Research on Direct Yaw Moment Control of Electric Vehicles Based on Electrohydraulic Joint Action

Abstract

:1. Introduction

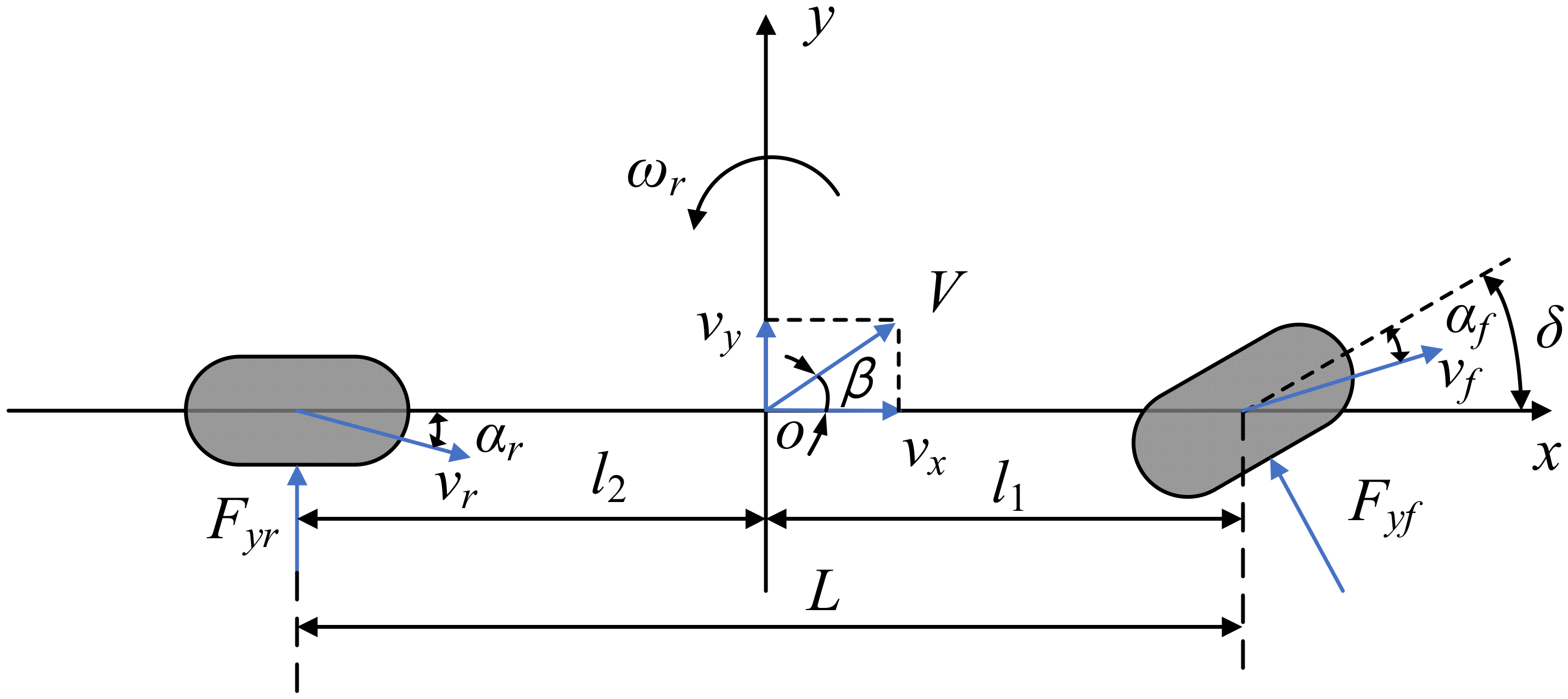

2. Vehicle Dynamics Model

2.1. Two Degrees of Freedom Vehicle Dynamics Model

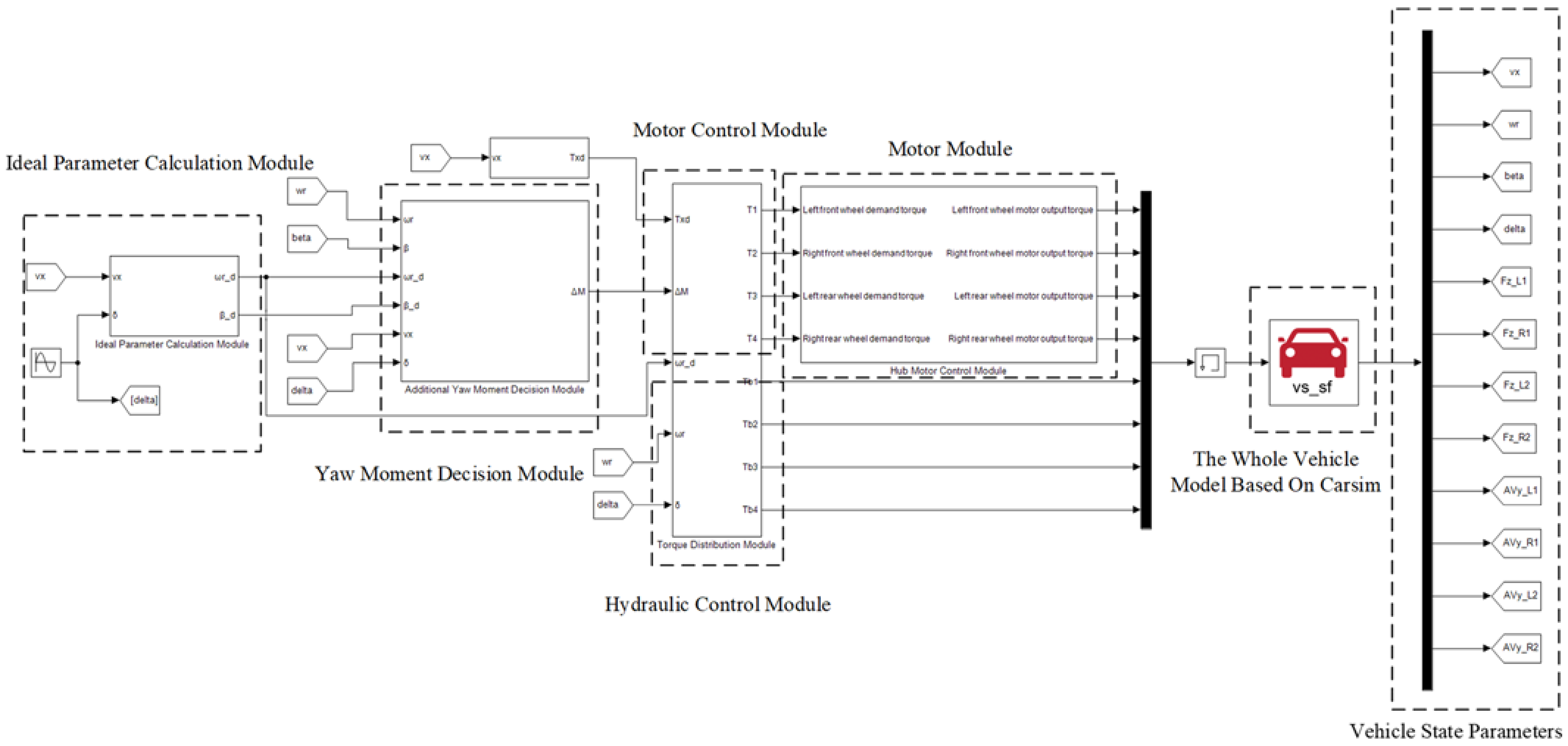

2.2. Vehicle Model Based on Carsim

3. Research on Yaw Moment Control Decision

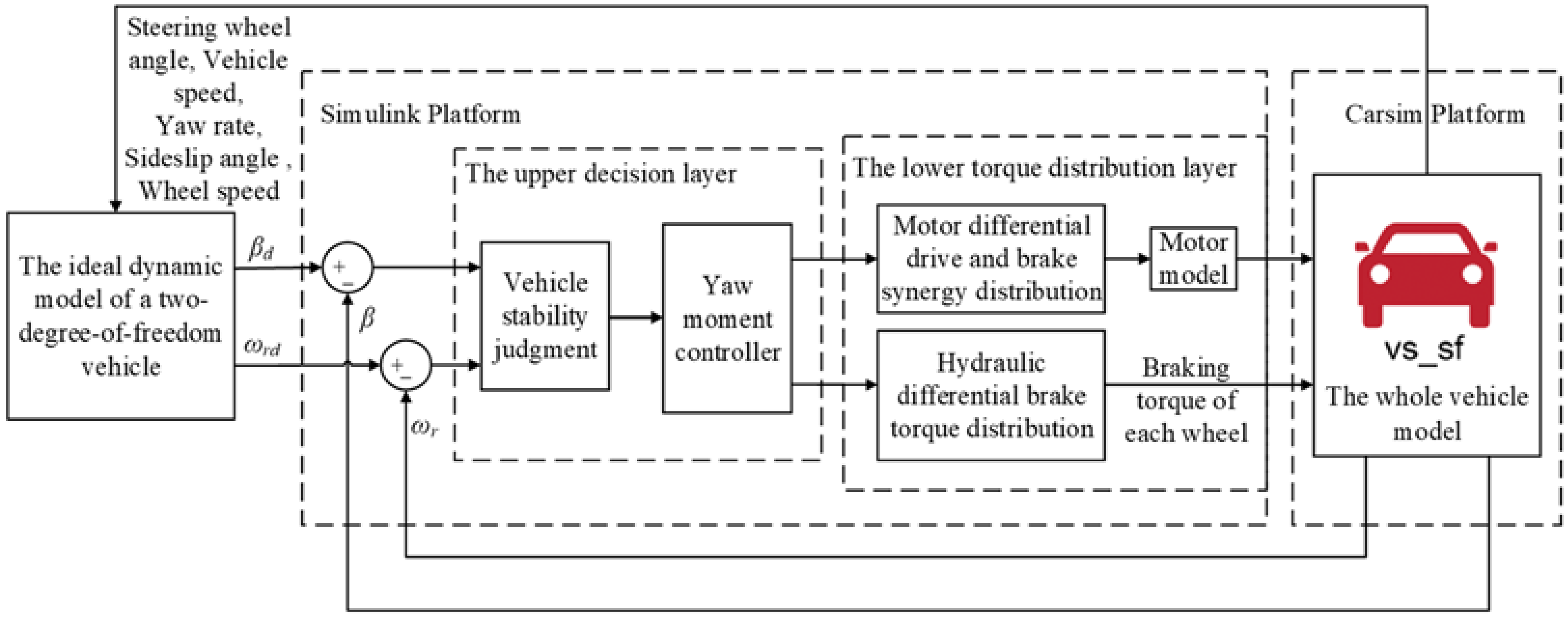

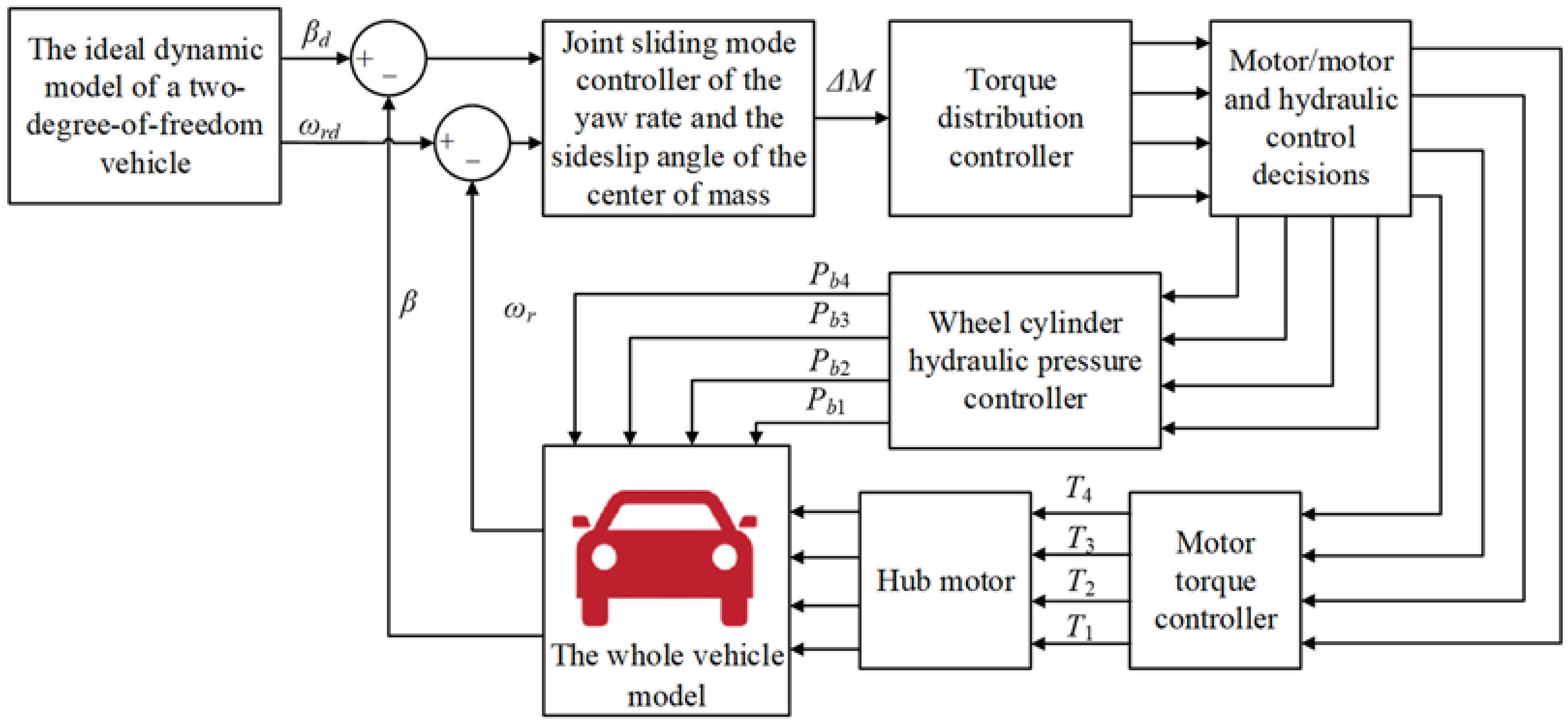

3.1. Design of the Yaw Moment Control Strategy Scheme

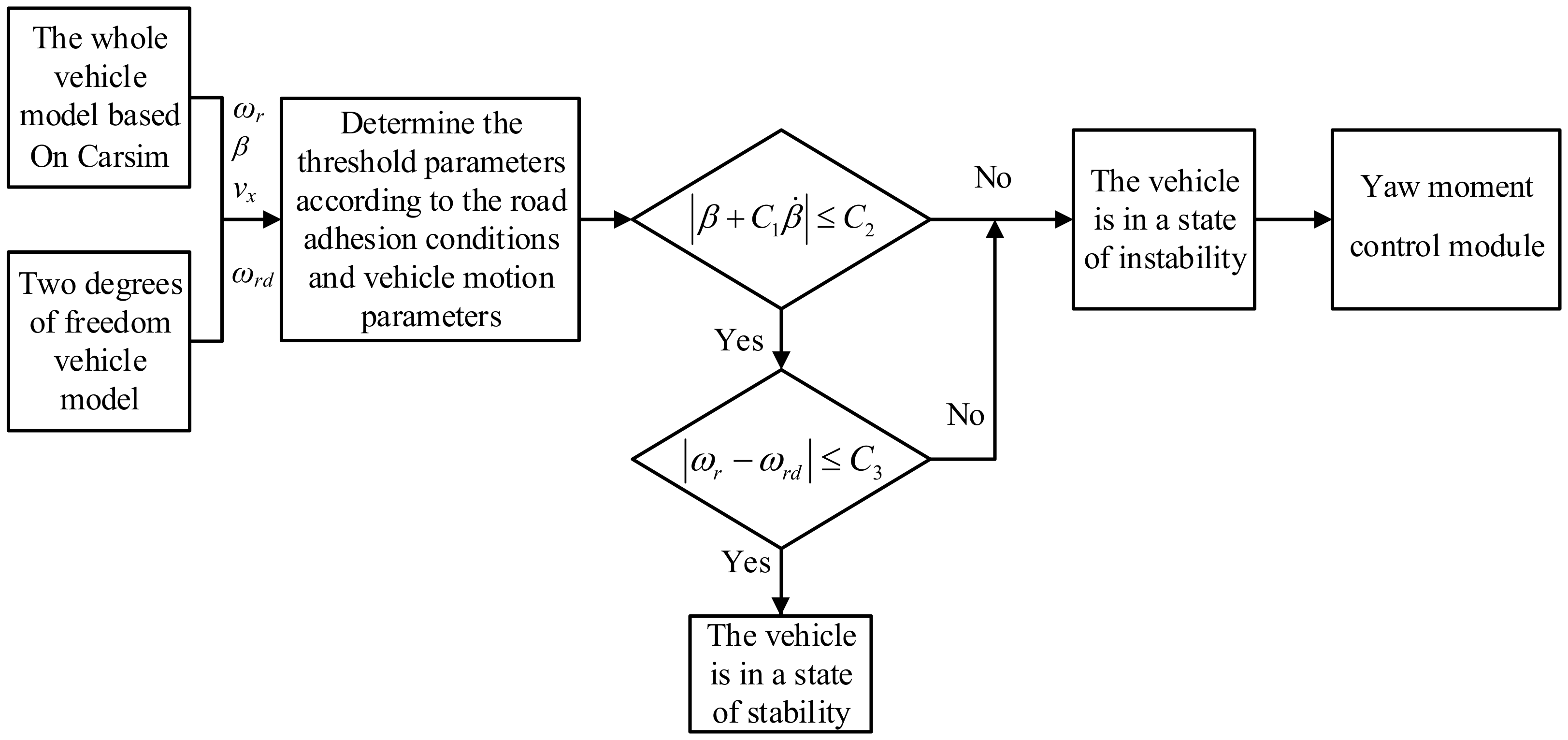

3.2. Vehicle Stability Judgment

3.3. Ideal Vehicle Dynamics Model

3.4. Design of the Yaw Moment Controller

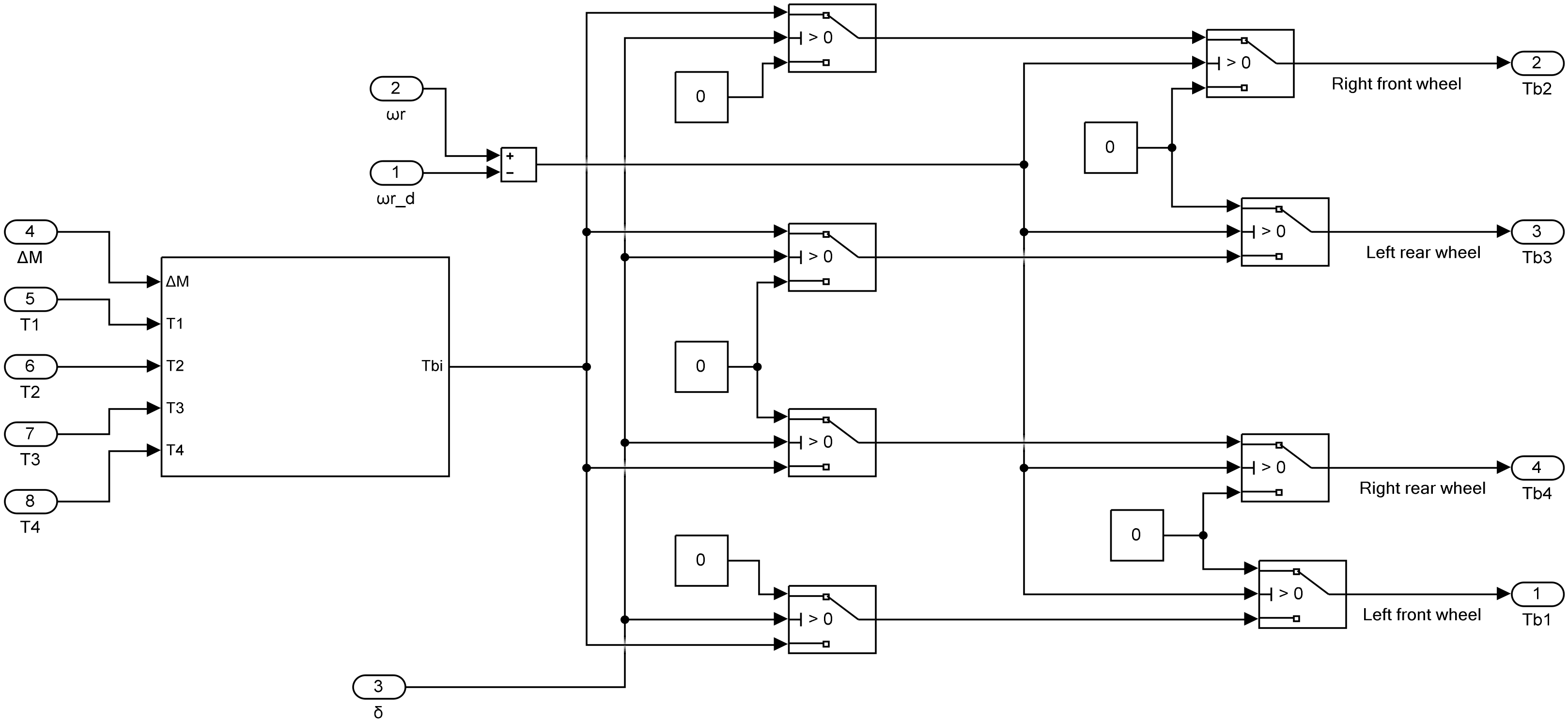

4. Research on the Distribution Strategy of Yaw Moments

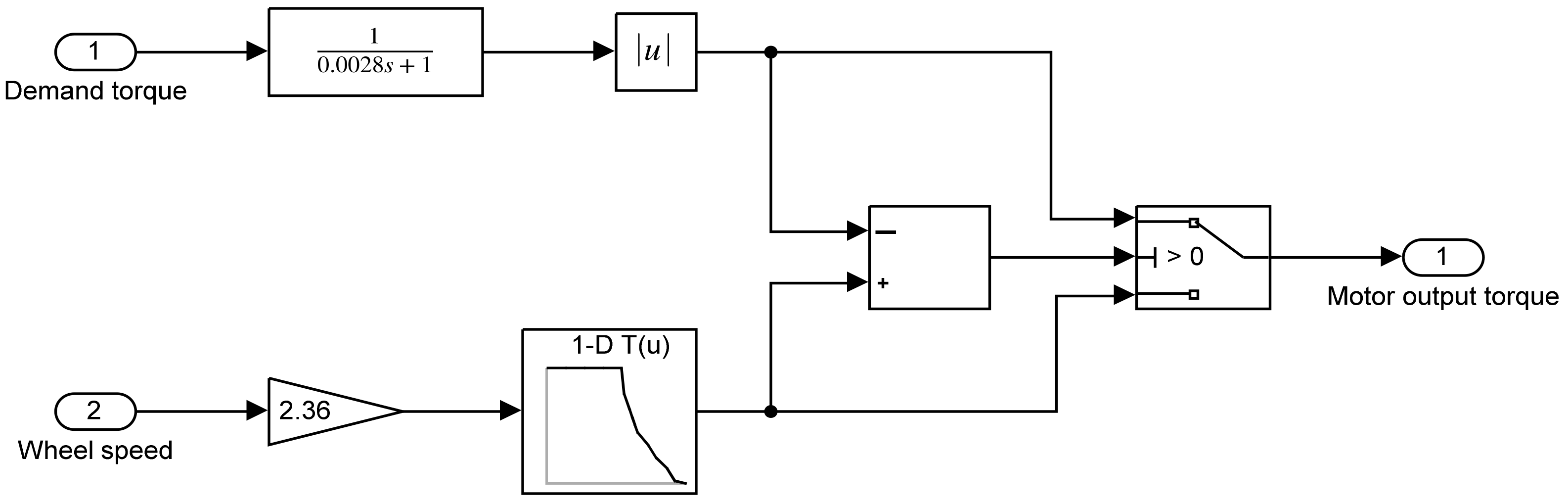

4.1. Distribution Strategy of Motor Torque

4.2. Hydraulic Brake Compensation Control Strategy

5. Stability Simulation Analysis of Yaw Moment Control

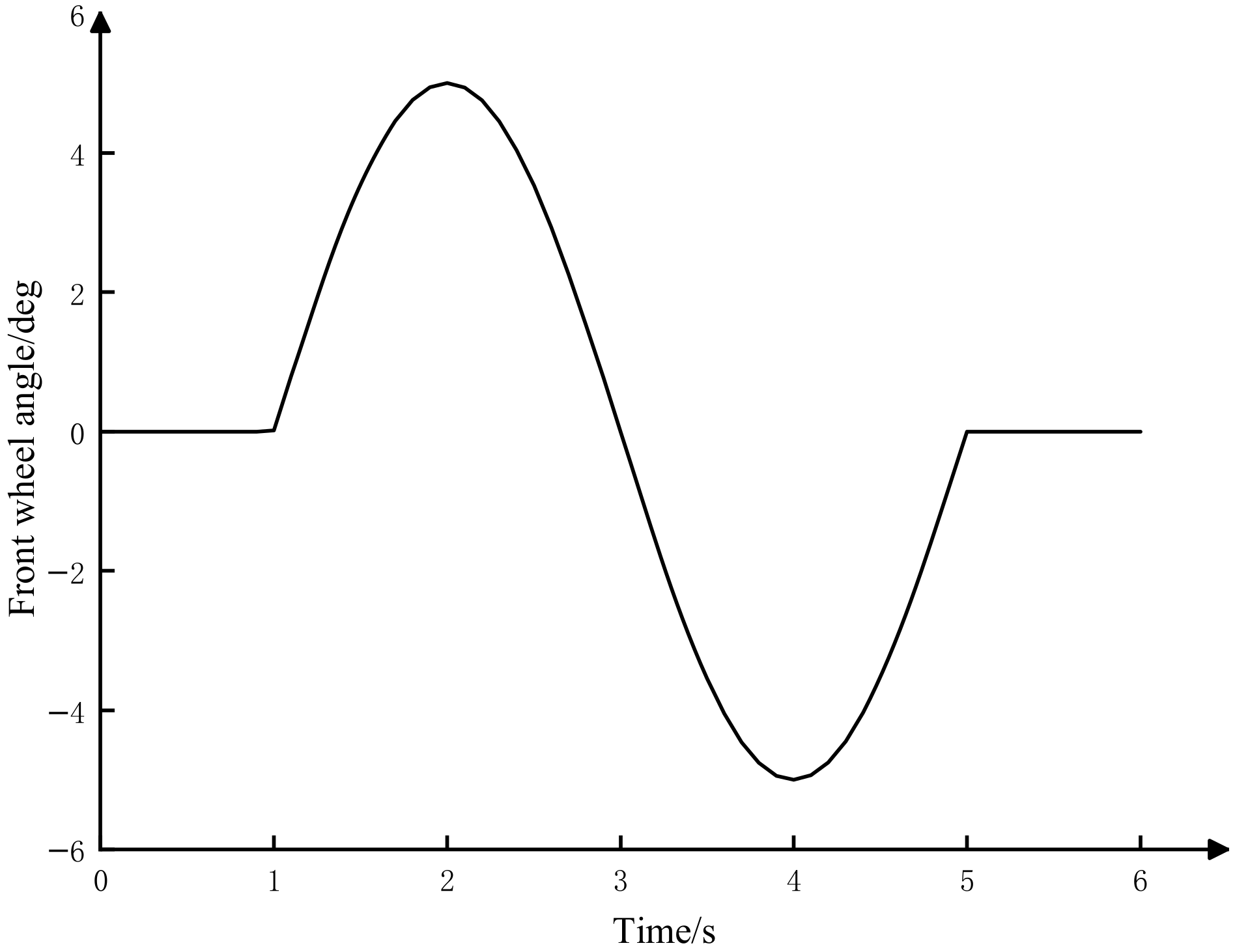

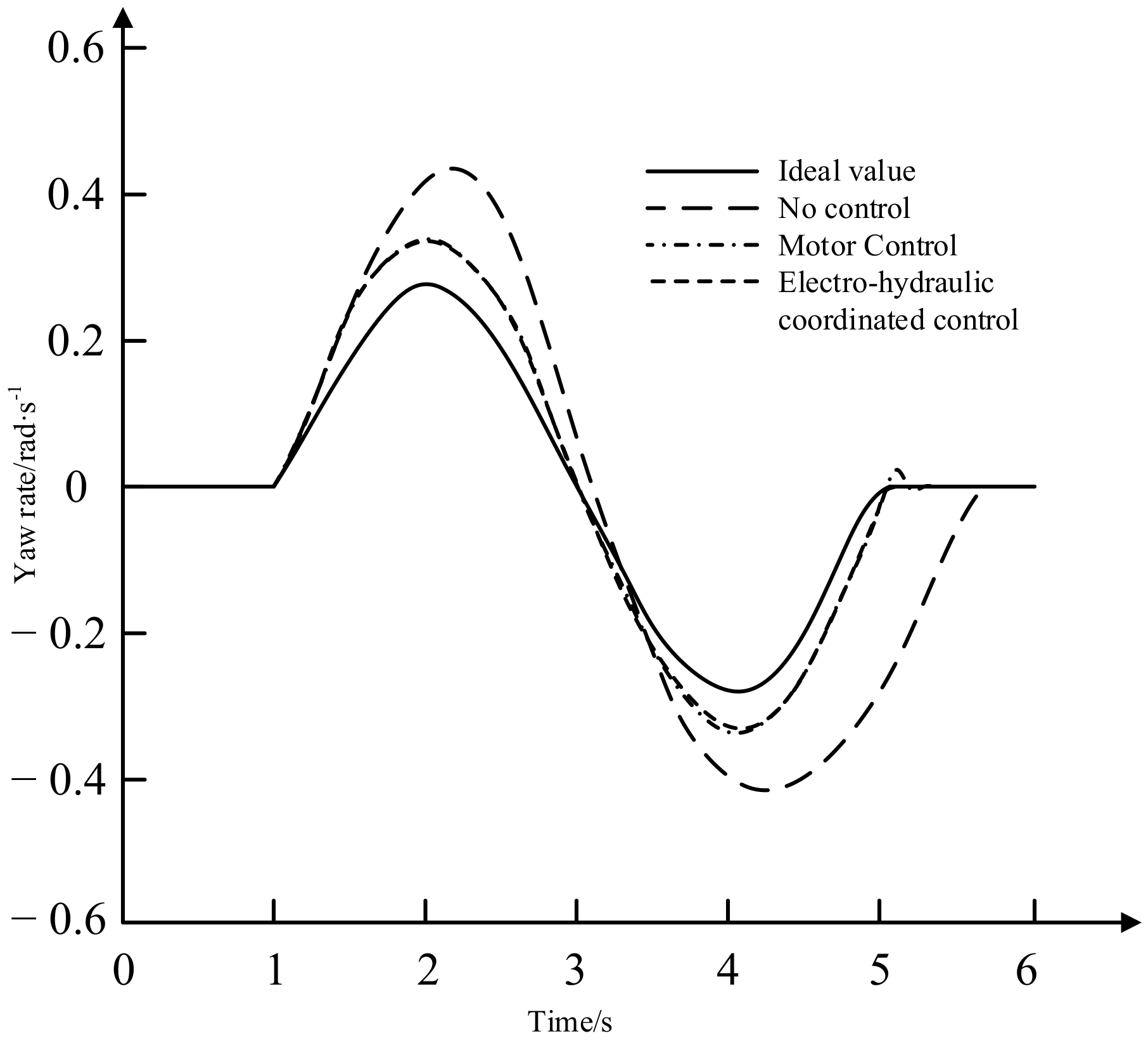

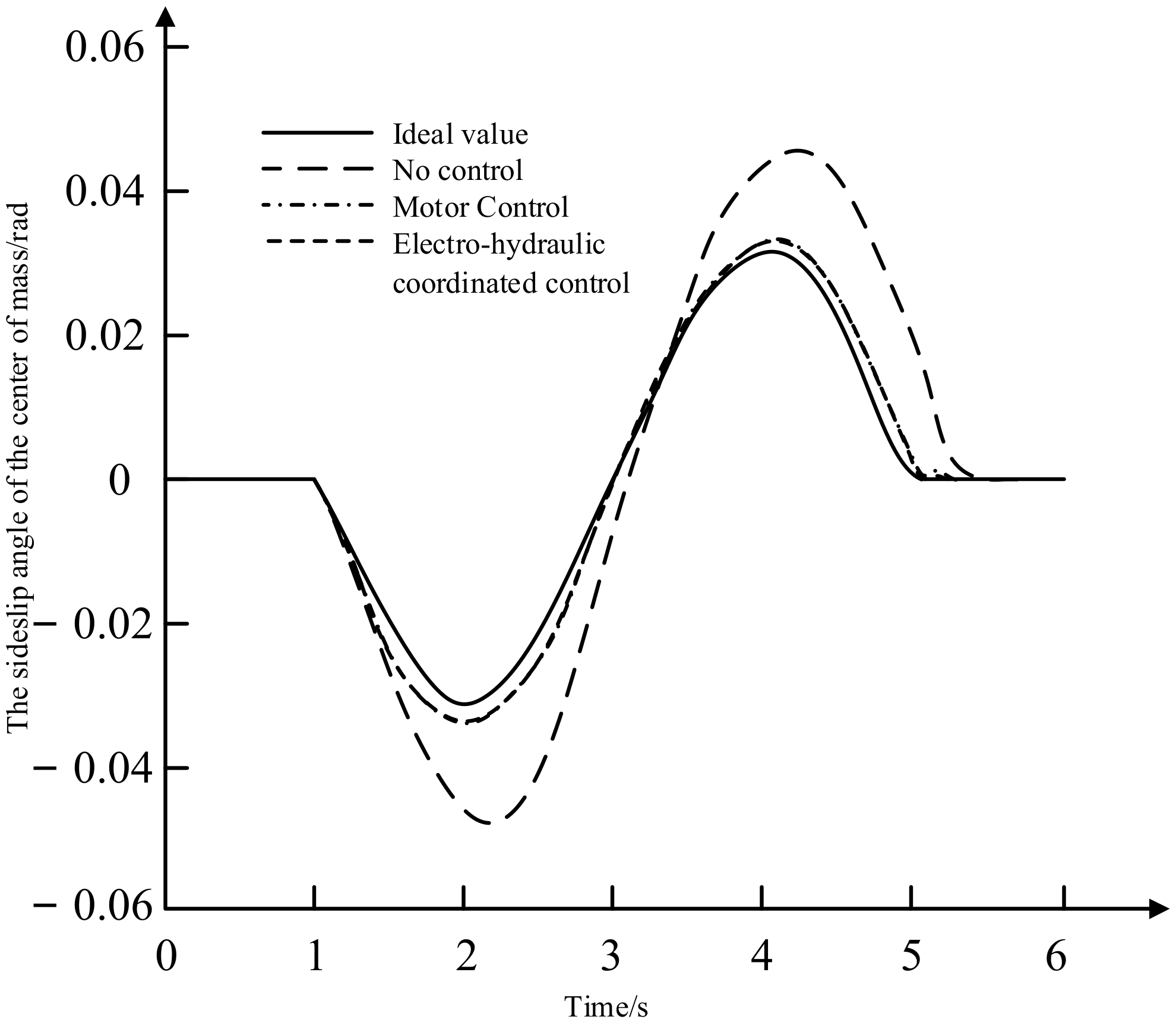

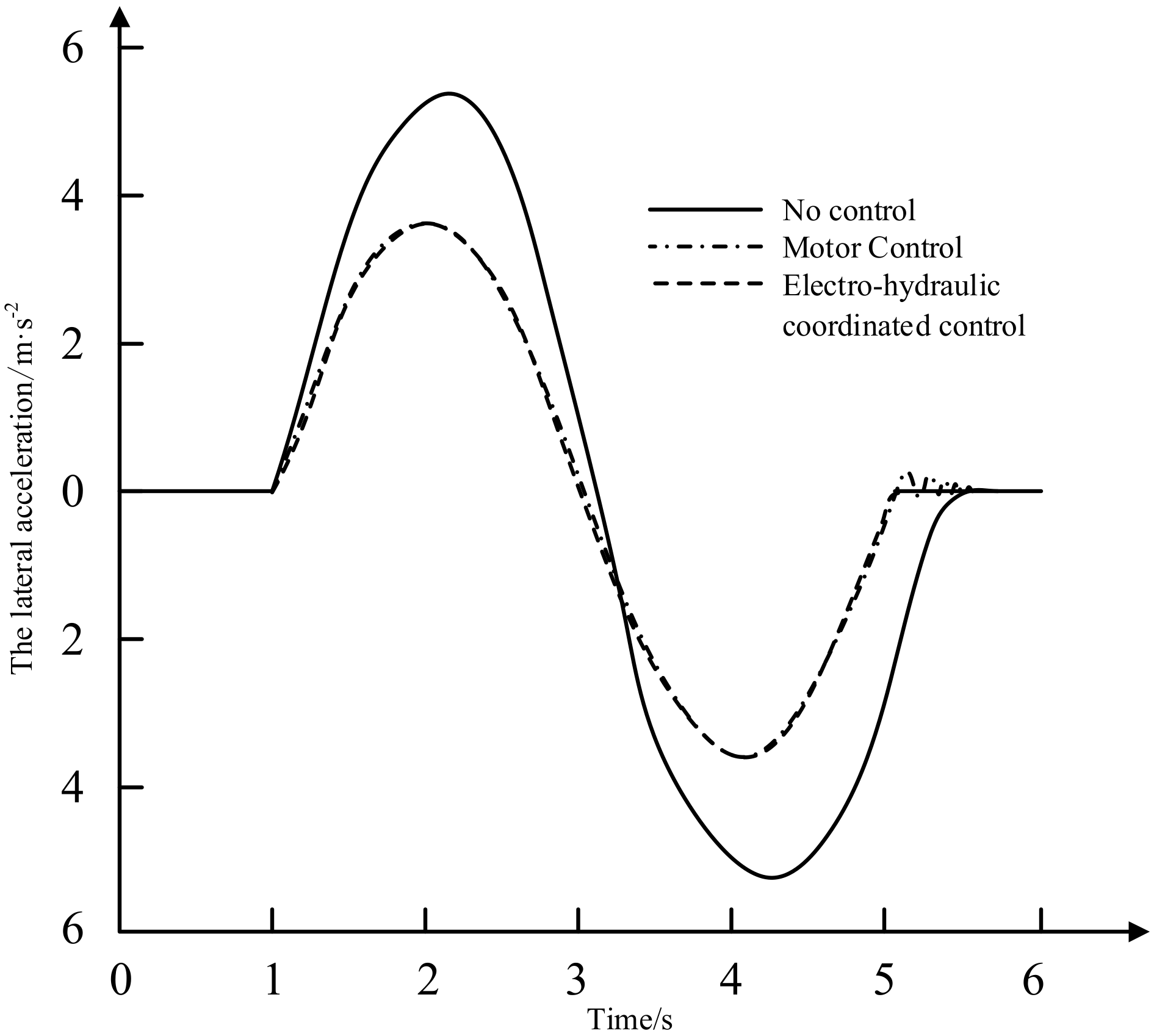

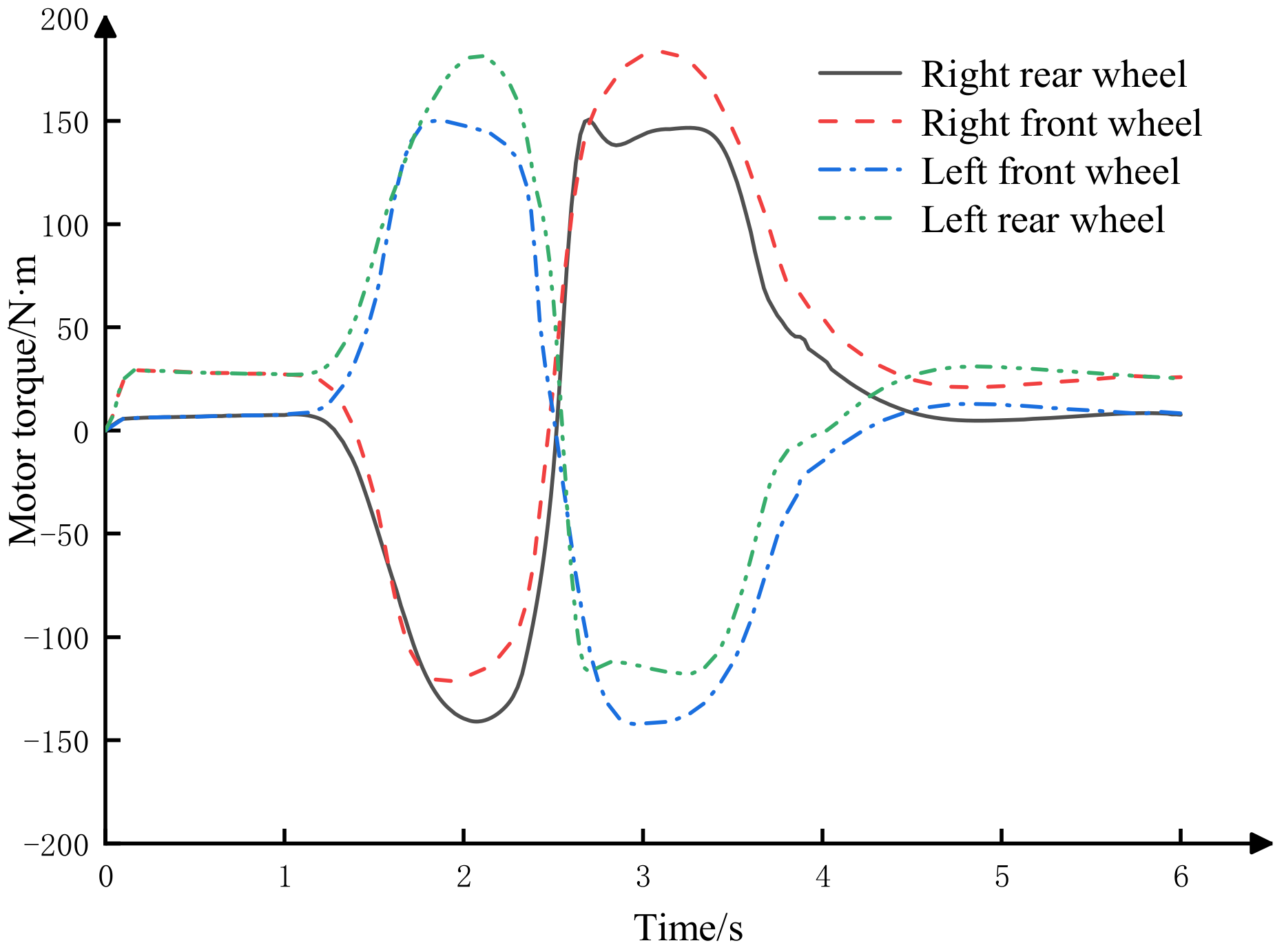

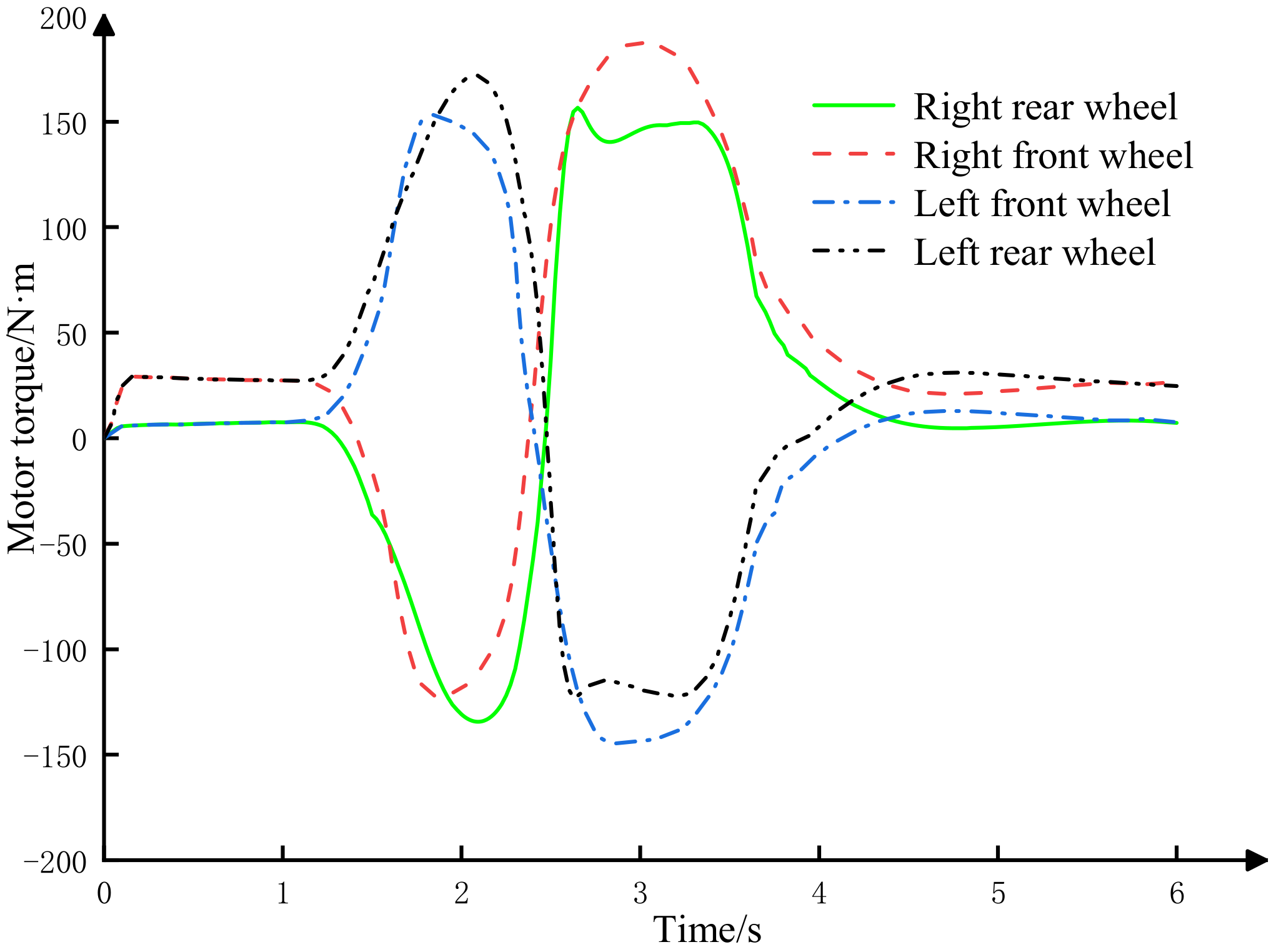

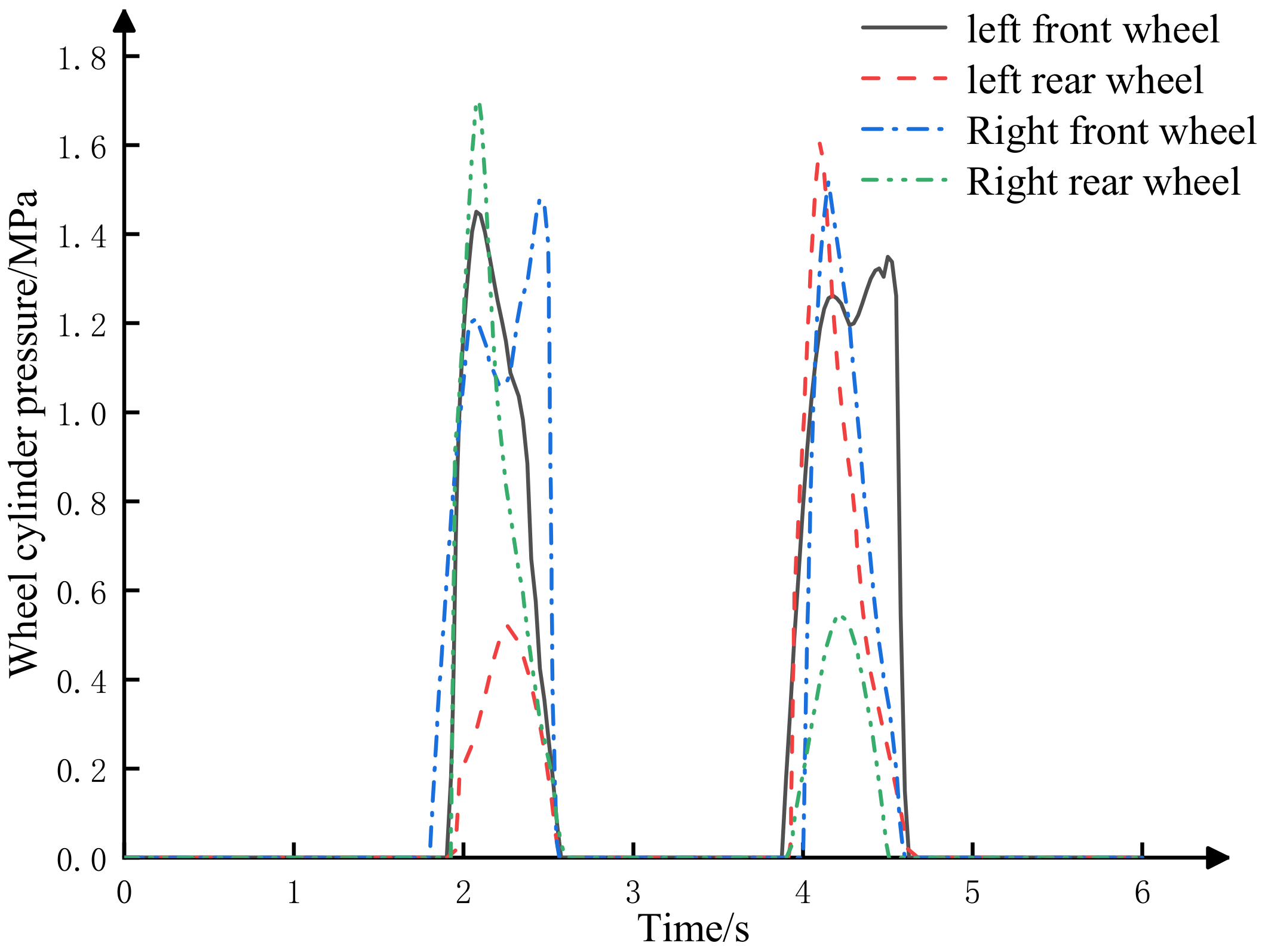

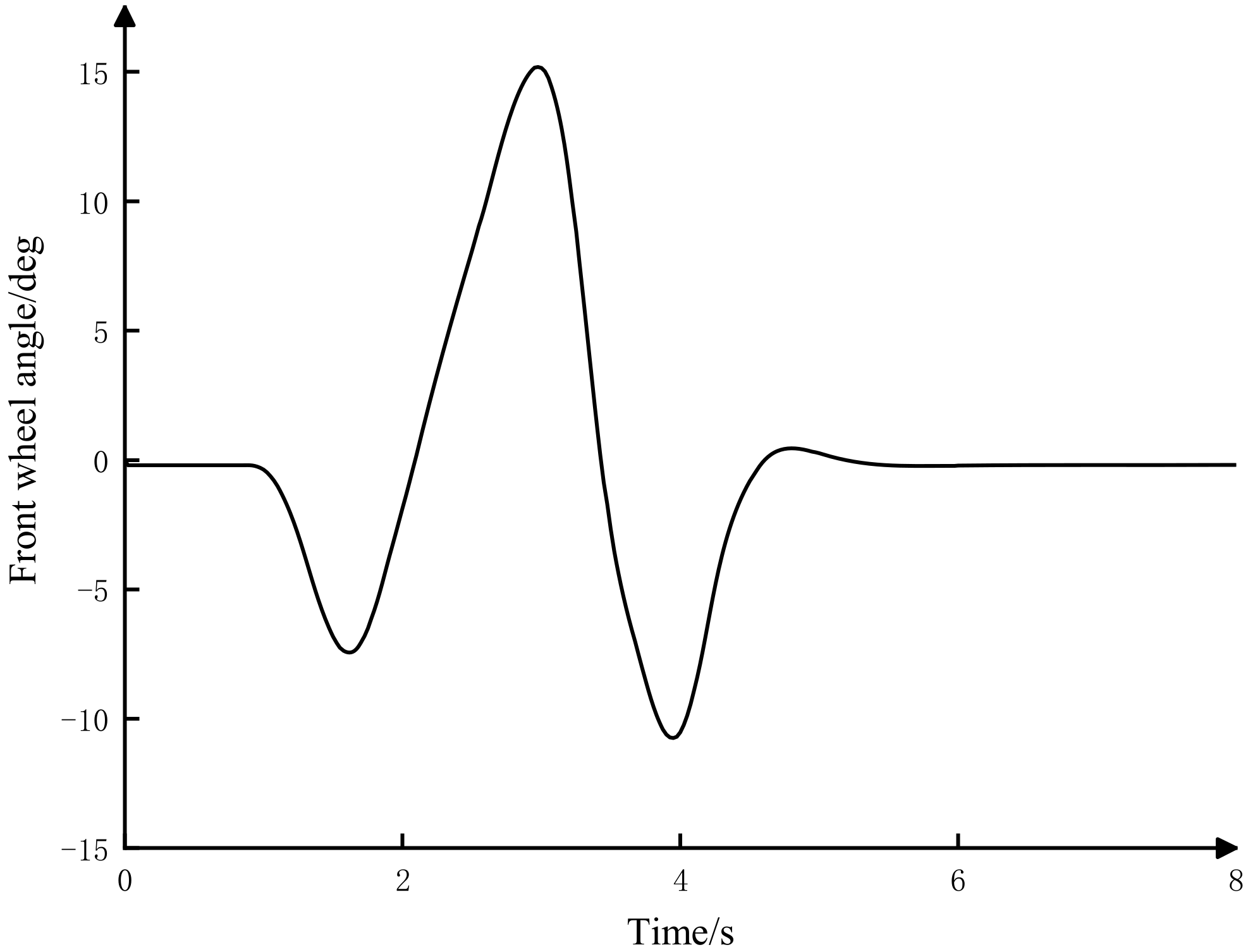

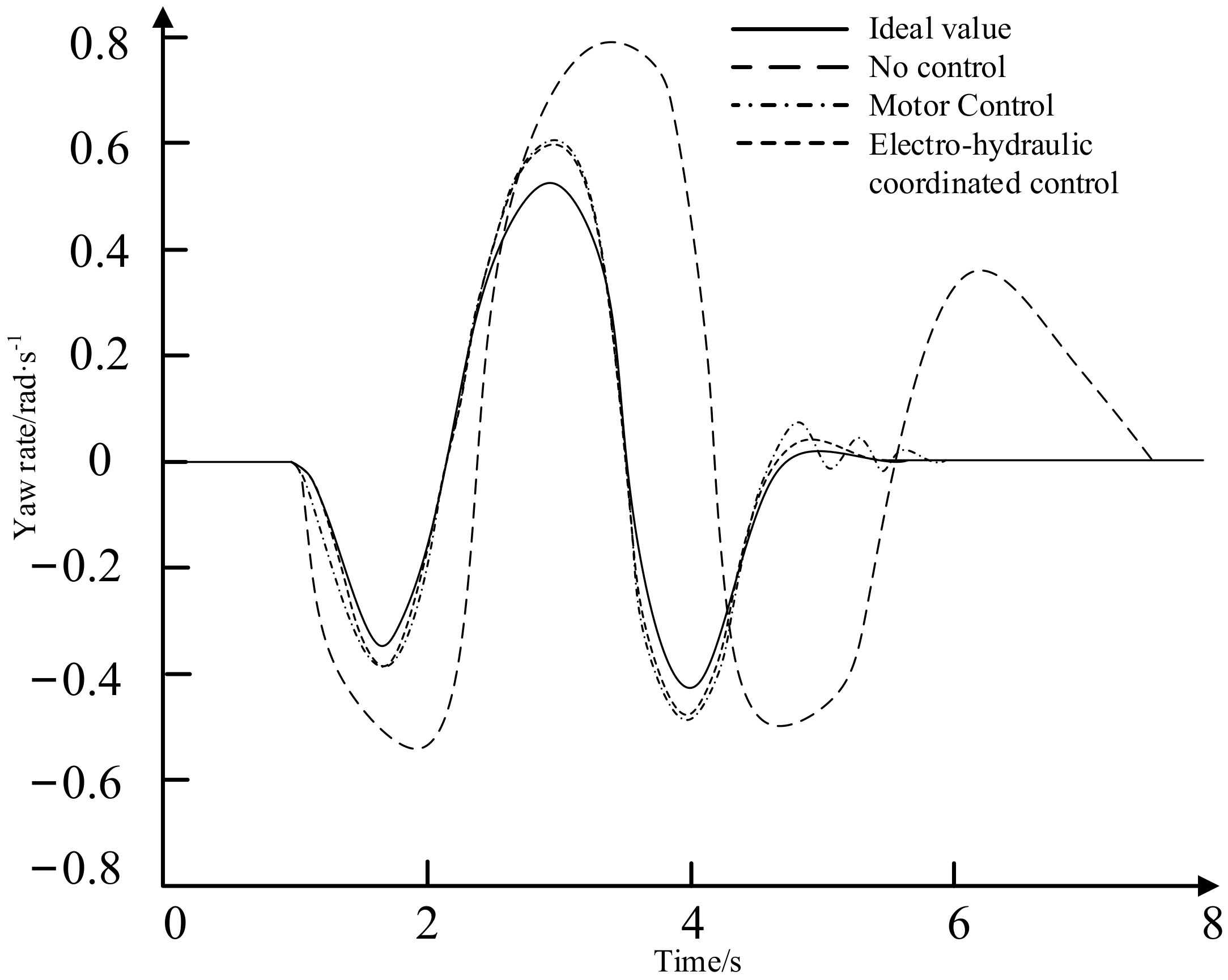

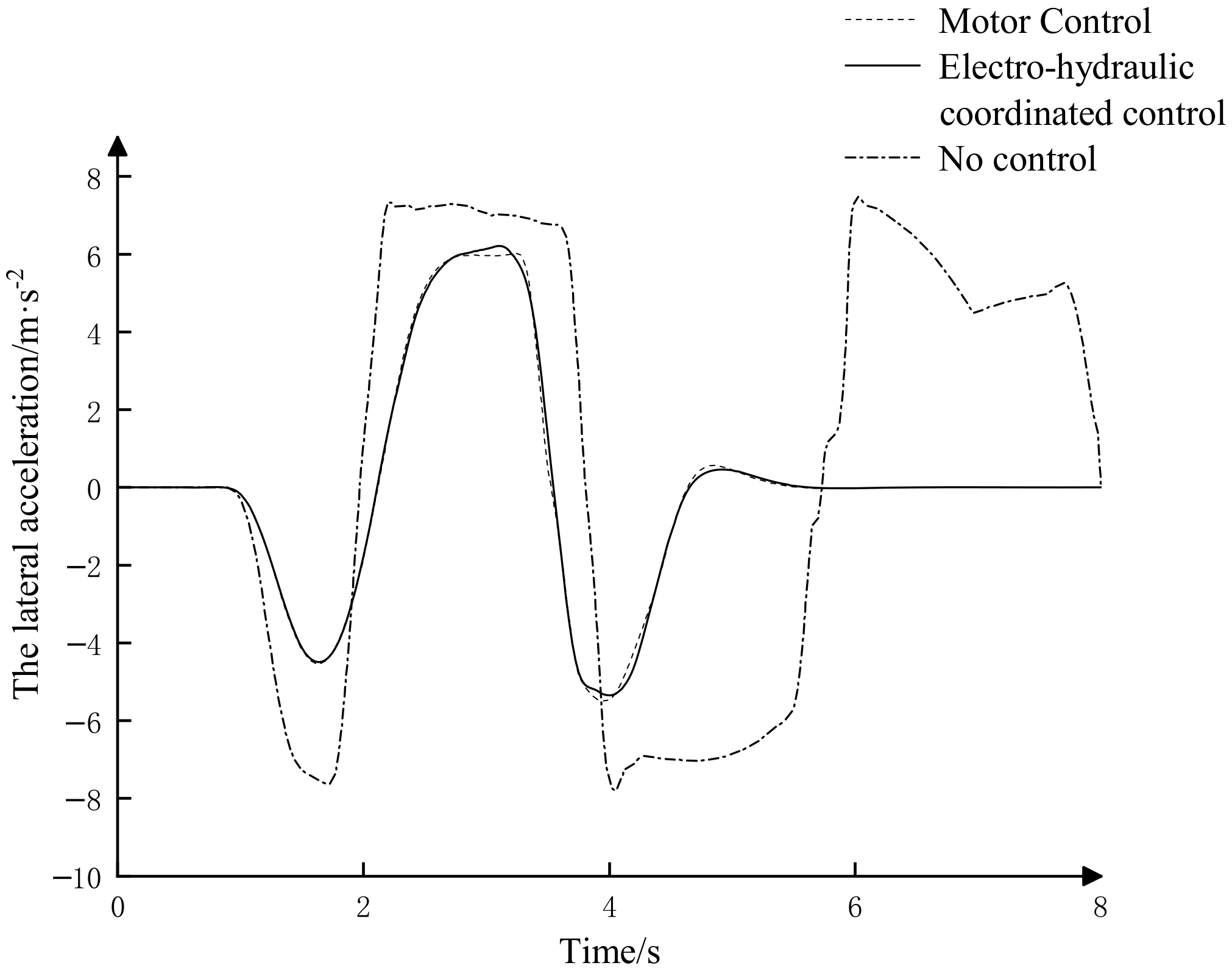

5.1. Sine Condition Test

5.2. Double-Lane Change Working Condition Test

6. Discussion

- (1)

- The relevant vehicle state parameters, such as the yaw rate and sideslip angle of the center of mass, are, in this paper, obtained through the Carsim vehicle model, and the vehicle state parameters are not estimated. In the future, the Kalman filtering algorithm can be added to estimate the vehicle state parameters.

- (2)

- Due to the limitations of experimental equipment, the proposed method could not be applied to the real vehicle test, and the control effect of the proposed method can be better tested by the real vehicle test.

7. Conclusions

- Through vehicle model establishment, motor parameterization matching, yaw moment control, torque distribution control and joint simulation, the yaw rate and the sideslip angle of the center of mass of the vehicle controlled by electro-hydraulic coordination are smaller than the output parameters of the vehicle without control applied, the yaw rate of the vehicle can better track the ideal yaw rate and the sideslip angle of center of mass can be kept in a small range and improved by about 27%, improving the vehicle’s ability to follow the desired path.

- Compared with pure motor control, a vehicle using electrohydraulic coordinated control does not show large fluctuations when entering a steady state, the time to enter a stable state is reduced and it can quickly enter a stable state, ensuring sufficient stability when the vehicle is turned. It can correct the body orientation in time, correct the vehicle trajectory and avoid vehicle sideslip destabilization and improve the vehicle handling stability.

- In extreme working conditions, pure motor control is limited by the limitation of the maximum output torque of the motor, and the hydraulic brake compensation control system intervenes in time to perform auxiliary braking so that the vehicle can turn in time and continue to maintain driving stability. Compared with pure motor control, the compensation braking torque effect of electrohydraulic coordination control is good. The torque distribution strategy of electrohydraulic coordinated control can provide sufficient demand torque to solve the problem of insufficient control torque when the vehicle is turning and maintain the vehicle in a stable driving state.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Cao, T.; Li, G.; Yu, Z.; Shen, Y. Summary of research on direct yaw moment control. Automot. Pract. Technol. 2020, 45, 270–272. [Google Scholar]

- Ding, S.; Liu, L.; Zheng, W. Sliding mode direct yaw moment control design for in-wheel electric vehicles. IEEE. Trans. Ind. Electron. 2017, 64, 6752–6762. [Google Scholar] [CrossRef]

- Zhao, W.; Qin, X.; Wang, C. Yaw and lateral stability control for four-wheel steer-by-wire system. IEEE ASME Trans. Mechatron. 2018, 23, 2628–2637. [Google Scholar] [CrossRef]

- Ren, B.; Chen, H.; Zhao, H.; Yuan, L. MPC-based yaw stability control in in-wheel-motored EV via active front steering and motor torque distribution. Mechatronics 2016, 38, 103–114. [Google Scholar]

- Yu, Z.; Xiao, Z.; Leng, B.; Wang, G.; Xiong, L. Control evaluation system testing of distributed drive electric vehicle handling stability. J. East. China Jiaotong Univ. 2016, 33, 25–32. [Google Scholar]

- Ma, H.; Li, C.; Wang, Z. Direct yaw-moment control based on fuzzy logic of four wheel drive vehicle under the cross wind. Energy Procedia 2017, 105, 2310–2316. [Google Scholar]

- Ding, X.; Li, L.; Yu, H.; Liu, X.; Pei, Y. Integrated DYC/ASR-based variable universe fuzzy control for electric vehicles. Automot. Eng. 2014, 36, 527–531+545. [Google Scholar]

- Jin, L.; Liu, G.; Chen, P. Hierarchical control for vehicle electronic stability control system. J. Jilin Univ. Eng. Sci. 2016, 46, 1765–1771. [Google Scholar]

- Kim, D.; Kim, C.; Kim, S.; Choi, J.; Han, C. Development of adaptive direct yaw-moment control method for electric vehicle based on identification of yaw-rate model. In Proceedings of the 2011 IEEE Intelligent Vehicles Symposium (IV), Baden, Germany, 5–9 June 2011; pp. 1098–1103. [Google Scholar]

- Lin, C.; Xu, Z.; Zhang, H.; Sun, S. Research on driving torque control strategy for distributed drive electric vehicle. J. Beijing Inst. Technol. 2016, 36, 668–672. [Google Scholar]

- Nam, K.; Fujimoto, H.; Hori, Y. Design of an adaptive sliding mode controller for robust yaw stabilisation of in-wheel-motor-driven electric vehicles. Int. J. Veh. Des. 2015, 67, 98–113. [Google Scholar] [CrossRef]

- Thang, D.; Meywerk, M.; Tomaske, W. Torque vectoring for rear axle using adaptive sliding mode control. In Proceedings of the 2013 International Conference on Control, Automation and Information Sciences (ICCAIS), Nha Trang, Vietnam, 25–28 November 2013; pp. 328–333. [Google Scholar]

- Zhang, Z.; Ma, X.; Liu, C.; Chen, L. Direct yaw moment control based on hierarchical model for In-wheel motor drive vehicles. J. Agric. Mach. 2019, 50, 387–394. [Google Scholar]

- Yang, K.; Wang, Z.; Zhao, S. Study of vehicle stability base on sliding model control. Mod. Manuf. Eng. 2014, 10, 53–59. [Google Scholar]

- Kawashima, K.; Uchida, T.; Hori, Y. Rolling stability control utilizing rollover index for in-wheel motor electric vehicle. IEEE. Trans. Ind. Appl. 2010, 130, 655–662. [Google Scholar] [CrossRef]

- Saikia, A.; Mahanta, C. Vehicle stability enhancement using sliding mode based active front steering and direct yaw moment control. In Proceedings of the 2017 Indian Control Conference (ICC), Guwahati, India, 4–6 January 2017; pp. 378–384. [Google Scholar]

- Yang, S.; Ou, J.; Yang, E.; Hu, J.; Zhang, Y. Research on electric vehicle yaw stability based on torque optimum distributions. China Mech. Eng. 2017, 28, 1664–1668. [Google Scholar]

- Goggia, T.; Sorniotti, A.; Leonardo, D. Integral sliding mode for the torque-vectoring control of fully electric vehicles: Theoretical design and experimental assessment. IEEE. Transact. Veh. Technol. 2015, 64, 1701–1715. [Google Scholar] [CrossRef]

- Goodarzi, A.; Diba, F.; Esmailzadeh, E. Innovative active vehicle safety using integrated stabilizer pendulum and direct yaw moment control. J. Dyn. Syst. Meas. Control. 2014, 136, 10–26. [Google Scholar] [CrossRef]

- Alcantar, J.; Assadian, F.; Kuang, M.; Tseng, E. Vehicle dynamics control of eAWD hybrid electric vehicle using slip ratio optimization and allocation. J. Dyn. Syst Meas. Control 2018, 140, 91–101. [Google Scholar] [CrossRef]

- Zhang, R.; Li, K.; Yu, F.; He, Z.; Yu, Z. Novel electronic braking system design for EVS based on constrained nonlinear hierarchical control. Int. J. Automot. Technol. 2017, 18, 707–718. [Google Scholar] [CrossRef]

- Zhang, H.; Liang, J.; Jiang, H.; Cai, Y.; Xu, X. Stability research of distributed drive electric vehicle by adaptive direct yaw moment control. IEEE. Access 2019, 7, 106225–106237. [Google Scholar] [CrossRef]

- Dizqah, A.; Lenzo, B.; Sorniotti, A.; Gruber, P.; Fallah, S.; De Smet, J. A fast and parametric torque distribution strategy for four-wheel-drive energy efficient electric vehicles. IEEE. Trans. Ind. Electron. 2016, 63, 4367–4376. [Google Scholar] [CrossRef] [Green Version]

- Tian, R.; Xiao, B. Research on direct yaw moment control of four-wheel steering vehicle. Mech. Des. Manuf. 2020, 5, 175–179+184. [Google Scholar]

- Xiong, L.; Gao, X.; Zou, T. Stability control based on electric-hydraulic allocation for distributed drive electric vehicles. J. Tongji Univ. Nat. Sci. 2016, 44, 922–929. [Google Scholar]

- Castro, D.R.; Araujo, R.; Tanelli, M.; Savaresi, M.S.; Freitas, D. Torque blending and wheel slip control in EVs with in-wheel motors. Veh. Syst. Dyn. 2012, 50, 71–94. [Google Scholar] [CrossRef]

- Wu, D.; Ding, H.; Du, C. Dynamics characteristics analysis and control of FWID EV. Int. J. Automot. Technol. 2018, 19, 135–146. [Google Scholar] [CrossRef]

- Ou, J.; Wu, P.; Ding, L.; Yang, E.; Xiao, H. Research on transverse stability control of electric vehicles based on hub motors. J. Chongqing Univ. Technol. Nat. Sci. 2021, 35, 58–65. [Google Scholar]

- Zhou, Z.; Wang, Y.; Ji, Q.; Wellmann, D.; Zeng, Y.; Yin, C. A hybrid lateral dynamics model combining data-driven and physical models for vehicle control applications. IFAC PapersOnLine 2021, 54, 617–623. [Google Scholar] [CrossRef]

- Eldho Aliasand, A.; Josh, F. Selection of motor for an electric vehicle: A review. Mater. Today. Proc. 2020, 24, 1804–1815. [Google Scholar] [CrossRef]

- Pan, S.; Zhou, H. An adaptive fuzzy PID control strategy for vehicle yaw stability. In Proceedings of the 2017 IEEE 2nd Information Technology, Networking, Electronic and Automation Control Conference (ITNEC), Chengdu, China, 15–17 December 2017; pp. 642–646. [Google Scholar]

- Liu, J.; Chen, P.; Li, D. Vehicle stability control based on phase plane method. J. Eng. Des. 2016, 23, 409–416. [Google Scholar]

- Song, C.; Feng, X.; Song, S.; Li, S.; Li, J. Stability control of 4WD electric vehicle with in-wheel-motors based on sliding mode control. In Proceedings of the 2015 Sixth International Conference on Intelligent Control and Information Processing (ICICIP), Wuhan, China, 26–28 November 2015; pp. 251–257. [Google Scholar]

- Ma, X.; Wang, K.; Zhang, Z. Sliding mode control of yaw stability for multi-wheel independent electric drive vehicles. Mech. Sci. Technol. 2021, 40, 442–447. [Google Scholar]

- Sun, J.; Ding, S.; Zhang, S.; Zhang, W. Nonsmooth stabilization for distributed electric vehicle based on direct yaw-moment control. In Proceedings of the 2016 35th Chinese Control Conference (CCC), Chengdu, China, 27–29 July 2016; pp. 8850–8855. [Google Scholar]

- Yue, M.; Yang, L.; Sun, X.-M.; Xia, W. Stability control for FWID-EVs with supervision mechanism in critical cornering situations. IEEE. Trans. Veh. Technol. 2018, 67, 10387–10397. [Google Scholar] [CrossRef]

| Parameter | Value | Symbol |

|---|---|---|

| Vehicle mass (kg) | 1235.0 | m |

| Wheel base (mm) | 2600.0 | L |

| Distance from the center of mass to the front axle (mm) | 1040.0 | l1 |

| Distance from the center of mass to the rear axle (mm) | 1560.0 | l2 |

| Front/rear wheel tread (mm) | 1480.0 | Bf/Br |

| Height of center of mass (mm) | 540.0 | h |

| Wheel radius (mm) | 357.0 | R |

| Front wheel cornering stiffness (N·rad−1) | −79,240.0 | kf |

| Rear wheel cornering stiffness (N·rad−1) | −87,002.0 | kr |

| Moment of inertia around z axis (kg·m2) | 1343.1 | Iz |

| Vehicle Dynamics Index | Value |

|---|---|

| Maximum speed (km/h) | 160 |

| Maximum grade (%) | 30 (20 km/h) |

| 100 km acceleration time (s) | <10 |

| Motor Parameters | Value |

|---|---|

| Rated power (kW) | 10 |

| Peak power (kW) | 25 |

| Rated torque (N·m) | 120 |

| Peak torque (N·m) | 370 |

| Rated speed (r/min) | 800 |

| Peak speed (r/min) | 1500 |

| Number | The Road Surface Adhesion Coefficient μ | C1 | C2 |

|---|---|---|---|

| one | μ < 0.2 | 0.284 | 2.577 |

| two | 0.2 ≤ μ < 0.4 | 0.297 | 3.345 |

| three | 0.4 ≤ μ < 0.6 | 0.303 | 4.228 |

| four | 0.6 ≤ μ < 0.8 | 0.357 | 4.654 |

| five | 0.8 ≤ μ < 1.0 | 0.357 | 5.573 |

| eω = ωr − ωrd | Front Wheel Angle δ | Direct Yaw Moment | State of the Vehicle | Brake Wheel | Drive Wheels |

|---|---|---|---|---|---|

| eω > 0 | δ > 0 | negative | oversteer | Reduced torque on the right side of the wheel | Increased torque on the left side of the wheel |

| eω < 0 | δ > 0 | positive | understeer | Reduced torque on the left side of the wheel | Increased torque on the right side of the wheel |

| eω > 0 | δ < 0 | negative | understeer | Reduced torque on the right side of the wheel | Increased torque on the left side of the wheel |

| eω < 0 | δ < 0 | positive | oversteer | Reduced torque on the left side of the wheel | Increased torque on the right side of the wheel |

| eω = ωr − ωrd | Front Wheel Angle δ | Direct Yaw Moment | State of the Vehicle | Brake Wheel |

|---|---|---|---|---|

| eω > 0 | δ > 0 | negative | oversteer | Right front wheel |

| eω < 0 | δ > 0 | positive | understeer | Left rear wheel |

| eω > 0 | δ < 0 | negative | understeer | Right rear wheel |

| eω < 0 | δ < 0 | positive | oversteer | Left front wheel |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, L.; Yan, T.; Pan, F.; Ge, W.; Kong, W. Research on Direct Yaw Moment Control of Electric Vehicles Based on Electrohydraulic Joint Action. Sustainability 2022, 14, 11072. https://doi.org/10.3390/su141711072

Zhang L, Yan T, Pan F, Ge W, Kong W. Research on Direct Yaw Moment Control of Electric Vehicles Based on Electrohydraulic Joint Action. Sustainability. 2022; 14(17):11072. https://doi.org/10.3390/su141711072

Chicago/Turabian StyleZhang, Lixia, Taofeng Yan, Fuquan Pan, Wuyi Ge, and Wenjian Kong. 2022. "Research on Direct Yaw Moment Control of Electric Vehicles Based on Electrohydraulic Joint Action" Sustainability 14, no. 17: 11072. https://doi.org/10.3390/su141711072

APA StyleZhang, L., Yan, T., Pan, F., Ge, W., & Kong, W. (2022). Research on Direct Yaw Moment Control of Electric Vehicles Based on Electrohydraulic Joint Action. Sustainability, 14(17), 11072. https://doi.org/10.3390/su141711072