1. Introduction

The impacts of plastic pollution on wildlife, the economy, and the environment have been clearly demonstrated [

1,

2,

3]. There is widespread recognition that plastic pollution is an issue of global importance, as demonstrated by the treaty signed at UNEA 5 [

4]. Solving the problem will require a multilateral approach, with a suite of interventions across the supply chain. One component of this multifaceted approach that has been shown to be effective is the implementation of standards. Defined by the International Organization for Standardization (ISO) and the International Electrotechnical Commission (IEC), a standard is a “document established by consensus and approved by a recognized body, that provides, for common and repeated use, rules, guidelines or characteristics for activities or their results, aimed at the achievement of the optimum degree of order in a given context” [

5]. To develop a standard, a standardisation body (such as Standards Australia) brings together key parties and stakeholders to form a technical committee to discuss the content of the standard and reach consensus.

On the grounds of the consensus, balance, and transparency, standards are considered significant guidelines and codes of practice, which are implemented widely by industry and communities. Standards can contribute to society and economy in many ways: they can improve safety, reduce information asymmetry, promote international trade, and enhance the interoperability of technologies [

6]. Standards can directly or indirectly help to identify, solve, and alleviate environmental issues and promote good practice in environmental management. For example, ISO 14000 series: Environmental Management provides standards and practical tools to companies and organizations to manage their environmental responsibilities.

Several studies have measured the economic impacts of standardisation and found that the contribution from standards to the economic growth rate varies from 0.2 per cent in Canada and 0.3 per cent in the UK to 0.8 per cent in Australia and 0.9 per cent in Germany [

7]. The impact of standards on international trade is also significant as it is estimated that 80 per cent of world trade is affected by standards [

8].

Depending on their effects, standards can be categorised into four groups [

9,

10]:

Minimum quality and safety standards: these standards can reduce information asymmetry, increase consumer confidence, decrease purchasing search costs, and facilitate trade.

Information and measurement standards: this group enhances knowledge dissemination, boosts consumer confidence, and improves market efficiency.

Variety-reducing standards: these standards aim to expand the scale of production and, thus, can increase productivity and market efficiency.

Compatibility and interface standards: these standards can contribute to network externalities by increasing the users of a product or service. They can also improve knowledge dissemination.

Standards have great potential to be used in promoting sustainability and solving environmental issues, including plastics use and waste management [

11,

12]. Addressing the plastic pollution crisis requires integrated environmental policies and waste management strategies that involve the entire life cycle of plastics, from design and production to use and disposal, including reusing and recycling [

13].

Standards can help governments and policy makers to set and achieve ambitious commitments to reduce plastic waste by providing relevant guidance, frameworks, and specifications that help to produce a better assessment of plastic life cycle and enhance the market for recyclable and reusable products [

12,

14]. For instance, terminology and classification standards (e.g., ASTM D883-00 Standard terminology relating to plastics) can result in better communication, improve exchange of information, and facilitate trade among market players. Using a common and agreed set of terminology is critical to ensuring consistency and reducing confusion for consumers or industry. Information and characterisation standards (such as EN 15342 Plastics—Recycled plastics—Characterization of polystyrene (PS) recyclates) provide specifications for different types of plastics and reduce information asymmetry. These standards can be used by recyclers to ensure that their recyclate meets certain characteristics, thereby providing assurance to the manufacturers using those plastics that they will be fit for use in a particular product.

Measurement and methods standards can improve knowledge dissemination by describing sampling and testing requirements to measure environmental and sustainability aspects of plastics (e.g., ISO 22526-3:2020 Plastics—Carbon and environmental footprint of biobased plastics—Part 3: Process carbon footprint, requirements, and guidelines for quantification). Life cycle assessment standards provide an assessment tool to evaluate the resource efficiency and eco-efficiency of products and organisations and increase productivity and market efficiency (e.g., ISO 14040:2006 Environmental management—Life cycle assessment—Principles and framework). Quality standards can increase consumer confidence and promote social acceptance of recycled products. They can also enhance the diffusion of knowledge, improve economy of scale, and advance the infrastructure of low-cost recycling plastics (e.g., ISO/IEC 24700:2005 Quality and performance of office equipment that contains reused components).

Thus, standards should be considered as a part of the solution to plastics problems. This involves a significant engagement in the creation and implementation of standards that address challenges and requirements of moving from the production and consumption of products with low recyclability and reuse potential (such as single-use plastics) towards a market with recyclable and reusable products.

Given the potential role of standards in the campaign to reduce plastic waste, we characterised the existing standards landscape to understand how Australia’s current deployment of standards compares internationally and to determine where opportunities exist to implement new standards.

3. Results

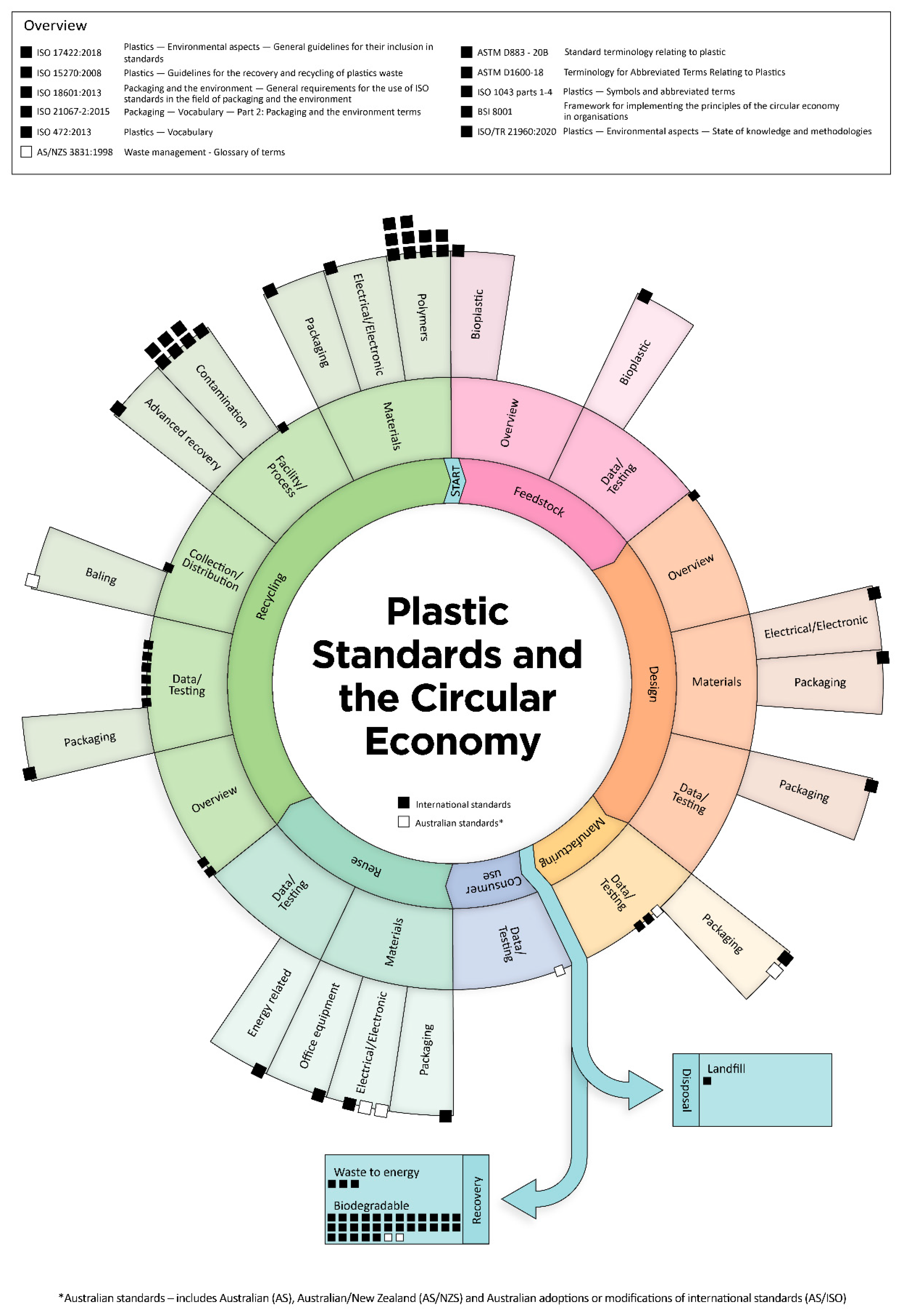

We found a total of 95 standards that met the search criteria. Five were Australian-originated standards and four were international standards that had been adopted in Australia. Most of the standards fall within the broader categories of recycling (n = 31) or recovery (n = 34), which encompasses compostable plastics and waste to energy. Significantly fewer address challenges of reuse (n = 6) or (re) design (n = 4) (

Figure 1 and

Supplementary Material).

Ten standards were in the “overview” category. These included mostly standards on guidance to create further standards (e.g., ISO 17422:2018: Plastics—Environmental aspects—General guidelines for their inclusion in standards) and terminology and vocabulary applicable to the plastics field (e.g., ISO 21067: Packaging—Vocabulary—Part 2: Packaging and the environment terms), plus one technical report which summarizes the current scientific state of knowledge on plastics in the environment and biota (ISO/TR 21960).

Only two standards fit within the feedstock category: general principles for the determination of biobased content in bioplastics (ISO160020) and techniques for determining a carbon and environmental footprint for bioplastics (ISO22526), though six additional standards characterise recycled polymers. These were categorised within recycling, with feedstock as a secondary category.

The design category included two standards on reduction of material in plastic packaging (while maintaining functionality), one on environmental management systems, and one technical report, focusing primarily on electrical and electronic goods. Manufacture standards are quite varied, including several guidelines for labelling, marking, and identification, one on the extrusion manufacturing process, one on calculating recyclability of electrical items, and one on the packaging of dangerous goods. Consumer use comprises only one Australian standard (and surprisingly, no international standards): AS 14021:2018—environmental labels and declarations. Each of the six reuse standards is aimed at a specific market sector.

Of the 31 recycling standards, two are overview standards on how to create standards. Three deal with the collection and processing of recycling, including one on chemical or advanced recycling. Seven deal with contamination and an additional seven outline characteristics of different polymer recyclates. Five deal with other specific items, including electrical equipment, wood plastic composites, and packaging. Finally, seven standards are in the subcategory of data and testing, including methods for validating and testing recycled content.

Of the 33 recovery standards, 30 are around compostability and biodegradability and three on waste to energy. There is one disposal standard.

4. Discussion

When viewed through a circular economy lens, the majority of existing plastic standards (international and Australian combined) falls within the recycling and recovery/disposal segments of the value chain. Very few standards pertain to the early segments, such as design or feedstock/raw materials. There are a few standards that were designated as fitting secondarily within the design category, but these predominantly pertain to how to design a product that will be compostable or used for waste to energy. This ultimately still relegates plastics standards to the lower parts of the waste hierarchy. While in theory, standards aimed at avoiding, reducing, or reusing waste could be applied within a manufacturing context, in practice, the standards we see in this space most commonly cover test requirements and labelling. While the total number of standards does not necessarily represent the best metric of standards effectiveness, it provides a guideline as to where priorities lie, in terms of top-down controls.

This emphasis on the end of the value chain is at odds with waste management principles best practices. Many jurisdictions in Australia and internationally have adopted a waste hierarchy to guide their approach to waste minimisation, which can be applied to plastic as well as to other forms of waste. In this approach, the most preferred option is to reduce or avoid waste altogether. There follows a series of other options, including reuse, recycling, and energy recovery, while plastic disposal is the least preferable option [

15].

This disconnect between what is recommended by the waste hierarchy and where the majority of standards are implemented may, in part, be explained by the evolution of understanding in circular economy principles. Whilst it is understood by practitioners that circular economy is a whole of supply-chain approach, the recycling phases are much better understood and this is reflected in the volume of standards in this area, as compared to newer topics, such as circular design and reuse. The growing adoption of circular economy principles highlights the significant potential for standards to act as levers in higher levels of the waste hierarchy, e.g., reuse and re-design.

About 10% of existing standards were applicable to the entire circular economy and were categorised as “overview” standards. These standards provide a framework for how to incorporate environmental and circular economy principles when drafting plastics standards and a common vocabulary for doing so. Overall, most standards do not specifically reference the “circular economy”, but the sole exception is overview standard BSI 8001: Framework for implementing the principles of the circular economy in organizations. BSI 8001 was drafted to create clear and practical guiding principles for organizations wanting to implement the broad goals of the circular economy and includes definitions, principles, and a management framework. Although it has been criticized for not offering a comprehensive suite of quantitative indicators [

16], BSI 8001 remains the sole circular economy standard globally. A technical committee was formed in ISO (ISO/TC 323 Circular Economy) to look into “standardization in the field of Circular Economy to develop frameworks, guidance, supporting tools and requirements for the implementation of activities of all involved organisations, to maximise the contribution to Sustainable Development.” [

17]. The committee consists of 73 participating members (including Australia) and 19 observing members and currently has six standards under development.

Moving into the circular economy framework, the first four categories (feedstock, design, manufacture, and consumer use) comprise relatively few standards. Feedstock standards are both around bioplastics, though the characterization of recycled polymers can also fall under this category. Bio-based (and biodegradable) polymers are a burgeoning area of interest and will certainly be important in the transition to a plastic circular economy [

18]. Bio-based polymers can help to reduce petroleum-based plastics in the value chain, which, at face value, is a positive outcome for the environment. However, there are certain challenges with replacing petroleum-based plastics with bio-based polymers. First, not all bio-based plastics are also biodegradable. Second, the process of manufacturing them can, in some cases, use more resources than fossil-fuel based plastics. Furthermore, they may actually serve as a contaminant in established recycling streams based on petroleum-based products. In this respect, it is critical to ensure adequate standardisation for the production and wise use of these bio-based plastics [

19]. Our analysis found only a handful of standards specifically on bio-based plastics, though there are quite a few standards for biodegradable plastics (see below in ‘Recovery’).

Of the four design standards, two are applicable to packaging and how to reduce the amount of packaging while ensuring functionality. Packaging is a critical area to address, as it tends to be single use, comprises nearly half of the world’s plastic waste, and can be quite challenging to recycle [

20]. However, it is not the only area that could benefit from design standards. It is possible that additional design standards for plastic may exist for specific products, which do not appear in this analysis, but there is certainly opportunity for further standardization within the design category.

The manufacturing category is quite eclectic, including mostly unrelated standards, some on labelling, and others on the manufacturing process for plastic itself. Several additional standards could be secondarily placed within manufacturing, as they provide guidance for how to design or create plastics that meet the criteria for recycling, biodegradability, or reuse, for example. These may be useful for manufacturers that want to ensure that their products contribute to a circular economy.

Only one standard, on environmental labels and declarations, sits within consumer use and, within the reuse category, there are six. While these are not product standards per se, they are mostly specific to different domains, such as electrical, office equipment, medical imaging equipment, packaging, and energy-related equipment. These areas are also ripe for future standards development.

The two categories of recycling and recovery contain the majority of existing standards. Recycling standards encompass a broad range, including facility and process standards (of which contamination is a large part), characteristics of specific polymers and materials, and a suite of data and testing standards. Of these, it is notable that three are around environmental claims, traceability of materials, and establishing the recycled content of an item. These types of standards (and associated labelling schemes) are garnering significant interest, as consumers are increasingly demanding recycled items. Encouraging and promoting recycled content is a key element for a circular economy, as it is not enough just to send polymers to a recycling facility, there must also be demand for the recycled polymers [

21].

The final two categories of standards, recovery and disposal, sit as an offshoot of the main circular economy diagram, because they remove plastic from the plastic circular economy. The bulk of the recovery standards are test methods to evaluate compostability and biodegradability of plastics, with a handful of standards for waste to energy. Although composting and waste to energy can be considered part of a broader circular economy, as they can provide usable resources, they do not return plastics to the beginning of the plastic circular economy as feedstock.

There are a number of areas where additional standards could be employed to reduce plastic waste and increase circularity (see examples below). Note, however, that the simple fact of a standard potentially reducing waste does not necessarily make it a good candidate for adoption. In Australia, there is a specified process for determining what standards will be drafted. This process takes into account the needs and viewpoints of a wide range of stakeholders and is predicated on the greatest good for the community and must demonstrate net benefit to society at large. A critical part of the discussion will be to determine what standards should be implemented and to prioritise the level of importance. This discussion incorporates not only the greatest environmental good, but also the needs and priorities of industry, government, and other user groups.

Quality and Safety Standards: Quality standards can provide guidance, in particular, for the design phase of the circular economy. These include design standards for the durability, reusability, or recyclability of products, ease of maintenance and repair, upgradability, ease of disassembly and reassembly [

22], and standards aimed at reducing packaging.

Information and Measurement Standards: One avenue to reducing plastic waste is by education, specifically by ensuring that consumers are aware of the environmental impacts of their purchasing choices. Currently, there are voluntary industry-led schemes, such as VinylCycle (

https://vinyl.org.au/vinylcycle (accessed on 28 February 2022)), which provide an indication of the level of recycled material in a product. Standardisation of labelling could be presented as a “green star” label to provide information to consumers. Of critical importance is determining the exact criteria on which to judge products. Amount of recycled content, recyclability or compostability of the product, and carbon emissions associated with the product are some elements that could be incorporated, though there are many others that could be incorporated into such a label.

Variety-Reducing Standards: Products, such as multi-layered laminated plastics, that are commonly used in packaging are challenging to recycle because of the vast number of different material types. Standards could help to increase the recyclability of products like these by reducing the number of multilayer polymers or the type of glue used. Similarly, standards harmonising what items can be recycled at a council level would reduce confusion and contamination and increase recycling levels.

Compatibility: In some instances, the lack of compatibility of standards between jurisdictions reduces efficiency and can hamper the use of recycled products. For example, the guidelines for the use of recycled pipe fittings can differ between neighbouring jurisdictions [

23]. In these instances, harmonisation of standards at a national and international level could be leveraged to reduce confusion, improve efficiency and reduce barriers to trade.

This snapshot image of the standards landscape also highlights significant opportunities for Australia. There are currently many areas where international standards exist that have not yet been adopted within Australia. We can identify already existing standards that are relevant within our context and begin the process of mirroring them here. Similarly, this gap analysis identifies areas where standards are lacking, both domestically as well as internationally. This is an opportunity for Australia to provide strong leadership and develop standards that can then be adopted internationally.

Standards are not the only top-down controls that can be implemented on a federal scale to address the plastic waste problem. Legislation can also play an important role. For example, in the US and Australia, container deposit schemes reduce waste lost to the environment [

24], while in Hong Kong, landfill levies have been shown to reduce waste overall [

25]. While this project did not attempt to quantify legislation around plastic waste, a report by PRI (Principles for Responsible Investment) indicated that most legislation relates either to consumer use of plastic—predominately single-use plastic bans or container deposit schemes [

26]. Plastic packaging is also a major subject of legislation, both in terms of manufacturing as well as recycling targets. Finally, in an international context (though not so in Australia), there is significant legislation around the disposal of plastics [

26].

Specifications are also a powerful tool that can often be drafted and implemented much more rapidly than standards. For example, various actors across the plastics industry, research, and government were convened by the Australian Packaging Council (APCO) to draft specifications for a variety of recycled polymers. While these specifications are not mandatory, they are a set of agreed guidelines, which will help to maintain or increase the value of recycled plastics, thus, decreasing the likelihood that they will end up as waste.