Abstract

Bone materials are mainly composed of an inorganic constituent called hydroxyapatite (HA). In the current study, mesoporous Zn2+/Ag+ doped hydroxyapatite nanoparticles (Zn-Ag doped HA) with high antibacterial activity were synthesized through ultrasonic coupled sol-gel techniques under calcination temperatures of 600 °C for 4 h and 1100 °C for 1 h. The variance in the molar ratio of Zn2+/Ag+ in Ca9.0Zn1.0−xAgx(PO4)6(OH)2 (x = 0.0, 0.25 to 1.0) and its effects on the chemical and physical properties of the powdered samples were investigated. The results show that the hexagonal framework of HA incorporated both the Zn2+ and Ag+ ions and the rhombohedral structure of β-TCP. The main functional groups of HA and Zn-Ag doped HA samples were hydroxyl and phosphate. All samples have mesoporous characteristics with a Type IV isotherm. The agar well diffusion process was used to examine antibacterial activity against E. coli, P. aeruginosa, S. aureus, B. cereus and B. subtilis. Effective antibacterial activity was displayed by Zn-Ag doped HA. Excellent antibacterial performance was shown by Ca9.0Zn0.75Ag0.25(PO4)6(OH)2 against all tested bacterial strains, except P. aeruginosa. This material showed inhibition zones ranging from 7 to 11 mm, implying that it is a suitable material with an antibacterial action for environmental applications, specifically for water purification.

1. Introduction

Hydroxyapatite (HA, Ca10(PO4)6(OH)2) is an outstanding bioactive material with chemical and structural properties similar to the primary inorganic component found in bone minerals [1,2]. Among the calcium phosphates, HA is a popular form due to its stable crystalline phase and its hexagonal structure of the space group P63/m [3]. HA is recognized for its attractive properties, such as its capacity to assist in bone growth and bind to living tissues via the formation of direct chemical bonds [4,5]. Other advantages of HA include its excellent bioactivity, non-toxicity, good osteoconductivity and increased biocompatibility [6,7]. Synthesized HA has a variety of applications in the field of tissue engineering, sensors, wastewater and water purification, dental and orthopedic, and catalysis [8,9,10,11,12,13,14,15]. In environmental applications, HA has numerous recognizable characteristics as an adsorbent material, such as low solubility in aqueous solutions, simple synthesis, non-toxicity, excellent adsorption capacity with a variety of contaminants and satisfactory ion exchange capacity [16,17]. Hence, HA and its modified forms have been extensively used as an adsorbent material in the removal of heavy metals, dyes and organic pollutants [11,18,19,20,21]. However, there are several drawbacks in utilizing HA for environmental applications, including poor antibacterial properties and lack of mechanical interfacial strength, as well as decreased wear resistance [22].

Water disinfection via various technologies, such as membrane filtration, ozonation, UV treatment and chlorination, have been utilized. However, these methods have several disadvantages, such as high capital costs, the generation of toxic by-products and a pre-treatment requirement [23]. Currently, metallic nanoparticles have gained attention in its application for water disinfection due to its high surface area to volume ratio and excellent anti-septic characteristics [24]. Current research has focused on the synthesis of HA and its modified forms to develop a more efficient adsorbent material. The substitution of trace metals, such as Cu2+, Ag+, Co2+, and Fe3+, into the HA structure has been investigated to help enhance adsorption efficiency and antibacterial properties as well as to improve the mechanical properties of these materials [14,25,26]. Most of the previous studies focused on use of metal dopants, such as Ag+, Co2+ and Cu2+, due to their excellent antibacterial properties, ability to impart mechanical strength and phase stability [27]. Ionic silver, Ag+, is well known for its strong antimicrobial activity with high thermal stability [28,29]. Additionally, silver has the capacity to attach to enzymes and proteins in bacterial cells and inhibit the major cell functions of several bacteria, including S. aureus and E. coli [30]. The incorporation of a second trace metal into the HA structure would yield a multi-functional adsorbent material. Ionic zinc, Zn2+, is widely recognized as an antibacterial and anti-fungal agent that inhibits inflammation [31,32]. Zn2+ exhibits higher stability than Ag+ and is non-toxic [33]. A literature review reveals that most previous reports on doping HA with one trace metal mainly investigated the enhancement of the adsorption capacity of the material. Srilakshmi et al. (2016) utilized a facile precipitation process in the production of Ag-doped HA, which showed a higher Ag content would result in an improved adsorption capacity of 554.54 mg/g in the removal of Congo red dye [11]. Hydroxyapatite combined with copper and ferrite was utilized in the adsorption of Fe(II) and Al(III) ions from aqueous solutions [34]. Panneerselvam et al. (2019) developed Fe-substituted HA and Co-substituted HA using a facile precipitation technique. These materials were applied in removal of dye from wastewater. Fe-substituted HA attained a 95.6% removal efficiency [35].

The synthesis of HA has been widely investigated using several preparation methods, such as wet precipitation, co-precipitation, a sol-gel technique, plasma spraying, and double decomposition. Sol-gel methods are low-cost, simple methods that involve molecular mixing of precursors at low calcination temperatures [36]. Moreover, the sol-gel method has the capacity to dope numerous metals and elements in trace quantities [37]. HA produced in this manner is characterized by its decreased crystallinity, homogeneity, high purity and satisfactory bioactivity [38]. The technique offers several advantages, such as the formation of HA particles with increased surface activity, enhanced mechanical characteristics and improved stability [39]. Past studies have shown that nano-sized HA can be achieved via a sonochemical technique that yields an increased interaction resulting from intense mixing between solid and liquid precursors caused by acoustic cavitation and ultrasonic irradiation. Additionally, nano-sized HA particles are purer, smaller and more uniform in size with minimal aggregation [40,41]. To date, no studies have been performed on the preparation of Ag-Zn doped HA via a sol-gel method assisted with ultrasonic irradiation and an evaluation of its antibacterial properties for water disinfection.

The present work aims to develop a HA material doped with Zn-Ag via an ultrasonic assisted sol-gel technique. The molar ratio of Zn/Ag was varied and the effects on the physicochemical properties, such as crystal phase content, surface morphology and anti-microbial performance, were examined. The anti-microbial capacity was examined using the agar well diffusion technique.

2. Materials and Methods

2.1. Materials

No additional purification was performed for the chemical reagents used and all were of analytical grade. The raw materials for Zn1.0−xAgx doped HA synthesis were silver nitrate (AgNO3, 99.9 wt.%, POCh), zinc nitrate hexahydrate (Zn(NO3)2 6H2O, 98.0 wt.%, UNIVAR), calcium nitrate tetrahydrate (Ca(NO3)2 4H2O, 99.9 wt.%, QREC), ammonium solution (NH3, 30 wt.%, Carlo Erba) and diammonium hydrogen phosphate ((NH4)2HPO4, 98.0 wt.%, UNIVAR). The Thailand Institute of Scientific and Technological Research (TISTR) provided the Gram-positive bacteria B. subtilis (TISTR 008), S. aureus (TISTR 1466), and B. cereus (TISTR 687) and the Gram-negative bacteria P. aeruginosa (TISTR 781) and E. coli (TISTR 780). Nutrient agar slants were used to preserve the microbes. Deionized water (DI) was used throughout the experiments.

2.2. Synthesis of Zn-Ag Doped HA Samples

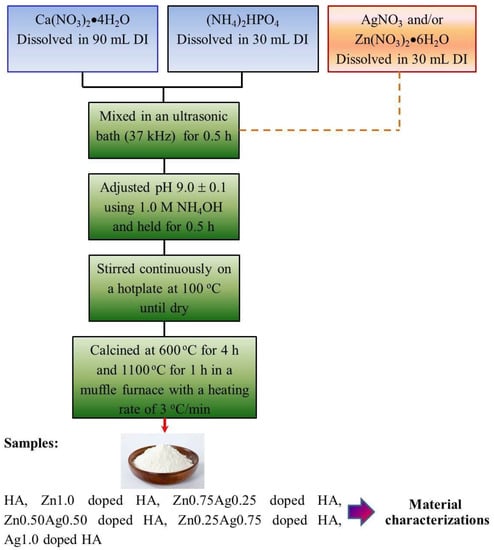

HA nanoparticles (Ca9.0Zn1.0−xAgx(PO4)6(OH)2), which are represented as Zn-Ag doped HA, were synthesized using an ultrasonic procedure in combination with sol-gel technique, similar to that of Kamonwannasit et al. (2020) [42]. Figure 1 illustrates a schematic flowchart for the synthesis of Zn-Ag doped HA. First, a pre-determined mass of precursors as shown in Table 1, (NH4)2HPO4, Ca(NO3)2 4H2O, AgNO3 and Zn(NO3)2 6H2O, was separately dissolved in DI water and mixed with constant stirring. Secondly, the dropwise addition of the (NH4)2HPO4 solution in Ca(NO3)2 4H2O solution was irradiated at 37 kHz frequency for 0.5 h in an ultrasonic bath. Next, mixed solutions of AgNO3 and Zn(NO3)2 6H2O with varying molar ratios (0.0, 0.25 to 1.0) were placed in the mixture in a dropwise fashion and accompanied by ultrasonic irradiation for 0.5 h. Then, adjustment of the mixture’s pH using 1.0 M NH4OH was performed to pH 9.0 ± 0.1 and the solutions were held for 0.5 h. On a hotplate, continuous stirring of the mixture was performed at 100 °C until dry. After which, calcination of the dried samples was performed at 600 °C for 4 h and 1100 °C for 1 h using a muffle furnace (SNOL 30/1100 LSF21) with a 3 °C/min as the heating rate. The various compositions of the synthesized Zn-Ag doped HA powders are described as Ca9.0Zn1.0−xAgx(PO4)6(OH)2 in which the molar ratios of Ag and Zn precursors are referred to as x. They are denoted as Ag1.0 doped HA, Zn0.25Ag0.75 doped HA, Zn0.50Ag0.50 doped HA, Zn0.75Ag0.25 doped HA and Zn1.0 doped HA.

Figure 1.

Schematic flowchart for the synthesis of Zn-Ag doped HA.

Table 1.

Pre-determined mass of precursors for the synthesis of Zn-Ag doped HA.

2.3. Characterization Analysis

Transmission electron microscopy (JEM-2100, JEOL, Tokyo, Japan) analyzed the morphology and particle size distribution of HA samples operated at 200 kV. Methanol medium was used to disperse the samples and then Ni TEM grids coated with carbon film were used for the sample deposition. XRD (D8 Advance Series 2, Bruker, Germany) operated at CuKα radiation (λ = 1.54184 Å), 2θ range from 20 to 60°, 35 mA, and 40 kV for accelerating voltage was used to identify the crystal phases of the HA and Zn-Ag doped HA samples. FT-IR spectroscopy (Spectrum Two, Perkin Elmer, Waltham, MA, USA) coupled with KBr pellet technique was utilized to determine the functional groups present in synthesized samples in the 4 cm−1 spectral resolution and 4000–500 cm−1 range. N2 adsorption-desorption isotherms of Zn-Ag doped HA samples were obtained on a BELSORP-Mini X at liquid nitrogen temperature. Sample preparation involves drying at 110 °C overnight for each sample. Then, under vacuum for 3 h, samples were degassed at 120 °C. Based on the adsorption isotherm data, Brunauer-Emmett-Teller (BET) method was used to measure the specific surface area of each sample under range of 0–1 for relative pressure (P/P0). Computation of the pore size distribution using a cylindrical pore model via the Barrett-Joyner-Halenda (BJH) desorption method was employed.

2.4. Antibacterial and Antimicrobial Activity of HA and ZnAg Doped HA

An agar well diffusion technique was used in determining the antimicrobial capacity of the synthesized Zn-Ag doped samples against the Gram-positive bacteria, S. aureus, B. cereus and B. subtilis and the Gram-negative bacteria, E. coli and P. aeruginosa [42]. Under 0.5 turbidity (McFarland standard) and 37 °C, Mueller-Hinton broth (MHB) was used to culture the bacterial strains for 18 h. In individual Mueller-Hinton agar plates, uniform spreading of each bacterial suspension (100 µL aliquot) with 1 × 108 colony forming units per ml (CFU mL−1) was performed. A sterile cork borer was employed to cut wells with diameter of 5 mm into the agar medium. Subsequently HA aliquots (50 µL) were placed in each well. Lastly, incubation for 24 h at 37 °C of the inoculated plates was performed. All samples were tested and applied dimethyl sulfoxide (DMSO) (10, 30 mg/mL) as the negative control while positive control used 30 μg of tetracycline. Finally, the analysis of the diameters of bacterial inhibition zones (mm) was performed. Experiments were carried out in triplicate.

2.5. Examination of Minium Bactericidal Concentration (MBC) and Minimum Inhibitory Concentration (MIC)

The repetition of the serial broth dilution method was employed to evaluate the minimum bactericidal concentration (MBC) and minimum inhibitory concentration (MIC) of the Zn-Ag doped samples. The lowest sample concentration that can disinfect about 99.9% bacteria after incubation is referred to as the MBC. The minimum sample concentration that could prevent apparent bacterial growth is referred to as the MIC. This employs the turbidity method at 37 °C after 24 h incubation [43]. With bacterial concentration of 107 CFU/mL in MHB, the concentration of the Zn-Ag doped HA (2.5, 5.0, 10.0, 20.0 and 40.0 mg/mL) was varied and MIC was determined. Inoculated tubes were incubated for 24 h at 37 °C. In pristine Mueller-Hinton agar plates, subculture of 100 μL from each tube was performed. The analysis of MBC was performed after incubation for 24 h at 37 °C with no apparent microbial growth. Experiments were carried out in triplicate.

3. Results and Discussion

3.1. XRD Analysis

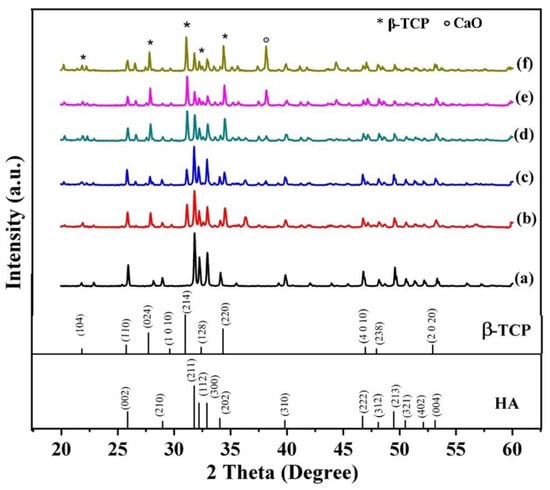

Figure 2 shows the lattice parameters and phase composition of Zn-Ag doped HA samples calcined at for 4 h at 600 °C and for 1 h at 1100 °C. The presence of the 2θ peaks at 2θ = 25.87 (002), 31.77 (211), 32.90 (300), 39.81 (310), 49.49 (213), 52.10 (402) and 53.14° (004) (JCPDS No. 09–0432) indicates a typical HA hexagonal crystal structure (P63/m space group) in all calcined samples. This indicates that all samples are predominantly HA rather than other calcium phosphates. The presence of secondary phases was also observed. The main peaks at 2θ = 13.63 (104), 21.87 (024), 27.76 (214), 32.44 (128) and 34.37° (220) (JCPDS No. 09-0169) imply the presence of beta-tricalcium phosphate (β-TCP, Ca3(PO4)2), while the peak at 39.20° (200) implies the formation of calcium oxide (CaO). This was attributed to elevated temperatures or HA decomposition due to chemical impurities [44,45,46]. Biphasic calcium phosphate (BCP) comprises both HA and β-TCP that can enhance the formation of new bone and bone remodeling due to phosphate and calcium ions being released, caused by BCP’s partial dissolution. Moreover, the incorporation of zinc and/or silver ions in HA caused a decrease in the crystallinity of the HA crystals. This is observed by a broadening of XRD diffraction peaks.

Figure 2.

XRD spectra of (a) HAp1100, (b) Zn1.0 doped HA1100, (c) Zn0.75Ag0.25 doped HA1100, (d) Zn0.5Ag0.5 doped HA1100 (e) Zn0.25Ag0.75 doped HA1100 and (f) Ag1.0 doped HA1100.

The Rietveld method was used to compute for the lattice parameters shown in Table 2. The presence of zinc and/or silver ions was observed to cause an increase in both lattice parameters (a and c). In comparison to Ca2+ (0.100 nm), Ag+ (0.115 nm) has a lower ionic radii while Zn2+ (0.074 nm) has a higher ionic radii, which causes the distortion.

Table 2.

Lattice parameters and crystallite size of Zn-Ag doped HA1100 samples obtained from XRD analysis.

From the (211), (300), (310), (213) and (402) planes, the Debye-Scherrer formula was applied to compute for the normal crystallite size of the material [42]:

where β2θ is the angular width (radians) at an intensity equal to the full width at half the maximum, λ refers to wavelength of X-ray radiation used, θ represents the angle of diffraction, k is a constant shape factor, and D is the average crystallite size (nm). From Table 2, the crystallite size was determined to be 71 nm for HA, while that of HA in Zn-Ag doped HA samples ranged from 55 to 85 nm. The size of HA tended to increase with the silver ion amount due to the different sizes of ionic radii for Ca2+, Zn2+ and Ag+ ions. The successful syntheses of both HA and Zn-Ag doped HA are validated by the XRD results.

3.2. FT-IR Analysis and N2 Adsorption-Desorption

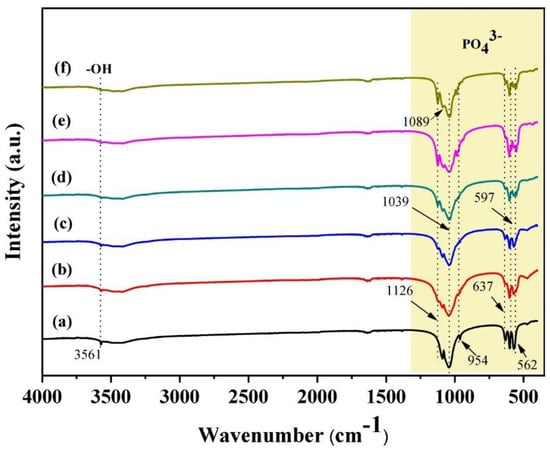

Figure 3 presents the FT-IR spectra of calcined samples. All of the characteristic vibration bands of hydroxyapatite were identified. These include the stretching (~3561 cm−1) in the HA lattice by the OH (O-H bond) and the ν4 bending (~560–600 cm−1), ν3 stretching (1039, 1089 and 1126 cm−1) and ν1 stretching (954 cm−1) modes of orthophosphate groups [47].

Figure 3.

FT-IR spectra of (a) HA1100, (b) Zn1.0 doped HA1100, (c) Zn0.75Ag0.25 doped HA1100, (d) Zn0.5Ag0.5 doped HA1100, (e) Zn0.25Ag0.75 doped HA1100 and (f) Ag1.0 doped HA1100.

Figure 4 displays the N2 adsorption-desorption isotherms of Zn-Ag doped HA and HA in which the insets are pore size distribution curves. In all samples, the presence of H1-type hysteresis loops is observed, which is a characteristic of a Type IV isotherm. This implies the occurrence of a mesoporous structure [48]. A parallel pattern of the adsorption branch to the desorption curve was observed, including a narrow area of the hysteresis loop. These phenomena suggest the formed HA have a microporous structure [48]. As shown in Table 3, the specific surface area of pristine HA is 2.675 m2/g. The surface area of Zn-Ag doped HA tends to gradually increase with the silver loading. The BJH nitrogen desorption was applied in the plot of the pore diameters’ distribution. The pore diameters and total pore volumes of the samples were in the range of 20–30 nm and 0.010–0.020 cm3/g, respectively. This implies that the synthesized Zn-Ag doped HA is a mesoporous material.

Figure 4.

N2 adsorption-desorption isotherms and pore size distribution of (A) HA1100, (B) Zn1.0 doped HA1100, (C) Zn0.75Ag0.25 doped HA1100 and (D) Ag1.0 doped HA1100.

Table 3.

Surface properties of HA and ZnAg doped samples estimated from nitrogen adsorption/desorption isotherms.

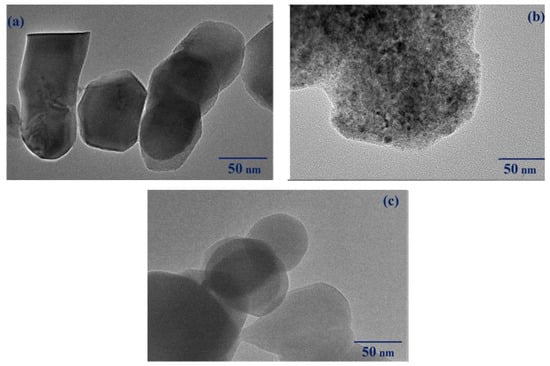

3.3. TEM Analysis

TEM images are displayed in Figure 5 for selected Zn-Ag doped HA and HA calcined at 1100 °C for 1 h and 600 °C for 4 h. The results show the presence of oval-shaped particles with diameters of 62.6 ± 3.41 nm for the morphology of HA1100 (Figure 5a). Numerous dark spots with diameters less than 5 nm were present in fine HA nanoparticles for Zn0.75Ag0.25 doped HA1100 (Figure 5b), which could imply the presence of Zn2+ and Ag+ species. The substitution of Ag+ and Zn2+ for Ca2+ in HA resulted in the agglomeration of HA, Ag+ and Zn2+ particles, which can be validated by the dense distribution on the HA surfaces by the nanoparticles.

Figure 5.

TEM images of (a) HA1100, (b) Zn0.75Ag0.25 doped HA1100 and (c) Zn0.5Ag0.5 doped HA1100.

In Figure 5c, HA nanoparticles of Zn0.50Ag0.50 doped HA1100 were observed to have spherical shapes with diameters of 61.72 ± 3.89 nm. Both the XRD results and the TEM results are in agreement with each other, which implies the incorporation in the HA structure by Zn2+ and Ag+. The antibacterial and mechanical characteristics of Zn-Ag doped HA samples are dependent on the distribution of Zn2+ and Ag+ nanoparticles and the formation of nano-sized HA.

3.4. Antibacterial Activity

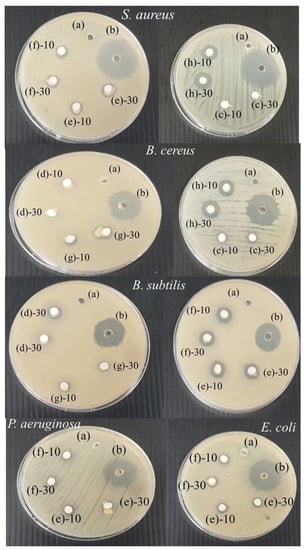

The agar well diffusion method was applied to all five bacterial strains and the antimicrobial activity of calcined Zn-Ag doped HA samples at concentrations of 10 and 30 mg/mL was examined, as seen in Figure 6. Table 4 shows an inhibition zone with a larger diameter implies that the antimicrobial agents are more effective against the bacterial strains. The inhibition zones for tetracycline control were observed to range from 17 to 26 mm, which indicates its efficacy against all bacterial strains. The presence of bacterial growth for HA1100 powder suggests that it has no antibacterial activity for all studied strains. The results show that the 30 mg/mL of Zn1.0 doped HA sample caused an inhibition zone with a 7.60 mm diameter for B. subtilis only. Gram-positive bacteria, such as B. subtilis, B. cereus, and S. aureus, were found to be susceptible towards Ag1.0 doped HA nanoparticles with inhibition zones ranging from 10 to 14 mm. Similar antibacterial activities were observed for both single Ag doped HA and dual doped Zn-Ag doped HA nanoparticles. Most of the synthesized samples inhibited the growth of the microorganisms tested. None of the synthesized samples were active against P. aeruginosa. This indicated that Gram-negative strains (E. coli and P. aeruginosa) are less susceptible than Gram-positive bacteria. Gram-negative bacteria are characterized by their thick cell wall located between the inner and outer lipid membranes, which is composed of several layers of structural lipopolysaccharides in a periplasmic space. Hence, the impermeability of the cell wall to lipophilic solutes is attributed to its complexity, which would result in enhanced stability against some chemical agents [49]. Moreover, Gram-negative bacteria have several efflux pumps that inhibit the buildup in the cell membrane of anti-microbial substances [50]. Alternatively, the simple cell wall of Gram-positive bacteria is composed of one layer of peptidoglycan and lipoteichoic acids [49,50].

Figure 6.

Images of the antibacterial activity of calcined samples against five strains of bacteria at doses of 10 and 30 mg/mL: (a) negative control, (b) positive control, (c) HA1100, (d) Zn1.0 doped HA1100, (e) Zn0.75Ag0.25 doped HA1100, (f) Zn0.5Ag0.5 doped HA1100, (g) Zn0.25Ag0.75 doped HA1100 and (h) Ag1.0 doped HA1100.

Table 4.

Diameter of inhibition zones of calcined samples against five different types of bacterial strains (ND = no detection).

The results show that the Zn0.75Ag0.25 doped HA1100 sample provided the best performance for antibacterial activity. Thus, the MIC and MBC values of this sample were further investigated against B. Subtilis, since it was shown to be the most susceptible to the Zn0.75Ag0.25 doped HA1100 sample. Zn0.75Ag0.25 doped HA1100 provided 20 mg/mL for its MIC value. This condition is well within the limits of cytotoxicity [51,52]. The bactericidal activity of Zn0.75Ag0.25 doped HA1100 was measured to be >40 mg/mL for its MBC values for B. Subtilis. Furthermore, a decreased silver content can imply lower costs in applying these nanoparticles.

4. Conclusions

The sol-gel technique combined with ultrasonic irradiation was successful in the synthesis of mesoporous zinc-silver doped HA with exceptional antimicrobial characteristics. The formation of numerous crystalline phases, such as β-TCP, CaO and HA, were observed after calcination at 600 °C for 4 h and 1100 °C for 1 h. However, the XRD patterns indicate the absence of oxides and phosphates of silver and zinc. The crystallite sizes of HA in Zn-Ag doped HA ranged from 55 to 85 nm. The main functional groups, OH- and PO43–, were fully supported by the XRD analysis. All samples had mesoporous characteristics with Type IV isotherms. The HA lattice displayed a homogeneous distribution of zinc and silver particles, as validated by the TEM analysis. The results of the agar well diffusion method illustrated the exceptional antimicrobial activity against both Gram negative and Gram-positive bacteria of the Zn0.75Ag0.25 doped HA1100 sample. Hence, Zn0.75Ag0.25 doped HA1100 displayed excellent antibacterial properties, which makes it a promising material in water purification.

Author Contributions

Conceptualization, P.P. and O.P.; methodology, N.P., S.K., A.K., W.R., S.P., C.M.F., P.K., T.B., S.Y. and J.C.M.; formal analysis, P.P.; writing—original draft preparation, P.P.; writing—review and editing, P.P., C.M.F. and O.P.; supervision, O.P.; project administration, O.P.; funding acquisition, O.P. All authors have read and agreed to the published version of the manuscript.

Funding

This research project was financially supported by Mahasarakham University (Thailand) and Mapua University (Philippines).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

Many thanks to Jeffrey C. Nash from the Office of Graduate Studies of the Udon Thani Rajabhat University, Thailand, for his assistance in proofreading this manuscript. The authors thank financial support from the Mahasarakham University (Thailand) and Mapua University (Philippines).

Conflicts of Interest

The authors declare no conflict of interest.

References

- Rey, C.; Combes, C.; Drouet, C.; Glimcher, M.J. Bone Mineral: Update on Chemical Composition and Structure. Osteoporos Int. 2009, 20, 1013–1021. [Google Scholar] [CrossRef] [PubMed]

- Nawang, R.; Hussein, M.Z.; Matori, K.A.; Che Abdullah, C.A.; Hashim, M. Physicochemical Properties of Hydroxyapatite/Montmorillonite Nanocomposite Prepared by Powder Sintering. Results Phys. 2019, 15, 102540. [Google Scholar] [CrossRef]

- Kalita, S.J.; Bhardwaj, A.; Bhatt, H.A. Nanocrystalline Calcium Phosphate Ceramics in Biomedical Engineering. Mater. Sci. Eng. C 2007, 27, 441–449. [Google Scholar] [CrossRef]

- Goodman, S.B.; Yao, Z.; Keeney, M.; Yang, F. The Future of Biologic Coatings for Orthopaedic Implants. Biomaterials 2013, 34, 3174–3183. [Google Scholar] [CrossRef]

- Currey, J. Sacrificial Bonds Heal Bone. Nature 2001, 414, 699. [Google Scholar] [CrossRef]

- Elliott, J.C. Structure and Chemistry of the Apatites and Other Calcium Orthophosphates, 1st ed.; Elsevier: Amsterdam, The Netherlands, 1994; Volume 18, Available online: https://www.elsevier.com/books/structure-and-chemistry-of-the-apatites-and-other-calcium-orthophosphates/elliott/978-0-444-81582-8 (accessed on 30 June 2022).

- Sadat-Shojai, M.; Khorasani, M.-T.; Dinpanah-Khoshdargi, E.; Jamshidi, A. Synthesis Methods for Nanosized Hydroxyapatite with Diverse Structures. Acta Biomater. 2013, 9, 7591–7621. [Google Scholar] [CrossRef]

- Mondal, S.; Nguyen, T.P.; Pham, V.H.; Hoang, G.; Manivasagan, P.; Kim, M.H.; Nam, S.Y.; Oh, J. Hydroxyapatite Nano Bioceramics Optimized 3D Printed Poly Lactic Acid Scaffold for Bone Tissue Engineering Application. Ceram. Int. 2020, 46, 3443–3455. [Google Scholar] [CrossRef]

- Jarcho, M. Calcium Phosphate Ceramics as Hard Tissue Prosthetics. Clin. Orthop. Relat. Res. 1981, 157, 259–278. [Google Scholar] [CrossRef]

- Gopi, D.; Kanimozhi, K.; Bhuvaneshwari, N.; Indira, J.; Kavitha, L. Novel Banana Peel Pectin Mediated Green Route for the Synthesis of Hydroxyapatite Nanoparticles and Their Spectral Characterization. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2014, 118, 589–597. [Google Scholar] [CrossRef]

- Srilakshmi, C.; Saraf, R. Ag-Doped Hydroxyapatite as Efficient Adsorbent for Removal of Congo Red Dye from Aqueous Solution: Synthesis, Kinetic and Equilibrium Adsorption Isotherm Analysis. Microporous Mesoporous Mater. 2016, 219, 134–144. [Google Scholar] [CrossRef]

- Vakili, S.N.; Rezayi, M.; Chahkandi, M.; Meshkat, Z.; Fani, M.; Moattari, A. A Novel Electrochemical DNA Biosensor Based on Hydroxyapatite Nanoparticles to Detect BK Polyomavirus in the Urine Samples of Transplant Patients. IEEE Sens. J. 2020, 20, 12088–12095. [Google Scholar] [CrossRef]

- Amjad, M.U.; Ahmed, B.A.; Ahmed, F.; Saeed, H.A. Development and Characterization of Silver-Doped Multi-Walled Carbon Nanotube Membranes for Water Purification Applications. Membranes 2022, 12, 179. [Google Scholar] [CrossRef] [PubMed]

- Fanta, F.T.; Dubale, A.A.; Bebizuh, D.F.; Atlabachew, M. Copper Doped Zeolite Composite for Antimicrobial Activity and Heavy Metal Removal from Waste Water. BMC Chem. 2019, 13, 44. [Google Scholar] [CrossRef]

- Hong, X.; Wu, X.; Zhang, Q.; Xiao, M.; Yang, G.; Qiu, M.; Han, G. Hydroxyapatite Supported Ag3PO4 Nanoparticles with Higher Visible Light Photocatalytic Activity. Appl. Surf. Sci. 2012, 258, 4801–4805. [Google Scholar] [CrossRef]

- Ghahremani, D.; Mobasherpour, I.; Salahi, E.; Ebrahimi, M.; Manafi, S.; Keramatpour, L. Potential of Nano Crystalline Calcium Hydroxyapatite for Tin(II) Removal from Aqueous Solutions: Equilibria and Kinetic Processes. Arab. J. Chem. 2017, 10, S461–S471. [Google Scholar] [CrossRef]

- Amenaghawon, A.N.; Anyalewechi, C.L.; Darmokoesoemo, H.; Kusuma, H.S. Hydroxyapatite-Based Adsorbents: Applications in Sequestering Heavy Metals and Dyes. J. Environ. Manag. 2022, 302, 113989. [Google Scholar] [CrossRef]

- Sangeetha, K.; Vidhya, G.; Vasugi, G.; Girija, E.K. Lead and Cadmium Removal from Single and Binary Metal Ion Solution by Novel Hydroxyapatite/Alginate/Gelatin Nanocomposites. J. Environ. Chem. Eng. 2018, 6, 1118–1126. [Google Scholar] [CrossRef]

- Zhou, C.; Wang, X.; Wang, Y.; Song, X.; Fang, D.; Ge, S. The Sorption of Single- and Multi-Heavy Metals in Aqueous Solution Using Enhanced Nano-Hydroxyapatite Assisted with Ultrasonic. J. Environ. Chem. Eng. 2021, 9, 105240. [Google Scholar] [CrossRef]

- Gibert, O.; Valderrama, C.; Martínez, M.M.; Darbra, R.M.; Moncunill, J.O.; Martí, V. Hydroxyapatite Coatings on Calcite Powder for the Removal of Heavy Metals from Contaminated Water. Water 2021, 13, 1493. [Google Scholar] [CrossRef]

- Rastgordani, M.; Zolgharnein, J. Simultaneous Determination and Optimization of Titan Yellow and Reactive Blue 4 Dyes Removal Using Chitosan@hydroxyapatite Nanocomposites. J. Polym. Environ. 2021, 29, 1789–1807. [Google Scholar] [CrossRef]

- Roy, M.; Bandyopadhyay, A.; Bose, S. Induction Plasma Sprayed Sr and Mg Doped Nano Hydroxyapatite Coatings on Ti for Bone Implant. J. Biomed. Mater. Res. B Appl. Biomater. 2011, 99, 258–265. [Google Scholar] [CrossRef] [PubMed]

- Milán, Z.; de Las Pozas, C.; Cruz, M.; Borja, R.; Sánchez, E.; Ilangovan, K.; Espinosa, Y.; Luna, B. The Removal of Bacteria by Modified Natural Zeolites. J. Environ. Sci. Health Part A Toxic Hazard. Subst. Environ. Eng. 2001, 36, 1073–1087. [Google Scholar] [CrossRef]

- DeAlba-Montero, I.; Guajardo-Pacheco, J.; Morales-Sánchez, E.; Araujo-Martínez, R.; Loredo-Becerra, G.M.; Martínez-Castañón, G.-A.; Ruiz, F.; Compeán Jasso, M.E. Antimicrobial Properties of Copper Nanoparticles and Amino Acid Chelated Copper Nanoparticles Produced by Using a Soya Extract. Bioinorg. Chem. Appl. 2017, 2017, 1064918. [Google Scholar] [CrossRef] [PubMed]

- Boanini, E.; Gazzano, M.; Bigi, A. Ionic Substitutions in Calcium Phosphates Synthesized at Low Temperature. Acta Biomater. 2010, 6, 1882–1894. [Google Scholar] [CrossRef]

- Jankauskaitė, V.; Vitkauskienė, A.; Lazauskas, A.; Baltrusaitis, J.; Prosyčevas, I.; Andrulevičius, M. Bactericidal Effect of Graphene Oxide/Cu/Ag Nanoderivatives against Escherichia Coli, Pseudomonas Aeruginosa, Klebsiella Pneumoniae, Staphylococcus Aureus and Methicillin-Resistant Staphylococcus Aureus. Int. J. Pharm. 2016, 511, 90–97. [Google Scholar] [CrossRef]

- Graziani, G.; Bianchi, M.; Sassoni, E.; Russo, A.; Marcacci, M. Ion-Substituted Calcium Phosphate Coatings Deposited by Plasma-Assisted Techniques: A Review. Mater. Sci. Eng. C 2017, 74, 219–229. [Google Scholar] [CrossRef]

- Singh, B.; Dubey, A.K.; Kumar, S.; Saha, N.; Basu, B.; Gupta, R. In Vitro Biocompatibility and Antimicrobial Activity of Wet Chemically Prepared Ca10−xAgx(PO4)6(OH)2 (0.0 ≤ x ≤ 0.5) Hydroxyapatites. Mater. Sci. Eng. C 2011, 31, 1320–1329. [Google Scholar] [CrossRef]

- Iqbal, N.; Abdul Kadir, M.R.; Nik Malek, N.A.N.; Humaimi Mahmood, N.; Raman Murali, M.; Kamarul, T. Rapid Microwave Assisted Synthesis and Characterization of Nanosized Silver-Doped Hydroxyapatite with Antibacterial Properties. Mater. Lett. 2012, 89, 118–122. [Google Scholar] [CrossRef]

- Lim, P.N.; Chang, L.; Thian, E.S. Development of Nanosized Silver-Substituted Apatite for Biomedical Applications: A Review. Nanomedicine 2015, 11, 1331–1344. [Google Scholar] [CrossRef]

- Guo, C.; Xue, J.; Dong, Y. Fabrication and Characterization of Hydroxyapatite Nanomaterial Dual Deposited with Nano Silver and Zinc Oxide. Mater. Lett. 2018, 219, 182–185. [Google Scholar] [CrossRef]

- Arumugam, M.; Pandi, P.; Balasubramanian, N.; Palanichamy, R.; Neyvasagam, K. Structural, Optical and Antimicrobial Activity of Copper and Zinc Doped Hydroxyapatite Nanopowders Using Sol-Gel Method. Mech. Mater. Sci. Eng. 2017, 9, 1. [Google Scholar] [CrossRef]

- Yang, Y.-C.; Chen, C.-C.; Wang, J.-B.; Wang, Y.-C.; Lin, F.-H. Flame Sprayed Zinc Doped Hydroxyapatite Coating with Antibacterial and Biocompatible Properties. Ceram. Int. 2017, 43, S829–S835. [Google Scholar] [CrossRef]

- Sery, A.A.; El-Boraey, H.A.; Abo-Elenein, S.A.; ElKorashey, R.M. CuFe2O4@ Hydroxyapatite Composite for the Environmental Remediation of Some Heavy Metal Ions: Synthesis and Characterization. Water Sci. 2021, 35, 154–164. [Google Scholar] [CrossRef]

- Panneerselvam, K.; Arul, K.T.; Warrier, A.R.; Asokan, K.; Dong, C.-L. Rapid Adsorption of Industrial Pollutants Using Metal Ion Doped Hydroxyapatite. AIP Conf. Proc. 2019, 2117, 020004. [Google Scholar] [CrossRef]

- Sopyan, I.; Pusparini, E.; Ramesh, S.; Tan, C.Y.; Ching, Y.C.; Wong, Y.H.; Abidin, N.I.Z.; Chandran, H.; Ramesh, S.; Bang, L.T. Influence of Sodium on the Properties of Sol-Gel Derived Hydroxyapatite Powder and Porous Scaffolds. Ceram. Int. 2017, 43, 12263–12269. [Google Scholar] [CrossRef]

- Triyono, D.; Hanifah, U.; Laysandra, H. Structural and Optical Properties of Mg-Substituted LaFeO3 Nanoparticles Prepared by a Sol-Gel Method. Results Phys. 2020, 16, 102995. [Google Scholar] [CrossRef]

- Chahkandi, M. Mechanism of Congo Red Adsorption on New Sol-Gel-Derived Hydroxyapatite Nano-Particle. Mater. Chem. Phys. 2017, 202, 340–351. [Google Scholar] [CrossRef]

- Varadarajan, N.; Balu, R.; Rana, D.; Ramalingam, M.; Kumar, T.S.S. Accelerated Sonochemical Synthesis of Calcium Deficient Hydroxyapatite Nanoparticles: Structural and Morphological Evolution. J. Biomater. Tissue Eng. 2014, 4, 295–299. [Google Scholar] [CrossRef]

- Rouhani, P.; Taghavinia, N.; Rouhani, S. Rapid Growth of Hydroxyapatite Nanoparticles Using Ultrasonic Irradiation. Ultrason. Sonochem. 2010, 17, 853–856. [Google Scholar] [CrossRef]

- Kim, W.; Saito, F. Sonochemical Synthesis of Hydroxyapatite from H3PO4 Solution with Ca(OH)2. Ultrason. Sonochem. 2001, 8, 85–88. [Google Scholar] [CrossRef]

- Kamonwannasit, S.; Futalan, C.M.; Khemthong, P.; Butburee, T.; Karaphun, A.; Phatai, P. Synthesis of Copper-Silver Doped Hydroxyapatite via Ultrasonic Coupled Sol-Gel Techniques: Structural and Antibacterial Studies. J. Sol-Gel Sci. Technol. 2020, 96, 452–463. [Google Scholar] [CrossRef]

- Ni, Z.; Gu, X.; He, Y.; Wang, Z.; Zou, X.; Zhao, Y.; Sun, L. Synthesis of Silver Nanoparticle-Decorated Hydroxyapatite (HA@Ag) Poriferous Nanocomposites and the Study of Their Antibacterial Activities. RSC Adv. 2018, 8, 41722–41730. [Google Scholar] [CrossRef] [PubMed]

- Guo, X.; Yan, H.; Zhao, S.; Li, Z.; Li, Y.; Liang, X. Effect of Calcining Temperature on Particle Size of Hydroxyapatite Synthesized by Solid-State Reaction at Room Temperature. Adv. Powder Technol. 2013, 24, 1034–1038. [Google Scholar] [CrossRef]

- Sompech, S.; Dasri, T.; Thaomola, S. Preparation and Characterization of Amorphous Silica and Calcium Oxide from Agricultural Wastes. Orient. J. Chem. 2016, 32, 1923–1928. [Google Scholar] [CrossRef]

- Miculescu, F.; Maidaniuc, A.; Miculescu, M.; Dan Batalu, N.; Cătălin Ciocoiu, R.; Voicu, Ş.I.; Stan, G.E.; Thakur, V.K. Synthesis and Characterization of Jellified Composites from Bovine Bone-Derived Hydroxyapatite and Starch as Precursors for Robocasting. ACS Omega 2018, 3, 1338–1349. [Google Scholar] [CrossRef]

- Nayak, B.; Samant, A.; Patel, R.; Misra, P.K. Comprehensive Understanding of the Kinetics and Mechanism of Fluoride Removal over a Potent Nanocrystalline Hydroxyapatite Surface. ACS Omega 2017, 2, 8118–8128. [Google Scholar] [CrossRef]

- Huang, A.; Dai, H.; Wu, X.; Zhao, Z.; Wu, Y. Synthesis and Characterization of Mesoporous Hydroxyapatite Powder by Microemulsion Technique. J. Mater. Res. Technol. 2019, 8, 3158–3166. [Google Scholar] [CrossRef]

- Brown, L.; Wolf, J.M.; Prados-Rosales, R.; Casadevall, A. Through the Wall: Extracellular Vesicles in Gram-Positive Bacteria, Mycobacteria and Fungi. Nat. Rev. Microbiol. 2015, 13, 620–630. [Google Scholar] [CrossRef]

- Gokcekaya, O.; Ueda, K.; Ogasawara, K.; Kanetaka, H.; Narushima, T. In Vitro Evaluation of Ag-Containing Calcium Phosphates: Effectiveness of Ag-Incorporated β-Tricalcium Phosphate. Mater. Sci. Eng. C 2017, 75, 926–933. [Google Scholar] [CrossRef]

- Nath, S.; Kalmodia, S.; Basu, B. Densification, Phase Stability and in Vitro Biocompatibility Property of Hydroxyapatite-10 wt% Silver Composites. J. Mater. Sci. Mater. Med. 2010, 21, 1273–1287. [Google Scholar] [CrossRef]

- Rajendran, A.; Barik, R.C.; Natarajan, D.; Kiran, M.S.; Pattanayak, D.K. Synthesis, Phase Stability of Hydroxyapatite–Silver Composite with Antimicrobial Activity and Cytocompatability. Ceram. Int. 2014, 40, 10831–10838. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).