3.1. Energy Audit

The survey indicates that above 90% of participants understand that it is important to save energy, while 8% partially agree. However, 2% do not think it is important to save energy. These results suggest high potential in approaching 98% of the campus population when any action in this regard will be taken. The majority of participants (88%) agree that saving energy produces a cleaner environment, which is aligned with the 90% who agree with the importance of saving energy in general.

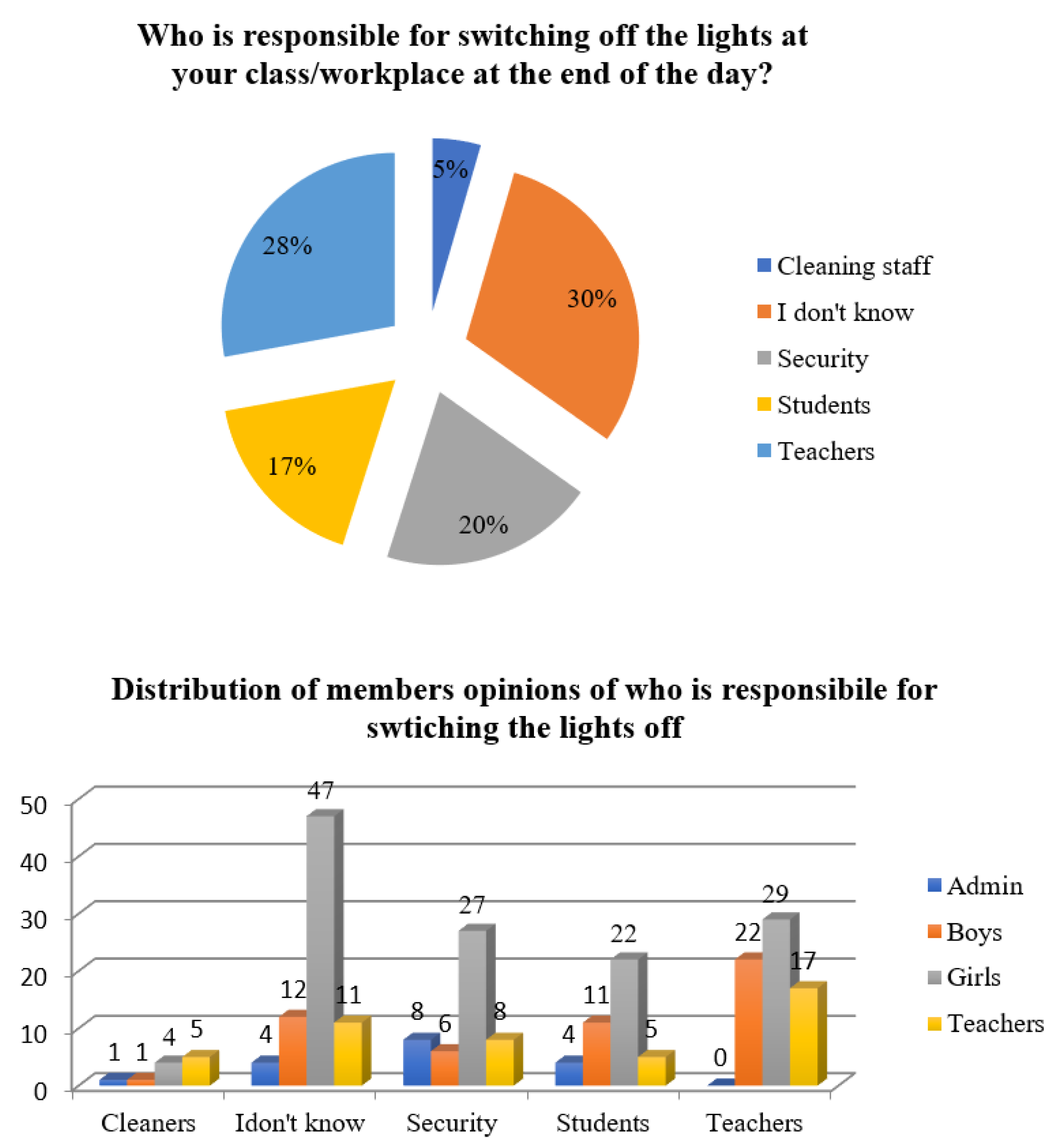

The pie chart shown in

Figure 4 demonstrates the diversity in responses shown in the chart above and it clearly shows that no one thinks it is his/her own responsibility to switch off the lights. The bar chart also demonstrates the differences in opinion regarding who is responsible for switching off the lights. The survey clearly shows that no one thinks it is his/her own responsibility to switch off the lights. Only 37% of teachers believe that it is their responsibility and only 18% of students think it is their responsibility. However, the highest percentage among all 30% of the respondents preferred to answer “I don’t know”.

The survey demonstrates the differences of opinion when it comes to turning off the projectors in the lab/classrooms, as 50% of the respondents think it is teachers’ responsibilities. Around 45% of teaching staff think it is their own responsibility, while 50% of the students think that it is the teachers’ responsibility. Furthermore, 23% do not know who is responsible for this action.

The survey shows that 88% of the survey respondents agree that saving energy should be rewarded. This indicates that the members of the campus wait for a type of recognition to save energy. Moreover, around 86% of the members believe that they need a reminder (signs to turn off lights/equipment) to do the right thing. However, 77% of respondents considered alternative methods to decrease their electricity bill in their home. The purpose of this question (Have you considered ways to decrease your electricity bill in your home?) is to relate to the respondent conscience towards saving energy, is it to save money? Or to save energy? The results suggest that 47% of respondents think of it, although only 30% think of it often. Although 90% of the participants are aware that saving energy is important, only 77% are considering saving energy at their homes.

Energy reducing strategies percentage is given in

Figure 5. According to

Figure 5 26% of members believe that turning off the light is a useful strategy to reduce energy consumption. The data above suggest recycling is the least chosen way of reducing energy usage, which indicates a lack of recycling awareness among the campus population. Moreover, most of the responses were towards turning off lights and unused equipment, yet it is worth mentioning that only 18% of the whole population (44 respondents) selected all five options, as shown in the below chart.

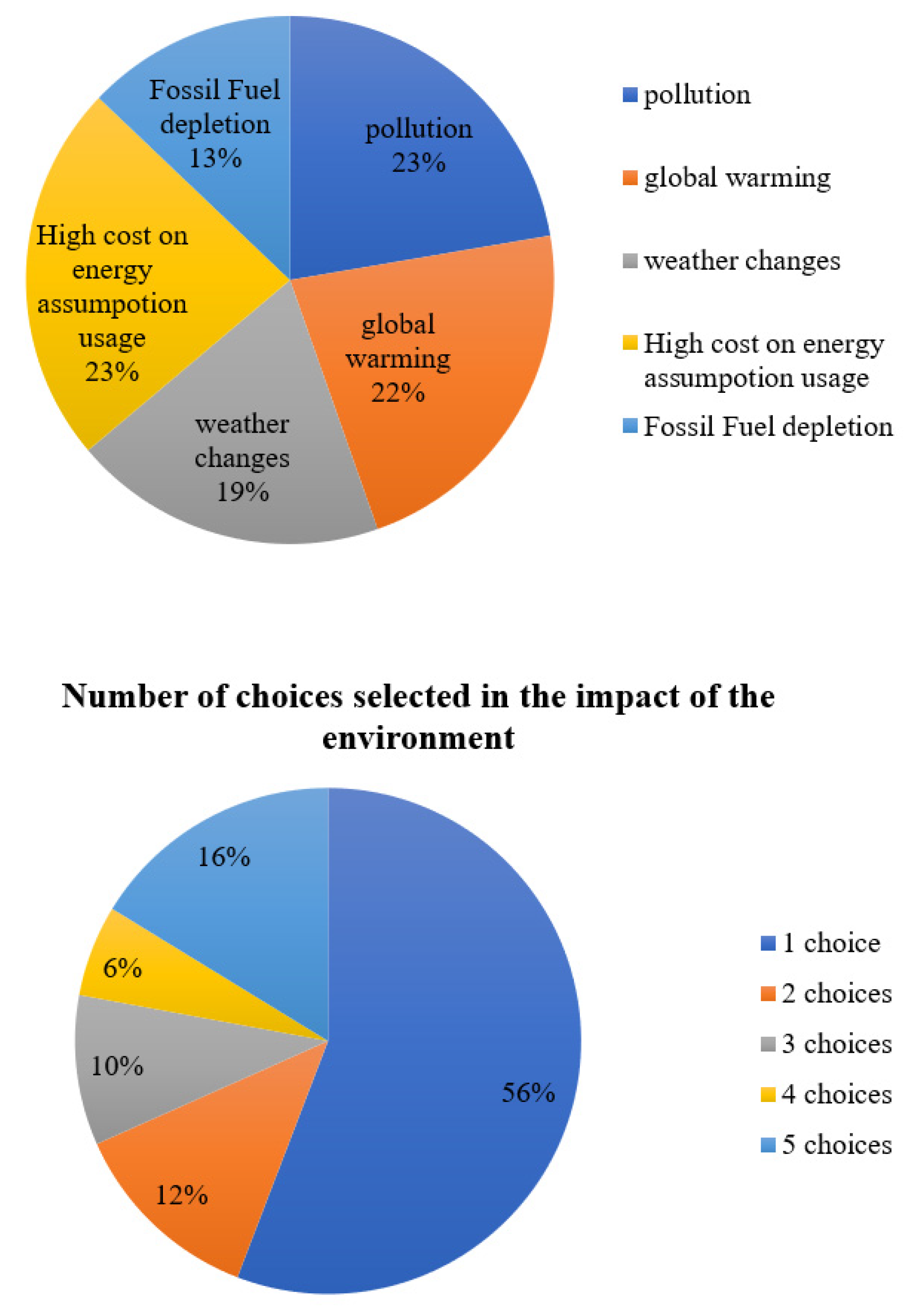

Figure 6 shows the impact on the environment. Although around 88% of the participants highlighted the importance of saving energy for a cleaner environment, only 16% selected the five choices and 56% selected one choice only. The survey shows that 80% of the school members are not aware of any energy waste. It also suggests that 57% of the school members think that the school is applying energy saving strategies while 36% are saying NO.

Based on the literature, the highest consumption of electricity in The Gulf Cooperation Council (GCC) is due to the air-conditioning. It is normal in a very hot climate such as the GCC to use AC most of the time [

30]. Comparing the electricity bill in March and September, a huge increase is noticed. Therefore, it was important to investigate the perception and usage of AC.

Figure 7a shows that the majority of the participants felt cold inside the classroom due to the AC. Most of the participants open the window sometimes as a result of the cold conditions. According to

Figure 7b, 86% of the responses shows that the temperature is set between 16 °C and 22 °C, and only 14% of the campus population is setting the temperature between 24 °C and 25 °C.

The survey was intended to target certain areas, members’ awareness, and sense of responsibility and their usage of the AC. The survey started with demographic questions to get to know participants’ positions, function in the school and their level of education. The reason behind the questions on educational level was to test if there is a relationship between the level of education and level of awareness, however the data did not show any clear pattern to help form a conclusion in this area.

The data demonstrates that the majority of the campus staff and students spend more time in the girls’ sections. Moreover, the results suggest that the campus members are aware of the importance of saving energy and its high relevance to a cleaner environment. Despite the level of awareness; the members expect rewards for energy saving.

Furthermore, the responses show that the members have a preference for the display or visible signage that reminds them to switch off the lights and other electrical appliances. Moreover, when it comes to responsibilities, the opinions are scattered as to who’s responsibility is to do different tasks that save energy, as only few think it is his/her responsibility to do so. The idea that is formed by the culture of the campus detects that there is a level of ignorance or laziness towards saving energy.

The point is emphasized by 77% of the participant responses that show their willingness to consider ways of reducing energy consumption at home, however, in school they show some ignorance. This was also clear in the AC usage, where most of the responses considered opening the window due to cold conditions despite the fact that 86% set the temperature between 16 °C and 22 °C. This could relate to who is paying the bill, and it might suggest that saving energy is only to save money rather than being to reduce the negative environmental impacts.

Moreover, the participants were asked two questions where they can have more than one answer. One question was about ways to reduce energy-wasting and the other was about the impact of wasting energy. Almost 50% of the participants chose only one choice despite the option of choosing more. This indicates the participants lack awareness. In both, cases a corrective action needs to be taken to increase awareness.

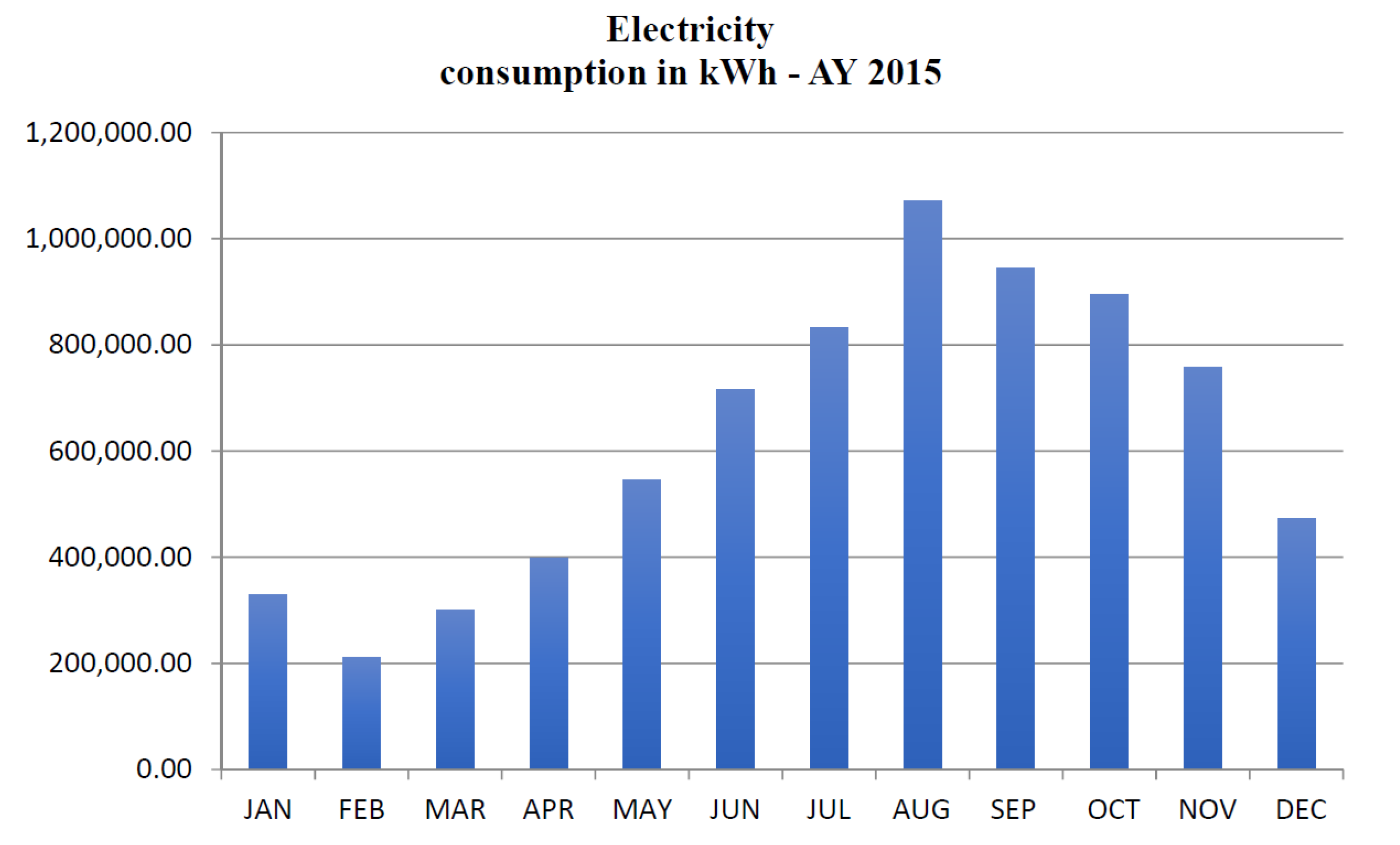

As any normal school, the campus receives its electricity bills on a monthly bases. Due to the size of the campus it was assumed that the electrical bill is normal. However, as time passed, the bill increased dramatically to reach its peak in August (2015), which is a month when the school is only considered to be fully operational for two weeks. The energy usage in GCC usually takes a bell shape, as illustrated by the school monthly consumption shown in

Figure 8.

In an attempt to understand whether the energy cost of the campus is realistic or overrated, we tried to compare the results with other schools in the UAE or the Middle East who are similarly studying their energy consumption. Unfortunately, it was very hard to find data for the Middle East, and therefore, the search was expanded to the US where some useful data were found to help in benchmarking the electricity consumption. The US government has started an initiative by launching an Energy Star website to encourage all types of building units to conserve energy by providing a benchmark and rewards for best practice by comparing similar units and weather conditions together, and each good practice is rewarded with a star. Using the Energy Star website, the annual electricity consumption data and area were plugged, and the website compared the consumption with the rest of schools with similar conditions in the data base. The Energy Use Intensity (EUI) is a unified measure to compile all types of energy consumption including water and natural gas.

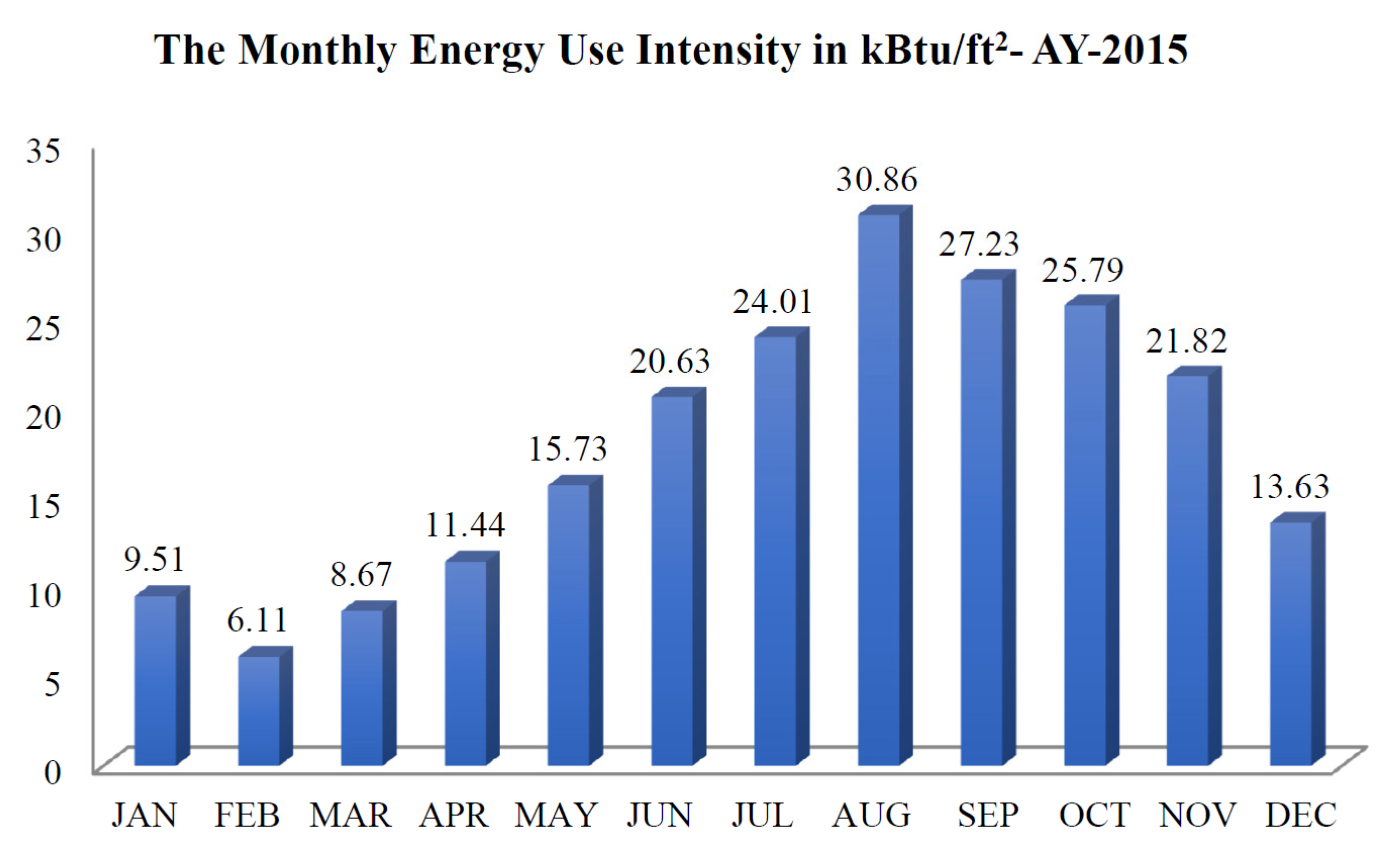

The school Energy Use Intensity (EUI) was first calculated from energy consumption by using the monthly consumption data and the school’s total area (the area is the total conditioned area). The units were converted to kBtu/ft

2, as shown in

Figure 9, in order to compare the data. The annual EUI was found to be 215.43 kBtu/ft

2. As shown in the graph, when the campus is compared with the median it is way above the average of other similar buildings. It is worth mentioning that the annual site EUI provided by the Energy Star web site is 215.4 kBtu/ft

2, which is similar to the value obtained by calculations 215.43 kBtu/ft

2.

The energy star initiative is a good measure of any energy usage, when compared with others. Therefore, using it to benchmark our school is very meaningful. The data shown in

Figure 9 for the comparison conducted using the Energy Star website, indicates that the school is in an immediate need of an energy audit.

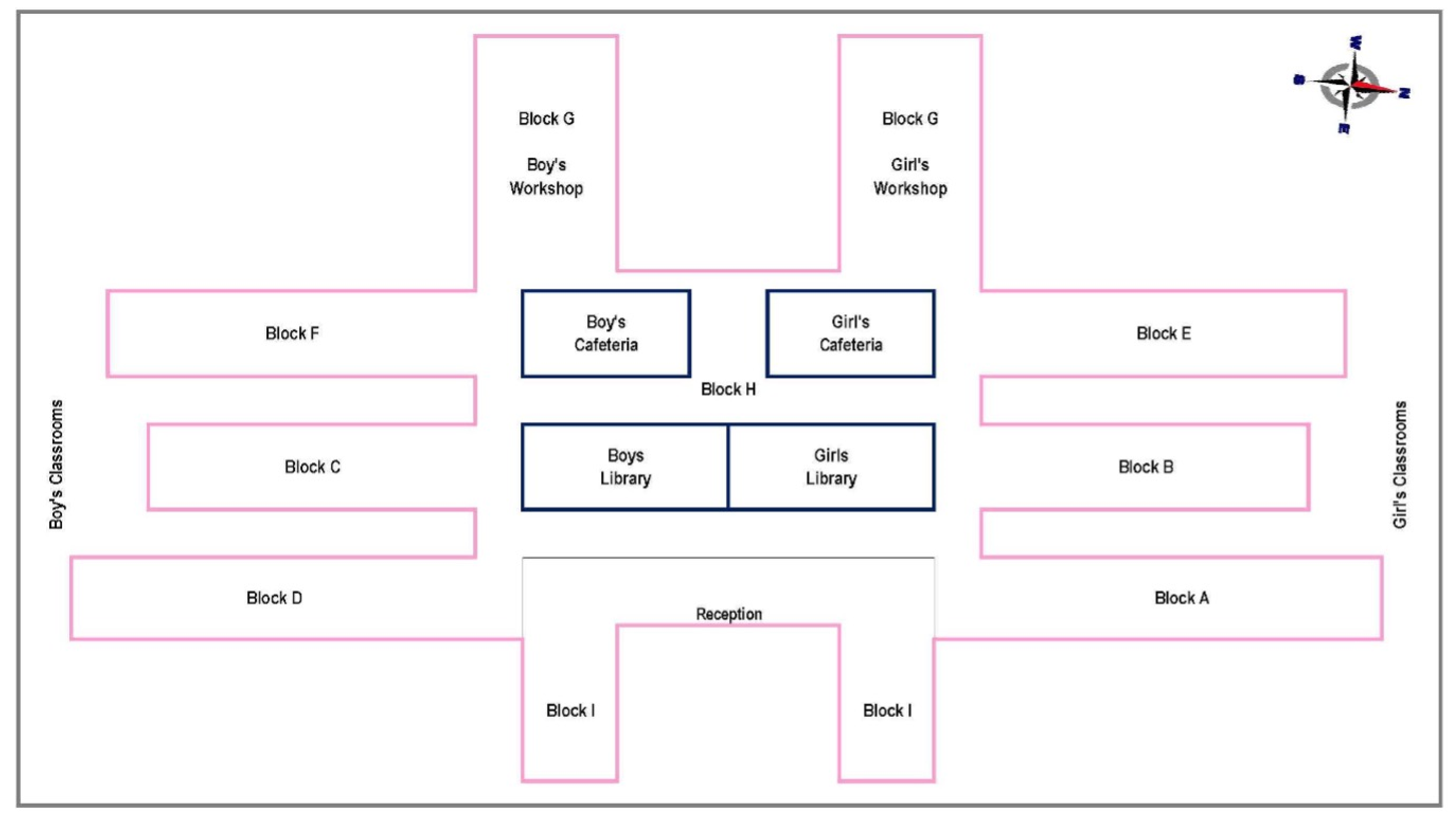

As part of the energy audit, a walk-through of the whole campus was conducted to give the means of identifying and evaluating energy use and pinpoint areas for possible energy-saving improvements. In the campus, the main two parts to look for were the lighting and HVAC system (air-conditioning mainly).

As for lighting, the inventory showed that the classrooms in the campus have excessive lighting, even when no students are there or it is sunny enough outdoors. In addition, the lights in the main corridors are always switched ON despite the presence of students or staff, even though most of the corridors do not need lighting as the sunbeams can easily get inside. The last observation is about the lighting in the libraries, where it was found to be poor for reading.

Air conditioning is believed to be a cause of energy waste in the campus, and the walk-through conducted was evidence of this. It was observed that the prayer room (mainly girls’ side), corridors “C” and “D” are cold all the time. Further inspection by the maintenance team showed that the 2-way valve in the air-handling unit is not working properly and has to be replaced for the corridors, however in the prayer room the AC programmable thermostat unit was not working properly according to the set temperature.

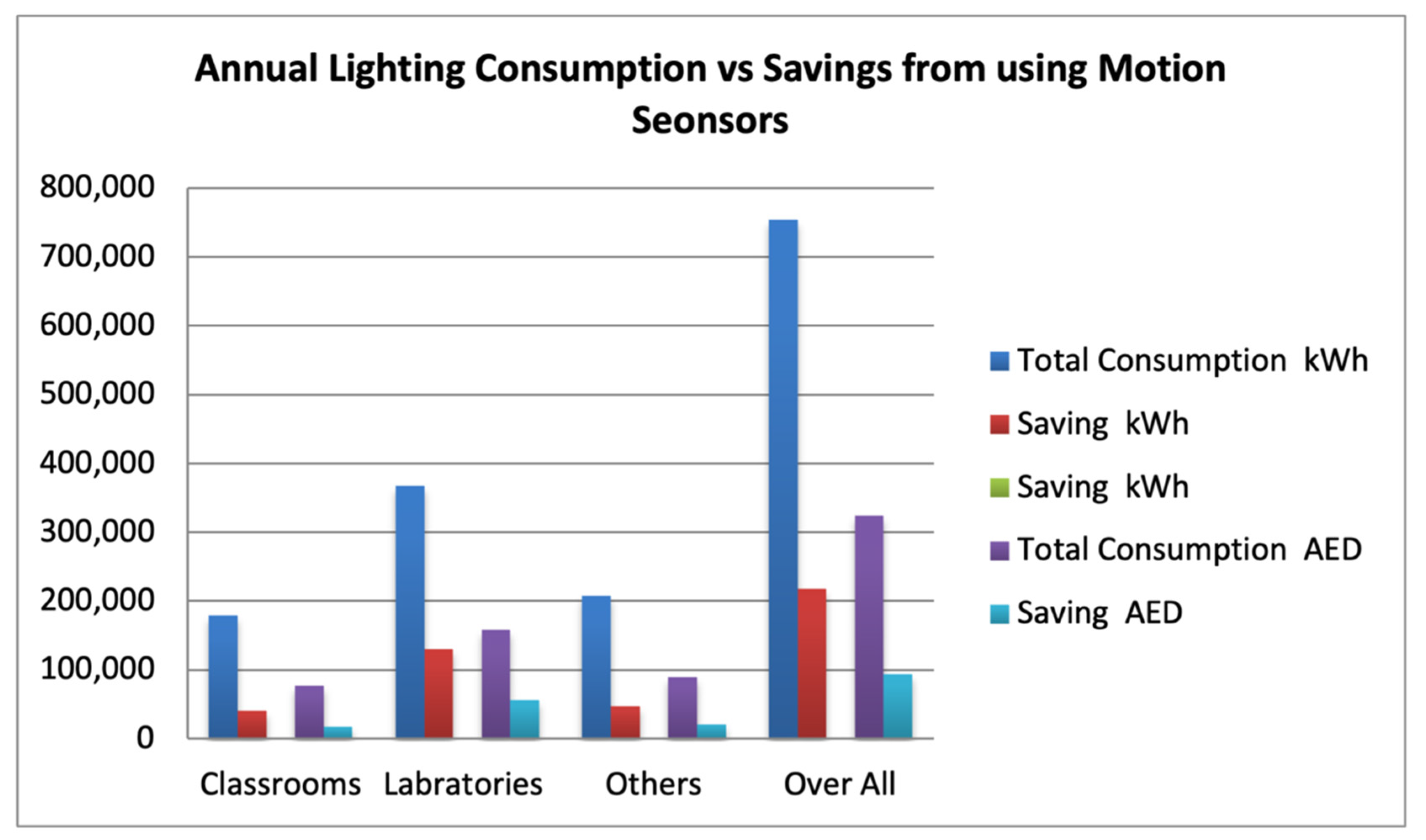

It was noticed from the walk-through observations that many locations have the lights switched on while the place is not occupied. Installing a motion sensor in all classrooms, and labs could help to reduce the amount of energy consumed and eventually the school electricity bill. The cost of installing motion sensors in the whole school facility will be approximately AED 20,000, and the savings are expected to be around AED 93,691 annually. Accordingly, the payback period is around 2.6 months.

Figure 10 is a bar chart showing the expected savings in kWh and AED.

The school lighting system constitutes a significant part of the school’s overall electrical power consumption. For this reason, a thorough study was performed to explore the different areas where energy can be saved from this component. There are many elements in the lighting system that have an impact on the electrical consumption, such as controlling when lights are turned on or off, choosing the appropriate lighting level, and the type of lamps used in schools.

Light intensity in a room or “Light Quantity” is the amount of light provided to a room. It is usually expressed in three types of units: watts; lumens; and foot-candles (FC) [

31]. The number of

lumens describes how much light is being produced by the light system. Finally, the number of

foot-candles shows how much light is actually reaching the workplace (desk level). The light intensity was measured using a light meter placed on the desk level where tasks are performed. Different locations were visited, the measurements were taken at 7:30 a.m., 11:00 a.m., and 1:30 a.m., and the results were averaged for each location. The results collected were compared to the standard amount of foot-candles in schools.

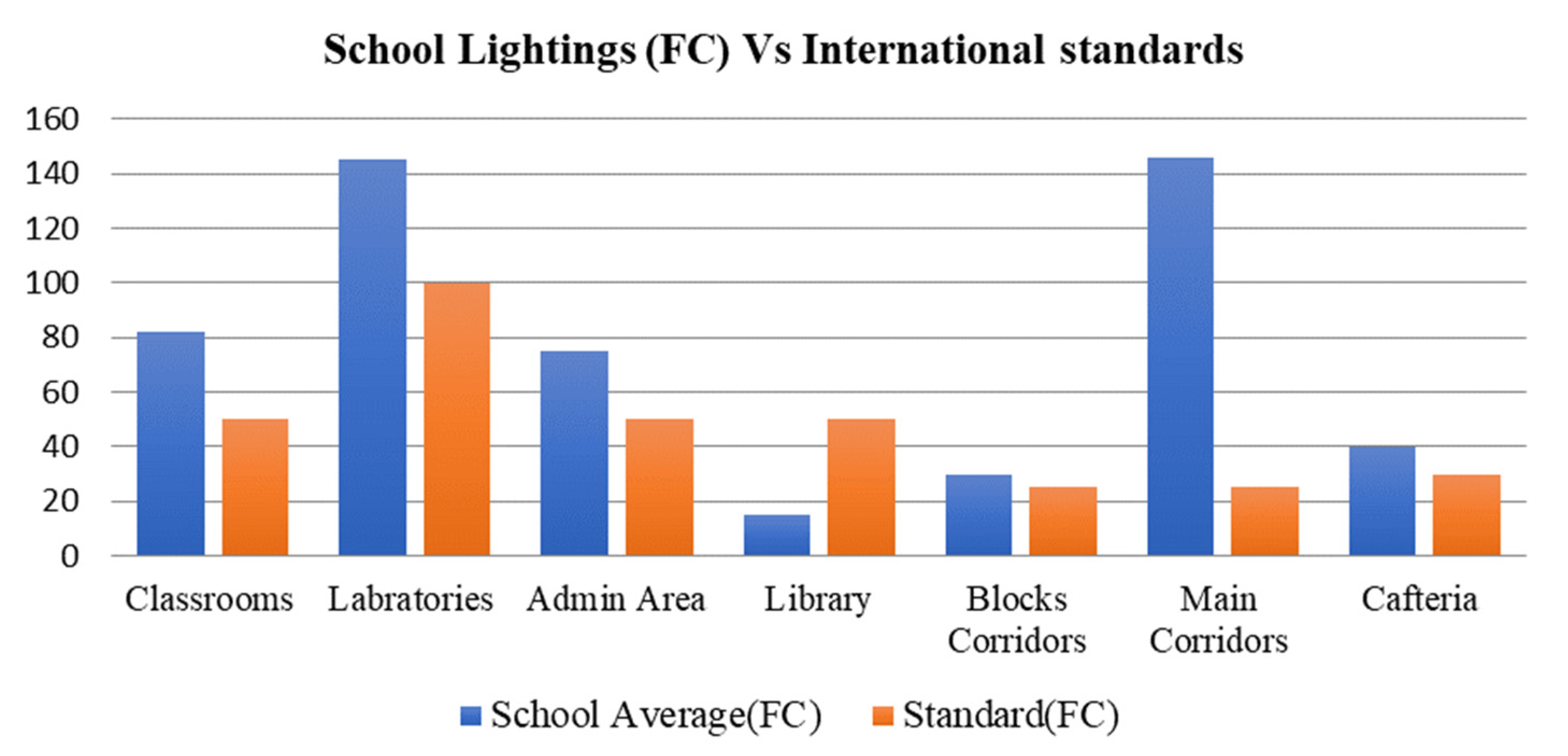

Figure 11 shows a comparison of the average school lighting compared to the international standards. It is obvious from the bar chart that except for the library, the illumination level in the school facilities exceeds international standards.

It was noticed that most classrooms has excessive lighting.

Table A15 in

Appendix D presents light intensity measured in Foot Candles (FC) compared to standard lightning. According to the table, the classrooms require a lighting of 50 FC for reading and writing, while the classrooms have a light intensity reading on average of 82 FC depending on the class size and sun exposure. The lights are controlled by three switches, and accordingly if one switch is turned off the light intensity measurement is 54–68 FC, which is above the standard.

In the observations for the school body practices it was noticed that all lights were on. Additionally, while measuring the light intensity in the reception corridor, an average value of 180 FC was recorded, while the standard is 20–30 FC. The reason for this is that the main hallways are exposed to direct sunlight during day hours, which indicates that there is no need for the lights to be on during daytime, yet with the observations it was noticed that the light is always on at all times.

Moreover, with most of the campus being over lamped, most classrooms can save energy on lighting, especially those with direct exposure to sunlight. On the other hand, in the library the standard lighting should be 50 FC, however the library recorded measurements at 10–19 FC. This should be taken into consideration for the safety of students and staff.

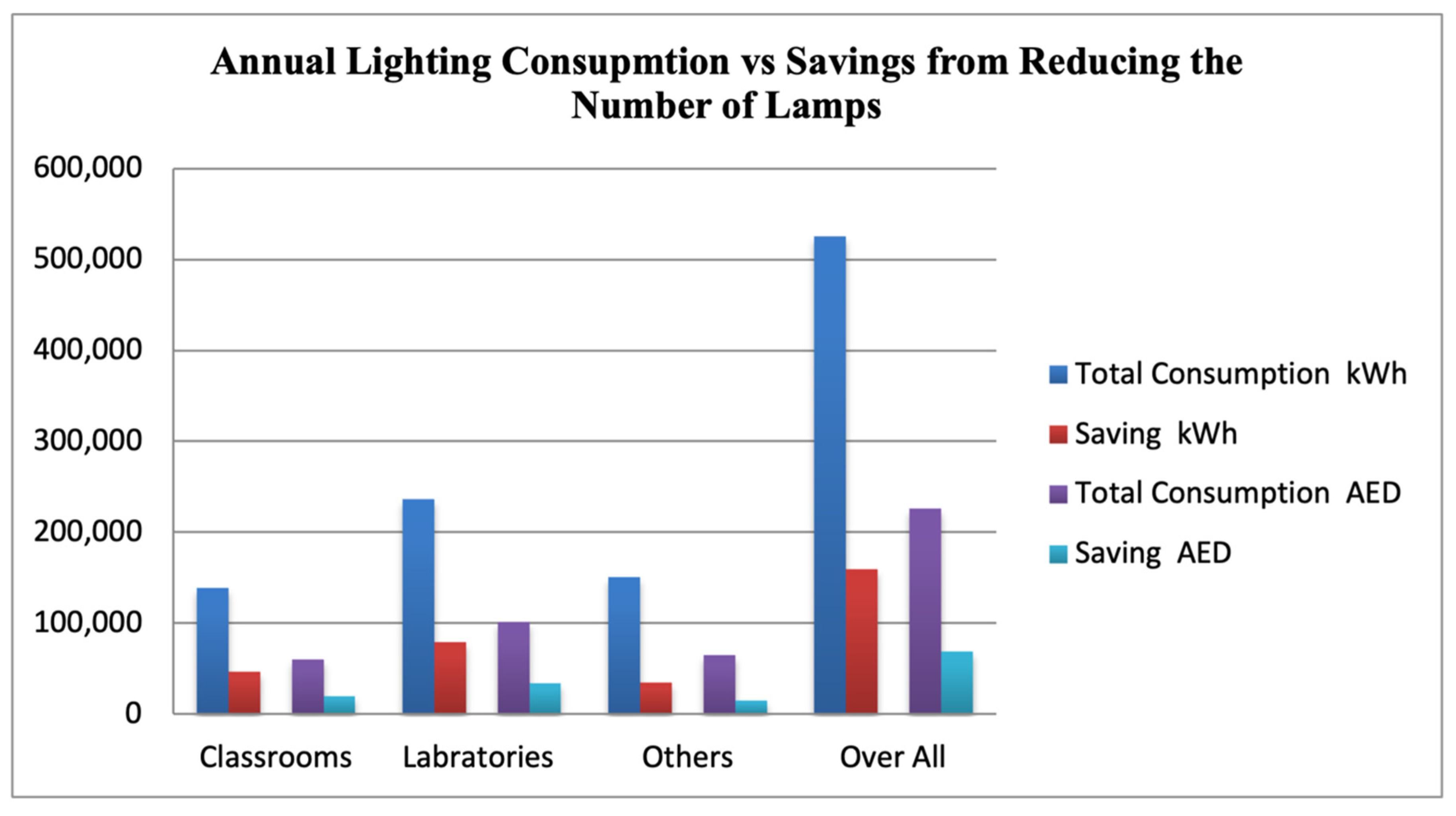

The electricity consumption from lighting can be easily reduced by 33.3% in the classrooms, laboratories, and workshops by removing 1/3 of the lamps or switching them off during operational hours. The lighting in the reception area and main corridors can be reduced by 100% during day light hours (school hours) as the readings shows an average light intensity of 140 FC with all the lights being switched off.

In order to calculate the total saving, the lighting inventory data shown in

Table A14,

Appendix D were used to calculate the total electricity consumption from lighting based on averaging the number of hours used annually in normal operational days (200 days) and the leave days (165 days including weekends).

Figure 12 shows the annual lighting consumption and savings.

A summary of the calculations shown in

Table 3 indicates that 159,548 kWh could be easily saved by switching off one third of the lights with a total annual saving of AED 68,606.

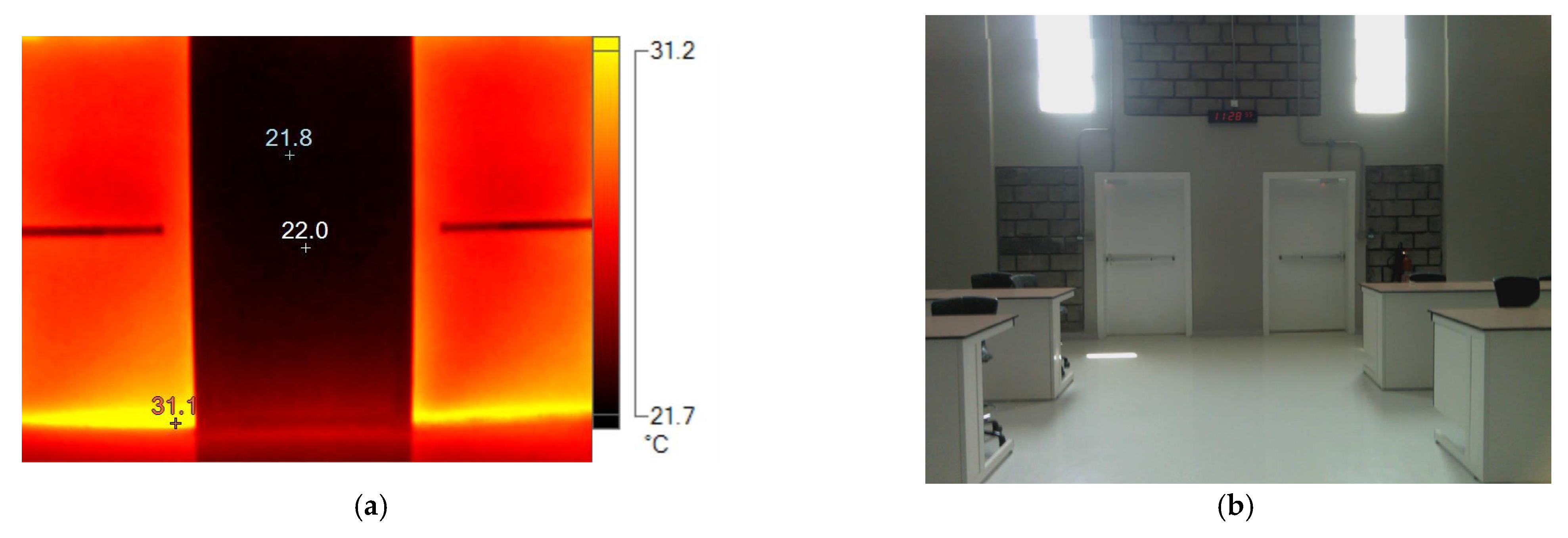

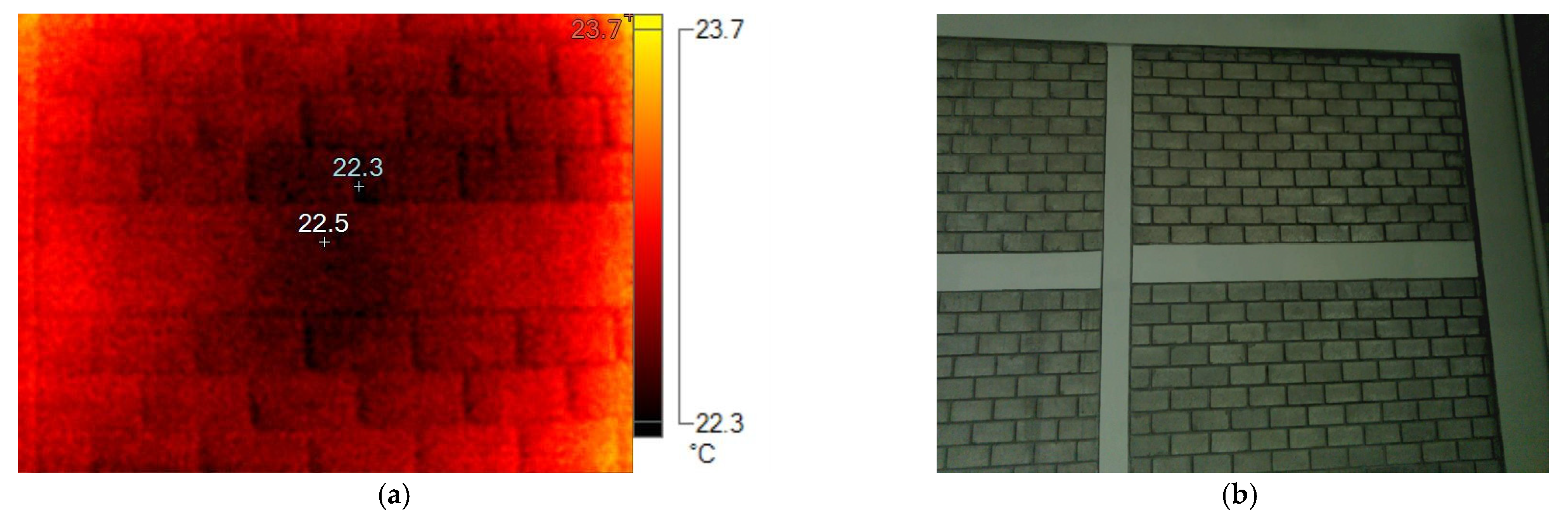

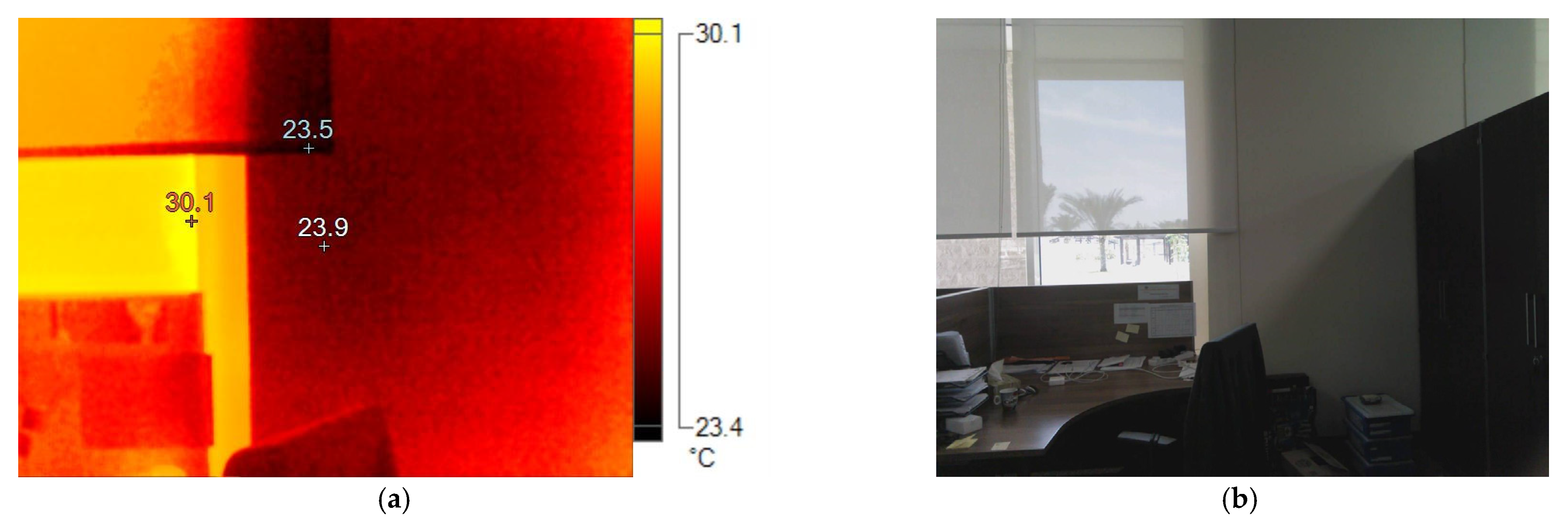

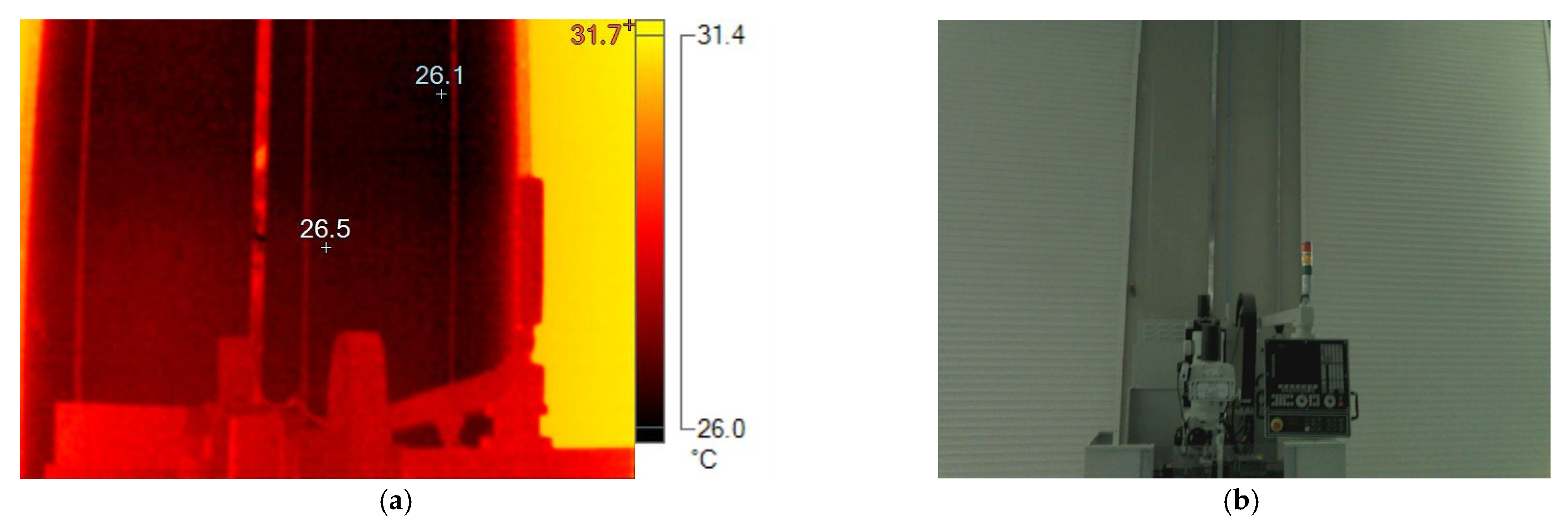

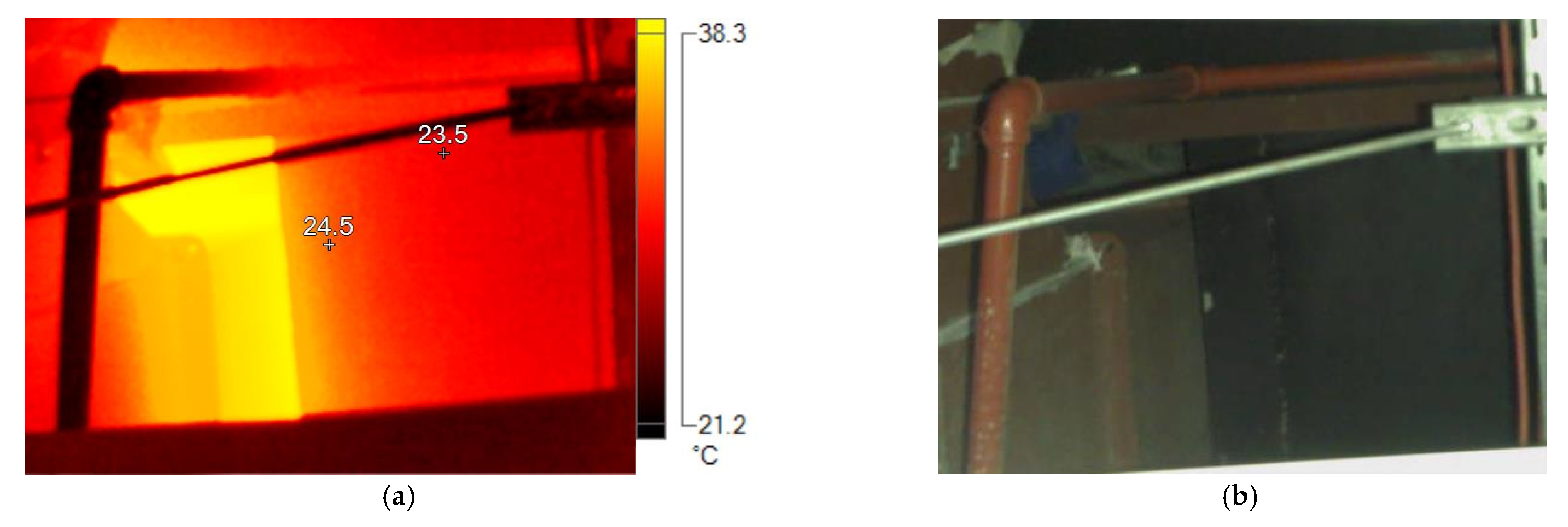

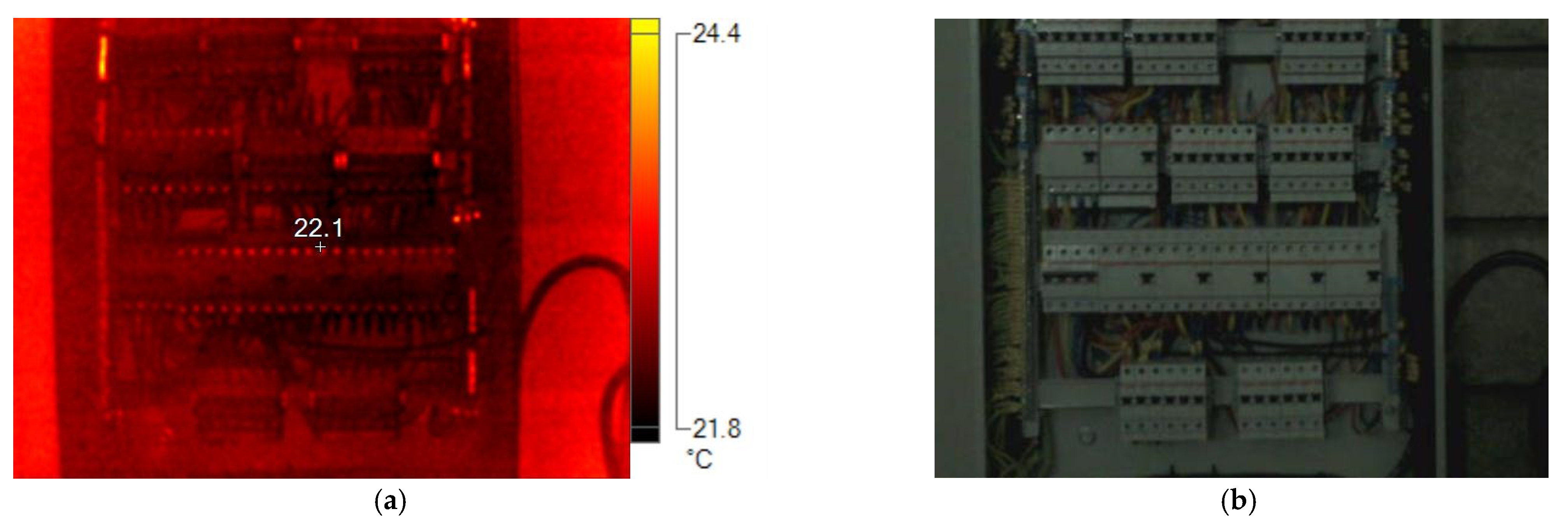

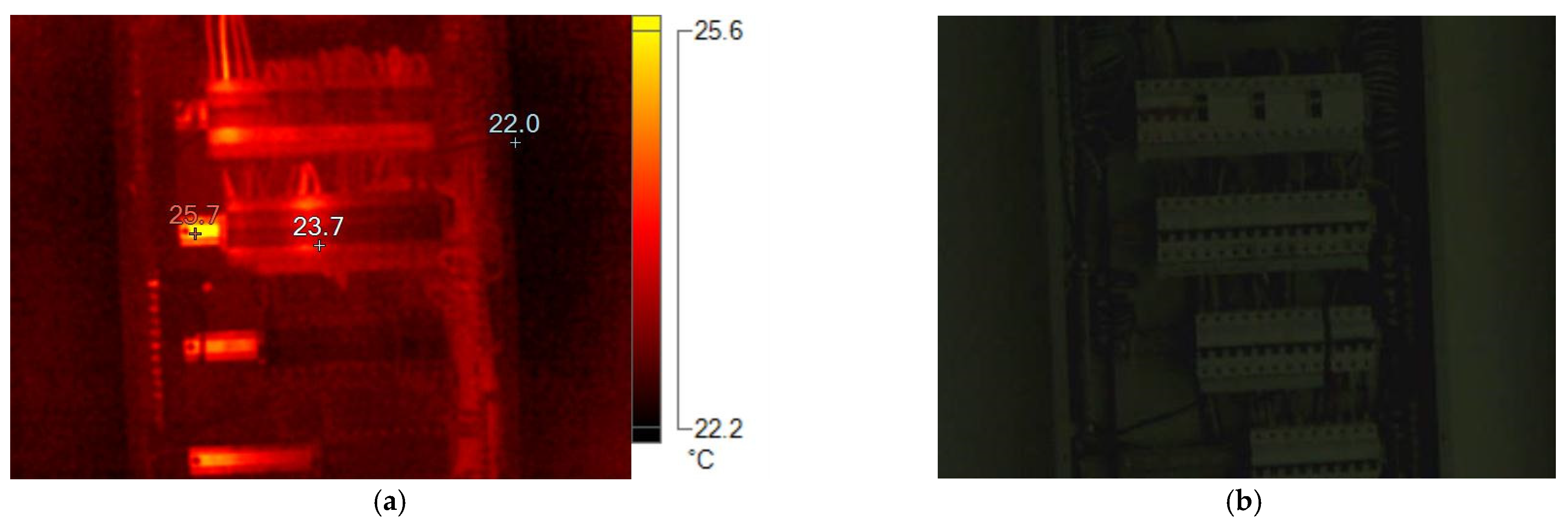

3.2. Thermography

In the study, thermography analysis was made on 16 April 2016 and the other surveys were also made around this time. The Fluke Ti200 camera [

32] was used to perform the work in this survey. To classify the severity of the thermal anomalies, the temperature difference between similar distribution boards was used. Temperature from the distribution board is likely to vary based on the electrical load consumed by the equipment at that time, the ambient temperature, and its emissivity value. In general, approximately 70 distribution boards were inspected and they appeared to be in good working condition. The electrical distribution boards showed a minor temperature difference (2–3 °C) due to the load conditions. Accordingly there is no energy saving opportunity in this area.

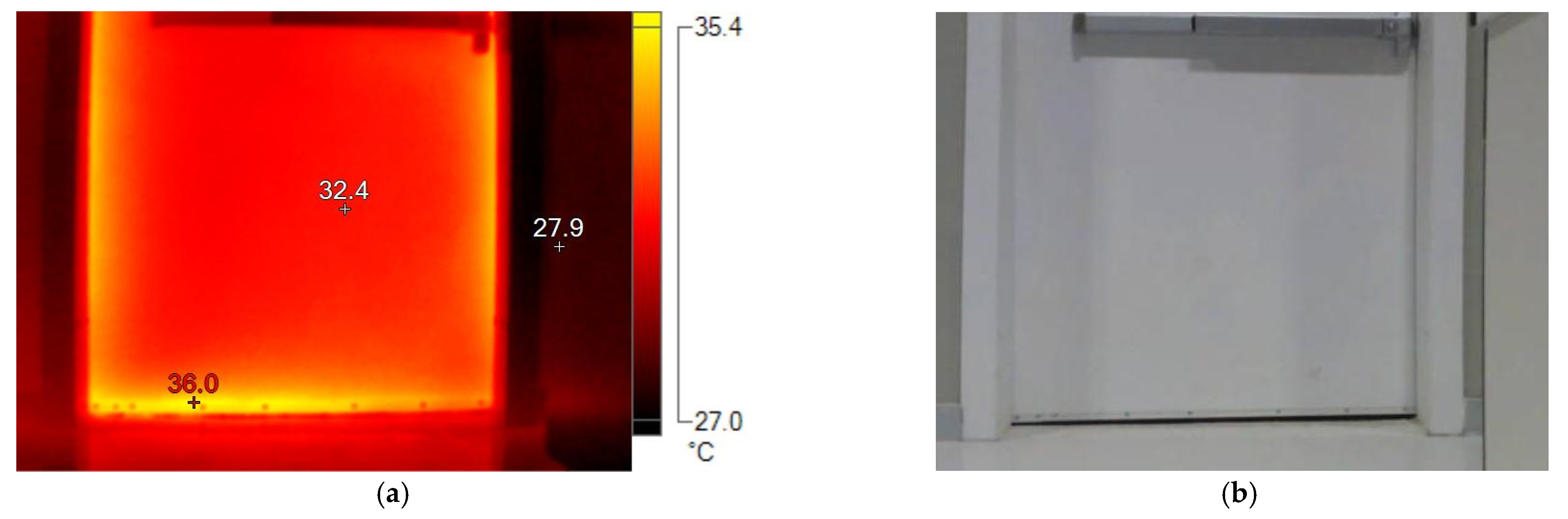

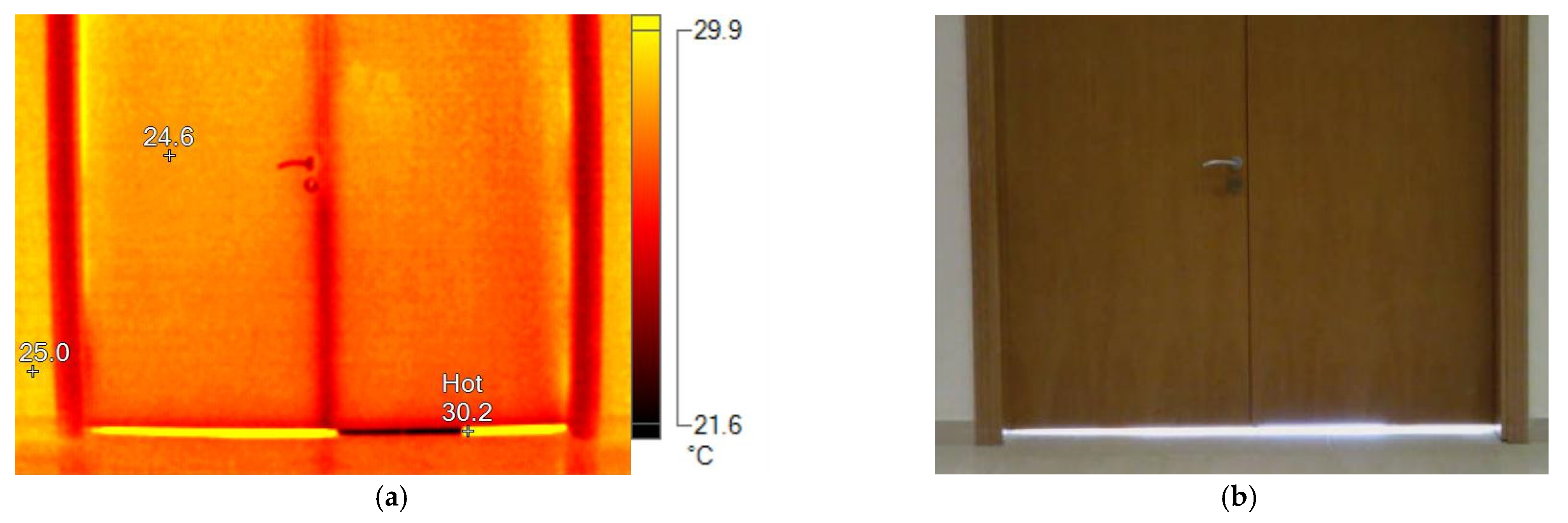

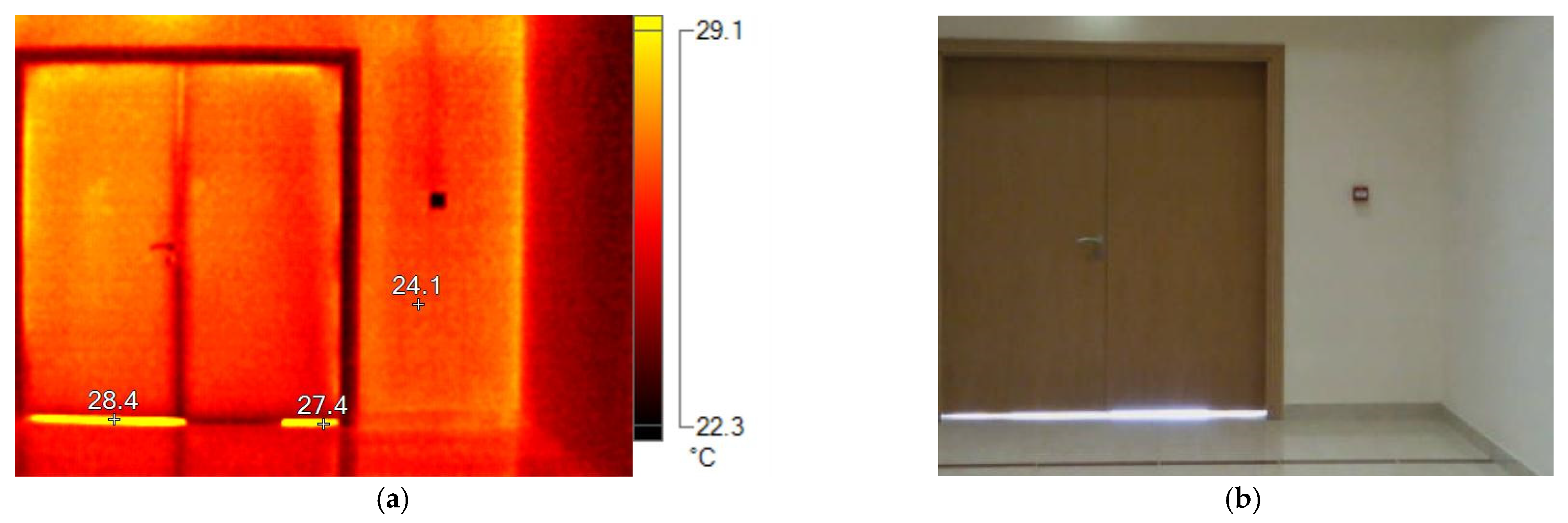

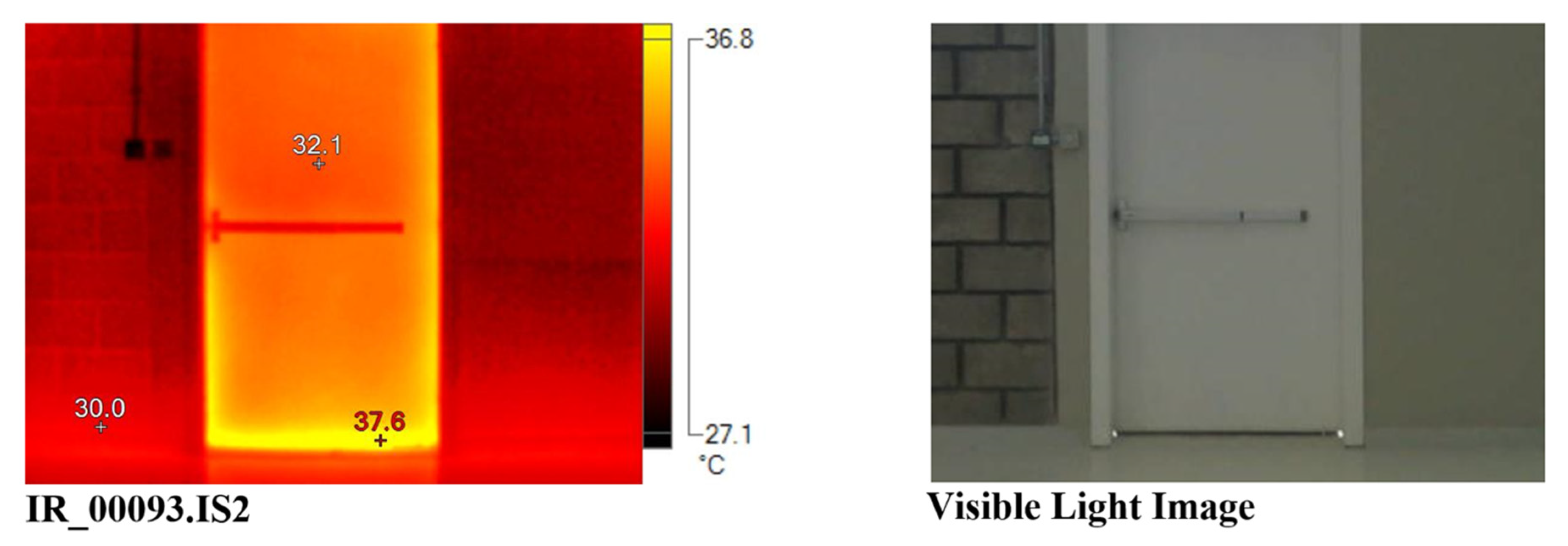

Thermography greatly helps detecting energy losses of buildings. It is applied to large buildings to help identify air leaks, insulation defects, voids within materials, moisture accumulation, and fungi formation leading to indoor air quality problems. Some Information about the buildings construction, type of roof insulation system, the location of water leaks, and other problems in the building are fundamental information that is necessary to perform an effective inspection. The building under inspection is new, the walls are insulated with a 40 mm foam board with thermal conductivity value k = 0.0227 W/mk. The roofs are insulated with a 70 mm thickness of the same material. The glass used in the envelope and windows is ASTM C1048-FTheat-strengthened and fully tempered flat glass, 6 mm thick blue from outside for shading, 16 mm air spacing, and 6 mm clear from inside (6 + 16 + 6 = 28 mm double glazing), which minimizes the heat transfer rate through the glass. Inspections are conducted at day time to ensure a minimum temperature difference between internal and external temperatures of at least 10 °C. For the building envelope, an internal inspection was performed for about 40 locations, which include interior and exterior walls, doors, and ceilings. The walls and ceilings inspected showed no noticeable temperature difference, which indicates proper insulation. However, some anomalies were found in doors. An example of these anomalies is shown in

Table 4 and

Figure 13. The

Appendix B section of this report includes all the building envelope thermographs and doors, and

Appendix C includes the distribution boards’ thermographs.

Figure 13 shows that the door is not sealed properly from the bottom and the sides as they show higher temperature than the wall. The door’s body shows higher temperature than the wall due to heat conduction.

The power consumption in one of the Distribution Boards (DBs) in the campus over one week is analyzed. The analysis took place from 30 April to 7 May and Fluke power analyzer was used to read the data. The results were expected to help us understand the power distribution and energy loss between work days and weekends, and between morning and night shifts as the DB was limited to the air handling units. However, the data could not be interpreted in such a way as to explain the main reasons for the huge power consumption in the school. The school, just like others, utilizes a three-phase power system. In a three-phase power supply system; three conductors are present and each one carries an alternating current of the same frequency and voltage amplitude relative to a common reference, but with a phase difference of one-third the period. The common reference is usually connected to ground and often to a current-carrying conductor called the neutral. Due to the phase difference, the voltage on any conductor reaches its peak at one third of a cycle after one of the other conductors and one third of a cycle before the remaining conductor. This phase delay gives constant power transfer to a balanced linear load.

Fluke analyzer offers an extensive and powerful set of measurements to check power distribution systems. Some give a general impression of power system performance and others are used to investigate specific details. In our testing, we used the analyzer to read the power in watts of one DB by properly connecting the analyzer and DB. The DB used in the testing controls two air handling units that are always running, morning and night every day, thus the trend of the power over all days was found to be almost the same.

Fluke analyzer measures some of the important power parameters and displays the power trending as changes over time for all the measuring values. The power calculations are based on the Unified Method developed at the Polytechnical University of Valencia, and build upon the IEEE1459 standard. Furthermore, the calculations are conducted for the Fundamental and Full frequencies. The Fundamental considers voltage and current only at the fundamental frequency (50 Hz in our case) for power calculations, whereas Full uses the full frequency spectrum (including harmonics and noise). In the experiment, only the total fundamental power was analyzed.

The averaged power consumed over the week (30 April–7 May) was around 9.5 kW and it goes up to 10 kW in the worst case scenario. To fully analyze and differentiate between the amount of power consumed during different time intervals, we have split the data into two periods. The first period belongs to the weekdays with an average power consumption of 9.487 kW, while the other one is for the weekends with an average of 9.3 kW.

The goal of this task was to identify, in order to optimize, some of the largest loads in our campus, where the most obvious one out of these loads is the air-conditioning system. Unfortunately, we could not use the main DB due to safety concerns and substituted our testing with a smaller one. Since the tested DB controls air handling units, which is always operating, the trend of the power consumption during weekdays and weekends was almost the same, and no obvious drift was found.

3.3. Energy Conservation Measures (ECM) and Economic Analysis

The energy audit conducted includes a comparison with benchmarked consumption rates at other similar facilities, and conducts a walk-through to visually identify energy savings and non-savings trends. A better understanding of the energy consumption pattern should lead to easier identification of more viable and cost-effective energy conservation measures, thus reducing operation costs in the long run. The recommendations and Energy Conservation Measures suggested in this report are based on the analysis of the school facility systems as well as the current practices of the staff and students.

ECM-1: Installing motion sensors in all the classrooms and labs. Installing a motion sensor in all classrooms, and labs, could help in reducing the amount of energy consumed and eventually the school electricity bill. The cost of installing motion sensors in classrooms, and labs will be approximately AED 20,000 the savings are expected to be AED 93,691 annually. Accordingly, the payback period is 2.6 months.

ECM-2: Remove the extra lamps as only 2/3 of all the classrooms and labs lights should be used during the school day. This could be achieved by removing 1/3 of the lamps or adjusting the control so that only 2/3 of lamps are switched on. The school lighting survey showed that most of the facility is over-lit when compared with international standards. The lighting economic analysis showed that an annual saving of AED 68,606 could be achieved by adjusting the light intensity to match international standards.

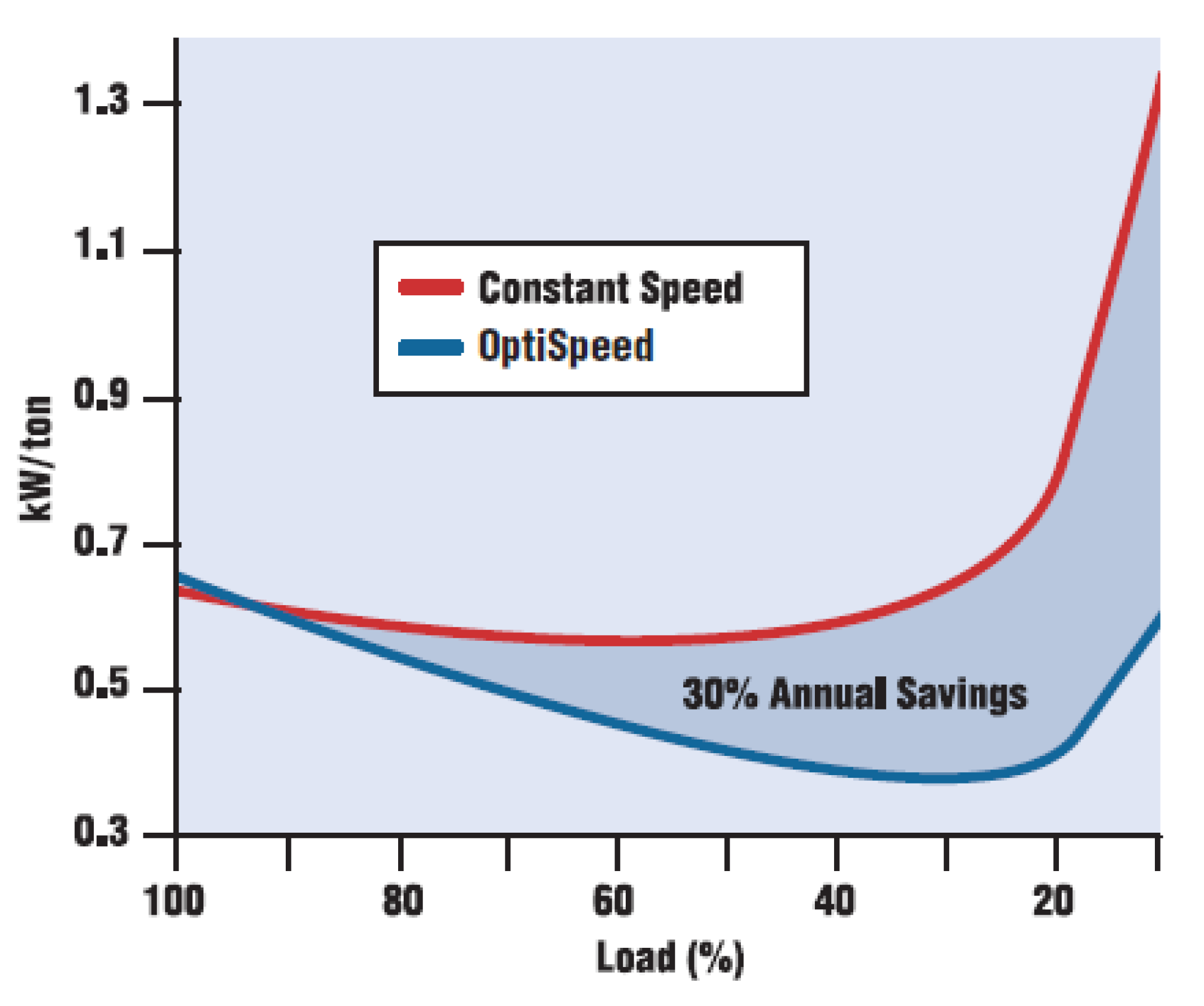

ECM-3: Integrating the Networked Optimization Software with the current HVAC automation system. In order to optimize the HVAC system consumption, it is recommended to use a Networked Optimization Software that can be integrated with the current automated system. The optimization software is developed by Johnson Control so it can be fully integrated with the current HVAC system for central plant optimization. The optimization software offers a relational control algorithm so that the control set points are calculated based on real time building load inputs received from the building automation system. A minimum of 10% savings could be achieved by utilizing the optimization software solution [

33]. As per the current HVAC system annual consumption calculations, approximately 469,000 kWh could be saved annually, which is around AED 202,000. The software installation and commissioning cost is AED 90,000 and, accordingly, the payback period is approximately 5.4 months.

ECM-4: Both wooden and shuttle doors in the workshop to be checked and sealed, and it is recommended to add sweepers to all the exterior wooden doors. The thermography survey for the building envelope shows that the envelope is well insulated (roof and walls) based on the captured thermographs. The glass used in the envelope and windows is ASTM C1048-FT heat-strengthened and fully tempered flat glass, 6 mm thick blue from outside for shading, 16 mm air spacing, and 6 mm clear from inside (6 + 16 + 6 = 28 mm double glazing), which minimizes the heat transfer rate through the glass. The exterior wooden doors and the shutter doors in the workshop area are not sealed properly as shown in

Appendix B, and the doors do not have sweepers, which leads to infiltration and waste of energy.

ECM-5: The temperature has to be set at 24 °C in all the campus facilities, and all stakeholders are to monitor the implementation of this measure and report any misuse to reduce the energy waste in the campus. The current practice in the campus, based on the survey findings, is that most of the teachers and students are setting the temperature between 18 °C and 22 °C and the majority felt the cold conditions and opened the windows due to coolness.

Figure 14 shows the expected savings in kWh and AED if ECMs 1–3 are to be considered. A total savings of AED 364,000 could be achieved.

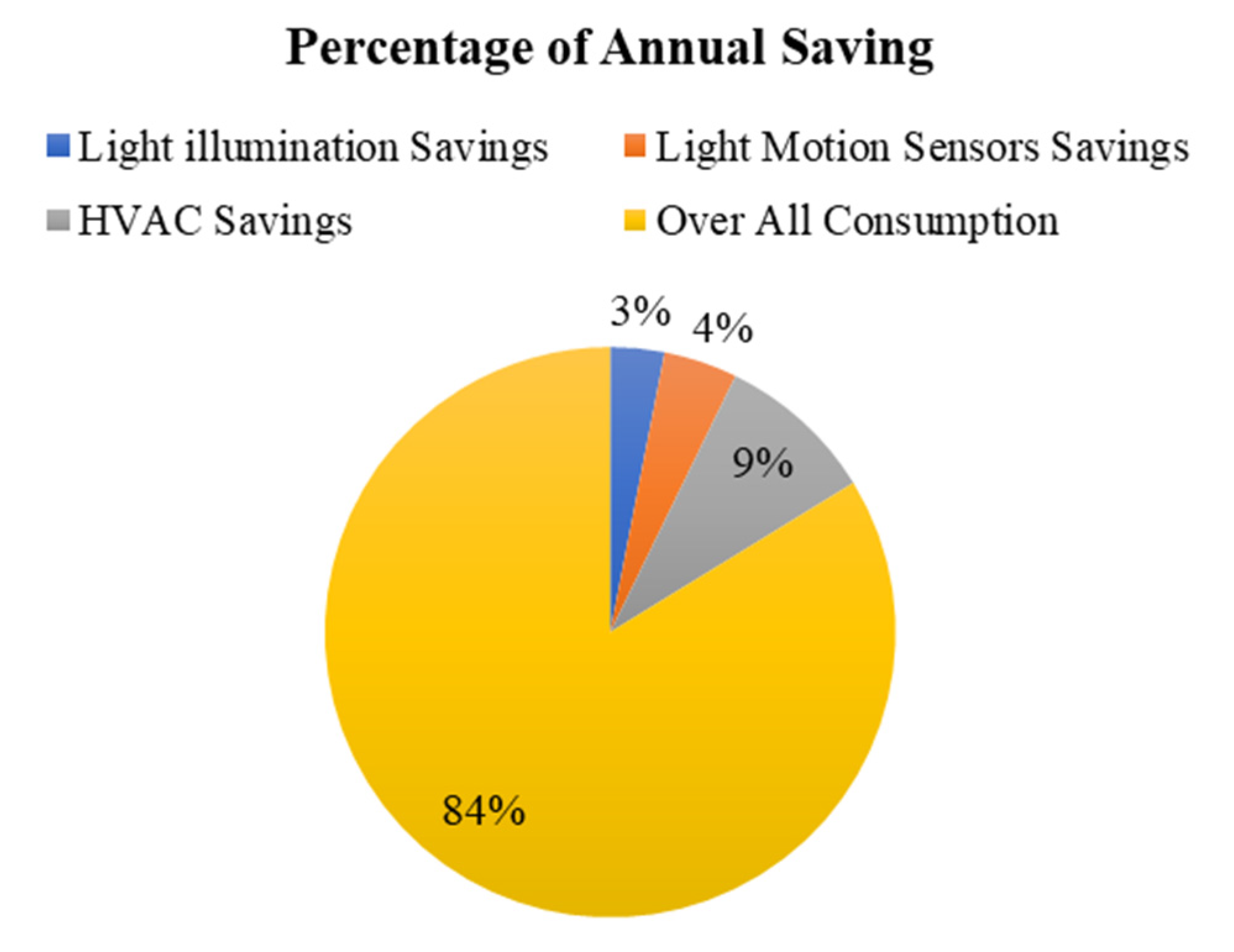

Figure 15 shows a pie chart of the total saving percentage from each ECM.

Based on the survey, walk-through observations and the investigation of current practices, further savings could be achieved by considering ECMs4 and 5. However in order to quantify the savings, the energy consumption should be monitored for one year starting from implementation.