The starting point of this study is a detailed literature review, providing an overview of existing LCA studies in the context of aviation. Thereby, a selection of suitable publications is identified to provide comparative data. Additionally, possible options for environmentally enhanced discrete-event simulation are highlighted and reviewed. As there is a lack of studies investigating discrete-event simulation and LCA in the field of aviation, the latter are related to various other industrial sectors.

2.1. Life Cycle Assessment in Aviation

The ecological assessment of aircraft and their operation using LCA is not entirely new. Several studies have dealt with the topic and carried out environmental impact assessments in a wide range of applications. In 2013, Atılgan et al. [

10] conducted an environmental impact assessment for a turboprop engine using an exergo-analysis. The related environmental impact of each component of the engine was first calculated and then an individual environmental performance was assigned to each component using the exergo rate. The combustion chamber was identified as having the highest environmental impact in the engine. Vinodh et al. [

11] published an LCA for a turbine blade. By focusing on the manufacturing phase, environmental issues could be identified as early as in the machining process, thus enabling the development of more environmentally friendly aircraft components. The environmental impact of the maintenance of an engine was assessed by Şohret et al. [

12]. The author considered routine maintenance (based on electricity consumption and utilised fuel) of a Cessna 172 Skyhawk and concluded, among other things, that fuel is a significant contributor to impact categories such as the global warming potential, acidification, or photochemical oxidation, whereas electricity consumption dominates in the impact category of ozone layer depletion. Altuntaş et al. [

13] considered the use of an Auxiliary Power Unit (APU) and Ground Power Unit (GPU) for a ground power supply and compared them based on LCA results. The study showed that the use of GPU at the airport has significantly lower impacts on human health, ecosystem quality, and resources compared to an APU. Another way to minimise the environmental impact of aircraft is to use lighter materials. A comparison of different materials in terms of environmental impact has been analysed, for example, using fuselage segments [

14,

15,

16], elevators [

17], aircraft interior panels [

18], and lightweight trolleys [

19]. These studies, however, usually only look at individual life cycle phases or materials in order to propose specific process improvements. Thus, they can only be considered as comprehensive LCA to a limited extent as the interactions and interdependencies between different phases are not taken into account.

For a holistic LCA, however, it is important to consider and assess the aircraft in all life cycle phases. Due to the extensive scope of such studies, many are based on master’s theses or dissertations. Johanning [

20], for example, investigated the integration of an environmental impact assessment into the conceptual aircraft design phase. The author concluded that the operational phase has by far the largest environmental impact, caused mainly by fuel combustion. Similarly, Howe et al. [

21] conducted an LCA of an Airbus A320, looking specifically at the manufacture, operation, and end-of-life to calculate the respective share of the total environmental impact. In this study, the operational phase accounted for 99% of the total environmental impact, with no distinction made between maintenance and flight operations. The figures in this study are given in percentages only and do not provide exact numerical values. In 2006, Facanha and Horvath [

22] calculated the environmental impact of a Boeing B747 freighter and compared the results with those of other means of transport. Not only was the entire life cycle of the vehicle considered, but also the construction and operation at the airport as well as fuel refining and distribution. In this study, however, only the inventory assessment was described in depth. The impact assessment was excluded from the study, resulting in a comparison of transport modes based only on air pollutants per freight activity. A similar approach to comparing aviation with other modes of transportation was used by Chester [

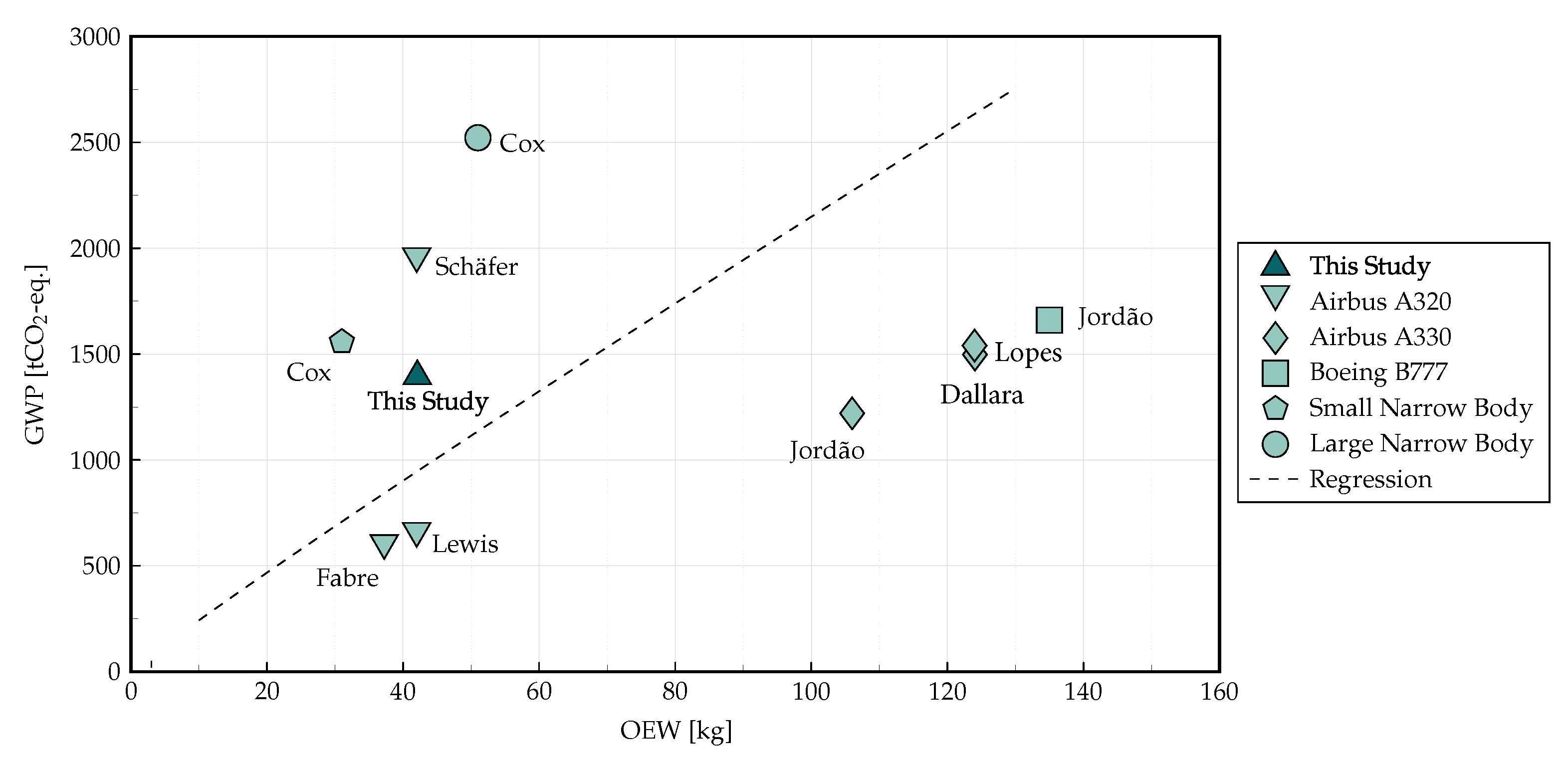

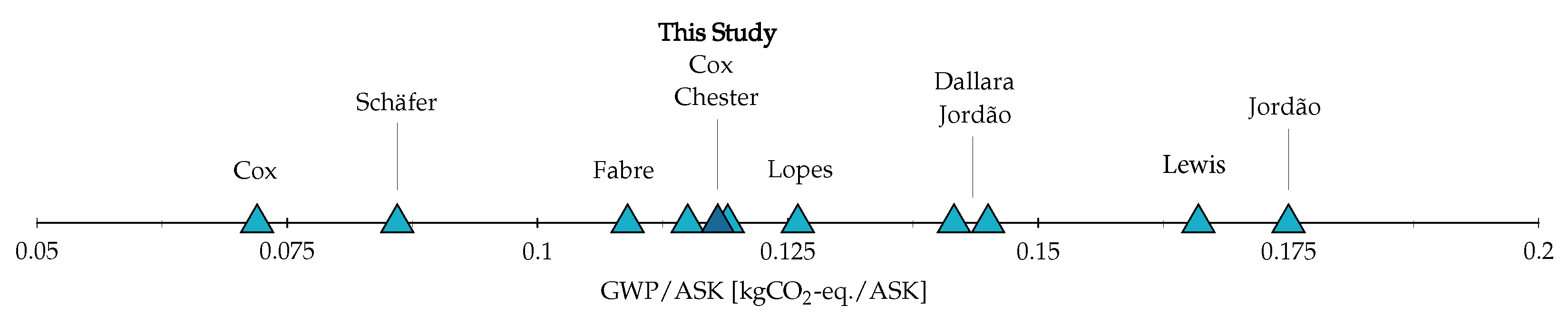

23], who compared an Embraer 145, a Boeing B737, and a Boeing B747, and by Cox [

24,

25] (more details of this study can be found in the master’s thesis by Jemioło [

26]), assessing a variation of short-haul and long-haul aircraft, i.e., Short Narrow Body (SNB) and Large Narrow Body (LNB), representing the aviation sector. For the environmental assessment, the authors used an Economic Input-Output Life Cycle Assessment (EIO-LCA), which is a top-down approach that estimates the environmental impact based on economic activities [

27], as the primary method leading to relatively high values. The reason for this is that the input-output approaches are rather approximate and usually contain wider system boundaries.

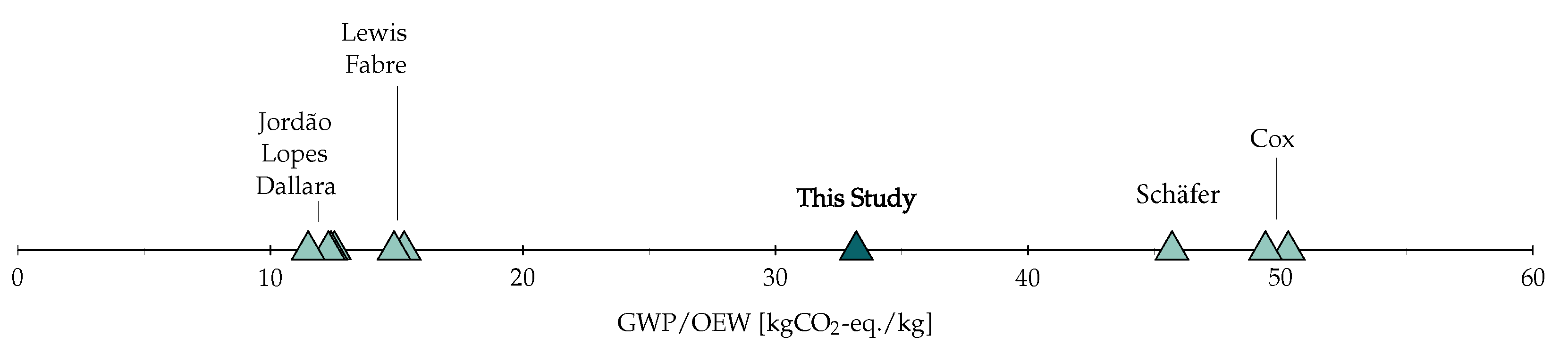

In a study by Lopes [

28], a holistic LCA was carried out for an Airbus A330. The inventory for the manufacturing phase of the aircraft published in this master’s thesis is used as a basis in many other studies. Another publication that is frequently referred to is that by Lewis [

29], who compared three flight scenarios with different flight distances and aircraft types (Airbus A320, Airbus A330, and Airbus A380). The author considered aircraft manufacturing and operations using a hybrid approach combining Process-Based Life Cycle Assessment (P-LCA) and EIO-LCA. Jordão [

30] applied an LCA study to the manufacturing, maintenance, and operational phases of an Airbus A330 and a Boeing B777 and compared these two aircraft types with each other. Noteworthy here is the relatively large ecological share of the maintenance phase of up to approximately 20%, which was calculated on the basis of the energy consumption of the airport and electricity price. In a recently published study by Fabre et al. [

31], an LCA of an Airbus A320 was carried out. The manufacturing of the aircraft, airport construction, as well as operations using different fuel types, were considered. Maintenance activities and end-of-life were, however, neglected due to a lack of data. The authors likewise concluded that LCA is a suitable tool for the evaluation of new technologies, such as hybrid-electric or hydrogen aircraft. The study by Schäfer [

32] aimed to develop a life cycle sustainability assessment methodology for the aircraft pre-design comprising an environmental and an economic assessment. For this purpose, all life cycle phases, including maintenance and end-of-life, were assessed based on CO

2, NO

X, and cumulated energy demand. In 2013, Dallara et al. [

33] analysed the environmental impact of aircraft production and operations activities using a parametric Streamlined Life Cycle Assessment (S-LCA) tool called qUWick. The aircraft under consideration included an Airbus A320 and a Boeing B737 and were compared with LCA outcomes from the literature and EIO-LCA tools.

An overview of these mentioned LCA studies, whose outcomes are further applied as comparative values in

Section 5, is provided in

Table 1. Due to differences in aircraft types, additional information, such as aircraft weight or number of Passenger (PAX), is listed to normalise the results on a functional unit basis. The table furthermore provides information on the life cycle stages considered in each study as well as the applied LCA methods. These can mainly be categorised as a common P-LCA, an EIO-LCA, and a hybrid model combining these two approaches. An S-LCA is a simplified method that is particularly preferred for complex products. In this approach, often only individual impact categories are considered, for example, to compare different design options with each other. The studies by Howe et al. [

21], Johanning [

20], and Facanha and Horvath [

22] are excluded from the table due to missing numerical values. Similarly, only a small selection of aircraft types was considered from the publications by Cox [

24] and Dallara et al. [

33].

In addition, a number of publications deal with the potential environmental impact of future aircraft concepts. These include hybrid-electric concepts [

34], universal-electric powered concepts [

35], or the use of Sustainable Aviation Fuels (SAFs) [

36,

37]. For these future technologies, a prospective LCA can be helpful for decision support in the design process or during engineering [

38]. Johanning and Scholz [

39], who compared electric, Liquid Hydrogen (LH

2), and SAF-powered aircraft, further indicated that additional renewable energy sources will be required to meet the increased energy demands of these concepts.

In summary, the environmental assessment of aircraft is currently an emerging topic. Most publications refer to the operational phase as by far the most influential phase of the entire life cycle. However, changes in operation, correlations, or other resulting dynamic effects cannot be adequately represented with the above-mentioned conventional LCA approaches. An extension of the classical LCA with, for example, a discrete-event simulation can enable a dynamic operating schedule for aircraft and can thus provide an even more detailed insight into the different life cycle phases and better represent technological effects.

2.2. Combination of Discrete-Event Simulation and Life Cycle Assessment

Discrete-event simulation consists of state variables that change at discrete points in time during a simulation and thus model and execute a process as a series of individual events [

40,

41]. Advantages of discrete-event simulations include the ability to simulate complex systems wherein inputs and variables can be quickly exchanged to gain insight into their significance [

42]. In addition, the simulated time can be easily varied and scaled without much effort. Due to the complex simulation setup, discrete event-driven simulations have thus far rarely been used for environmental issues [

43]. However, according to Thiede et al. [

44], a combination of LCA and discrete-event simulation is an effective solution that can overcome some of the problems of classical LCA, such as its static and disregard behaviour. Since there are no publications in the field of aviation dealing with a combination of LCA and discrete-event simulation, studies from other industrial sectors are considered in this section.

The authors de Oliveira Gomes et al. [

45] compared the environmental impact of different fuels for forklift trucks in a production facility. Thereby, discrete-event simulation and LCA were carried out consecutively. The discrete events contained input data such as fuel type and consumption or the amount of products handled by the forklifts and were used to simulate different scenarios. After this simulation, the results were then used to perform an LCA by adopting the global warming method. A similar approach was followed by Bengtsson et al. [

46], who analysed the energy and GHG emissions of Boeing machine tools to achieve benchmarks for sustainable manufacturing. The discrete-event simulation was performed with input data, such as cycle, setup, and down times for the machining tools. The results of the discrete-event simulation were then evaluated in an LCA focusing on direct and indirect energy consumption (kWh), carbon dioxide emissions (CO

2), and nitrogen oxide emissions (NO

X). Muroyama et al. [

47] integrated discrete-event simulation input data into an LCA simulation to assess the environmental impact of a golf ball factory. Discrete parameters included the number of machines, type of polymer, and number of repair workers. The result of this simulation then provided the energy and material consumption, CO

2 emissions, and flow rate. The approach provided more effective resource management in the production process, but the authors were faced with large uncertainties due to the lack of LCI data. Comparable approaches were used, for example, by Sproedt et al. [

48] to optimise the operational management of a factory, by Andersson [

49] to analyse the material and energy consumption of an assembly line production, and by Löfgren and Tillman [

50] to weight decision-making processes in a manufacturing process. These studies have in common that discrete-event simulation and LCA were carried out independently of each other. The results of the discrete-event simulation were hereby used as a basis for the LCA, with no possibility to intervene in the simulation itself due to ecological factors.

Apart from these sequential approaches, discrete-event simulation and LCA can be used simultaneously to enhance a combined model. Johansson et al. [

51] focused on alternative solutions for a juice production plant. Using a discrete-event simulation enriched with LCA data, several factory configurations with different numbers of tanks and batches were compared. Each time an event was triggered, an LCA was automatically performed and the resulting environmental values instantly updated the model’s output parameters. The focus of this study was to compare the carbon dioxide equivalents (CO

2-eq.) of the factory settings. The authors concluded that combining discrete events with LCA was much more time-efficient than applying independent analyses. A similar approach was used by Sigurðardóttir et al. [

52] examining cod fishing in Iceland with a focus on the comparison of different vessel types. Each fishing activity represented a discrete event that was automatically updated with environmental impact parameters (e.g., CO

2 of the vessels) from an LCA. This allowed the environmental impact model to be traceable and easily scalable. In addition to these publications focusing mainly on the production and manufacturing phases of products, a study by Barletta et al. [

53] addressed the management of electronic waste. In this context, different sorting methods were evaluated in order to obtain real-time data on energy consumption. Widok et al. [

54] created a joint model for discrete-event simulation and material flow analysis, which was linked to environmental impact data to analyse different scenarios for manufacturing processes. The advantages mentioned here are again the possibility for precise analyses as well as simple and rapid adjustments of input data. Other publications have focused on construction processes in the building sector and examined the environmental impact of construction machinery and equipment [

55,

56] as well as the environmental performance of supply chains and on-site equipment [

57].

Based on this literature review, a simultaneous approach was chosen for the present study in order to ensure a realistic variation in life cycle simulation based on ecological impacts. The methodology presented in the following sections is able to simulate an aircraft’s life cycle in detail and environmentally assess it with the help of an LCA.