Effect of Freeze-Thaw on Mechanical Properties of Loess with Different Moisture Content in Yili, Xinjiang

Abstract

:1. Introduction

2. Materials and Methods

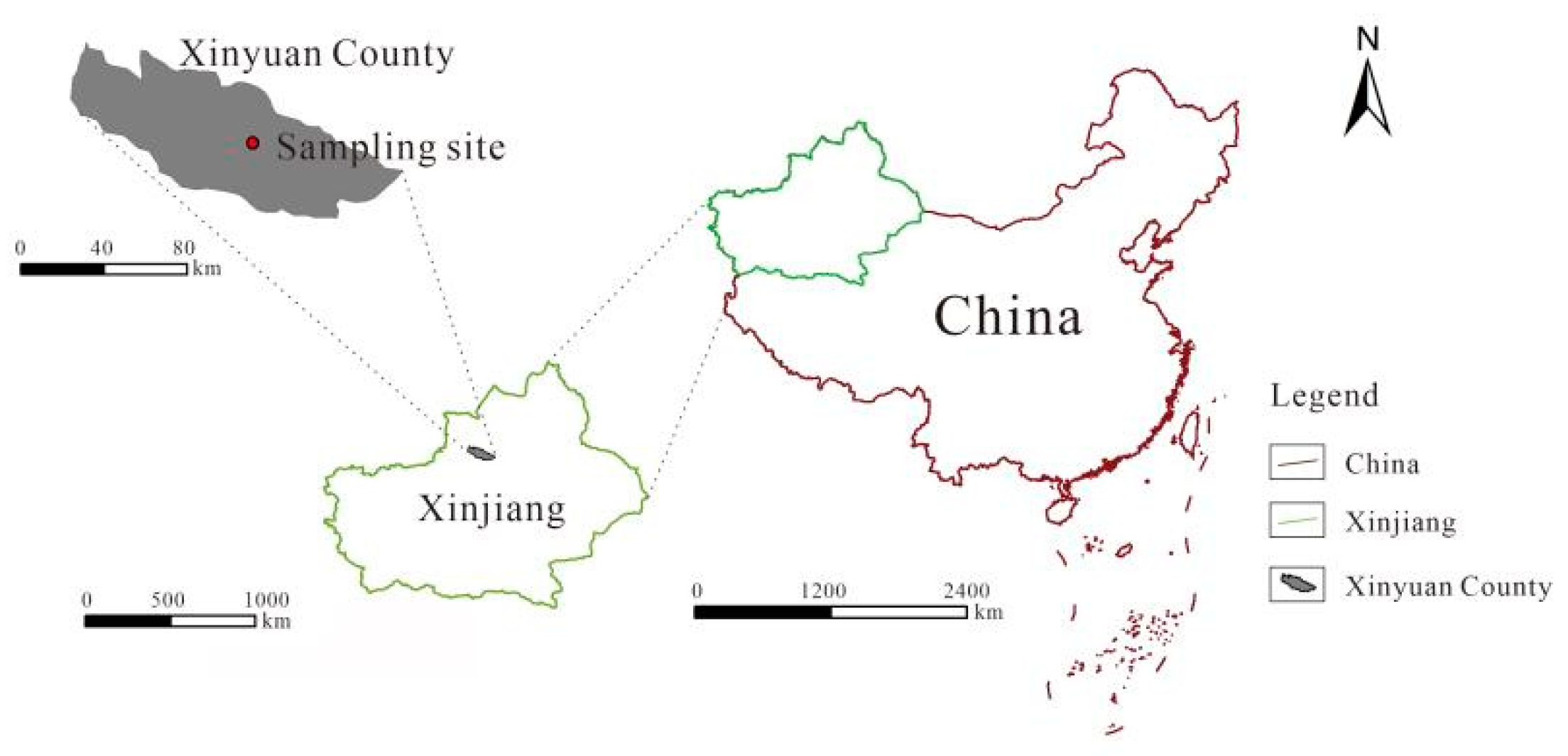

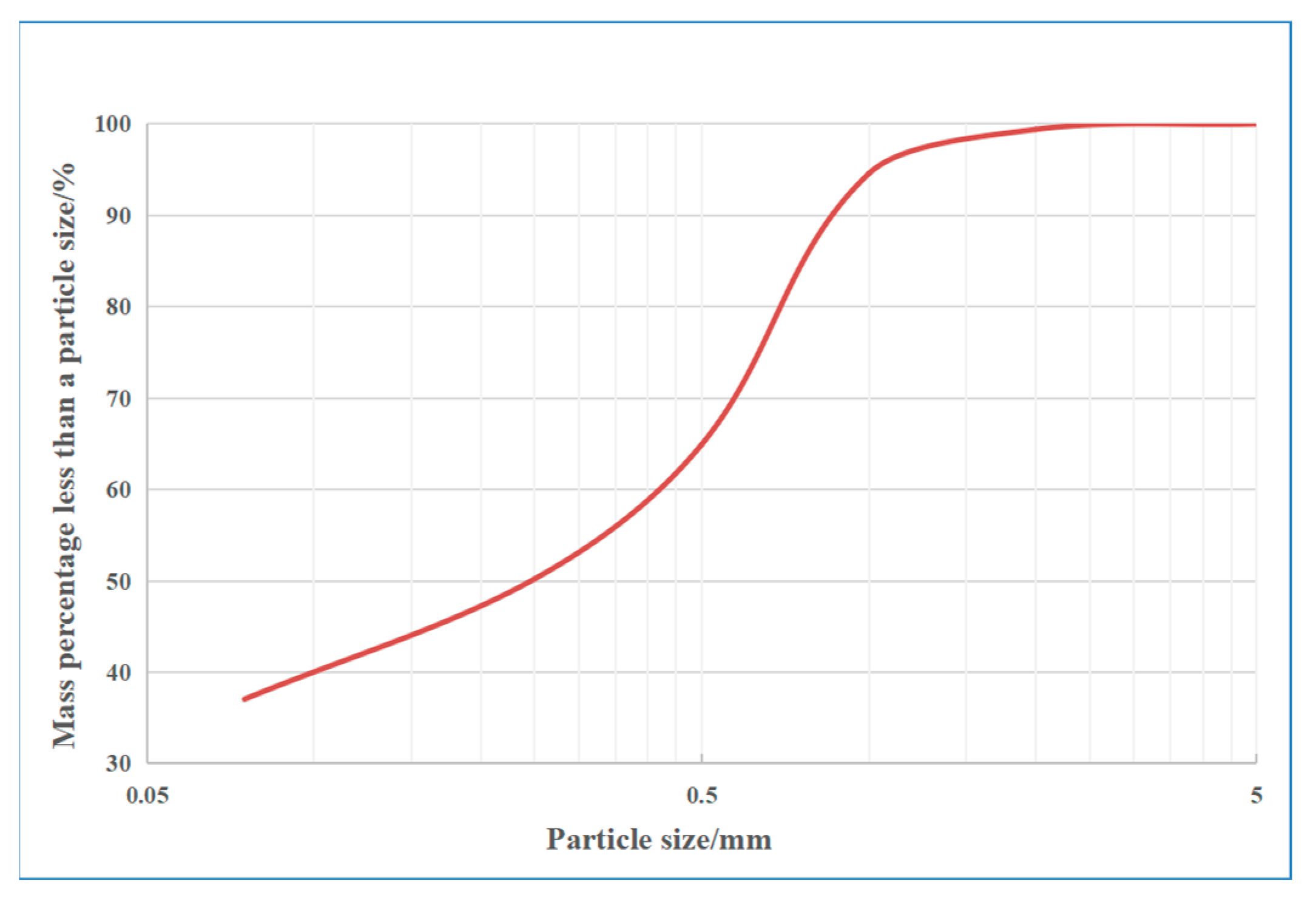

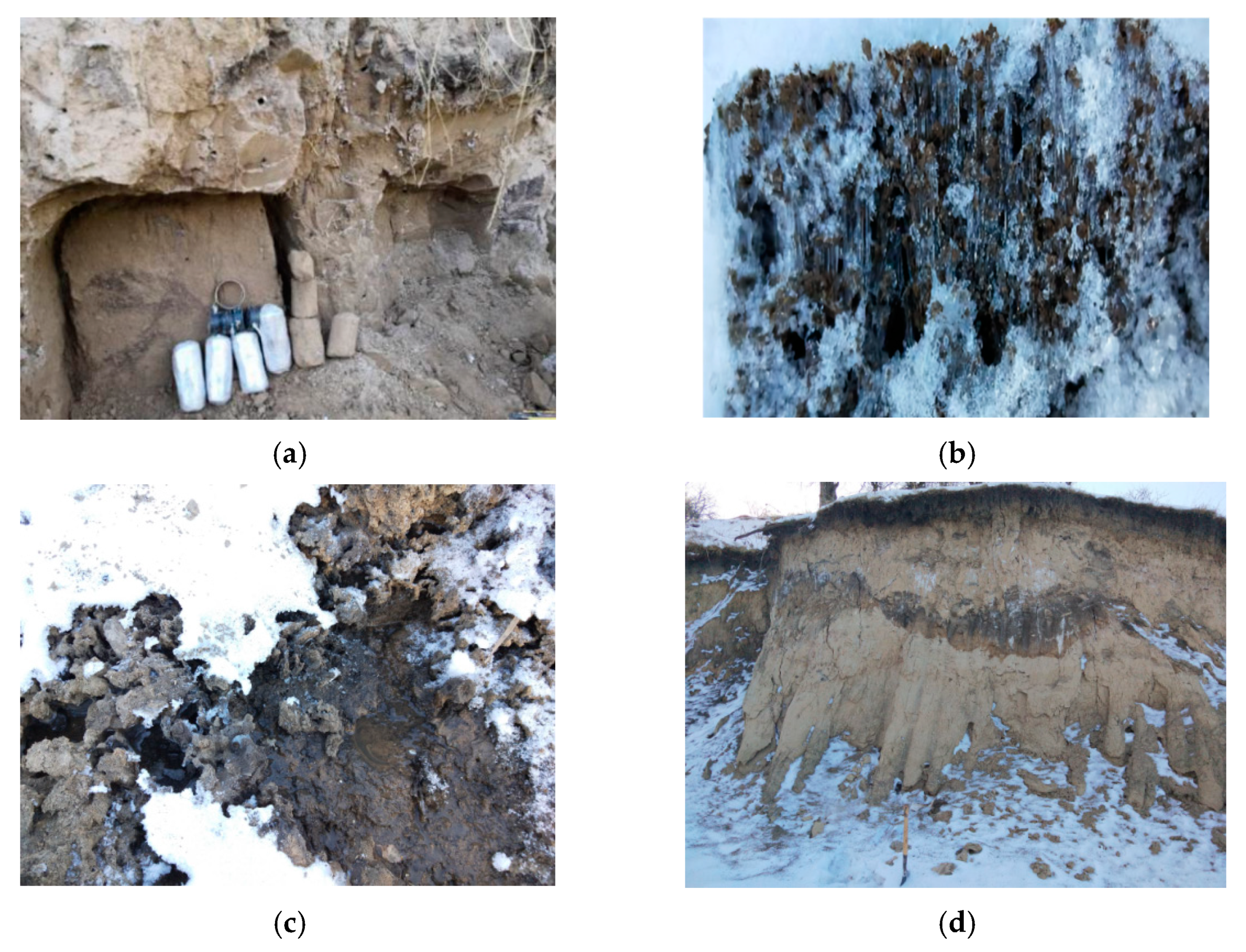

2.1. Acquisition and Basic Physical Properties of Soil Samples

2.2. Specimen Preparation

2.3. Method

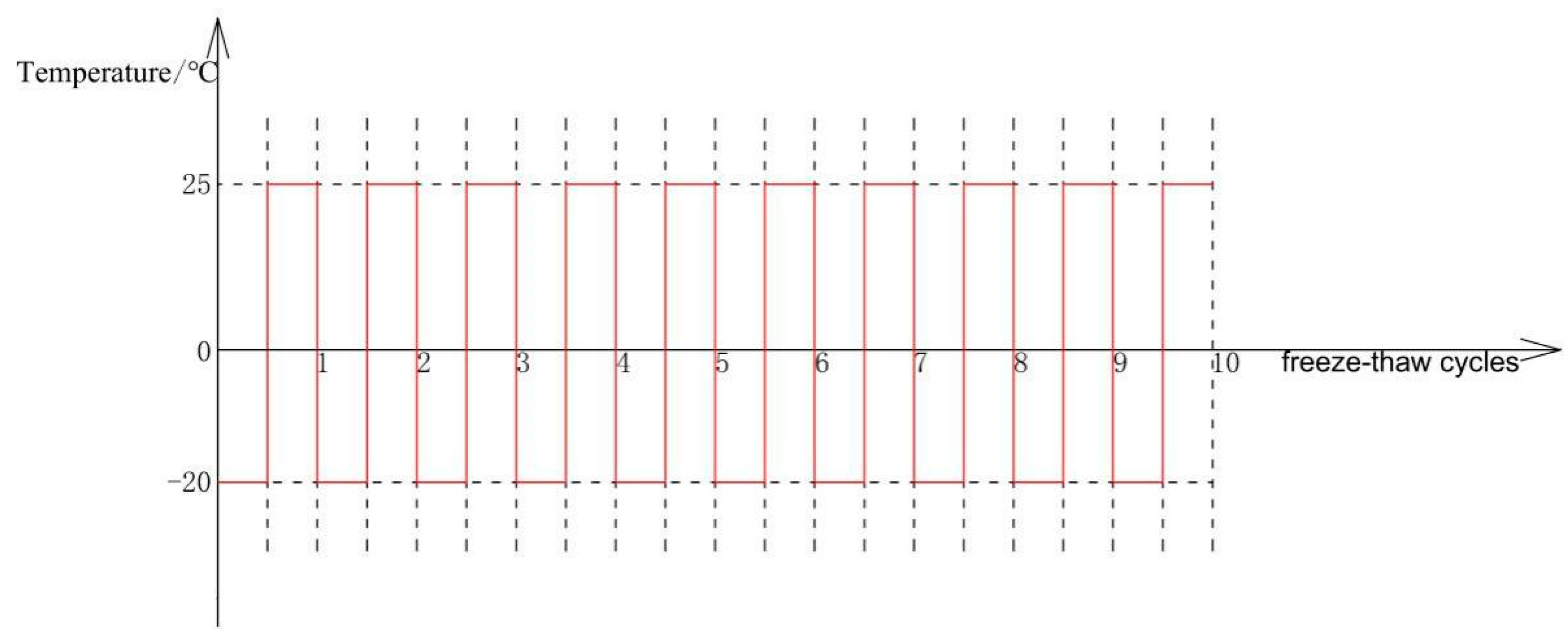

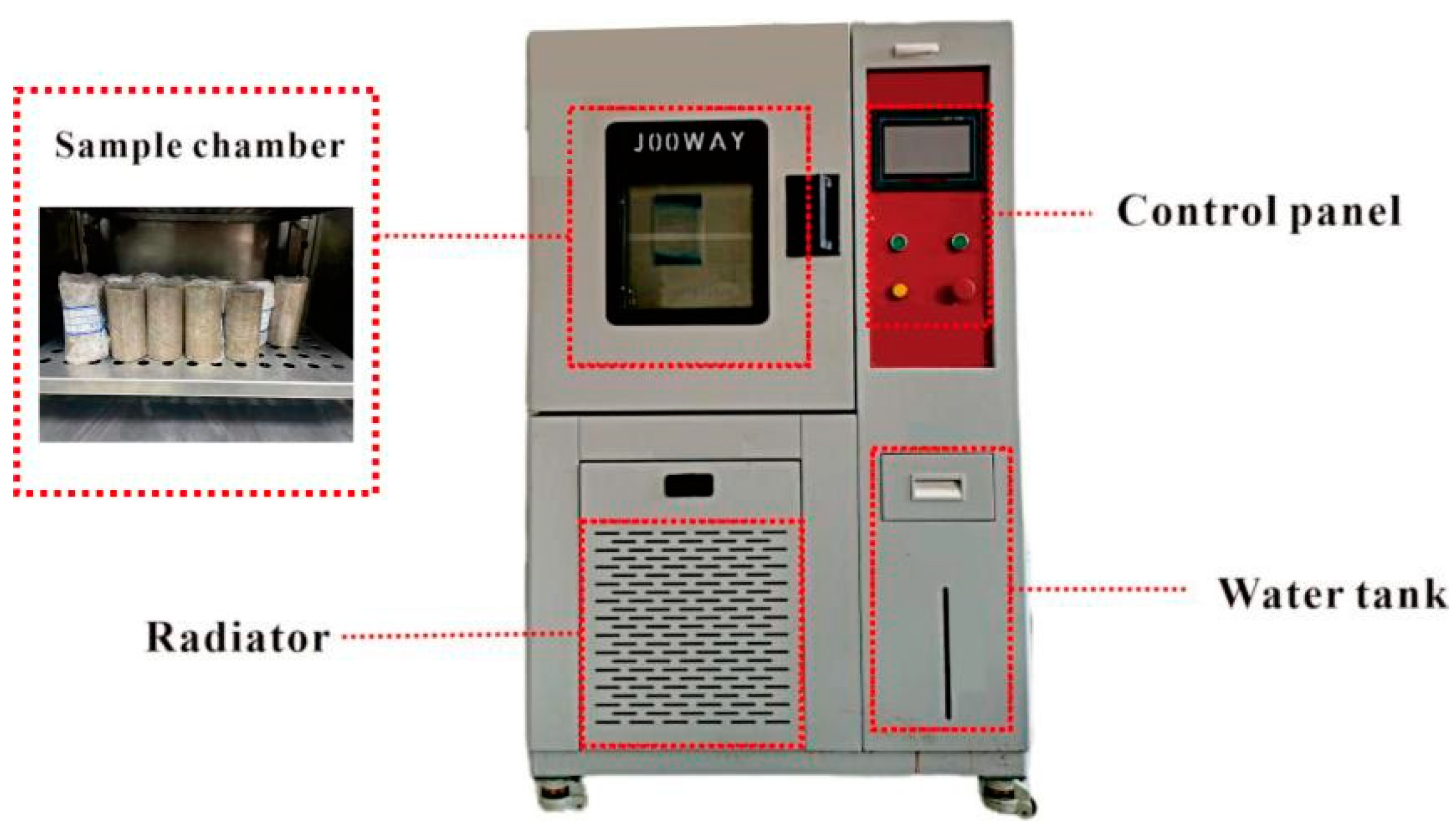

2.3.1. Freeze–Thaw Cycle Test

2.3.2. Observation of Apparent Characteristics

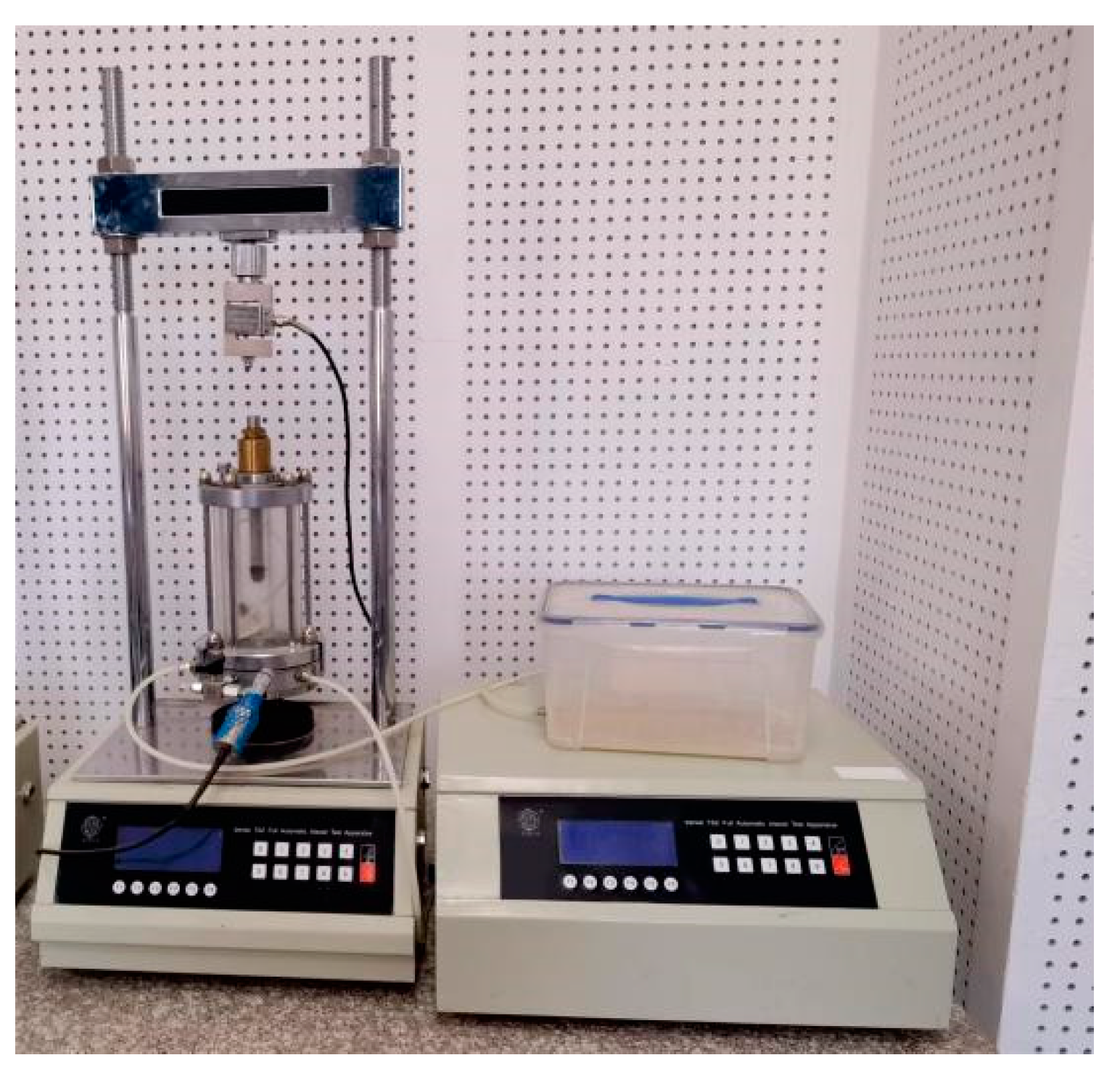

2.3.3. Triaxial Compression Test

3. Results

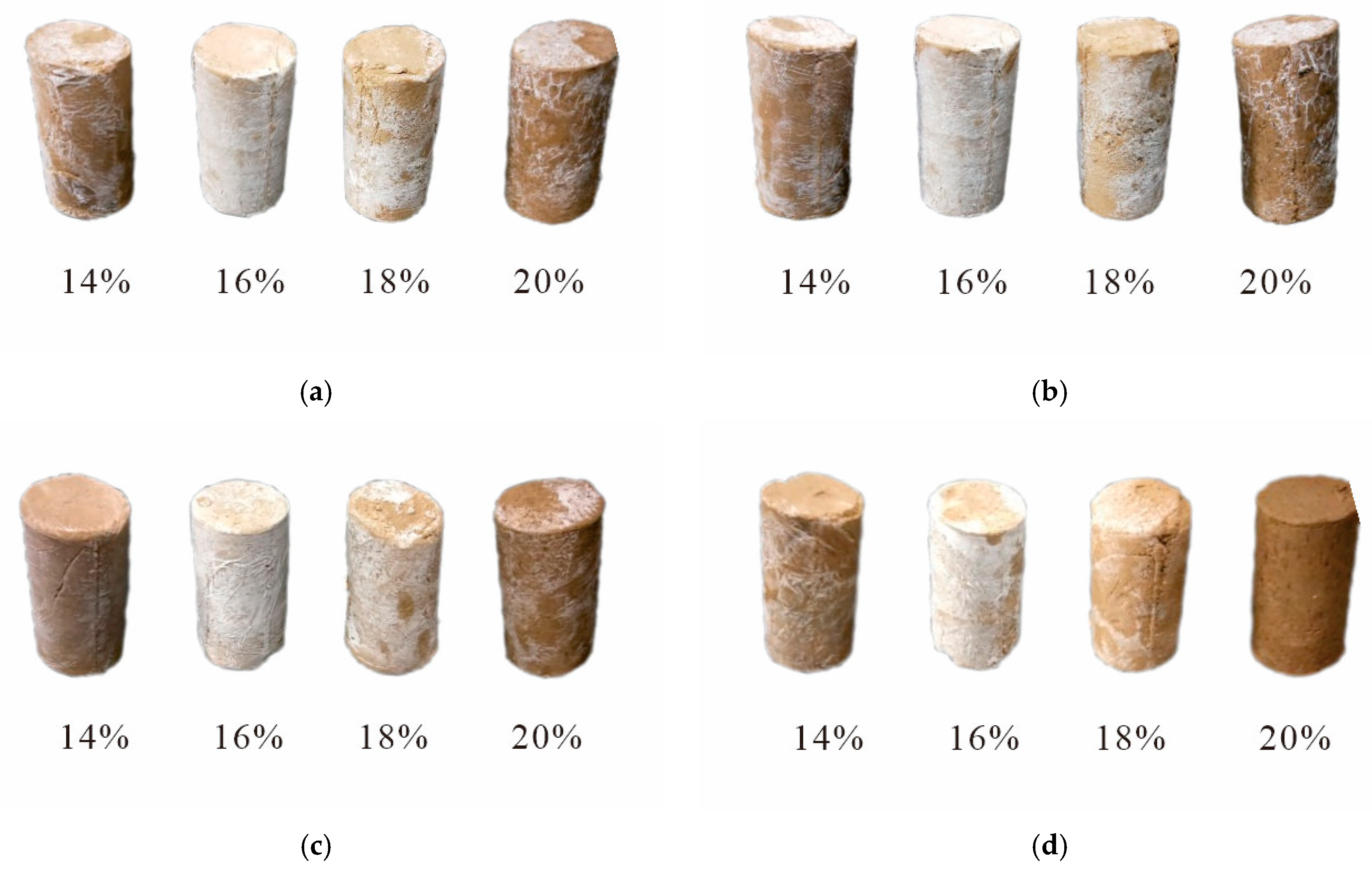

3.1. Analysis of Loess Apparent Characteristics

3.2. Triaxial Compression Test Results

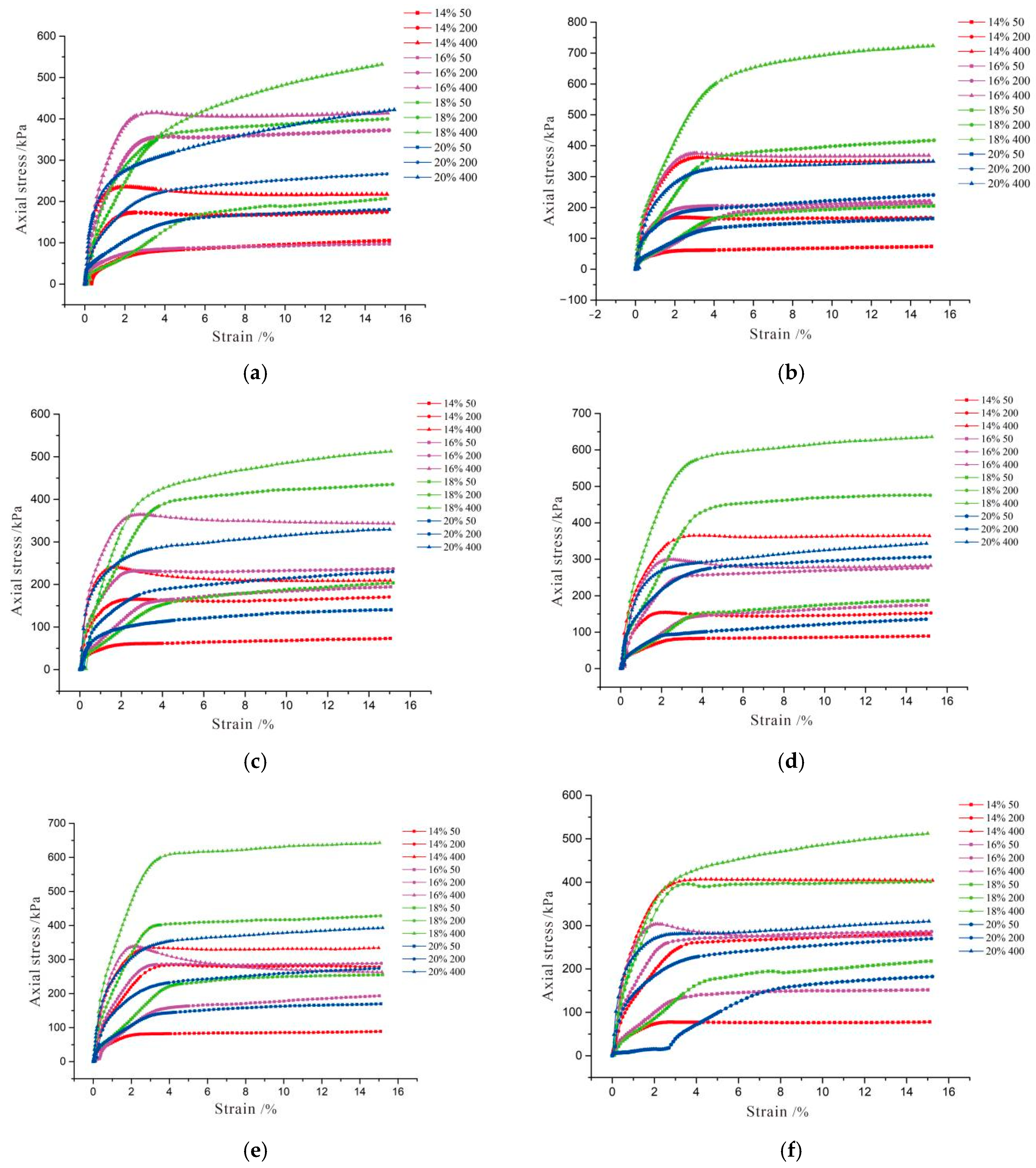

3.2.1. Stress-Strain Characteristics of Loess

3.2.2. Effects of the Number of Freeze–Thaw Cycles on Shear Strength Parameters

4. Discussion

5. Conclusions

- (1)

- During the freeze–thaw process, the frosting rate of the sample increased with the increase of freeze–thaw cycles, accompanied by a gradual conversion from frost crystals into ice crystals. Moreover, peeling occurred on the sample surface. The distribution of crystals showed no apparent correlation with the moisture content.

- (2)

- The ice and frost crystals produced in the cyclic freeze–thaw process changed the soil structure and reduced the soil’s shear strength. As a result, we observed dilatancy to varying degrees during the shearing process, and the strain-softening was mainly in the 2%~7% strain range.

- (3)

- During freeze–thaw cycles, the number of freeze–thaw cycles differently affected the shear strength parameters. As the number of freeze–thaw cycles increased, soil cohesion first dropped, then rose, and finally fell, while the internal friction angle first increased, then dropped, and finally tended to stabilize.

- (4)

- The cohesion and internal friction angle mainly increased first and then decreased with the increase of moisture content. The engineering properties of the soil were the best near the optimal moisture content.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ministry of Land and Resources. Issued the 13th Five–Year Plan for National Geological Disaster Prevention and Control. China Emerg. Manag. 2016, 12, 39–44. [Google Scholar]

- Mikaeil, R.; Esmaeilzadeh, A.; Shaffiee Haghshenas, S.; Ataei, M.; Hajizadehigdir, S.; Jafarpour, A.; Kim, T.H.; Geem, Z.W. Evaluation of dimension stone according to resistance to freeze–thaw cycling to use in cold regions. J. Soft Comput. Civ. Eng. 2022, 6, 88–109. [Google Scholar] [CrossRef]

- Zhu, S.; Yin, Y.; Wang, W.; Wei, Y.; Shao, H.; Huang, Z.; Zhuang, M.; Shi, A. Mechanism of Freeze–thaw Loess Landslide in Yili River Valley, Xinjiang. Acta Geosci. Sin. 2019, 40, 339–349. [Google Scholar]

- Han, Y.; Wang, Q.; Wang, N.; Wang, J.; Zhang, X.; Cheng, S.; Kong, Y. Effect of freeze–thaw cycles on shear strength of saline soil. Cold Reg. Sci. Technol. 2018, 154, 42–53. [Google Scholar] [CrossRef]

- Kong, F.; Nie, L.; Xu, Y.; Rui, X.; He, Y.; Zhang, T.; Wang, Y.; Du, C.; Bao, C. Effects of freeze–thaw cycles on the erodibility and microstructure of soda-saline loessal soil in Northeastern China. CATENA 2022, 209 Pt 1, 105812. [Google Scholar] [CrossRef]

- Wang, M.; Meng, S.; Sun, Y.; Fu, H. Shear strength of frozen clay under freezing–thawing cycles using triaxial tests. Earthq. Eng. Eng. Vib. 2018, 17, 761–769. [Google Scholar] [CrossRef]

- Wang, L.; Zuo, X.; Zheng, F.; Wilson Glenn, V.; Zhang, X.; Wang, Y.; Fu, H. The effects of freeze–thaw cycles at different initial soil moisture contents on soil erodibility in Chinese Mollisol region. CATENA 2020, 193, 104615. [Google Scholar] [CrossRef]

- Cui, H.; Qin, X.; Wang, W.; Wang, P. Study on the strength and microscopic characteristics of unsaturated subgrade soil under freezing–thawing conditions. J. Glaciol. Geocryol. 2019, 41, 1115–1121. [Google Scholar]

- Lei, D.; Lin, H.; Chen, Y.; Cao, R. Effect of Cyclic Freezing–Thawing on the Shear Mechanical Characteristics of Nonpersistent Joints. Adv. Mater. Sci. Eng. 2019, 2019, 9867681. [Google Scholar] [CrossRef]

- Wang, S.; Ding, J.; Xu, J.; Ren, J.; Yang, Y. Shear Strength Behavior of Coarse–Grained Saline Soils after Freeze–Thaw. KSCE J. Civ. Eng. 2019, 23, 2437–2452. [Google Scholar] [CrossRef]

- Jing, X.; Cui, Z.; Doh, S.; Ma, L.; Wei, L.; Liu, D. Effect of freeze–thaw cycles on shear strength of unsaturated bentonite modified clay. Phys. Chem. Earth Parts A/B/C 2021, 121, 102955. [Google Scholar] [CrossRef]

- Cheng, S.; Wang, Q.; Wang, J.; Han, Y. Experimental Study on Undrained Shear Properties of Saline Soil under Freeze–Thaw Cycles. Geofluids 2021, 2021, 9987414. [Google Scholar] [CrossRef]

- Zheng, F.; Shao, S.; Wang, S. Influences of freeze–thaw on strength of loess under complex stress path. Chin. J. Geotech. Eng. 2021, 43 (Suppl. S1), 224–228. [Google Scholar]

- Zhang, W.; Ma, J.; Tang, L. Experimental study on shear strength characteristics of sulfate saline soil in Ningxia region under long–term freeze–thaw cycles. Cold Reg. Sci. Technol. 2019, 160, 48–57. [Google Scholar] [CrossRef]

- Yang, Z.; Zhang, Q.; Shi, W.; Lu, Z.; Tu, Z.; Ling, X. Study of a strength prediction model of unsaturated compacted expansive soil under freeze–thaw cycles. Arab. J. Geosci. 2022, 15, 130. [Google Scholar] [CrossRef]

- Ma, B.; Yang, G.; Tian, J.; Pan, Z.; Liu, H. Variation law of remolded loess strength under the action of freeze–thaw cycle based on nuclear magnetic resonance. Sci. Technol. Eng. 2019, 19, 318–323. [Google Scholar]

- Chen, S.; Luo, T.; Li, G.; Zhang, Y. Effects of Cyclic Freezing–Thawing on Dynamic Properties of Loess Reinforced with Polypropylene Fiber and Fly Ash. Water 2022, 14, 317. [Google Scholar] [CrossRef]

- Wang, W.; Cao, G.; Li, Y.; Zhou, Y.; Lu, T.; Zheng, B.; Geng, W. Effects of Freeze–Thaw Cycles on Strength and Wave Velocity of Lime-Stabilized Basalt Fiber-Reinforced Loess. Polymers 2022, 14, 1465. [Google Scholar] [CrossRef]

- Xu, J.; Ren, J.; Wang, Z.; Wang, S.; Yuan, J. Strength behaviors and meso–structural characters of loess after freeze–thaw. Cold Reg. Sci. Technol. 2018, 148, 104–120. [Google Scholar] [CrossRef]

- Wei, Y.; Yang, G.; Ye, W.; Wang, L. Factorial experiment on unconfined compression strength of freeze–thawing loess. J. Xi’an Univ. Sci. Technol. 2019, 39, 103–111. [Google Scholar]

- Ye, W.; Qiang, Y.; Jing, H.; Zou, Y. Freeze–thaw cycle experiment of loess paleosol with different moisture content based on nuclear magnetic resonance. J. Eng. Geol. 2022, 30, 144–153. [Google Scholar] [CrossRef]

- Ye, W.; Wei, W.; Zheng, C.; Chen, M. Effect of Initial Moisture Content on Mechanical Properties of Expansive Paleosol. J. Civ. Eng. Manag. 2019, 36, 28–32. [Google Scholar] [CrossRef]

- Ye, W.; Chen, Y.; Zhang, D.; Bai, Y. Macro and Micro Experimental study on the influence of Moisture migration on the strength of compacted loess under freeze–thaw cycling. China J. Highw. Transp. 2021, 34, 27–37. [Google Scholar] [CrossRef]

- Li, B.; Ping, G.; Zhang, Y.; Yang, Q. Effects of freeze–thaw cycles on mechanical properties of loess under plane strain. J. Civ. Environ. Eng. 2021, 43, 41–48. [Google Scholar]

- Zhang, S.; Kuang, H.; Jin, Z.; Xu, G. An experimental study of the stress–strain characteristics of frozen silty clay with high moisture content. Hydrogeol. Eng. Geol. 2020, 47, 116–124. [Google Scholar] [CrossRef]

- Sun, Y.; Meng, S.; Wang, M.; Mu, H.; Tang, X. Deterioration effect of freeze–thaw on mechanical properties of roadbed clay under unfavorable conditions. Bull. Eng. Geol. Environ. 2021, 80, 4773–4790. [Google Scholar] [CrossRef]

- Long, J.; Zhang, L.; Xing, X.; Guo, X. Study on the strength and microstructure of loess under freezethaw based on temperature path. Coal Geol. Explor. 2021, 49, 242–249. [Google Scholar] [CrossRef]

- Liu, L.; Zhang, W.; Zhang, B.; Gu, Y.; Xie, B. Effect of freezing–thawing cycles on mechanical properties and microscopic mechanisms of loess. Hydrogeol. Eng. Geol. 2021, 48, 109–115. [Google Scholar] [CrossRef]

- Yu, L.; Xu, X.; Qiu, M.; Yan, Z.; Li, P. Influnce of freeze–thaw on shear strength properties of saturated silty clay. Rock Soil Mech. 2010, 31, 2448–2452. [Google Scholar] [CrossRef]

- Li, S.; Li, Y.; Gao, X.; Shi, D. Effect of freezing and thawing on shear strength of intact loess. J. Civ. Environ. Eng. 2020, 42, 48–55. [Google Scholar]

- Zhang, A.; Xing, Y.; Hu, X.; Wang, H.; Guo, M.; Zhang, B.; Gao, Y. Influence factors of strong self–weight collapsibility of Ili loess. Chin. J. Geotech. Eng. 2016, 38 (Suppl. S2), 117–122. [Google Scholar]

- Zeng, M.; Song, Y. Mineral Composition and Their Weathering Significance of Zhaosu Loess–Paleosol Sequence in the Ili Basin. Xinjiang Geol. Rev. 2013, 59, 575–586. [Google Scholar]

- Lv, Q.; Zhang, Z.; Zhang, T.; Hao, R.; Guo, Z.; Huang, X.; Zhu, J.; Liu, T. The Trend of Permeability of Loess in Yili, China, under Freeze–Thaw Cycles and Its Microscopic Mechanism. Water 2021, 13, 3257. [Google Scholar] [CrossRef]

- Mo, T.; Guo, M.; Lou, Z.; Gao, Y. The Effect of Moisture Content on Deformation and Shearing Characteristics of Ili Loess. China Rural. Water Hydropower 2018, 4, 87–90, 94. [Google Scholar]

- GB/T 50123-2019; The Standard for Geotechnical Testing Method. Ministry of Housing and Urban–Rural Development of the People’s Republic of China. China Planning Press: Beijing, China, 2019.

- Wu, X.; Liang, Q.; Niu, F.; Li, C. Study on Hardened and Softened Classification in Shear test. Chin. J. Undergr. Space Eng. 2017, 13, 1457–1466. [Google Scholar]

| Natural Density (g·cm−3) | Natural Moisture Content (%) | Plastic Limit (%) | Liquid Limit (%) | Plastic Index | Liquid Index | Maximum Dry Density (g·cm−3) | Optimum Moisture Content (%) |

|---|---|---|---|---|---|---|---|

| 1.94 | 20.25 | 22.85 | 30.55 | 7.70 | −0.34 | 1.74 | 18.5 |

| Year | Month | Extreme High Temperature (°C) | Extreme Low Temperature (°C) | Year | Month | Extreme High Temperature (°C) | Extreme Low Temperature (°C) |

|---|---|---|---|---|---|---|---|

| 2011 | 2 | 6 | −14 | 2016 | 2 | 16 | −17 |

| 3 | 20 | −11 | 3 | 26 | −4 | ||

| 2012 | 2 | 8 | −17 | 2017 | 2 | 10 | −16 |

| 3 | 23 | −9 | 3 | 24 | −6 | ||

| 2013 | 2 | 7 | −17 | 2018 | 2 | 13 | −14 |

| 3 | 26 | −4 | 3 | 25 | −5 | ||

| 2014 | 2 | 7 | −21 | 2019 | 2 | 8 | −18 |

| 3 | 22 | −11 | 3 | 24 | −3 | ||

| 2015 | 2 | 10 | −11 | 2020 | 2 | 12 | −9 |

| 3 | 24 | −7 | 3 | 20 | −9 |

| Hardening Degree | Highly Hardened | General Hardened | Weakly Hardened |

|---|---|---|---|

| <0.1 | 0.1~0.4 | >0.4 |

| Softening Degree | Highly Softened | General Softened | Weakly Softened |

|---|---|---|---|

| |k| | >1.0 | 0.1~1.0 | <0.1 |

| Sample | Hardening/Softening Degree | Sample | Hardening/Softening Degree | ||

|---|---|---|---|---|---|

| 4%, σ3 = 50 kPa | D = 0 | General hardened | 6%, σ3 = 50 kPa | D = 0 | Weakly hardened |

| D = 1 | Weakly hardened | D = 1 | General hardened | ||

| D = 3 | Weakly hardened | D = 3 | Weakly hardened | ||

| D = 5 | Weakly hardened | D = 5 | Weakly hardened | ||

| D = 7 | Weakly hardened | D = 7 | General hardened | ||

| D = 10 | Weakly softened | D = 10 | Weakly hardened | ||

| 4%, σ3 = 200 kPa | D = 0 | Weakly hardened | 6%, σ3 = 200 kPa | D = 0 | General hardened |

| D = 1 | Weakly softened | D = 1 | Weakly hardened | ||

| D = 3 | Weakly hardened | D = 3 | Weakly hardened | ||

| D = 5 | Weakly softened | D = 5 | Weakly hardened | ||

| D = 7 | Weakly softened | D = 7 | Weakly hardened | ||

| D = 10 | Weakly hardened | D = 10 | Weakly hardened | ||

| 4%, σ3 = 400 kPa | D = 0 | Weakly softened | 6%, σ3 = 400 kPa | D = 0 | Weakly softened |

| D = 1 | Weakly softened | D = 1 | Weakly softened | ||

| D = 3 | Weakly softened | D = 3 | Weakly softened | ||

| D = 5 | Weakly softened | D = 5 | Weakly softened | ||

| D = 7 | Weakly hardened | D = 7 | Weakly softened | ||

| D = 10 | Weakly softened | D = 10 | Weakly softened | ||

| 8%, σ3 = 50 kPa | D = 0 | General hardened | 0%, σ3 = 50 kPa | D = 0 | Weakly hardened |

| D = 1 | General hardened | D = 1 | Weakly hardened | ||

| D = 3 | Weakly hardened | D = 3 | Weakly hardened | ||

| D = 5 | Weakly hardened | D = 5 | Weakly hardened | ||

| D = 7 | Weakly hardened | D = 7 | Weakly hardened | ||

| D = 10 | General hardened | D = 10 | General hardened | ||

| 8%, σ3 = 200 kPa | D = 0 | General hardened | 0%, σ3 = 200 kPa | D = 0 | Weakly hardened |

| D = 1 | Weakly hardened | D = 1 | Weakly hardened | ||

| D = 3 | Weakly hardened | D = 3 | General hardened | ||

| D = 5 | General hardened | D = 5 | Weakly hardened | ||

| D = 7 | Weakly hardened | D = 7 | Weakly hardened | ||

| D = 10 | Weakly hardened | D = 10 | Weakly hardened | ||

| 8%, σ3 = 400 kPa | D = 0 | Highly hardened | 0%, σ3 = 400 kPa | D = 0 | General hardened |

| D = 1 | General hardened | D = 1 | General hardened | ||

| D = 3 | Highly hardened | D = 3 | Weakly hardened | ||

| D = 5 | Weakly hardened | D = 5 | Weakly hardened | ||

| D = 7 | Weakly hardened | D = 7 | Weakly hardened | ||

| D = 10 | General hardened | D = 10 | Weakly hardened | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, Z.; Zhang, Z.; Mu, Y.; Li, T.; Zhang, Y.; Shi, G. Effect of Freeze-Thaw on Mechanical Properties of Loess with Different Moisture Content in Yili, Xinjiang. Sustainability 2022, 14, 11357. https://doi.org/10.3390/su141811357

Guo Z, Zhang Z, Mu Y, Li T, Zhang Y, Shi G. Effect of Freeze-Thaw on Mechanical Properties of Loess with Different Moisture Content in Yili, Xinjiang. Sustainability. 2022; 14(18):11357. https://doi.org/10.3390/su141811357

Chicago/Turabian StyleGuo, Zekun, Zizhao Zhang, Yanxiao Mu, Ting Li, Yanyang Zhang, and Guangming Shi. 2022. "Effect of Freeze-Thaw on Mechanical Properties of Loess with Different Moisture Content in Yili, Xinjiang" Sustainability 14, no. 18: 11357. https://doi.org/10.3390/su141811357

APA StyleGuo, Z., Zhang, Z., Mu, Y., Li, T., Zhang, Y., & Shi, G. (2022). Effect of Freeze-Thaw on Mechanical Properties of Loess with Different Moisture Content in Yili, Xinjiang. Sustainability, 14(18), 11357. https://doi.org/10.3390/su141811357