as filling and passing capabilities. Mechanical properties were examined using compressive, tensile, and flexure strength, while the durability characteristics of SCC were examined through water absorption, porosity, sorptivity, and chloride resistance. The internal structure of SCC, with and without SF, is reviewed through scan electronic microscopy (SEM). The results indicate that SF lacked the filling and passing ability of SCC, but is still within the limit defined by the technical specification for SCC. However, the study suggests a larger dosage of plasticizer for a higher dose of SF. Improvements in SCC’s strength and durability were also seen; however, greater doses had a negative impact on these attributes due to an absence of flowability. Researchers recommended the ideal SF dosage ranges from 10 to 15% by volume of cement. The assessment also reveals research gaps that need to be addressed.

1. Introduction

Self-compacting concrete (SCC) is a unique kind of concrete that is flowable, non-segregating, and expands into the formwork by its own mass without the aid of external vibrators, even when there is heavy reinforcement present. SCC is becoming more popular in civil engineering. SCC continues to explore a variety of applications and characteristics [1]. Four parameters, including flowability, viscosity, passing ability, and segregation resistance, may be used to differentiate SCC from conventional concrete. If the concrete has all four of the aforementioned traits, it is referred to as SCC [2]. In terms of history, the SSC idea was initially established in 1986 [3]. However, in 1988, Japan was the first nation to successfully create a prototype of SCC. Similar to ordinary concrete, the SCC building is unsustainable due to its high natural resource use.

According to the idea of environmental development, environmental resources should be preserved as limited commodities and wastes should be adequately controlled [4,5,6,7]. The growing quantities of composed trash, up to 2500 million tons annually around the globe, encouraged the development of a contemporary method of dumping [8]. There are various options to use leftover raw materials in concrete in the cement manufacturing sector [5,9,10,11,12]. Waste may be used in concrete as cement, or fine or coarse aggregate.

In the construction industry, concrete is the most often used man-made construction resource, and hydraulic cement is an essential component of this material [13,14,15]. Nearly 30 billion tons of concrete were produced in 2015, using approximately four enormous volumes of hydraulic cement annually [16]. The findings presented at the World Cement Association Conference demonstrate that the yearly rate of global cement production has increased [17]. There has been significant industrial expansion as a result of the expanding need for cement in modern structures and infrastructure, notably in developing nations like China, Russia, and Japan [18]. The capacity to manufacture 59.5 million tons of cement per year was built due to the projection of future demand for expanding infrastructure. The cost of cement has increased by roughly 150% in only 10 years [19]. Therefore, it’s crucial to use alternative materials wherever feasible, instead of cement [20].

The use of a mineral additive is one of the ways SCC differs from conventional concrete. Viscosity-increasing additives, or fillers, are used in SCC to prevent the separation of big particles. When casting concrete underwater, or for SCC in tunnels, an additive to improve viscosity is often employed. To enhance the viscosity of SCC, mineral admixture fillers may be added to the slurry [11]. The performance of SCC with various pozzolanic materials substituted for cement has been studied by researchers [21,22,23]. According to Siddique et al. [24], the use of mineral admixtures raises the slump without raising the cost of the mixture, and lowers the amount of superplasticizer required. According to earlier research, fly ash-containing mixtures had less compressive capacity values at early ages. The sluggish pozzolanic reaction between the binder (OPC) and fly ash (FA) was the root cause of this issue [25]. Furthermore, the rate of pozzolanic reaction of secondary cementitious material also depends on the temperature.

Silica fume (SF) is a poisonous material that harms the environment and its surroundings. Nearly all SF was discharged into the environment up until the mid-1970s. There were many uses for SF even as environmental concerns about it increased. SF is a very pozzolanic substance due to its tiny particle size and high concentration of amorphous silicon dioxide, as seen in the Table 1.

Table 1.

Chemical composition (wt%) of silica fume (SF).

Silica fume’s amorphous structure makes it very reactive; they are round and have a sizable surface. SF particles are packed densely with cement grains because they are 100 times smaller than OPC grains, which allows calcium hydroxide and SiO2 to react to produce more CSH and earlier strength [30]. SF increases the concrete’s packing density because of its microscopic size. SF concrete has been applied extensively in high-strength concrete for highway bridges, marine constructions, and parking decks, because of its outstanding performance [31]. The benefits of using SF in concrete are shown in Figure 1.

Figure 1.

Advantages of silica fume in concrete.

To accomplish sustainable construction and formwork, silica fumes have recently grown in prominence as a partial alternative for cement. SF was used by Ardalan and Joshaghani [32] in SSC in combination with pumice. An increase in SSC workability and compressive strength was observed. A study [33] found that the greatest mechanical qualities were produced by a ternary combination of nano-silica (2.5%) and micro silica fumes (2.5%). A researcher [34] studied the use of electrical resistivity of SSC (containing SF and metakaolin) to determine the amount of calcium hydroxide. The correlation coefficient of the relationship between Ca(OH)2 content and electrical resistivity was found to be 0.95 with a positive slope for reference SCC and 0.97 with a negative slope for samples containing pozzolans. It can be suggested to apply the electrical resistivity as a simple method to calculate CH content in cement paste. Leung and Kim [35] conducted research on the SSC’s moisture absorption capabilities after replacing some of the cement with flaky ash and SF. With partial substitution, moisture absorption was reduced, but compressive strength was increased. The link between moisture absorption and compressive strength was not found. SF in SSC (created using leftover concrete aggregates) have reduced porosity and moisture absorption, according to researchers [36]. Fouroghi et al. found that a SF concentration of 5% in SSC had the best pore characteristics [37].

Some literature shows that SF improved the strength and mechanical properties of SCC; however, information is scattered, and no one can easily judge the exact benefits of SF in concrete. Furthermore, according to the author’s best information, most researchers focus on reviewing the properties of conventional concrete with the substitution of SF, while no research considers the SF benefits in SCC. Therefore, a detailed assessment is essential to explore the benefits of SF in SCC. The aim of this review is to collect information on SSC with the substation of SF. The review focuses on the general background of SSC, the physical and chemical composition of SCC, the impact of SF on fresh properties, strength properties, and the durability aspects of SCC. The results depict that SF reduced the filling and passing ability of SCC, but is still within the limit defined by the guidelines for SCC. However, for a higher dose, the review recommends a higher dose of plasticizer. Improvement in the strength and durability of SCC was also observed, but a higher dose of SF adversely affects strength and durability properties, due to a lack of flowability. Different scholars recommend different optimal percentages of SF, due to changes in the source. However, the typical optimum dose range of SF varies from 10 to 15%. Finally, the review also identifies a research gap for future research that must be explored before being used practically.

2. Fresh Properties

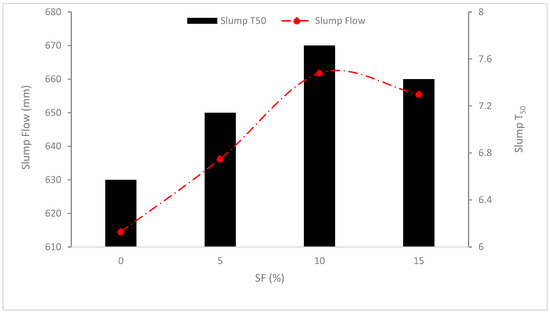

The slump flow test was based on the European SCC criteria, and the mixes with a flow diameter range of 600 mm and 800 mm were taken into consideration (EFNARC 2002) [38]. The slump flow and slump T50 of SCC with SF replacement are shown in Figure 2.

Figure 2.

Slump flow and slump T50: Data Source [26].

Mortars constructed exclusively with Portland cement are substantially less cohesive than secondary cementitious materials (SCMs) including 6% SF. The flowability of mortars with SF is not as excellent as that of mortars with fly ash (FA) because there is greater contact between the higher cohesiveness (FA) [39]. Due to its lower particle size compared to cement, SF loses workability [40]. Since SF has a greater specific surface area than cement, a substantial volume of water is required to fuel hydration processes [41]. To attain the requisite workability in all SF concrete combinations, the superplasticizer dosage was raised. It should be noticed that concrete’s flowability declined as the SF substation increased. Because silica interacts with calcium hydroxide when it is in its finely divided state, secondary cementitious calcium silicate hydrate is created, which makes the concrete stiffer and more cohesive and contributes to the reduction in flowability with SF substitution [42]. However, all SCC combinations have outstanding flowability and are within the confines of the SCC technical standard [38].

Due to the SF and FA particles’ spherical form, which creates a ball-bearing action, the packing effect was more severe. With less intra-particle friction, the lubricated spherical particles provided effective rolling. Since the amounts of water and superplasticizer were maintained throughout the formulations, the rolling action could be produced with up to 20% replacement level lubrication. Following that, the overall powder surface area increased, requiring more water and superplasticizer to reach the same workability level. This result causes the overall spread to steadily diminish after the replacement level of 20%. The overview of slump flow with SF replacement in SCC is shown in the Table 2.

Table 2.

Summary of flowability of SCC with SF.

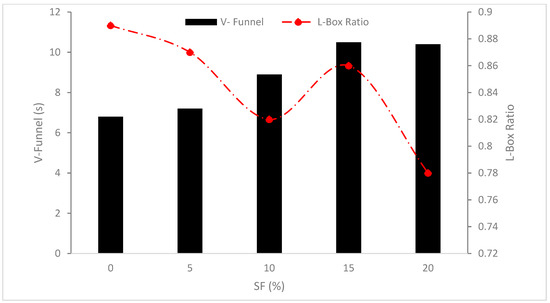

The L-box and U-box tests were applied to evaluate SCC’s capacity for filling and passing. In both procedures, the concrete to be tested was placed in a closed, vertical chamber to provide a hydrostatic pressure head. The concrete must level out across the vertical or horizontal flow obstructions once a slide is opened. The likelihood of blocking was influenced by the level discrepancy. When the blocking ratio (H2/H1) was between 0.8 and 1.0 and the L-box blocking ratio was less than 0.8, the EFNARC guideline [38] states that a combination provide a blocking risk.

SF was added in varying binder concentrations of 5, 10, 15, 20, 25, and 30%, respectively. According to the findings, increasing the amount of SF in the mixes caused a decrease in the slump flow, while simultaneously increasing the amount of time the mixtures spent flowing through the V-funnel [45]. In contrast, the research said that the V-duration funnel steadily reduces with an increase in SF concentration, suggesting that this improves the vertical passage of fragments by reducing air bubbles that obstruct the vertical flow of the paste [49]. However, research [29] found that 5% SF results in an L-Box test ratio of 0.78, which is beyond the acceptable limit for SCC as stipulated by technical criteria, as shown in Figure 3. Although research [50] found that blocking ratios up to 0.60 had a high passing ability, the blocking ratio value in the L box test must be greater than 0.8 for the SCC to have a satisfactory passing ability, according to the technical standard [51].

Figure 3.

V Funnel and L Box Ratio: Data Source [29].

3. Mechanical Properties

3.1. Compressive Strength (CS)

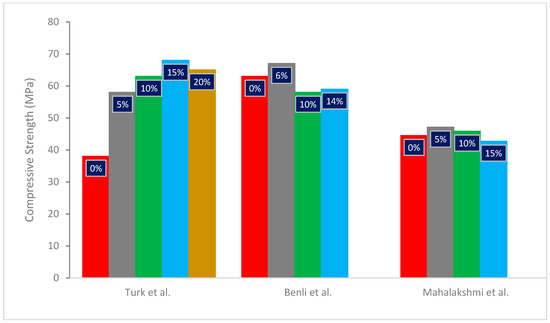

The compressive strength (CS) of the SCC with the SF substation is displayed in Figure 4. The substitution of SF enhanced the CS of concrete. The CS improved as the substitute percentages of SF enhanced, but the CS decreased when FA concentration increased. The SCC mixes with the best CS included 15% SF instead of cement. The results of tests on both freshly poured and cured concrete shown that it is feasible to create SCC using SF and FA with usable SCC qualities [26]. Over 130 days, SCC with 15% SF exhibited the greatest compressive and tensile capacity, measuring 73.87 and 5.489 MPa, respectively. When the FA/SF level in SCC mixes rose, the UPV values of SCC specimens with FA/SF generally decreased for all curing durations. However, at 28 and 130 days, normal concrete (NC) and SCC samples with SF exhibited the maximum UPV values, followed by SCC samples with FA [27]. The reinforced self-compacting concrete with recycled steel fiber of 0.75% has the greatest rate of increasing CS as a result of substituting cement with SF [43].

The research studied how SF and FA affected the concrete’s fresh and hardened qualities, alone and in combination. Results showed that SF increases elastic dynamic modulus, pulse velocity, and CS [52]. Due to the sluggish pozzolanic activity and diluting impact of FA, the CS of SCC comprising 25% FA and 0% SF, and is 35% lower than that of the reference. However, the inclusion of SF increased the CS of concrete made with cement [28].

Figure 4.

Compressive strength: Data Source [27,46,53].

Concretes containing SF perform better in hardened conditions than concretes with viscosity-modifying admixtures (VMA). Unusually, SF10 and VMA0.10 have almost the same mechanical attributes (compressive flexural and modulus of elasticity) [45]. The impact of several curing regimes, air, water, and steam, on the compressive characteristics of SCC with various ratios of SF and FA substitutions, were investigated. They emphasized that standard cured samples had the greatest CS results (cured in water for 28 days). The compressive capacity increased as the water curing period lengthened. Compression strength decreased during air curing, and air-cured specimens had the lowest strength values across all groups [26].

The compressive capacity of cement mortars including FA and SF during autoclaved curing was studied. They demonstrated that the FA blended cement mortar’s compressive capacity tended to be lower than the control mortar, owing to greater FA replacement. However, SF enhanced the compressive capacity of the binary mixed cement mortar, making it stronger than the reference sample. The increase in CS was due to the rise in SF. However, the opposite was true when it came to the rise in FA content. CS increased owing to a rise in the SF ratio; an increase in FA content had the opposite effect [53].

By adding SF to concrete, it becomes more durable and has a higher early compressive, tensile, and flexural strength. It also has a substantial influence on the elastic modulus [54]. Strength is one characteristic, particularly in design mixtures that include 30% CR substitution. When 30% of CR and 5% of SF were used, the minimum 28-day CS of 5.29 MPa was obtained. Additionally, model equations for predicting the compressive, flexural, and splitting tensile strengths were effectively created, and optimization was carried out [47].

The compressive capacity of all SCM samples, excluding 15% of the SF, tends to decline after 90 days of immersion, except for those samples that were aged for 90 days. Binary mixtures of v displayed superior sulfate resistance even when exposed for longer periods [55]. Similar findings to those found in this inquiry have been found in other investigations. Sasanipour and Aslani also noted a reduction in CS in SSC, with 50% cement substitution for SF [36].

Due to a poor interfacial transition zone, CS decreases when silica fumes are partially substituted for cement. The application of SF has a poor transition zone that harms the strength qualities of curing [56]. Higher CS than the strength of the control sample was produced by the application of SF. Increases in the amount of SF and the use of metakaolin, which account for up to 15% of the total cement mass, both boosted compressive strengths. The increased compressive and tensile capacity was achieved by employing the recommended optimal proportion of replacement, 15 % mixed pozzolan (7.5 % metakaolin and 7.5 % of SF) [29].

The CS and structural durability of concrete that is environmentally friendly, and environmentally friendly for construction, are only slightly impacted by the addition of 20% SF. The findings of this research show that using SF in lieu of cement, and adding steel fiber, resulted in a more durable and economically viable SCC [57].

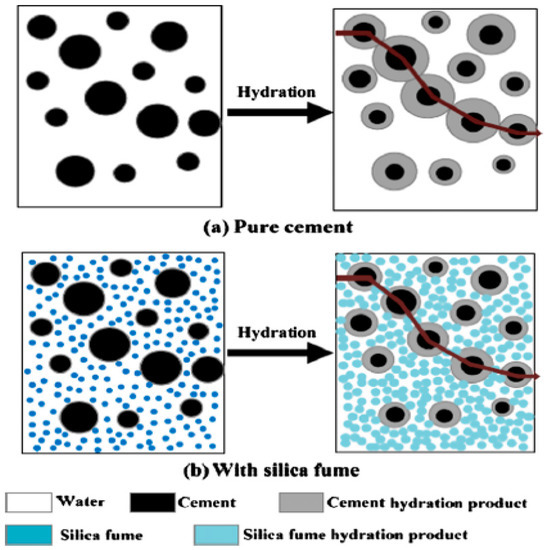

Figure 5 shows a schematic illustration of the solid phase percolation for pastes with and without SF. Figure 5a makes it abundantly evident that a greater hydration product is required for pure cement for the solid phase percolation to occur. However, the hydrated SF particles fill the gaps between the grains of Portland cement after a few minutes, precisely as is seen in Figure 5b for the paste containing SF. Numerous nucleation sites are produced when SF concentration rises. A high SF concentration causes the percolation threshold to occur sooner. When the amount of SF is higher, the cement and SF particles are closer together, causing the setting to happen more quickly. The summary of SCC performance with SF substitute is shown in Table 3.

Figure 5.

Paste with and without SF [58]: (Used as per Elsevier permission).

Table 3.

Summary of mechanical properties of SCC with substitution of SF.

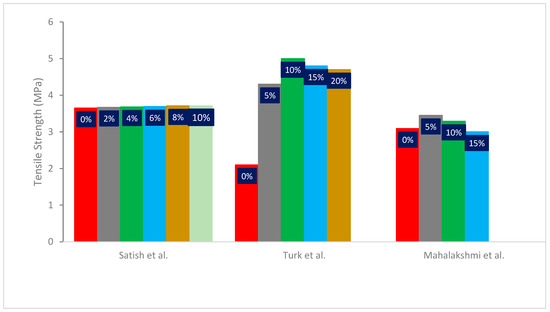

3.2. Tensile Strength (TS)

The tensile strength of SCC with a SF substation is displayed in Figure 6. As with the compressive capacity, it can be shown that SF replacement increased the flexural capacity of concrete. Due to pozzolanic and filling voids, the substitution of SF has improved the TS of the material. The TS increased gradually when FA and SF were substituted. The percentage of SF increased the Portland-fly ash-silica fume concrete mixture’s TS [60].

Figure 6.

Tensile Strength: Data Source [27,42,46].

For all curing regimens at the age of 28 days, binary mixtures of SF and ternary mixtures of SF and FA yielded the greatest tensile capacity. Binary blends of SF, except SF (14%), and ternary blends of FA (10%), and SF (6%), performed better for self-curing at the age of 180 days compared to other curing regimens [53]. The reinforced SSC with recycled steel fiber of 0.75% has the greatest rate of increasing compressive, tensile, and flexural capacity as a result of substituting cement with SF [43].

Askari et al. [61] examined the compressive, tensile capacity, fresh qualities, and mechanical characteristics of SCC incorporating FA and SF. The findings showed that between 28 and 120 days of curing, a large volume of FA content increases the CS. This result has demonstrated that FA’s pozzolanic activity has persisted throughout time, however, FA concentration increases as tensile strength declines. However, the tensile strength of SCC having a large volume FA is improved and maintained with a 10% SF substitution of cement [61]. In a similar study, with SF added at a constant rate of 10% and constant water to a binder ratio of 0.28, Yazici et al. [62] studied the impact of substitution of cement with class C FA at different substitute levels from 30 to 60% on the fresh assets, compressive, tensile capacity, modulus of elasticity, and durability aspects. They discovered that using class C FA in place of cement raised the compressive aspect. The results showed that increasing the SF content in SCC increased its overall tensile strength for the FA replacement levels [62]. At 28 days, the splitting tensile capacity of SCC improves from 4.84 to 5.86 MPa. The tensile capacity of concrete increased gradually when FA and SF were added to the concrete mixtures. The splitting tensile capacity is improved by the addition of 10% SF [28].

The splitting tensile capacity is improved by 27% with the addition of 5% SF to the reference concrete, and it lowers by 14% with the addition of 10% SF. Crumb rubber considerably lowers the concrete splitting tensile to roughly half of its control mixture [63]. The usage of metakaolin and SF had a large and modest impact on tensile strength, respectively. The increased compressive and tensile capacity was achieved by employing the recommended optimal proportion of replacement, 15% mixed pozzolan (7.5% metakaolin and 7.5% SF) [29]. The silicon carbide whiskers increased the cement-based materials’ tensile strength, and the ideal dose was 0.1% by weight [64].

Another similar study shows a 12% increase in tensile capacity compared to the reference sample, which included 10% SF and 1% steel fibers [65]. By adding SF to concrete, CS, splitting tensile strength, and resistance to freezing and thawing, are all increased [66]. The compressive and splitting tensile capacity were unchanged when brick debris made up to 25% of the sand. Therefore, using this replacement % in RCC is simple. However, the compressive and splitting tensile capacity was decreased by utilizing this replacement ratio [59].

While only SF was employed as the pozzolanic material, as opposed to FA, the CS, as well as TS, progressively rose [42]. The behavior of the tensile strength of concrete changes dramatically when SF or micro silica is substituted for M40 or M50 grade concrete by 0, 5, 7.5, 10, or 15%. Beyond 28 days, the maximum tensile capacity of concrete containing SF was achieved; after that point, it began to decline [67]. According to research, the M35 grade of concrete exhibits an amazing improvement in the tensile characteristics of concrete when SF is substituted by 0, 5, 10, 15, or 20. With split tensile strength, 10% was found to be the greatest improvement [68].

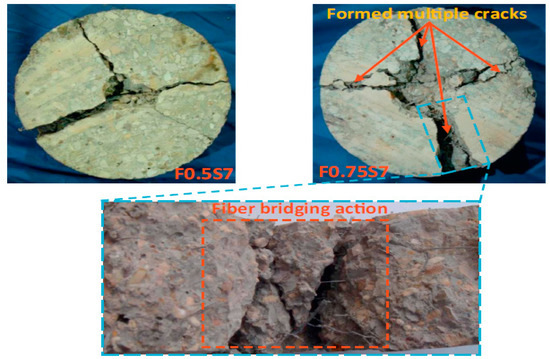

Figure 7 depicts the fracture patterns that developed on several test discs that were plain and reinforced with 0.75% recycled steel fiber. Due to enhancements at the interface of the aggregate-paste and fiber-matrix, and an improved fiber bridging action, the simultaneous use of SF and recycled steel fiber led to the formation of additional fractures on the specimens’ surfaces, as illustrated in Figure 7.

Figure 7.

Failure of sample: [43] (Used as per Elsevior permission).

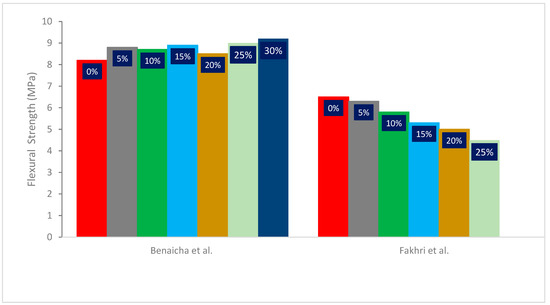

3.3. Flexural Strength (FS)

Figure 8 displays the SCC’s flexural strength (FS) with a SF substation. As with the CS, it can be shown that SF substitute enhanced the FS of concrete. The flexural toughness factors are increased by substituting cement with SF, and the specimens reinforced with recycled steel fiber at a rate of 0.5%, and the highest substitute ratio of cement with SF showed the greatest improvement (14%). Furthermore, assuming a consistent amount of SF in the substituted cement, adding recycled fiber lowers the flexural toughness indices [43]. The FS of mixes increased by around 24 to 50% when SF was increased from 0 to 25%. The enhanced pozzolanic activity as a result of the increased development of calcium silicate hydrate (C-S-H) gels is primarily responsible for the increase in strength that results from the inclusion of SF as a supplemental cementitious ingredient. On the other hand, since SF particles are smaller in size, more gaps are filled and the porosity on the surface junction of rubber and surrounding materials is reduced, which results in the strengthening of paste [44].

Figure 8.

Flexural strength: Data Source [44,45].

Binary blends of SF and ternary combinations of SF and FA produced the highest levels of flexural capacity for all treatment regimens at the age of 28 days. In comparison to other curing regimens, binary mixes of SF, other than SF14 and ternary blends of FA10SF6, performed better for self-curing (LPWC) at the age of 180 days [53].

The addition of SF to concrete increases the concrete’s toughness, while also delivering early high levels of compressive, tensile, and flexural strength. It also has a substantial influence on the elastic modulus. Additionally, SF renders concrete resistant to chemical assaults. Because of this, high-performance concrete with SF is preferred for parking decks, overpasses, and maritime constructions [54].

The FS of the SSC was decreased during the whole curing period when cement was partially substituted with SF. Due to a poor interfacial transition zone, the CS decreases when SF are partially substituted for cement. The application of SF has a poor transition zone that has a damaging impact on the strength qualities [56]. According to research, the compressive, flexural, and modulus of elasticity may all be increased by 10% of SF without negatively affecting any of the other properties by 29%, 22%, and 14%, respectively [69]. According to one study, using FA and SF increases concrete’s flexural capacity by 10%. The mixtures containing 5% of SF and 10% of FA had the best replacement percentage in terms of flexural capacity [70]. According to Fakhri et al. [71], adding rubber particles and SF to RCC at the same time boosts the concrete’s compressive and flexural capacity, decreases water absorption, and improves density [71].

4. Durability

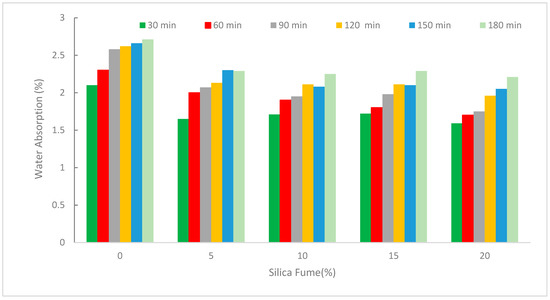

4.1. Water Absorption

High water absorption values may affect concrete durability because water allows the majority of very corrosive elements to penetrate the concrete. The water absorption is shown in the image with various SF replacement ratios. Due to pozzolanic reaction and micro-void filling, concrete’s water absorption reduced when SF was substituted. Figure 9 depicts the water absorption of SCC with SF.

Figure 9.

Water absorption: Data Source [29].

The specific surface was enhanced by growing the proportion of SF, which may help to reduce the amount of water that concretes absorb [29]. According to the study, SF samples absorb the least water when compared to samples made of FA and zeolite [72].

According to the study [73], pozzolanic materials boosted concrete density. Owing to the pozzolanic materials’ micro-filling properties, which fill the spaces between the components in concrete and create a more dense mixture, the density of the concrete is increased when using these materials [73]. Less water is absorbed when density increases.

However, the research found that the maximum water absorption occurred at higher doses (35% SF). Quick water absorption was seen, although it eventually subsided in the early days (1 day) [56]. Due to the existence of porous structures, concrete absorbs more water [74,75]. The lack of flowability, which required more energy for compaction and resulted in larger pores in the concrete, may be blamed for the increased water absorption at higher doses of SF.

4.2. Porosity and Sorptivity

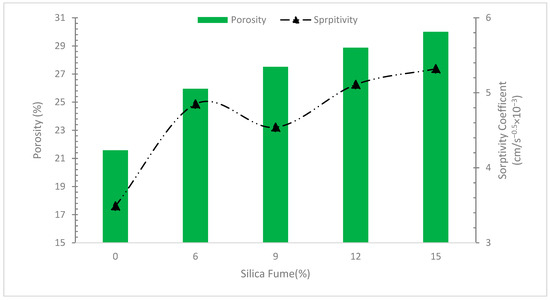

One of the often recognized extreme physical features of construction material is porosity, primarily because of its impact on crucial characteristics such as strength and durability. Figure 10 depicts the porosity and sorptivity with various SF replacement ratios. With the replacement of silica, concrete’s porosity and sorptivity increased. The greater water-to-binder ratio in binary mixes including SF, compared to other mixes and control specimens, may be the cause of the enhanced porosity [55].

Figure 10.

Porosity and sorptivity: Data Source [55].

Contrarily, several studies have shown that the replacement of pozzolanic material reduces the porosity of concrete because the pozzolanic reaction produces secondary cementitious materials (CSH), which enhance the mortar’s binding properties and result in a reduction in porosity [18]. Additionally, the micro-filling action of SF, which fills the gaps in aggregate, results in a dense mixture, reducing the penetrability of the concrete. The penetrability of the concrete is favorably impacted by the combined pozzolanic reaction and micro filling voids. The findings demonstrated that SF may reduce porosity and water absorption [36]. However, other research indicates that using more pozzolanic elements in concrete leads to larger voids since they are harder to work with due to a lack of flowability [76,77]. Concrete’s porosity often rises when there are more voids present.

4.3. Chloride Resistance

The most serious factor that has to be taken into account is chlorine assault on concrete’s long-term durability. About 40% of the failures of concrete structures are caused by chlorine assault. Because oxygen and water are present, chloride attack corrodes the steel, drastically reducing the structural capacity. When chloride ions came into contact with steel and nearby reactive materials, corrosion occurs. This causes a chemical process that yields hydrochloric acid (HCL). The HCL eats away at the steel reinforcing, causing the concrete structure to fracture, spall, and ultimately collapse [78]. The corrosion process is started by chloride ions entering deep sections via pores [72].

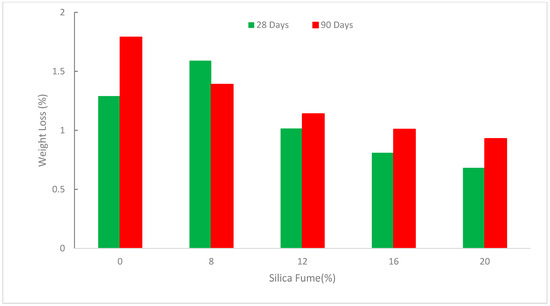

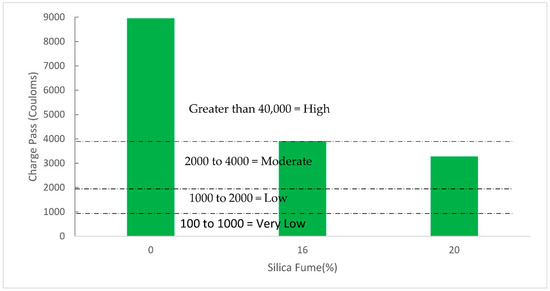

Figure 11 depicts how much weight concrete loses when exposed to chloride solution (NaCl). Loss of weight diminishes as the amount of SF replacement rises because SF improves the concrete’s pores, makes it denser, and makes it more resistant to chloride attack. According to research, adding 20% more SF to cement results in concrete that is far better resistant to chloride attack than conventional concrete because silica fume’s filler effects create small, discontinuous pore structures that improve microstructure [79].

Figure 11.

Weight loss due to NaCI: Data Source [80].

The charges that passed the SCC with varying amounts of SF are shown in Figure 12. Charges passed were shown to decrease as SF replacement increased. According to research, SF was utilized instead of some of the conventional cement in concrete samples to dramatically reduce the penetrability of chloride particles, which in turn reduced the rate of corrosion of the reinforcement [80].

Figure 12.

Charge pass: Data Source [80].

The use of FA and SF exposed to harsh maritime conditions greatly lessens the impact of chloride ions, according to the analysis of the findings of several research [81,82], while SF significantly reduces the level of chloride at various depths [47,48]. Additionally, further cementitious materials often lower the level of chloride at various depths. According to research [82], the addition of cement components enhances porosity and raises the quality of the microstructure. The size and connectivity of pores are both dramatically reduced by SF. As a result, it densifies the material’s microstructure and decreases chloride’s capacity to flow through it [72].

The pozzolanic activity and micro-filling of voids, which cause compact mass with reduced porosity, may be blamed for the lower chloride ion penetration with the SF substitute. The mortar’s porosity makes it easier for chloride ions to penetrate more deeply [83]. According to research, SF may significantly reduce and regulate the entry of chloride ions; the improvement in permeability on the surface brought on by the creation of dense C-S-H by SF may be the cause [43].

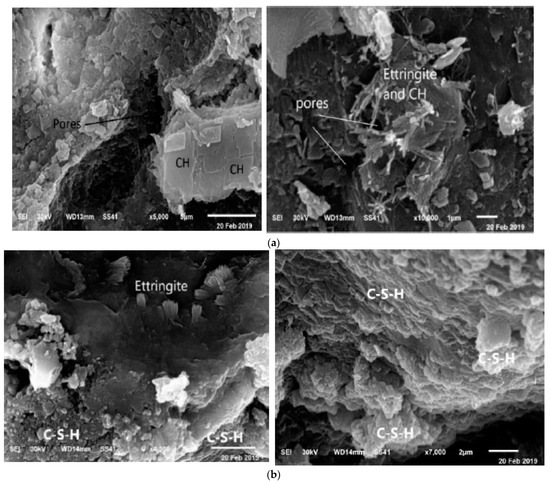

5. Scan Electronic Microscopy (SEM)

The most crucial component of concrete is the gap between cementitious and stone components, which also happens to be the weakest link in the chain and the key factor limiting strength and durability. The calcium silicate hydrate formed by the hydration process of the OPC nanostructure fills this space and boosts its strength and longevity. Due to its very large specific surface area, SF has a high degree of reactivity, which causes it to react with calcium hydroxide quickly and contributes to the creation of calcium silicate hydrate [84].

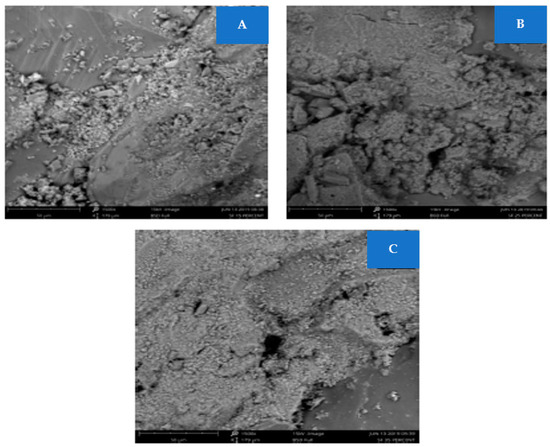

Figure 13 displays SEM micrographs of the hardened SSC partial replacement cement. Micro-clusters may be seen on the sample’s surface where cement has partially replaced 15% of the SF, but there are no significant surface voids. After curing, larger micro-clusters (lumps) and some deep spaces are present on the surface of the sample with a cement substitute of 25%. These lumps are a consequence of the concrete’s use of coarse aggregate. There are no visible lumps or micro-clusters on the surface of the specimens with cement substitute of 35% SF, but a large void can be seen. When the cementitious material has a poor interfacial interaction with the coarse aggregate, due to its uneven shape, voids are created that cause interstitials to develop during the curing process.

Figure 13.

Scan electronic microscopy (A): 15%, (B) 25%, and (C) 35% SF [56]: (Open Access Source).

Self-compacting concrete (SCC) mix had a significant number of voids and a poor paste-aggregate interface zone (ITZ). However, a solid structure and comparatively excellent paste-aggregate interface zone (ITZ) emerged when SF was substituted with 16%, as seen in Figure 14. This microstructure was distinguished by scattered, compact aggregates with previously employed auxiliary components that helped reduce further tiny holes. The material behavior of mixtures has an influence on the main activities that modify the characteristics of concrete. The improvement of the microstructure of the solidified matrix and, by extension, the improvement of the paste-aggregate interface zone, determines the mechanical characteristics and, therefore, the durability of concrete (ITZ) [80]. Due to its pozzolanic reactions, which result in finer hydration reactions and densification in the microstructure, cement content has been shown to enhance the compressive capacity and decrease the porosity of solidified concrete when the extra material was replaced. Research also concluded that the SEM pictures showed that the relationship between the sand particles and the calcium carbonate generated by microorganisms in the gaps was the crucial element [85]. It was discovered that carbon nanotubes reinforce the interfacial transition zone and bridge over concrete microcracks to slow the spread of those fractures [86].

Figure 14.

Scan electronic microscopy: (a) control and (b) 16% SF [80]: (Open Access Source).

6. Conclusions

The paper compiles data on SSCs with SF substations. Fresh properties, mechanical characteristics, durability aspects, and microstructure analysis were reviewed through scan electronic microscopy (SEM) review. The following conclusion can be drawn based on analysis:

- The flowability and passing ability decreased with the substitution of SF due to its finesse, which required more cement paste. Although most research observed that all the mixes fall within the limit of SCC, most research recommends a higher dose of plasticizer.

- Strength characteristics, such as the compressive, tensile, and flexural capacity of SCC enhanced with the substitution of SF due to filling voids and pozzolanic reaction. However, a higher dose of SF adversely affects strength properties due to the lack of flowability and dilution effect. Different researchers recommend different optimum doses, due to changes in source and mix design. However, the typical optimum dose of SF varies from 10 to 15%.

- Increased durability aspects, such as porosity, water absorption, and chloride resistance, were also noted; however, less data is accessible in this area.

- The microstructure becomes denser, and the CS and durability performance are improved, according to scanning electron microscopy evidence that SF particles serve as C-S-H phase nucleation and crystallization sites.

The overall review suggests that SF can be used up to 15% as a cement substitute without any negative effect on strength and durability properties.

7. Recommendations

Various research focuses on SF as a cement alternative in SCC, and concludes that SF might be used as a binder in concrete. However, there are still some areas that are not clear and this review recommends exploring them further before they are used. Namely:

- Durability aspects should be explored in more detail.

- A detailed study on microstructure analysis, such as thermogravimetric and Fourier-Transform Infrared, should be investigated.

- No or little information is available on the thermal properties of SCC with SF.

- Cost benefits analysis should be performed.

- The effect of curing temperature should be explored.

Author Contributions

Writing—original draft preparation, J.A.; Conceptualization, J.A., A.M. and S.R.A.; methodology, J.A.; software, A.H.; validation, A.F.D., A.M. and M.M.A.; formal analysis, writing—review and editing, A.F.D. and A.M.; visualization, A.F.D. and A.H. and M.M.A.; supervision, S.R.A. and M.M.A.; project administration, J.A.; funding acquisition, A.F.D. and S.R.A. All authors have read and agreed to the published version of the manuscript.

Funding

The authors would like to thank the Deanship of Scientific Research at Umm Al-Qura University for funding this work by Grant Code: (22UQU4250045DSR06).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

All the data are available in manuscript.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Ostrowski, K.; Sadowski, Ł.; Stefaniuk, D.; Wałach, D.; Gawenda, T.; Oleksik, K.; Usydus, I. The Effect of the Morphology of Coarse Aggregate on the Properties of Self-Compacting High-Performance Fibre-Reinforced Concrete. Materials 2018, 11, 1372. [Google Scholar] [CrossRef] [PubMed]

- Grdic, Z.J.; Toplicic-Curcic, G.A.; Despotovic, I.M.; Ristic, N.S. Properties of Self-Compacting Concrete Prepared with Coarse Recycled Concrete Aggregate. Constr. Build. Mater. 2010, 24, 1129–1133. [Google Scholar] [CrossRef]

- Okamura, H. Self-Compacting High-Performance Concrete. Concr. Int. 1997, 19, 50–54. [Google Scholar]

- Ahmad, J.; Martínez-García, R.; De-Prado-Gil, J.; Irshad, K.; El-Shorbagy, M.A.; Fediuk, R.; Vatin, N.I. Concrete with Partial Substitution of Waste Glass and Recycled Concrete Aggregate. Materials 2022, 15, 430. [Google Scholar]

- Al-Bayati, M.A.; Abdulrahman, M.B.; Alzeebaree, R.; Arbili, M.M. The Effect of Materials and Curing System on the Behavior of Self-Compacting Geopolymer Concrete. J. Mech. Behav. Mater. 2022, 31, 710–718. [Google Scholar] [CrossRef]

- Van Lam, T.; Bulgakov, B.; Bazhenov, Y.; Aleksandrova, O.; Anh, P.N. Effect of Rice Husk Ash on Hydrotechnical Concrete Behavior. IOP Conf. Ser. Mater. Sci. Eng. 2018, 365, 032007. [Google Scholar] [CrossRef]

- Hu, Z.; Shi, T.; Cen, M.; Wang, J.; Zhao, X.; Zeng, C.; Zhou, Y.; Fan, Y.; Liu, Y.; Zhao, Z. Research Progress on Lunar and Martian Concrete. Constr. Build. Mater. 2022, 343, 128117. [Google Scholar] [CrossRef]

- Agrawal, D.; Hinge, P.; Waghe, U.P.; Raut, S.P. Utilization of Industrial Waste in Construction Material–A Review. Int. J. Innov. Res. Sci. Eng. Technol. 2014, 3, 8390–8397. [Google Scholar]

- Saikia, N.; de Brito, J. Use of Industrial Waste and Municipality Solid Waste as Aggregate, Filler or Fiber in Cement Mortar and Concrete. Adv. Mater. Sci. Res. 2009, 3, 65–116. [Google Scholar]

- Dolamary, P.Y.; Dilshad, J.A.F.; Arbili, M.M.; Karpuzcu, M. Validation of Feret Regression Model for Fly Ash Based Geopolymer Concrete. Polytech. J. 2018, 8, 173–189. [Google Scholar]

- Althoey, F.; Farnam, Y. The Effect of Using Supplementary Cementitious Materials on Damage Development Due to the Formation of a Chemical Phase Change in Cementitious Materials Exposed to Sodium Chloride. Constr. Build. Mater. 2019, 210, 685–695. [Google Scholar] [CrossRef]

- Mermerdaş, K.; Arbili, M.M. Explicit Formulation of Drying and Autogenous Shrinkage of Concretes with Binary and Ternary Blends of Silica Fume and Fly Ash. Constr. Build. Mater. 2015, 94, 371–379. [Google Scholar] [CrossRef]

- Smirnova, O. Compatibility of Shungisite Microfillers with Polycarboxylate Admixtures in Cement Compositions. ARPN J. Eng. Appl. Sci. 2019, 14, 600–610. [Google Scholar]

- Ahmad, J.; Majdi, A.; Deifalla, A.F.; Kahla, N.B.; El-shorbagy, M.A. Concrete Reinforced with Sisal Fibers (SSF): Overview on Mechanical and Physical Properties. Crystals 2022, 12, 952. [Google Scholar] [CrossRef]

- Handayani, L.; Aprilia, S.; Abdullah, A.; Rahmawati, C.; Abdullah, M.M.A.B.; Aziz, I.H.; Azimi, E.A. Synthesis of Sodium Silicate from Rice Husk Ash as an Activator to Produce Epoxy-Geopolymer Cement. J. Phys. Conf. Ser. 2021, 1845, 012072. [Google Scholar] [CrossRef]

- Yang, K.-H.; Jung, Y.-B.; Cho, M.-S.; Tae, S.-H. Effect of Supplementary Cementitious Materials on Reduction of CO2 Emissions from Concrete. J. Clean. Prod. 2015, 103, 774–783. [Google Scholar] [CrossRef]

- World Cement Association. Oyak Cement. Available online: https://www.globalcement.com/news/item/14248-oyak-cement-publishes-integrated-report-2021 (accessed on 14 August 2022).

- Ahmad, J.; Zaid, O.; Shahzaib, M.; Abdullah, M.U.; Ullah, A.; Ullah, R. Mechanical Properties of Sustainable Concrete Modified by Adding Marble Slurry as Cement Substitution. AIMS Mater. Sci. 2021, 8, 343–358. [Google Scholar] [CrossRef]

- Mirza, J.; Riaz, M.; Naseer, A.; Rehman, F.; Khan, A.N.; Ali, Q. Pakistani Bentonite in Mortars and Concrete as Low Cost Construction Material. Appl. Clay Sci. 2009, 45, 220–226. [Google Scholar] [CrossRef]

- Shi, T.; Liu, Y.; Zhang, Y.; Lan, Y.; Zhao, Q.; Zhao, Y.; Wang, H. Calcined Attapulgite Clay as Supplementary Cementing Material: Thermal Treatment, Hydration Activity and Mechanical Properties. Int. J. Concr. Struct. Mater. 2022, 16, 10. [Google Scholar] [CrossRef]

- Boukendakdji, O.; Kadri, E.-H.; Kenai, S. Effects of Granulated Blast Furnace Slag and Superplasticizer Type on the Fresh Properties and Compressive Strength of Self-Compacting Concrete. Cem. Concr. Compos. 2012, 34, 583–590. [Google Scholar] [CrossRef]

- Valcuende, M.; Marco, E.; Parra, C.; Serna, P. Influence of Limestone Filler and Viscosity-Modifying Admixture on the Shrinkage of Self-Compacting Concrete. Cem. Concr. Res. 2012, 42, 583–592. [Google Scholar] [CrossRef]

- Ahmad, J.; Aslam, F.; Martinez-Garcia, R.; Ouni, M.H.E.; Khedher, K.M. Performance of Sustainable Self-Compacting Fiber Reinforced Concrete with Substitution of Marble Waste (MW) and Coconut Fibers (CFs). Sci. Rep. 2021, 11, 23184. [Google Scholar] [CrossRef] [PubMed]

- Siddique, R. Properties of Self-Compacting Concrete Containing Class F Fly Ash. Mater. Des. 2011, 32, 1501–1507. [Google Scholar] [CrossRef]

- Felekoğlu, B.; Tosun, K.; Baradan, B.; Altun, A.; Uyulgan, B. The Effect of Fly Ash and Limestone Fillers on the Viscosity and Compressive Strength of Self-Compacting Repair Mortars. Cem. Concr. Res. 2006, 36, 1719–1726. [Google Scholar] [CrossRef]

- Bingöl, A.F.; Tohumcu, İ. Effects of Different Curing Regimes on the Compressive Strength Properties of Self Compacting Concrete Incorporating Fly Ash and Silica Fume. Mater. Des. 2013, 51, 12–18. [Google Scholar] [CrossRef]

- Turk, K.; Turgut, P.; Karatas, M.; Benli, A. Mechanical Properties of Selfcompacting Concrete with Silica Fume/Fly Ash. In Proceedings of the 9th International Congress on Advances in Civil Engineering, Ghent, Belgium, 2–3 August 2010; pp. 27–30. [Google Scholar]

- Falmata, A.M.; Sulaiman, A.; Mohamed, R.N.; Shettima, A.U. Mechanical Properties of Self-Compacting High-Performance Concrete with Fly Ash and Silica Fume. SN Appl. Sci. 2020, 2, 33. [Google Scholar] [CrossRef]

- Sharbatdar, M.K.; Abbasi, M.; Fakharian, P. Improving the Properties of Self-Compacted Concrete with Using Combined Silica Fume and Metakaolin. Period. Polytech. Civ. Eng. 2020, 64, 535–544. [Google Scholar] [CrossRef]

- Siddique, R.; Jameel, A.; Singh, M.; Barnat-Hunek, D.; Aït-Mokhtar, A.; Belarbi, R.; Rajor, A. Effect of Bacteria on Strength, Permeation Characteristics and Micro-Structure of Silica Fume Concrete. Constr. Build. Mater. 2017, 142, 92–100. [Google Scholar] [CrossRef]

- Jena, S.; Panigrahi, R. Performance Evaluation of Sustainable Geopolymer Concrete Produced from Ferrochrome Slag and Silica Fume. Eur. J. Environ. Civ. Eng. 2022, 26, 5204–5220. [Google Scholar] [CrossRef]

- Ardalan, R.B.; Joshaghani, A.; Hooton, R.D. Workability Retention and Compressive Strength of Self-Compacting Concrete Incorporating Pumice Powder and Silica Fume. Constr. Build. Mater. 2017, 134, 116–122. [Google Scholar] [CrossRef]

- Bernal, J.; Reyes, E.; Massana, J.; León, N.; Sánchez, E. Fresh and Mechanical Behavior of a Self-Compacting Concrete with Additions of Nano-Silica, Silica Fume and Ternary Mixtures. Constr. Build. Mater. 2018, 160, 196–210. [Google Scholar] [CrossRef]

- Ghoddousi, P.; Saadabadi, L.A. Study on Hydration Products by Electrical Resistivity for Self-Compacting Concrete with Silica Fume and Metakaolin. Constr. Build. Mater. 2017, 154, 219–228. [Google Scholar] [CrossRef]

- Leung, H.Y.; Kim, J.; Nadeem, A.; Jaganathan, J.; Anwar, M.P. Sorptivity of Self-Compacting Concrete Containing Fly Ash and Silica Fume. Constr. Build. Mater. 2016, 113, 369–375. [Google Scholar] [CrossRef]

- Sasanipour, H.; Aslani, F.; Taherinezhad, J. Effect of Silica Fume on Durability of Self-Compacting Concrete Made with Waste Recycled Concrete Aggregates. Constr. Build. Mater. 2019, 227, 116598. [Google Scholar] [CrossRef]

- Zarnaghi, V.N.; Fouroghi-Asl, A.; Nourani, V.; Ma, H. On the Pore Structures of Lightweight Self-Compacting Concrete Containing Silica Fume. Constr. Build. Mater. 2018, 193, 557–564. [Google Scholar] [CrossRef]

- EFNARC, S. Guidelines for Self-Compacting Concrete. Lond. UK Assoc. House 2002, 32, 34. [Google Scholar]

- Turk, K. Viscosity and Hardened Properties of Self-Compacting Mortars with Binary and Ternary Cementitious Blends of Fly Ash and Silica Fume. Constr. Build. Mater. 2012, 37, 326–334. [Google Scholar] [CrossRef]

- Xu, Y.; Chung, D.D.L. Improving the Workability and Strength of Silica Fume Concrete by Using Silane-Treated Silica Fume. Cem. Concr. Res. 1999, 29, 451–453. [Google Scholar] [CrossRef]

- Erdoğdu, Ş.; Arslantürk, C.; Kurbetci, Ş. Influence of Fly Ash and Silica Fume on the Consistency Retention and Compressive Strength of Concrete Subjected to Prolonged Agitating. Constr. Build. Mater. 2011, 25, 1277–1281. [Google Scholar] [CrossRef]

- Satish, K.; Kumar, S.; Rai, B. Self Compacting Concrete Using Fly Ash and Silica Fumes as Pozzolanic Material. J. Eng. Technol. 2017, 6, 394–407. [Google Scholar]

- Mastali, M.; Dalvand, A. Use of Silica Fume and Recycled Steel Fibers in Self-Compacting Concrete (SCC). Constr. Build. Mater. 2016, 125, 196–209. [Google Scholar] [CrossRef]

- Fakhri, M.; Yousefian, F.; Amoosoltani, E.; Aliha, M.R.M.; Berto, F. Combined Effects of Recycled Crumb Rubber and Silica Fume on Mechanical Properties and Mode I Fracture Toughness of Self-compacting Concrete. Fatigue Fract. Eng. Mater. Struct. 2021, 44, 2659–2673. [Google Scholar] [CrossRef]

- Benaicha, M.; Roguiez, X.; Jalbaud, O.; Burtschell, Y.; Alaoui, A.H. Influence of Silica Fume and Viscosity Modifying Agent on the Mechanical and Rheological Behavior of Self Compacting Concrete. Constr. Build. Mater. 2015, 84, 103–110. [Google Scholar] [CrossRef]

- Mahalakshmi, S.H.V.; Khed, V.C. Experimental Study on M-Sand in Self-Compacting Concrete with and without Silica Fume. Mater. Today Proc. 2020, 27, 1061–1065. [Google Scholar] [CrossRef]

- Alaloul, W.S.; Musarat, M.A.; Haruna, S.; Law, K.; Tayeh, B.A.; Rafiq, W.; Ayub, S. Mechanical Properties of Silica Fume Modified High-Volume Fly Ash Rubberized Self-Compacting Concrete. Sustainability 2021, 13, 5571. [Google Scholar] [CrossRef]

- Rahmani, Y.; Sohrabi, M.R.; Askari, A. Mechanical Properties of Rubberized Self Compacting Concrete Containing Silica Fume. Adv. Mater. Res. 2011, 261, 441–445. [Google Scholar] [CrossRef]

- Arshad, M.T.; Ahmad, S.; Khitab, A.; Hanif, A. Synergistic Use of Fly Ash and Silica Fume to Produce High-Strength Self-Compacting Cementitious Composites. Crystals 2021, 11, 915. [Google Scholar] [CrossRef]

- Hamzah, A.F.; Ibrahim, M.H.W.; Jamaluddin, N.; Jaya, R.P.; Arshad, M.F.; Abidin, N.E.Z. Fresh Characteristic and Mechanical Compressive Strength Development of Self-Compacting Concrete Integrating Coal Bottom Ash as Partial Fine Aggregates Replacement. Int. J. Mech. Mechatron. Eng. 2015, 15, 61–67. [Google Scholar]

- Iqbal, S.; Ali, A.; Holschemacher, K.; Ribakov, Y.; Bier, T.A. Effect of Fly Ash on Properties of Self-Compacting High Strength Lightweight Concrete. Period. Polytech. Civ. Eng. 2017, 61, 81–87. [Google Scholar] [CrossRef]

- Safiuddin, M.; Zain, M.F.M. Effects of Silica Fume and Fly Ash on the Properties of High Performance Concrete. In Proceedings of the Annual Conference on Canadian Society for Civil Engineering, Toronto, ON, Canada, 2–4 June 2005. [Google Scholar]

- Benli, A.; Karataş, M.; Bakir, Y. An Experimental Study of Different Curing Regimes on the Mechanical Properties and Sorptivity of Self-Compacting Mortars with Fly Ash and Silica Fume. Constr. Build. Mater. 2017, 144, 552–562. [Google Scholar] [CrossRef]

- Siddique, R. Utilization of Silica Fume in Concrete: Review of Hardened Properties. Resour. Conserv. Recycl. 2011, 55, 923–932. [Google Scholar] [CrossRef]

- Benli, A.; Karataş, M.; Gurses, E. Effect of Sea Water and MgSO4 Solution on the Mechanical Properties and Durability of Self-Compacting Mortars with Fly Ash/Silica Fume. Constr. Build. Mater. 2017, 146, 464–474. [Google Scholar] [CrossRef]

- Ofuyatan, M.O.; Adeniyi, A.G.; Ighalo, J.O. Evaluation of Fresh and Hardened Properties of Blended Silica Fume Self-Compacting Concrete (SCC). Res. Eng. Struct. Mater. 2021, 7, 211–223. [Google Scholar] [CrossRef]

- Saba, A.M.; Khan, A.H.; Akhtar, M.N.; Khan, N.A.; Koloor, S.S.R.; Petrů, M.; Radwan, N. Strength and Flexural Behavior of Steel Fiber and Silica Fume Incorporated Self-Compacting Concrete. J. Mater. Res. Technol. 2021, 12, 1380–1390. [Google Scholar] [CrossRef]

- Zhang, W.; Zhang, Y.; Liu, L.; Zhang, G.; Liu, Z. Investigation of the Influence of Curing Temperature and Silica Fume Content on Setting and Hardening Process of the Blended Cement Paste by an Improved Ultrasonic Apparatus. Constr. Build. Mater. 2012, 33, 32–40. [Google Scholar] [CrossRef]

- Tavakoli, D.; Fakharian, P.; de Brito, J. Mechanical Properties of Roller-Compacted Concrete Pavement Containing Recycled Brick Aggregates and Silica Fume. Road Mater. Pavement Des. 2022, 23, 1793–1814. [Google Scholar] [CrossRef]

- Wu, W.; Wang, R.; Zhu, C.; Meng, Q. The Effect of Fly Ash and Silica Fume on Mechanical Properties and Durability of Coral Aggregate Concrete. Constr. Build. Mater. 2018, 185, 69–78. [Google Scholar] [CrossRef]

- Askari, A.; Sohrabi, M.R.; Rahmani, Y. An Investigation into Mechanical Properties of Self Compacting Concrete Incorporating Fly Ash and Silica Fume at Different Ages of Curing. Adv. Mater. Res. 2011, 261, 3–7. [Google Scholar] [CrossRef]

- Yazıcı, H. The Effect of Silica Fume and High-Volume Class C Fly Ash on Mechanical Properties, Chloride Penetration and Freeze–Thaw Resistance of Self-Compacting Concrete. Constr. Build. Mater. 2008, 22, 456–462. [Google Scholar] [CrossRef]

- Mohammed, B.S.; Adamu, M. Mechanical Performance of Roller Compacted Concrete Pavement Containing Crumb Rubber and Nano Silica. Constr. Build. Mater. 2018, 159, 234–251. [Google Scholar] [CrossRef]

- Shi, T.; Lan, Y.; Hu, Z.; Wang, H.; Xu, J.; Zheng, B. Tensile and Fracture Properties of Silicon Carbide Whisker-Modified Cement-Based Materials. Int. J. Concr. Struct. Mater. 2022, 16, 2. [Google Scholar] [CrossRef]

- Tabatabaeian, M.; Khaloo, A.; Joshaghani, A.; Hajibandeh, E. Experimental Investigation on Effects of Hybrid Fibers on Rheological, Mechanical, and Durability Properties of High-Strength SCC. Constr. Build. Mater. 2017, 147, 497–509. [Google Scholar] [CrossRef]

- Bhanja, S.; Sengupta, B. Influence of Silica Fume on the Tensile Strength of Concrete. Cem. Concr. Res. 2005, 35, 743–747. [Google Scholar] [CrossRef]

- Hussain, S.T.; Sastry, K. Study of Strength Properties of Concrete by Using Micro Silica and Nano Silica. Int. J. Res. Eng. Technol. 2014, 3, 103–108. [Google Scholar]

- Guleria, A.N.; Salhotra, S. Effects of Silica Fume (Micro Silica or Nano Silica) on Mechanical Properties of Concrete: A Review. Int. J. Civ. Eng. Technol. 2016, 7, 345–357. [Google Scholar]

- Hassani, A.; Arjmandi, M. Enhancement of Concrete Properties for Pavement Slabs Using Waste Metal Drillings and Silica Fume. Waste Manag. Res. 2010, 28, 56–63. [Google Scholar] [CrossRef]

- Yener, E.; Hinislioğlu, S. The Effects of Silica Fume and Fly Ash on the Scaling Resistance and Flexural Strength of Pavement Concretes. Road Mater. Pavement Des. 2011, 12, 177–194. [Google Scholar] [CrossRef]

- Fakhri, M. The Effect of Waste Rubber Particles and Silica Fume on the Mechanical Properties of Roller Compacted Concrete Pavement. J. Clean. Prod. 2016, 129, 521–530. [Google Scholar] [CrossRef]

- Sabet, F.A.; Libre, N.A.; Shekarchi, M. Mechanical and Durability Properties of Self Consolidating High Performance Concrete Incorporating Natural Zeolite, Silica Fume and Fly Ash. Constr. Build. Mater. 2013, 44, 175–184. [Google Scholar] [CrossRef]

- Ahmad, J.; Majdi, A.; Babeker Elhag, A.; Deifalla, A.F.; Soomro, M.; Isleem, H.F.; Qaidi, S. A Step towards Sustainable Concrete with Substitution of Plastic Waste in Concrete: Overview on Mechanical, Durability and Microstructure Analysis. Crystals 2022, 12, 944. [Google Scholar] [CrossRef]

- Ahmad, J.; Majdi, A.; Al-Fakih, A.; Deifalla, A.F.; Althoey, F.; El Ouni, M.H.; El-Shorbagy, M.A. Mechanical and Durability Performance of Coconut Fiber Reinforced Concrete: A State-of-the-Art Review. Materials 2022, 15, 3601. [Google Scholar] [CrossRef] [PubMed]

- Ahmad, J.; Majdi, A.; Deifalla, A.F.; Isleem, H.F.; Rahmawati, C. Concrete Made with Partially Substitutions of Copper Slag (CPS): State of the Art Review. Materials 2022, 15, 5196. [Google Scholar] [CrossRef] [PubMed]

- Ahmad, J.; Martínez-García, R.; Szelag, M.; de-Prado-Gil, J.; Marzouki, R.; Alqurashi, M.; Hussein, E.E. Effects of Steel Fibers (SF) and Ground Granulated Blast Furnace Slag (GGBS) on Recycled Aggregate Concrete. Materials 2021, 14, 7497. [Google Scholar] [CrossRef] [PubMed]

- Ahmad, J.; Kontoleon, K.J.; Majdi, A.; Naqash, M.T.; Deifalla, A.F.; Ben Kahla, N.; Isleem, H.F.; Qaidi, S. A Comprehensive Review on the Ground Granulated Blast Furnace Slag (GGBS) in Concrete Production. Sustainability 2022, 14, 8783. [Google Scholar] [CrossRef]

- Shi, X.; Xie, N.; Fortune, K.; Gong, J. Durability of Steel Reinforced Concrete in Chloride Environments: An Overview. Constr. Build. Mater. 2012, 30, 125–138. [Google Scholar] [CrossRef]

- Karthick, M.; Nirmalkumar, K. Durability Properties of High Strength Self Compacting Concrete Using Silica Fume and Quarry Dust. Int. J. Sci. Eng. Appl. Sci. 2016, 2, 389–395. [Google Scholar]

- Taha, T.E.; Tahwia, A.M.; Abdelraheem, A.H. Durability Performance of Silica Fume Self-Compacting Concrete. Eng. Res. J. 2019, 164, 193–213. [Google Scholar]

- Ghods, P.; Chini, M.; Alizadeh, R.; Hoseini, M.; Shekarchi, M.; Ramezanianpour, A.A. The Effect of Different Exposure Conditions on the Chloride Diffusion into Concrete in the Persian Gulf Region; University of Tehran: Tehran, Iran, 2005. [Google Scholar]

- Samimi, K.; Kamali-Bernard, S.; Maghsoudi, A.A.; Maghsoudi, M.; Siad, H. Influence of Pumice and Zeolite on Compressive Strength, Transport Properties and Resistance to Chloride Penetration of High Strength Self-Compacting Concretes. Constr. Build. Mater. 2017, 151, 292–311. [Google Scholar] [CrossRef]

- Kapoor, K.; Singh, S.P.; Singh, B. Durability of Self-Compacting Concrete Made with Recycled Concrete Aggregates and Mineral Admixtures. Constr. Build. Mater. 2016, 128, 67–76. [Google Scholar] [CrossRef]

- Caetano, H.; Ferreira, G.; Rodrigues, J.P.C.; Pimienta, P. Effect of the High Temperatures on the Microstructure and Compressive Strength of High Strength Fibre Concretes. Constr. Build. Mater. 2019, 199, 717–736. [Google Scholar] [CrossRef]

- Yuan, J.; Lei, D.; Shan, Y.; Tong, H.; Fang, X.; Zhao, J. Direct Shear Creep Characteristics of Sand Treated with Microbial-Induced Calcite Precipitation. Int. J. Civ. Eng. 2022, 20, 763–777. [Google Scholar] [CrossRef]

- Lan, Y.; Zheng, B.; Shi, T.; Ma, C.; Liu, Y.; Zhao, Z. Crack Resistance Properties of Carbon Nanotube-Modified Concrete. Mag. Concr. Res. 2022, 21, 227. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).