Abstract

This study aims to obtain a desirable 3D printing product based on the knowledge of the material and suitable printing parameters. This study used high-methoxy pectin (HMP) as the ingredient of pectin jelly candy to understand the effect of different pectin concentrations and printing parameters (nozzle height, extrusion rate, printing layer height, nozzle movement speed, and nozzle diameter). Machine learning was used to learn and analyze the data of different 3D printing parameters to find out a suitable parameter. Rheological analysis revealed that a 16% pectin (w/v) concentration had the height of G′ and G″, and all pectin jelly candy showed the characteristic of shearing thinning. A parameter analysis decision tree revealed that the pectin concentration of 12–14% (w/v), printing layer height below 1.5 mm, extrusion rate below 0.305 mm3/s, nozzle height above 0.5 mm, and printing rate of 5–10 mm were able to allow pectin jelly candy to be printed with an error below 5%. Machine learning helps researchers find appropriate parameters and reach the design of molding height quickly, and it helps them discuss how molecule interaction causes different 3D printing results.

1. Introduction

Three-dimensional food printing is one of the most popular technologies nowadays. It is used to print food with a 3D structure via a 3D printer. Additive manufacturing is the most used technology within the 3D printing field [1], including in biomedical applications and construction industries [2,3]. In food industries, 3D printing is used to print food products with different patterns and shapes; it has been applied to sugar, meat products, chocolate, flour, etc. [4]. Three-dimensional food printing is usually printed and stacked layer by layer; however, with soft material, different mechanical propulsion methods (piston extrusion, air pressure extrusion, and screw extrusion) were used to let the printing material be able to extrude, print, and stack on the specific place such that the targeted 3D pattern is printed after this repeat action is performed [5]. The 3D printing material must fulfill a few requirements, including being able to extrude in a liquid or molten state, solidify rapidly, and support high strength. Besides the characteristic of the printing material, the concentration and discharge pattern of material need to be considered before printing to prevent collapse and deformation during and after 3D printing [4,6,7]. According to Yang et al.’s and Zheng et al.’s statements, 3D printing material should fulfill fluid-shear-thinning properties and support high strength so that the material can be easily extruded and solidified rapidly [8,9]. Based on the literature above, the characteristics of the printing material in the extrusion system are important and should be understood before printing.

Studies of 3D printing with hydrocolloids have usually been focused on the stability of products with complex formulas [10,11,12]; however, in 3D printing with pectin, the stability of the product was highly influenced by the material added [13,14,15]. Pectin has the functions of gelation, emulsification, thickening, and stabilization; it also has certain effects on chronic diseases such as hypertension and hyperlipidemia and is widely used in food, medical, chemical, and other industries [16]. Pectin gelation is a three-dimensional network structure of polymer molecular chains that traps the solvent and solute in the chain. The conditions required for gelation and the properties of the gel ultimately depend on the molecular structure, maintaining the intermolecular forces and the polymer molecular chain [17]. Gelation is the most important characteristic of pectin. The HMP solution has over 60% soluble solid content and a pH value between 2.8 and 3.2, which cause pectin and sugar to form a three-dimensional network structure, which is irreversible. The high sucrose concentration causes dehydration of pectin molecules and leads to gelation due to intermolecular hydrogen bonding [16]. Guimarães et al. also reported that HMP produces products with higher viscosity, which is mainly due to the increase in hydrophobic effects [18]. pH is an important factor for HMP; the dissociation of the carboxyl group produces a negative charge, which makes the molecules repel each other. Therefore, reducing pH value allows protonating the carboxyl matrix and reducing the electrostatic repulsion between the pectin chains [19]. The diluted pectin solution contains evenly dispersed pectin molecules, but these molecules are too far apart to interact with each other, so the shear-rate pattern of the liquid changes as the proportion of water molecules increases [18]. The viscosity of the pectin solution increases with increasing pectin concentration [20]. The pectin transformation from Newtonian fluid to shear-thinning behavior mainly depends on the molecular weight of the actual pectin used [16]. Shear thinning behavior occurs when the concentration increases, which is similar to increasing shear rate when the viscosity decreases [20]. Many studies have reported that pseudoplasticity increases with increasing pectin concentration [21,22,23]. A linear relationship can be observed between the shear stress of the pectin solution and the shear rate. Thus, pectin concentration, pH, and water content will affect the effect of the pectin gel and will affect the properties of extrusion and solidification.

Stable extrusion characteristics are related to the 3D printer’s parameters, and this will affect the fineness and completeness of the printed products [24]. At the same extrusion speed, higher nozzle movement speed may cause shape deformation, and lower nozzle movement speed may cause material accumulation, thereby increasing the thickness of the printed layer and weight. Hao et al. stated that the nozzle diameter, nozzle height, and nozzle movement speed are some of the key factors affecting the geometric pattern of printed chocolate. Three-dimensional-printing parameters affect the finished product and accuracy [25].

In the context of 3D printed soft candy, the gelation during 3D printing with different parameters is not fully understood. Little research has studied the relationship between 3D printing materials and parameters, nor has it studied the relationship between accuracy and parameters. Therefore, this study discusses the relationship between sugar and HMP systems in 3D printing and then evaluates the effect of fluidity and solidification of printing materials and determines the appropriate pectin jelly candy printing parameters.

2. Materials and Methods

2.1. Materials

Materials (high-methoxy pectin, citric acid) were purchased from Zhenfang Co., Ltd. (Taipei, Taiwan), and sugars (refined and glucose) were purchased from Taiwan Sugar Co., Ltd., (Yunlin, Taiwan).

2.2. Preparation of Pectin Jelly Candy

Boil 100 mL distilled water within a magnetic stirrer (Model HMS-102, FARGO), and mix with 10, 12, 14, and 16 g pectin powder and 5 g glucose, 35 g sucrose, and 0.07 g citric acid (pH value controlled at 3.0 until fully dissolved). Heat continuously to evaporate water and concentrate until the total volume was 100 mL and start the 3D printing process.

2.3. Rheological Analysis

Different pectin concentration (10, 12, 14, 16% (w/v)) was chosen to determine the rheology analysis with 25 mm parallel plate probe equipped rotary rheometer (Model MCR92, Anton Paar, Austria) [8]. The spacing was set to 1 mm and shear rate was set at 0–300 s−1.

η is the apparent viscosity (Pa·s), σ is the shear stress (Pa), and is the shear rate (1/s).

2.4. Viscoelastic Analysis

Zheng et al.’s research was modified with the storage modulus (G′), loss modulus (G″), and tangent delta (tanδ) with an angular frequency of 0.1–1.0 rad/s, shear strain of 5%, and temperature of 25 °C. The linear viscoelastic regions were determined from scans of the oscillation frequency at a constant stress.

2.5. Three-Dimensional-Printing Parameters

Pectin jelly candy was printed with the D-Force printer (D-Force, V2-300, Koyo International, Taiwan). The pectin jelly candy was printed after different parameters were set under appropriate conditions. The parameters included are listed below. Each parameter used different conditions to print a hollow cube, and the average height was used to calculate the final height of printed pectin jelly candy. Each formula was performed in triplicate, and the pattern was designed with 123D Design software.

2.5.1. Pectin Concentration

The pectin solution (10, 12, 14, 16% (w/v)) was prepared according to Section 2.2 and loaded in the 3D printer to print a 2 cm3 hollow cube.

2.5.2. Nozzle Height

Nozzle height (hc), i.e., the first layer height, is the distance between the tip of extrusion nozzle and the printing bed and has a great influence on the extruded geometry [26]. The first layer height determines the thickness of the first layer which is printed on the bed. The optimal nozzle height can be calculated by the following Equation (1) [27].

where Vd is the amount of extrude material (cm3/s), Vn is the moving speed of the nozzle (mm/s), and Dn is the diameter of the nozzle.

Four different nozzle heights (0.5, 1.5, 2, 3 mm) were used to print the first layer and the 2 cm3 hollow cube.

2.5.3. Printing Layer Height

The printing layer height is a measurement of how much material the printer’s nozzle extrudes for each layer of the part. In this study, printing layers of 1, 1.5, 2, and 2.5 mm were used to print the hollow cube.

2.5.4. Nozzle Movement Speed

Nozzle movement speed is the speed of the nozzle moved during printing. Different nozzle movement speeds (5, 10, 15, 20 mm/s) were used to print the hollow cubes.

2.5.5. Nozzle Diameter

The diameter of the nozzle is the width of the output of the printing nozzle. Different nozzle diameters (1.5, 2, 2.5, and 3 mm) were first printed with a 3D printer and then used to print the hollow cubes.

2.5.6. Extrusion Rate

Extrusion rate is the amount of material that can be extruded per unit time. Four different extrusion rates (0.016, 0.030, 0.045, 0.056 cm3/s) were used to print hollow cubes. The extrusion rate was calculated by determining the total volume of the cylindrical syringe and calculate the outflow volume per unit second.

2.6. Statistical Analysis

Statistical analysis was performed with SAS statistical software, and the significant differences were investigated with Duncan’s multiple range test. XLSTAT 2019 was used for machine learning classification and regression trees (decision tree) to analyze printing parameters.

3. Results

3.1. Viscosity Analysis

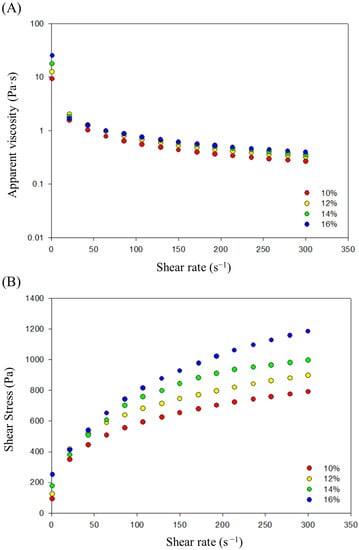

The rheological properties of printing material used for 3D food printing are important. The rheological properties can generally classified into elastic and viscosity [28]. The viscosity is another important factor for materials. Generally, 3D printing materials should have shear-thinning properties to lower the viscosity and extrude easily [29]. The viscosity will be affected by the material’s concentration and the shear stress. Figure 1A reveals the different concentrations of pectin jelly candy and shear stress. The viscosity of the pectin at different concentrations decreased to 0.62, 0.32, 0.36, and 0.39 Pa·s as the shear rate increased from 0 to 300 s−1. This indicated that HMP represents a shear-thinning pseudoplastic fluid, which helps the pectin solution to pump easily from nozzle. However, at the shear rate of 300 s−1, the viscosity increased, and the concentration increased. A result was that the distance between pectin molecules decrease, which allows an improved interaction between them and increased viscosity. This phenomenon is common in polysaccharides systems: when the pectin concentration increases, the zero shear viscosity is the highest and the viscosity decreases with the increase in the shear rate [30]. As shown in Figure 1B, there was no linear relation between these parameters; thus, the pectin solutions were not Newtonian fluids but were shear-thinning fluids, because when the shear rate increased, the shear stress lowered.

Figure 1.

Viscosity analysis of different concentrations pectin solution: (A) viscosity curve and (B) flow curve.

3.2. Viscoelastic Analysis

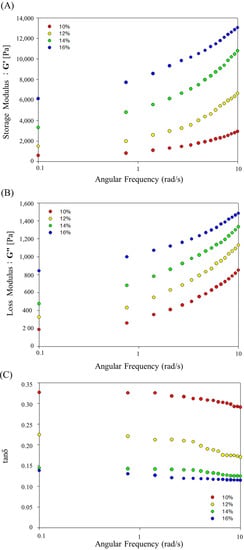

Storage modulus (G′) represents the elastic behavior in solid, and it reflects the materials’ strength by determining the elastic recovery ability of materials. Loss modulus (G″) represents the viscosity behavior of liquid. When loss tangent (tanδ = G″/G′) was greater than 1, the material exhibited predominantly viscous behavior, whereas when it was less than 1, the material exhibited predominately elastic behavior; higher tanδ showed liquid behavior, while lower tanδ showed solid behavior [31].

From Figure 2A, the storage modulus increased from 573.70 Pa to 6128.43 Pa when the pectin concentration increased. There was a similar trend observed in Figure 2B, which was mainly due to the gelling state formed by the interaction between pectin molecules. At different pectin concentrations, the G′ was greater than G″, which meant that pectin molecules formed an elastic gelling structure. In Figure 2C, the tanδ was less than 1, but under 0.1 rad/s, the tanδ decreased from 0.33 to 0.14 as pectin concentration increased. This is due to the stronger network structure formed by the pectin molecules. With increasing oscillation frequency, the tanδ decreased. This indicates that the structure underwent molecule entanglement under strong oscillation frequency [32].

Figure 2.

Viscoelastic analysis of different concentrations of pectin solution: (A) storage modulus, (B) loss modulus, and (C) loss tangent.

3.3. Printing Parameter

3.3.1. Pectin Concentration

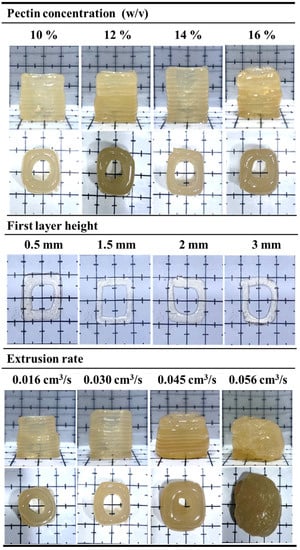

Figure 3 shows the result of a hollow cube printed with different pectin concentrations. Cubes with pectin concentrations of 10 and 12% (w/v) collapsed, and the base showed a wider structure. This is due to the pectin solution not having a good gelling condition. This condition was similar to the result of the storage modulus. Table 1 shows the height of printed products: all the pectin solutions had lower heights than the target height, except for the 14% pectin concentration. When the pectin concentration was increased to 16% (w/v), the structure did not collapse, but the printed pattern was not good. This was due to the blockage of the nozzle leading to difficulty extruding the material. The optimal pectin concentration was 14% (w/v), and the printed height was 20.53 ± 0.27 mm, which was only 2.67 ± 1.35% away from the target height. A better elastic modulus will have a better structure support but if the elastic modulus is too high, it will lead to difficulty extruding material [33].

Figure 3.

Appearance of pectin jelly candy with different pectin concentration, nozzle height, extrusion rate, and height.

Table 1.

Pectin concentration, nozzle height, extrusion rate, and height of pectin jelly candy.

3.3.2. Nozzle Height

The results in Figure 3 and Table 1 show the printed layer with different nozzle heights. For the first printing layer, the nozzle height may affect the printing accuracy. When the nozzle height was at 0.5 mm, the resulting printed layer was a thick and wide line, the nozzle tip squeezed with the extruded material, and thus the material was spread. This situation was similar to the printing of a hollow cube. The hollow cube was 9.13 ± 0.45% lower than the targeted height. When the nozzle was at 1.5 mm high, the printing was better, and the hollow cube printed did not collapse or squeeze. The height was measured with a height of 20.13 ± 0.58 mm with a difference of 0.65 ± 2.91% with the targeted height. However, when the nozzle height was set at 2 or 3 mm, the pattern printed was round. The nozzle height was too high, leading the material being unable to adhere to the surface of the last layer. The printed hollow cube was higher than the targeted height of 2.97 ± 0.27 and 3.42 ± 1.12%. When the nozzle height was set higher than the optimal nozzle height, the extruded material was unable to adhere at the sharp corner of the expected pattern, which caused the printed pattern to look incomplete [27]. Furthermore, when the nozzle height was too high, the extruded material dragged and could not be correctly stacked on the previous layer [34]. According to the literature, the diameter of the print nozzle should be the same as the height of the nozzle [35,36]. However, when the nozzle height was 2 mm, the pattern was not printed accurately, but 1.5 mm had a better printed pattern. The main reason was that when the material was discharged, the material was in a semi-melted state, which reduces the diameter of the deposited extruded material. Therefore, reducing the nozzle height can more stably adhere the extrusion to the printed layer and achieve the target molding height.

3.3.3. Extrusion Rate

The extrusion rate decided the volume of material deposited per unit time [36]. The results of different extrusion rates used are shown in Figure 3 and Table 1. Among these results, the lower extrusion rate (0.016 cm3/s) showed an inaccurate printed pattern; the printed pattern was relatively short and round due to the extruded material being unable to match the nozzle’s movement speed. The product height of 17.72 ± 0.20 mm was lower than the target height of 11.38 ± 1.01%. The optimal extrusion rate was 0.030 cm3/s; the printed product did not collapse and showed a complete shape, and it had a height of 20.06 ± 0.41 mm with a difference of 0.28 ± 2.03% from the target height. When the extrusion rate was increased, the printed pattern showed a round pattern and the structure collapsed. A higher extrusion rate will result in a larger extruded diameter, while if the extrusion rate is too low, the extruded material will be inconsistent [27].

3.3.4. Printing Layer Height

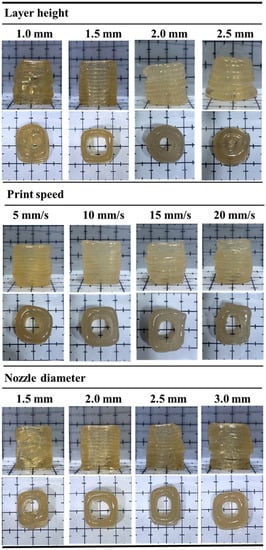

Printing layer height is a measurement of how much material the printer’s nozzle extrudes for each layer of the part. Generally, it can be understood as the height of every story of the building. Four different printing layer heights were used to print pectin jelly candy and measure the height, as shown in Figure 4, Table 2. The printing layer height of 1 mm printed a less accurate pattern, as the printing layer height was lower than the nozzle, such that the nozzle damaged the printed pattern. The product height was higher than the target height by 7.75 ± 3.69% because reducing the printed layer height increases the number of layers of the printed cube, resulting in an increase in the product height. When the printing layer height was increased to 2 or 2.5 mm, the printing pattern became round in shape; the main reason was that the nozzle height was too high, leading the material being unable to adhere to the upper printed layer. The optimal printing layer height was 1.5 mm, which enabled printing a more accurate pattern. At this height appearance was great: the product height was 20.55 ± 0.28 mm with a difference of 2.77 ± 1.41% from the target height. The nozzle height needed to be similar to the printing-layer height [9].

Figure 4.

Appearance of pectin jelly candy with different printed layer height, nozzle movement speed, and nozzle diameter height.

Table 2.

Printed layer height, nozzle movement speed, and nozzle diameter height of pectin jelly candy.

3.3.5. Nozzle Movement Speed

The nozzle movement speed determined the product’s shape and the height of the product in a hot-extrusion 3D printing system. Thus, it is necessary to investigate the suitable nozzle speed for 3D printing [37]. As Figure 4 reveals, four different nozzle movement speed were set for comparison to determine which one has a more accurate printed pattern. When the nozzle movement speed was 5 mm/s, the product height was the lowest. This situation might be because the pectin had formed a stronger gel structure and led to the gel being too hard to extrude by the 3D printer, resulting in less pectin jelly candy being extruded and the product height being unable to reach the model. Additionally, it can be seen that when the nozzle movement speed was 20 mm/s, the product height was also lower, because with too fast of a moving speed, the pectin jelly candy was also extruded faster through the nozzle because the pectin jelly candy could not have enough time to form a stronger gel structure. This leads the button layer’s pectin jelly candy being unable to support the upper layers of pectin jelly candy, thus causing a deformation. When the print speeds were 10 and 15 mm/s, the system was able to print and achieve the design model. This was because, during printing, the pectin jelly candy had enough time to exhibit gelation to support the upper layer, but also had flowability to extrude. To understand this situation, one can refer to Lille et al.’s [33] study, which found that printed products with moderate elastic modulus had better structural support due to higher elastic modulus causing the material to be unable to extrude, leading to inaccurate pattern printing. This experiment shows that the final product shape is related to the print speed and is mainly affected by how materials can reach the desirable elastic modulus.

3.3.6. Nozzle Diameter

The nozzle diameter mainly affected the fineness and surface roughness of the printed products [38]. Four nozzles with different diameters were used to print the first layer of pectin jelly candy and hollow cubes and measure the formation height of the first layer and the finished product. These results are shown in Figure 4 and Table 2. When the nozzle diameter was 1.5 mm, the first layer was printed more finely than the other, and the height was 1.21 ± 0.05 mm. When this diameter was used to print hollow cubes, the printed cubes were inconsistent, which was caused by the uneven material extruded. The hollow cube had a height of 19.03 ± 0.05 mm, which was lower than the target height of 4.85 ± 0.25%. When the nozzle diameter was increased to 2.5 or 3 mm, the first printed layer showed wider printing, and the hollow cube had an uneven shape and collapsed. The heights of the first printed layers were 1.54 ± 0.01 and 1.59 ± 0.02 mm, while those of the printed hollow cube were 20.27 ± 0.35 and 20.72 ± 0.31 mm, which differed from the target height by 1.35 ± 1.74% and 3.58 ± 1.57%. The optimal nozzle diameter was 2 mm; at this diameter, the system printed the hollow cube with an accurate pattern, and the cube did not collapse. The height of first printed layer was 1.53 ± 0.03 mm, and that of the hollow cube was 20.32 ± 0.19 mm, which differs from the targeted height by only 1.60 ± 0.94%. There was no difference in the formation height of the nozzle diameter of 2.5, 3 mm, and 2 mm hollow cubes. It was also observed that there was no significant difference in the height of the three cubes in the first printing layer. When the nozzle diameter was larger, more consistent lines can be printed, but the resolution and fineness of the final product will be poor [27].

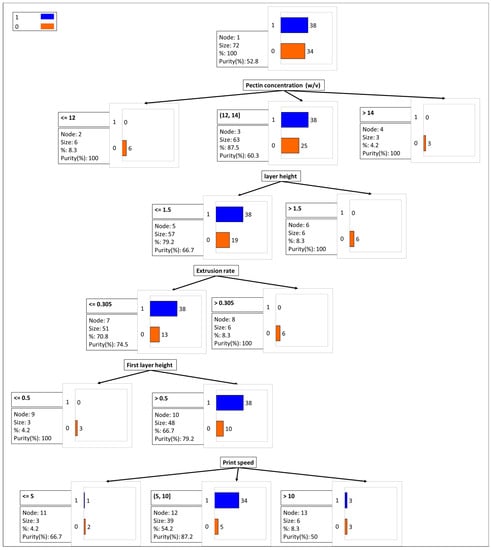

3.4. Decision Tree

The decision tree mainly analyzed the data from machine learning, the determined parameter and quality were analyzed using regression and clustering, and then the data simulated the possible result under an actual situation. The decision tree then decided an answer (either yes or no) for the machine. This study referred to Nijdam’s investigation as the control group (deformation within 5% was accepted) [7]. The results showed that the decision tree had 87.50% accuracy in predicting and classifying the parameters. Figure 5 indicates that the printed product, with less than 5% deformation, was printed under a pectin concentration of 12–14% (w/v), a printing layer height less than 1.5 mm, an extrusion rate less than 0.305 mm3/s, a nozzle height greater than 0.5 mm, and nozzle movement speed of 5–10 mm. However, nozzle diameter was not included in the decision tree analysis as the diameter did not cause the deformation greater than 5%.

Figure 5.

A schematic of the decision tree for different printing parameters: 1 and 0 represent printing product error below 5% and higher than 5%, respectively.

4. Discussion

Different pectin concentrations were used in 3D printing to print a pectin jelly candy. Results showed that structures printed with a 14% concentration (w/v) had the finest pattern and structure and were also able to reach the targeted height. In rheological analysis, 14% (w/v) showed the best storage modulus and loss modulus. In decision tree analysis, printing parameters of a nozzle height of 1.5 mm, a printing layer height of 1.5 mm, a nozzle moving speed of 10 mm/s, a nozzle diameter of 2 mm, and an extrusion rate of 0.030 cm3/s gave the result of about 87.2%. The means had 87.2% confidence, which could provide a desirable printing product and a product error below 5%. These were the optimal printing parameters for the printing conditions.

This study found two important points in 3D food printing, including the importance of structural support and the relationship between optimal printing parameters and the shape deformation of printed products. The material used in 3D food printing must be able to support the printed structure to prevent collapsing and deformation. Furthermore, printing parameters (nozzle height, nozzle diameter, printing layer height, nozzle movement speed and extrusion rate) affect the printing patterns.

This study found the relationship between the pectin concentration and the printing parameters in a 3D food printing system. Other factors that may affect the supporting strength and printing, including colling rate and withdrawal rate of the motor, could be studied in the future to print more accurate patterns. Additionally, in the future, this work could help consumers in their kitchens to be able to quickly print their foods, and in addition, nutrition, correction of food shapes, and customization can be achieved within suitable printing parameters.

Author Contributions

Conceptualization, J.H.R.H., C.-Y.W. and H.-M.C.; methodology, J.H.R.H. and C.-Y.W.; software, J.H.R.H.; validation, J.H.R.H.; formal analysis, J.H.R.H. and C.-Y.W.; investigation, J.H.R.H., C.-Y.W. and H.-M.C.; resources, J.-Y.C.; data curation, J.H.R.H., C.-Y.W. and H.-M.C.; writing—original draft preparation, J.H.R.H. and C.-Y.W.; writing—review and editing, J.-Y.C.; visualization, J.H.R.H. and H.-M.C.; supervision, J.-Y.C.; project administration, J.-Y.C. All authors have read and agreed to the published version of the manuscript.

Funding

The authors would like to acknowledge the Ministry of Science and Technology of Taiwan for financial support (Project number 109-2813-C-029-001-E and 110-2221-E-029-008-MY2).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Mallakpour, S.; Azadi, E.; Hussain, C.M. State-of-the-art of 3D printing technology of alginate-based hydrogels—An emerging technique for industrial applications. Adv. Colloid Interface Sci. 2021, 293, 102436. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Chen, M.; Luo, J.; Zhao, H.; Zhou, X.; Gu, Q.; Yang, H.; Zhu, X.; Cui, W.; Shi, Q. Immunopolarization-regulated 3D printed-electrospun fibrous scaffolds for bone regeneration. Pharmacol. Res. 2021, 276, 121037. [Google Scholar] [CrossRef] [PubMed]

- Yu, S.; Xia, M.; Sanjayan, J.; Yang, L.; Xiao, J.; Du, H. Microstructural characterization of 3D printed concrete. J. Build. Eng. 2021, 44, 102948. [Google Scholar] [CrossRef]

- Godoi, F.C.; Prakash, S.; Bhandari, B.R. 3d printing technologies applied for food design: Status and prospects. J. Food Eng. 2016, 179, 44–54. [Google Scholar] [CrossRef]

- Periard, D.; Schaal, N.; Schaal, M.; Malone, E.; Lipson, H. Printing Food. In Proceedings of the 2007 International Solid Freeform Fabrication Symposium, The University of Texas in Austin, Austin, TX, USA, 6–8 August 2007. [Google Scholar]

- Masbernat, L.; Berland, S.; Leverrier, C.; Moulin, G.; Michon, C.; Almeida, G. Structuring wheat dough using a thermomechanical process, from liquid food to 3D-printable food material. J. Food Eng. 2021, 310, 110696. [Google Scholar] [CrossRef]

- Nijdam, J.J.; LeCorre-Bordes, D.; Delvart, A.; Schon, B.S. A rheological test to assess the ability of food inks to form dimensionally sTable 3D food structures. J. Food Eng. 2021, 291, 110235. [Google Scholar] [CrossRef]

- Zheng, Z.; Zhang, M.; Liu, Z. Investigation on evaluating the printable height and dimensional stability of food extrusion-based 3D printed foods. J. Food Eng. 2021, 306, 110636. [Google Scholar] [CrossRef]

- Yang, F.; Zhang, M.; Bhandari, B.; Liu, Y. Investigation on lemon juice gel as food material for 3D printing and optimization of printing parameters. LWT-Food Sci. Technol. 2018, 87, 67–76. [Google Scholar] [CrossRef]

- Dick, A.; Bhandari, B.; Dong, X.; Prakash, S. Feasibility study of hydrocolloid incorporated 3D printed pork as dysphagia food. Food Hydrocoll. 2020, 107, 105940. [Google Scholar] [CrossRef]

- Montoya, J.; Medina, J.; Molina, A.; Gutiérrez, J.; Rodríguez, B.; Marín, R. Impact of viscoelastic and structural properties from starch-mango and starch-arabinoxylans hydrocolloids in 3D food printing. Addit. Manuf. 2021, 39, 101891. [Google Scholar] [CrossRef]

- Tian, H.; Wang, K.; Lan, H.; Wang, Y.; Hu, Z.; Zhao, L. Effect of hybrid gelator systems of beeswax-carrageenan-xanthan on rheological properties and printability of litchi inks for 3D food printing. Food Hydrocoll. 2021, 113, 106482. [Google Scholar] [CrossRef]

- Guo, C.; Zhang, M.; Devahastin, S. Improvement of 3D printability of buckwheat starch-pectin system via synergistic Ca2+-microwave pretreatment. Food Hydrocoll. 2021, 113, 106483. [Google Scholar] [CrossRef]

- Vancauwenberghe, V.; Mbong, V.B.M.; Vanstreels, E.; Verboven, P.; Lammertyn, J.; Nicolai, B. 3D printing of plant tissue for innovative food manufacturing: Encapsulation of alive plant cells into pectin based bio-ink. J. Food Eng. 2019, 263, 454–464. [Google Scholar] [CrossRef]

- de Avelar, M.H.M.; Efraim, P. Alginate/pectin cold-set gelation as a potential sustainable method for jelly candy production. LWT 2020, 123, 109119. [Google Scholar] [CrossRef]

- Chan, S.Y.; Choo, W.S.; Young, D.J.; Loh, X.J. Pectin as a rheology modifier: Origin, structure, commercial production and rheology. Carbohydr. Polym. 2017, 161, 118–139. [Google Scholar] [CrossRef] [PubMed]

- Gawkowska, D.; Cybulska, J.; Zdunek, A. Structure-Related Gelling of Pectins and Linking with Other Natural Compounds: A Review. Polymers 2018, 10, 762. [Google Scholar] [CrossRef]

- Guimarães, G.C.; Júnior, M.C.C.; Rojas, E.E.G. Density and Kinematic Viscosity of Pectin Aqueous Solution. J. Chem. Eng. Data 2009, 54, 662–667. [Google Scholar] [CrossRef]

- Lara-Espinoza, C.; Carvajal-Millán, E.; Balandrán-Quintana, R.; López-Franco, Y.; Rascón-Chu, A. Pectin and Pectin-Based Composite Materials: Beyond Food Texture. Molecules 2018, 23, 942. [Google Scholar] [CrossRef]

- Nascimento, G.E.D.; Simas-Tosin, F.F.; Iacomini, M.; Gorin, P.A.J.; Cordeiro, L.M. Rheological behavior of high methoxyl pectin from the pulp of tamarillo fruit (Solanum betaceum). Carbohydr. Polym. 2016, 139, 125–130. [Google Scholar] [CrossRef]

- Muhammad, K.; Zahari, N.I.M.; Gannasin, S.P.; Adzahan, N.M.; Bakar, J. High methoxyl pectin from dragon fruit (Hylocereus polyrhizus) peel. Food Hydrocoll. 2014, 42, 289–297. [Google Scholar] [CrossRef]

- Sato, A.C.; Oliveira, P.R.; Cunha, R.L. Rheology of Mixed Pectin Solutions. Food Biophys. 2008, 3, 100–109. [Google Scholar] [CrossRef]

- Sousa, A.G.; Nielsen, H.L.; Armagan, I.; Larsen, J.; Sørensen, S.O. The impact of rhamnogalacturonan-I side chain monosaccharides on the rheological properties of citrus pectin. Food Hydrocoll. 2015, 47, 130–139. [Google Scholar] [CrossRef]

- Ligon, S.C.; Liska, R.; Stampfl, J.; Gurr, M.; Mülhaupt, R. Polymers for 3D Printing and Customized Additive Manufacturing. Chem. Rev. 2017, 117, 10212–10290. [Google Scholar] [CrossRef] [PubMed]

- Hao, L.; Seaman, O.; Mellor, S.; Henderson, J.; Sewell, N.; Sloan, M. Extrusion behavior of chocolate for additive layer manufacturing. In Innovative Developments in Design and Manufacturing; CRC Press: Boca Raton, FL, USA, 2009; pp. 263–268. [Google Scholar] [CrossRef]

- Attalla, R.; Ling, C.; Selvaganapathy, P. Fabrication and characterization of gels with integrated channels using 3D printing with microfluidic nozzle for tissue engineering applications. Biomed. Microdevices 2016, 18, 1–12. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Zhang, M.; Bhandari, B.; Yang, C. Investigation on fish surimi gel as promising food material for 3D printing. J. Food Eng. 2018, 220, 101–108. [Google Scholar] [CrossRef]

- Yang, F.; Zhang, M.; Bhandari, B. Recent development in 3D food printing. Crit. Rev. Food Sci. Nutr. 2017, 57, 3145–3153. [Google Scholar] [CrossRef]

- Mantihal, S.; Prakash, S.; Godoi, F.C.; Bhandari, B. Optimization of chocolate 3D printing by correlating thermal and flow properties with 3D structure modeling. Innov. Food Sci. Emerg. Technol. 2017, 44, 21–29. [Google Scholar] [CrossRef]

- May, C.D. Pectins. In Thickening and Gelling Agents for Food; Springer: Boston, MA, USA, 1997. [Google Scholar]

- Eidam, D.; Kulicke, W.-M.; Kuhn, K.; Stute, R. Formation of Maize Starch Gels Selectively Regulated by the Addition of Hydrocolloids. Starch-Stärke 1995, 47, 378–384. [Google Scholar] [CrossRef]

- Steffe, J.F. Rheological Methods in Food Process Engineering; Freeman Press: East Lansing, MI, USA, 1996. [Google Scholar]

- Lille, M.; Nurmela, A.; Nordlund, E.; Metsä-Kortelainen, S.; Sozer, N. Applicability of protein and fiber-rich food materials in extrusion-based 3D printing. J. Food Eng. 2018, 220, 20–27. [Google Scholar] [CrossRef]

- Dick, A.; Bhandari, B.; Prakash, S. 3D printing of meat. Meat Sci. 2019, 153, 35–44. [Google Scholar] [CrossRef]

- Khalil, S.; Sun, W. Biopolymer deposition for freeform fabrication of hydrogel tissue constructs. Mater. Sci. Eng. C 2007, 27, 469–478. [Google Scholar] [CrossRef]

- Wang, J.; Shaw, L.L. Rheological and extrusion behavior of dental porcelain slurries for rapid prototyping applications. Mater. Sci. Eng. A 2005, 397, 314–321. [Google Scholar] [CrossRef]

- Hao, L.; Mellor, S.; Seaman, O.; Henderson, J.; Sewell, N.; Sloan, M. Material characterisation and process development for chocolate additive layer manufacturing. Virtual Phys. Prototyp. 2010, 5, 57–64. [Google Scholar] [CrossRef]

- Vogeler, F.; Verheecke, W.; Voet, A.; Valkenaers, H. An Initial Study of Aerosol Jet® Printed Interconnections on Extrusion-Based 3D-Printed Substrates. Stroj. Vestn./J. Mech. Eng. 2013, 59, 689–696. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).