Cold Chain Energy Analysis for Sustainable Food and Beverage Supply

Abstract

:1. Introduction

- -

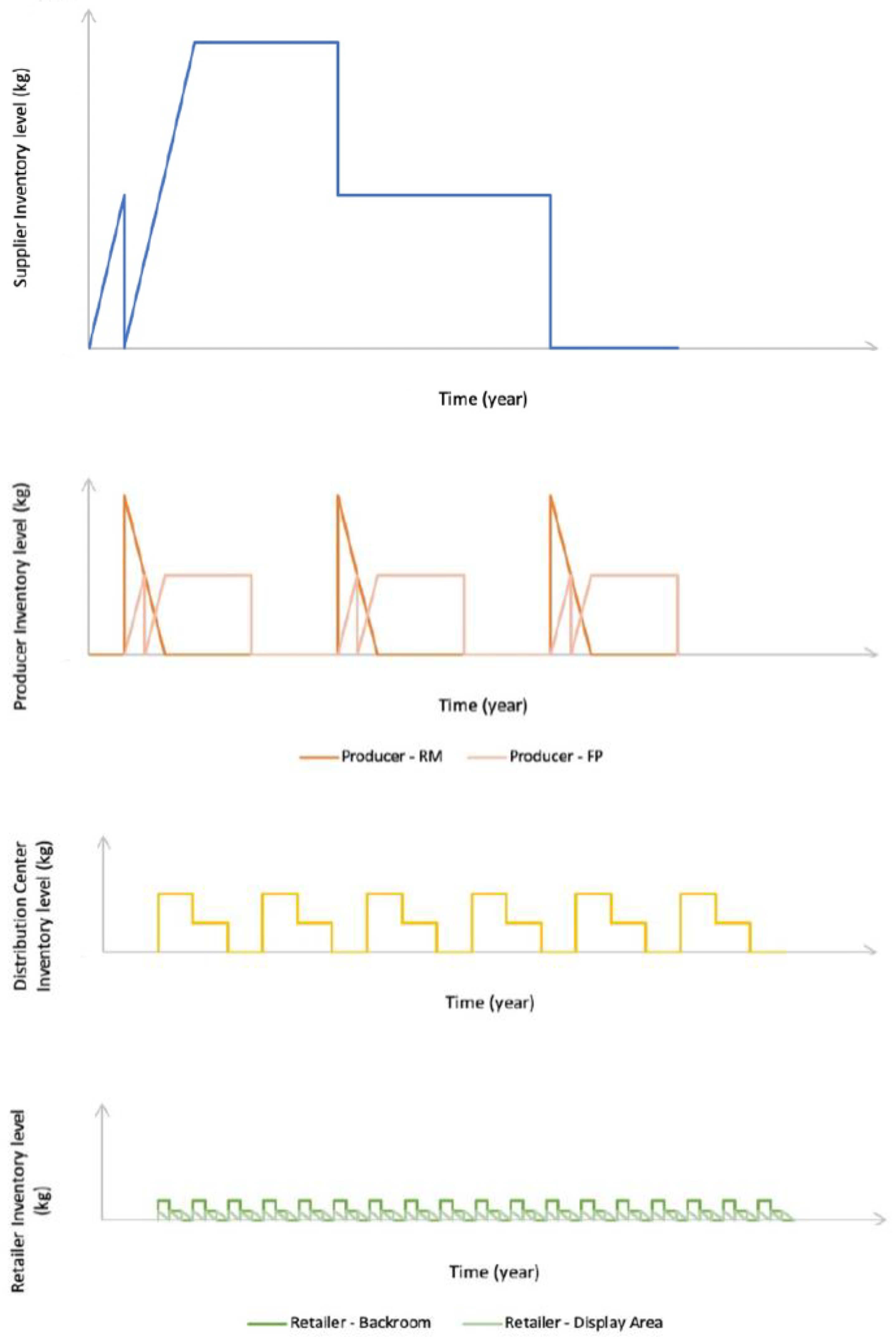

- Multi stages perspective: A multidisciplinary and integrated view has been considered. For instance, inventory levels have been modelled for each stage of the cold chain, since they affect each other and impact on the specific energy consumption;

- -

- Methodology for the assessment of cold chain energy performance: A practical approach is proposed for the evaluation of the cold chain energy performance for supporting decisionmakers. Specifically, the described approach has also been used for the development of benchmarking datasets for food and beverage cold chains;

- -

- Methodology for the prioritization of energy efficiency measures: The potential of energy efficiency measures (especially, of the maintenance and operational ones) in reducing the overall specific energy consumption of the cold chain depends on the stage at which they are implemented. The most benefits are obtained if measures are implemented at stages with the poorest energy performance;

- -

- Real case study for the dairy sector: one of the main literature gaps is the absence of practical case studies providing real managerial insights.

2. Cold Chain Energy Analysis

2.1. Problem Definition

- The time horizon is infinite;

- The final demand rate and the demand for raw material are deterministic and constant over time;

- The production rate is deterministic, constant, and greater than the demand rate ();

- The replenishment cycle is the same, and it is repeated times in a year;

- No stockout is allowed at the costumer ends;

- The lead times are negligible and assumed as zero.

2.2. Storage Activities

2.3. Transport Activities

2.4. Quality Losses

3. The Dairy Cold Chain Case Study

4. Discussion

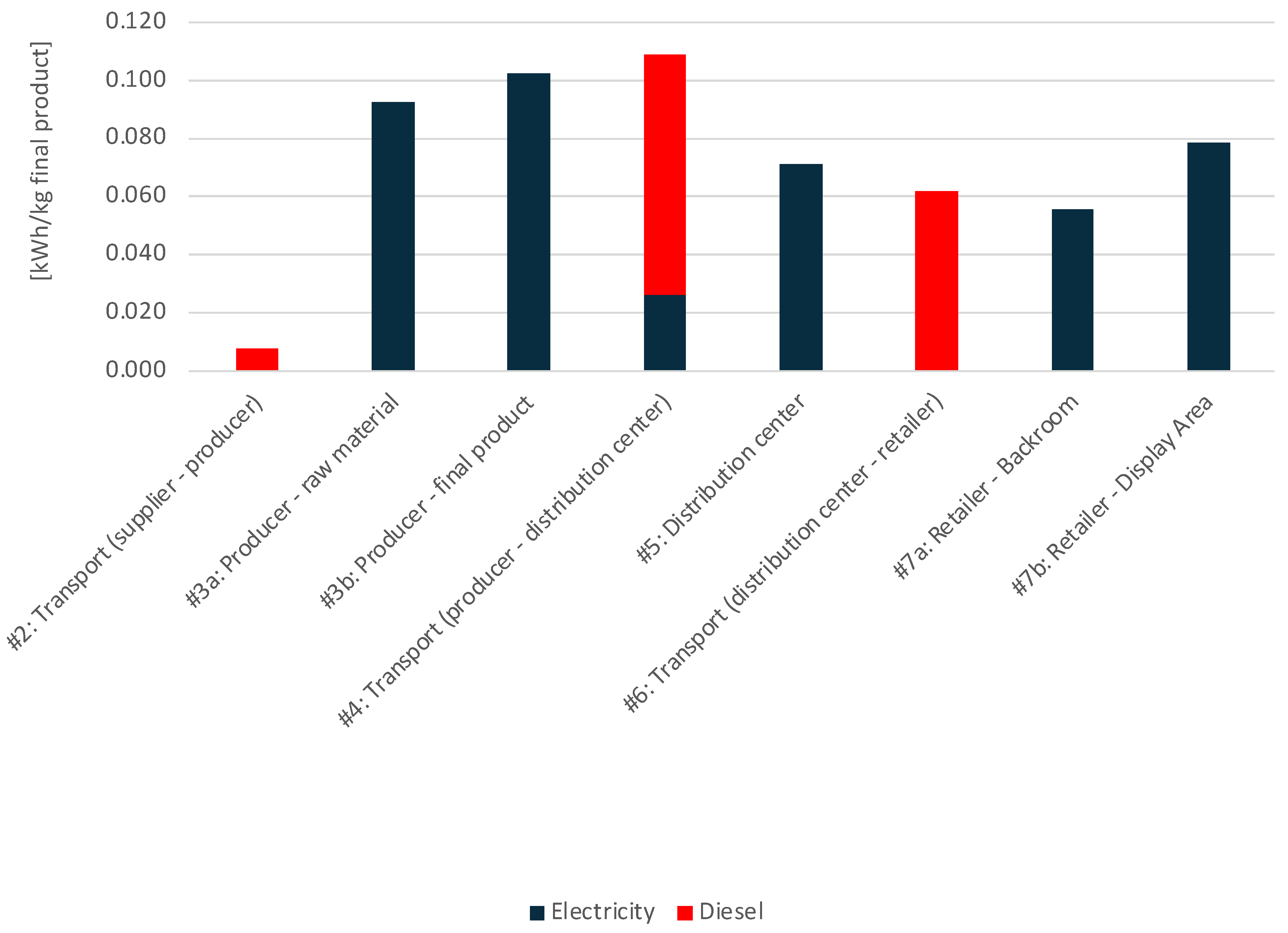

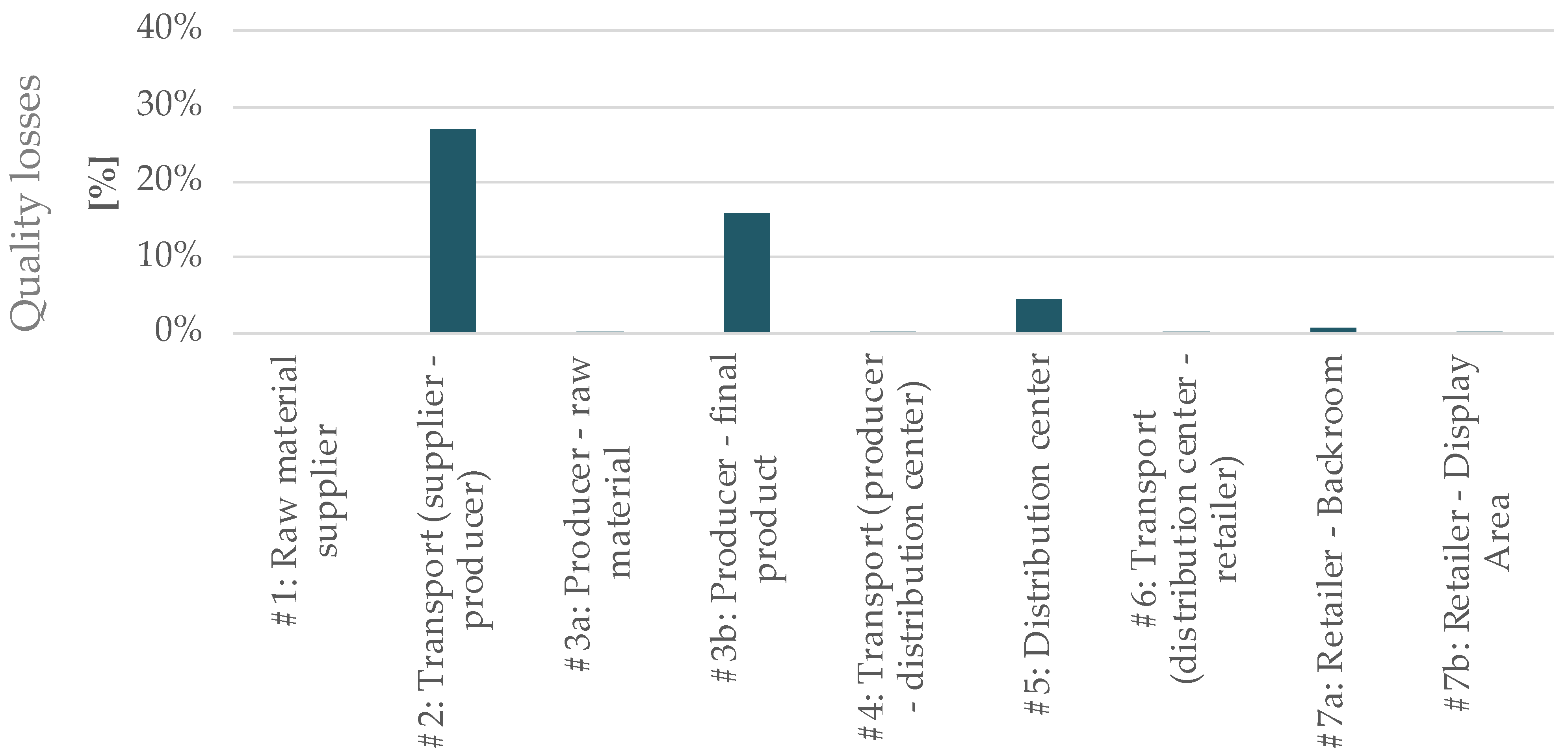

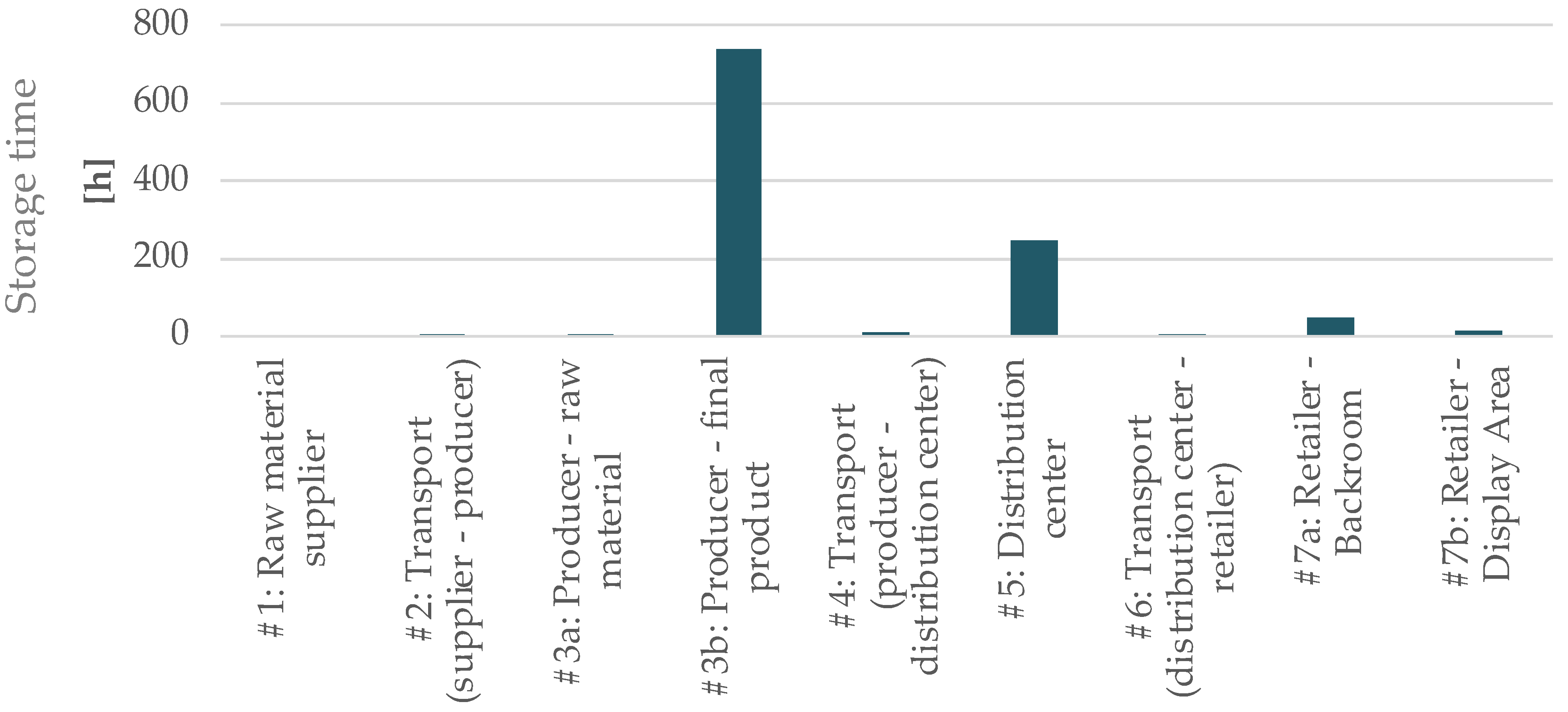

- The producer represents the stage of the cold chain with the highest share of the SEC (about 33%, while considering both the warehouse of the raw material and the one of the finished products). However, the cooling and refrigeration of the goods is not sufficient since at this stage, in which 43% of quality degradation occurs;

- Electricity is the main energy carrier (up to 71% of the SEC), but diesel consumption is also relevant for transportation activities (29% of the SEC);

- The overall SEC, with consideration of the quality degradation, is almost twice the SEC related to the logistic activities;

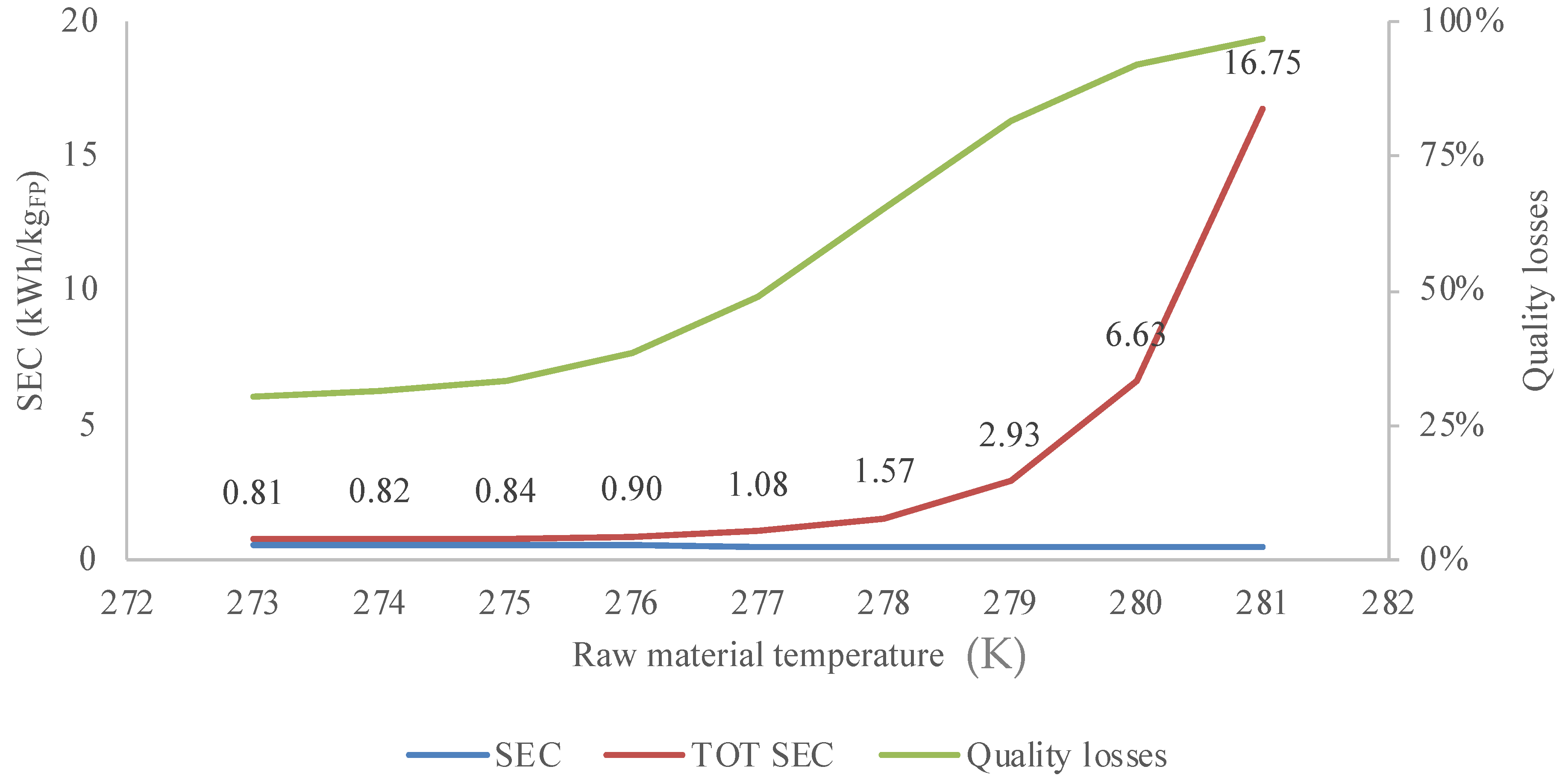

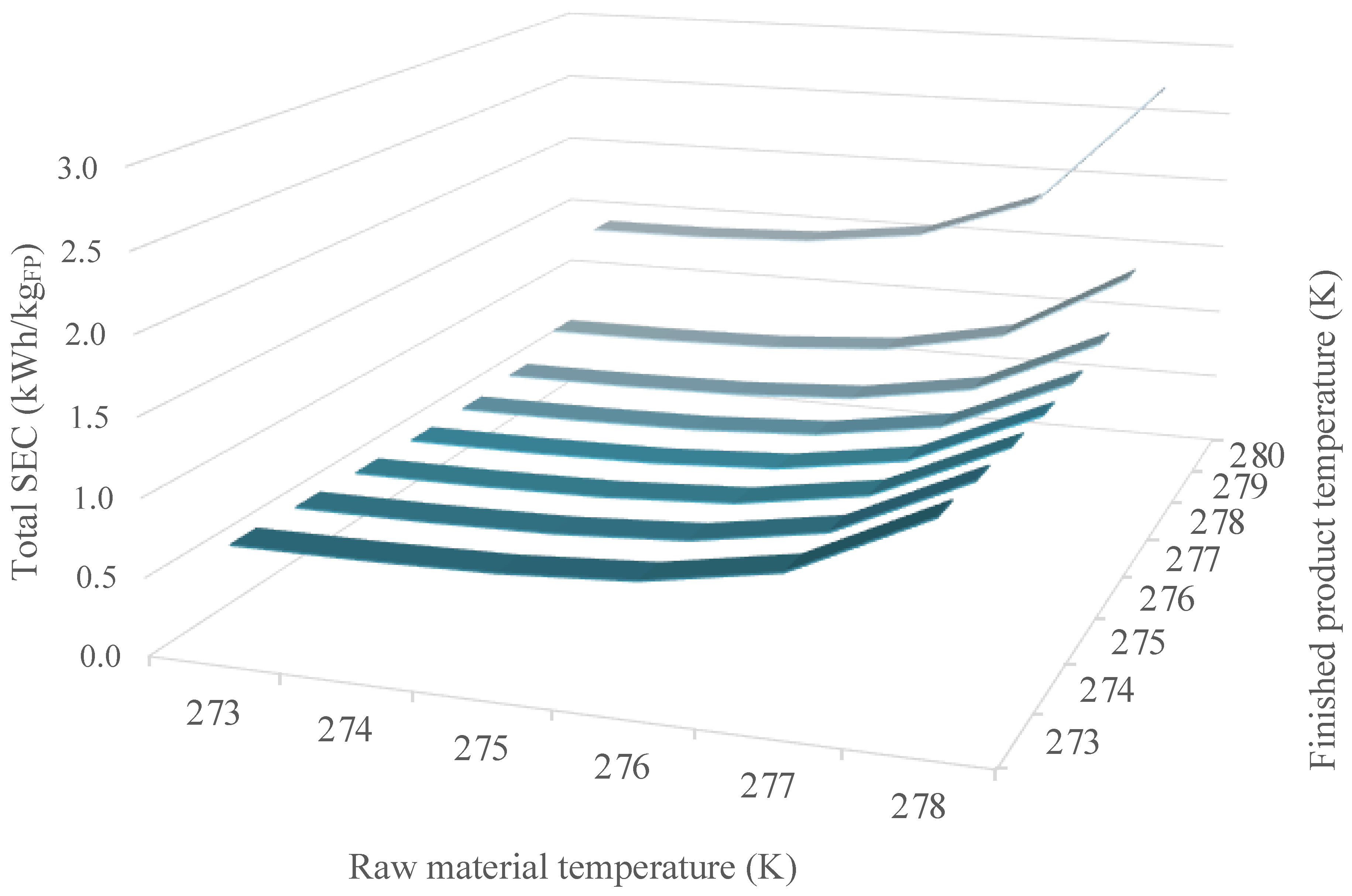

- Setting lower temperatures to the raw material warehouses (which reduces quality losses) and higher temperatures to the finished product warehouses (which avoids temperature abuses), it is possible to reduce the overall SEC of about 41%;

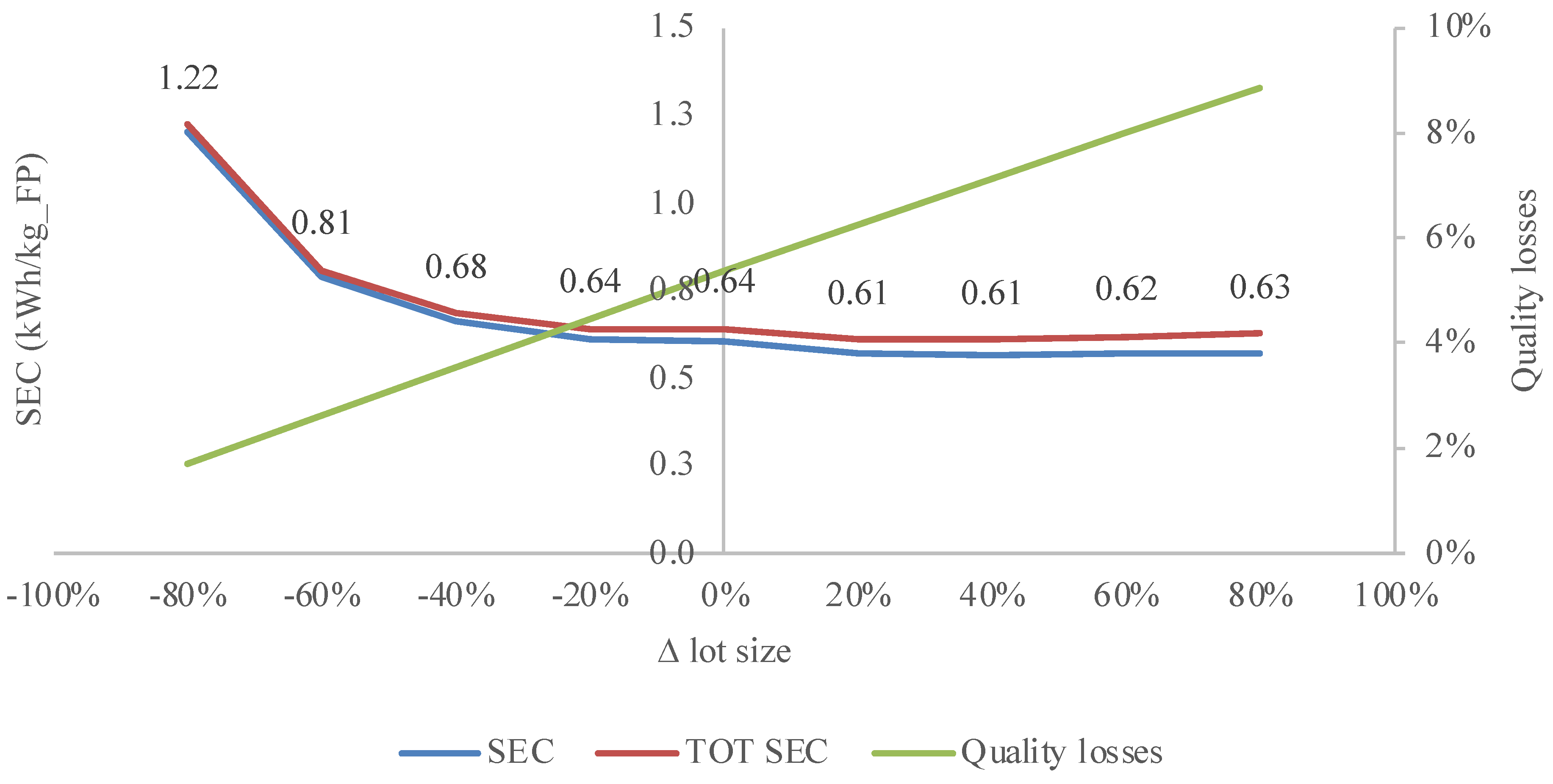

- The lot size at the display area of the retailer represents another managerial lever for increasing the energy efficiency of the cold chain. However, in the case study proposed, the lot should be increased by 40%; however, this is not possible due to the limited space available;

- To improve the energy efficiency at the PF warehouse, the producer can fasten the replenishment cycles, which reduces the storage time. This means lower quality degradation and lower energy demand (i.e., refrigeration equipment operating for lower periods);

- Other energy efficiency measures can be implemented at the transport stage from the producer to the distribution center since it is responsible of 19% of the SEC. Specifically, due to high diesel consumption and the long trip requiring refrigeration, improving the insulation of the vehicle, or increasing its saturation, allows for a reduction in the SEC.

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

Notation

| conversion factor of raw materials in finished products, | |

| average inventory level of raw material at stage (kg) | |

| , , | product- and temperature-dependent coefficients for the evaluation of the quality level |

| coefficients for the evaluation of the filling level impact on the specific energy consumption at stage | |

| annual demand rate of finished product from final customers (kg/year) | |

| annual demand rate of raw material (kg/year) | |

| fuel conversion factor for stage (kWh/L) | |

| annual energy use of the warehouse for cooling purposes (kWh/year) | |

| fuel consumption per trip for stage (L/trip) | |

| sub-index defining the considered warehouse of the supply chain (S: supplier, P_RM: raw material warehouse of the producer, P_FP: finished product warehouse of the producer, DC: distribution center, R_B: backroom warehouse of the retailer, R_DA: display area of the retailer) | |

| sub-index defining the considered transportation stage of the supply chain (S–P: from supplier to producer, P–DC: from producer to distribution center, DC-R: from distribution center to retailer) | |

| sub-index defining the considered product (RM: raw material, FP: finished product) | |

| inventory level of the stage at time (kg) | |

| , | product-dependent constant for the evaluation of and |

| number of shipments from stage for each production and/or ordering cycle (-) | |

| production rate of stage (kg/year) | |

| order lot size of the retailer (kg) | |

| order lot size of stage (kg) | |

| , | quality level for stage and as a function of the temperature set and the storage time (%) |

| , | initial quality level for stage and (%) |

| coefficient defining the effect of different storage temperatures on the specific energy consumption | |

| size of the cold warehouse at stage (m3) | |

| specific energy consumption of the storage activities per unit of product at stage (kWh/kg) | |

| Specific energy consumption of a warehouse at stage (kWh/m3) | |

| Specific energy consumption of the transportation activities per unit of product at stage (kWh/kg) | |

| average storage time at stage (year) | |

| average travelling time requiring refrigeration at stage (h/trip) | |

| , | reference temperature for energy consumption measures at stage and (°C) |

| , | effective temperature set during storage and transportation activities at stage and (°C) |

| number of vehicles necessary to deliver a lot of size at stage | |

| specific storage time, in the interval (year) | |

| electrical power required to power on cooling equipment on vehicles t stage (kW) | |

| specific volume of the product (kg/m3) |

References

- Marchi, B.; Zavanella, L.E.; Zanoni, S. Supply chain finance for ameliorating and deteriorating products: A systematic literature review. J. Bus. Econ. 2022, 1–30. [Google Scholar] [CrossRef]

- Kefalidou, A.A. Sustainable Energy Solutions to ‘Cold Chain’ Food Supply Issues. Brief for GSDR–2016 Update. Available online: https://sustainabledevelopment.un.org/content/documents/968624_Kefalidou_Sustainable%20energy%20solutions%20to-cold%20chain-food%20supply%20issues.pdf (accessed on 22 July 2022).

- Ndraha, N.; Hsiao, H.; Vlajic, J.; Yang, M.; Lin, H.V. Time-temperature abuse in the food cold chain: Review of issues, challenges, and recommendations. Food Control 2018, 89, 12–21. [Google Scholar] [CrossRef]

- Winkworth-Smith, C.G.; Foster, T.J.; Morgan, W. The Impact of Reducing Food Loss in The Global Cold Chain; University of Nottingham: Nottingham, UK, 2015. [Google Scholar]

- Sarr, J.; Dupont, J.L.; Guilpart, J. The Carbon Footprint of the Cold Chain, 7th Informatory Note on Refrigeration and Food; International Institute of Refrigeration: Paris, France, 2021. [Google Scholar] [CrossRef]

- Coulomb, D. Refrigeration and cold chain serving the global food industry and creating a better future: Two key IIR challenges for improved health and environment. Trends Food Sci. Technol. 2008, 19, 413–417. [Google Scholar] [CrossRef]

- James, S.J.; James, C. The food cold-chain and climate change. Food Res. Int. 2010, 43, 1944–1956. [Google Scholar] [CrossRef]

- Knowles, M.; Baglee, D. The role of maintenance in energy saving in commercial refrigeration. J. Qual. Maint. Eng. 2012, 18, 282–294. [Google Scholar] [CrossRef]

- Zanoni, S.; Marchi, B. Environmental impacts of foods refrigeration. In Environmental Impact of Agro-Food Industry and Food Consumption; Academic Press: Cambridge, MA, USA, 2021; Chapter 11; pp. 239–259. ISBN 9780128213636. [Google Scholar] [CrossRef]

- Meneghetti, A.; Ceschia, S. Energy-efficient frozen food transports: The Refrigerated Routing Problem. Int. J. Prod. Res. 2020, 58, 4164–4181. [Google Scholar] [CrossRef]

- Chen, G.; Wahab, M.I.M.; Fang, L. Optimal replenishment strategy for a single-manufacturer multi-retailer cold chain considering multi-stage quality degradation. Appl. Math. Model. 2022, 104, 96–113. [Google Scholar] [CrossRef]

- Marchi, B.; Zanoni, S. Supply chain management for improved energy efficiency: Review and opportunities. Energies 2017, 10, 1618. [Google Scholar] [CrossRef] [Green Version]

- Manzini, R.; Accorsi, R. The new conceptual framework for food supply chain assessment. J. Food Eng. 2013, 115, 251–263. [Google Scholar] [CrossRef]

- Neusel, L.; Hirzel, S.; Zanoni, S.; Marchi, B. Energy efficiency from farm to fork ? On the relevance of non-energy benefits and behavioural aspects along the cold supply chain. ECEEE Ind. Summer Study Proc. 2020, 101–110. Available online: https://www.eceee.org/library/conference_proceedings/eceee_Industrial_Summer_Study/2020/2-sustainable-production-towards-a-circular-economy/energy-efficiency-from-farm-to-fork-on-the-relevance-of-non-energy-benefits-and-behavioural-aspects-along-the-cold-supply-chain/2020/2-084-20_Neusel.pdf/ (accessed on 22 July 2022).

- Laguerre, O.; Duret, S.; Hoang, H.M.; Flick, D.; Ing, U.M.R. Using simplified models of cold chain equipment to assess the influence of operating conditions and equipment design on cold chain performance. Int. J. Refrig. 2014, 47, 120–133. [Google Scholar] [CrossRef]

- Marchi, B.; Zanoni, S.; Jaber, M.Y. Energy Implications of Lot Sizing Decisions in Refrigerated Warehouses. Energies 2020, 13, 1739. [Google Scholar] [CrossRef]

- Zanoni, S.; Zavanella, L. Chilled or frozen? Decision strategies for sustainable food supply chains. Int. J. Prod. Econ. 2012, 140, 731–736. [Google Scholar] [CrossRef]

- Peleg, M.; Engel, R.; Gonzalez-martinez, C.; Corradini, M.G. Non-Arrhenius and non-WLF kinetics in food systems. J. Sci. Food Agric. 2002, 82, 1346–1355. [Google Scholar] [CrossRef]

- Mercier, S.; Mondor, M.; Villeneuve, S.; Marcos, B. The Canadian food cold chain: A legislative, scientific, and prospective overview. Int. J. Refrig. 2018, 88, 637–645. [Google Scholar] [CrossRef]

- Marchi, B.; Zanoni, S.; Ferretti, I.; Zavanella, L.E.L.E. Stimulating Investments in Energy Efficiency Through Supply Chain Integration. Energies 2018, 11, 858. [Google Scholar] [CrossRef]

- Diaz, F.; Vignati, J.A.; Marchi, B.; Paoli, R.; Zanoni, S.; Romagnoli, F. Effects of Energy Efficiency Measures in the Beef Cold Chain: A Life Cycle-based Study. Rigas Teh. Univ. Zinat. Raksti 2021, 25, 343–355. [Google Scholar] [CrossRef]

- Fikiin, K.; Stankov, B.; Evans, J.; Maidment, G.; Foster, A.; Brown, T.; Radcliffe, J.; Youbi-idrissi, M.; Alford, A.; Varga, L.; et al. Refrigerated warehouses as intelligent hubs to integrate renewable energy in industrial food refrigeration and to enhance power grid sustainability. Trends Food Sci. Technol. 2017, 60, 96–103. [Google Scholar] [CrossRef]

- Meneghetti, A.; Dal Magro, F.; Simeoni, P. Fostering Renewables into the Cold Chain: How Photovoltaics Affect Design and Performance of Refrigerated Automated Warehouses. Energies 2018, 11, 1029. [Google Scholar] [CrossRef] [Green Version]

| General | Storage Activities | Transportation Activities |

|---|---|---|

|

|

|

| Actor | Producer | Distribution Center | Retailer | ||

|---|---|---|---|---|---|

| Warehouse | Raw Material | Finished Product | Backroom | Display Area | |

| Electricity consumption (MWh/year) | 34 | 340.6 | 552 | 18 | 3.854 |

| Ambient temperature, (K) | 303 | 303 | 303 | 303 | 303 |

| Reference temperature, (K) | 273 | 278 | 277 | 274 | 275 |

| Set temperature, (K) | 277 | 279 | 279 | 279 | 279 |

| Storage size, (m3) | 50 | 7200 | 25600 | 70 | 4 |

| Production rate, (ton/year) | 86.8 | - | - | ||

| Transport (From–To) | Supplier–Producer | Producer–Distribution Center | Distribution Center–Retailer |

|---|---|---|---|

| Type | Single drop | Single drop | Multi drop |

| Vehicle | Truck | Trailer | Small delivery vehicle |

| Fuel type | Diesel oil | Diesel oil | Diesel oil |

| Refrigeration system driven by | - | Truck engine | Truck engine |

| Average distance travelled (km) | 50 | 150 | 50 |

| Average travelling time (h) | 1 | 10 | 4 |

| Distance travelled per liter of fuel (km/L) | 4 | 3 | 8.5 |

| Average amount of product transported (kg) | 11,000 | 7000 | 1000 |

| Electrical power for refrigeration equipment (kW) | - | 17 | - |

| Parameter | Value |

|---|---|

| 0.1 | |

| Fuel conversion factor, (kWh/L) | 10.9 |

| 0.5 | |

| h | 1 |

| 1 | |

| 5 (RM) and 14 (FP) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Marchi, B.; Zanoni, S. Cold Chain Energy Analysis for Sustainable Food and Beverage Supply. Sustainability 2022, 14, 11137. https://doi.org/10.3390/su141811137

Marchi B, Zanoni S. Cold Chain Energy Analysis for Sustainable Food and Beverage Supply. Sustainability. 2022; 14(18):11137. https://doi.org/10.3390/su141811137

Chicago/Turabian StyleMarchi, Beatrice, and Simone Zanoni. 2022. "Cold Chain Energy Analysis for Sustainable Food and Beverage Supply" Sustainability 14, no. 18: 11137. https://doi.org/10.3390/su141811137

APA StyleMarchi, B., & Zanoni, S. (2022). Cold Chain Energy Analysis for Sustainable Food and Beverage Supply. Sustainability, 14(18), 11137. https://doi.org/10.3390/su141811137