Circular Economy Initiatives: Strategic Implications, Resource Management, and Entrepreneurial Innovation in a Brazilian Craft Beer Ecosystem during the COVID Era

Abstract

:1. Introduction

2. Theoretical Background

2.1. Keystones of the Circular Economy

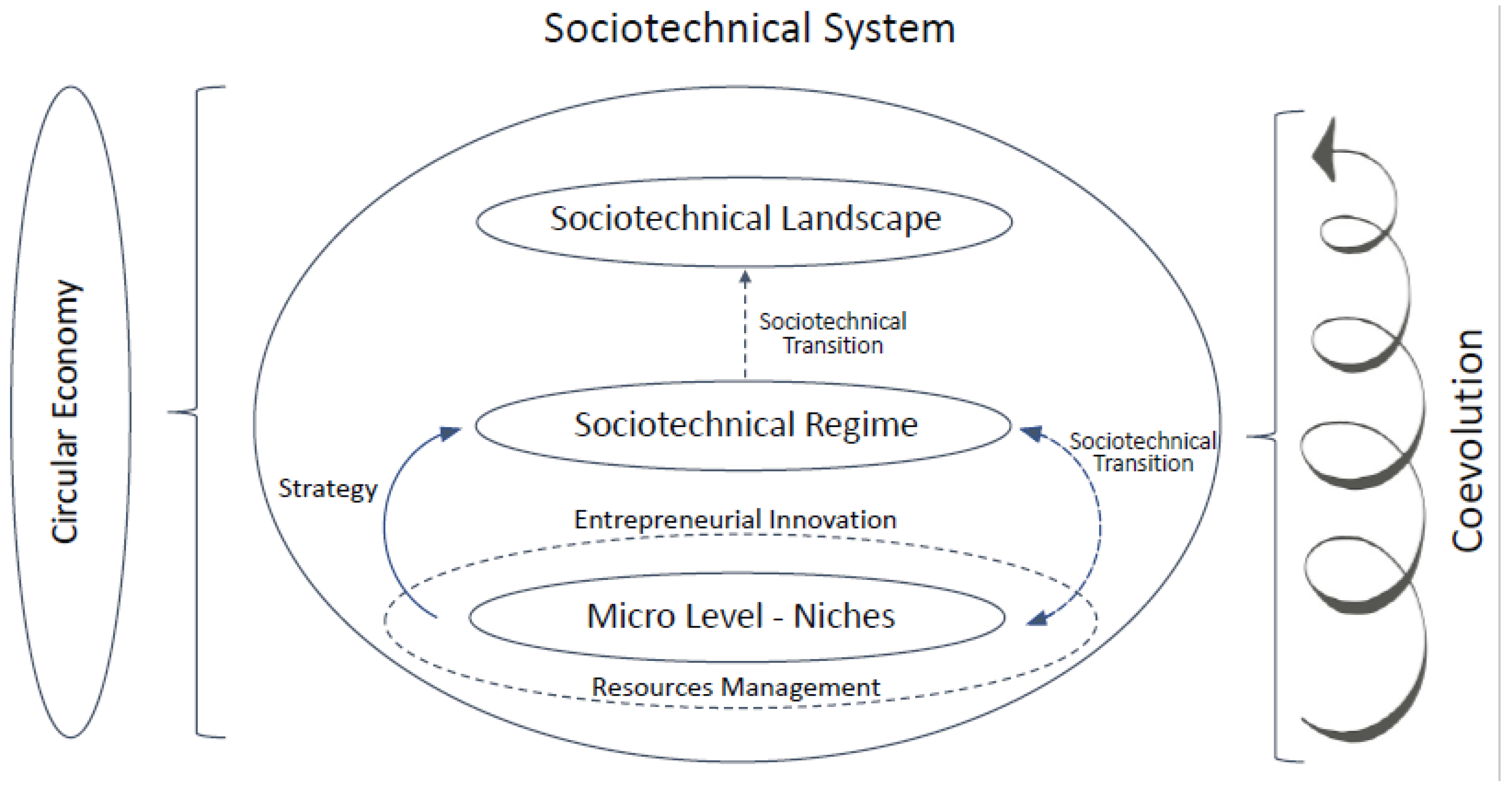

2.2. The Confluence of Sociotechnical Systems, the Multilevel Approach, and Coevolution

2.3. Strategy as the Propellant of Action

2.4. Strategic Relevance of Resource Management

2.5. Entrepreneurial Innovation

3. Data and Methods

4. Results

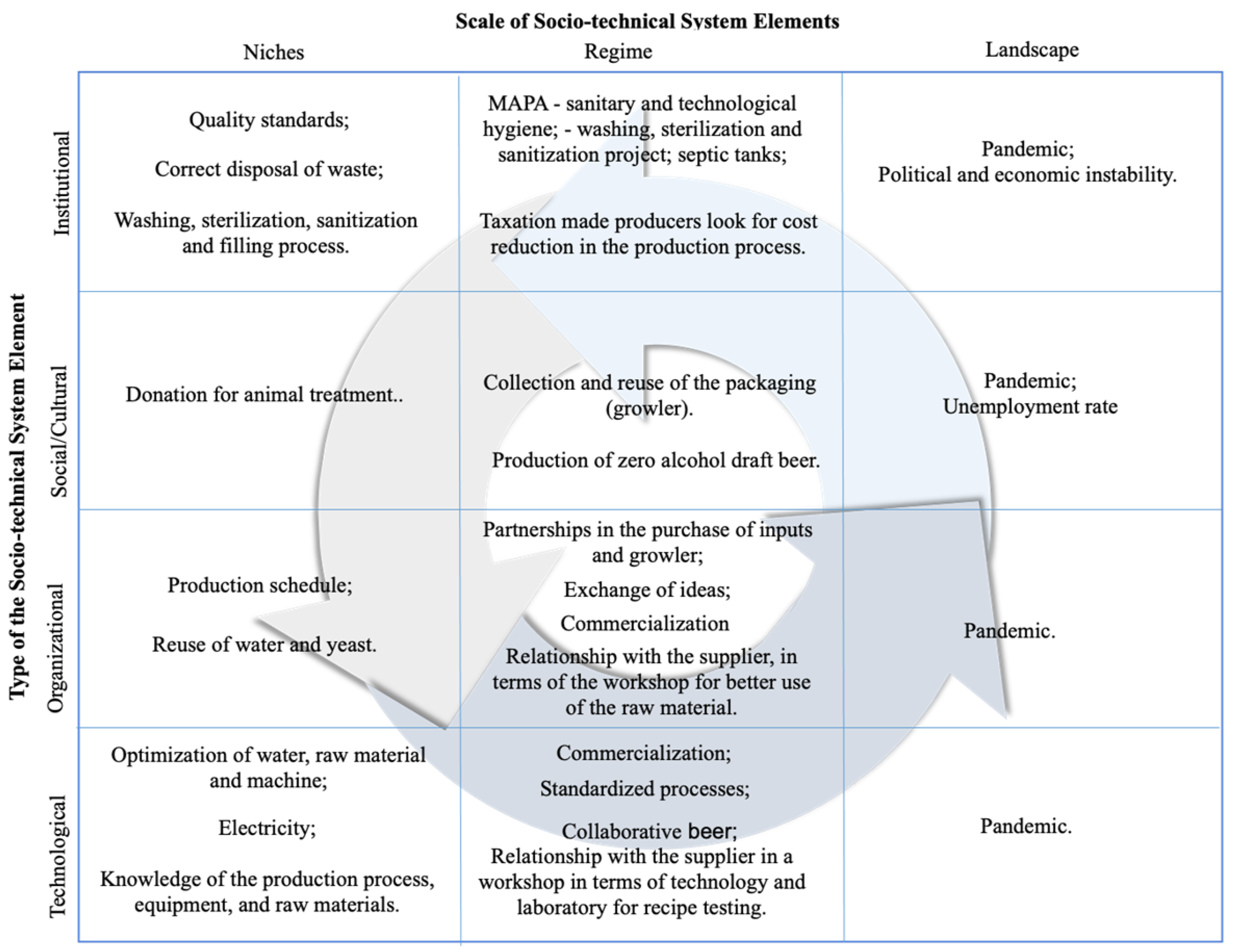

4.1. Coevolution of the Sociotechnical System

4.2. Circular Economy, Strategic Implications, and Resource Management

4.3. Comparison to Other Studies

5. Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ministério Da Agricultura, Pecuária e Abastecimento, MAPA (Ministry of Agriculture, Livestock and Supply). Available online: https://www.gov.br/agricultura/pt-br (accessed on 12 August 2022).

- Prestes, D.N. Desenvolvimento Tecnológico de Cervejas Com Matérias-Primas de Importância Regional (Technological Development of Beers with Regional Importance Raw Materials). Ph.D. Thesis, Universidade Federal de Pelotas (Federal University of Pelotas), Pelotas, Brazil, 2019. [Google Scholar]

- Associação Brasileira De Cervejaria Artesanal, ABRACERVA (Brazilian Craft Beer Association). Available online: https://abracerva.com.br (accessed on 20 October 2020).

- Folha de Londrina. Available online: https://www.folhadelondrina.com.br/economia/pandemia-derruba-faturamento-de-cervejarias-em-80-2996528e.html (accessed on 19 August 2022).

- Fortune Business Insight. Available online: https://www.fortunebusinessinsights.com/industry-reports/craft-beer-market-100736 (accessed on 19 August 2022).

- Fortune Business Insight. Available online: https://www.fortunebusinessinsights.com/beer-market-102489 (accessed on 19 August 2022).

- Statista. Available online: https://www.statista.com/statistics/270275/worldwide-beer-production/#statisticContainer (accessed on 19 August 2020).

- Wu, P.P.; Fookes, C.; Pitchforth, J.; Mengersen, K. A framework for model integration and holistic modelling of socio-technical systems. Decis. Support Syst. 2015, 71, 14–27. [Google Scholar] [CrossRef]

- Trist, E. The Evolution of Socio-Technical Systems; Occasional Paper; Ontario Quality of Working Life Centre: Toronto, ON, Canada, 1981; p. 67. [Google Scholar]

- Saviotti, P.P.; Pyka, A. On the co-evolution of innovation and demand: Some policy implications. Revue de l’Ofce 2012, 124, 347–388. [Google Scholar] [CrossRef]

- Geissdoerfer, M.; Savaget, P.; Bocken, N.M.P.; Hultink, E.J. The circular economy—A new sustainability paradigm? J. Clean. Prod. 2017, 143, 757–768. [Google Scholar] [CrossRef]

- Ghisellini, P.; Cialani, C.; Ulgiati, S. A review on circular economy: The expected transition to a balanced interplay of environmental and economic systems. J. Clean. Prod. 2016, 114, 11–32. [Google Scholar] [CrossRef]

- Geels, F.W. Technological Transitions as evolutionary reconfiguration process: A multi-level perspective and a case-study. Res. Policy 2002, 31, 1257–1274. [Google Scholar] [CrossRef]

- Czainska, K.; Sus, A.; Thalassinos, E.I. Sustainable Survival: Resource Management Strategy in Micro and Small Enterprises in the Rubber Products Market in Poland during the COVID-19 Pandemic. Resources 2021, 10, 85. [Google Scholar] [CrossRef]

- Golinska-Dawson, P.; Werner-Lewandowska, K.; Kosacka-Olejnik, M. Responsible Resource Management in Remanufacturing—Framework for Qualitative Assessment in Small and Medium-Sized Enterprises. Resources 2021, 10, 19. [Google Scholar] [CrossRef]

- Kouhizadeh, M.; Zhu, Q.; Sarkis, J. Blockchain and the circular economy: Potential tensions and critical reflections from practice. Prod. Plan. Control 2019, 31, 950–966. [Google Scholar] [CrossRef]

- Mattos Nascimento, D.L.; Alencastro, V.; Quellas, O.L.G.; Caiado, R.C.G.; Garza-Reyes, J.A.; Rocha-Lona, L.; Tortorella, G. Exploring Industry 4.0 technologies to enable circular economy practices in a manufacturing context: A business model proposal. J. Manuf. Technol. Manag. 2019, 30, 607–627. [Google Scholar] [CrossRef]

- Kristoffersen, E.; Blomsmab, F.; Mikalefa, P.; Lia, J. The smart circular economy: A digital-enabled circular strategies framework for manufacturing companies. J. Bus. Res. 2020, 120, 241–261. [Google Scholar] [CrossRef]

- Potting, J.; Hekkert, M.; Worrell, E.; Hanemaaijer, A. Circular Economy: Measuring Innovation in the Product Chain; Policy Report; PBL Netherlands Environmental Assessment Agency: The Hague, The Netherlands, 2017. [Google Scholar]

- Barreiro-Gen, M.; Lozano, R. How circular is the circular economy? Analysing the implementation of circular economy in organisations. Bus. Strategy Environ. 2020, 29, 3484–3494. [Google Scholar] [CrossRef]

- Blomsma, F.; Brennan, G. The Emergence of Circular Economy: A New Framing Around Prolonging Resource Productivity. J. Ind. Ecol. 2017, 21, 603–614. [Google Scholar] [CrossRef]

- United States Government. The Circular Economy as a Concept for Creating a More Sustainable Future; Hearing before the Committee of Environment and Public Works, United States Senate; U.S. Government Publishing Office: Washington, DC, USA, 2021.

- Imoniana, J.O.; Silva, W.L.; Reginato, L.; Slomski, V.; Slomski, V.G. Sustainable Technologies for the Transition of Auditing towards a Circular Economy. Sustainability 2021, 13, 218. [Google Scholar] [CrossRef]

- Sohal, A.; Nand, A.A.; Goyal, P.; Bhattacharya, A. Developing a circular economy: An examination of SME’s role in India. J. Bus. Res. 2022, 142, 435–447. [Google Scholar] [CrossRef]

- Eisenreich, A.; Füller, J.; Stuchtey, M. Open Circular Innovation: How Companies Can Develop Circular Innovations in Collaboration with Stakeholders. Sustainability 2021, 13, 13456. [Google Scholar] [CrossRef]

- Haezendonck, E.; Van den Berghe, K. Patterns of Circular Transition: What Is the Circular Economy Maturity of Belgian Ports? Sustainability 2020, 12, 9269. [Google Scholar] [CrossRef]

- Hysa, E.; Kruja, A.; Ur Rehman, N.; Laurenti, R. Circular Economy Innovation and Environmental Sustainability Impact on Economic Growth: An Integrated Model for Sustainable Development. Sustainability 2020, 12, 4831. [Google Scholar] [CrossRef]

- Korhonen, J.; Honkasalo, A.; Seppälä, J. Circular economy: The concept and its limitations. Ecol. Econ. 2018, 143, 37–46. [Google Scholar] [CrossRef]

- Jawahir, I.S.; Bradley, R. Technological elements of circular economy and the principles of 6R-based closed-loop material flow in sustainable manufacturing. Procedia Cirp. 2016, 40, 103–108. [Google Scholar] [CrossRef]

- Kirchherr, J.; Reike, D.; Hekkert, M. Conceptualizing the circular economy: An analysis of 114 definitions. Resour. Conserv. Recycl. 2017, 127, 221–232. [Google Scholar] [CrossRef]

- Corvellec, H.; Stowell, A.F.; Johansson, N. Critiques of the circular economy. J. Ind. Ecol. 2022, 26, 421–432. [Google Scholar] [CrossRef]

- Chauhan, C.; Parida, V.; Dhir, A. Linking circular economy and digitalization technologies: A systematic literature review of past achievements and future promises. Technol. Forecast. Soc. Change 2022, 177, 121508. [Google Scholar] [CrossRef]

- Huang, L.; Zhen, L.; Wang, J.; Zhang, X. Blockchain implementation for circular supply chain management: Evaluating critical success factors. Ind. Mark. Manag. 2022, 102, 451–464. [Google Scholar] [CrossRef]

- Liu, Q.; Hoffman Trevisan, A.; Yang, M.; Mascarenhas, J. A framework of digital technologies for the circular economy: Digital functions and mechanisms. Bus. Strategy Environ. 2022, 31, 2171–2192. [Google Scholar] [CrossRef]

- Khan, S.A.R.; Ponce, P.; Thomas, G.; Yu, Z.; Al-Ahmadi, M.S.; Tanveer, M. Digital Technologies, Circular Economy Practices and Environmental Policies in the Era of COVID-19. Sustainability 2021, 13, 12790. [Google Scholar] [CrossRef]

- Gaziulusoy, A.I.; Brezet, H. Design for system innovations and transitions: A conceptual framework integrating insights from sustainability science and theories of system innovations and transitions. J. Clean. Prod. 2015, 108, 558–568. [Google Scholar] [CrossRef]

- Markard, J.; Suter, M.; Ingold, K. Socio-technical transitions and policy change–Advocacy coalitions in Swiss energy policy. Environ. Innov. Soc. Transit. 2016, 18, 215–237. [Google Scholar] [CrossRef]

- Fuenfschilling, L.; Truffer, B. The structuration of socio-technical regimes: Conceptual foundations from institutional theory. Res. Policy 2014, 43, 772–791. [Google Scholar] [CrossRef]

- Kompella, L. A Co-evolution Framework towards Stable Designs from Radical Innovations for Organizations Using IT. J. Technol. Manag. Innov. 2019, 14, 44–58. [Google Scholar] [CrossRef]

- Geels, F. Understanding system innovations: A critical literature review and a conceptual synthesis. In System Innovation and the Transition to Sustainability: Theory, Evidence and Policy; Elzen, B., Geels, F.W., Green, K., Eds.; Edward Elgar Publishing: Cheltenham, UK; Northampton, MA, USA, 2004; pp. 9–47. [Google Scholar]

- Geels, F.W. Processes and patterns in transitions and system innovations: Refining the co-evolutionary multi-level perspective. Technol. Forecast. Soc. Change 2005, 72, 681–696. [Google Scholar] [CrossRef]

- Geels, F.W. Ontologies, socio-technical transitions (to sustainability), and the multi-level perspective. Res. Policy 2010, 39, 495–510. [Google Scholar] [CrossRef]

- Geels Frank, W. The multi-level perspective on sustainability transitions: Responses to seven criticisms. Environ. Innov. Soc. Transit. 2011, 1, 24–40. [Google Scholar] [CrossRef]

- Geels, F.W. Socio-technical transitions to sustainability: A review of criticisms and elaborations of the Multi-Level Perspective. Curr. Opin. Environ. Sustain. 2019, 39, 187–201. [Google Scholar] [CrossRef]

- dos Santos Carstens, D.D.; da Cunha, S.K. Challenges and opportunities for the growth of solar photovoltaic energy in Brazil. Energy Policy 2019, 125, 396–404. [Google Scholar] [CrossRef]

- Vähäkari, N.; Lauttamaki, V.; Tapio, P.; Ahvenainen, M.; Assmuth, T.; Lyytimaki, J.; Vehmas, J. The future in sustainability transitions: Interlinkages between the multi-level perspective and futures studies. Futures 2020, 123, 102597. [Google Scholar] [CrossRef]

- Rip, A.; Kemp, R. Technological change: Human Choice and Climate Change; Battelle Press: Columbus, OH, USA, 1998; Volume 2, pp. 327–399. [Google Scholar]

- Verbong, G.; Geels, F.W. The ongoing energy transitions: Lessons from a sociotechnical, multi-level analysis of the Dutch electricity system (1960–2004). Energy Policy 2007, 35, 1025–1037. [Google Scholar] [CrossRef]

- Mohr, B.J.; Dessers, E. Designing from a socio-technical systems perspective. In Designing Integrated Care Ecosystems: A Sociotechnical Perspective; Mohr, B.J., Dessers, E., Eds.; Springer International Publishing: Cham, Switzerland, 2019; pp. 25–48. [Google Scholar] [CrossRef]

- Kemp, R.; Loorbach, D.; Rotmans, J. Transition management as a model for managing processes of co-evolution towards sustainable development. Int. J. Sustain. Dev. World Ecol. 2007, 14, 78–91. [Google Scholar] [CrossRef]

- Burgelman, R.A. A Model of the Interaction of Strategic Behavior, Corporate Context, and the Concept of Strategy. Acad. Manag. Rev. 1983, 8, 61–70. [Google Scholar] [CrossRef]

- Burgelman, R.A.; Grove, A.S. Let chaos reign, then rein in chaos-repeatedly: Managing strategic dynamics for corporate longevity. Strateg. Manag. J. 2007, 28, 965–979. [Google Scholar] [CrossRef]

- Burgelman, R.A.; Floyd, S.W.; Laamanen, T.; Mantere, S.; Vaara, E.; Whittington, R. Strategy processes and practices: Dialogues and intersections. Strateg. Manag. J. 2017, 39, 531–558. [Google Scholar] [CrossRef]

- MacKay, B.; Chia, R.; Nair, A.K. Strategy-in-Practices: A process philosophical approach to understanding strategy emergence and organizational outcomes. Hum. Relat. 2021, 74, 1337–1369. [Google Scholar] [CrossRef]

- Mintzberg, H.; Ahlstrand, B.; Lampel, J.B. Strategy Safari: The Complete Guide through the Wilds of Strategic Management, 2nd ed.; Pearson Education: North York, ON, Canada, 2008; pp. 183–240. [Google Scholar]

- Mintzbeg, H.; Waters, J.A. Of Strategies, Deliberate and Emergent. Strateg. Manag. J. 1985, 6, 257–272. [Google Scholar] [CrossRef]

- Borrello, M.; Caracciolo, F.; Lombardi, A.; Pascutti, S.; Cembalo, L. Consumers’ Perspective on Circular Economy: Strategy for Reducing Food Waste. Sustainability 2017, 9, 141. [Google Scholar] [CrossRef]

- Stewart, R.; Niero, M. Circular economy in corporate sustainability strategies: A review of corporate sustainability reports in the fast-moving consumer goods sector. Bus. Strategy Environ. 2018, 27, 1005–1022. [Google Scholar] [CrossRef]

- Viles, E.; Santos, J.; Arevalo, T.F.; Tanco, M.; Kalemkerian, F. A New Mindset for Circular Economy Strategies: Case Studies of Circularity in the Use of Water. Sustainability 2020, 12, 9781. [Google Scholar] [CrossRef]

- Dieterle, M.; Schäfer, P.; Viere, T. Life cycle gaps: Interpreting LCA results with a circular economy mindset. Procedia CIRP 2018, 69, 764–768. [Google Scholar] [CrossRef]

- Hernández, A.E.B.; Lu, T.; Beno, T.; Fredriksson, C.; Jawahir, I.S. Process sustainability evaluation for manufacturing of a component with the 6R application. Procedia Manuf. 2019, 33, 546–553. [Google Scholar] [CrossRef]

- Lungu, A.E. Comparative Analysis of Entrepreneurial Innovation Factors in 25 National States. ANDULI 2022, 21, 55–73. [Google Scholar] [CrossRef]

- Laceta, J.M.; Könnöla, T. Fostering entrepreneurial innovation ecosystems: Lessons learned from the European Institute of Innovation and Technology. Innov. Eur. J. Soc. Sci. Res. 2021, 34, 475–494. [Google Scholar] [CrossRef]

- Scaringella, L.; Radziwonb, A. Innovation, entrepreneurial, knowledge, and business ecosystems: Old wine in new bottles? Technol. Forecast. Soc. Change 2018, 136, 59–87. [Google Scholar] [CrossRef]

- Autio, E.; Kenney, M.; Mustard, P.; Siegele, D.; Wright, M. Entrepreneurial innovation: The importance of context. Res. Policy 2014, 43, 1097–1108. [Google Scholar] [CrossRef]

- Garud, R.; Gehman, J.; Giuliani, A.P. Contextualizing entrepreneurial innovation: A narrative perspective. Research Policy 2014, 43, 1177–1188. [Google Scholar] [CrossRef]

- Ghorbel, F.; Hachicha, W.; Boujelbene, Y.; Aljuaid, A.M. Linking Entrepreneurial Innovation to Effectual Logic. Sustainability 2021, 13, 2626. [Google Scholar] [CrossRef]

- Guerrero, M.; Urbano, D. The impact of Triple Helix agents on entrepreneurial innovations’ performance: An inside look at enterprises located in an emerging economy. Technol. Forecast. Soc. Change 2017, 119, 294–309. [Google Scholar] [CrossRef]

- Khalid, N.; Salykova, L.; Capar, N. The Contribution of Environmental Strategies, Entrepreneurial Innovation and Entrepreneurial Orientation in Enhancing Firm Environmental Performance and Energy Efficiency. Int. J. Energy Econ. Policy 2020, 10, 282–288. [Google Scholar] [CrossRef]

- Znaniecki, F. The Method of Sociology; Farrar and Rinehart: New York, NY, USA, 1934. [Google Scholar]

- Penrose, E.T. The Theory of the Growth of the Firm; John Wiley: New York, NY, USA, 1959. [Google Scholar]

- Barney, J.B. Firm resources and sustained competitive advantage. J. Manag. 1991, 17, 99–120. [Google Scholar] [CrossRef]

- Miller, D. An asymmetry-based view of advantage: Towards an attainable sustainability. Strateg. Manag. J. 2003, 24, 961–976. [Google Scholar] [CrossRef]

- Hamel, G.; Prahalad, G.K. Competing for the Future; Harvard Business School Press: Boston, MA, USA, 1994. [Google Scholar]

- Teece, D.J.; Pisano, G.P.; Shuen, A. Dynamic capabilities and strategic management. Strateg. Manag. J. 1997, 18, 509–533. [Google Scholar] [CrossRef]

- Grant, R.M. Toward a knowledge-based theory of the firm. Strateg. Manag. J. 1996, 17, 109–122. [Google Scholar] [CrossRef]

- Litz, R.A. A resource-based-view of the socially responsible firm: Stakeholder interdependence, ethical awareness, and issue responsiveness as strategic assets. J. Bus. Ethics 1996, 15, 1355–1363. [Google Scholar] [CrossRef]

- Savino, M.M.; Shafiq, M. An extensive study to assess the sustainability drivers of production performances using a resource-based view and contingency analysis. J. Clean. Prod. 2018, 204, 744–752. [Google Scholar] [CrossRef]

- Foxton, T.J. A coevolutionary framework for analysing a transition to a sustainable low carbon economy. Ecol. Econ. 2011, 70, 2258–2267. [Google Scholar] [CrossRef]

- Kallis, G.; Norgaard, R. Coevolutionary ecological economics. Ecol. Econ. 2010, 69, 690–699. [Google Scholar] [CrossRef]

- Robinson, W.S. The logical structure of analytic induction. Am. Sociol. Rev. 1951, 16, 812–818. [Google Scholar] [CrossRef]

- Katz, J. Analytic Induction. In International Encyclopedia of the Social and Behavioral Sciences; Smels, J., Baltes, P.B., Eds.; Elsevier: Oxford, UK, 2001; Volume 1, pp. 480–484. [Google Scholar] [CrossRef]

- Hammersley, M.; Cooper, B. Analytic induction versus qualitative comparative analysis. In Challenging the Qualitative-Quantitative Divide: Explorations in Case-focused Causal Analysis; Cooper, B., Glaesser, J., Gomm, R., Hammersley, M., Eds.; Continuum/Bloomsbury: London, UK, 2012. [Google Scholar]

- Bansal, P.; Roth, K. Why companies go green: A model of ecological responsiveness. Academy of management journal 2000, 43, 717–736. [Google Scholar] [CrossRef]

- Busch, T. Organizational adaptation to disruptions in the natural environment: The case of climate change. Scand. J. Manag. 2011, 7, 389–404. [Google Scholar] [CrossRef]

- Hoffmann, V.H.; Trautmann, T.; Hamprecht, J. Regulatory uncertainty: A reason to postpone investments? Not necessarily. J. Manag. Stud. 2009, 46, 1227–1253. [Google Scholar] [CrossRef]

- Bardin, L. Análise de Conteúdo. (Content Analysis), 3ª Reimpressão da 1ª ed.; Edições: São Paulo, Brazil, 2016; Volume 70. [Google Scholar]

- Edmondson, D.L.; Kern, F.; Rogge, K.S. The co-evolution of policy mixes and socio-technical systems: Towards a conceptual framework of policy mix feedback in sustainability transitions. Res. Policy 2019, 48, 103555. [Google Scholar] [CrossRef]

- Urmee, T.; Md, A. Social, cultural and political dimensions of off-grid renewable energy programs in developing countries. Renew. Energy 2016, 93, 159–167. [Google Scholar] [CrossRef]

- Sehnem, S.; Ndubisi, N.O.; Preschlak, D.; Bernardy, R.J.; Santos, S., Jr. Circular economy in the wine chain production: Maturity, challenges, and lessons from an emerging economy perspective. Prod. Plan. Control 2019, 31, 1014–1034. [Google Scholar] [CrossRef]

- Colpo, I.; Rabenschlag, D.R.; de Lima, M.S.; Martins, M.E.S.; Sellitto, M.A. Economic and Financial Feasibility of a Biorefinery for Conversion of Brewers’ Spent Grain into a Special Flour. J. Open Innov. Technol. Mark. Complex. 2022, 8, 79. [Google Scholar] [CrossRef]

- Sehnem, S.; Jabbour, A.L.B.S.; Conceição, D.A.; Weber, D.; Julkowski, D.S. The role of ecological modernization principles in advancing circular economy practices: Lessons from the brewery sector. Benchmarking: Int. J. 2021, 28, 2786–2807. [Google Scholar] [CrossRef]

- Morgan, D.F.; Styles, D.; Lane, E.T. Packaging choice and coordinated distribution logistics to reduce the environmental footprint of small-scale beer value chains. J. Environ. Manag. 2022, 307, 114591. [Google Scholar] [CrossRef] [PubMed]

| Region | Craft Beer Production (Millions of Liters) |

|---|---|

| Guarapuava (Paraná, Brazil) [3] | 0.9 |

| Parana State (Brazil) [4] | 9.6 |

| Brazil [3] | 380.0 |

| Worldwide [5,6,7] | 23,000.0 |

| Categories of Analysis | Dimensions of Analysis | |

|---|---|---|

| Coevolution of the sociotechnical system | Institutional | Policies, laws, agreements, strategies, and plans businesses must follow |

| Cultural/Social | Consumer, values, beliefs, market influence changes | |

| Organizational | Individual changes resulting from the business community or unions and partnerships | |

| Technological | Resulting from products or services, technological regime, or infrastructure | |

| Circular economy, strategic implications, and resource management | Reduce | Reduce the use of resources |

| Recycle | Conversion of material that would be considered waste in new materials or products | |

| Reuse | Reuse of products or components as a whole | |

| Redraw | Redesign the next generation of products, which would use components, materials, and resources recovered from the previous life cycle | |

| Remanufacture | Reprocessing products already used for restoration purposes | |

| Recover | Collection of products at the end of the use stage for use in subsequent product life cycles | |

| Producers | Insertion in the Craft Beer Sector | Business Formalization | Business Type | Volume/ Month (liters) | Beer Styles |

|---|---|---|---|---|---|

| Producer 01 | 2012 | 2019 | Industry | 10,000 | Pilsen, Weiss, Belgian Pale Ale, IPA, Stout, Session, Fruit Beer of Guabiroba |

| Producer 02 | 2016 | 2017 | Industry and emporium for the commercialization of beer from all producers | 4000 | Orange Beer, Yerba Mate Beer, Coffee Beer, IPA, Zero Alcohol, Passion Fruit Mango Beer, Fruit Beer, Strawberry Hibiscus Beer, Belgian, Dark Beer, Cocoa Beer, Brown Ale, Wine Beer, Red Ale |

| Producer 03 | 2014 | 2019 | Brewpub | 10,000 | American and Belgian School, German Pale Ale, IPA, Red Ale, Ris, Weiss, Pumpkin Ale, Trappist Single, Belgian Dubbel, Saison, Barley Wine, Purpura Sour, Pilsen, Witbier |

| Producer 04 | 2004 | 2004 | Industry and restaurant with typical German food | 20,000 | Traditional Pilsen, German Pilsen, Red Lager, Pale Ale, Dark Beer |

| Producer 05 | 2014 | 2016 | Industry | 5000 | Pilsen, Vienna Lager, Weizen, Citrus Pale Ale, Ra IPA |

| Producer 06 | 2008 | 2015 | Beer production, beer shop with several brands, and snack store | 6000 | Pilsen, IPA, Sour Beers, American Pale Ale |

| Producer 07 | 2000 | 2014 | Industry and store for consumption and commercialization | 15,000 | Helix, Bohemia Pilsen, Bock, Trippel, Bubbler, Red Large, Witbier, Weiss, IPA, and American Pale Ale |

| Producer 08 | 2016 | 2019 | Beer production and snack store | 5000 | Carrier and Porter, Porter with Coffee, Vanilla and Fruit |

| Sociotechnical System Actor | Interviewed Role | Interview Code | Gender | Age | Interview Duration (HH:MM) | Occupation |

|---|---|---|---|---|---|---|

| Association of Craft Beer Producers of Guarapuava | President | P1 | F | 55 | 1:20 | University Affairs Technician |

| Caminhos do Malte Project | Coordinator | C1 | F | 52 | 2:00 | Businesswoman, responsible for tourism projects. |

| Craft Beer Producers | Producer 01 | P1 | M | 46 | 1:00 | Producer of Mushrooms and Craft Beer |

| Producer 02 | P2 | F | 45 | 1:15 | Entrepreneur and Craft Beer Producer | |

| Producer 03 | P3 | F | 40 | 1:20 | Professor, Entrepreneur and Craft Beer Producer | |

| Producer 04 | P4 | M | 56 | 1:25 | Entrepreneur, Rural and Craft Beer Producer | |

| Producer 05 | P5 | M | 40 | 1:30 | Rural and Craft Beer Producer | |

| Producer 06 | P6 | M | 40 | 1:15 | Entrepreneur and Craft Beer Producer | |

| Producer 07 | P7 | M | 45 | 1:35 | Milk Producer, Craft Beer Producer and Entrepreneur | |

| Producer 08 | P8 | M | 40 | 1:55 | Entrepreneur, Rural and Craft Beer Producer | |

| Provider | Business Unit Manager | F1 | M | 40 | 1:20 | Entrepreneur, Rural and Craft Beer Producer |

| Theoretical Grounds | Evidence from the Interviews |

|---|---|

| Institutional Dimension | |

| [1,37,38,44,88] | P2 on institutional coevolution, “authorization filing request occurs simultaneously with the industry registration request filing. Laws were set to regulate the market and guarantee the quality of the product and are constantly updated through normative instructions with a 365-day period for adjustments.” [sic]. P2 additional evidence on institutional coevolution, “The laws come from above, and must be obeyed, then it changes. It is a permanent adaptation, you are always adapting to the environment, there is no way to escape” [sic]. |

| Cultural/Social Dimension | |

| [37,89,90] | P1, at consumer level, “You know your clientele, and that’s how it is, at the moment it’s trial and error, you’re going to launch a new product and you’re going to put it on the market. The [customer] response is immediate, in a month you already know if that product of yours, the product will be produced again, or if you are going to give up and make a new recipe, change your recipe profile. The customer dictates which style of beer sells the most, which is the best, best of all, customers are becoming beer experts. There’s a guy I know who knows more about beer than I do and doesn’t make it, he just drinks it” [sic]. P1, at market level, “nowadays, not only beer, but anything and everything that says crafted, special, family made, or similar denominations, has a quite large demand. The vast majority go after it out of curiosity” [sic]. P5 additional evidence at market level, “People still attribute craft beer as extreme, or very different, beers. This has changed a lot, but it depends on the person’s income as well” [sic]. P2, within the religious context, “at church parties we started with zero alcohol draft beer, we had the idea of zero alcohol to serve customers who like craft beer, but couldn’t drink with alcohol, but we only do it on demand” [sic]. |

| Organizational Dimension | |

| [37,44,48] | P8, on management, “there is always something to change, as we were released by the map not so long ago, the pandemic has already come, our business has been affected, […] We need this pandemic to pass so that we can begin to have a real sense of our business” [sic]. F1, on suppliers’ bias, “the cooperative has sought to communicate with the microbrewery market, as a supplier, not only of inputs, but also of solutions, technology, and knowledge to add value to the product and retain customers” [sic]. F1 goes further,” International Technical Congress, lasting 15 days in 2020, where the lectures were online, which can become a trend in the Brazilian market” [sic] P5, on relationships with the public sector, “the local government is a partner, the Caminhos do Malte [Malt Ways] project by the Secretariat and the Agriculture and Tourism Secretariat itself, the Association never really existed, […] the local government can help us through the Association. If you are member, you can participate in the events of the local government” [sic]. |

| Technological Dimension | |

| [11,37] | F1, on offering product, production, and management technology, “raw material that leads to better results, where there is a whole research technology in the background. Today we have an experimental brewery, where the breweries can come to test their products, test our products, and test new recipes” [sic]. P4, on production and management technology, “the factory is already more technological, it is not so artisanal. We have all the production equipment and always leave it at the same level” [sic]. P3, on technological changes at niche level, “Each technology that comes will shake you, sometimes it takes you a while to understand, how it works, but they are technologies that help a lot, I mean technologies even for product use, even in sales, now we have the internet channel for sale, we didn’t have it before, they change the dynamics of the thing, they are allies, they take us out of comfort, so we can experiment with them” [sic]. |

| Theoretical Grounds | Evidence from the Interviews |

|---|---|

| Reuse, Recycle, Redesign, Remanufacture, Reduce, and Recover (6Rs) Dimensions | |

| [1,30,31,37,61] | P3, on strategic implications of reusing, redesigning, and reducing resources, “When we set up the factory, water was one of the first [resources] that we needed to optimize in the production process, when it is sent for cooling. So, we put cold water to cool the hot must. One of the things we did was to create a long water box, for this water that comes in cold and comes out hot, we return it to the box, because in the process we reuse it for beer production. Water was what we thought most, we have some taps of hot water for cleaning, we don’t spend energy heating, we have the box, there are some streamers that keep it warm” [sic]. P1, similarly on strategic implications of reusing, redesigning, reducing, and recovering resources, “Optimization of water consumption, even for the sake of final effluent, optimization of input, also of electrical energy, not only electrical energy, but energy as a whole, our boiler is firewood, we try to optimize, compile, we are creating a kind of calendar to optimize all of these resources. We managed to optimize raw materials, readjusting, and making a recipe look good, with less product and for that, you need to know your process and your machines, so you can optimize production, producing more with less. Machine optimization is one of the factors that adds more gain, so you can decrease the cost of production. These actions directly lead to a cost reduction” [sic]. P4 on redesigning and reducing resources, “with standardized processes, you reduce the malt, before we milled the malt and put it into production without counting how much it yielded or how much was lost, now I manufacture the same volume with less malt, reduce purchase, cost” [sic]. P4, further on redesigning and adding on recovering resources, “over time we have been able to optimize our process, because there is one thing, inside a factory beer, you find another factory, when you optimize processes, a bad grind gives you a loss of 2 to 5% on the final product” [sic]. P4 on reusing resources (beer growler), “I take it back, for every 10 empty packages it takes one full, I do the process of washing, sterilizing, sanitizing and filling beer again” [sic]. P3 on reusing, recycling, and recovering resources, “each brewer informs MAPA how they do it [product collection process at the end of the use stage is for use in subsequent product life cycles], and MAPA analyzes whether they approve it or not. Producers send a picture of the equipment, components they are using and quantities. I had to adopt peracetic acid” [sic] |

| Comparison Item | Comparison Study | ||

| Regional Level (Southern Brazil) | National Level (Brazil) | International Level (UK) | |

| Feasibility of a Bio-refinery for Conversion of Brewers’ Spent Grain [91] | Modernization Principles in Circular Economy Practices [92] | Distribution Logistics to Reduce the Environmental Footprint [93] | |

| Research method | Quantitative (Monte Carlo method) | Qualitative (multiple case studies) | Qualitative (multiple case studies) |

| Coevolution of the sociotechnical system | Coevolution was not directly addressed. Coevolutionary inferences can be made on the supply chain of craft beer production. | Clear for the technological component, where technology is essential to strengthen production | Coevolution was not directly addressed. Coevolutionary inferences can be made on transportation logistics, packaging suppliers, and craft beer makers |

| Circular Economy– 6R framework | Evidence on resource waste transformation, implying in resource reutilization. | Companies studied have pursued the adoption of circular economy practices. No evidence found on remanufacturing | Evidence on reuse (bottle return), redesign (packaging type), and reduce (transport load and handling costs) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gruba, M.C.; Denes, D.; Lobo, R.C.G.; Isaak, A.J. Circular Economy Initiatives: Strategic Implications, Resource Management, and Entrepreneurial Innovation in a Brazilian Craft Beer Ecosystem during the COVID Era. Sustainability 2022, 14, 11826. https://doi.org/10.3390/su141911826

Gruba MC, Denes D, Lobo RCG, Isaak AJ. Circular Economy Initiatives: Strategic Implications, Resource Management, and Entrepreneurial Innovation in a Brazilian Craft Beer Ecosystem during the COVID Era. Sustainability. 2022; 14(19):11826. https://doi.org/10.3390/su141911826

Chicago/Turabian StyleGruba, Marcia Cristiane, Danielle Denes, Rodrigo Cortopassi Goron Lobo, and Andrew Jay Isaak. 2022. "Circular Economy Initiatives: Strategic Implications, Resource Management, and Entrepreneurial Innovation in a Brazilian Craft Beer Ecosystem during the COVID Era" Sustainability 14, no. 19: 11826. https://doi.org/10.3390/su141911826

APA StyleGruba, M. C., Denes, D., Lobo, R. C. G., & Isaak, A. J. (2022). Circular Economy Initiatives: Strategic Implications, Resource Management, and Entrepreneurial Innovation in a Brazilian Craft Beer Ecosystem during the COVID Era. Sustainability, 14(19), 11826. https://doi.org/10.3390/su141911826