Influence of Pilot-Fueling and Nozzle-Opening Pressure on Performance and Tailpipe Emissions of WCO Biodiesel in a CRDi Engine

Abstract

:1. Introduction

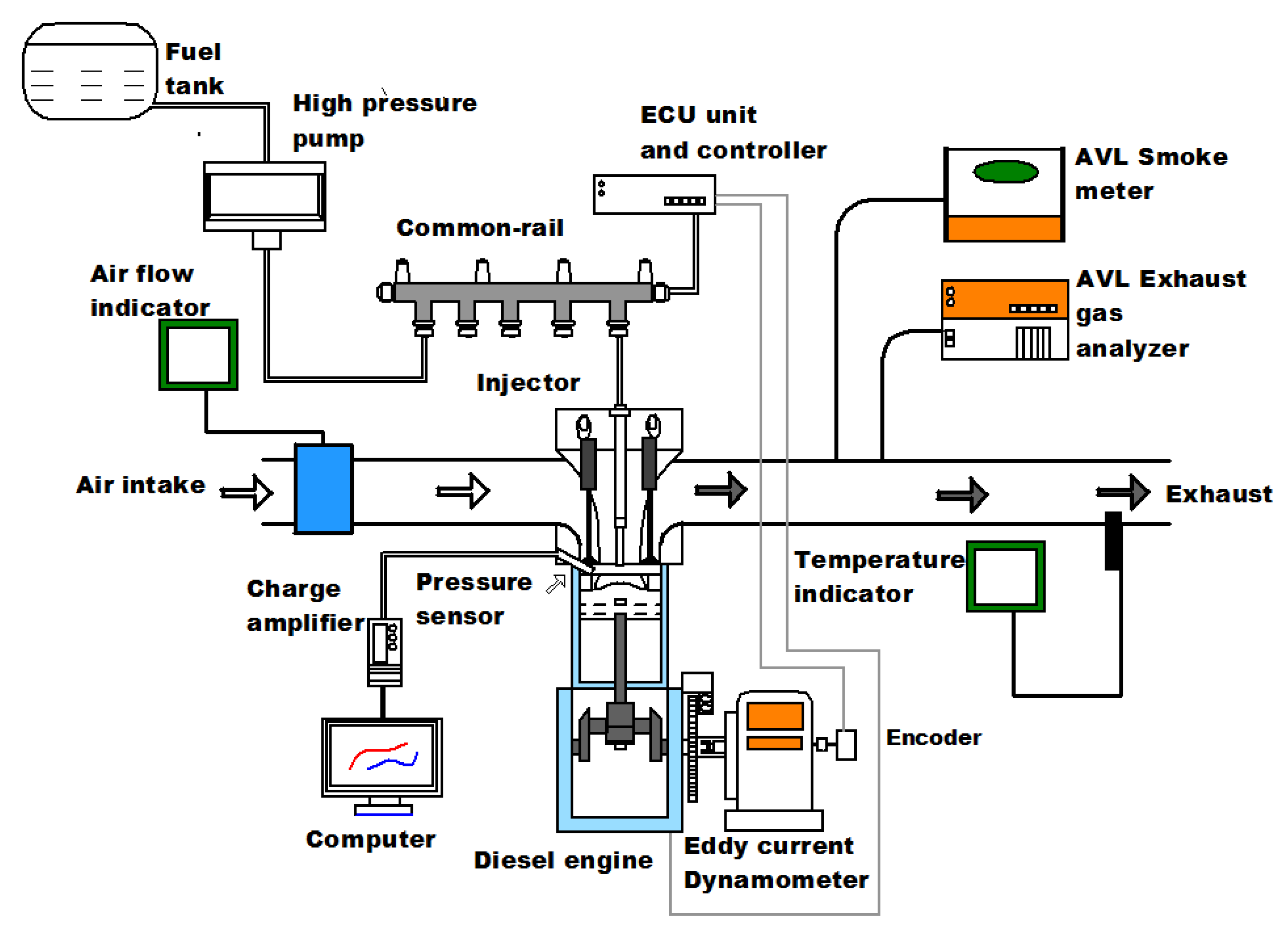

2. Experimental Setup

3. Results and Discussion

3.1. Performance

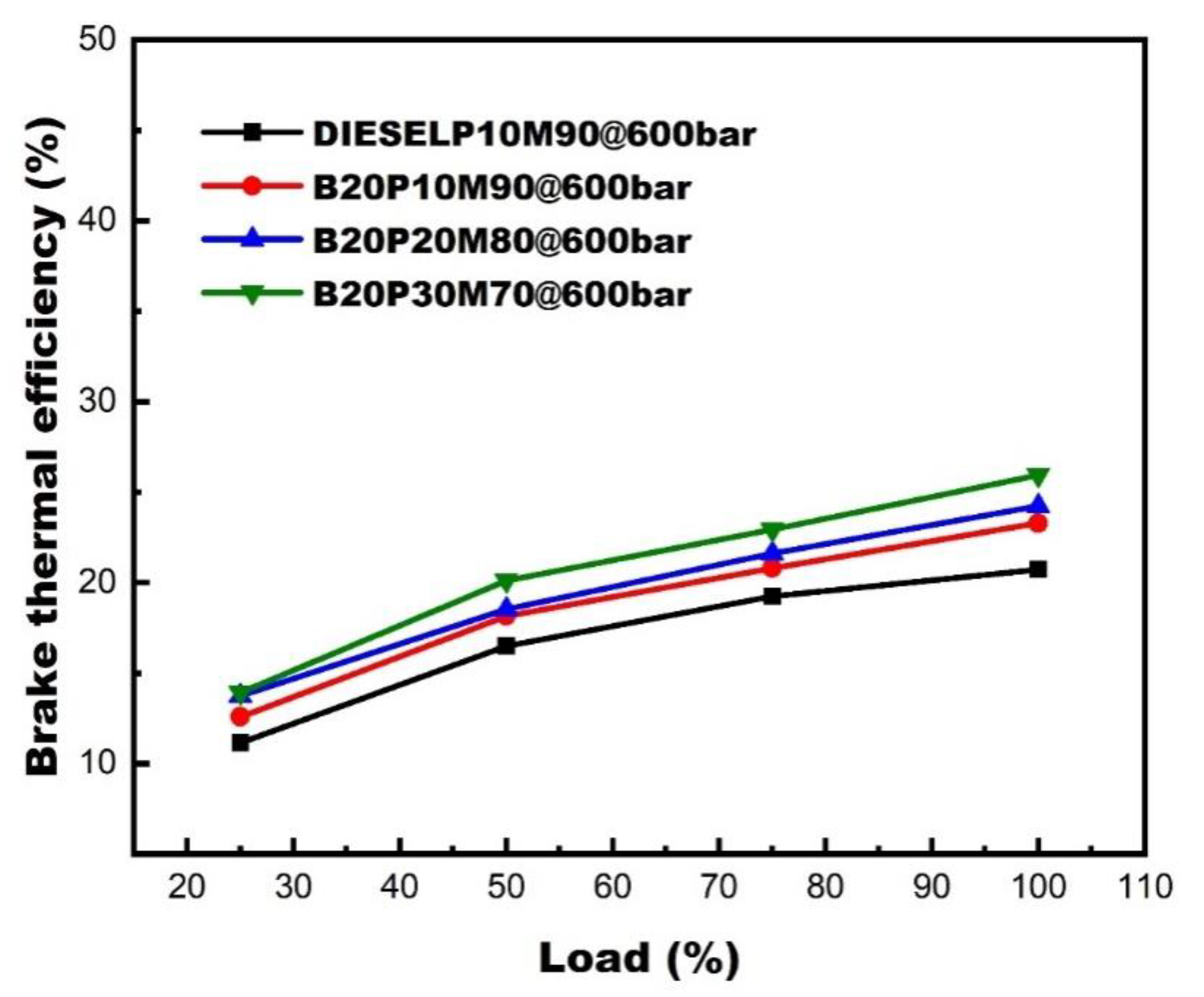

3.1.1. Brake Thermal Efficiency

3.1.2. Brake-Specific Fuel Consumption

3.2. Emissions

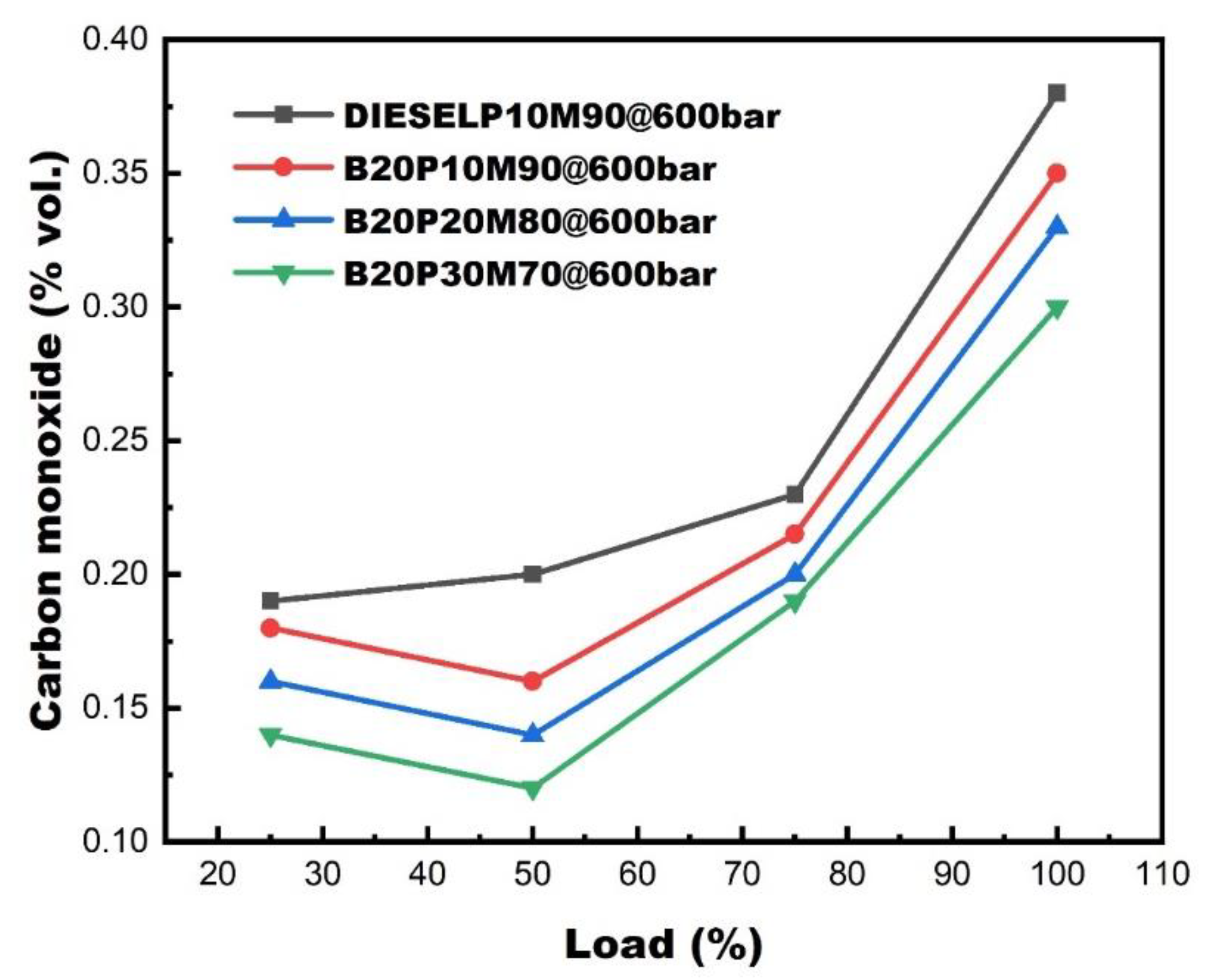

3.2.1. Carbon Monoxide

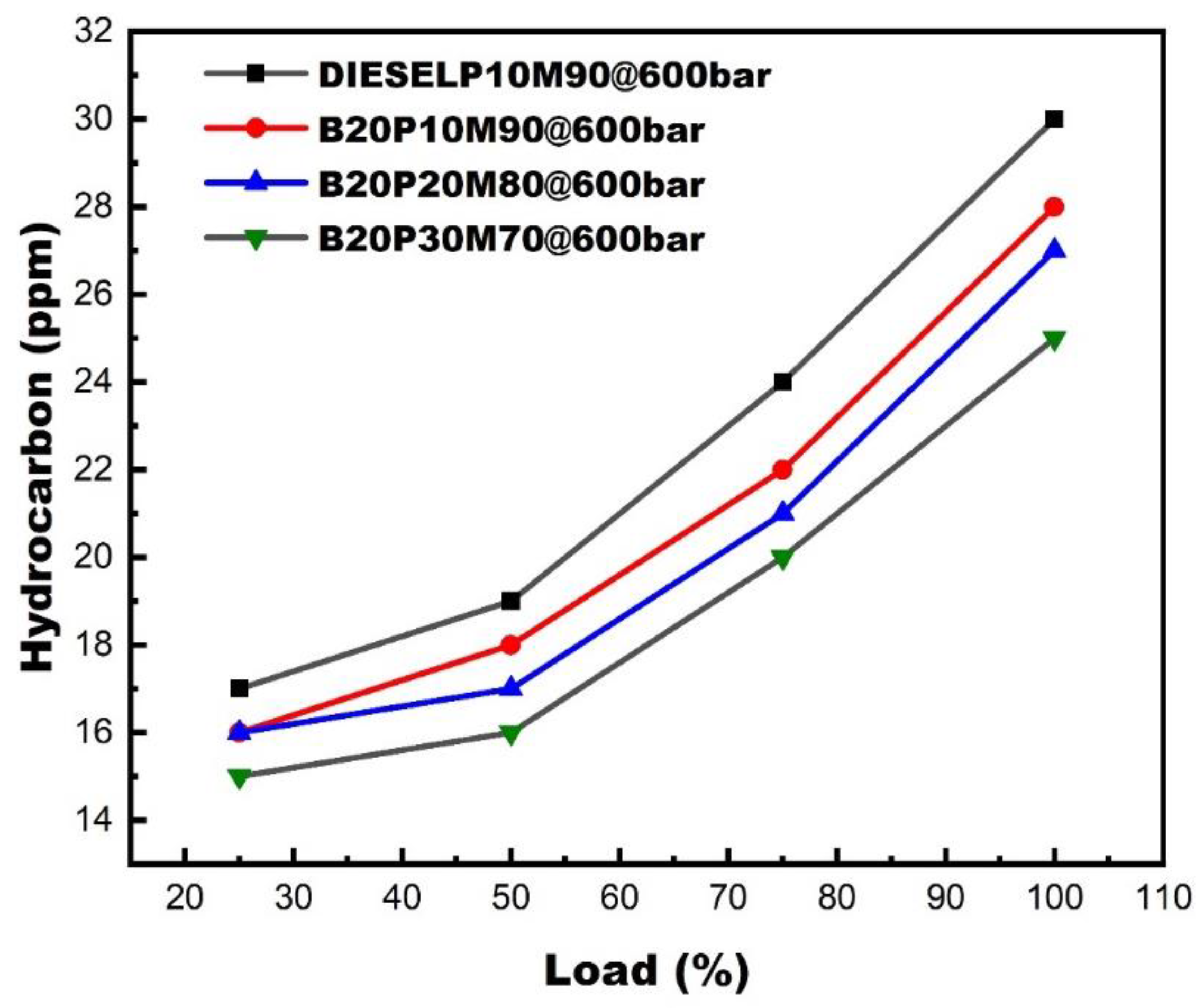

3.2.2. Hydrocarbon

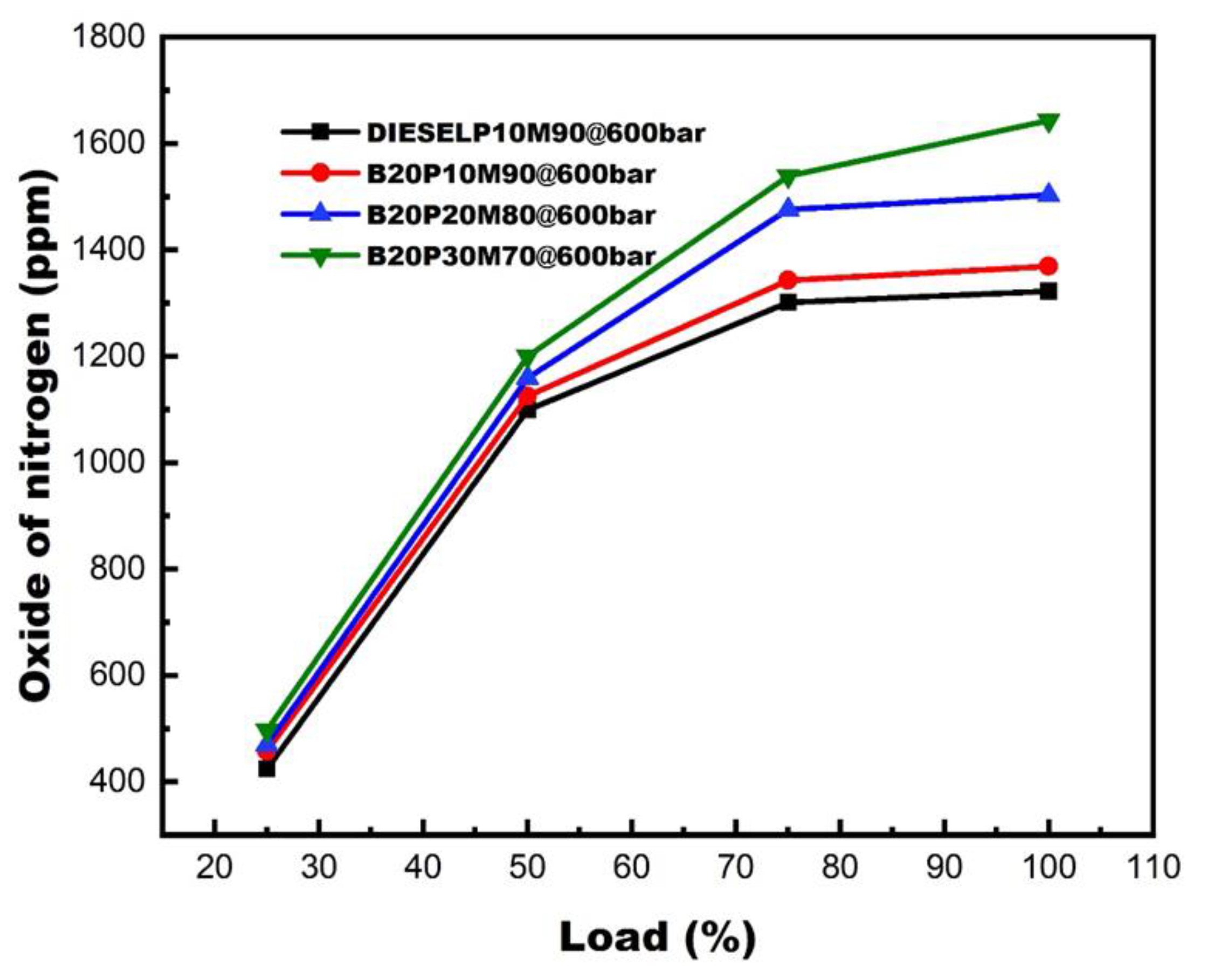

3.2.3. Oxide of Nitrogen

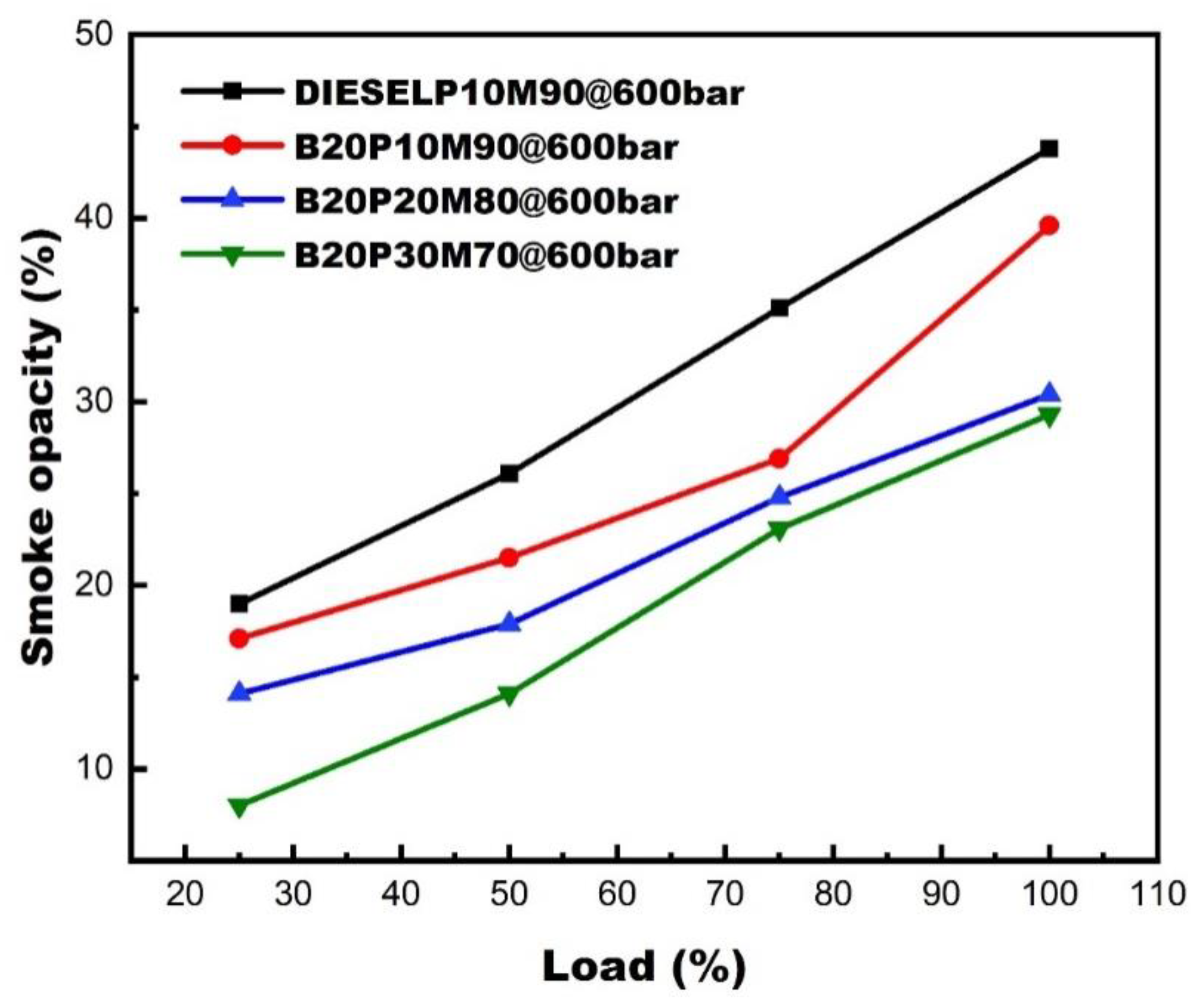

3.2.4. Smoke Opacity

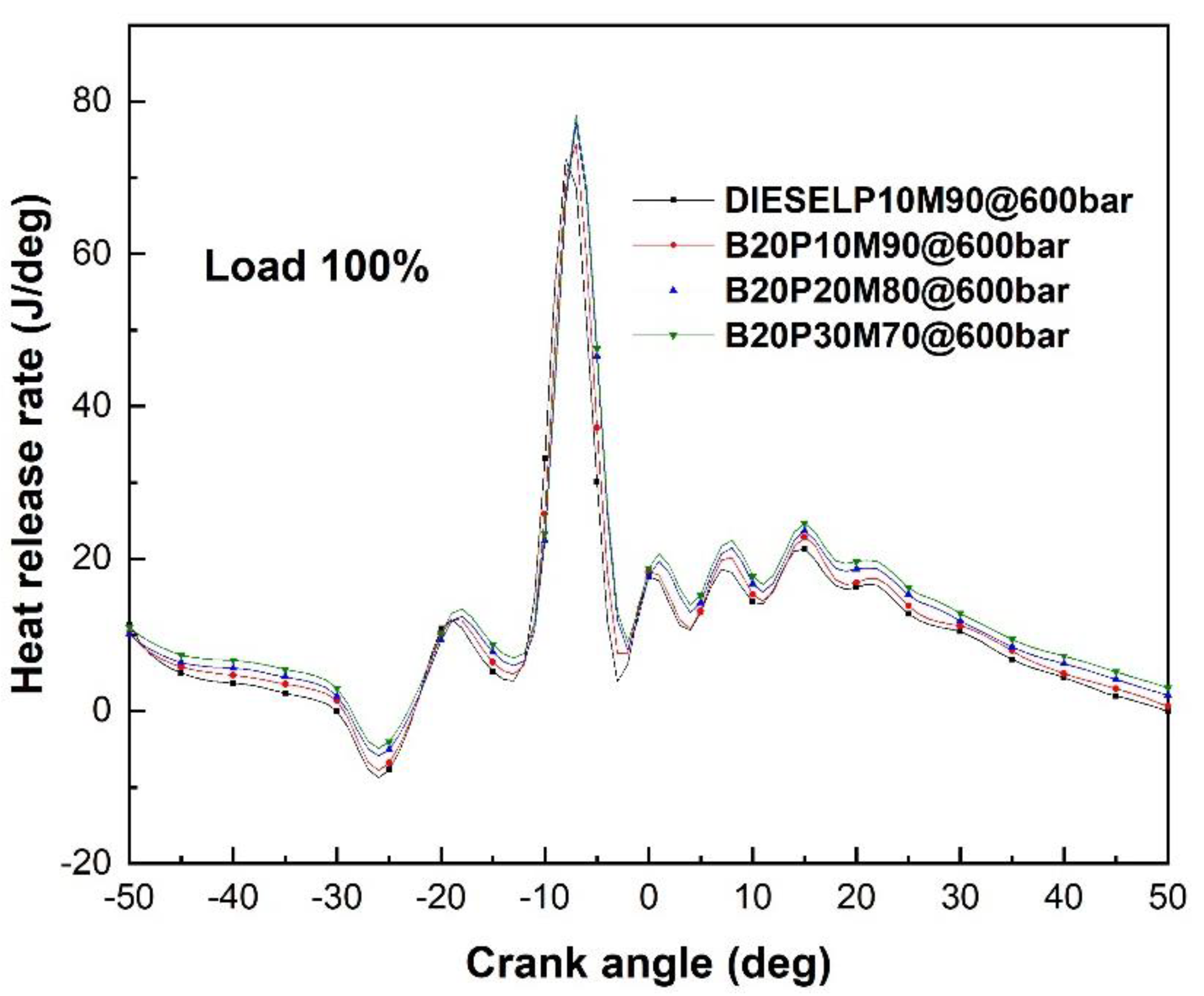

3.3. Combustion

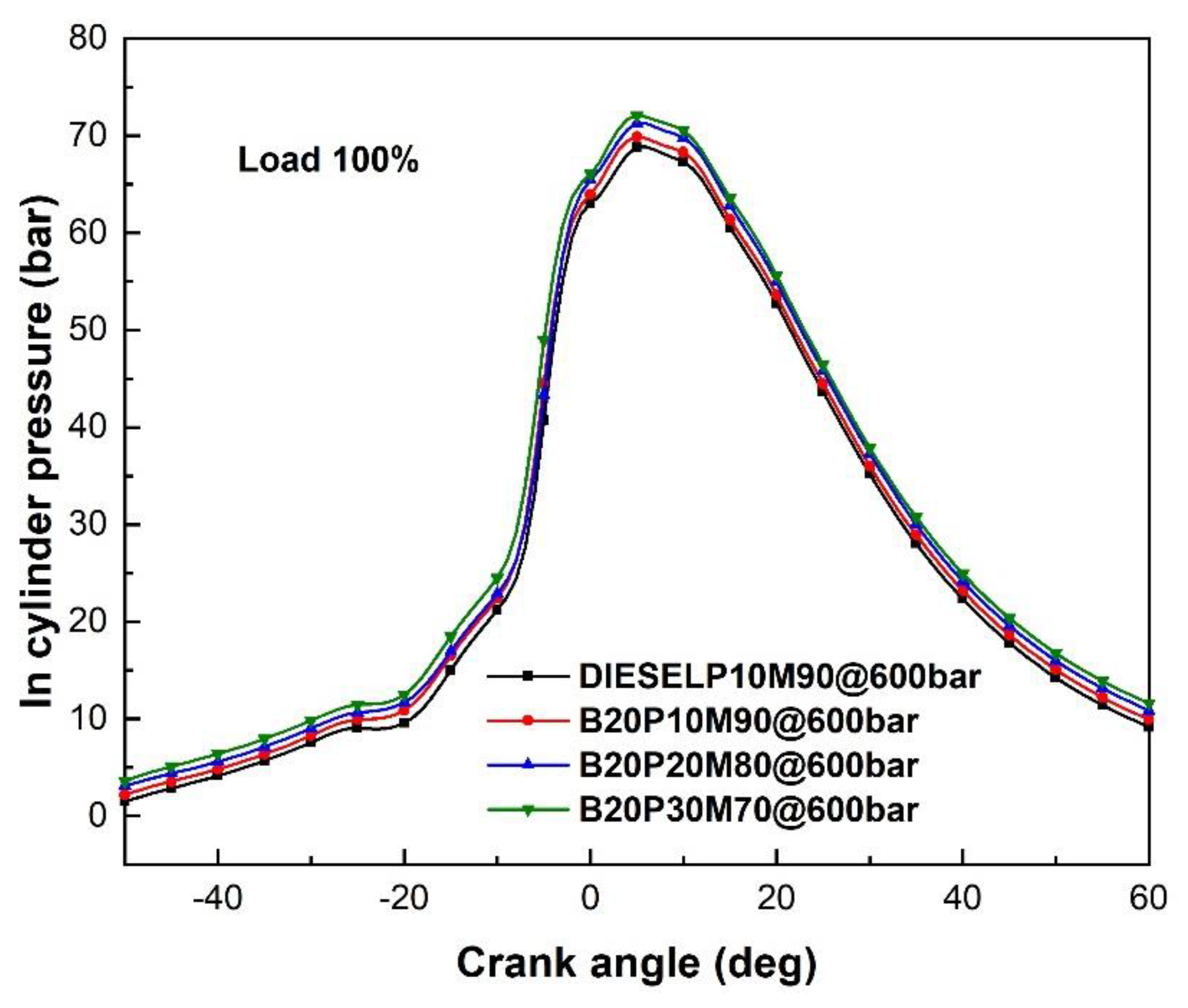

3.3.1. Cylinder Pressure

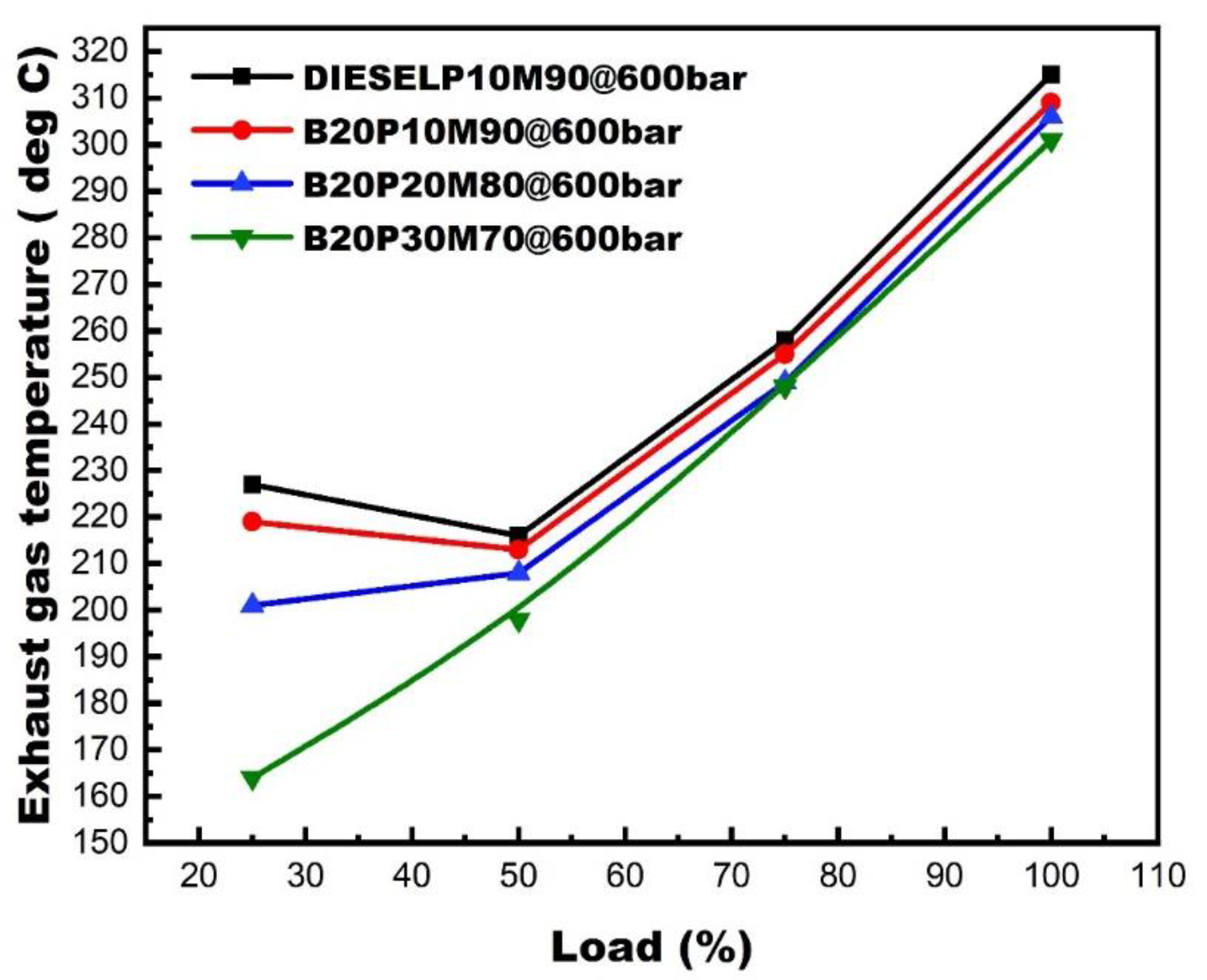

3.3.2. Exhaust-Gas Temperature

3.3.3. Net Heat Release

4. Conclusions

- The implementation of the pilot-fueling and nozzle-opening pressure at 600 bar was found to be more effective on the performance and emission characteristics;

- At a 50% engine load, the CO emissions were lower for the WCO-biodiesel blends, and later increased for the full-load conditions. Moreover, the exhaust-gas temperature decreased under partial-load conditions. The CO emissions, smoke opacity, NOx emissions, and exhaust-gas temperature curves were not similar among the different engine loads due to differences in the ambient conditions from change over time of the fuel, and the rich content of oxygen in the biodiesel blends;

- For the higher pilot-fueling quantity of the WCO B20 blend, the BSFC decreased and the BTE increased by 13.88% and 25.13%, respectively, compared with the diesel at 10% pilot fueling. The brake-specific fuel consumption for the B20P30M70 was lower compared with the B20P10M90 and B20P20M80. The BTE for the B20P30M70 was higher compared with the B20P10M90 and B20P20M80;

- The carbon monoxide, hydrocarbon, and smoke emissions were drastically reduced for the higher pilot-fueling quantity by 21.05%, 16.66%, and 33.10%, respectively, compared with the diesel at 10% pilot fueling;

- The nitrogen oxide emissions were found to be higher as the pilot-fueling quantity increased. The NOx level for the B20P30M70 was higher compared with diesel at 10% pilot fueling.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Krishnakumar, S.; Khan, T.Y.; Rajashekhar, C.R.; M. Soudagar, M.E.; Afzal, A.; Elfasakhany, A. Influence of Graphene Nano Particles and Antioxidants with Waste Cooking Oil Biodiesel and Diesel Blends on Engine Performance and Emissions. Energies 2021, 14, 4306. [Google Scholar] [CrossRef]

- Nandeesh, M.; Harishkumar, R.; Rajashekar, C.R.; Banapurmath, N.R.; Yaliwal, V.S. Effect of Injection Timing on Performance, Combustion and Emission Characteristics of Dairy Scum Methyl Esters in CRDI Engine. Int. J. Veh. Struct. Syst. (IJVSS) 2020, 12, 363–368. [Google Scholar] [CrossRef]

- Nandeesh, M.; Rajashekar, C.R.; Harishkumar, R.; Banapurmath, N.R. Significance of injection pressure on the overall performance of common rail direct injection engine using dairy scum oil methyl esters. Int. J. Ambient. Energy 2022, 43, 2260–2270. [Google Scholar] [CrossRef]

- Kumar, S.; Dinesha, P. Combined influence of fuel injection strategy and nanoparticle additives on the performance and emission characteristics of a biodiesel fueled engine. Cogent Eng. 2021, 8, 1939515. [Google Scholar] [CrossRef]

- Kannan, G.R.; Anand, R. Effect of injection pressure and injection timing on DI diesel engine fuelled with biodiesel from waste cooking oil. Biomass Bioenergy 2012, 46, 343–352. [Google Scholar] [CrossRef]

- Yesilyurt, M.K. The effects of the fuel injection pressure on the performance and emission characteristics of a diesel engine fuelled with waste cooking oil biodiesel-diesel blends. Renew. Energy 2019, 132, 649–666. [Google Scholar] [CrossRef]

- Hwang, J.; Qi, D.; Jung, Y.; Bae, C. Effect of injection parameters on the combustion and emission characteristics in a common-rail direct injection diesel engine fueled with waste cooking oil biodiesel. Renew. Energy 2014, 63, 9–17. [Google Scholar] [CrossRef]

- Kumar, R.; Gakkhar, R.P. Influence of nozzle opening pressure on combustion, performance and emission analysis of waste cooking oil biodiesel fuelled diesel engine. Int. J. Renew. Energy Technol. 2018, 9, 244–259. [Google Scholar] [CrossRef]

- How, H.G.; Masjuki, H.H.; Kalam, M.A.; Teoh, Y.H. Influence of injection timing and split injection strategies on performance, emissions, and combustion characteristics of diesel engine fueled with biodiesel blended fuels. Fuel 2018, 213, 106–114. [Google Scholar] [CrossRef]

- Indudhar, M.R.; Banapurmath, N.R.; Rajulu, K.G.; Khan, T.Y.; Manoj, E.K. Effects of single and split injection on the performance, emission and combustion attributes of a CRDI engine powered with diesel and honge biodiesel. Sustain. Energy Fuels 2019, 3, 2275–2286. [Google Scholar] [CrossRef]

- Dhar, A.; Agarwal, A.K. Experimental investigations of the effect of pilot injection on performance, emissions and combustion characteristics of Karanja biodiesel fuelled CRDI engine. Energy Convers. Manag. 2015, 93, 357–366. [Google Scholar] [CrossRef]

- Bala Prasad, K.; Meduri, O.; Dhana Raju, V.; Azmeera, A.K.; Venu, H.; Subramani, L.; Soudagar, M.E.M. Effect of split fuel injection strategies on the diverse characteristics of CRDI diesel engine operated with tamarind biodiesel. Energy Sources Part A Recovery Util. Environ. Eff. 2020, 1–19. [Google Scholar] [CrossRef]

- Senthil Kumar, D.; Thirumalini, S. Investigations on effect of split and retarded injection on the performance characteristics of engines with cashew nut shell biodiesel blends. Int. J. Ambient Energy 2022, 43, 2251–2259. [Google Scholar] [CrossRef]

- Plamondon, E.; Seers, P. Parametric study of pilot–main injection strategies on the performance of a light-duty diesel engine fueled with diesel or a WCO biodiesel–diesel blend. Fuel 2019, 236, 1273–1281. [Google Scholar] [CrossRef]

- Kumar, A.N.; Kishore, P.S.; Raju, K.B.; Nanthagopal, K.; Ashok, B. Experimental study on engine parameters variation in CRDI engine fuelled with palm biodiesel. Fuel 2020, 276, 118076. [Google Scholar] [CrossRef]

- Bhowmick, P.; Jeevanantham, A.K.; Ashok, B.; Nanthagopal, K.; Perumal, D.A.; Karthickeyan, V.; Jain, A. Effect of fuel injection strategies and EGR on biodiesel blend in a CRDI engine. Energy 2019, 181, 1094–1113. [Google Scholar] [CrossRef]

- Babu, J.M.; Prasad, K.S.; Ganji, P.R.; Ravikiran, C.; Velu, R. Analysis on the effect of pilot injection strategies on combustion and emission characteristics of palm-munja biodiesel/diesel blend on CRDI diesel engine. Int. J. Ambient Energy 2022, 43, 618–621. [Google Scholar] [CrossRef]

- Pavan, P.; Bhaskar, K.; Sekar, S. Effect of split injection and injection pressure on CRDI engine fuelled with POME-diesel blend. Fuel 2021, 292, 120242. [Google Scholar] [CrossRef]

- Senthil Kumar, D.; Thirumalini, S. Effect of injection parameters and EGR on performance and emissions in a CRDI engine fuelled with cashew nut shell biodiesel blend. Int. J. Ambient Energy 2020, 43, 3085–3095. [Google Scholar] [CrossRef]

- Nanthagopal, K.; Ashok, B.; Susanth Kishna, R.; Srinath, R.; Pranava Kumar, M.; Karthickeyan, V. Experimental investigation on engine parameters variation in common rail direct injection engine fueled with biodiesel. Clean Technol. Environ. Policy 2020, 22, 459–479. [Google Scholar] [CrossRef]

- Prem Anand, B.; Prasanna Raj Yadav, S.; Aasthiya, B.; Akshaya, G.; Arulmozhi, K. Effect of fuel injection strategies on the performance of the common rail diesel injection (CRDI) engine powered by biofuel. Int. J. Ambient Energy 2020, 41, 1577–1586. [Google Scholar] [CrossRef]

- Chacko, N. Effect of pilot and post fueling on the combustion and emission characteristics of a light-duty diesel engine powered with diesel and waste cooking biodiesel blend. Energy Sources Part A Recovery Util. Environ. Eff. 2020, 1–24. [Google Scholar] [CrossRef]

- Teoh, Y.H.; Masjuki, H.H.; How, H.G.; Kalam, M.A.; Yu, K.H.; Alabdulkarem, A. Effect of two-stage injection dwell angle on engine combustion and performance characteristics of a common-rail diesel engine fueled with coconut oil methyl esters-diesel fuel blends. Fuel 2018, 234, 227–237. [Google Scholar] [CrossRef]

- Edara, G.; Murthy, Y.S.; Nayar, J.; Ramesh, M.; Srinivas, P. Combustion analysis of modified light duty diesel engine under high pressure split injections with cooled EGR. Eng. Sci. Technol. Int. J. 2019, 22, 966–978. [Google Scholar] [CrossRef]

- Chiavola, O.; Recco, E. Emission performance of a diesel engine fuelled with petrol diesel, green diesel, and waste cooking oil blends. J. Combust. 2018, 2018, 4819175. [Google Scholar] [CrossRef]

- Das, M.; Sarkar, M.; Datta, A.; Santra, A.K. An experimental study on the combustion, performance and emission characteristics of a diesel engine fuelled with diesel-castor oil biodiesel blends. Renew. Energy 2018, 119, 174–184. [Google Scholar] [CrossRef]

| Parameter | Specification |

|---|---|

| Make | Kirloskar |

| Engine type | Single cylinder, 4-stroke |

| Bore and stroke | 87.5 mm and 110 mm |

| Compression ratio | 18:1 |

| Rated power | 3. 5 kW at 1500 rev/min |

| Speed | 1500 rev/m |

| Nozzle-opening pressure | 600 bar |

| Injection timing | 23° bTDC |

| Type of injection | Common rail direct injection |

| ECU | Nira i7r with solenoid injector |

| Measurement | Range | Accuracy | Percentage Uncertainty |

|---|---|---|---|

| Speed | 0–1500 rpm | ±1 rpm | ±1.0 |

| Load | 0–50 kg | ±0.1 kg | ±0.5 |

| Pressure sensor | 0–34,475 kPa | 10 kPa | ±0.5 |

| Crank-angle encoder | 0–6000 rpm | 1 rpm | ±0.1 |

| NOx | 0–20,000 ppm | ±10 ppm | ±1.0 |

| CO | 0–15% vol. | ±0.01% vol. | ±0.2 |

| HC | 0–20,000 ppm | ±10 ppm | ±0.15 |

| Smoke opacity | 0–100% | ±0.1% | ±1 |

| Properties | ASTM Standards | Diesel | Neat WCO Biodiesel | B20 Biodiesel |

|---|---|---|---|---|

| Density (kg/m3) | ASTM D287 | 816 | 875 | 833 |

| Viscosity, 40 °C (cSt) | ASTM D445 | 2.09 | 4.07 | 2.78 |

| Flash point (°C) | ASTM D93-58T | 53 | 160 | 78 |

| Calorific value (MJ/kg) | ASTM D4809 | 45.30 | 41.82 | 44.19 |

| Abbreviations | Fuel | Nozzle-Opening Pressure (bar) | Pilot Fueling (%) | Main Fueling (%) | Pilot-Fueling Timing | Main-Fueling Timing |

|---|---|---|---|---|---|---|

| DieselP10 | Diesel | 600 | 10 | 90 | 33° bTDC | 23° bTDC |

| B20P10M90 | 80% Diesel + 20% WCO | 10 | 90 | |||

| B20P20M80 | 80% Diesel + 20% WCO | 20 | 80 | |||

| B20P30M70 | 80% Diesel + 20% WCO | 30 | 70 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fernandes, L.J.; Rajashekhar, C.R.; Khan, T.M.Y.; Javed, S.; Baig, R.U. Influence of Pilot-Fueling and Nozzle-Opening Pressure on Performance and Tailpipe Emissions of WCO Biodiesel in a CRDi Engine. Sustainability 2022, 14, 11146. https://doi.org/10.3390/su141811146

Fernandes LJ, Rajashekhar CR, Khan TMY, Javed S, Baig RU. Influence of Pilot-Fueling and Nozzle-Opening Pressure on Performance and Tailpipe Emissions of WCO Biodiesel in a CRDi Engine. Sustainability. 2022; 14(18):11146. https://doi.org/10.3390/su141811146

Chicago/Turabian StyleFernandes, Lawrence Joseph, C. R. Rajashekhar, T. M. Yunus Khan, Syed Javed, and Rahmath Ulla Baig. 2022. "Influence of Pilot-Fueling and Nozzle-Opening Pressure on Performance and Tailpipe Emissions of WCO Biodiesel in a CRDi Engine" Sustainability 14, no. 18: 11146. https://doi.org/10.3390/su141811146

APA StyleFernandes, L. J., Rajashekhar, C. R., Khan, T. M. Y., Javed, S., & Baig, R. U. (2022). Influence of Pilot-Fueling and Nozzle-Opening Pressure on Performance and Tailpipe Emissions of WCO Biodiesel in a CRDi Engine. Sustainability, 14(18), 11146. https://doi.org/10.3390/su141811146